A kind of phosphorus-free automobile cleaning liquid and preparation method thereof

A car cleaning liquid, cleaning liquid technology, applied in the direction of chemical instruments and methods, inorganic/element cleaning composition, detergent composition, etc., can solve the problems of cleaning agents such as laborious scrubbing, and achieve reduced adhesion and good stability , Applicable to the effect of wide ambient temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The cleaning solution preparation method provided by the invention comprises the following steps:

[0055] (1) Mix the fatty alcohol polyoxyethylene ether sodium sulfate with the solubilizer in the formula ratio, stir until the fatty alcohol polyoxyethylene ether sodium sulfate is completely dissolved; then dissolve the mixture in deionized water to form a mixed solution.

[0056] (2) Add alkyl glycoside, phosphorus-free metal chelating agent, penetrant and leveling film-forming agent in sequence to the mixed solution in step (1), and stir evenly.

[0057] (3) Add sodium lauryl sulfate in the formula ratio to the mixture in step (2), and after mixing evenly, add the anti-redeposition agent in the formula ratio, and after mixing evenly, add the inorganic base in the formula ratio and mix evenly.

[0058] (4) Let the mixed solution obtained in step (3) stand until a colorless and transparent mixed solution is obtained, and the cleaning solution is obtained.

[0059] The ...

Embodiment 1

[0072] Cleaning liquid provided by the invention comprises by weight ratio:

[0073] Surfactant:

[0074] Sodium Fatty Alcohol Polyoxyethylene Ether Sulfate 5.0%

[0075] Alkyl glucoside 0814 10.0%

[0076] Sodium Lauryl Sulfate 6.5%

[0077] Penetrant:

[0078] Fatty alcohol polyoxyethylene ether 9.0%

[0079] Detergents:

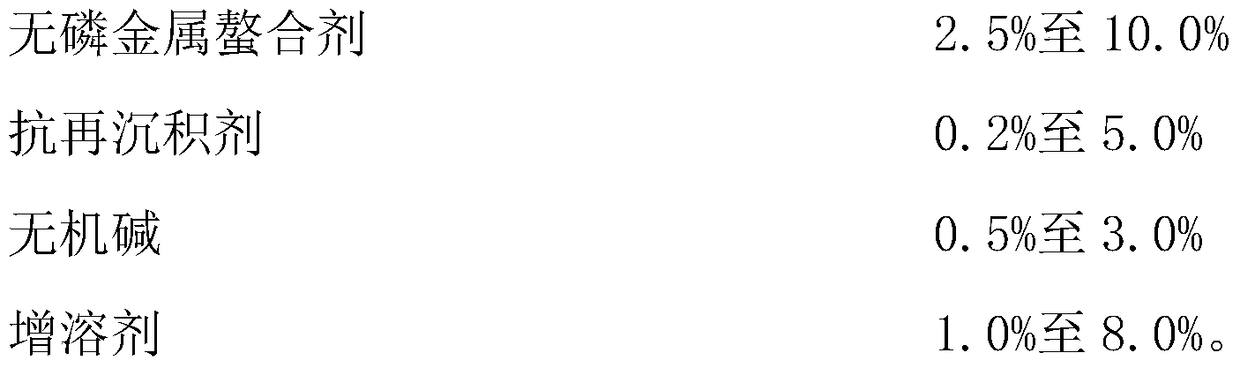

[0080]

[0081] Leveling film former:

[0082] Fluorocarbon leveling agent FC-129 0.05%

[0083] other:

[0084] Deionized water balance.

[0085] The preparation method of described cleaning liquid, comprises the following steps:

[0086] (1) Mix the sodium fatty alcohol polyoxyethylene ether sulfate and ethanol in the formula ratio, stir until the sodium fatty alcohol polyoxyethylene ether sulfate is completely dissolved; then dissolve the mixture in deionized water to form a mixed solution.

[0087] (2) Add alkyl glucoside 0814, sodium citrate, fatty alcohol polyoxyethylene ether and fluorocarbon leveling agent FC-129 to the mixture in step...

Embodiment 2

[0094] Cleaning liquid provided by the invention comprises by weight ratio:

[0095] Surfactant:

[0096] Sodium fatty alcohol polyoxyethylene ether sulfate 3.5%

[0097] Alkyl glucoside 0810 24.0%

[0098] Sodium Lauryl Sulfate 2.5%

[0099] Penetrant:

[0100] Fatty alcohol polyoxyethylene ether 4.0%

[0101] Detergents:

[0102]

[0103] Leveling film former:

[0104] Fluorocarbon leveling agent FC-129 0.4%

[0105] other:

[0106] Deionized water balance.

[0107] The preparation method of described cleaning liquid, comprises the following steps:

[0108] (1) Mix the sodium fatty alcohol polyoxyethylene ether sulfate and methanol in the formula ratio, stir until the sodium fatty alcohol polyoxyethylene ether sulfate is completely dissolved; then dissolve the mixture in deionized water to form a mixed solution.

[0109] (2) Add alkyl glucoside 0810, sodium citrate, fatty alcohol polyoxyethylene ether and fluorocarbon leveling agent FC-129 in sequence to the mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com