Hydrophilic coating easy to clean and preparing method of hydrophilic coating

A hydrophilic, easy-to-clean technology, applied in the direction of anti-corrosion coatings, coatings, etc., can solve problems such as damage, affecting product appearance, and easily damaged electrical product materials, so as to achieve good acid and alkali resistance and avoid scratches.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

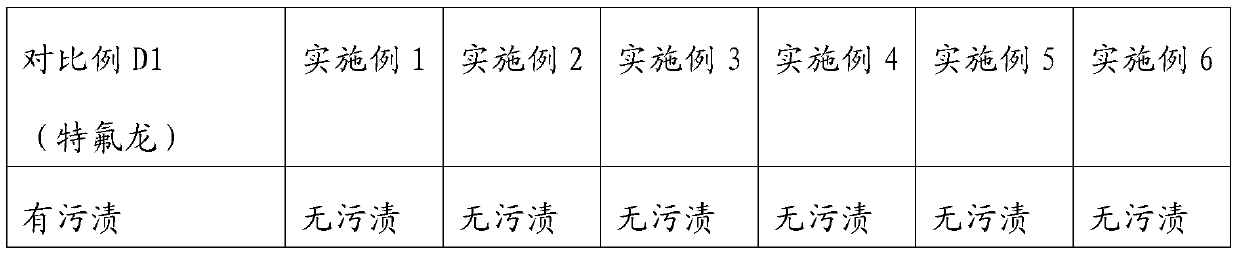

Examples

Embodiment 1

[0084] A hydrophilic easy-to-clean coating, the components of the coating are calculated by mass percentage: 31% of silica sol, 25% of aluminum sol, 11% of titanium sol, 6% of lithium silicate aqueous solution, hydrophilic gas phase two Silicon oxide is 6%, auxiliary agent is 1%, and solvent is 20%. The solvent includes two parts, namely: deionized water in step 1) and isopropanol in step 2).

[0085] The specific parameters of silica sol are: average particle size 8nm, SiO 2 The mass percentage is 20%, the viscosity is 20Pa.S, the solvent is water, and the pH is 10.

[0086] The specific parameters of aluminum sol are: average particle size 10nm, Al 2 o 3 The mass percentage is 20%, the viscosity is 20Pa.S, the solvent is water, and the pH is 4.5.

[0087] The preferred specific parameters of titanium sol are: the average particle diameter is 15nm, TiO 2 The mass percentage is 20%, the viscosity is 20Pa.S, the solvent is water, and the pH is 6.5.

[0088] The specific p...

Embodiment 2

[0097] A preparation of a hydrophilic easy-to-clean coating. The components of the coating are calculated by mass percentage: 25% of silica sol, 30% of aluminum sol, 25% of titanium sol, 5% of potassium silicate aqueous solution, hydrophilic type Fumed silica 4%, auxiliary agent 0.7% and solvent 10.3%. The solvent includes two parts, namely: the deionized water added in step 1) and the dipropylene glycol dimethyl ether added in step 2).

[0098] The specific parameters of silica sol are: average particle size 20nm, SiO 2 The mass percentage is 35%, the viscosity is 30Pa.S, the solvent is water, and the pH is 9.

[0099] The specific parameters of aluminum sol are: average particle size 25nm, Al 2 o 3 The mass percentage is 30%, the viscosity is 30Pa.S, the solvent is water, and the pH is 4.

[0100] The preferred specific parameters of titanium sol are: the average particle diameter is 15nm, TiO 2 The mass percentage is 30%, the viscosity is 30Pa.S, the solvent is water, ...

Embodiment 3

[0110] A preparation of a hydrophilic easy-to-clean coating. The components of the coating are calculated by mass percentage: 35% of silica sol, 15% of aluminum sol, 20% of titanium sol, 9% of sodium silicate aqueous solution, and hydrophilic type Fumed silica was 5%, adjuvant was 1% and solvent was 15%. The solvent in this formula includes two parts, namely: deionized water in step 1) and ethanol in step 2).

[0111] The specific parameters of silica sol are: average particle size 12nm, SiO 2 The mass percentage is 30%, the viscosity is 25Pa.S, the solvent is water, and the pH is 11.

[0112] The specific parameters of aluminum sol are: average particle size 15nm, Al 2 o 3 The mass percentage is 25%, the viscosity is 25Pa.S, the solvent is water, and the pH is 6.

[0113] The preferred specific parameters of titanium sol are: the average particle size is 10nm, TiO 2 The mass percentage is 25%, the viscosity is 25Pa.S, the solvent is water, and the pH is 7.

[0114] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com