Extruder

A technology of extruder and frame, applied in the field of extruder, can solve the problems of uneconomical, narrow feeding port, increased cost, etc., and achieve the effect of increasing output, shortening cycle and increasing material quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

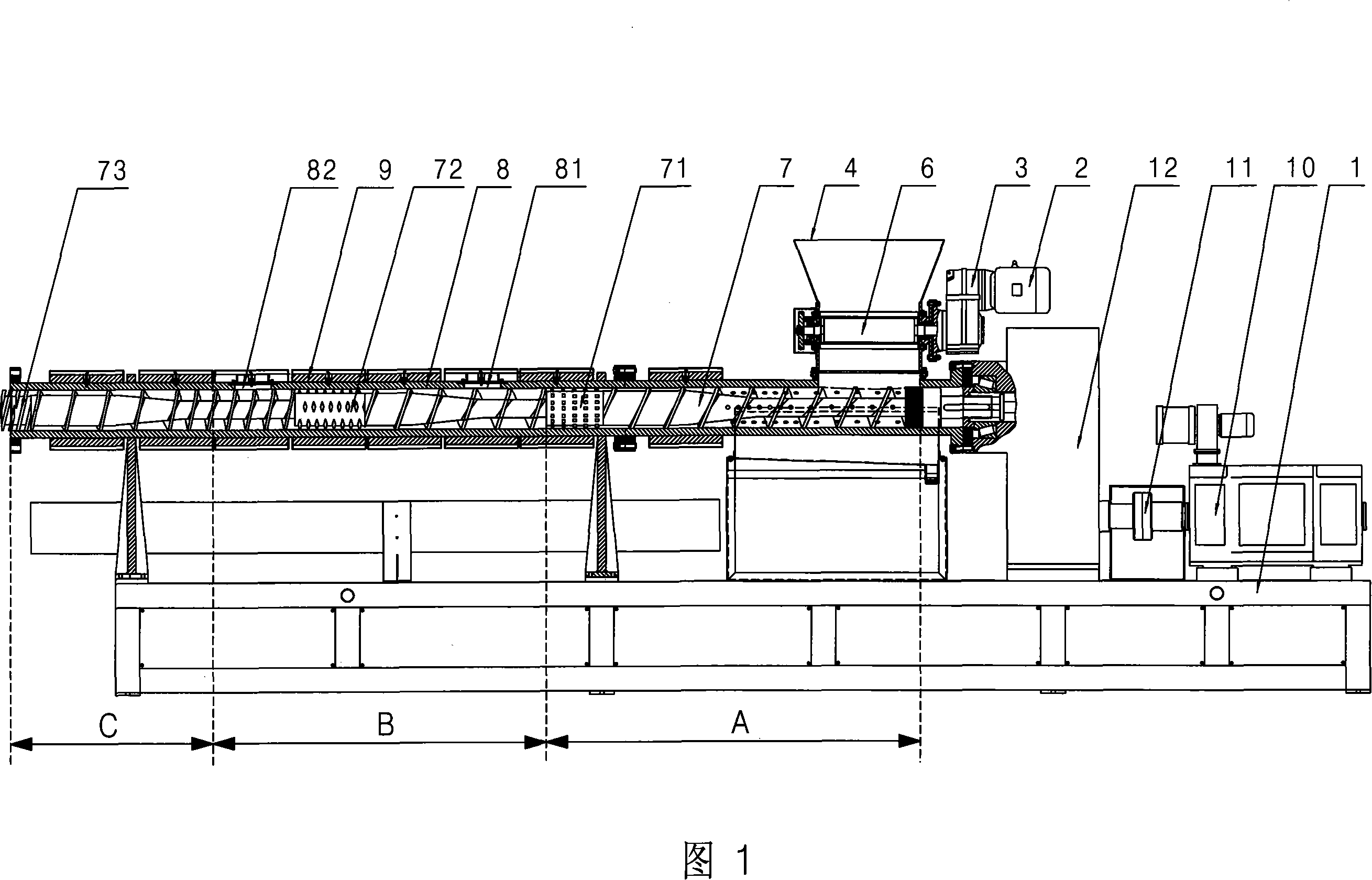

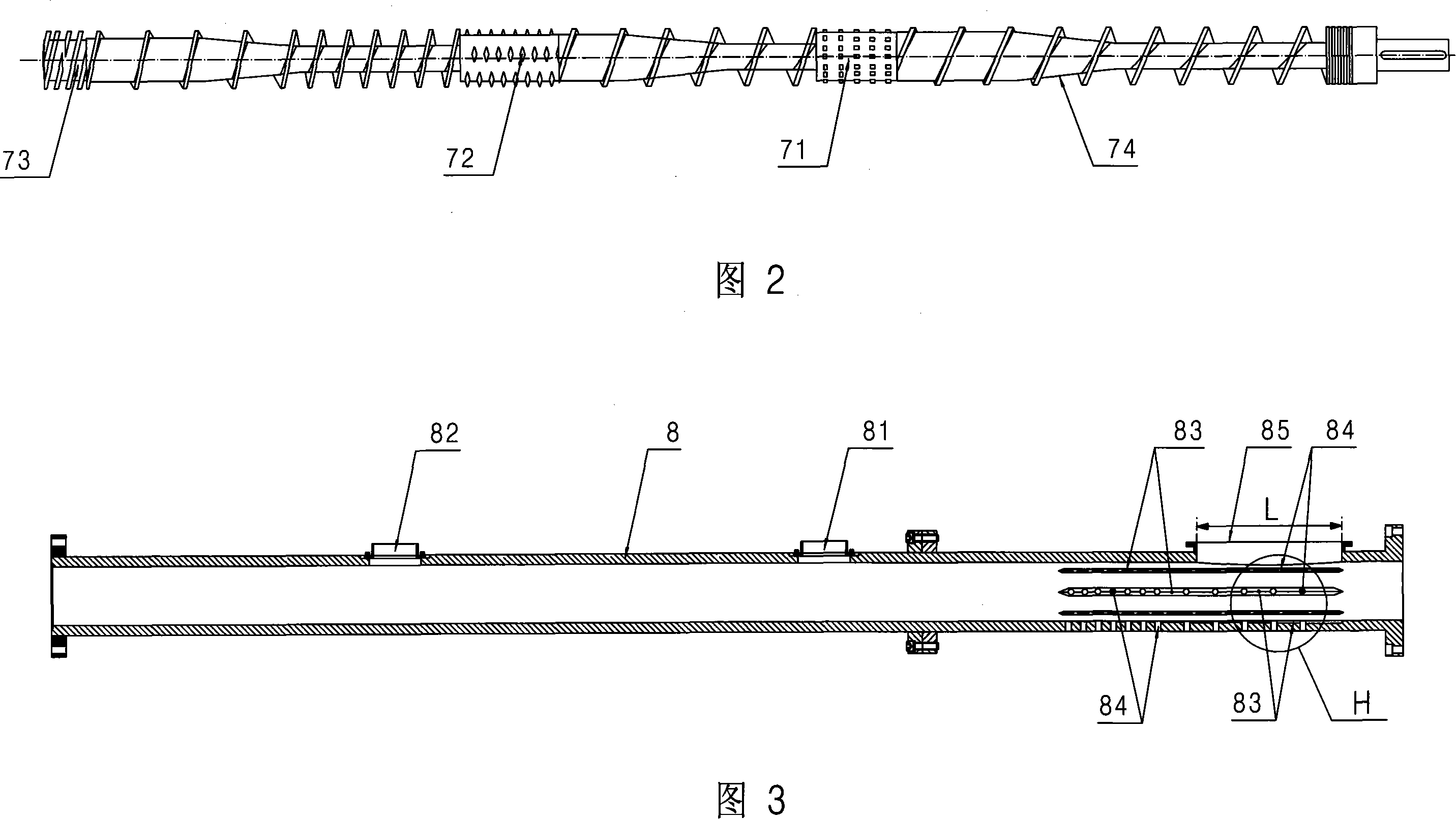

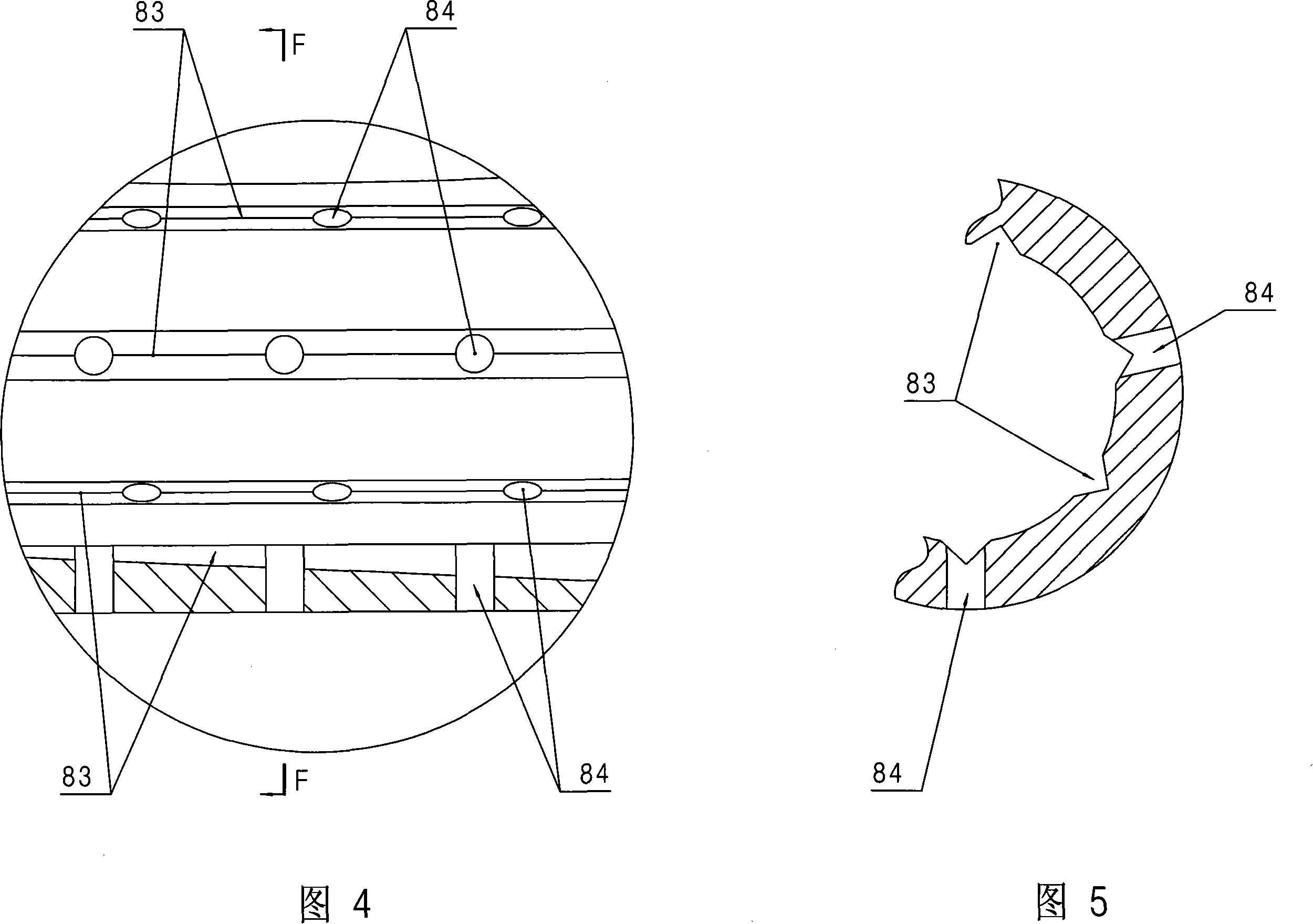

[0018] As shown in Figure 1, the extruder of the present invention comprises: frame 1, is provided with screw barrel 8 and power unit on frame 1, is provided with heater 9 on screw barrel 8, is provided with in screw barrel 8 Screw rod 7, described power unit comprises: motor 10 and speed reducer 12, the output shaft of motor 10 links to each other with the input shaft of speed reducer 12 by coupling 11, and the output shaft of speed reducer 12 is the output shaft of power unit and screw rod 7 are connected at one end; the screw barrel 8 and the screw 7 are provided with corresponding conveying section A, plasticizing section B and melting section C, and the conveying section A of the screw barrel 8 is provided with a feed port 85—see figure 3, and the feeding hopper 4 matched with the feed inlet 85, the plasticizing section B and the melting section C of the screw barrel 8 are respectively provided with exhaust holes 81 and 82 - see Figure 2, on the screw 7 The plasticizing s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com