Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Improves ease of cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Spraying process for fluorocarbon surface layer paint

ActiveCN102357454AImprove anti-pollution performanceImproves ease of cleaningPretreated surfacesCoatingsSurface layerFluorocarbon

The invention relates to spraying a process for fluorocarbon surface layer paint, which comprises the following steps of: (1) cleaning and grinding; (2) primer spraying; (3) finish spraying; and (4) fluorocarbon surface layer paint spraying. The aircraft skin processed by the process has strong stain resistance, and the easy cleaning property is obviously improved.

Owner:吉林航空维修有限责任公司

Hydrophilic and oleophobic easy-to-clean organic coating and preparation method thereof

ActiveCN102585664AImprove wettabilityEasy to replaceEpoxy resin coatingsOrganic solventFluorine containing

The invention discloses a hydrophilic and oleophobic easy-to-clean organic coating and a preparation method thereof. The organic coating is obtained by curing an organic solution by a curing agent, the organic solution is a fluorine-containing polyurethane modified epoxy resin solution formed by carrying out a reaction on fluorine-containing polyurethane and an epoxy resin in an organic solvent, and the fluorine-containing polyurethane and the epoxy resin form a semi-interpenetrating network structure formed through the bonding of chemical bonds. A micro area with uniformly distributed hydrophilicity and oleophobicity is constructed on the surface of an object to be coated through the semi-interpenetrating structure and low surface performances of fluorine, so the hydrophilic and oleophobic easy-to-clean organic coating is formed. Experiments prove that the lowest contact angle between the organic coating and water can reach 15DEG, and the highest contact angle between the organic coating and oil can reach 90DEG, so water can thoroughly displace oil stains on the surface of an original solid, and an easy-to-clean effect is reached.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Hydrophilic coating easy to clean and preparing method of hydrophilic coating

ActiveCN105504898AGood acid and alkali resistanceAvoid scratchesAnti-corrosive paintsSolventTitanium

The invention relates to a hydrophilic coating easy to clean and a preparing method of the hydrophilic coating. The hydrophilic coating easy to clean comprises, by mass, 25%-44% of silica sol, 15%-40% of aluminum sol, 10%-25% of titanium sol, 5%-9% of an alkali metal silicate aqueous solution, 3%-6% of hydrophilic fumed silica, 0.5%-1% of assistant and 10%-20% of solvent. The preparing method includes the steps that the silica sol, the aluminum sol, the titanium sol, the alkali metal silicate aqueous solution, the hydrophilic fumed silica, the assistant and the solvent are mixed together according to the ratio to prepare the hydrophilic coating easy to clean. The hydrophilic coating easy to clean has the easily-cleaned performance, acid resistance, base resistance, scraping resistance and other performances.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

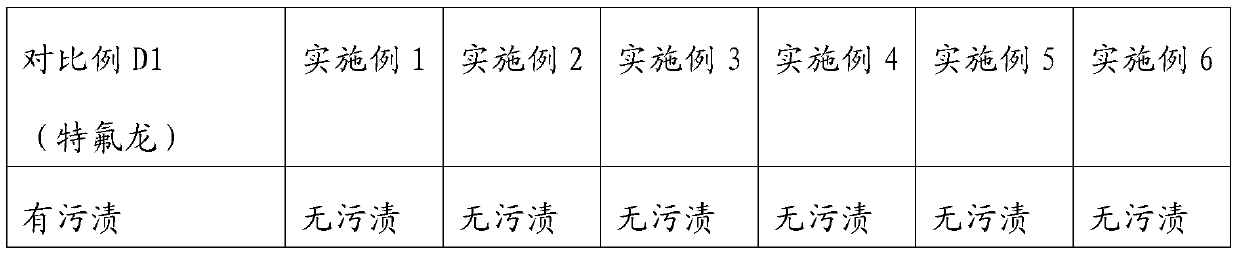

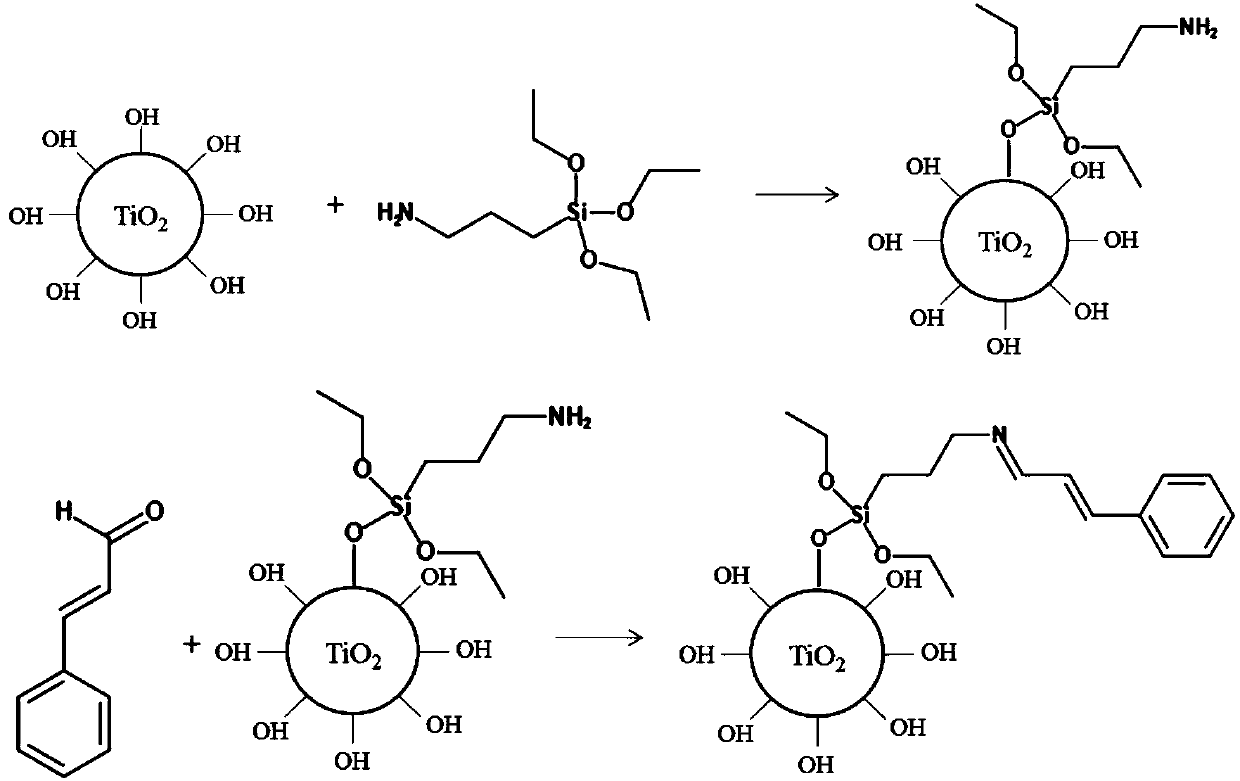

Preparation method of inorganic-organic hybrid antibacterial agent with antibacterial and hydrophobic functions and application of antibacterial agent

ActiveCN109627492ANo pollution in the processPolarity adjustableEscherichia coliStaphylococcus aureus

The invention relates a preparation method of an inorganic-organic hybrid antibacterial agent with antibacterial and hydrophobic functions and application of the antibacterial agent in a polymer material matrix. The antibacterial agent overcomes the problem in the prior art that the antibacterial performance of a natural antibacterial agent cannot completely meet the demands of users when being used alone. Specifically, the antibacterial agent adopts an amino-containing coupling agent as a bridge, and antibacterial inorganic nanoparticles such as titanium dioxide and zinc oxide are coated withantibacterial aldehydes such as organic citral and cinnamaldehyde to form the inorganic-organic hybrid antibacterial agent. The inorganic-organic hybrid antibacterial agent can be widely applied to polymer materials such as PP and ABS and achieve an antibacterial and hydrophobic effect; the antibacterial rate of the antibacterial agent for gram-negative bacteria such as escherichia coli can reach99.9%, the antibacterial rate of the antibacterial agent for gram-positive bacteria such as staphylococcus aureus can reach 99.9%, the antibacterial rate of the antibacterial agent for aspergillus niger and other molds can reach 0 grade, and the contact angle between the material surface and water can reach 120 degrees. Meanwhile, the antibacterial polymer material maintains the great mechanicalproperty.

Owner:ZHEJIANG UNIV OF TECH

Ash-scraping structure

PendingCN110537873AAchieve scrape cleanupWill not polluteCleaning filter meansEngineeringDust collector

The invention discloses an ash-scraping structure. The ash-scraping structure comprises a dust collecting tube, an ash-scraping tube, and an air draft tube; the internal of the dust collecting tube ishollow, and end parts of the dust collecting tube are opened so as to form an air inlet port and a fitting port at two ends; the internal of the ash-scraping tube is hollow, and one end thereof is internally connected with the fitting port of the dust collecting tube; the internal of the air draft tube is hollow, and the air draft tube is separately butted joint with the fitting port of the dustcollecting tube; when the air draft tube is butted joint with the fitting port of the dust collecting tube, the ash-scraping tube is coaxially embedded into the air draft tube, and an ash-scraping ring is fixedly connected to a place, connected with the dust collecting tube, on the ash-scraping tube. Through the ash-scraping structure arranged on a filter screen, the dirt accumulated on the filterscreen can be scraped and cleaned without dismounting a dust-air separating structure, the ash-scraping is simple and easy to operate, and an operator and an operation space cannot be polluted, the cleanliness of a dust collector and the clean class in the cleaning process are enhanced, and the ash-scraping structure has extensive market application prospect.

Owner:DREAM INNOVATION TECH (SUZHOU) CO LTD

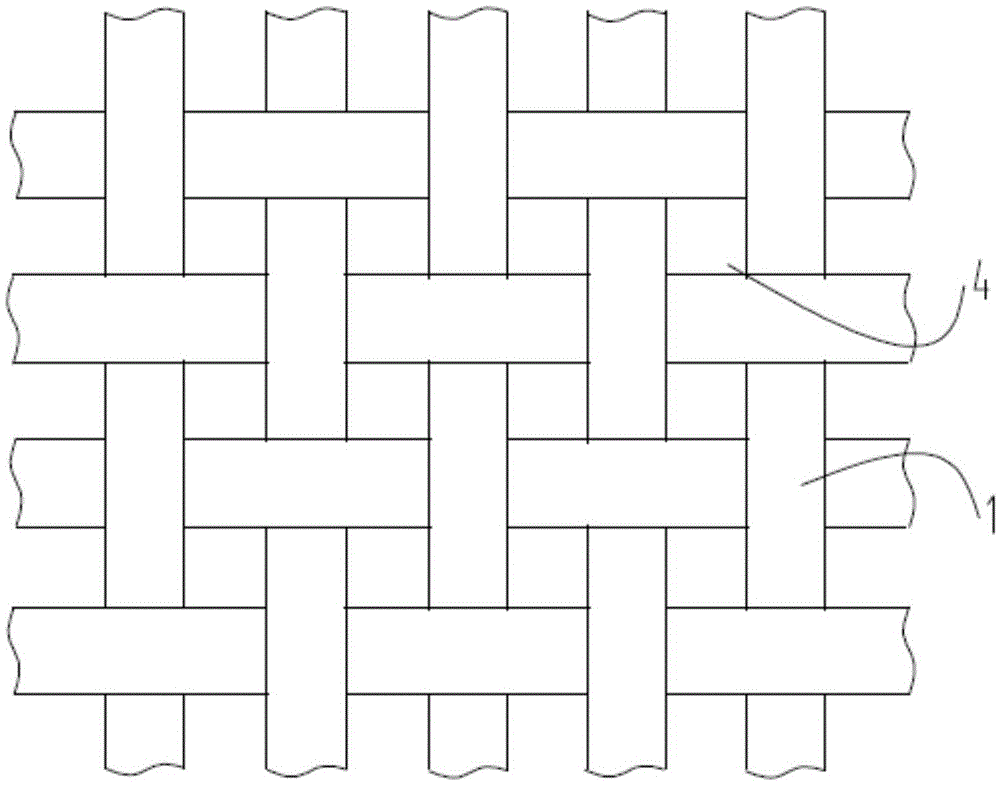

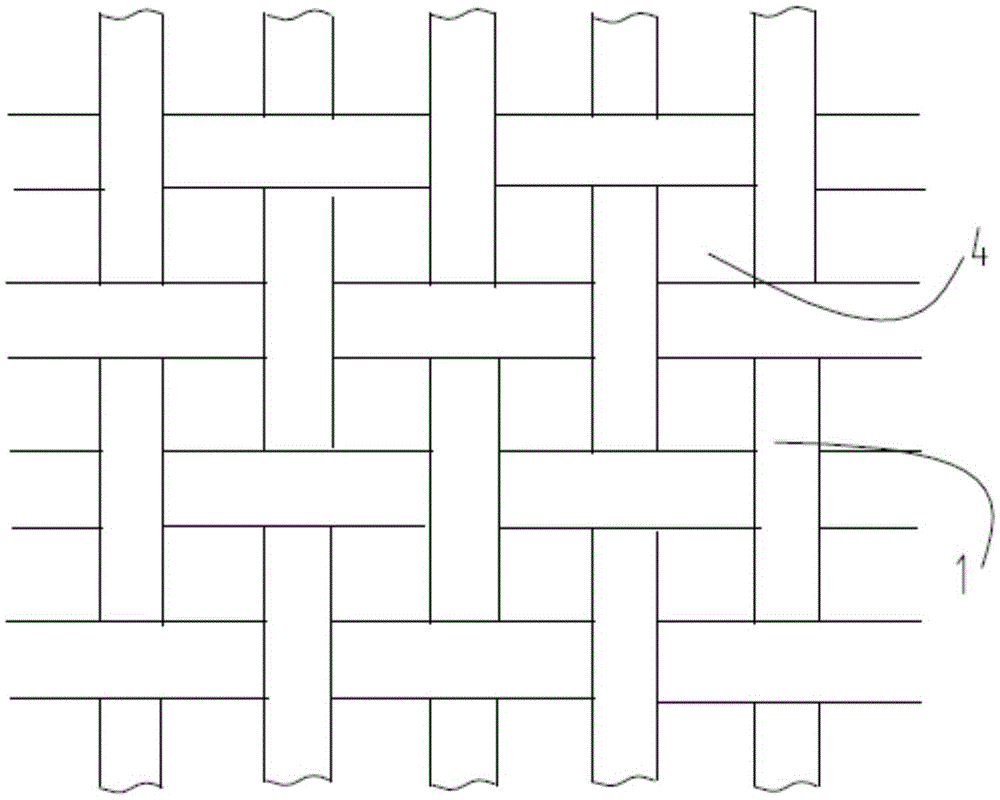

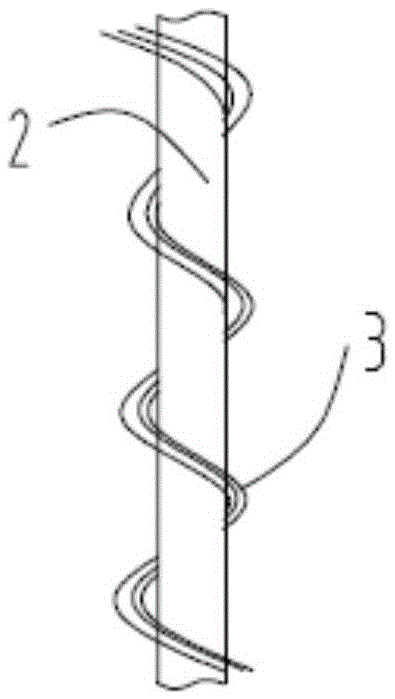

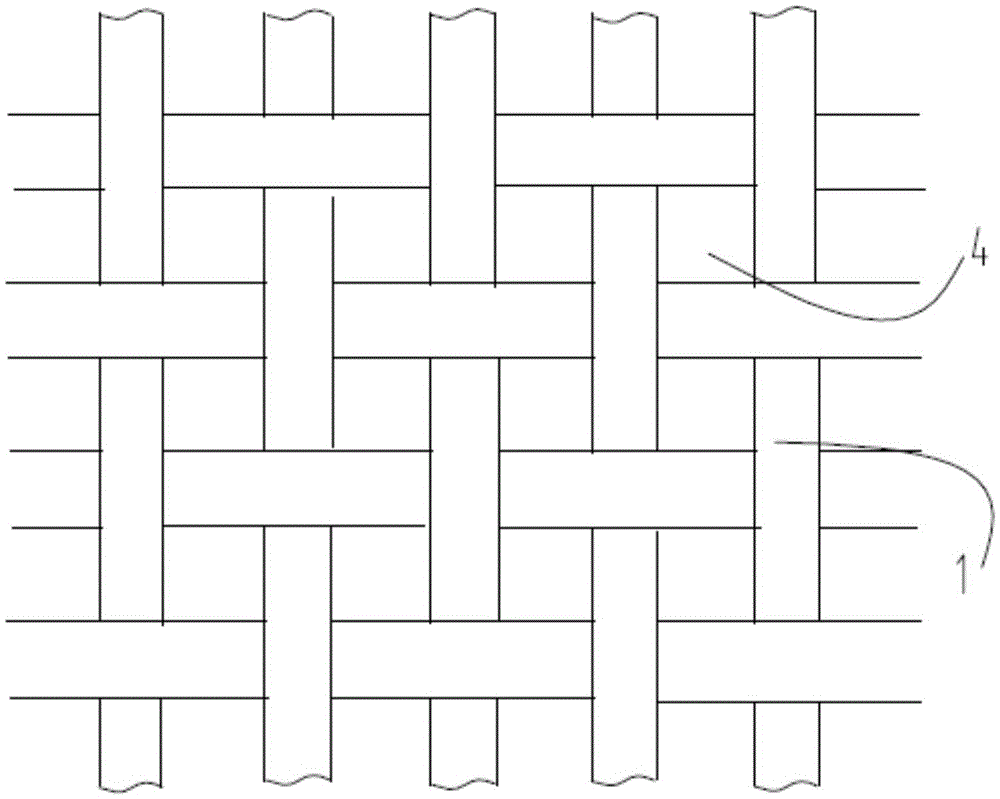

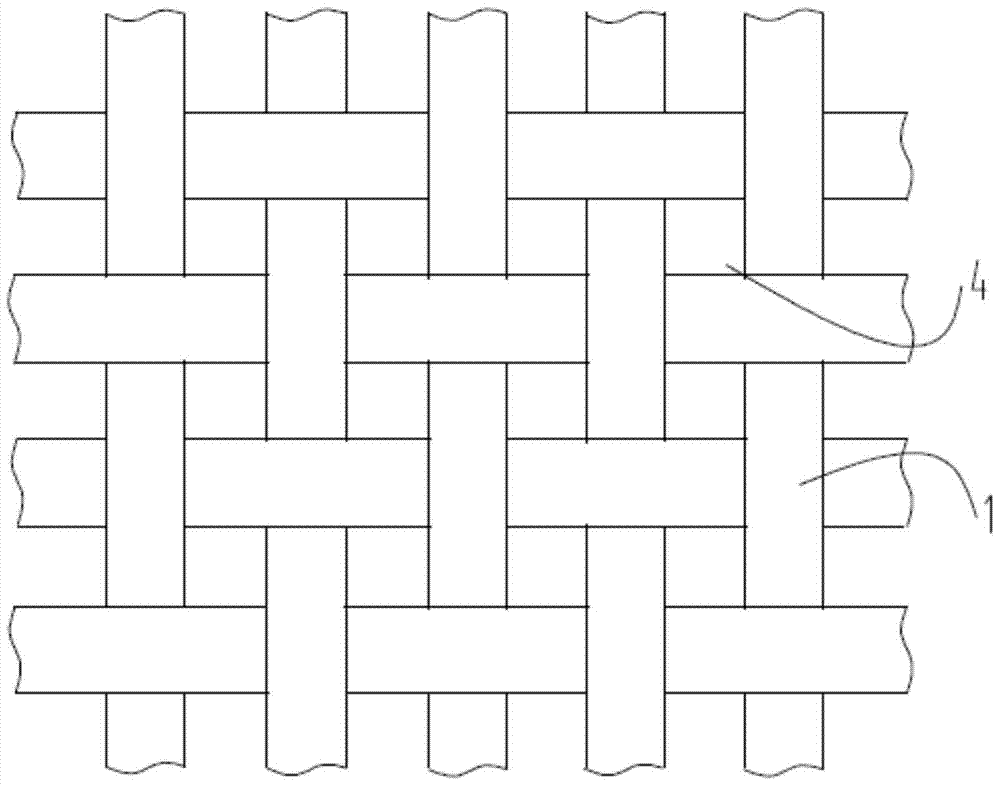

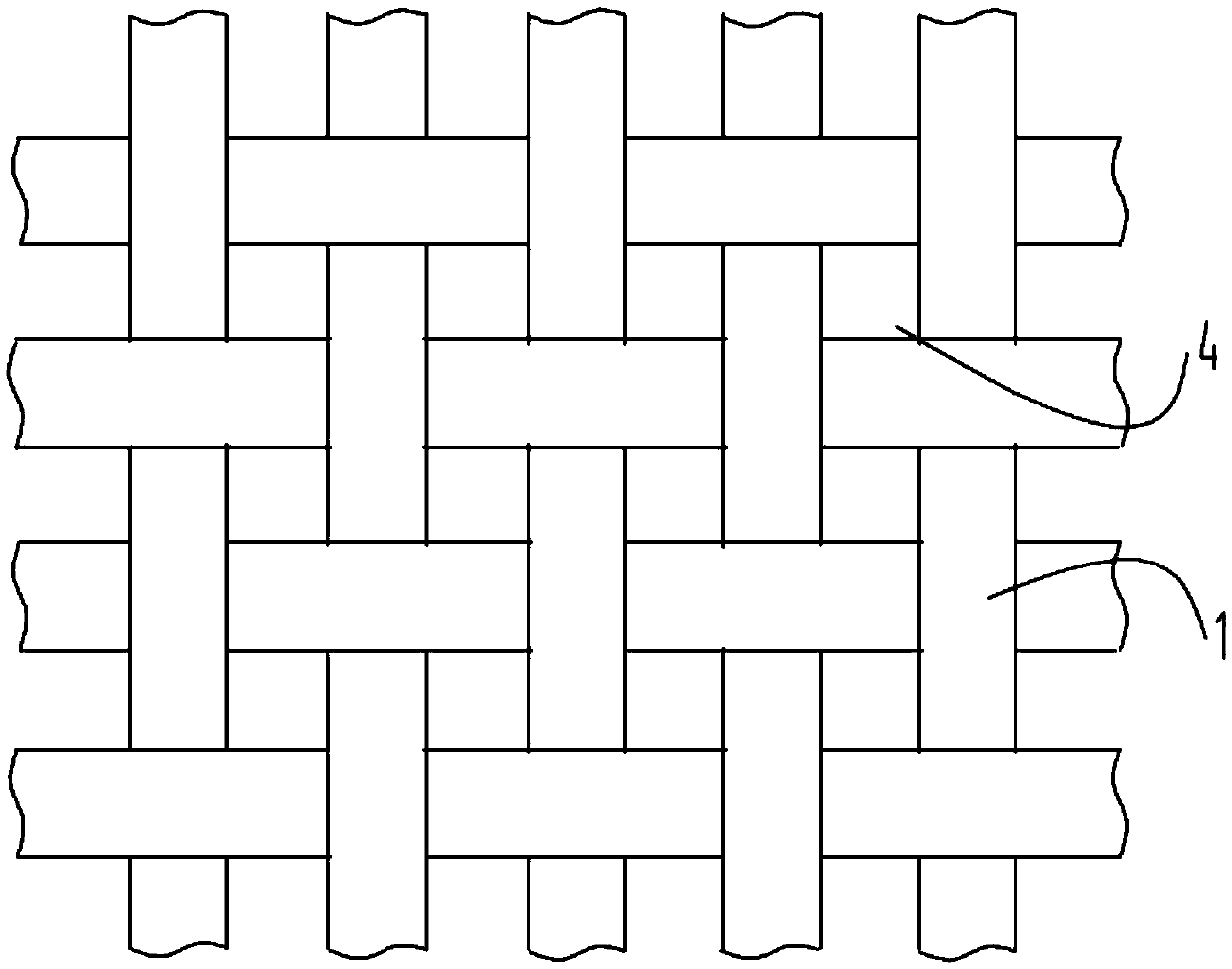

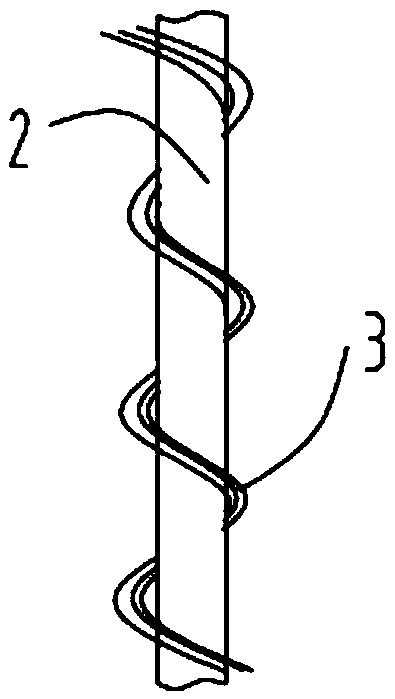

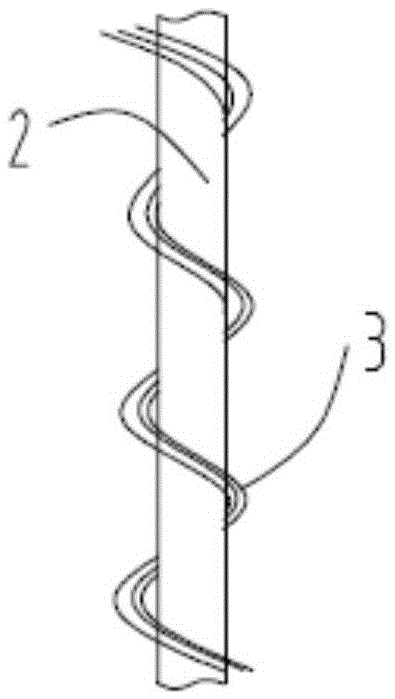

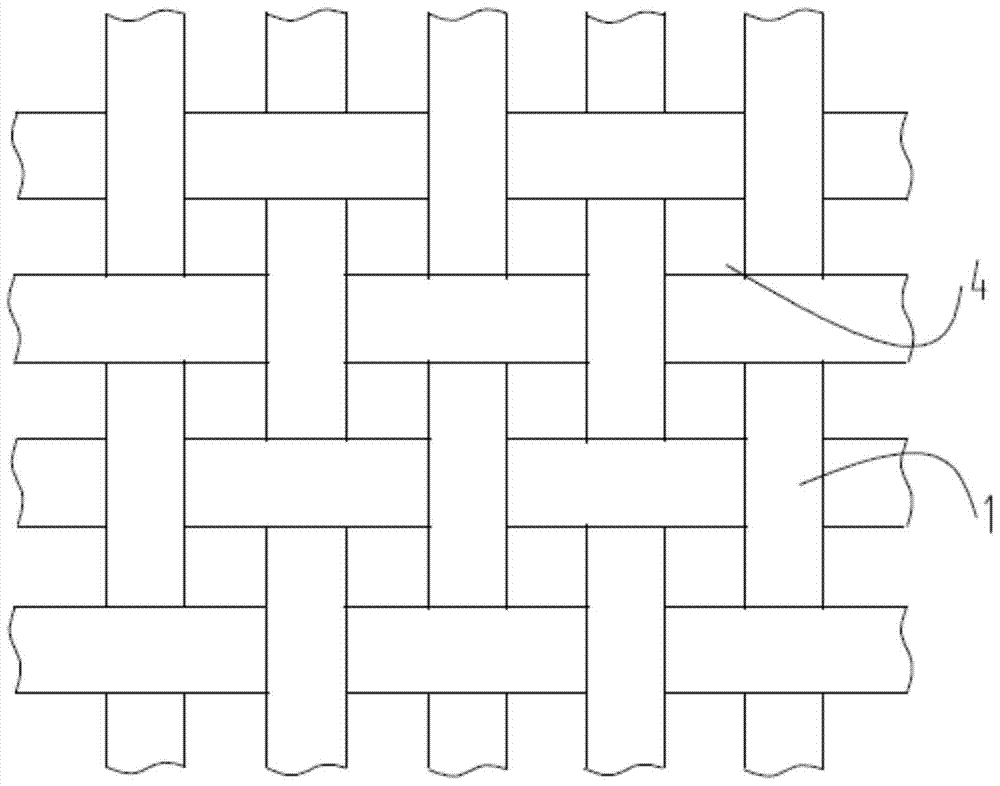

Novel fabric

ActiveCN105648560AImproves ease of cleaningImprove insulation effectConjugated synthetic polymer artificial filamentsYarnYarnPigment

The invention relates to a novel fabric. A yarn of the novel fabric is a core-spun yarn; a yarn core part is prepared from a functional fiber for temperature rise and heat storage; a winding part is prepared from a functional fiber beneficial to dehumidification; the functional fiber for temperature rise and heat storage is prepared by melt spinning of the following raw materials in parts by weight: 60-80 parts of a conventional fiber material, 15-20 parts of carbon black particles for pigments and 5-20 parts of color master batches; and the functional fiber beneficial to dehumidification is prepared by melt spinning of a fiber material of which the crimp percentage is reduced in water and the conventional fiber material at the ratio of 1 to 1. The clothes washing and drying efficiency is improved by combined action of temperature rise and heat storage and fabric gap increase.

Owner:江苏智光创业投资有限公司

Lens optical coating surface treatment process and lens obtained by process

InactiveCN110093587AExtended service lifeEasy to useVacuum evaporation coatingSputtering coatingOptical coatingEvaporation

The invention provides a lens optical coating surface treatment process and a lens obtained by the process. The process comprises the following steps of (1), performing plasma bombardment on the surface of the lens to activate a substrate; (2), preparing a coating material, specifically, ion-assisted plating is adopted; (3), performing electron beam evaporation plating to obtain a waterproof film;(4), preventing evaporation AF; and (5) standing. The process is simple, the properties of all aspects of the obtained lens are improved, and new technical requirements can be met. The obtained lens(such as a sunglass lens) is easy to clean, good in waterproof and antifogging performance and not likely to scratch, and the service time of the obtained lens is prolonged.

Owner:湖南宏泰新材料有限公司

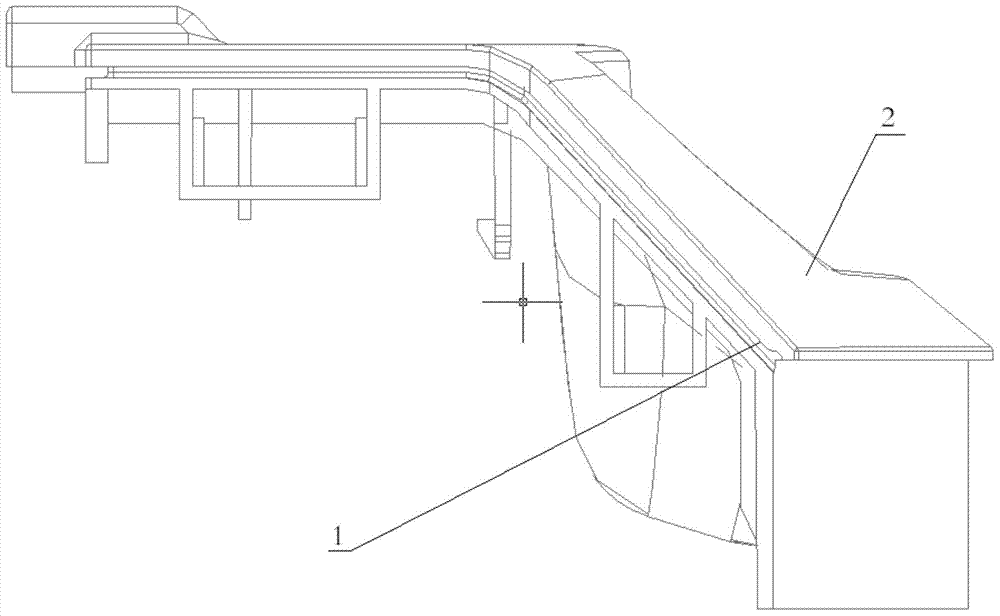

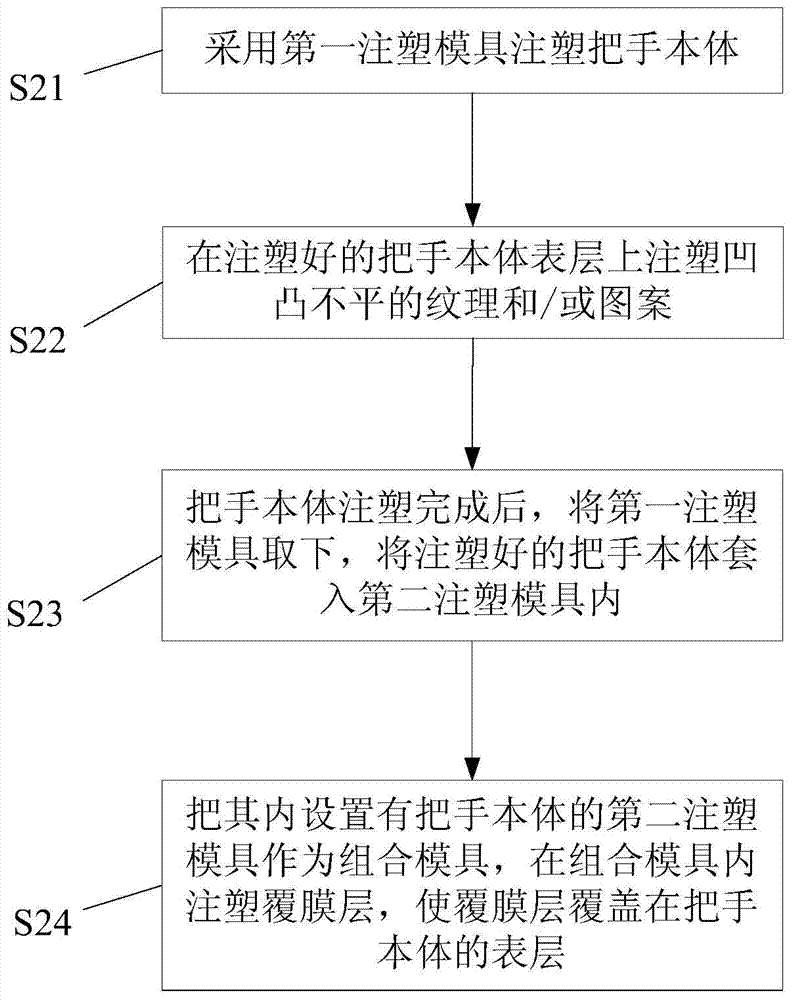

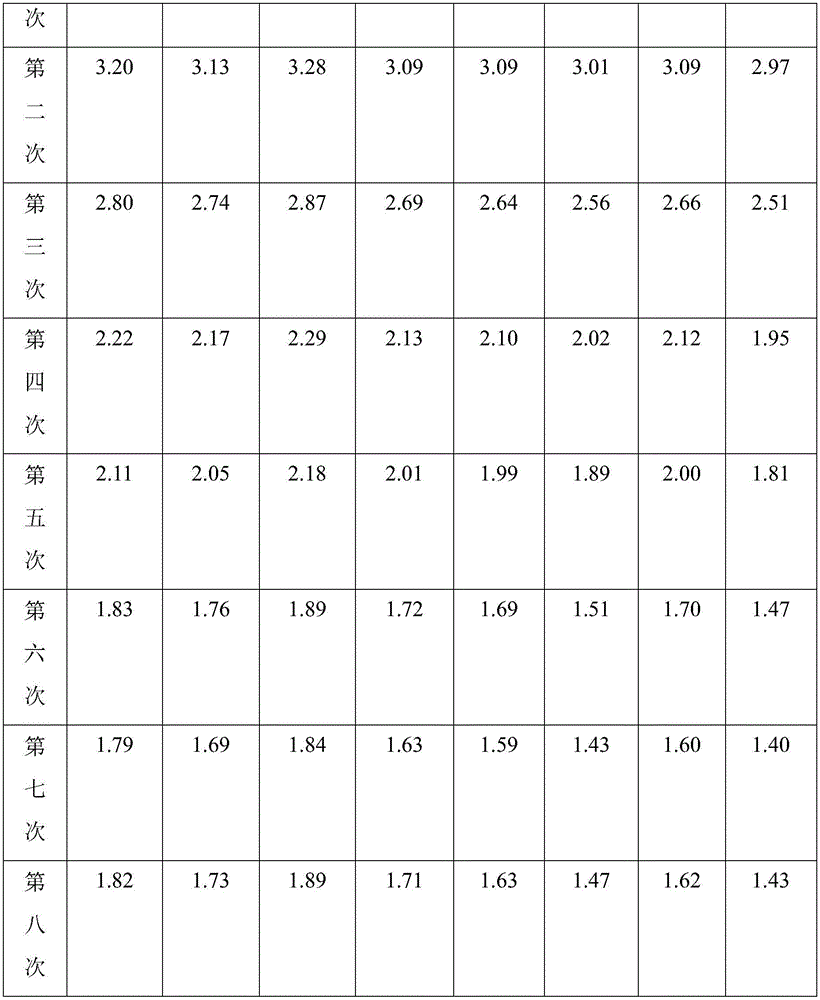

Refrigerator handle injection molding method and refrigerator handle

The invention relates to the field of white electric appliances, and in particular to a refrigerator handle injection molding method and a refrigerator handle. According to the refrigerator handle injection molding method, a filming layer is molded on the surface of a handle body by using an injection molding process, and at least part of the surface of the handle body is covered with the filming layer. The surface of the refrigerator handle manufactured by using the injection molding method does not fade or change forever; due to adoption of a double-color injection molding process of the refrigerator handle, not only is the production efficiency high, but also the manufacturing process is simple and easy to achieve, the expected process time is short, the manufacturing cost is low, and a product is variable; meanwhile, compared with a handle manufactured in a conventional single-color injection molding mode, the handle manufactured in the double-color injection molding mode is very good in three-dimensional effect and touch effect in color and hand feeling effect, and the requirements of users on appearance, hand feeing and color of the refrigerator handle are met.

Owner:HEFEI KINGHOME ELECTRICAL CO LTD

Conductive paste and preparation method thereof

InactiveCN106531284ASimple preparation processImproves easy-to-clean performanceNon-metal conductorsNon-conductive material with dispersed conductive materialHibiscus syriacusCarbon particle

The invention discloses conductive paste. The conductive paste comprises the following constituents based by parts by mass: 50-70 parts of water, 5-20 parts of sodium chloride, 1-5 parts of glycerin, 5-20 parts of macromolecule substance, 1-5 parts of natural plant carbon particle, 1-5 parts of plant extract and 1-3 parts of thickening agent, wherein the plant extract is one or more of a honeylocust fruit extract, a hibiscus syriacus extract and a gleditsia sinensis extract. The conductive paste is short in effective impedance time, does not contain a substance harmful to a human body, is easy to clean and has relatively high safety performance, the added plant carbon can be used for making conductive factors uniformly distributed and effectively reducing the impedance between human skin and an electrode, and the conductive paste has excellent conductive performance.

Owner:WUHAN ZHIPU TIANCHUANG TECH CO LTD

Novel functional fabric

The invention relates to a novel functional fabric. Yarn of the novel functional fabric is core-spun yarn, the yarn core part is composed of functional fibers with a heating and heat accumulating function, and the wrapping part is composed of functional fibers beneficial to dehumidification. The functional fibers with a heating and heat accumulating function are formed by a conventional fiber material and a nano-unit in a melt spinning mode, wherein the conventional fiber material accounts for 99.91-99.95% of the total weight of the yarn core part, and the nano-unit accounts for 0.05-0.09% of the total weight of the yarn core part. The crimp rate of the functional fibers beneficial to dehumidification is decreased when the functional fibers beneficial to dehumidification encounter water. The nano-unit comprises 8500-9000-nanometer particles, and the particles contain 300-500 weight units of zinc, 350-450 weight units of aluminum and 150-350 weight units of iron. According to the novel functional fabric, the clothes cleaning and airing efficiency is improved under the combined effect of heating and heat accumulating and fabric gap increasing.

Owner:浙江朗莎尔维迪制衣有限公司

Bathroom floor forming part

InactiveCN102926520AReliable drying performanceImproves ease of cleaningSewerage structuresFlooringEngineering

The invention aims to provide a bathroom floor forming part which is provided with a water drain hole and a bath region, wherein the bath region is provided with an inclined part for draining water from the end portion to the water drain hole; micro concavo-convex parts for preventing water gathering and avoiding water soaking spreading are formed on the surface of the bath region; and as the micro concavo-convex parts are appropriately regulated, the drying performance, the skid resistance, the easiness of dirt removal and the like of the floor forming part can be improved.

Owner:株式会社好适特

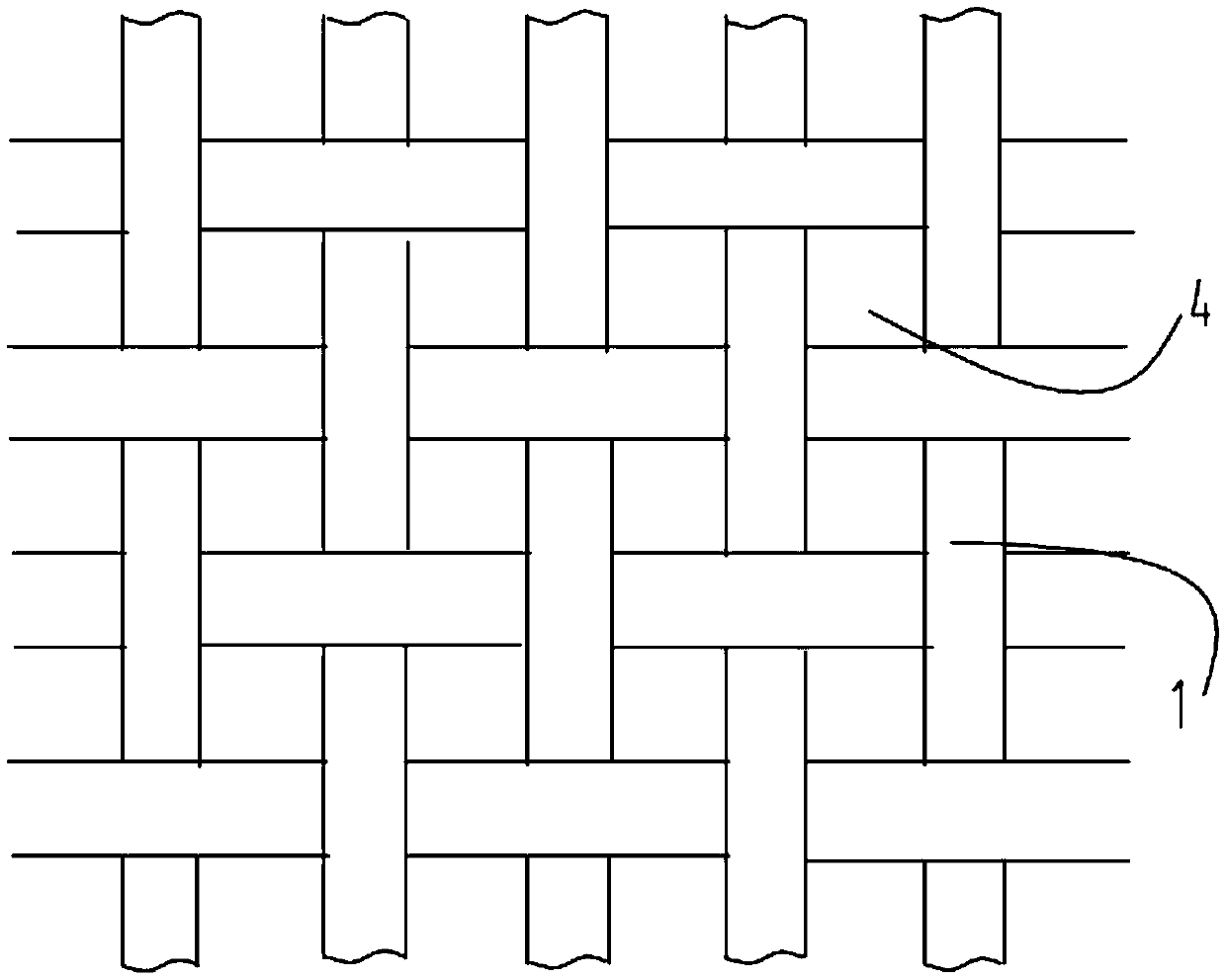

New functional fabric

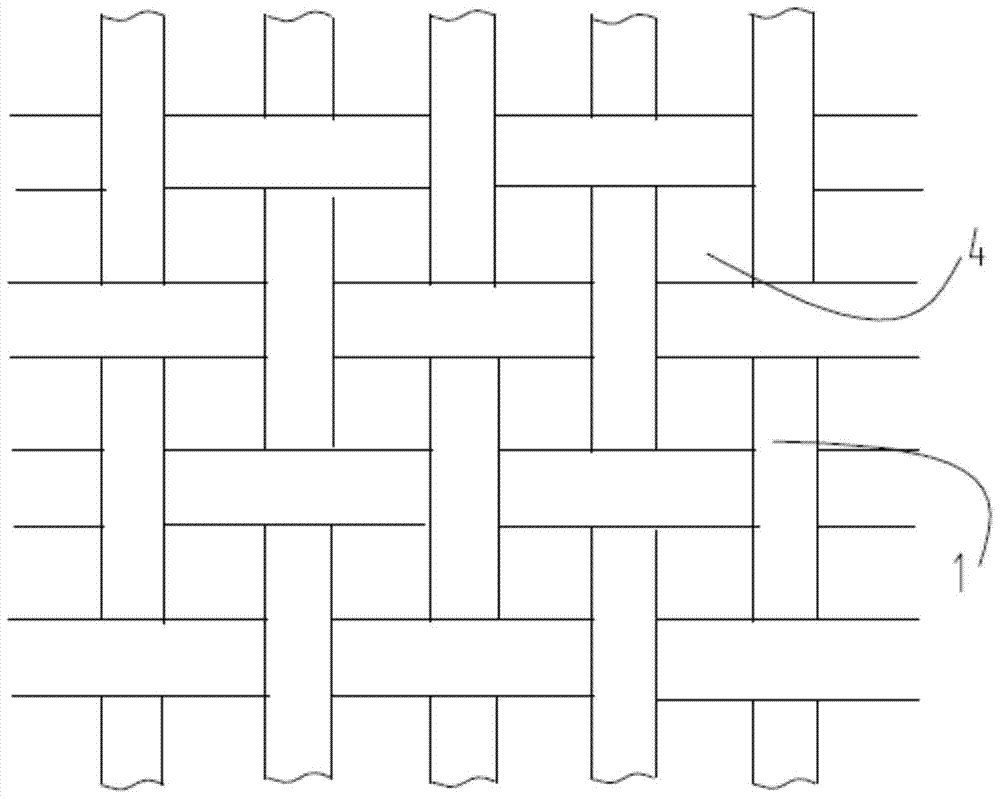

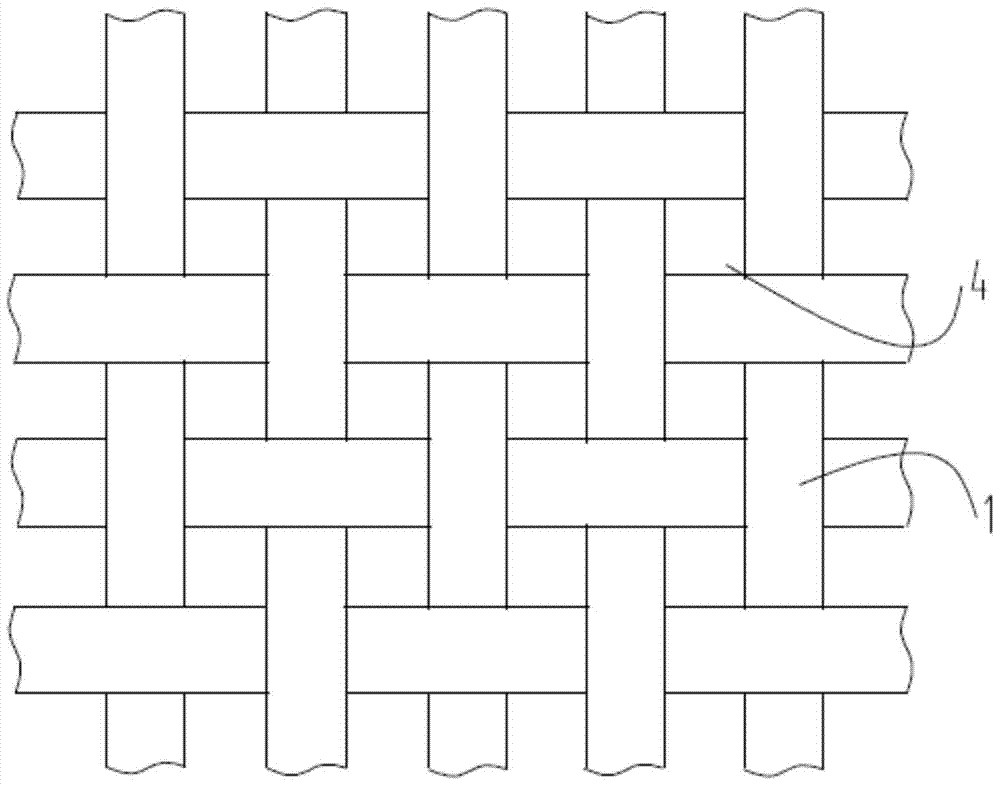

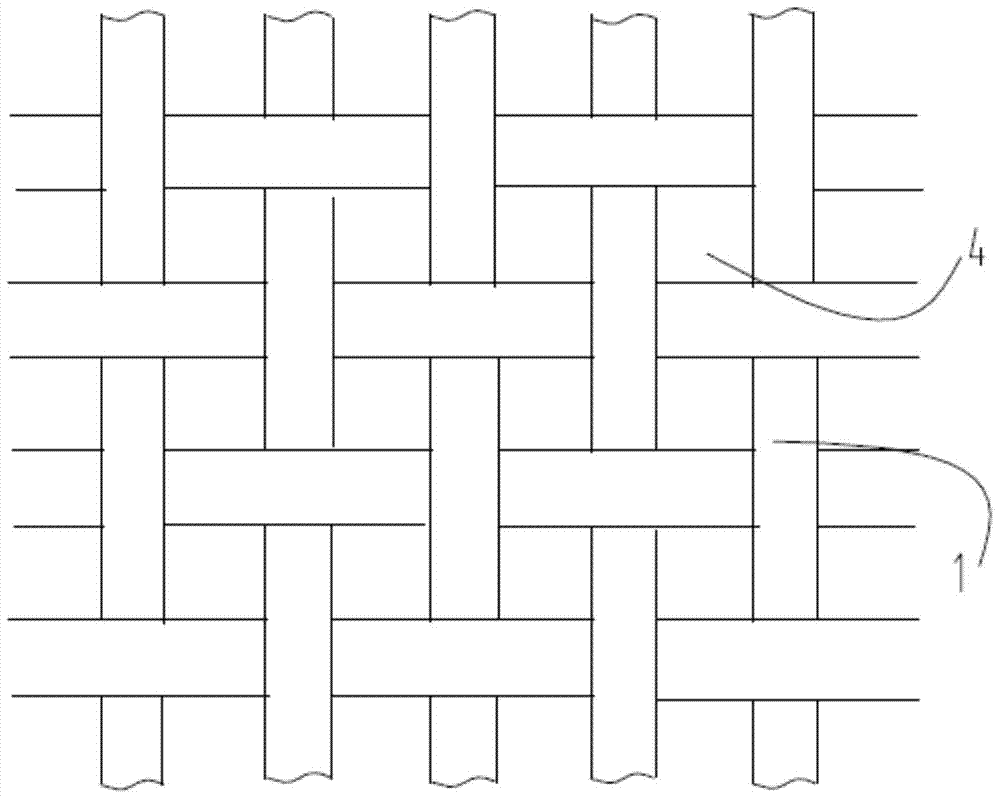

ActiveCN105671731BImproves ease of cleaningImprove drying efficiencyWoven fabricsYarnMasterbatchYarn

The invention relates to a new type of functional fabric. The yarn of the new type of functional fabric is a core-spun yarn. The core part of the yarn is composed of a functional fiber that heats up and stores heat. The functional fiber for heat storage is composed of 60 to 80 parts by weight of conventional fiber materials, 15 to 20 parts by weight of carbon black particles for pigments, and 5 parts by weight. 1 to 20 parts of color masterbatch is melt-spun; the functional fiber beneficial to dehumidification is a fiber whose curl rate becomes smaller when it encounters water. The present invention improves the efficiency of washing and airing clothes through the combined effect of temperature rise and heat storage and enlarging the voids of fabrics.

Owner:浙江西大门新材料股份有限公司

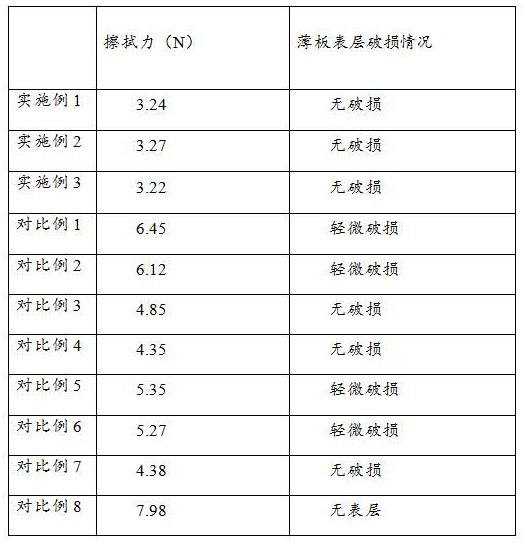

Dustproof easy-to-clean ceramic sheet and preparation method thereof

ActiveCN114853491AEasy to handleImproves ease of cleaningCeramic materials productionEpoxy resin coatingsFiberBarium titanate

The invention discloses a dustproof ceramic sheet easy to clean. The dustproof ceramic sheet is prepared from the following raw materials in parts by weight: 20-30 parts of cordierite, 15-25 parts of fluorite, 5-10 parts of potassium feldspar, 3-6 parts of a self-cleaning additive, 1-2 parts of a barium titanate sintering aid, 0.2-0.6 part of talcum powder and 0.1-0.3 part of modified nano silicon dioxide. The ceramic sheet is formed by matching raw materials such as cordierite, fluorite, potassium feldspar and talcum powder, sintering molding is performed through a barium titanate sintering aid, the added self-cleaning additive and modified nano silicon dioxide are matched to enhance the easy-to-clean effect of the product, the self-cleaning additive adopts mullite fiber irradiation, the activity is improved, and the service life of the product is prolonged. According to the invention, mullite fibers are used as raw materials, modification treatment is carried out in a sheet boron nitride modifier, a composite is formed through thermal modification and grinding, mullite fibers with needle-like structures are arranged on sheet boron nitride, and uniform stain-resistant and self-cleaning point locations are formed on the surface of the sheet, so that cleaning is convenient.

Owner:GUANGDONG OVERLAND CERAMICS CO LTD

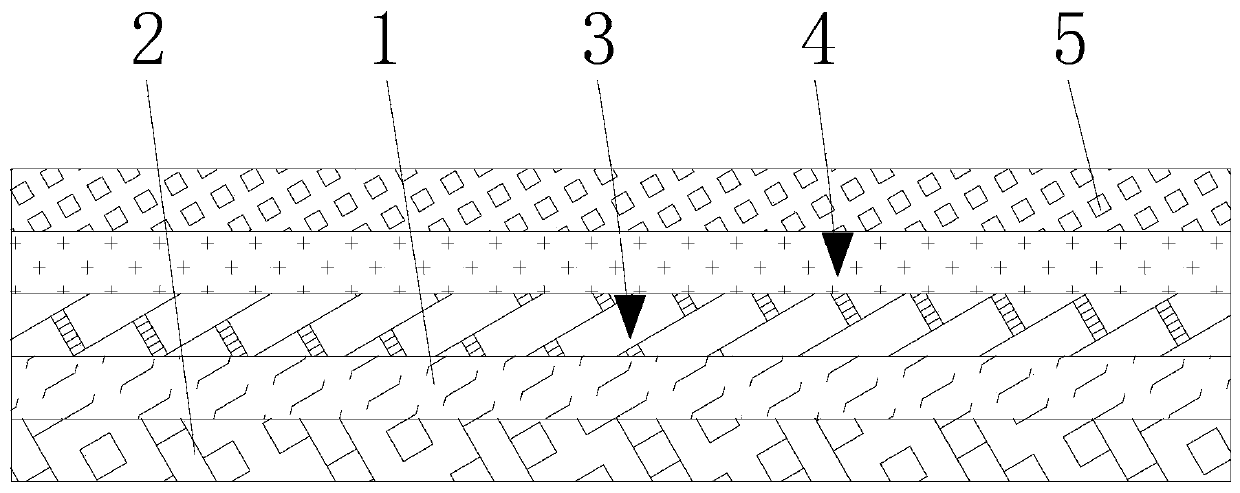

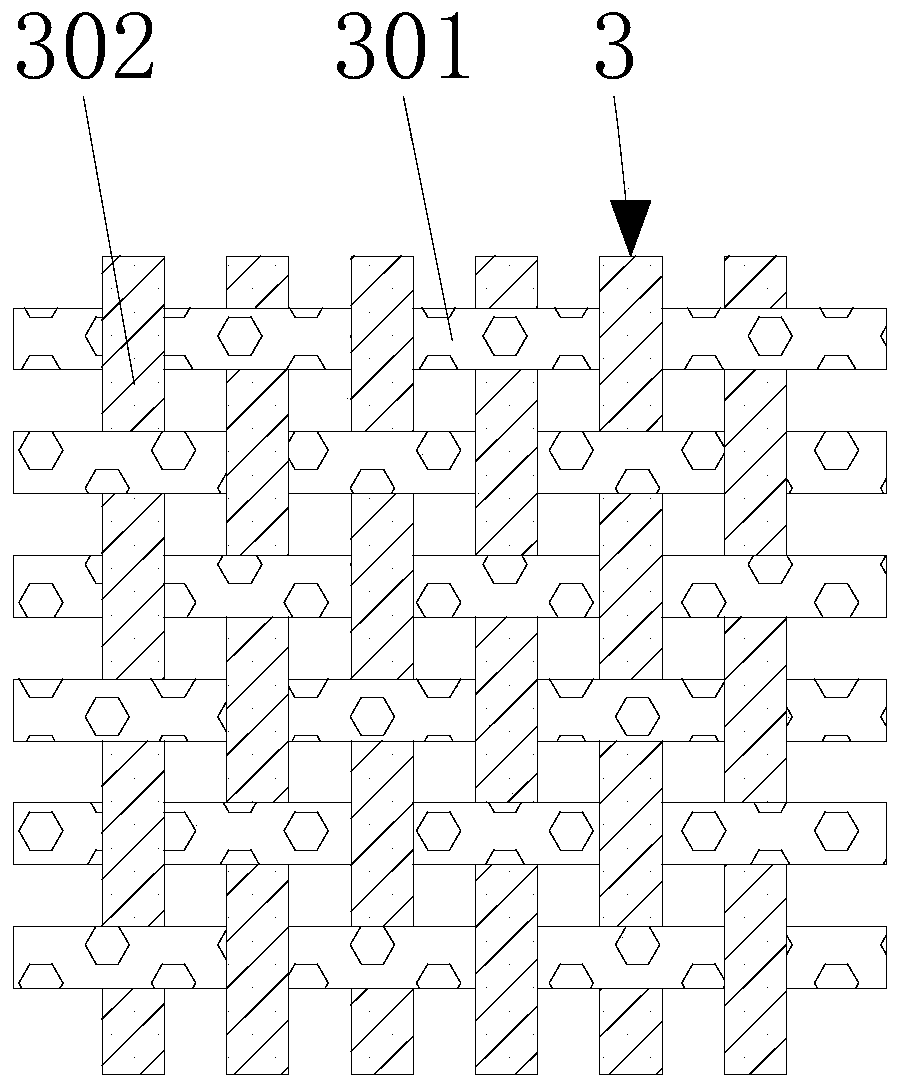

Antistatic and anti-oil polyester-mixed cotton cloth

PendingCN110271241AGood anti-static effectGood air permeabilitySynthetic resin layered productsMetal layered productsFiber layerCotton cloth

The invention discloses antistatic and anti-oil polyester-mixed cotton cloth which comprises a polyester-mixed cotton layer. An antibacterial layer is attached to the bottom of the polyester-mixed cotton layer through waterborne polyurethane. An antistatic layer is attached to the top of the polyester-mixed cotton layer through waterborne polyurethane. An anti-oil layer is attached to the top of the antistatic layer through waterborne polyurethane. A high-temperature-resistant layer is attached to the top of the anti-oil layer through waterborne polyurethane. The antistatic layer comprises a carbon black series conductive fiber layer and a metal series conductive fiber layer. The carbon black series conductive fiber layer is made of warp, and the metal series conductive fiber layer is made of weft. The carbon black series conductive fiber layer and the metal series conductive fiber layer are interwoven. By using the antistatic layer, the carbon black series conductive fiber layer, the metal series conductive fiber layer, the anti-oil layer, a bamboo fiber layer and a nano silica fiber layer in cooperation, the problem that existing polyester-mixed cotton cloth is poor in antistatic and anti-oil effect and not convenient to use is solved.

Owner:吴江市美林格纺织品有限公司

Preparation method of multifunctional anti-rust oil

The invention discloses a preparation method of multifunctional anti-rust oil, and belongs to the technical field of metal protective agents. The preparation method comprises the following steps: mixing petroleum resin with paraffin according to the mass ratio ranging from 3:2 to 3:1, and adding a treating agent, wherein the mass of the treating agent is 0.2 to 0.3 time of the mass of the petroleum resin; after stirring and mixing, obtaining a compound corrosion inhibitor; in parts by weight, weighing 50 to 80 parts of base oil, 18 to 25 parts of a diluent, 5 to 15 parts of an additive, 10 to20 parts of the compound corrosion inhibitor, 3 to 5 parts of a diluent and 5 to 8 parts of isophorone diisocyanate in sequence; mixing the base oil and the diluent into a stirring machine, and addingthe additive, the compound corrosion inhibitor, the isophorone diisocyanate and the silane coupling agent into the stirring machine in sequence; stirring and mixing for 20 to 50 min under the conditions that the temperature is 40 to 50 DEG C and the rotating speed is 300 to 500 rpm, to obtain the multifunctional anti-rust oil.

Owner:袁杰

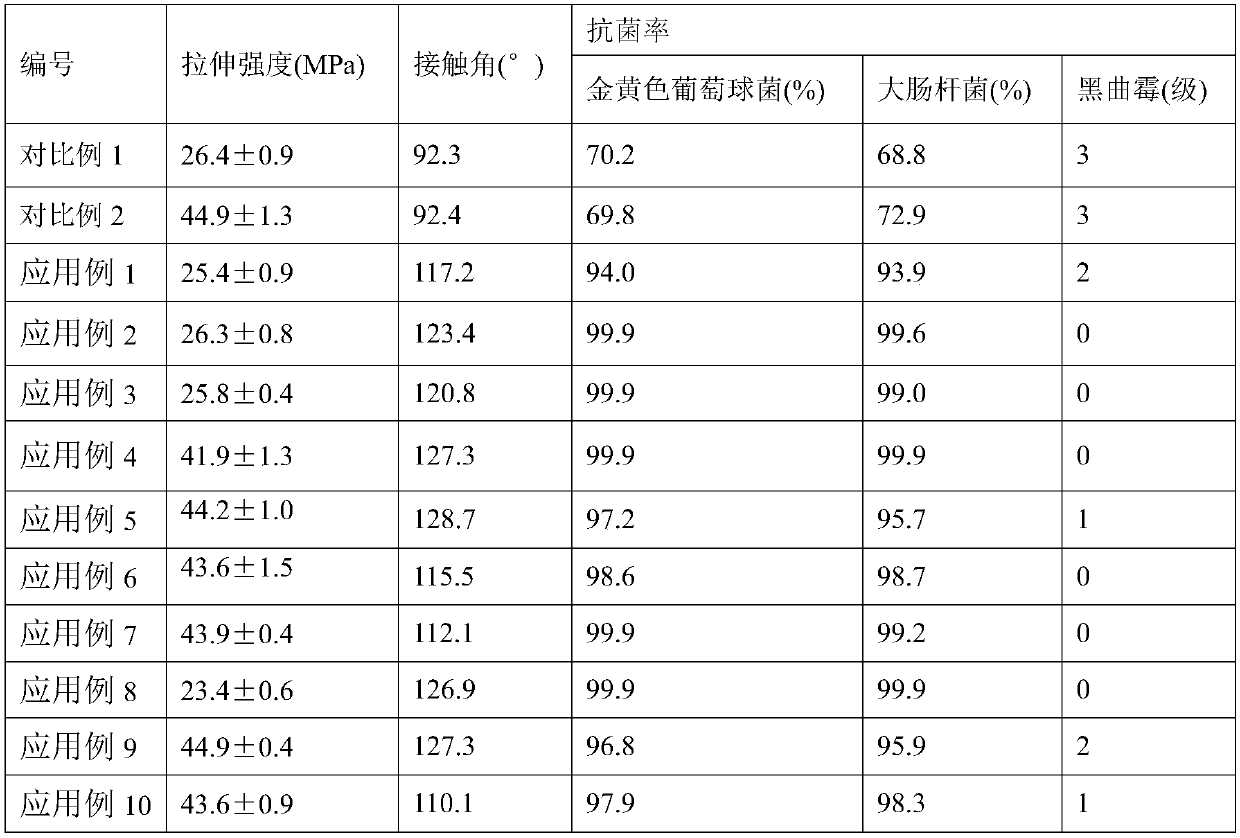

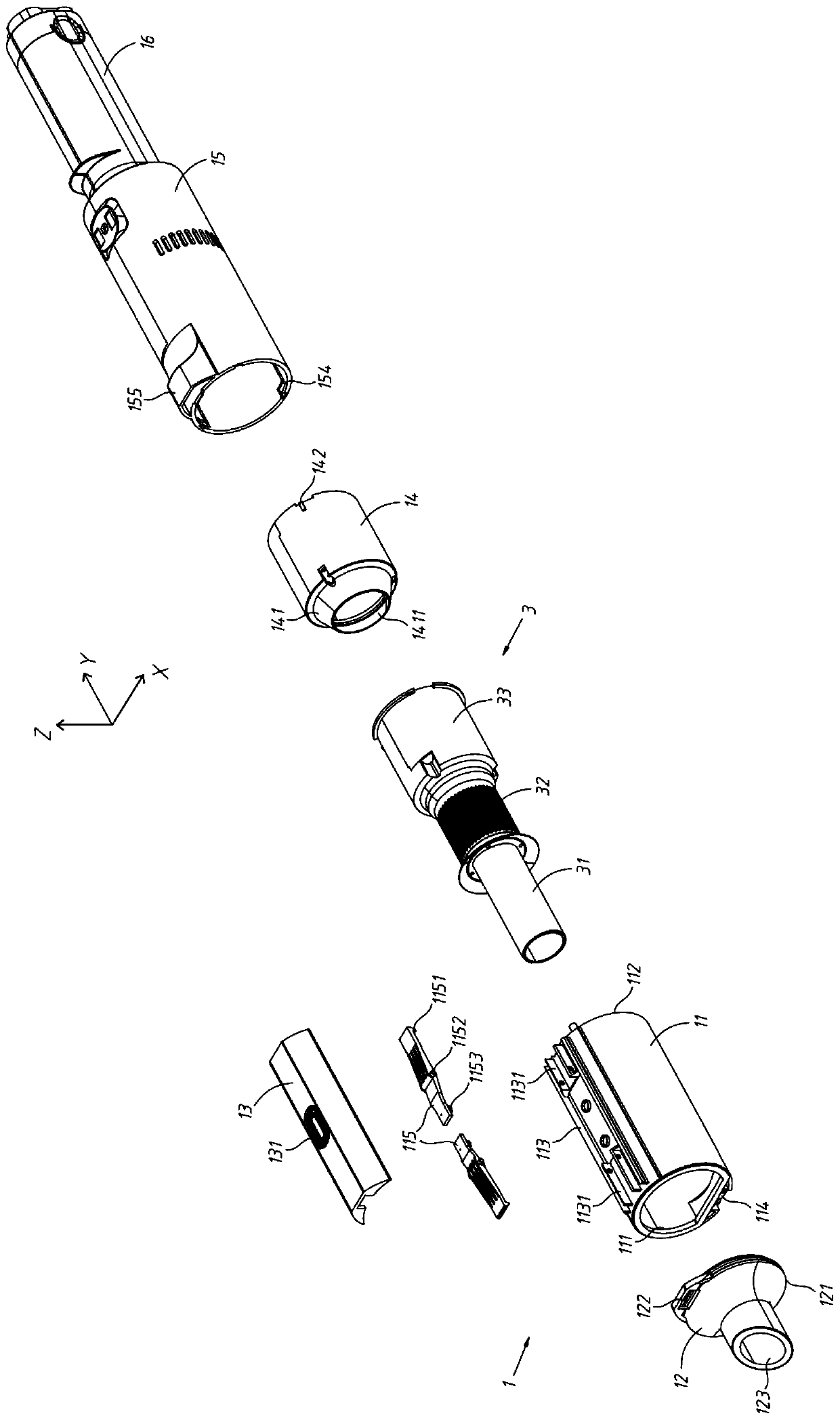

Easy-to-disassemble/assemble water-gas separation structure

PendingCN110960146AAchieve separationEasy to cleanLiquid degasificationCarpet cleanersEngineeringProcess engineering

The invention discloses an easy-to-disassemble / assemble water-gas separation structure, which comprises: a hollow water collecting cup, which is opened at the top to form an opening, and is used for collecting sewage after water-gas separation; a pipeline assembly that is connected to the bottom of the water collecting cup and used for guiding the pumped dirty water and air mixed fluid into the water collecting cup and keeping air pressure balance between the interior of the water collecting cup and the outside; a water-gas separation assembly that is detachably connected to the top of the water collecting cup so as to seal the opening; and at least one set of lock assembly that is used for locking and unlocking the connection state between the water-gas separation assembly and the water collecting cup. According to the invention, the separation of the water collecting cup and the water-gas separation assembly can be quickly realized by pressing the locking piece by one key, so that the sewage collected in the water collecting cup is convenient to discharge and clean, the water-gas separation assembly is also convenient to clean, and the easy-to-clean property and the use experience of customers are greatly improved.

Owner:DREAM INNOVATION TECH (SUZHOU) CO LTD

Novel textile fabric

InactiveCN105506823AImproves ease of cleaningImprove drying efficiencyWoven fabricsArtifical filament manufactureYarnEngineering

The invention relates to a novel textile fabric. The novel textile fabric is characterized in that yarns of the novel textile fabric are core spun yarns; yarn core parts are formed by functional fibers beneficial to dehumidification; winding parts are formed by functional fibers with the functions of raising temperature and storing heat; the functional fibers with the functions of raising temperature and storing heat are formed by carrying out melt spinning on 60-80 parts of conventional fiber materials, 15-20 parts of carbon black particles used for pigments and 5-20 parts of color master batches by weight; the functional fibers beneficial to dehumidification are formed by carrying out melt spinning on fiber materials and conventional fiber materials in a ratio of 1 to 1; the crimp percentages of the fiber materials become low when the fiber materials encounter water. The novel textile fabric has the beneficial effect that the clothes washing and airing efficiency is improved through combined action of temperature rise, heat storage and increase of gaps of the fabric.

Owner:JIANGSU HAIYANG CHEM FIBERS +1

Novel functional textile fabric

ActiveCN105648626AImproves ease of cleaningImprove drying efficiencyMelt spinning methodsWoven fabricsMasterbatchYarn

The invention relates to a novel functional textile fabric. Yarn of the novel functional textile fabric is composite yarn, the yarn core part is composed of functional fibers facilitating moisture removal, and the winding part is composed of functional fibers capable of rising temperature and storing heat; the functional fibers capable of rising the temperature and storing the heat are formed by conducting melt spinning on 60-80 parts by weight of standard fibers, 15-20 parts by weight of carbon black particles for pigment and 5-20 parts by weight of color masterbatch; the functional fibers facilitating the moisture removal are fibers of which the curl ratio becomes smaller when the fibers encounter water. According to the novel functional textile fabric, the washing and airing efficiency of clothes are improved by means of combined effects of temperature rising, heat storing and fabric gap increasing.

Owner:BAIFENG SHAOXING TEXTILE

A new type of functional fabric

InactiveCN105671732BImproves ease of cleaningImprove drying efficiencyWoven fabricsYarnYarnMicroparticle

The invention relates to a new type of functional fabric. The yarn of the new type of functional fabric is a core-spun yarn. The core part of the yarn is composed of a functional fiber that heats up and stores heat. The heat-storing functional fiber is composed of conventional fiber materials accounting for 99.91-99.95% of the total weight of the yarn core and melt-spun nano-units accounting for 0.05-0.09% of the total weight of the yarn core. The functional fiber that is beneficial to dehumidification is a fiber that has a smaller curling rate when exposed to water; the nano-unit includes microparticles of 8500-9000 nanometers, and the micro-particles include 300-500 weight units of zinc, 350-9000 nanometers 450 weight units of aluminum and 150-350 weight units of iron. The present invention improves the efficiency of washing and airing clothes through the combined effect of temperature rise and heat storage and enlarging the voids of fabrics.

Owner:浙江朗莎尔维迪制衣有限公司

A functional textile fabric

InactiveCN105483893BImproves ease of cleaningImprove insulation effectWeft knittingWarp knittingYarnMaterials science

The invention relates to a functional textile fabric. The yarn of the functional textile fabric is a core-spun yarn. The core part of the yarn is composed of a functional fiber that is beneficial to dehumidification, and the winding part is composed of a function of heating and heat storage. The functional fiber for heat storage is composed of conventional fiber materials accounting for 99.91-99.95% by weight of the total weight of the winding part and nano-unit melt spinning accounting for 0.05-0.09% of the total weight of the winding part. The functional fiber that is beneficial to dehumidification is a fiber that has a smaller curling rate when encountering water; the nano-units include 8500-9000 nanometer particles, and the particles include 300-500 weight units of zinc, 350-450 weight units Units of aluminum and 150 to 350 weight units of iron. The present invention improves the efficiency of washing and airing clothes through the combined effect of temperature rise and heat storage and enlarging the voids of fabrics.

Owner:绍兴满和纺织有限公司

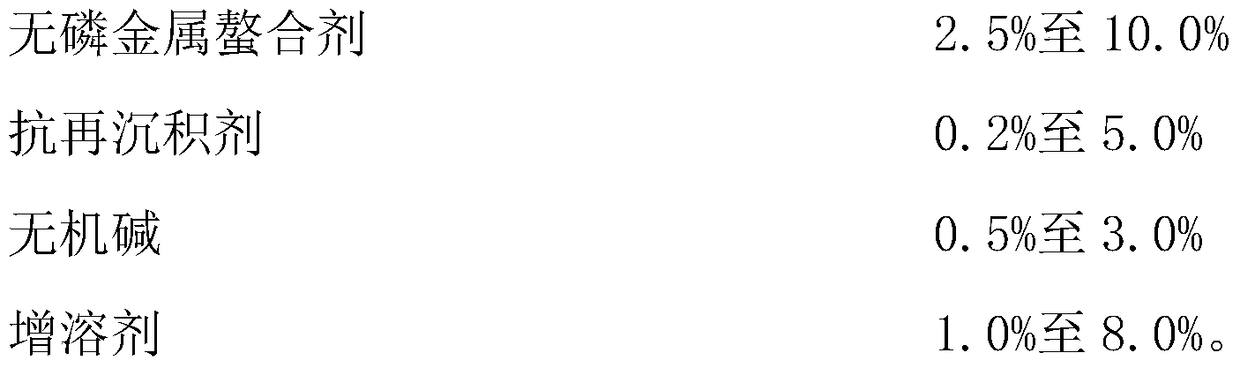

A kind of phosphorus-free automobile cleaning liquid and preparation method thereof

InactiveCN104745322BPenetrates quickly and evenlyDisintegrate quicklyInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsFilm-forming agentSolvent

The invention discloses a phosphorus-free automobile cleaning solution and a preparation method thereof. The cleaning solution comprises the following components in percentage by weight: 6.5-48.0% of a surfactant, 4.2-26.0% of a washing assistant, 1.0-15.0% of a penetrating agent, 0.05-1.0% of a leveling film forming agent and the balance of deionized water. The preparation method comprises the following steps: (1) mixing fatty alcohol-polyoxyethylene ether sodium sulfate with a solubilizer, and adding the deionized water; (2) mixing with the surfactant, the phosphorus-free metal chelating agent, the penetrating agent and the leveling film forming agent in the formula; (3) mixing the mixture with an anti-redeposition agent and an inorganic base; and (4) standing to obtain the cleaning solution. The automobile cleaning solution provided by the invention can realize wiping-free cleaning, is high in cleaning rate, can form an anti-fouling film after cleaning, is environment-friendly and can be degraded easily; and the preparation method provided by the invention is mild in condition and suitable for large-scale production.

Owner:HUAZHONG UNIV OF SCI & TECH

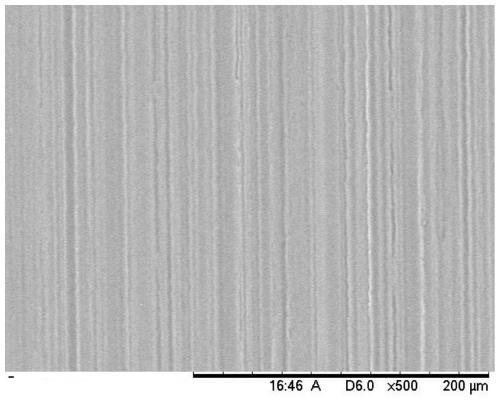

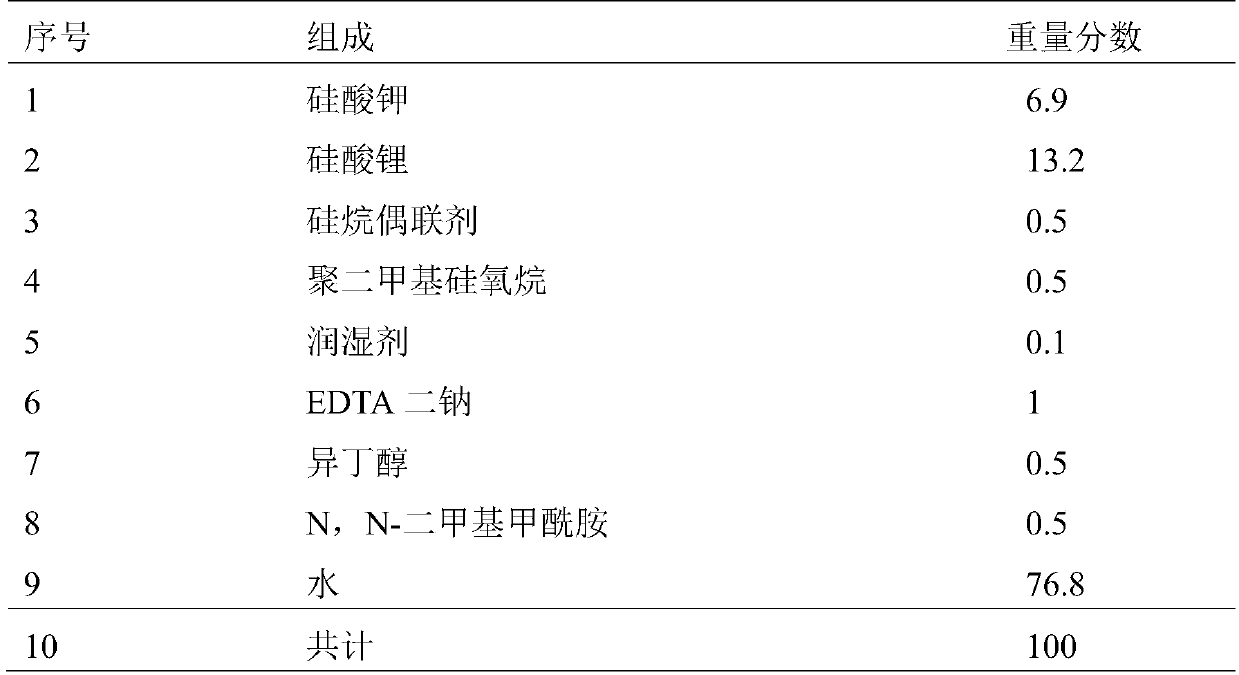

Hard clear, easy-to-clean hydrophobic coating for wood, metal and plastic surfaces

ActiveCN108276812BHigh hardnessImprove hydrophobicityFireproof paintsAlkali metal silicate coatingsLithiumPotassium silicate

The invention discloses a high-hardness, transparent, easily cleaned and hydrophobic coating for wood, metal and plastic surfaces. The high-hardness, transparent, easily cleaned and hydrophobic coating for the wood, metal and plastic surfaces comprises the following raw material components calculated in percentage by mass: 5 to 15% of potassium silicate, 10 to 30% of lithium silicate, 0.5 to 5% ofa silane coupling agent, 1 to 5% of fluorosilicate, 1 to 5% of borate, 0.1 to 2% of a wetting agent, 0.5 to 2% of a buffering agent, 1 to 5% of a coalescing agent and the balance of water. The preparation process of the high-hardness, transparent, easily cleaned and hydrophobic coating for the wood, metal and plastic surfaces comprises the following steps: uniformly mixing the components at roomtemperature, stirring for 1 to 3 h at the temperature between 25 to 60 DEG C, filtering and packing. The high-hardness, transparent, easily cleaned and hydrophobic coating for the wood, metal and plastic surfaces disclosed by the invention has excellent protection ability to a substrate, and makes the surface of the substrate hydrophobic, thereby being capable of improving the wear resistance, high-temperature resistance and easy cleaning ability of the substrate.

Owner:SOUTH CHINA UNIV OF TECH

New Textile Fabric

InactiveCN105506823BImproves ease of cleaningImprove drying efficiencyWoven fabricsArtifical filament manufactureYarnMasterbatch

The invention relates to a new type of textile fabric, the yarn of the new type of textile fabric is a core-spun yarn, the yarn core part is composed of a functional fiber that is beneficial to dehumidification, and the winding part is composed of a temperature-raising and heat-storing functional fiber Composition: The functional fibers for temperature rise and thermal storage are composed of 60-80 parts by weight of conventional fiber materials, 15-20 parts by weight of carbon black particles for pigments, and 5-20 parts by weight of 20 parts of color masterbatch are melt-spun; the functional fiber beneficial to dehumidification is melt-spun from a fiber material with a reduced curling rate when exposed to water and a conventional fiber material at a ratio of 1:1. The present invention improves the efficiency of washing and airing clothes through the combined effect of temperature rise and heat storage and enlarging the voids of fabrics.

Owner:JIANGSU HAIYANG CHEM FIBERS +1

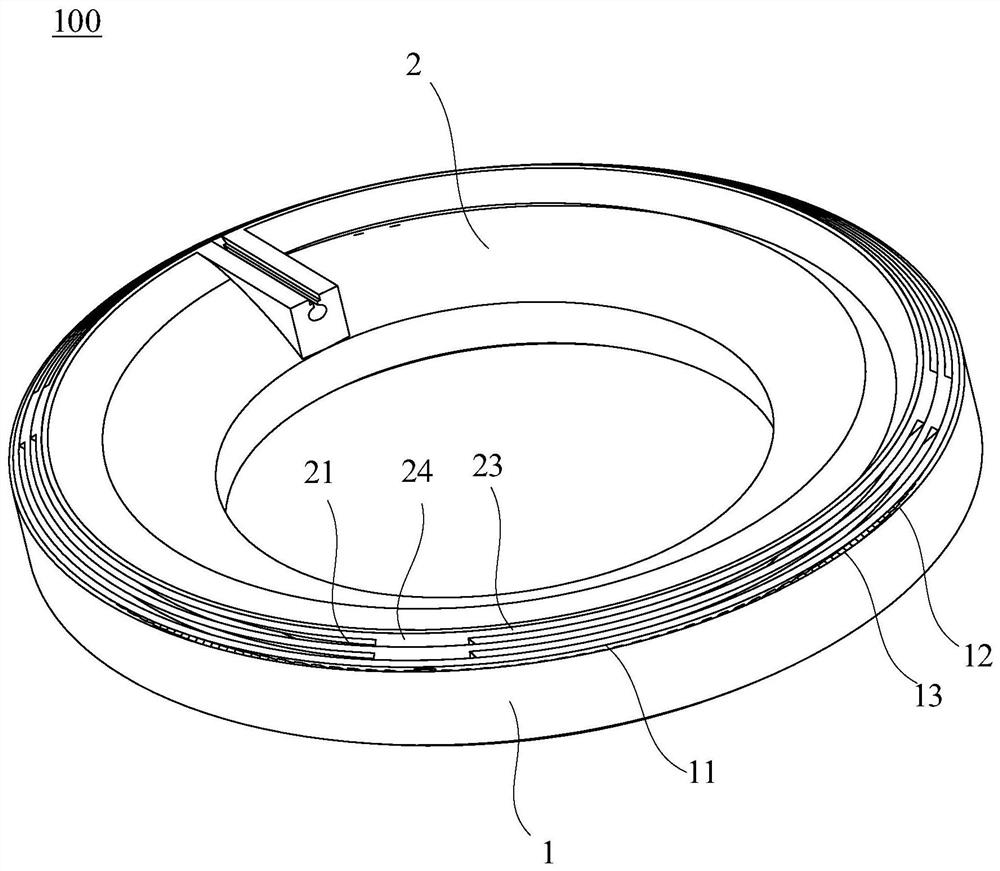

Burner cap and stove burner comprising same

ActiveCN113375156AImprove combustion efficiencyEasy to cleanGaseous fuel burnerHome appliance efficiency improvementThermodynamicsCombustor

The invention discloses a burner cap and a stove burner comprising same. The burner cap comprises an annular burner cap body and a cap plate assembly, wherein the outer ring of the cap plate assembly is detachably connected with the upper end of the burner cap body, and the cap plate assembly and the burner cap body are jointly formed into a gas mixing cavity with a downward opening; and an arc-shaped main fire outlet hole extending in the circumferential direction is formed in the outer edge of the cap plate assembly, an annular fire outlet ring is arranged between the cap plate assembly and the burner cap body, and the main fire outlet hole and the fire outlet ring communicate with the gas mixing cavity. The main fire outlet hole is arc-shaped, and the area of the main fire outlet holes is larger than that of a conventional discrete round fire outlet hole, so that the strength of the fire hole is relatively low, the amount of injected primary air is large, and combustion is more sufficient; secondly, the flame distribution of the arc-shaped main fire outlet hole in the circumferential direction is more uniform than that of the conventional discrete round fire outlet hole, so that the heating uniformity and heat absorption of the bottom of cookware are improved favorably; and it is not easy for the wall surface of the arc-shaped main fire outlet hole to adhere to a liquid to cause blocking, and the main fire outlet hole is easy to clean.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Hydrophilic and oleophobic easy-to-clean organic coating and preparation method thereof

The invention discloses a hydrophilic and oleophobic easy-to-clean organic coating and a preparation method thereof. The organic coating is obtained by curing an organic solution by a curing agent, the organic solution is a fluorine-containing polyurethane modified epoxy resin solution formed by carrying out a reaction on fluorine-containing polyurethane and an epoxy resin in an organic solvent, and the fluorine-containing polyurethane and the epoxy resin form a semi-interpenetrating network structure formed through the bonding of chemical bonds. A micro area with uniformly distributed hydrophilicity and oleophobicity is constructed on the surface of an object to be coated through the semi-interpenetrating structure and low surface performances of fluorine, so the hydrophilic and oleophobic easy-to-clean organic coating is formed. Experiments prove that the lowest contact angle between the organic coating and water can reach 15DEG, and the highest contact angle between the organic coating and oil can reach 90DEG, so water can thoroughly displace oil stains on the surface of an original solid, and an easy-to-clean effect is reached.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

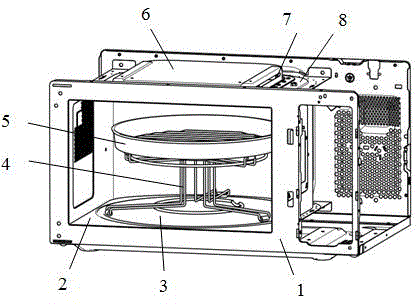

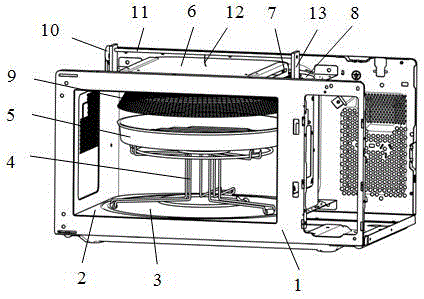

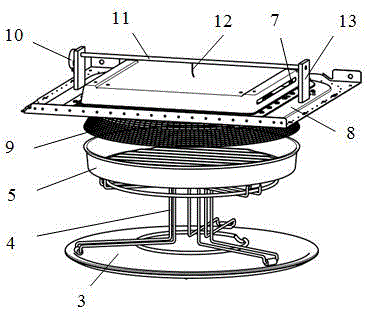

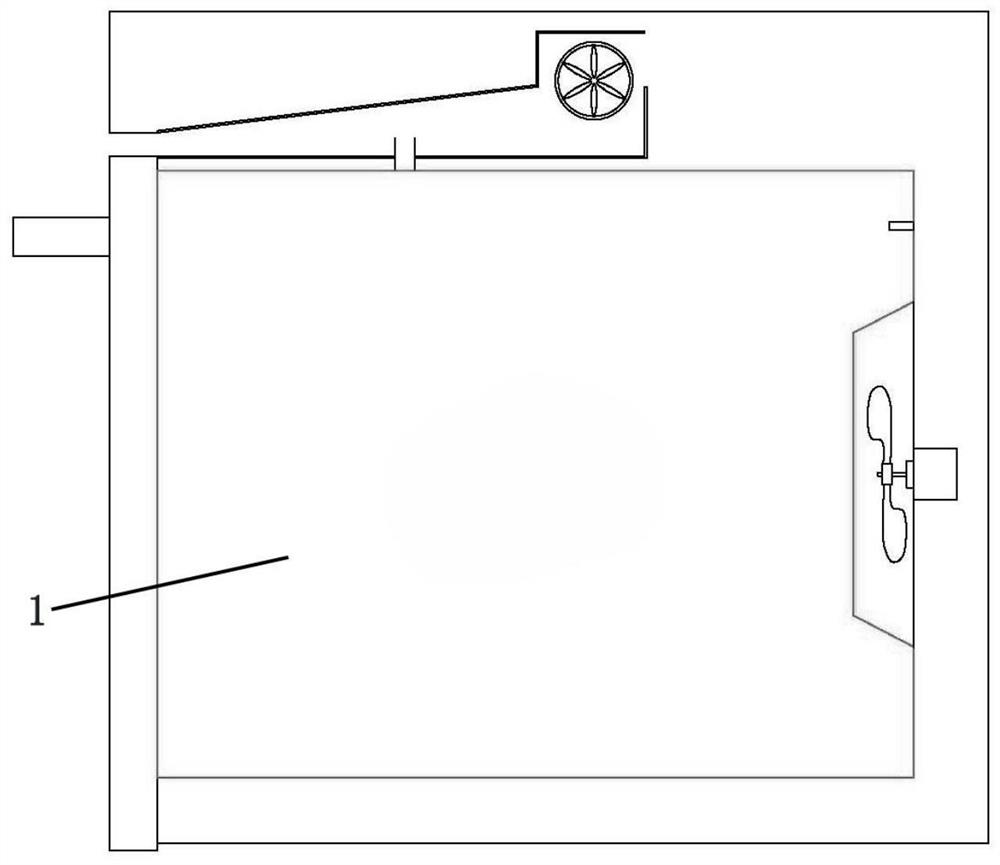

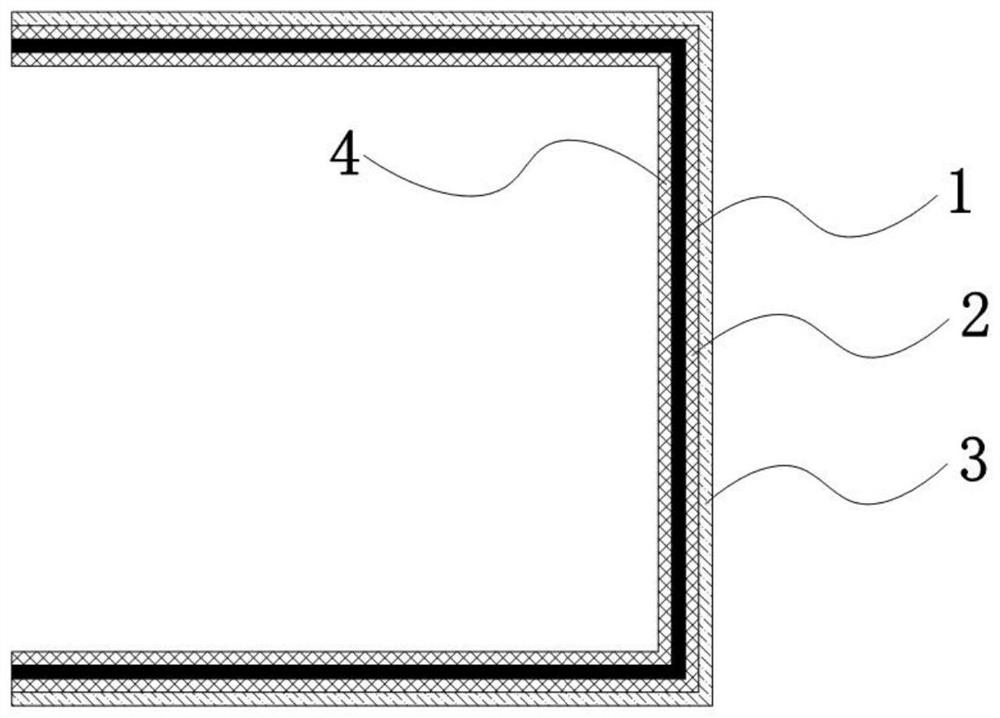

Electric oven to prevent splashing of oil

InactiveCN102188165BPrevent splashSolve cleaning difficultiesRoasters/grillsAutomatic controlEngineering

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

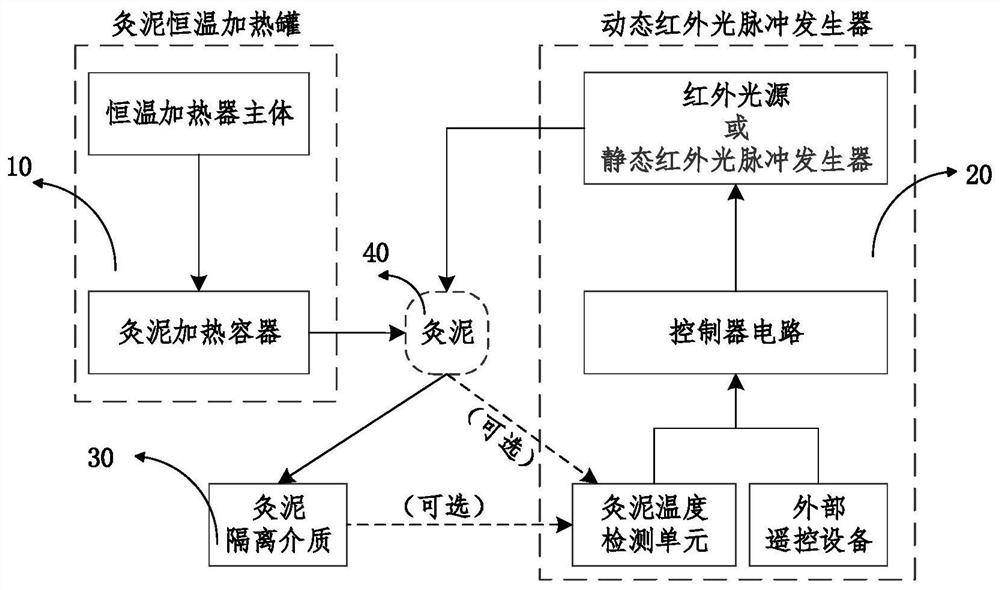

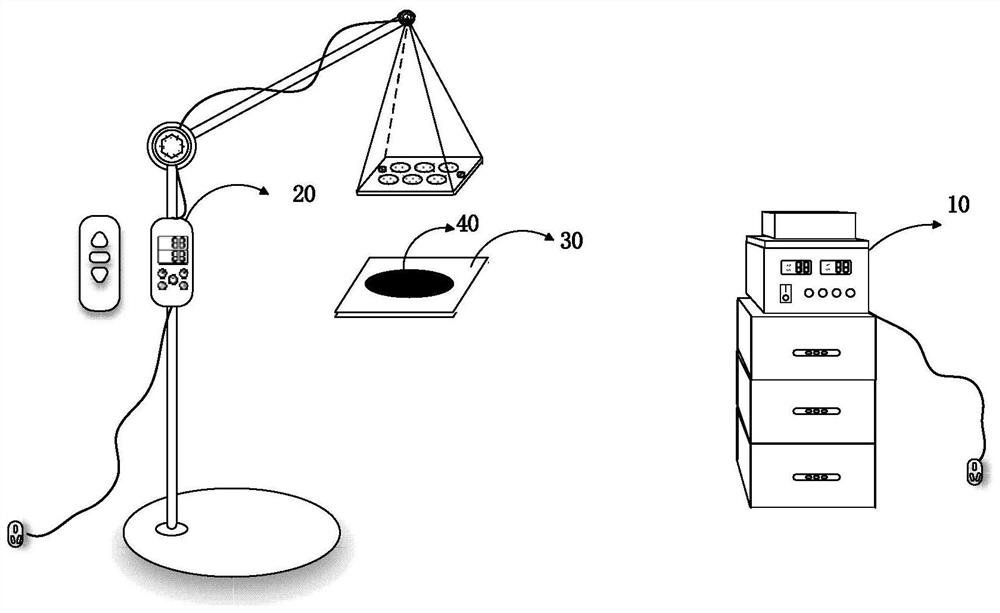

System for improving mud moxibustion effect by combining dynamic infrared light pulse stimulation and use method

PendingCN112022689APrecisely control the initial temperatureReduce the amount of moxibustion mudDevices for heating/cooling reflex pointsLight therapyInfraredMedicine

The invention provides a system for improving a mud moxibustion effect by combining dynamic light pulse stimulation. The system comprises a constant-temperature moxibustion mud heating tank, a dynamicinfrared light pulse generator, a moxibustion mud isolation medium and moxibustion mud. The constant-temperature moxibustion mud heating tank is composed of a constant-temperature heater body, a moxibustion mud container and the like and used for completing constant-temperature heating and heat preservation of moxibustion mud. The dynamic infrared light pulse generator is composed of an infraredlight source or a static infrared light generator, a controller circuit, a moxibustion mud temperature detection unit, a remote controller, a support and the like and used for generating dynamic infrared light pulses. The moxibustion mud isolation medium is used for isolating moxibustion mud from a mud moxibustion object. The invention further discloses a use method of the system suitable for improving the mud moxibustion effect by combining dynamic infrared light pulse stimulation. The defects that in a traditional method, the temperature of moxibustion mud is uncontrollable, and burning is likely to happen are overcome; meanwhile, the advantages of reducing the use amount of the moxibustion mud, shortening the mud moxibustion conditioning time, improving the mud moxibustion sanitary condition and the like are achieved; double moxibustion integration of mud moxibustion and imitation moxibustion is achieved, and the comprehensive effect of mud moxibustion is improved.

Owner:洪文学

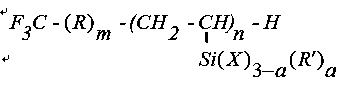

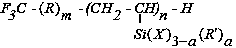

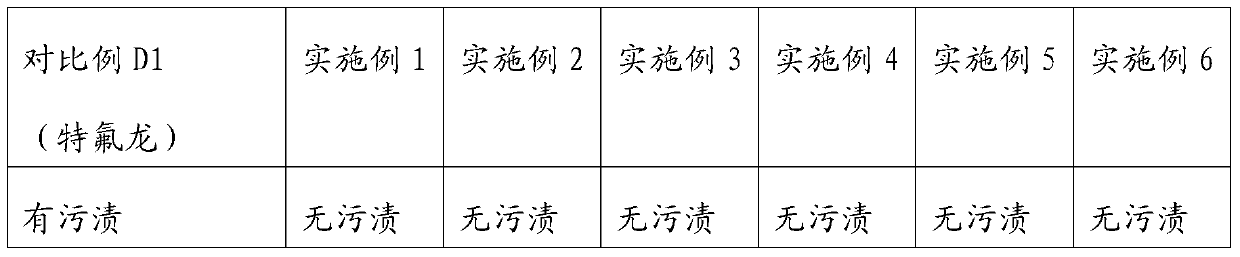

A kind of preparation method of antifouling and antibacterial composite coating

ActiveCN107033650BImproves ease of cleaningReduce the total number of coloniesAntifouling/underwater paintsPaints with biocidesMicrosphereSilanes

The invention relates to a preparation method of antifouling anti-bacterial composite coating. The preparation method includes steps of (1), dispersing ethyl orthosilicate in alcohol / water solution to form solution (A); adding ammonium hydroxide into alcohol to form alcohol amine solution (B); adding form alcohol amine solution (B) in the solution (A) and stirring; then performing standing of the mixture to obtain solution (C) and nanometer spherical SiO2 particle in the solution (C); (2), dispersing the prepared nanometer SiO2 microsphere in an acid water solution containing SnCl2.2H2O and performing sensitization treatment to obtain a SiO2 microsphere (D) absorbed with Sn2+, and dispersing the SiO2 microsphere (D) absorbed with Sn2+ in the water and adding AgNO3 solution and reducing agent to obtain the Ag-loaded nanometer SiO2 microsphere; (3), dispersing the prepared Ag-loaded nanometer SiO2 microsphere in the alcohol-water solution; then adding silane hydrolysate containing perfluoroalkyl group in the solution to obtain the antifouling anti-bacterial composite coating.

Owner:CHERY AUTOMOBILE CO LTD

A kind of hydrophilic easy-to-clean coating and preparation method thereof

ActiveCN105504898BImprove adhesionImprove temperature resistanceAnti-corrosive paintsHydrophilic coatingGas phase

The invention relates to a hydrophilic coating easy to clean and a preparing method of the hydrophilic coating. The hydrophilic coating easy to clean comprises, by mass, 25%-44% of silica sol, 15%-40% of aluminum sol, 10%-25% of titanium sol, 5%-9% of an alkali metal silicate aqueous solution, 3%-6% of hydrophilic fumed silica, 0.5%-1% of assistant and 10%-20% of solvent. The preparing method includes the steps that the silica sol, the aluminum sol, the titanium sol, the alkali metal silicate aqueous solution, the hydrophilic fumed silica, the assistant and the solvent are mixed together according to the ratio to prepare the hydrophilic coating easy to clean. The hydrophilic coating easy to clean has the easily-cleaned performance, acid resistance, base resistance, scraping resistance and other performances.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

Inner container structure, cooking equipment and preparation method of inner container structure of cooking equipment

PendingCN112315305ASimple structureFast temperature riseLiquid surface applicatorsSteam cooking vesselsInfraredEngineering

The invention discloses an inner container structure, cooking equipment and a preparation method of the inner container structure of the cooking equipment. The inner container structure comprises an inner container, an insulating layer is arranged on the outer wall of the inner container, a conductive layer is arranged on the outer surface of the insulating layer, and the conductive layer can release infrared rays under the action of voltage. The structure is simple, the inner container structure has the advantage of being fast in temperature rise, and the uniformity of the temperature field of the inner container is further improved.

Owner:VATTI CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com