Dustproof easy-to-clean ceramic sheet and preparation method thereof

A ceramic thin plate, easy-to-clean technology, applied in the production of ceramic materials, coatings, epoxy resin coatings, etc., can solve the problems of few convenient cleaning, improvement of dust removal function, etc., to achieve convenient cleaning, enhance self-cleaning effect, improve The effect of self-cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

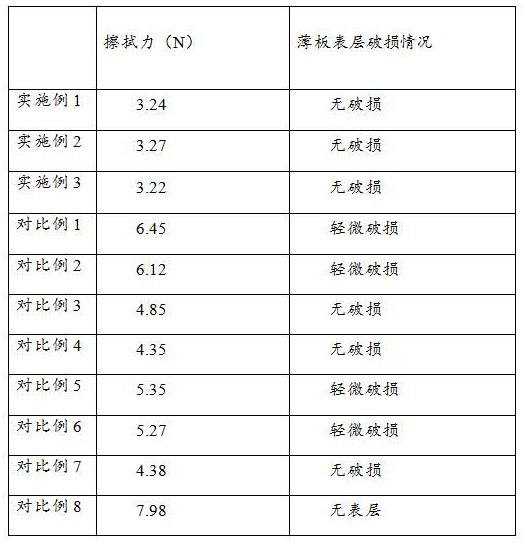

Examples

preparation example Construction

[0036] The preparation method of the self-cleaning additive of the present embodiment is:

[0037] S1: The mullite fiber is first placed in the radiation field for radiation treatment, and the radiation is irradiated with protons, and the irradiation dose is 40-100 kGy. After the irradiation, the irradiation modified mullite fiber is obtained;

[0038] S2: The irradiation-modified mullite fiber is sent into 2-3 times of flake boron nitride modifier for stirring and dispersing. The stirring speed is 500-600r / min, the stirring time is 45-55min, and the stirring temperature is The temperature is 75-85°C, the stirring is completed, washed with water, and dried to obtain a mullite-flaky boron nitride composite;

[0039] S3: subjecting the mullite-flaky boron nitride composite to thermal improvement treatment, finishing the treatment, and finally air-cooling to room temperature to obtain a mullite-flaky boron nitride modified body;

[0040] S4: The mullite-flaky boron nitride impro...

Embodiment 1

[0056] A dust-proof and easy-to-clean ceramic thin plate of the present embodiment includes the following raw materials in parts by weight:

[0057] 20 parts of cordierite, 15 parts of fluorite, 5 parts of potassium feldspar, 3 parts of self-cleaning additive, 1 part of barium titanate sintering aid, 0.2 part of talc, and 0.1 part of modified nano-silica.

[0058] The preparation method of the self-cleaning additive of the present embodiment is:

[0059] S1: The mullite fiber is first placed in the radiation field for radiation treatment, and the radiation adopts proton irradiation, and the irradiation dose is 40kGy. After the irradiation, the irradiation modified mullite fiber is obtained;

[0060] S2: The irradiation-modified mullite fiber is sent into 2 times of flake boron nitride modifier for stirring and dispersing. The stirring speed is 500r / min, the stirring time is 45min, the stirring temperature is 75℃, and the stirring is finished. , washed with water and dried to ...

Embodiment 2

[0078] A dust-proof and easy-to-clean ceramic thin plate of the present embodiment includes the following raw materials in parts by weight:

[0079] 30 parts of cordierite, 25 parts of fluorite, 10 parts of potassium feldspar, 6 parts of self-cleaning additive, 2 parts of barium titanate sintering aid, 0.6 part of talc, and 0.3 part of modified nano-silica.

[0080] The preparation method of the self-cleaning additive of the present embodiment is:

[0081] S1: Place the mullite fiber in the radiation field for radiation treatment, and the radiation adopts proton irradiation, and the irradiation dose is 100kGy. After the irradiation, the irradiation modified mullite fiber is obtained;

[0082] S2: The irradiation-modified mullite fiber is sent into 3 times of flake boron nitride modifier for stirring and dispersing. The stirring speed is 600r / min, the stirring time is 55min, the stirring temperature is 85℃, and the stirring is finished. , washed with water and dried to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com