Unigraphics NX-based blade profile software reshaping method

A technology of software and blades, which is applied in the field of UG-based blade surface software shaping, can solve problems such as unstable orthopedic effects, inability to use, and easy deformation and rebound of orthopedics, so as to reduce mechanical orthopedic procedures, stabilize the shaping effect, and improve processing Effects on Quality and Process Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

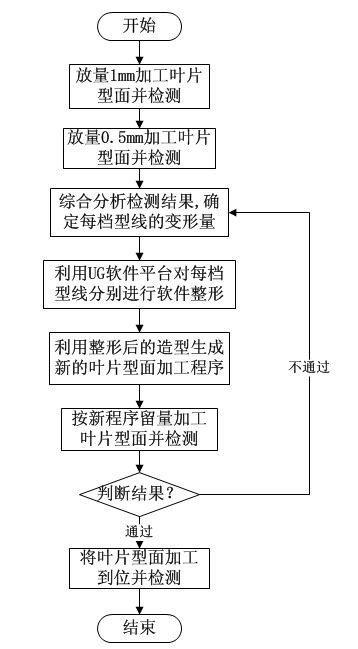

[0015] 1. Machining the processed blade profile by 1mm and inspecting it;

[0016] 2. Process and inspect the processed blade profile by 0.5mm;

[0017] 3. Analyze the deformation trend of the above two inspection results (see Table 1), determine the correction amount of each profile line, and make the following trimmings:

[0018] a) The first gear mould line remains unchanged

[0019] b) The second gear profile, the inner arc is set to 0.1mm, and the back arc remains unchanged

[0020] c) The third gear profile, the inner arc remains unchanged, and the back arc is set to 0.1mm

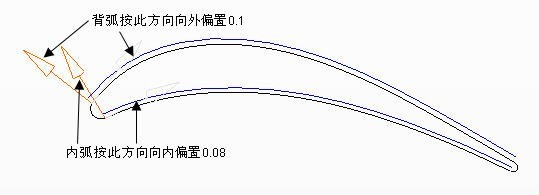

[0021] d) The fourth gear profile, the inner arc is 0.08mm, the back arc is 0.1mm

[0022] e) The fifth gear profile, the inner arc is closed by 0.1mm, the back arc is set by 0.1mm

[0023]

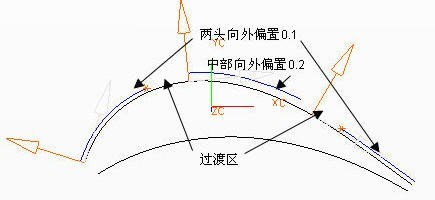

[0024] 4. In the UG software, perform software shaping for each profile line according to the deformation of the profile.

[0025] a) The offset direction and offset of the profile line are the same. For example, the fourth g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com