Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

81results about How to "Improve the one-time pass rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aqueous macromolecule-isocyanic ester stalk artificial board and preparation thereof

ActiveCN101314235ARealize green productionGood workmanshipPolyureas/polyurethane adhesivesFlat articlesWater basedVolatiles

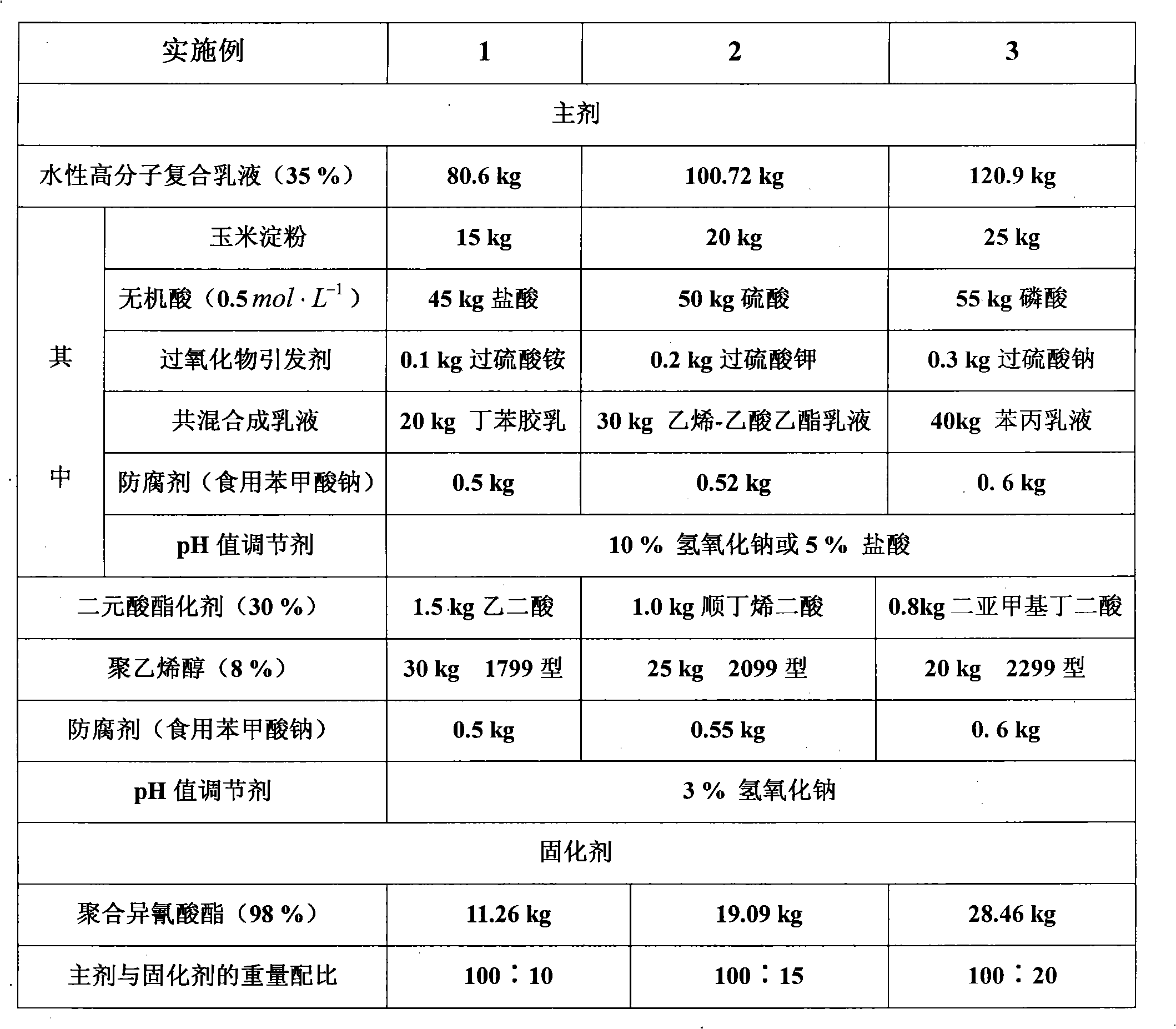

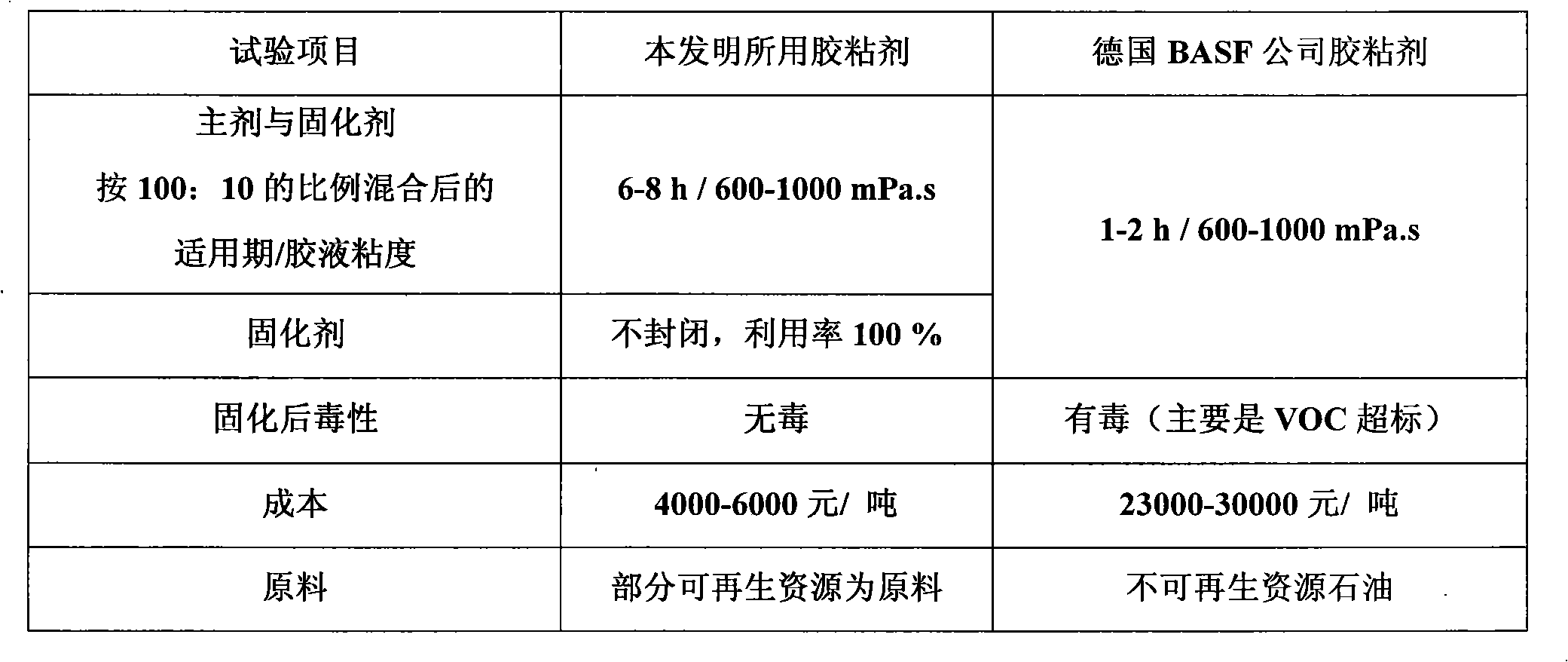

The invention relates to a water-based macromolecule-isocyanate straw hard board and a preparation method thereof. Straws of rice, wheat, corn or other crops, a water-based macromolecule-isocyanate adhesive and a straw interface performance modifying agent are used as raw materials, and the straws are treated by section cutting, kneading and modification, adhesive application and heat pressing to produce the water-based macromolecule-isocyanate straw hard board. A mixture ratio of the absolute dry straws to the water-based macromolecule-isocyanate adhesive to the straw interface performance modifying agent by weight is 100 to 10-16 to 0.05-0.15. The straw hard board uses the water-based macromolecule-isocyanate adhesive to replace a pure isocyanate adhesive, radically improves the problems of toxic organic volatiles, poor prepressing performance, adhesion on boards, etc., remarkably reduces cost and really realizes green production, and the raw materials after the treatment of kneading and modification have good prepressing and molding performances and high one-off qualified rate. The water-based macromolecule-isocyanate straw hard board has the characteristics of unique design, long active period, excellent aging, water and heat resisting performances, simple operation, easy availability of equipment, no environmental pollution, easy implementation, etc., and produces huge entironmental, social and economical benefits after the water-based macromolecule-isocyanate straw hard board is popularized.

Owner:BEIHUA UNIV

Method for producing wooden floor with platinum crystal surface

InactiveCN101301764ASolve the problem of insufficient adhesionIncrease pressureLiquid surface applicatorsWood treatment detailsPlatinumLacquer

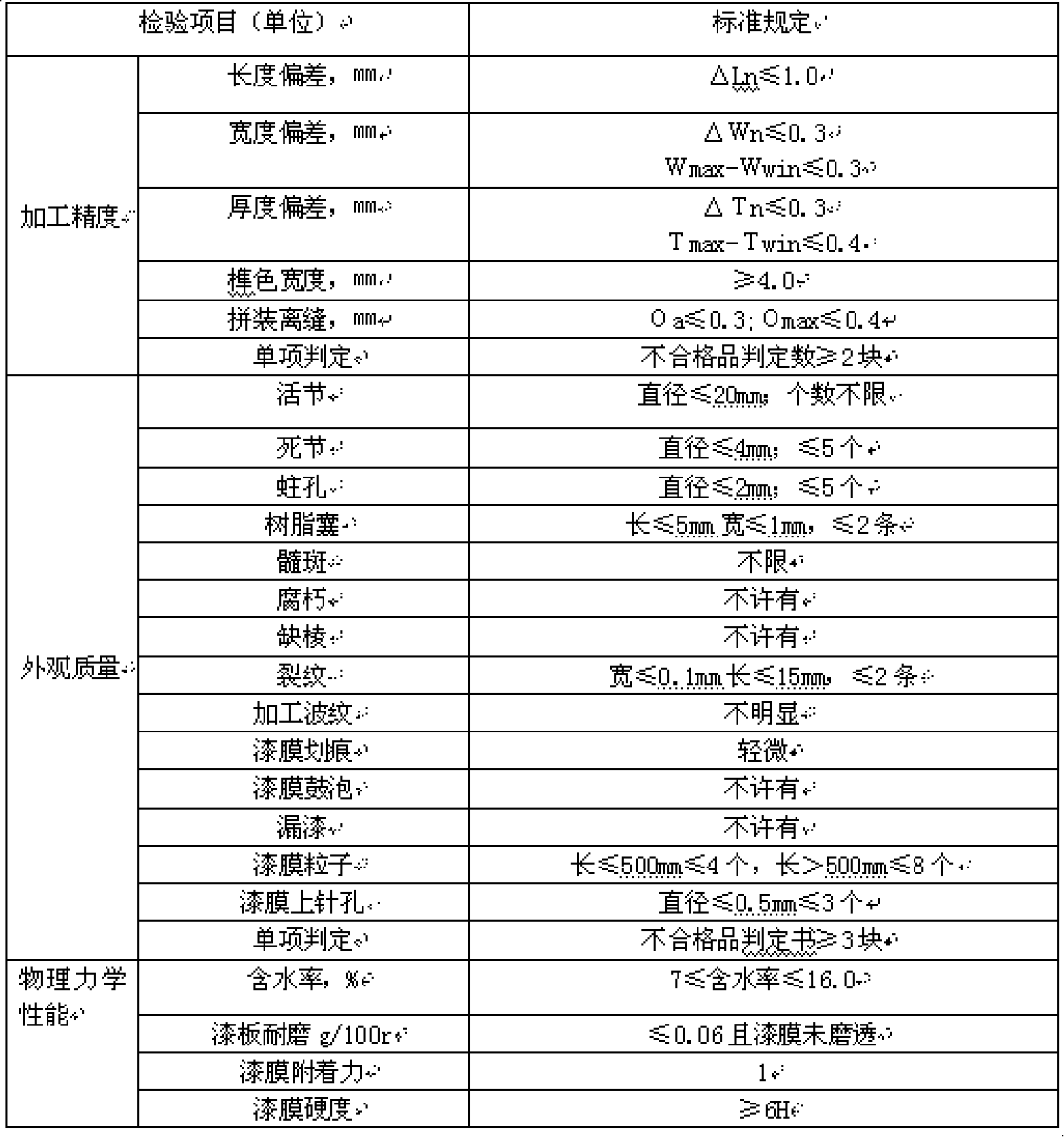

The invention discloses a production method for a platinum crystal face wood floor, which comprises the production steps as follows: drying and curing of floor blank, blank processing, primer and paint painting. The invention adopts a vertical-lubrication penetration roller spraying technique, carries out the pre-heating disposal, drying disposal, balance disposal, humidifying treatment, temperature reduction kiln outgoing and curing to the floor blank, then processes the blank and paints the primer; the paint is then coated by adopting eight-bottom and four-surface so as to gain a finished product. The platinum crystal face wood floor prepared by the invention has the advantages that the paint adhesion of the tree with high grease (oil) content is improved; the floor has ultra-strong adhesion from the interior of the wood to the surface; a production process of eight-bottom and four-surface is adopted to combine an elastic, abration and friction resistance environmental protection paint; therefore, the surface filling of the floor is saturated, clear and natural, the chamfers are smoother and the wood floor is more scraping- resistant and wear-resistant; the one-off qualification rate of the product is improved and achieves 99.5 percent, thus improving the quality of the product.

Owner:浙江上臣家居科技有限公司

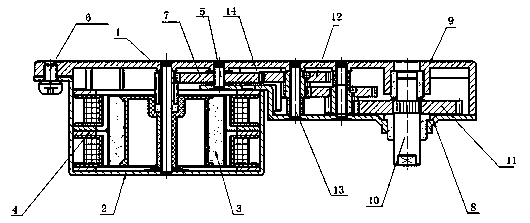

Automatic assembly device for plane thrust retainer and assembly method for automatic assembly device

ActiveCN104482060AThe product has a high one-time pass rateReduce labor costsBearing componentsLifting gasGas cylinder

The invention relates to an automatic assembly device for a plane thrust retainer and an assembly method for the automatic assembly device. The automatic assembly device comprises a base. The automatic assembly device is characterized in that a feeding positioning device, a clamping moving device, an automatic ball assembly device and a riveting device are arranged on the base, wherein the feeding positioning device comprises a material path, a loading base, a feeding gas cylinder, two workpiece release gas cylinders, a pressing gas cylinder, a pressing sleeve and positioning rubber; the automatic ball assembly device comprises a lifting gas cylinder, a ball assembly gas cylinder, a ball assembly gas cylinder bracket, a material accumulator, a stirring plate, a swinging rod, a rotary shaft, a guide sleeve and a ball assembly base; the riveting device comprises a fixed base, a riveting gas cylinder, an upper mould seat, an upper mould and a lower mould; the clamping moving device comprises a moving gas cylinder, a slide table, a lifting plate, a lifting gas cylinder and four finger gas cylinders. The automatic assembly device can be used for automatically and rapidly assembling the retainer, and automatically completing the feeding and the discharging of the retainer, so that the one-time qualified rate of the product is high, the labor cost is greatly reduced, and the large-scale popularization and application are facilitated.

Owner:新昌县精艺轴承有限公司

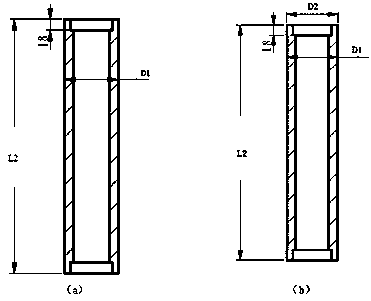

Polishing method for tiny ceramic product

ActiveCN104708525AImprove the one-time pass rateReduce surface roughnessEdge grinding machinesPolishing machinesEtchingMetallurgy

The invention provides a polishing method for a tiny ceramic product. The polishing method includes the step that by means of a rolling polishing machine and a polishing solution, a cambered surface and a straight body position of the tiny ceramic product are polished simultaneously. The polishing method concretely includes the steps that firstly, the polishing solution is prepared, secondly, multiple blocks of the tiny ceramic products and the polishing solution are placed in the rolling polishing machine, the rotational speed of the rolling polishing machine is controlled ranging from 10 rpm to 60 rpm, and the polishing time is controlled ranging from 2 hours to 60 hours; with the actions of mechanical friction and chemical etching, polished tiny ceramic products are obtained in the rolling polishing machine; the polishing solution comprises, by mass, ceramic polishing powder, high-frequency porcelain and water at the ratio of 1: 50-200 :20-120, the ceramic polishing powder comprises SiO [2] particles with an average diameter ranging from 20 nm to 300 nm and cylinder-shaped Al [2]O [3] with a diameter ranging from 1 mm to 10 mm and a height ranging from 2 mm to 20 mm. The one-time yield of obtained tiny ceramic products is larger than 95 %, the surface roughness of the obtained tiny ceramic products is smaller than 5 nm, forty thousand tiny ceramic products can be processed simultaneously at one time, the processing time is shortened, and the production cost is saved.

Owner:LENS TECH

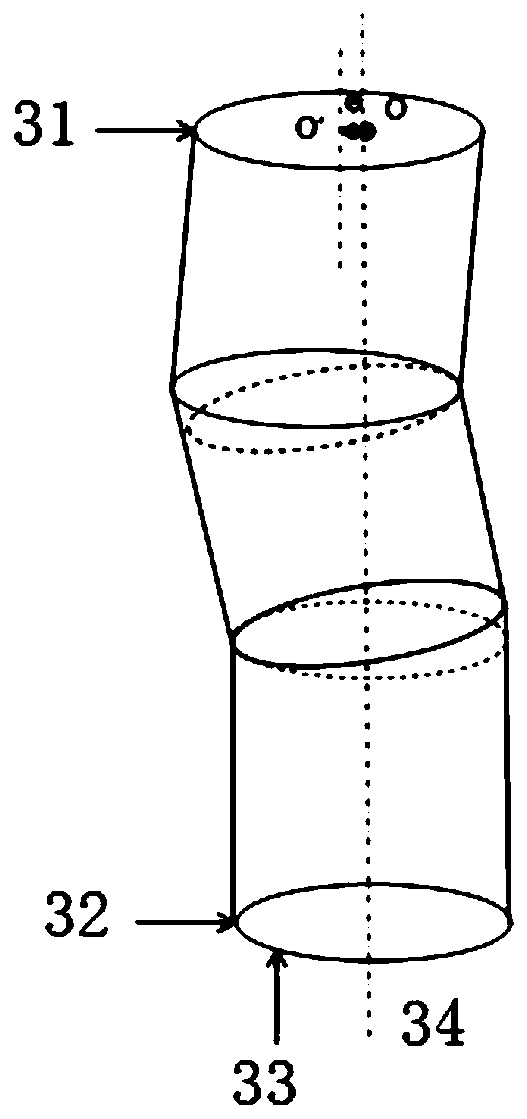

Manufacturing method of reinforcing steel bar component of super large variable cross-section cable pylon

ActiveCN109183628AMinimize impact on personal safetyEasy to assembleWire networkBridge structural detailsVertical edgeTower

The invention relates to a manufacturing method of a cable tower reinforcement skeleton, in particular to a reinforcing steel bar component of a super large variable cross-section cable pylon. The manufacturing method includes the steps: arranging stirrups horizontally and horizontally according to the designed spacing, binding the longitudinal bars arranged along the horizontal longitudinal direction on the stirrups according to the designed spacing, bending the stirrups at the intersection of the stirrups and the bending edge along the axial direction and the circumferential direction of thebending edge respectively, so as to form a ring corresponding to the lower large and upper small variable cross-section reinforcing bar mesh of the cable tower structure, sequentially nesting the reinforcing bar mesh of different sizes corresponding to the same segment of the cable tower according to the flow chart, and binding and fixing the reinforcing bar mesh into a complete section of reinforcing bar parts through the bracing hook bars; the bending edge finger stirrup corresponds to the connecting line of the points of the same vertical edge of the cable tower. The manufacturing method of the invention is simple and efficient, greatly improves the precision degree of the reinforcing steel bar components, reduces the man-hour of welding construction, improves the efficiency of assembling construction, and has great popularization value.

Owner:CCCC SECOND HARBOR ENG +1

Tooling clamp for processing insulating collar turning and method for processing same

InactiveCN103223610AIncrease contact areaAvoid deformationPositioning apparatusMetal-working holdersGrip forceConvex side

The invention discloses a tooling clamp for processing an insulating collar turning. The tooling clamp comprises a concave clamp (8) and a convex clamp (9), wherein the concave clamp (8) comprises a jaw chuck A (10) and a plurality of equant sectorial blocks A (11), the sectorial concave part in each equant sectorial blocks A (11) is composed of a sectorial plane A (13) and a arc-shaped surface side wall A (14), the convex clamp (9) comprises a jaw chuck B (15) and a plurality of equant sectorial blocks B (16), a sectorial plane C (19) is also arranged on the outer side of each equant sectorial block B (16), and the invention further discloses a processing method. The tooling clamp provided by the invention has the advantages that the gripping force is even, so that the deformation of a workpiece is avoided, the clamping efficiency is improved, the time is saved, the workpiece quality and the processing efficiency are improved, and the consistency and the reliability of a part is increased as well.

Owner:CHENGDU JINJIANG ELECTRONICS SYST ENG

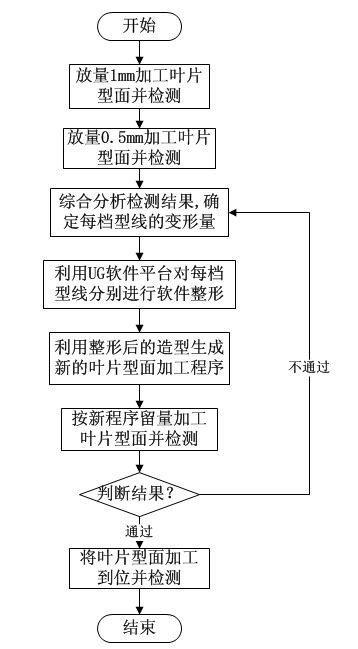

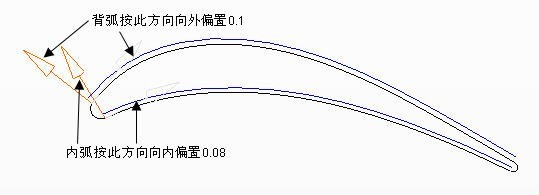

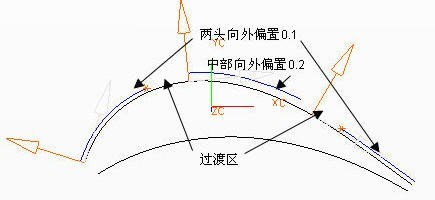

Unigraphics NX-based blade profile software reshaping method

ActiveCN102145354AThere will be no deformation rebound phenomenonImprove quality and efficiencySoftwareProcess requirements

The invention discloses a Unigraphics-NX (UG)-based blade profile software reshaping method. The method can effectively solve the problems that the orthopedic effect is instable and the deformation rebound is easily caused because the conventional mechanical orthopedics mainly depend on human experience, and can solve the problem that a mechanical orthopedic method cannot be used for blade profile reshaping due to special blade materials. The method comprises the following steps of: pre-processing a blade profile, and detecting the size of an inner arc and a rear arc of each gear of the pre-processed blade profile; analyzing the detection report, and listing deformation of comparing the steam admission side, the middle part and the steam outlet side of the inner arc and the rear arc of the profile line of each gear with the designed theoretical value of a blade; determining the correction quantity of the profile line of each gear according to the deformation, and performing different bias on the profile line of each gear according to the correction quantity to realize profile software reshaping; performing fairing and rounding on the software reshaped profile line data to generate a new model serving as a molding, compiling and processing program, and processing and detecting the profile according to the new program; if the blade profile processed by using the new program still does not accord with the requirement, continuing the adjustment; and if the detection result meets the process requirement, finishing the software reshaping operation, and performing batch production.

Owner:WUXI TURBINE BLADE

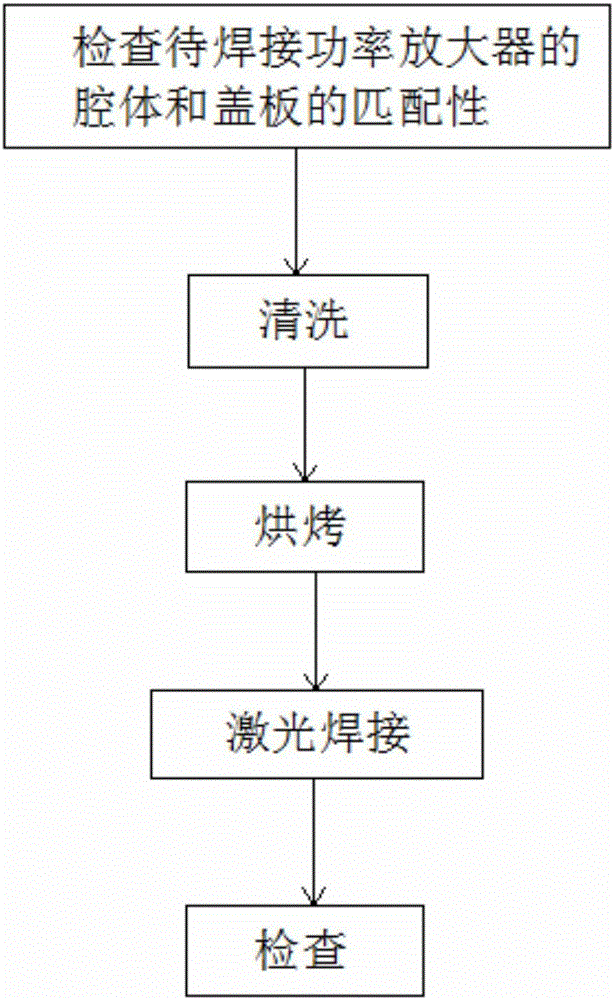

Laser sealed welding method for L-waveband power amplifier cavity

InactiveCN107433392AImprove the one-time pass rateNo influence on welding qualityLaser beam welding apparatusAudio power amplifierCost savings

The invention discloses a laser sealed welding method for an L-waveband power amplifier cavity. The laser sealed welding method for the L-waveband power amplifier cavity comprises the following steps: step 1, examining matching between a cavity of a power amplifier to be welded and a cover plate; step 2, cleaning the cavity of the power amplifier to be welded and the cover plate; step 3, baking the power amplifier to be welded and the cover plate in a vacuum oven; step 4, welding the baked cover plate to the cavity of the power amplifier to be welded; and step 5, examining a welded part. By the laser sealed welding method, one-time qualified rate of laser seal welding is increased; and the laser sealed welding method plays an important role in cost saving, efficiency improving and product improving.

Owner:HUADONG PHOTOELECTRIC TECHN INST OF ANHUI PROVINCE

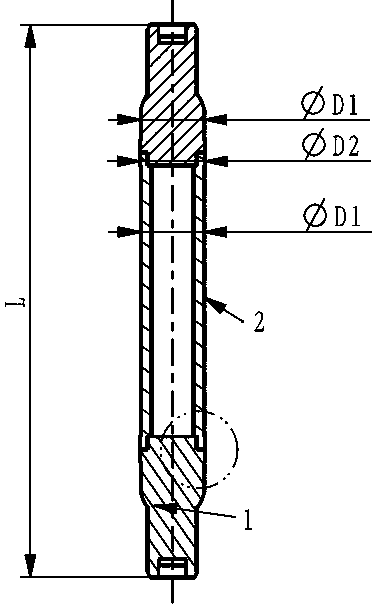

Aluminum alloy conductor pole manufacturing method

ActiveCN106825903ASolve quality problemsSolve the problem of longevityConductorsMetal working apparatusFriction weldingAutomatic control

The invention provides an aluminum alloy conductor pole manufacturing method. According to the method, a conducting body is manufactured firstly, specifically, extrusion forming, broaching forming and mechanical turning of a conducting rod are carried out; then a conducting head is manufactured, specifically, machining of the conducting head is mainly carried out; and finally, the conducting head and the conducting rod are connected through a no-keyhole stirring friction welding technology. By means of the aluminum alloy conductor pole manufacturing method, the problem of the welding quality of large-thickness small-diameter circular seams is solved, and the method has remarkable advantages compared with the prior art. By adoption of the conductor pole manufacturing method, the joint assembly design of the conducting rod and the conducting head as well as the no-keyhole stirring friction welding technology, the qualified rate of manufacturing of conductor poles is greatly improved, the production efficiency is improved, and the production cost is reduced. Tests prove that by adoption of the aluminum alloy conductor pole manufacturing method, the manufacturing dimension precision of the conductor poles meets the design requirement, weld joints are continuous and compact in texture, the defects including pores, impurities and keyholes are avoided, and automatic control is achieved in the production process; and the yield of one-time welding is increased from 40% to 95%.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

Optimization method for rotor assembly assembling

InactiveCN111384828AImprove the one-time pass rateStatic/dynamic balance measurementManufacturing stator/rotor bodiesEngineeringMechanical engineering

The invention relates to an optimization method for rotor assembly assembling. The optimization method comprises the steps of obtaining all levels of rotor assembling phases with the minimum coaxiality of a rotor assembly through optimization by means of an optimization algorithm; obtaining all levels of rotor assembling phases with the minimum unbalance amount of the rotor assembly through optimization by means of the optimization algorithm; and finding all levels of rotor assembling phases which not only can meet the coaxiality index and but also can meet the unbalance amount index through optimization by means of a comprehensive optimization algorithm of the coaxiality of the rotor assembly and the unbalance amount of the rotor assembly. According to the invention, the rotor coaxialityand the initial unbalance amount can meet the requirements at the same time, and the one-time qualification rate of rotor assembly assembling is improved.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

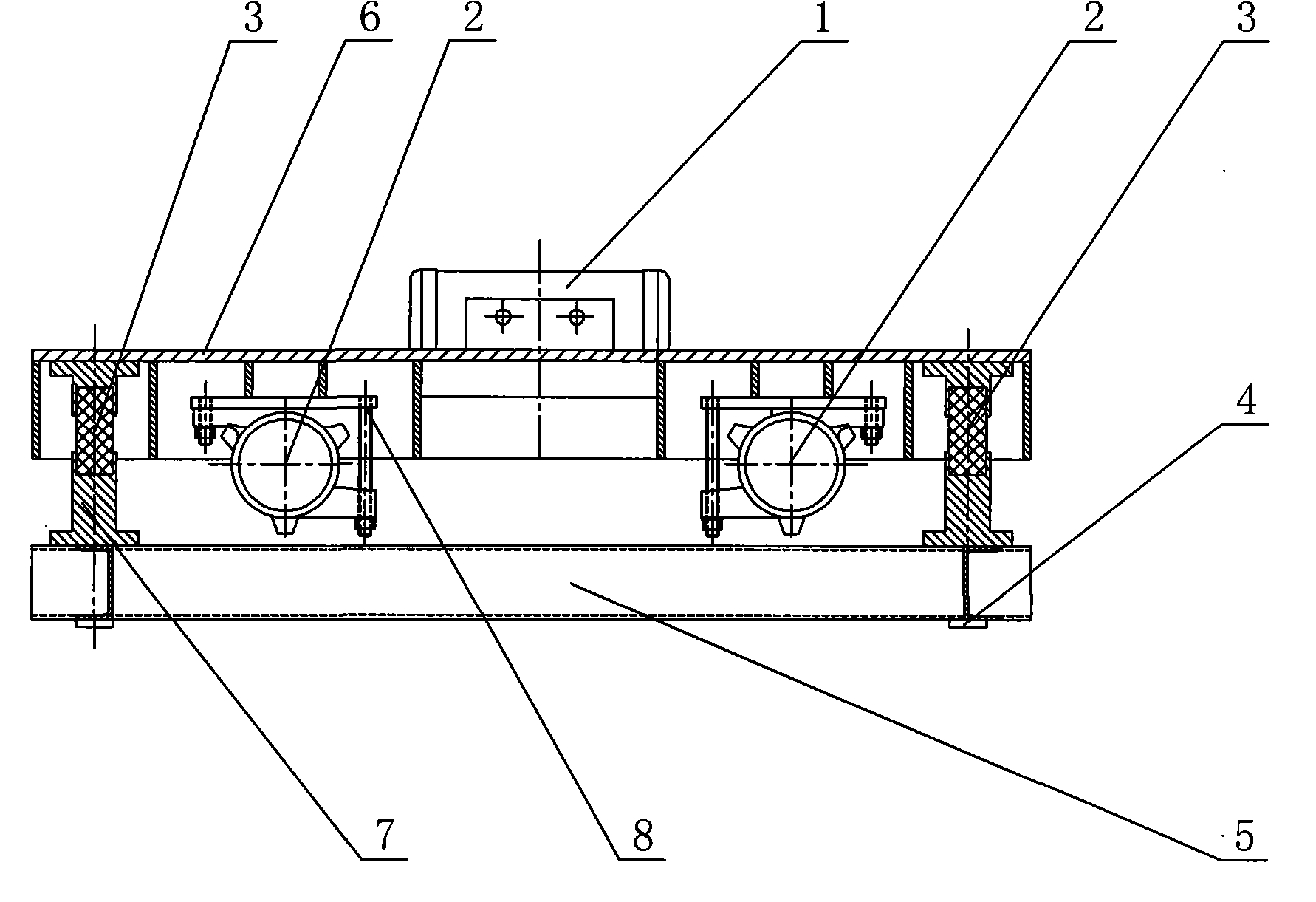

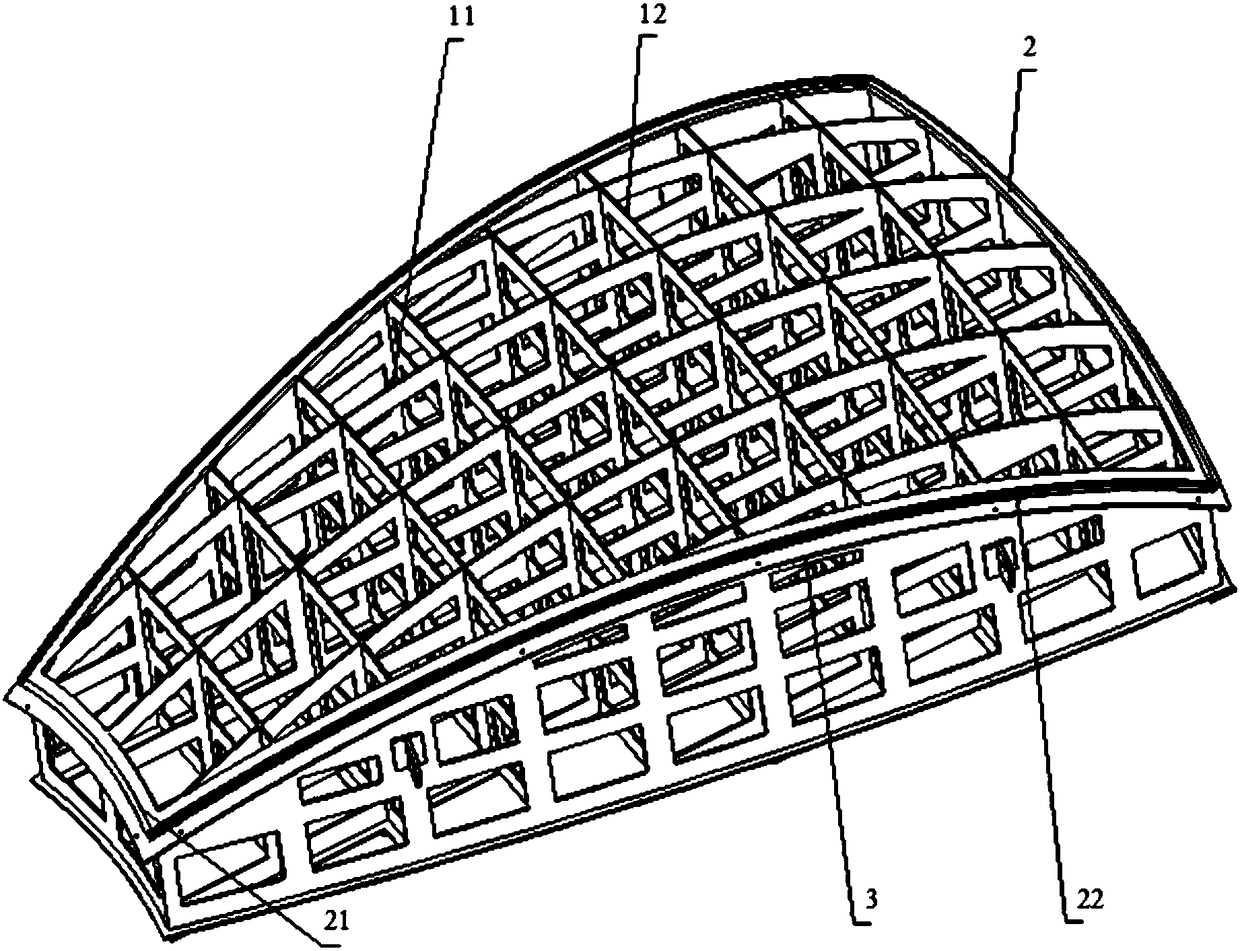

Milling cutting method of large melon petal shaped aluminum alloy component

ActiveCN108580985AImprove efficiencyImprove detection accuracyMilling equipment detailsPositioning apparatusMilling cutterFirst pass yield

The invention provides a milling cutting method of a large petal shaped aluminum alloy component. The method involves a milling cutting device. The method comprises the steps of 1, clamping the melonpetal shaped component with supporting of a C-shaped clamp and fixing through bolts, namely, fixing the wide end of the component firstly; secondarily fixing the left side edge and the right side edge, close to a line in the length direction of the wide end, of the component; thirdly fixing the left side edge and the right side edge, close to a line in the length direction of a narrow edge, of thecomponent; and fixing the melon petal shaped component to a bearing plate of the device; and 2, etching a product theory line on the melon petal through a milling cutter; then performing allowance milling and cutting on the melon petal shaped component based on a milling and cutting track line under the reference which is the product theory line through the milling cutter, wherein the milling andcutting track line bypasses each bolt to form a bolt fixing lug; and then milling and cutting the bolt fixing lugs. According to the method, the melon petal shaped component milling cutting method corresponding to the device is simple to operate; the product accuracy is high; and the first pass yield is high.

Owner:CENT SOUTH UNIV

Welding process for ball mill seal head end cover

InactiveCN105364271AAchieve straight placementEasy to placeWelding accessoriesEngineeringSpot welding

The invention belongs to the technical field of tank welding, and relates to a welding process for a ball mill seal head end cover. The welding process for the ball mill seal head end cover is characterized by including the welding steps that indexing tack welding is carried out on rib plates and a seal head end cover through welding robots; a reinforcing plate is welded to a main shaft of the seal head end cover through the welding robots; the main shaft, provided with the reinforcing plate in a welded mode, of the seal head end cover is relatively clamped fixedly through a welding positioner arranged horizontally and a clamping part, and all the rib plates are welded in a sealed mode through the welding robots. The welding process of the whole seal head end cover can be implemented in a streamline mode, the production efficiency of the seal head end cover is greatly improved, the welding quality of the seal head end cover is greatly improved while the uniform product specification is ensured, the one-time qualified rate is increased, and the service life of a ball mill is prolonged.

Owner:淄博大工机械有限公司

Leakage testing and running-in testing method of fuel cell

ActiveCN109883625AImprove pass rateImprove assembly efficiencyMeasurement of fluid loss/gain rateElectrical testingFuel cellsEngineering

The invention relates to a leakage testing and running-in testing method of a fuel cell. After quality testing is conducted on the fuel cell, before the fuel cell is overlaid to form a whole pile, leakage testing and running-in testing are conducted according to the following method: a plurality of membrane electrodes and bipolar plates are piled on a piling clamping device to form a leakage testing unit, and the number of the membrane electrodes and the bipolar plates is 5-10 groups; the leakage testing unit is taken out of the piling clamping device and put into a leakage testing clamping device, and leakage testing is conducted; a C-shaped clamp is mounted on the leakage testing unit meeting the requirement to form a testing unit; the testing unit is put into a testing table, and thus running-in testing is conducted; and the C-shaped clamp on the qualified testing unit is disassembled, the membrane electrodes and the bipolar plates are taken out to be used for assembling a fuel cellpile. According to the leakage testing and running-in testing method of the fuel cell, assembling of the testing unit can be fast, efficiently and reliably completed, before the fuel cell is piled, leakage full testing and running-in testing are conducted on the membrane electrodes and the bipolar plates, the assembling efficiency and success rate of the pile can be effectively improved, running-in time after the pile is formed is reduced, and performance consistency of the pile is guaranteed.

Owner:BEIJING NOWOGEN TECH CO LTD

Vibration platform for counterweight block for washing machine

InactiveCN101898383AReduce generationShorten feeding timeOther washing machinesCeramic shaping apparatusElastomerFixed frame

The invention relates to a vibration platform for a counterweight block for a washing machine, comprising a working plate and a base arranged below the working plate. The invention is characterized in that the working plate and the base are connected by elastic bodies; first motors are arranged at the two sides of the working plate by first mounting seats; second motors are arranged at the lower side of the working plate by second mounting seats; the upper ends of the elastic bodies are connected with fixing frames on the lower surface of the working plate and the lower ends thereof are connected with fixing frames on the upper surface of the base; anti-vibration pads are arranged on the lower surface of the base; and the elastic bodies are prepared from rubbers or polyurethane. The vibration motors with frequency of 20-30Hz are adopted as the first motors and the vibration motors with frequency of 80-120Hz are adopted as the second motors. The vibration platform greatly shortens the feeding time, effectively improves the compactness and strength of the product and improves the unit strength of the product.

Owner:无锡市红光标牌有限公司

Electromagnetic valve coil riveting machine

The invention provides an electromagnetic valve coil riveting machine. The machine comprises a frame, and a rotating disc and a riveting cylinder arranged on the frame up and down; three lower grinding tools are uniformly arranged on the rotating disc; and an upper grinding tool is arranged at a piston end of the riveting cylinder, and can be closed with the lower grinding tools on a vertical surface. The electromagnetic valve coil riveting machine can once successfully rivet by using a gas-liquid boost cylinder; the grinding tools are fixed on the rotating disc; products can automatically rotate in to finish the riveting action; a positioning cylinder realizes no riveting if the rotating disc dose not rotate in place or rotates beyond the place; and the once pass percent of products riveted by the equipment is higher.

Owner:合肥齐兴电器有限责任公司

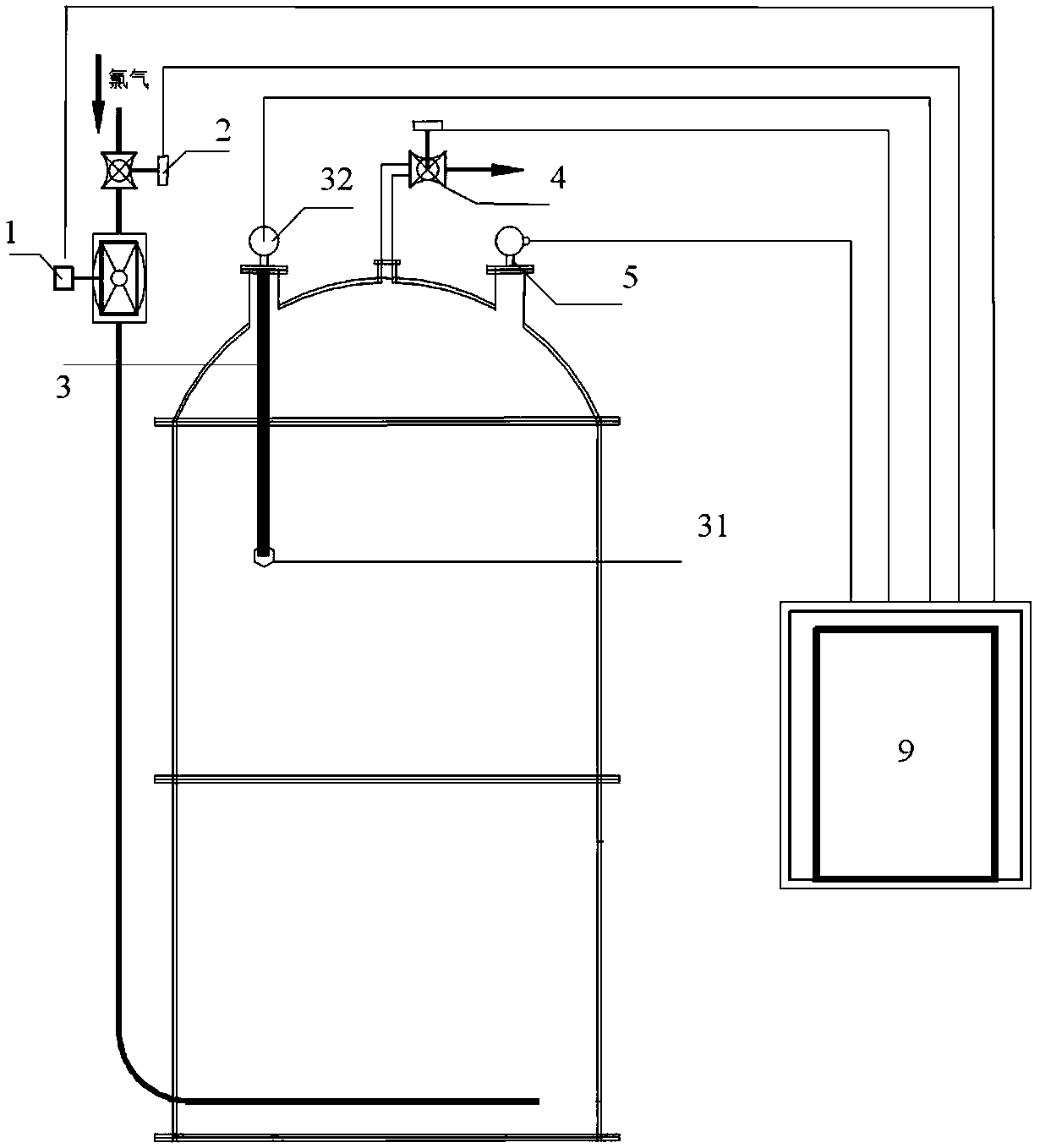

Technology control method of production process of ferric trichloride and reaction tower

ActiveCN108404828AGuaranteed thermal stabilityChlorination speedProcess control/regulationIron halidesReaction temperatureTower

The invention discloses a technology control method of the production process of ferric trichloride and a reaction tower. The technology control method comprises the steps that the opening degree of achlorination controller is conditioned according to the temperature, the pressure, the inlet gas flux and the tail gas flux in the reaction tower, and the reaction temperature lower than 90 DEG C, the pressure lower than 0.05 MPa, and the tail gas flux of the inlet gas flux smaller than 5% in the reaction tower is controlled; and the condition that the opening degree of the chlorination controller is lower than 10%, and the exhaust gas pipe flux is larger than the inlet gas pipe flux is taken as a reaction ending point to judge. The system device comprises a temperature sensor, a pressure sensor, a flux monitoring device and the chlorination controller. The technology control method achieves accurate control of the production process of ferric trichloride, the utilization rate of chlorineis improved to reach 95.5-99.5%, the reaction ending point is accurately judged, the product pass percent is improved to reach 99.8%, and the content of ferrous chloride is lower than 0.25%. The technology control method improves the safety of the production technology of ferric trichloride, the utilization rate of the raw materials and the production efficiency.

Owner:北京万水净水剂有限公司

Large-scale aluminum alloy bent member molded surface precision measurement and milling method

ActiveCN108580986AImprove efficiencyImprove detection accuracyMechanical counters/curvatures measurementsMilling equipment detailsNumerical controlMilling cutter

The invention provides a large-scale aluminum alloy bent member molded surface precision measurement and milling method. The method is characterized in that a molded surface precision measurement andmilling composite device is used; the method comprises the following steps that A, an aluminum alloy member obtained after hot rolling is positioned and placed on the composite device; B, molded surface precision measurement is carried out, wherein after the member is positioned, a feeler gauge is used for measuring a gap between a member molded face and a theory molded face, namely the top face of the peripheral narrow molded plate, at a peripheral narrow molded plate, and whether the requirement is met or not is checked; C, member fixation is carried out, wherein a bolt is used for connecting the member and a bearing plate, and the member is fixed; and D, allowance milling is carried out on the member, wherein a programming of a numerically-controlled machine tool is carried out to enable a milling cutter to conduct allowance milling on the member according to a preset track. According to the composite device in the method, the member molded surface precision measurement function andthe allowance milling function are achieved at the same time, another allowance milling tool does not need to be designed again, and the manufacturing cost and time cost are greatly reduced.

Owner:CENT SOUTH UNIV

Correction processing method of fixture wheel groove profile for static-frequency detection

ActiveCN106180842AReduce friction areaReduce frictional resistanceMilling equipment detailsFrequency detectionMechanical engineering

The invention provides a correction processing method of a fixture wheel groove profile for static-frequency detection and can solve problems that scratches and drawing marks are produced easily due to small gaps between blade root profiles and wheel groove profile non-working surfaces and high dead weight of blades in processes that the blades are mounted in wheel groove blocks and then move at present. The method comprises steps of finish milling processing and correction processing which are conducted sequentially; in the finish milling step, a blade root wheel groove profile is processed by the aid of a finish milling molding knife according to a designed blade root wheel groove profile; in the correction processing step, finish milling processing is performed once again in the position with the correction height h lifted overall on the basis of the blade root wheel groove profile by the aid of the finish milling molding knife used in finish milling processing, only an inside back working surface of a blade root wheel groove is processed in correction processing, and a non-working surface of the blade root wheel groove is not cut, so that a non-working surface profile, obtained through finish milling processing, of the blade root wheel groove and an inside back working surface profile, obtained through correction processing, of the blade root wheel groove are connected to form a correction profile of the blade root wheel groove, and the correction height h ranges from 0.2 mm to 1.0 mm.

Owner:WUXI TURBINE BLADE

Production method of round conductor low-voltage power cable with high roundness

InactiveCN107946000AIncrease productivityImprove the one-time pass rateCable/conductor manufacturePower cableElectrical conductor

The present invention discloses a production method of a round conductor low-voltage power cable with a high roundness. The production method of the round conductor low-voltage power cable with the high roundness is characterized in that: 4 strands of round-shaped wires are selected for core portions as conductors, the conductors are subjected to high-roundness insulation, filling strips are customized, the stands of conductors form an integrated round body through the heterogenic filling strips, a high-intensity elastic belting is arranged at the external portion of the integrated round body,an inner sheath is arranged at the external portion of the high-intensity elastic belting, an armor layer is arranged at the external portion of the inner sheath, and an outer sheath is arranged at the external portion of the armor layer; tension force of each pay-off rack is regulated prior to cabling, tension force balance between cores of strands of cables is ensured, instant tension forces ofthe cores of strands of cables are randomly monitored and regulated; the wrapping angle of the high-intensity elastic belting is less than 45 degrees; and the inner sheath and the outer sheath are subjected to extrusion molding through an extrusion-type head. The production method of the round conductor low-voltage power cable with the high spherical degree improves the production efficiency andhas good physical and mechanical properties, are flat in surface, high in spherical degree and convenient to construct, save raw materials and simple and clear in production process.

Owner:HANGZHOU CABLE

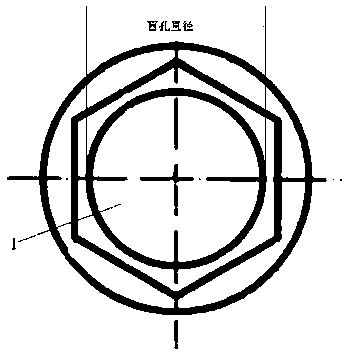

Tire nut deep blind hole plating and coating process

InactiveCN109537009ASolve easy rustPrevent rustMetallic material coating processesDehydrogenationStain

The invention discloses a tire nut deep blind hole plating and coating process. The process comprises the steps that firstly, the parts are sequentially subjected to pretreatment including thermokalite oil removing, thermokalite oil removing, electrolytic oil removing, acid pickling, electrolytic oil removing, excitation, pre-electroplating, stripping and electroplating; the two passes of thermokalite oil removing ensure that oil stain inside blind holes is cleaned away; stripping is conducted after pre-electroplating, and oxide skin inside the blind holes is stripped; additives are added intoelectroplating liquid medicine during electroplating; residual water in the blind holes of the electroplated parts is thrown away through rotation of a production line roller and a discharging centrifugal drier; then dehydrogenation baking is conducted, and residual water inside the blind holes is evaporated through high-temperature baking; and finally, passivation and closing are conducted. Theproblems that the covering power of zinc-nickel alloys is not sufficient, and consequently no clad layer exists in the blind holes and the blind holes rust easily are solved, and the process has the beneficial effects that oil stain and oxide layers in the blind holes are effectively removed, uniform zinc-nickel clad layers are plated, the interiors of the blind holes are prevented from rusting, and the first pass yield of products is improved to be 95% or above.

Owner:鹰普航空科技(南通)有限公司

Tooling clamp for processing insulating collar turning and method for processing same

InactiveCN103223610BIncrease contact areaAvoid deformationPositioning apparatusMetal-working holdersGrip forceConvex side

The invention discloses a tooling clamp for processing an insulating collar turning. The tooling clamp comprises a concave clamp (8) and a convex clamp (9), wherein the concave clamp (8) comprises a jaw chuck A (10) and a plurality of equant sectorial blocks A (11), the sectorial concave part in each equant sectorial blocks A (11) is composed of a sectorial plane A (13) and a arc-shaped surface side wall A (14), the convex clamp (9) comprises a jaw chuck B (15) and a plurality of equant sectorial blocks B (16), a sectorial plane C (19) is also arranged on the outer side of each equant sectorial block B (16), and the invention further discloses a processing method. The tooling clamp provided by the invention has the advantages that the gripping force is even, so that the deformation of a workpiece is avoided, the clamping efficiency is improved, the time is saved, the workpiece quality and the processing efficiency are improved, and the consistency and the reliability of a part is increased as well.

Owner:CHENGDU JINJIANG ELECTRONICS SYST ENG

A method of manufacturing an aluminum alloy conductive rod

ActiveCN106825903BObvious technological advancementAchieve full penetrationConductorsMetal working apparatusElectrical conductorWeld seam

The invention provides an aluminum alloy conductor pole manufacturing method. According to the method, a conducting body is manufactured firstly, specifically, extrusion forming, broaching forming and mechanical turning of a conducting rod are carried out; then a conducting head is manufactured, specifically, machining of the conducting head is mainly carried out; and finally, the conducting head and the conducting rod are connected through a no-keyhole stirring friction welding technology. By means of the aluminum alloy conductor pole manufacturing method, the problem of the welding quality of large-thickness small-diameter circular seams is solved, and the method has remarkable advantages compared with the prior art. By adoption of the conductor pole manufacturing method, the joint assembly design of the conducting rod and the conducting head as well as the no-keyhole stirring friction welding technology, the qualified rate of manufacturing of conductor poles is greatly improved, the production efficiency is improved, and the production cost is reduced. Tests prove that by adoption of the aluminum alloy conductor pole manufacturing method, the manufacturing dimension precision of the conductor poles meets the design requirement, weld joints are continuous and compact in texture, the defects including pores, impurities and keyholes are avoided, and automatic control is achieved in the production process; and the yield of one-time welding is increased from 40% to 95%.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

V-groove cutting method for optical fiber connector

ActiveCN102211858BSolve the force problemSolve the errorGlass severing apparatusOptical light guidesFiberEngineering

The invention discloses a method for cutting V-grooves of an optical fiber connector. The method comprises the following steps of: a, cutting a concave-down plane on the upper surface of a quartz base material of the optical fiber connector along the length direction, wherein the concave-down plane corresponds to top planes of the V-grooves; and b, cutting a plurality of V-grooves, which are arranged in parallel in turn along the width direction, on the concave-down plane. In the method, the quartz base material is cut step by step, the cut amount of each time is small, and the cutting feed is shallow, so the method can effectively improve non-uniform stress during cutting to meet requirements on cutting accuracy.

Owner:深圳光通汇联技术有限公司

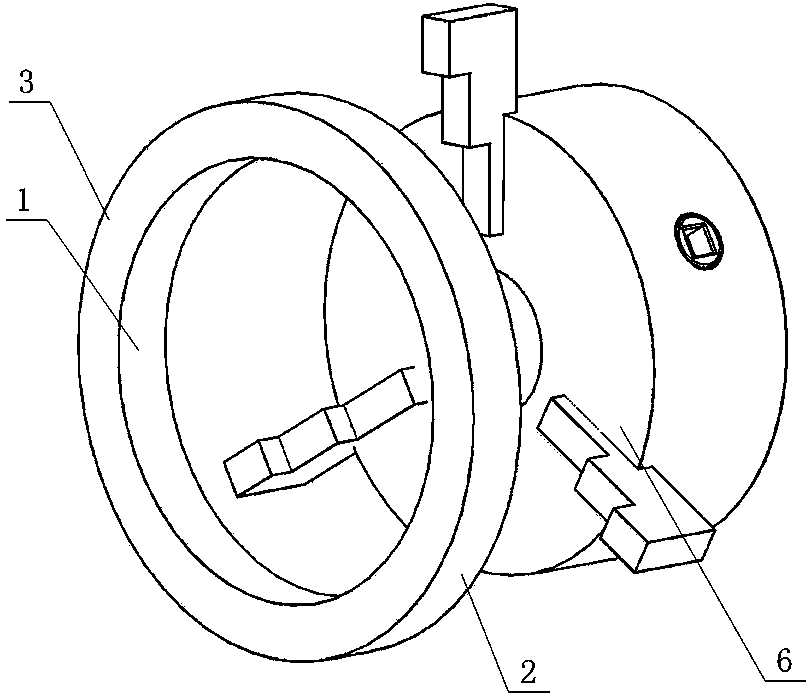

Assembling device of microwave isolator

InactiveCN101777689AImprove electrical performance parametersImprove alignment accuracyWaveguide type devicesIsolatorElectrical conductor

The invention provides an assembling device of a microwave isolator. The assembling device comprises a workbench and pressing mechanisms. The assembling device is characterized in that side plates are arranged on the front and back ends of the workbench, the workbench is supported by the front and back side plates, a central great-circle guide slot is arranged in the central part of the workbench transversely, auxiliary small-circle guide slots are arranged on the left and right sides of the central great-circle guide slot transversely, screwed holes are arranged on the front or back side plate transversely, and the pressing mechanisms penetrate through the transverse screwed holes of the side plate to form a screw transmission pair which can move along the direction of the central great-circle guide slot. The centring, positioning and fastening of a central conductor and a microwave ferrite are realized, and the electric performance parameters of the microwave isolator are increased. Dozens of central conductors and microwave ferrite components can be bound once so that the centring accuracy and positioning accuracy of the microwave isolator are increased significantly, the one-time pass rate is greatly improved, the assembly time is significantly shortened, the cost is reduced, the consistency of the production is greatly improved, and the assembling device is in particular applicable to the mass production of microwave isolators.

Owner:SDP TELECOM SUZHOU

Arc extinguish chamber assembling tool

Owner:SUZHOU TIANYE MECHANICAL IND

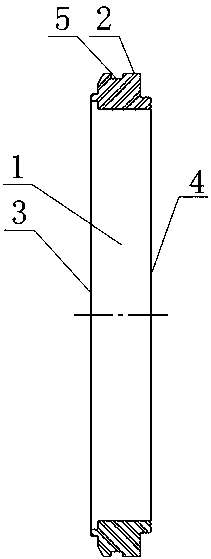

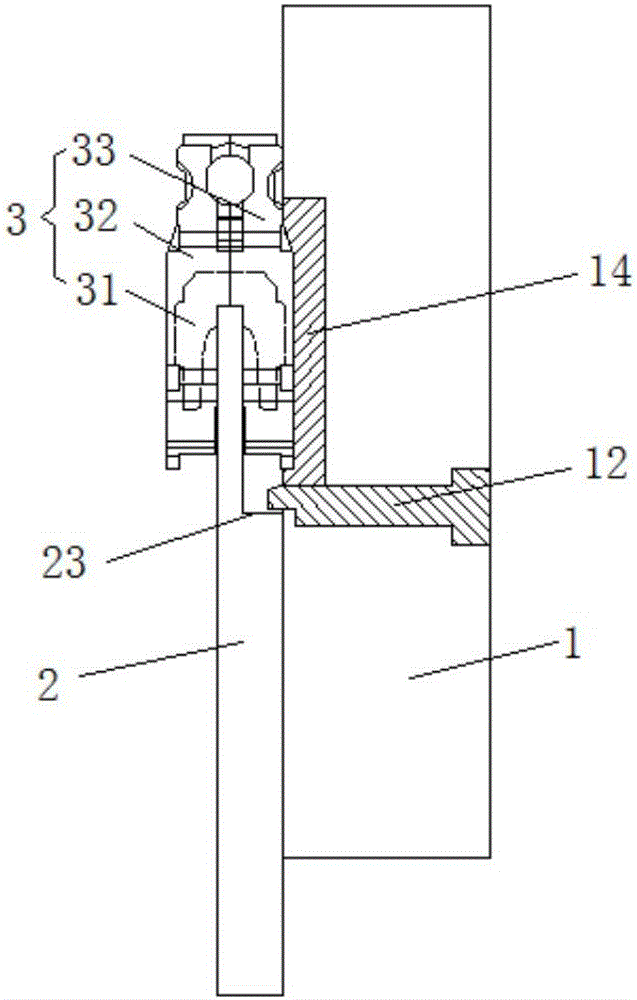

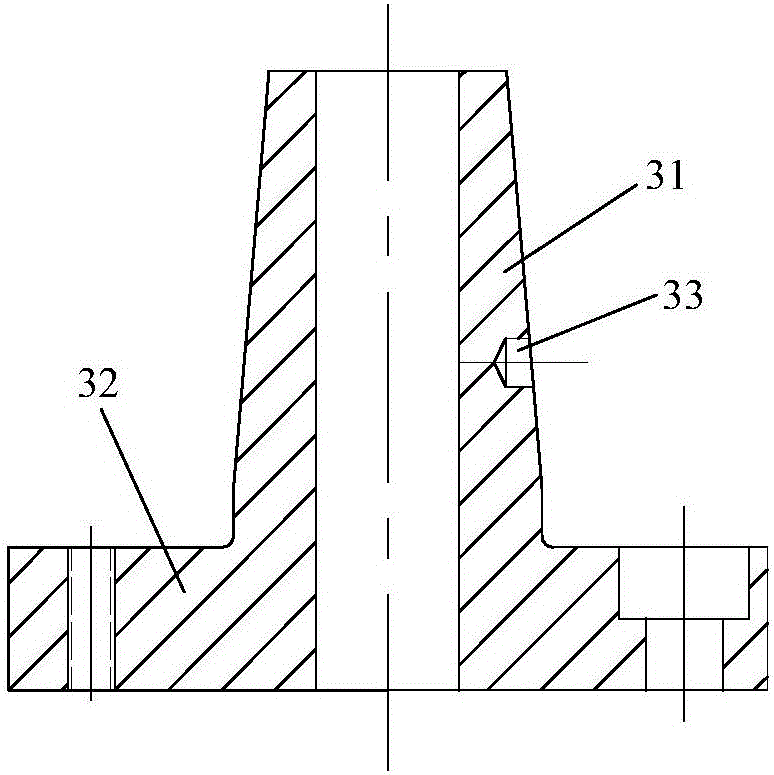

Vacuum stopper applicable to LNG (liquefied natural gas) cylinder

InactiveCN107726047AEliminate thermal deformationImprove the one-time pass rateVessel mounting detailsVessel geometry/arrangement/sizeEngineeringBottle

The invention discloses a vacuum plug for LNG liquefied natural gas bottle, relates to the technical field of liquefied natural gas equipment, and comprises a C-shaped sealing ring, a first O-shaped sealing ring and several second O-shaped sealing rings; the plug seat is hollow Cylindrical structure, the inside is divided into a first opening chamber, a connecting chamber and a second opening chamber from inside to outside, and the diameters of the first opening chamber and the second opening chamber are larger than the diameter of the connecting chamber; the plug The body is a cylindrical structure, and the diameter of the plug body is adapted to the diameter of the second opening chamber; a first annular groove and several second annular grooves are opened on the plug body; a column is also arranged inside the plug body Plug body, the diameter of the plunger body matches the diameter of the connecting chamber; a third annular groove is opened on the plunger body; the C-shaped sealing ring is clamped in the third annular groove; the first O-shaped sealing ring It is clamped in the first annular groove; each second O-ring is clamped in a corresponding second annular groove.

Owner:HUBEI YINLILAI CONTAINER

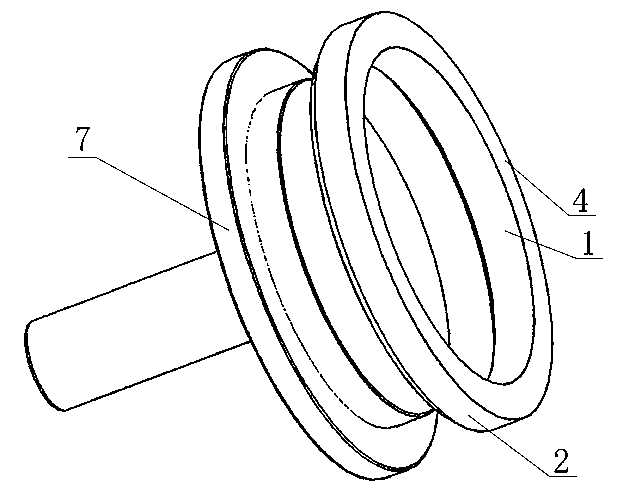

Elastic expanding sleeve applicable to engine crankshaft damping belt pulley dynamic balance fixture

InactiveCN106112043AImprove the efficiency of dynamic balance detectionUniform expansion and fixationStatic/dynamic balance measurementExpansion mandrelsDynamic balanceEngineering

The invention discloses an elastic expanding sleeve applicable to an engine crankshaft damping belt pulley dynamic balance fixture. The elastic expanding sleeve comprises an end cover, a plurality of expanding blocks connected with the end cover and uniformly arranged in the circumferential direction, first sectioning gaps located between every two adjacent expanding blocks and second sectioning gaps formed in the expanding blocks and located between every two adjacent first sectioning gaps. The elastic expanding sleeve applicable to the engine crankshaft damping belt pulley dynamic balance fixture is good in elasticity. The upper end and the lower end of the elastic expanding sleeve can be evenly expanded and contracted. It is guaranteed that a damping belt pulley can be evenly expanded and fixed. The coaxiality of the damping belt pulley and the fixture is guaranteed. The positioning accuracy and the machining precision of the damping belt pulley are improved. The accuracy of dynamic balance data is guaranteed. The one-time qualified rate of products is increased. Meanwhile, the crankshaft damping belt pulley dynamic balance detection efficiency can also be improved, and the stability of production takt and balanced production is guaranteed.

Owner:WUHU JINYUAN MACHINERY MFG

A gear reduction claw pole type permanent magnet synchronous motor

InactiveCN109245475AFlexibilityFlexible replacementMagnetic circuit rotating partsSynchronous machine detailsPermanent magnet synchronous motorEnergy loss

The invention belongs to the technical field of motors, in particular to a gear reduction claw-pole type permanent magnet synchronous motor. A gear reduction claw-pole type permanent magnet synchronous motor includes a mounting base plate, a motor housing and a gearbox housing, A motor housing is arranged on the assembly bottom plate, a reduction gear housing is arrange on the assembled bottom plate at one side of that motor house, A motor housing is communicated with a reduction box housing, and a transmission gear assembly is arranged at the communication part; a rotor assembly and a statorassembly are arranged in the motor housing; a reduction gear assembly and a reduction box output shaft are arranged in the reduction box housing; and the rotor assembly drives the reduction box outputshaft through the transmission gear assembly and the reduction gear assembly. The invnetion has the advantages of simple structure, convenient installation, low energy consumption, high production efficiency, short and small flat structure, and is suitable for various occasions, so that the efficiency of the product is improved compared with the traditional product in batch production, and the one-off qualification rate is improved.

Owner:WUXI TIANZHIJIAO MOTOR CO LTD

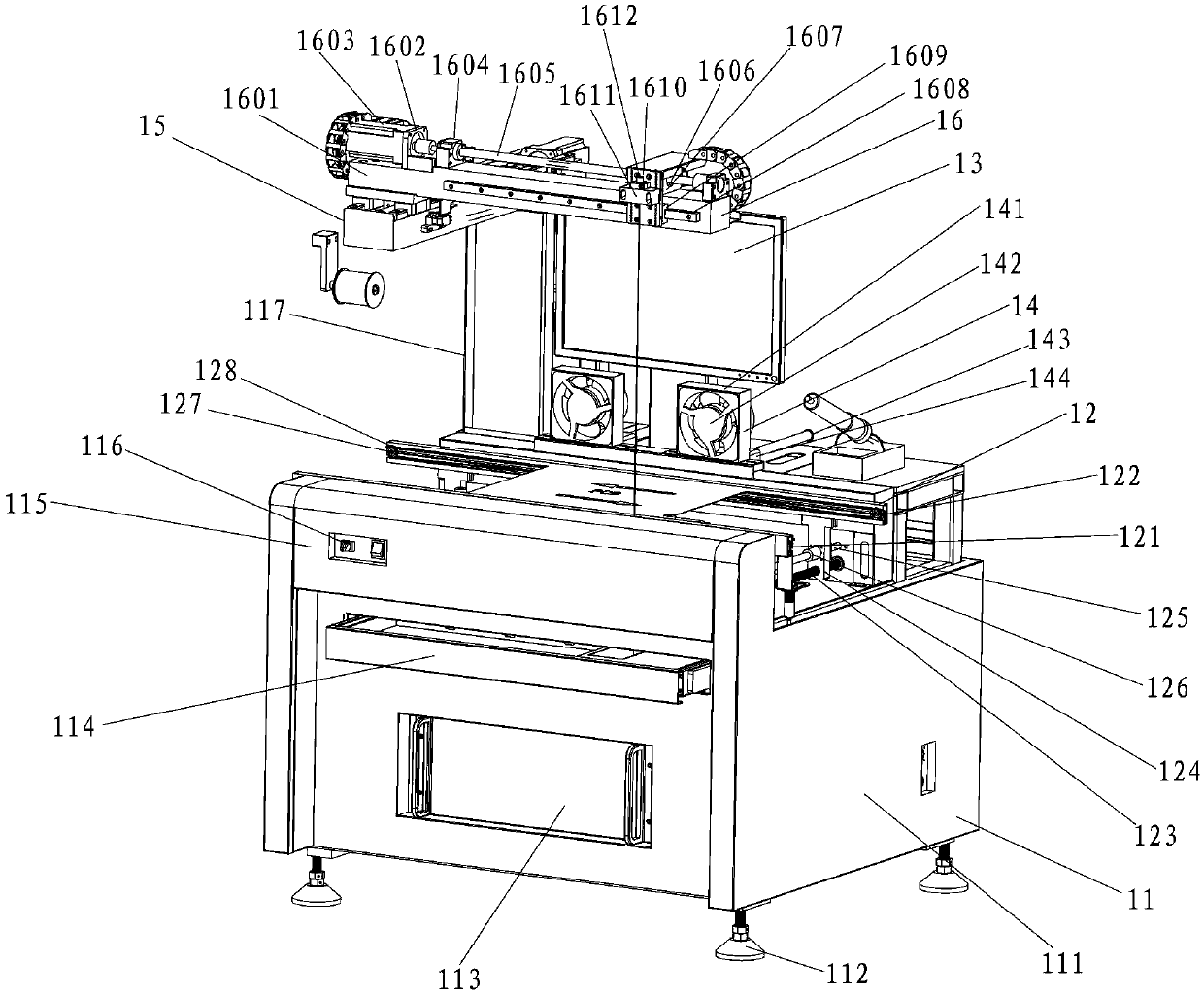

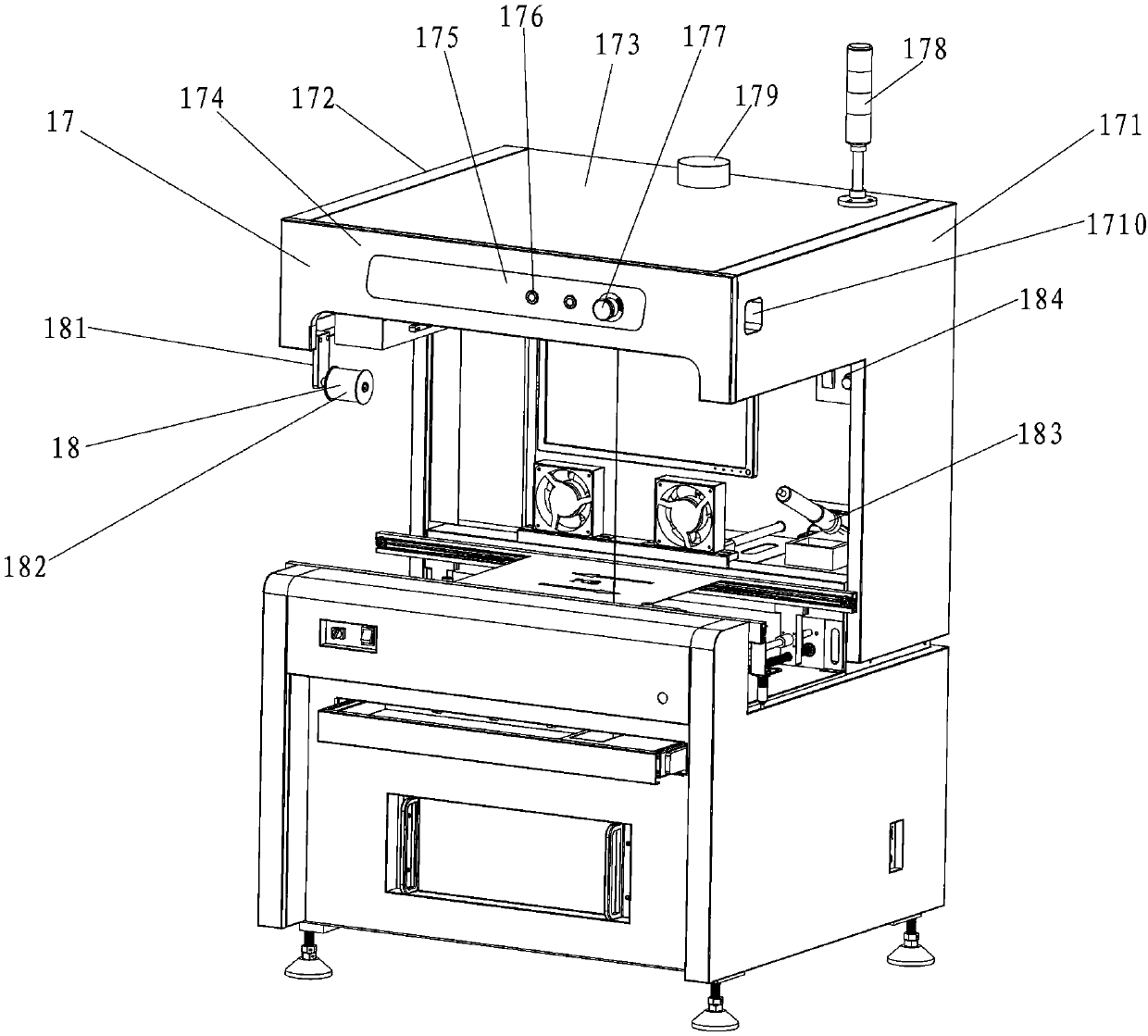

On-line laser guiding type repairing equipment

PendingCN109590566AReduce the difficulty of operationFind quicklyDirt cleaningPrinted circuitsMechanical engineeringLaser

The invention discloses on-line laser guiding type repairing equipment. The on-line laser guiding type repairing equipment is connected behind automatic optical inspection equipment, and can achieve on-line repair of a defective PCB. The on-line laser guiding type repairing equipment comprises a base mechanism, a conveying rail mechanism and a display mechanism are arranged on the base mechanism,a smoking suction mechanism is arranged at the position adjacent to the conveying rail mechanism, a Y movement mechanism and an X movement mechanism are arranged above the conveying rail mechanism, acolored laser device is arranged on the X movement mechanism, an outer cover mechanism is arranged outside the Y movement mechanism and the X movement mechanism, and a maintenance welding mechanism isarranged on the base mechanism and the outer cover mechanism. The on-line laser guiding type repairing equipment can assist an operator in accurately finding defective positions on the PCB and rapidly repairing on line, the operation is convenient, the effect of being more humanized is achieved, and the beneficial effects that the repair efficiency and the repair quality of the PCB are improved,and the reject ratio is reduced are achieved.

Owner:深圳市振华兴科技有限公司

Making method of honeycomb ceramic support protective agent

The invention relates to a making method of a honeycomb ceramic support protective agent. The making method comprises the following steps: 1. batching: weighing and preparing raw materials: 80-90 parts by weight of high alumina clay, 2-3 parts by weight of calcined alpha-aluminum oxide, 8-10 parts by weight of celluloses, 1-2 parts by weight of aluminum stearate and 1-3 parts by weight of rapeseed oil according to the mass ratio; 2. kneading; 3. vacuum pugging; 4. extrusion molding; 5. cutting off; 6. cutting to obtain formed honeycomb ceramic protective agent semi-finished products; 7. screening and selecting: selecting out the deformed and cracked honeycomb ceramic support protective agent semi-finished products, and returning the step 3; 8. placing in a kiln, sintering and forming. The making method provided by the invention is simple in process, convenient to operate, low in labor intensity, stable in product quality and very environment-friendly in the high quality production process.

Owner:HUNAN JINLIANXING SPECIAL MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com