Device and method for controlling feeding amount of machine-made sand equipment

A technology for controlling device and feeding amount, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problem of inaccurate control of feeding amount of machine-made sand equipment, achieve the effects of reducing pollution, increasing material amount, and avoiding material accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

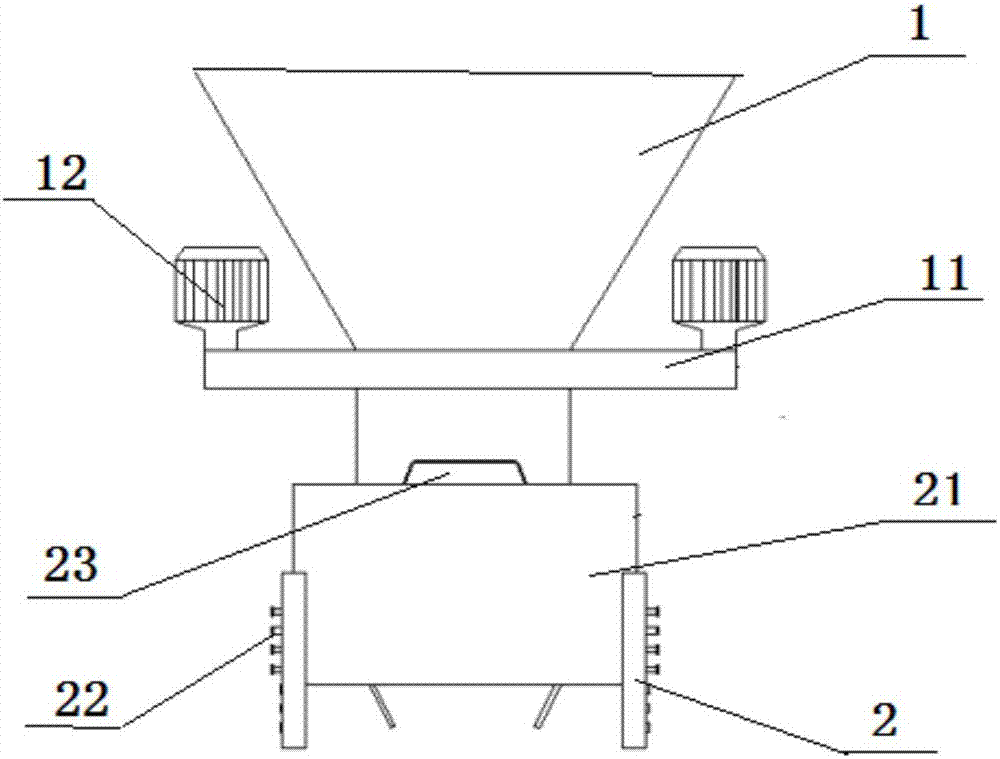

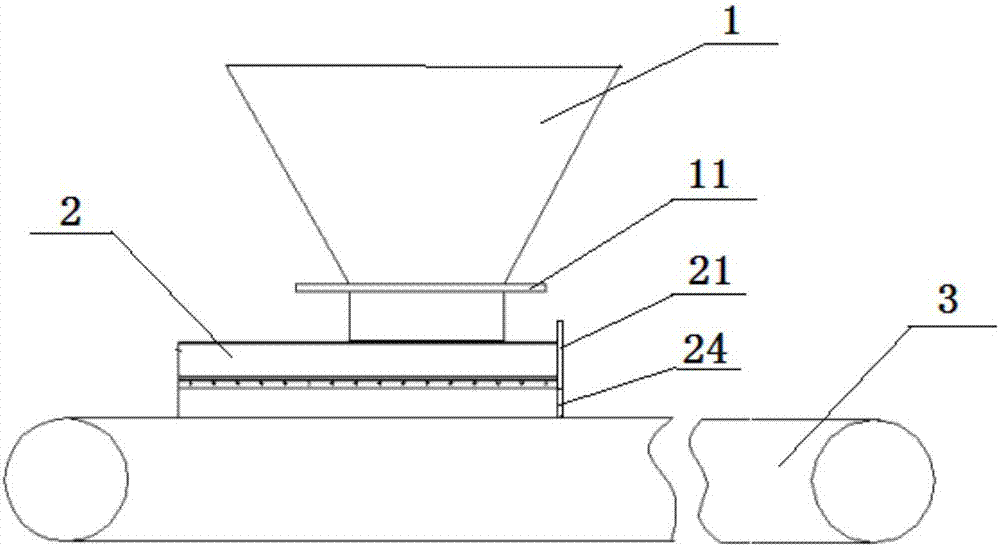

[0039] As mentioned in the background art, it is difficult to accurately control the feeding amount of the current machine-made sand equipment, thereby reducing the production efficiency of the machine-made sand equipment.

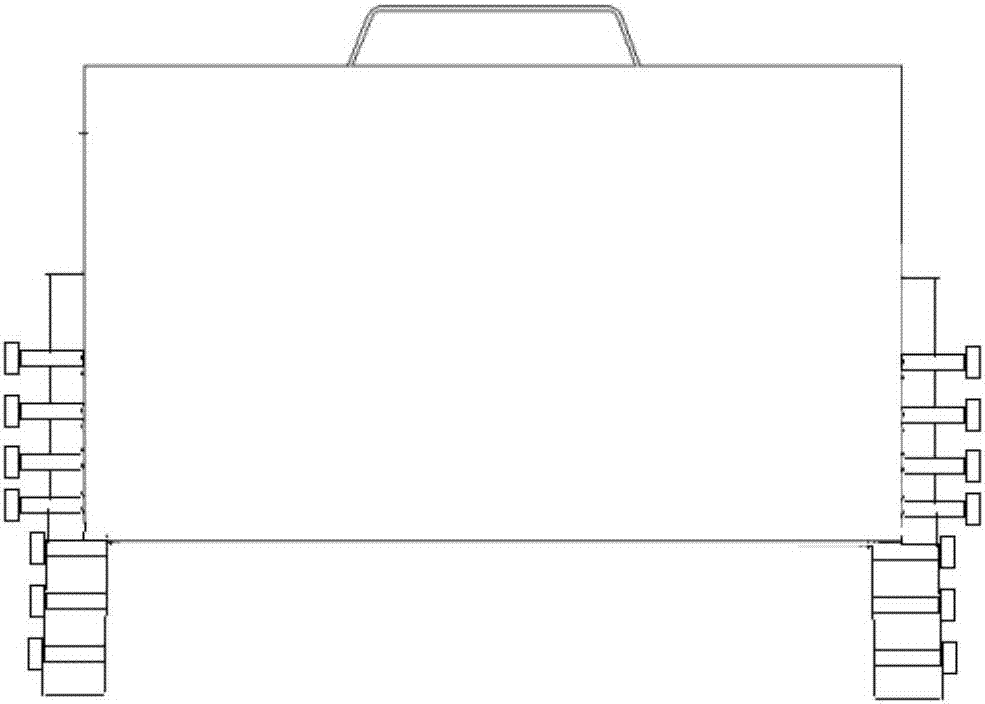

[0040] Based on the above research, the embodiment of the present invention provides a feed volume control device for machine-made sand equipment. The material volume in the chamber is detected by the material level detector, and the controller controls the material volume according to the material volume detected by the material level detector. The gate works, for example, when the amount of material in the chamber is too small to meet the demand of the machine-made sand equipment, the controller will automatically control the gate to open, and then make the discharge port of the hopper larger, so as to increase the chamber The amount of material in the chamber can increase the amount of material supplied to the machine-made sand equipment; when the amount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com