Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51results about How to "Improve spot" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

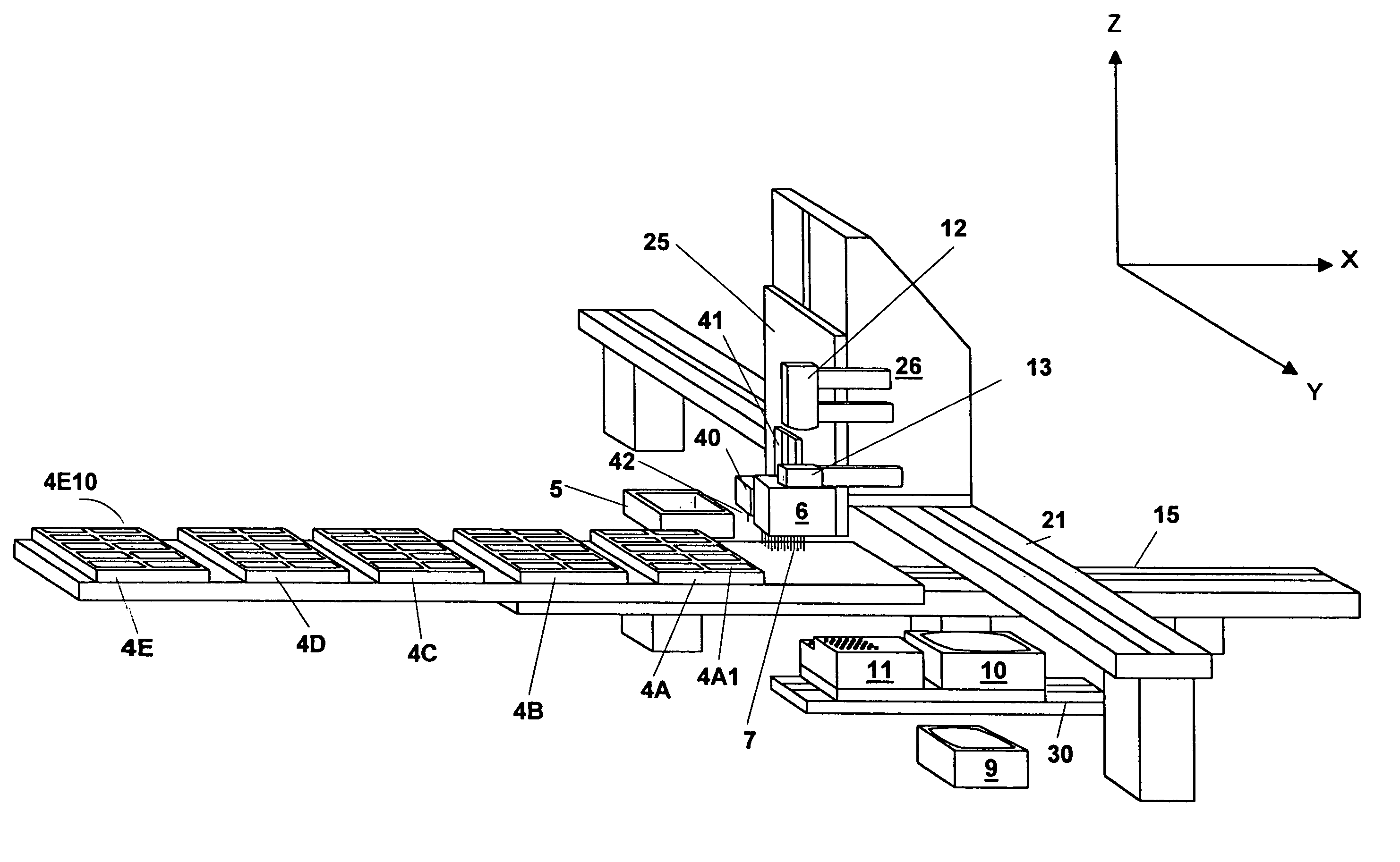

Microarray dispensing with real-time verification and inspection

InactiveUS7025933B2Improve spotImprove accuracySequential/parallel process reactionsElement comparisonAnalysis dataReal time validation

A microarrayer for spotting solution onto a receiving surface in an automated microarray dispensing device. Elements of the present invention include: at least one dispense head for spotting the receiving surface, at least one light source capable of illuminating the receiving surface, at least one camera operating in conjunction with the at least one light source. The at least one camera is capable of acquiring and transmitting surface image data to a computer. The computer is programmed to receive the surface image data and analyze it. The computer will then generate post analysis data based on the analysis of the surface image data. The post analysis data is available for improving the spotting of the solution onto the receiving surface. In a preferred embodiment, the surface image data includes information relating to receiving surface alignment, information relating to spot quality, and receiving surface identification information. In a preferred embodiment, the analysis of the information relating to receiving surface alignment enables the computer to make automatic adjustments to the relative positions of the at least one dispense head and the receiving surface to increase the accuracy of the spotting. In a preferred embodiment, the analysis of the information relating to spot quality identifies a spot as pass or fail. An operator is then able to rework the spot. In a preferred embodiment, the analysis of the receiving surface identification information enables the computer to track each receiving surface. In a preferred embodiment the receiving surface is a plurality of slides.

Owner:AGENA BIOSCI

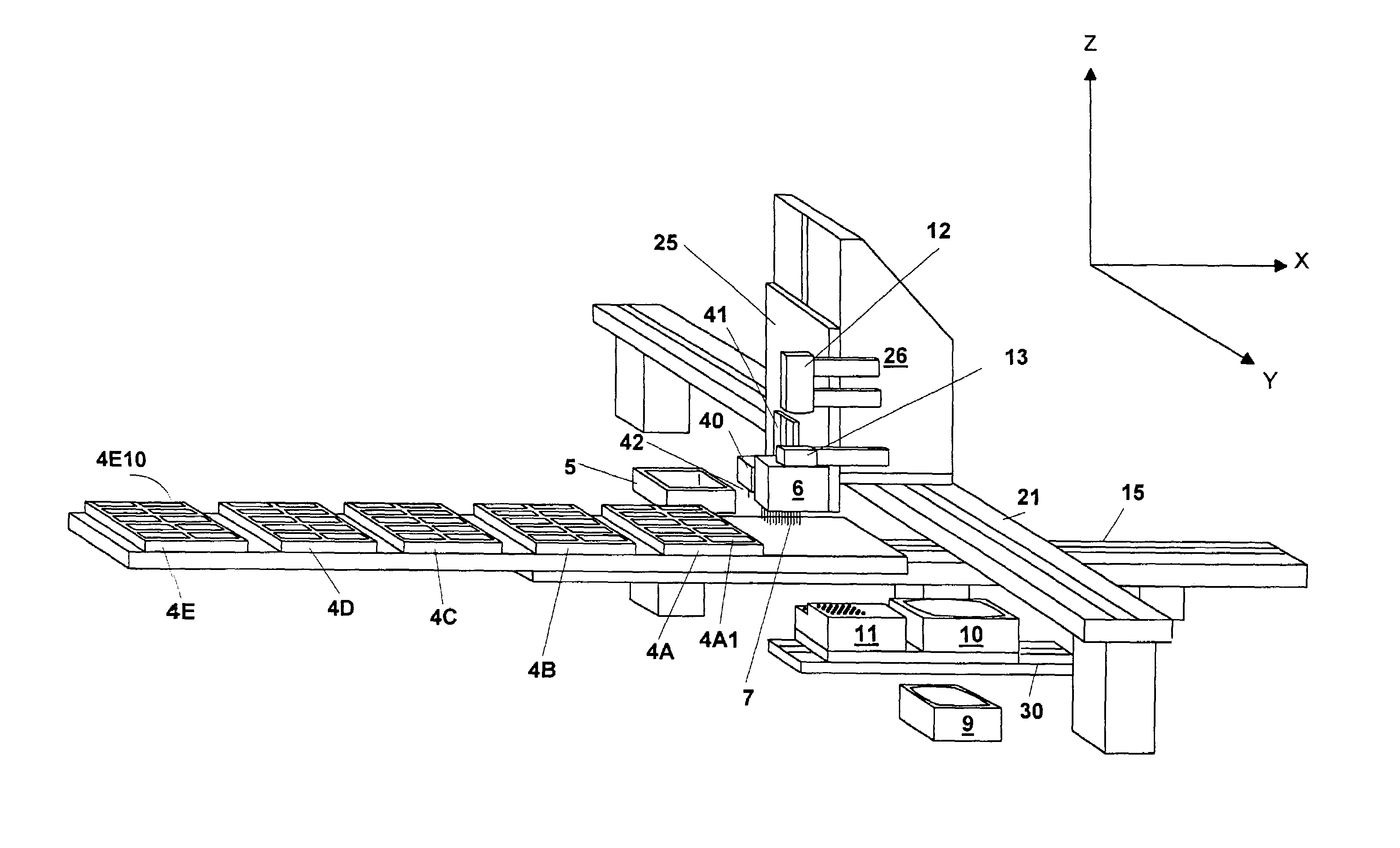

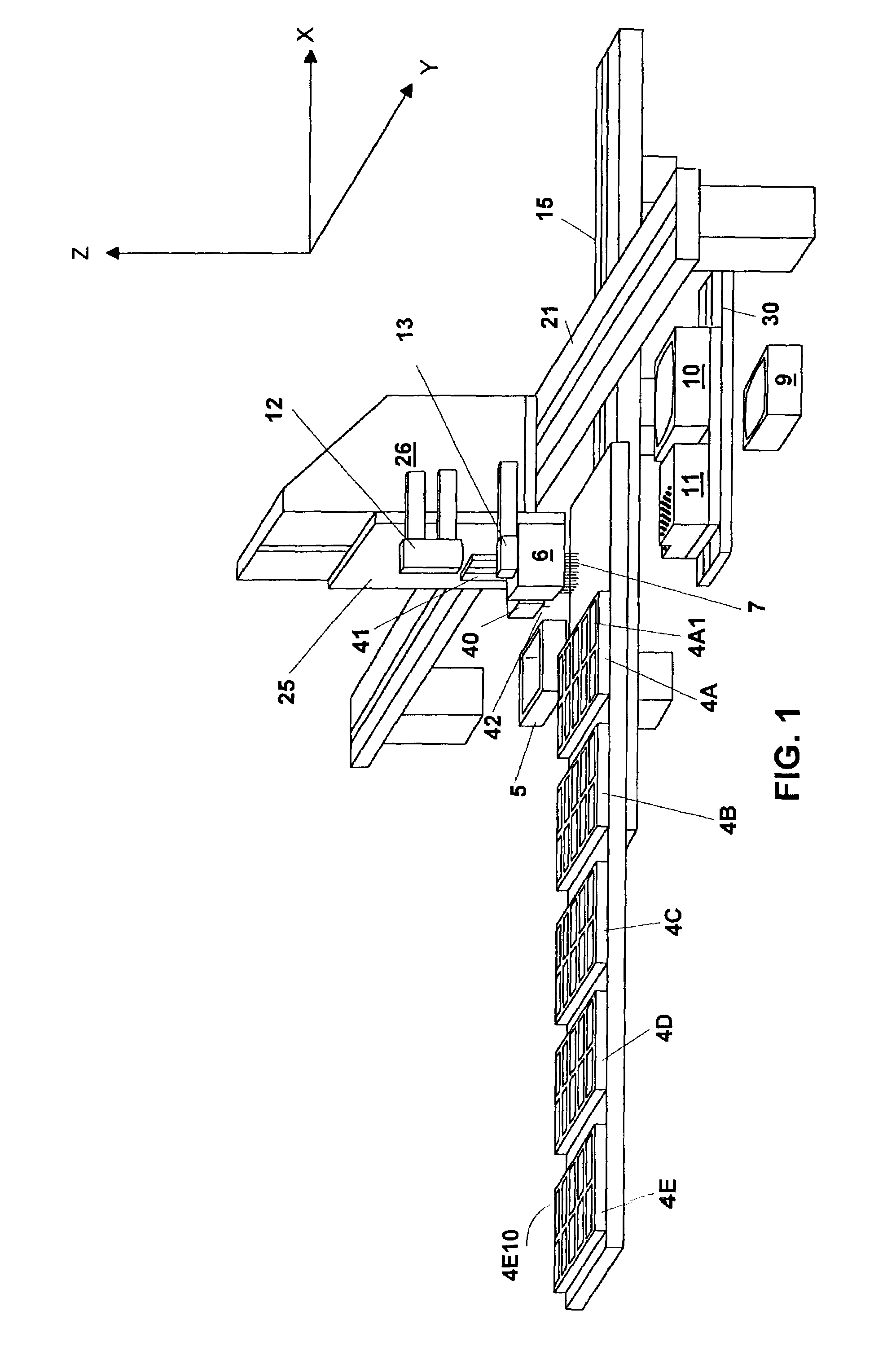

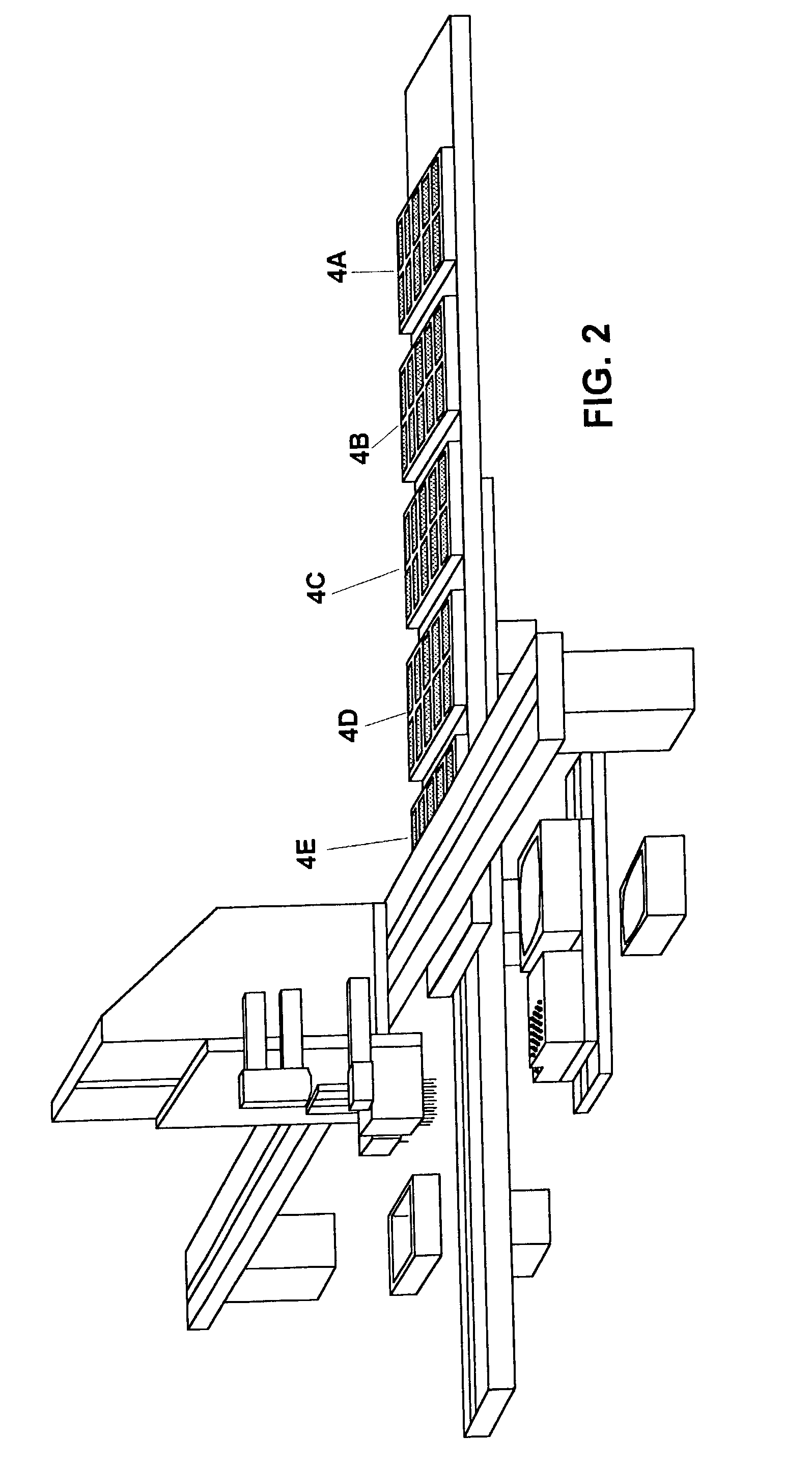

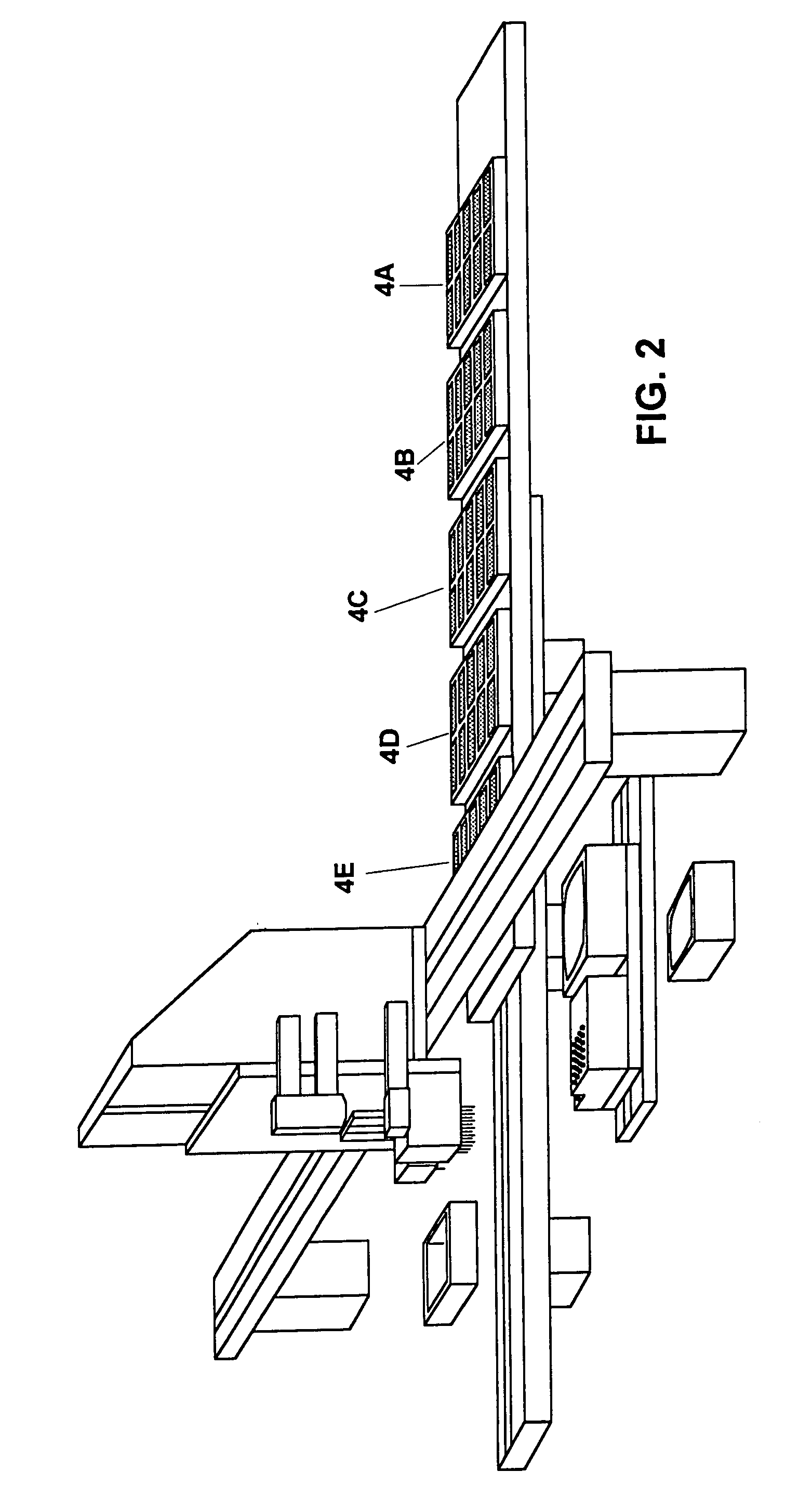

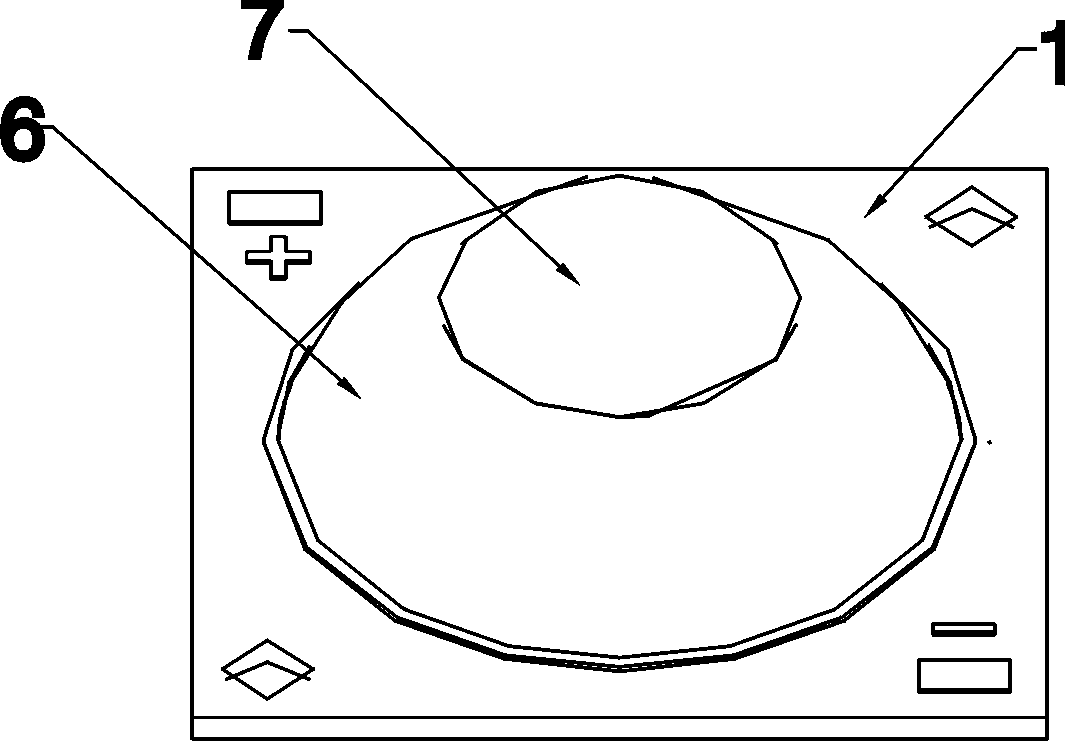

High capacity microarray dispensing

InactiveUS6979425B1Improve spotImprove accuracySequential/parallel process reactionsWithdrawing sample devicesAnalysis dataMicroplate Well

A high capacity microarrayer for spotting solution onto slides in an automated microarray dispensing device. A microplate indexing device automatically moves, in sequence, a plurality of microplates to a solution removal area. A dispense head accesses each microplate at the solution removal area to remove solution from the microplate. The dispense head then moves to a slide positioning station to spot slides at the slide positioning station. In a preferred embodiment of the present invention, the microplate indexing station has at least one input stacking chamber for stacking microplates, and at least one output stacking chamber for stacking microplates. A walking beam indexer is disposed between the at least one input stacking chamber and the at least one output stacking chamber. The walking beam indexer is for moving microplates from said at least one input stacking chamber to said at least one output stacking chamber. While at the solution removal area, a lid lifter lifts the lid off each microplate to permit the microplate to be accessed by the dispense head for solution removal. After the solution is removed, the lid lifter replaces the lid. In another preferred embodiment, there is at least one light source capable of illuminating the slides, and at least one camera operating in conjunction with the at least one light source. The at least one camera is capable of acquiring and transmitting slide image data to a computer. The computer is programmed to receive the slide image and analyze it. The computer will then generate post analysis data based on the analysis of the slide image data. The post analysis data is available for improving the spotting of the solution onto the slides. In a preferred embodiment, the slide image data includes information relating to slide alignment, information relating to spot quality, and slide identification information. In a preferred embodiment, the analysis of the information relating to slide alignment enables the computer to make automatic adjustments to the relative positions of the at least one dispense head and the slides to increase the accuracy of the spotting. In a preferred embodiment, the analysis of the information relating to spot quality identifies a spot as pass or fail. An operator is then able to rework the spot. In a preferred embodiment, the analysis of the slide identification information enables the computer to track each slide.

Owner:AGENA BIOSCI

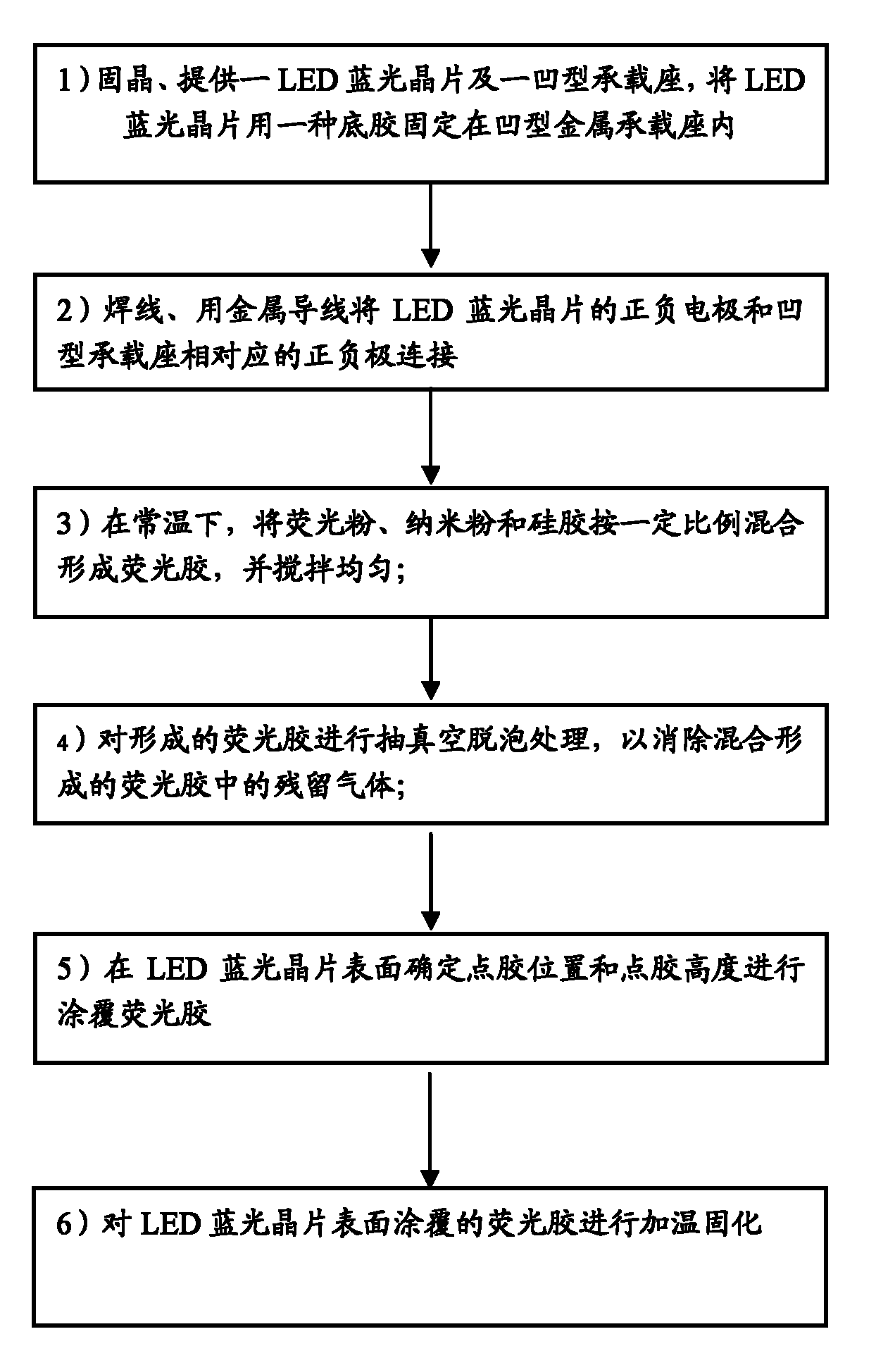

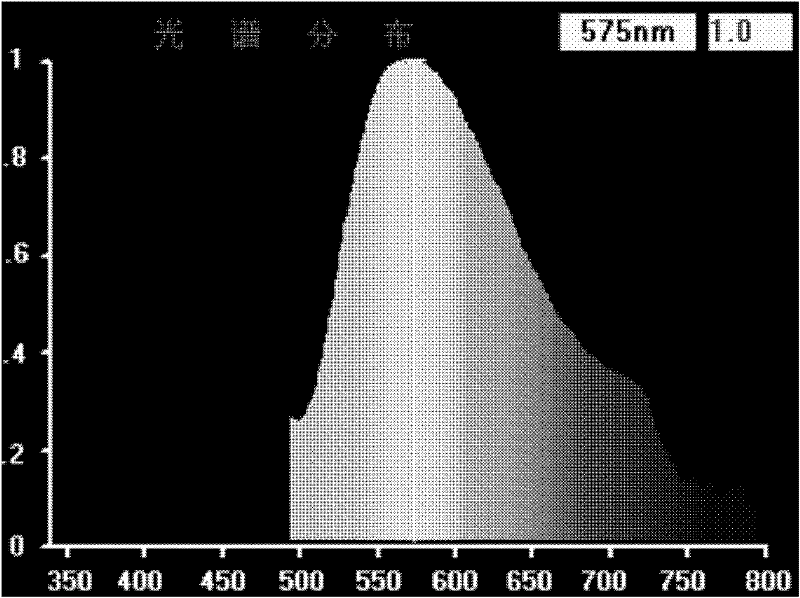

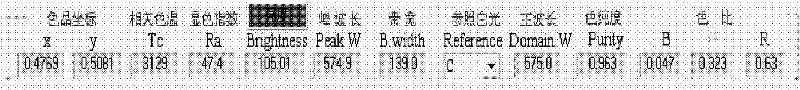

LED and dispensing method of LED fluorescent powder

ActiveCN102120212AEliminate residual gasUniform divergenceSolid-state devicesCoatingsEngineeringSilica gel

The invention discloses an LED and a dispensing method of LED fluorescent powder. The dispensing method comprises the steps of: A, providing a bearing seat and an LED blue light chip, and fixing the LED blue light chip on the bearing seat through primer; B, respectively connecting the positive and the negative electrodes of the LED blue light chip with the positive and the negative electrodes of the bearing seat by using wires; C, mixing the fluorescent powder, nano powder and silicon gel according to a preset proportion to form fluorescent gel, and uniformly stirring; D, carrying out vacuumizing defoaming treatment on the fluorescent gel to eliminate remained gases in the fluorescent gel formed through mixing; E, coating the fluorescent gel on a dispensing position on the surface of the LED blue light chip at a dispensing height; and F, heating and curing the fluorescent gel coated on the surface of the LED blue light chip. The method has better effect on improving excitation efficiency of the fluorescent powder, uniformity of emitted light distribution and consistency of color temperature.

Owner:LEDMAN OPTOELECTRONIC HZ CO LTD

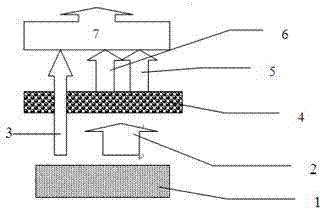

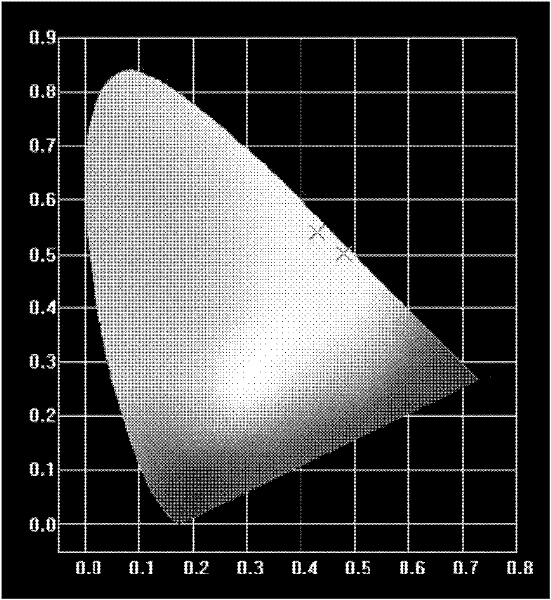

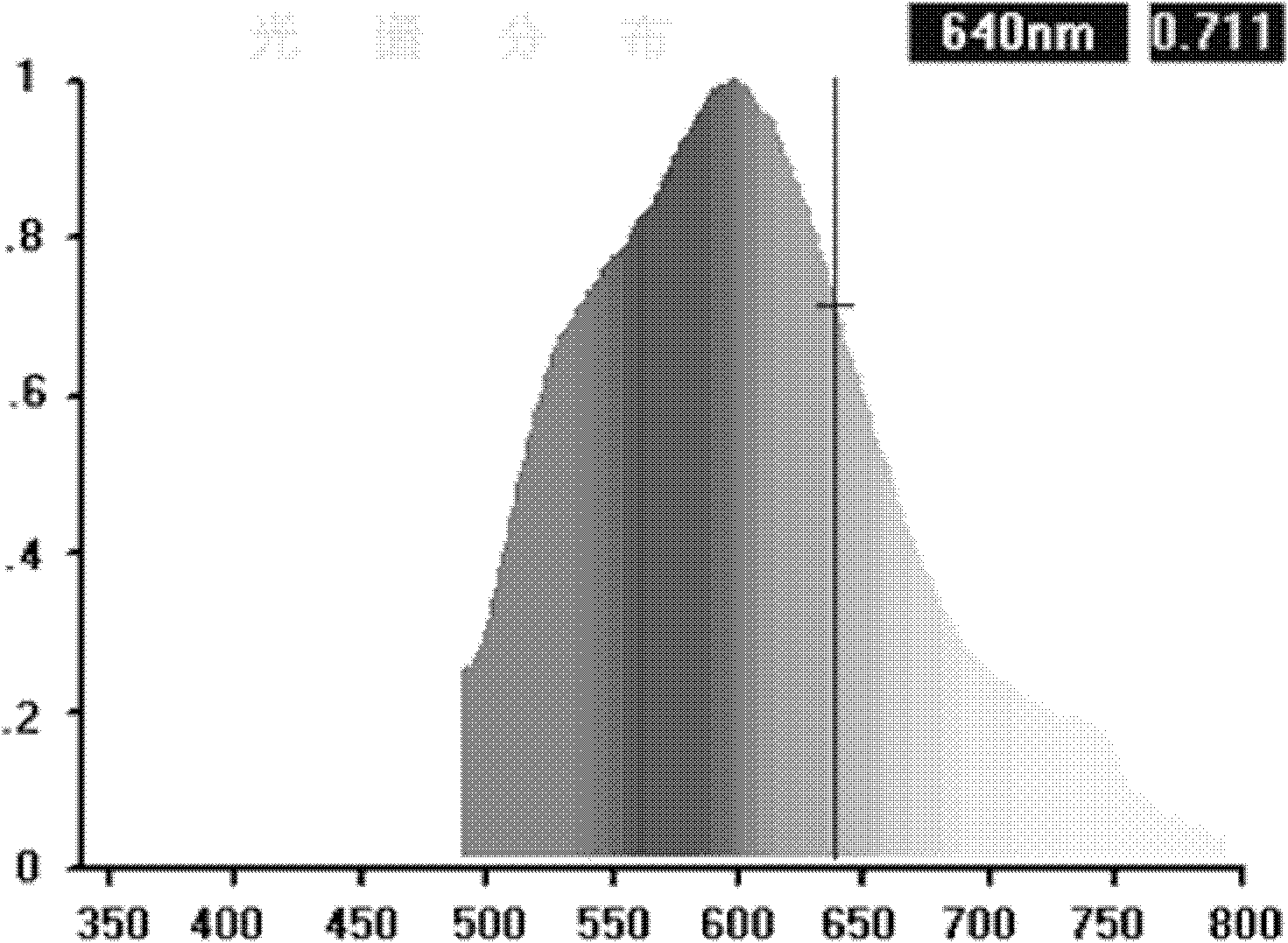

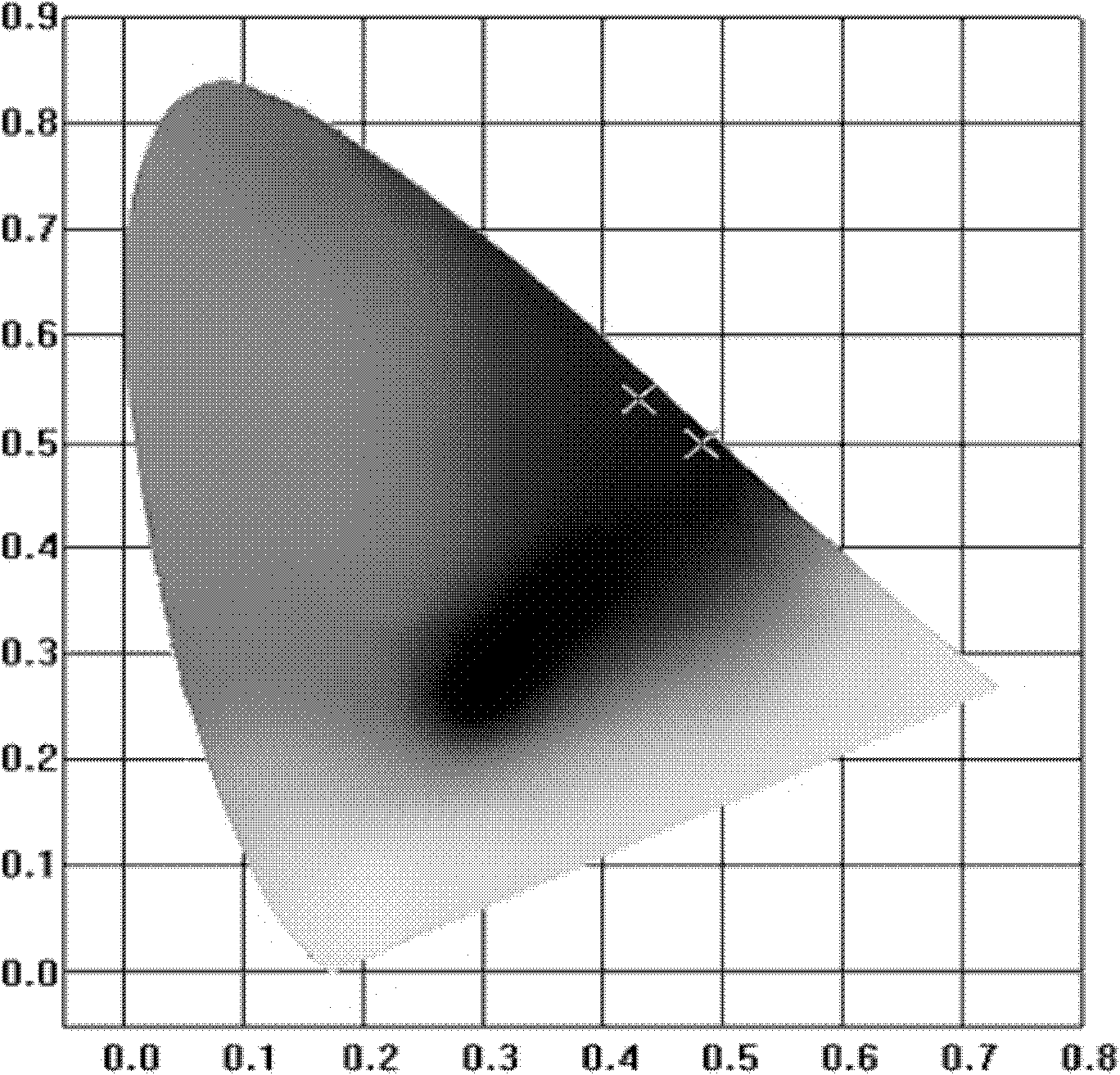

White-light LED (Light Emitting Diode) light source

ActiveCN102760820AOvercoming secondary absorptionImprove light extraction efficiencySemiconductor devicesColor rendering indexRare earth

The invention relates to a white-light LED (Light Emitting Diode) light source. The white-light LED light source comprises a bowl cup, a blue-light LED chip arranged at the bottom of the bowl cup, yellow-green fluorescent powder and red fluorescent powder, wherein the yellow-green fluorescent powder and red fluorescent powder are arranged above the blue-light LED chip, and the yellow-green fluorescent powder is arranged above the red fluorescent powder. The white-light LED light source selects the yellow-green fluorescent powder with high luminous efficacy and a rare earth aluminate matrix, yellow-green silicate fluorescent powder and silica-based nitride red powder which are combined and matched with the blue-light LED chip, and through the reasonable design of the spatial layout of fluorescent powder with different systems inside an LED, the secondary absorption of yellow-green light by the nitride red fluorescent powder can be effectively overcome, and the relatively high emergent light efficiency also can be obtained simultaneously when a color rendering index is obviously promoted. A light-emitting system provided by the invention can realize white light with high luminous efficacy and a high color rendering index by adjusting the proportioning of fluorescent powder with different emission spectrums so as to meet the technical requirements of general lighting.

Owner:江西省兆驰光电有限公司

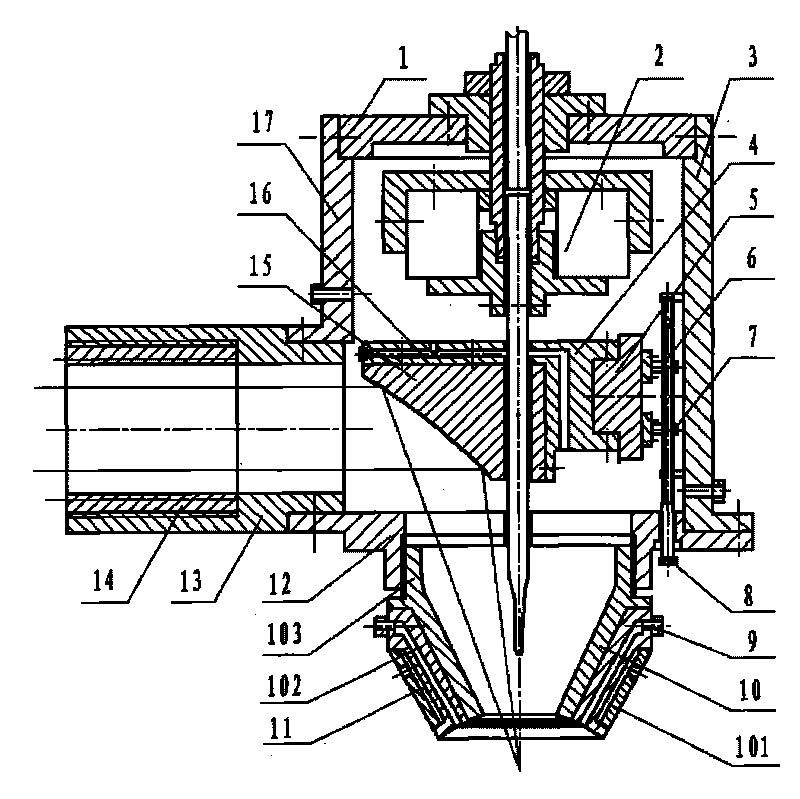

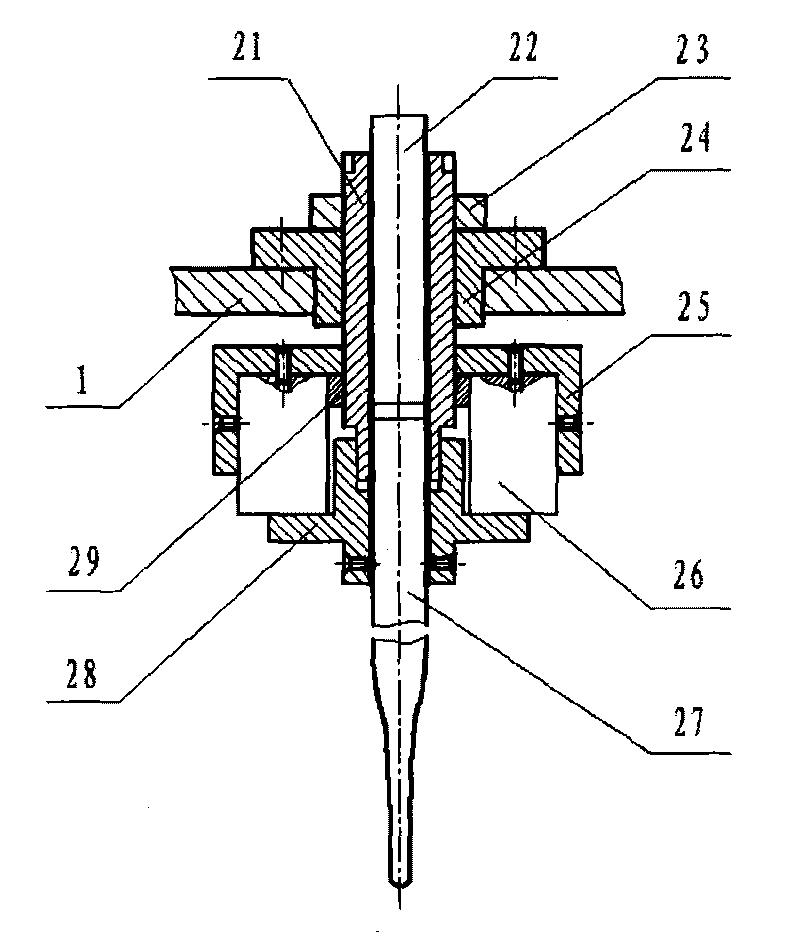

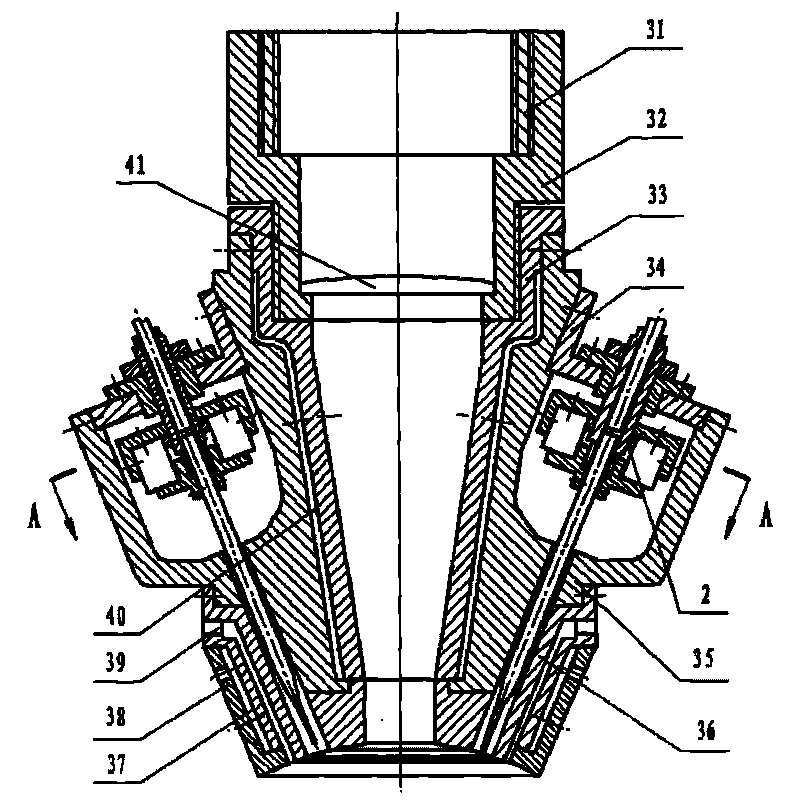

Precise laser micro-forming and powder feed method and coaxial laser powder device thereof

InactiveCN101695752AHigh resolutionContinuously adjustable amplitudeMetallic material coating processesPiezoelectric actuatorsGradient material

The invention discloses a precise laser micro-forming and powder feed method and a coaxial laser powder device thereof. The precise laser micro-forming and powder feed method of the invention adopts a powder feed device to perform piezoelectricity actuated powder feed; after a piezoelectric cermic in a piezoelectric actuator in the power feed device is electrified, the pulse inertial force generated by a converse piezoelectric effect thereof is conducted to a quartz micro-nozzle to actuate metal powder to overcome a resistance to spout to a former pulse continuously; and the piezoelectric cermic of the piezoelectric actuator is controlled to work by a computer. When micro-forming or micro-cladding a metal component of a uniform material, a central single-powder pipe powder feed method is adopted; and when micro-forming or micro-cladding a metal component of a gradient material or a multilayer compound layer, a lateral multi-path powder feed method is adopted. The invention also discloses a coaxial laser powder device thereof for realizing the laser precisely micro-forming and powder feed method, which has the advantages that: the defocusing distance and powder feed speckle thereof are convenient and adjustable; the powder feed resolution is high; the single pulse discharge is accurate to the magnitude of microgramme; the powder feed is uniform, stable and continuous; and the powder feed density meets the requirement of micro-forming.

Owner:HUAIHAI INST OF TECH

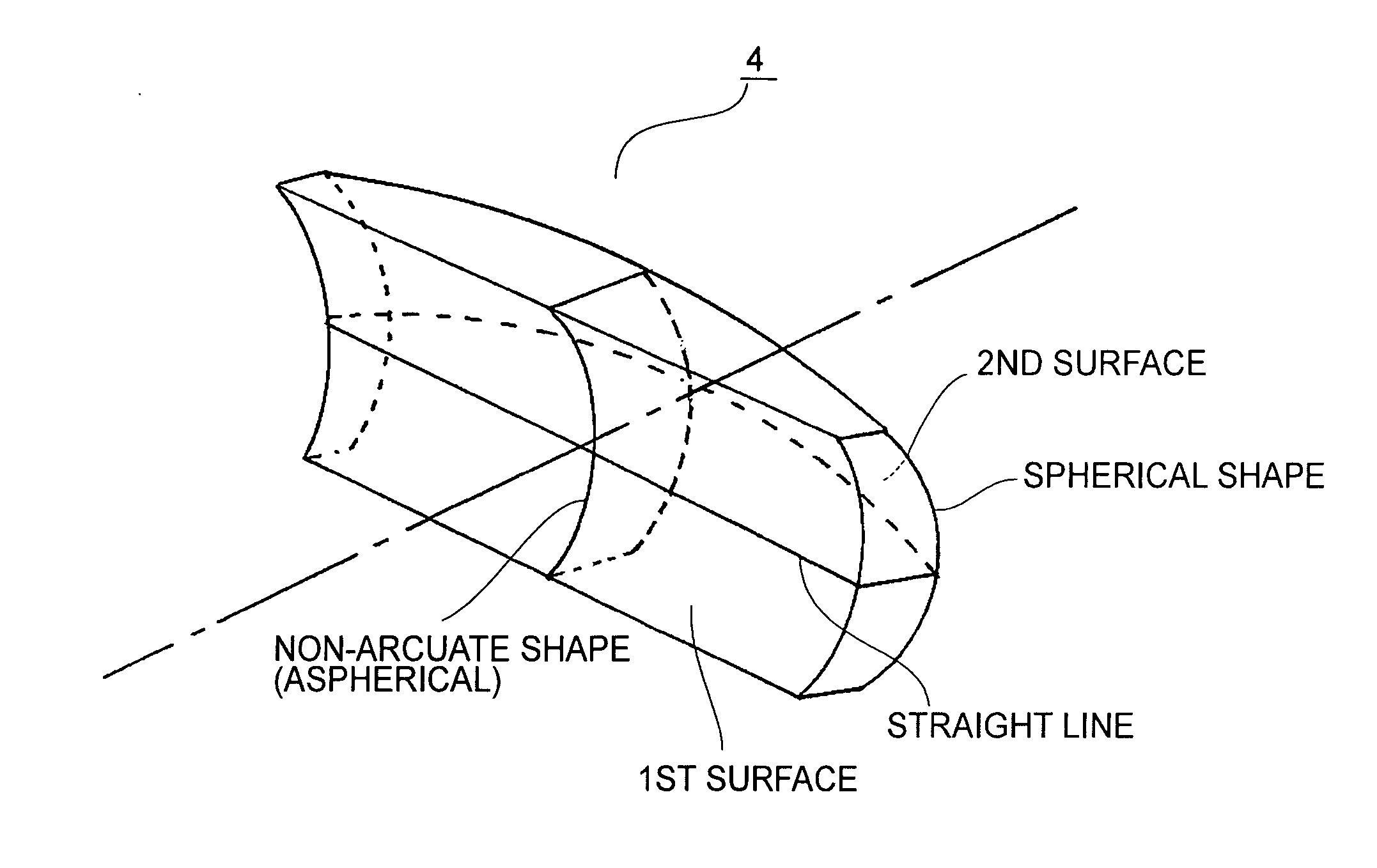

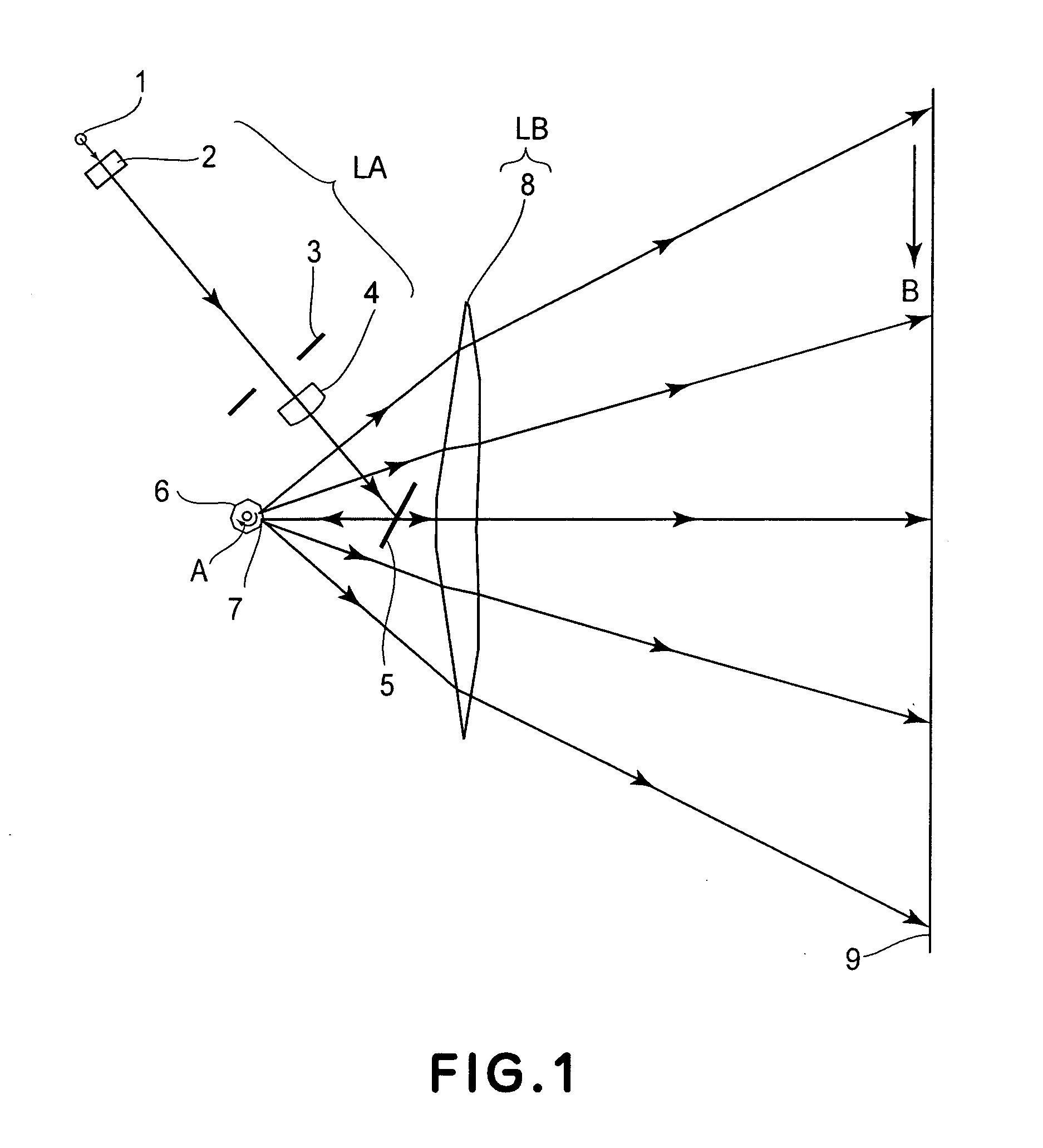

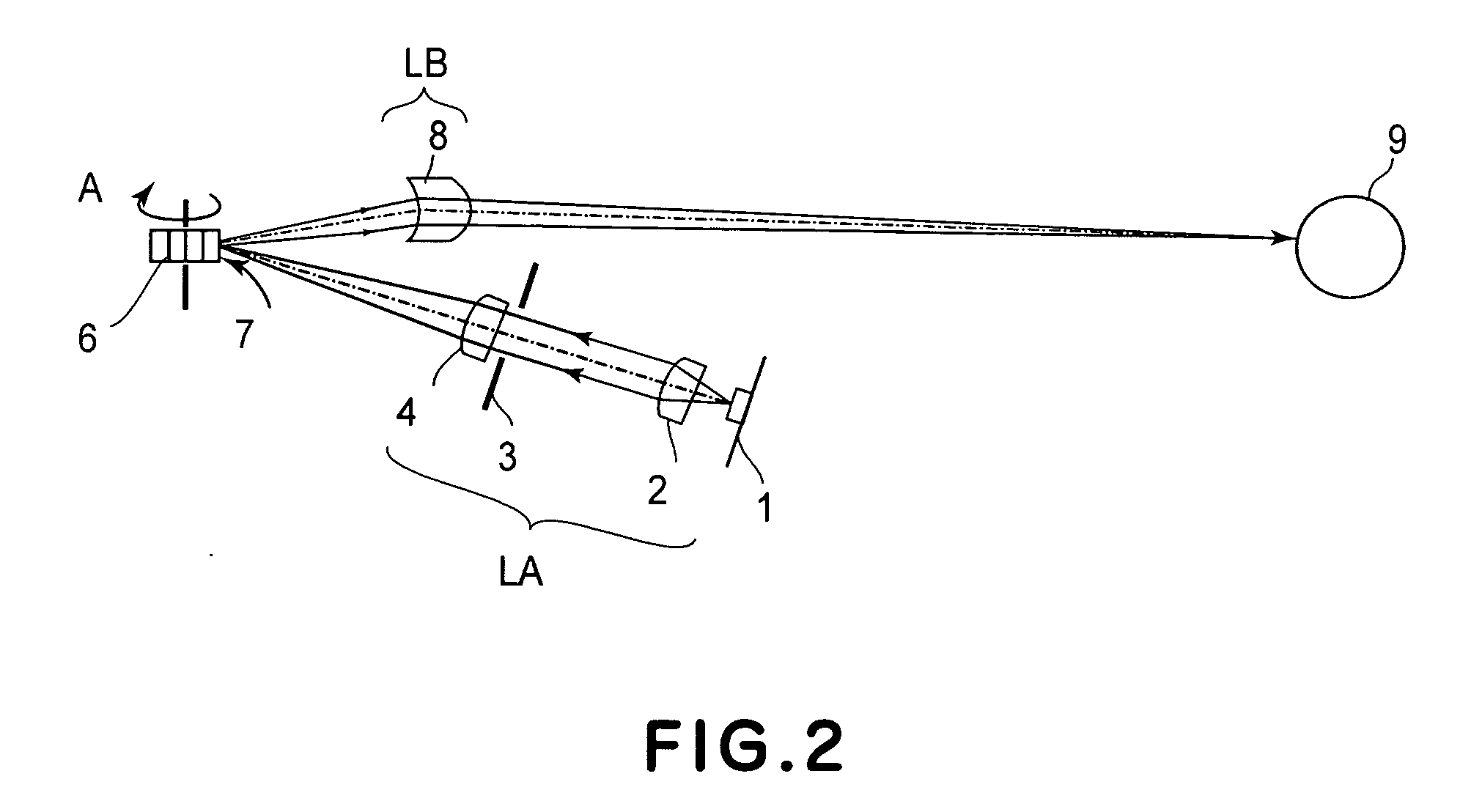

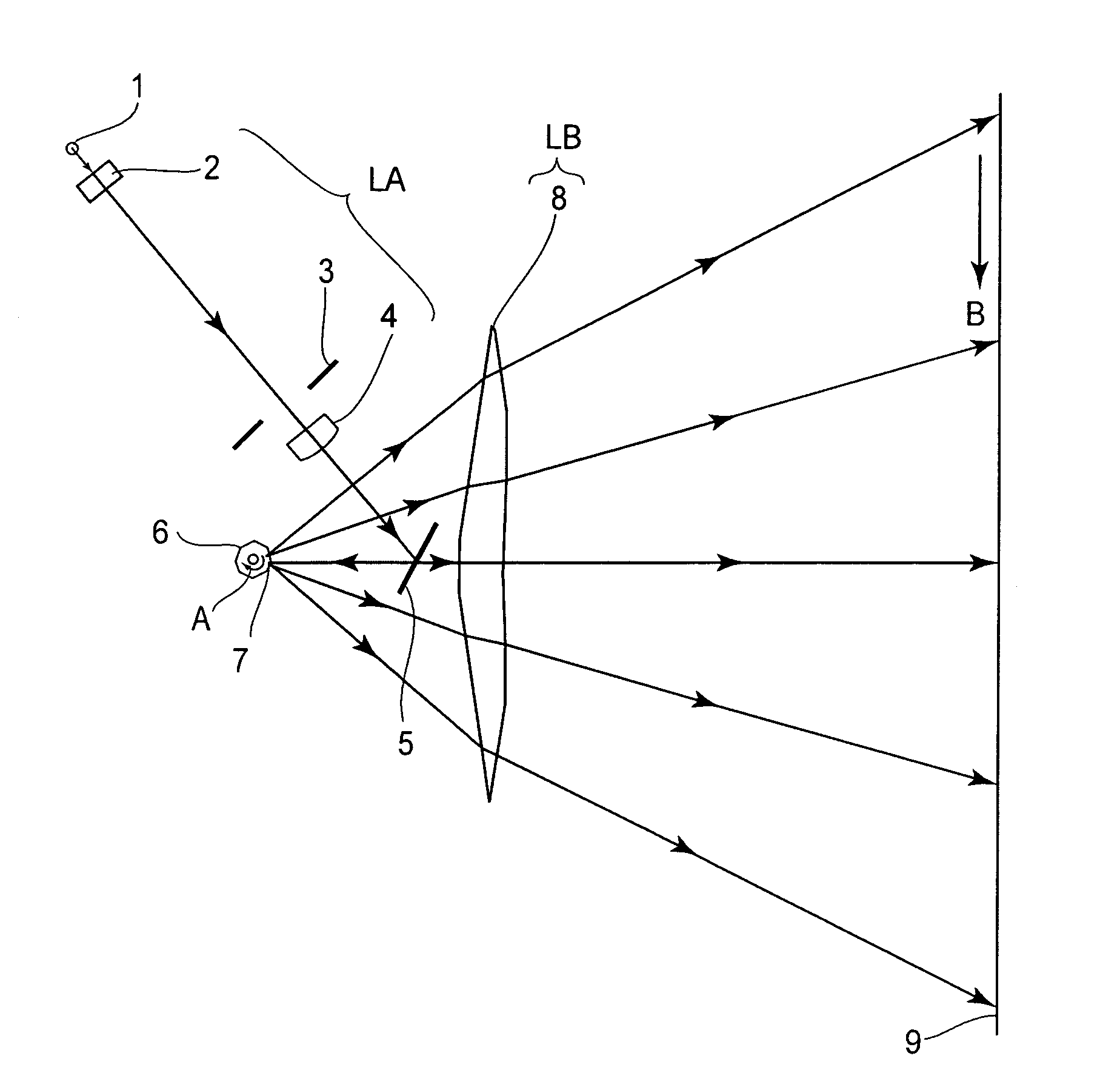

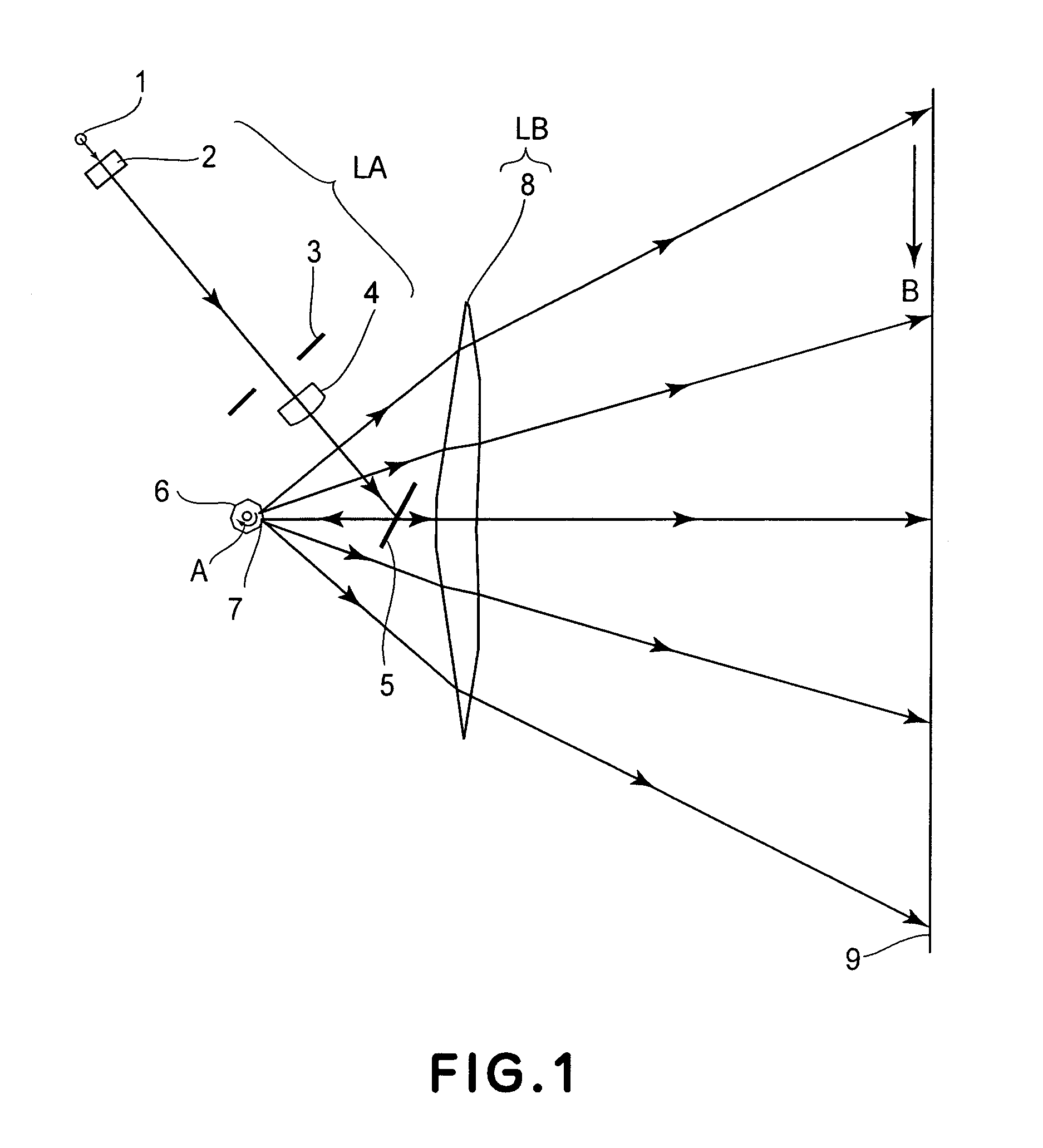

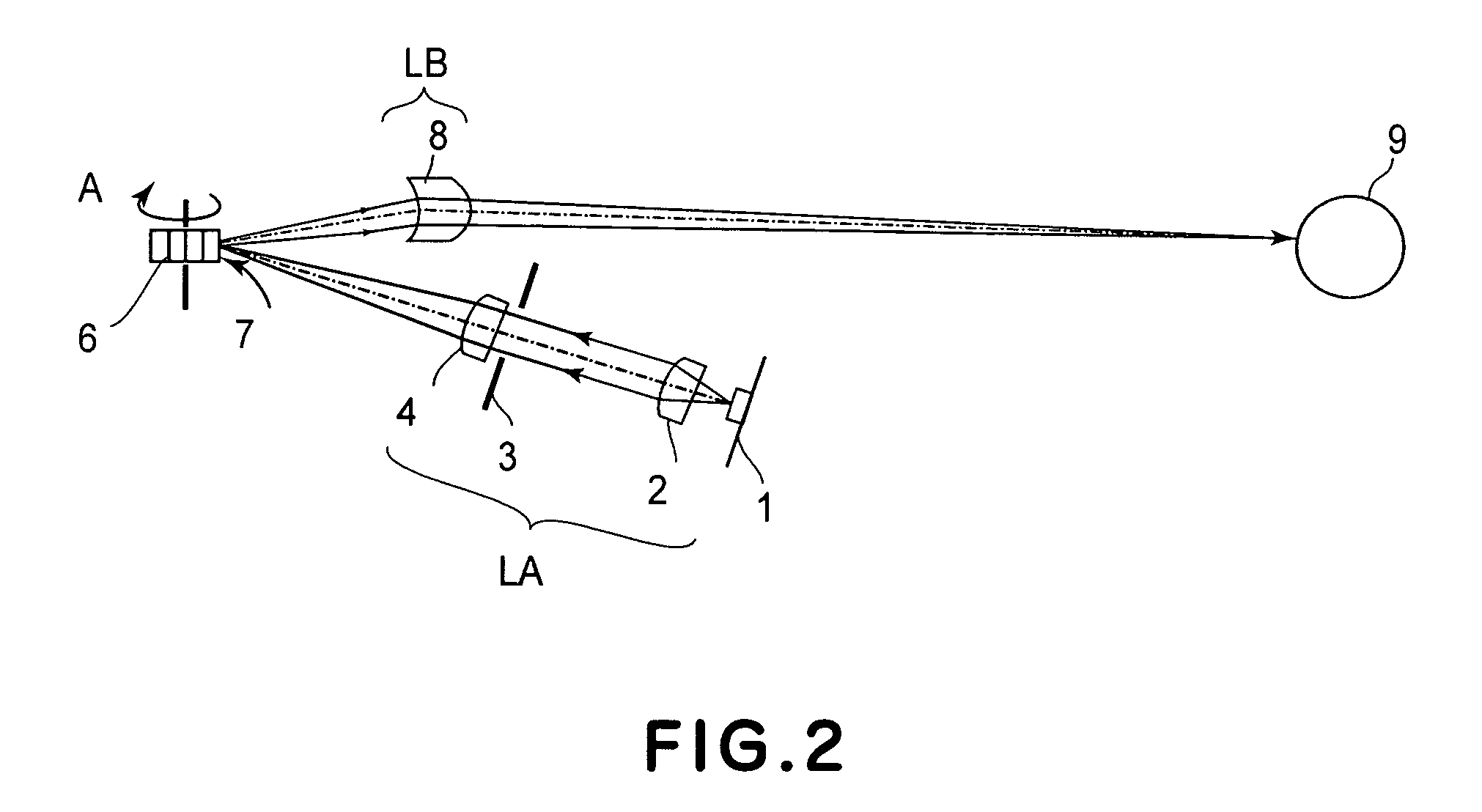

Optical scanning system and image forming apparatus using the same

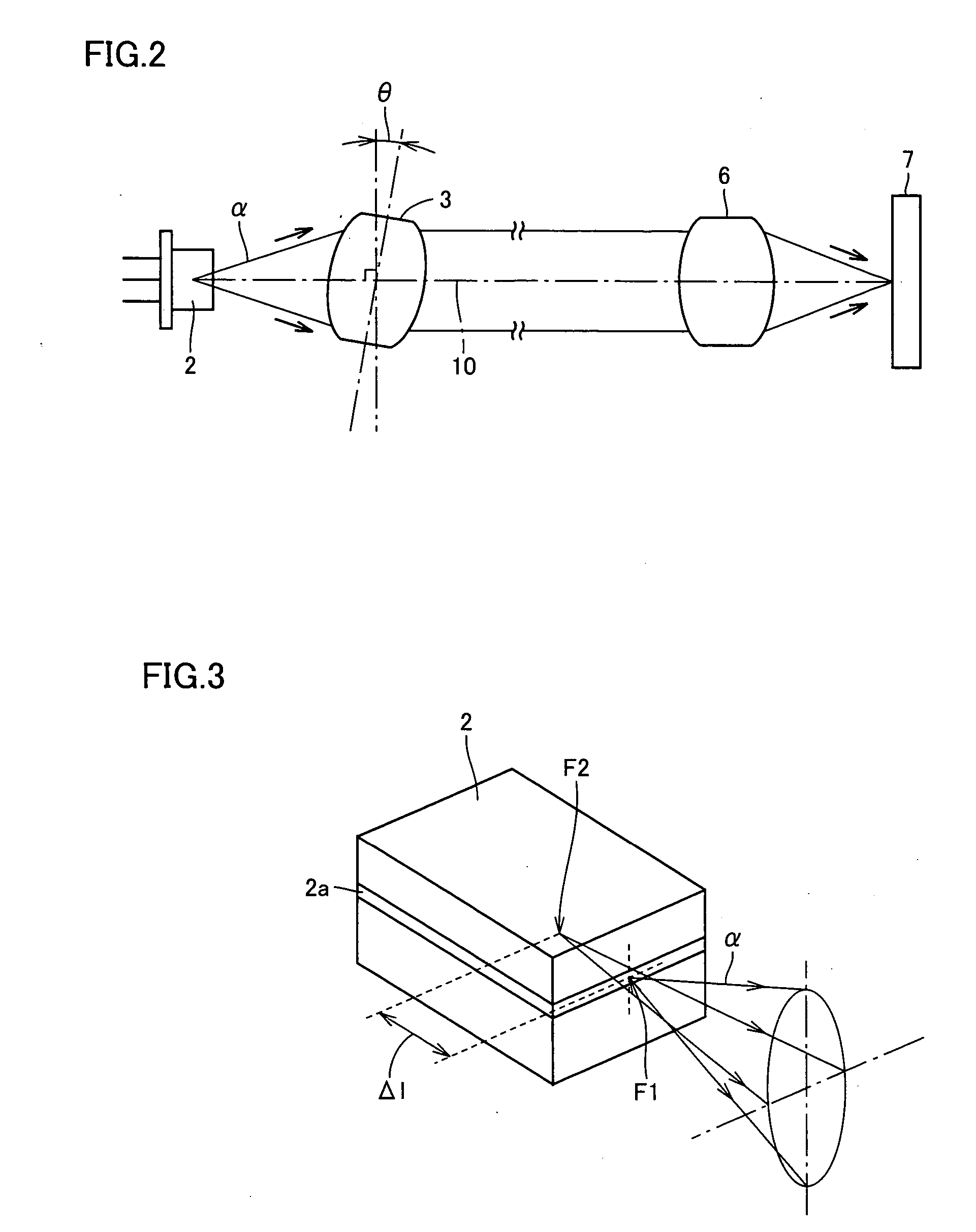

InactiveUS20070091402A1Improve spotHigh precisionInking apparatusBeam/ray focussing/reflecting arrangementsLight beamImage formation

Disclosed are an optical scanning system and an image forming apparatus having the same, wherein the optical scanning system includes a light source, a deflector, an input optical system for directing a light beam from the light source to the deflector, and an imaging optical system for directing the light beam deflected by the deflector onto a surface to be scanned, wherein the input optical system includes a first optical element having a power both in a main-scan sectional plane and in a sub-scan sectional plane, and a second optical element having a power in the sub-scan sectional plane, and wherein at least one surface of the first optical element has a shape being rotationally asymmetrical and, in the sub-scan sectional plane, being non-arcuate.

Owner:CANON KK

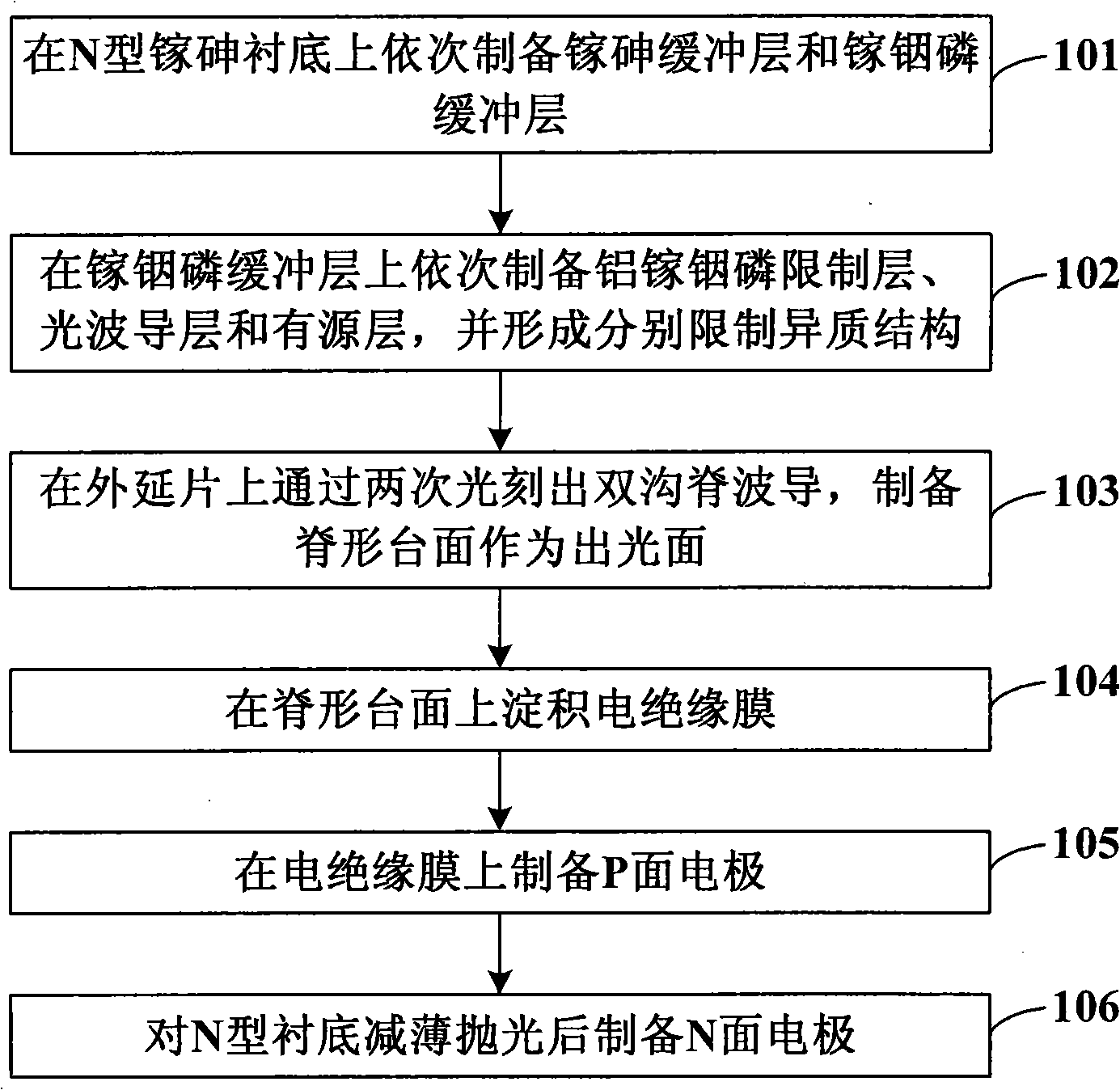

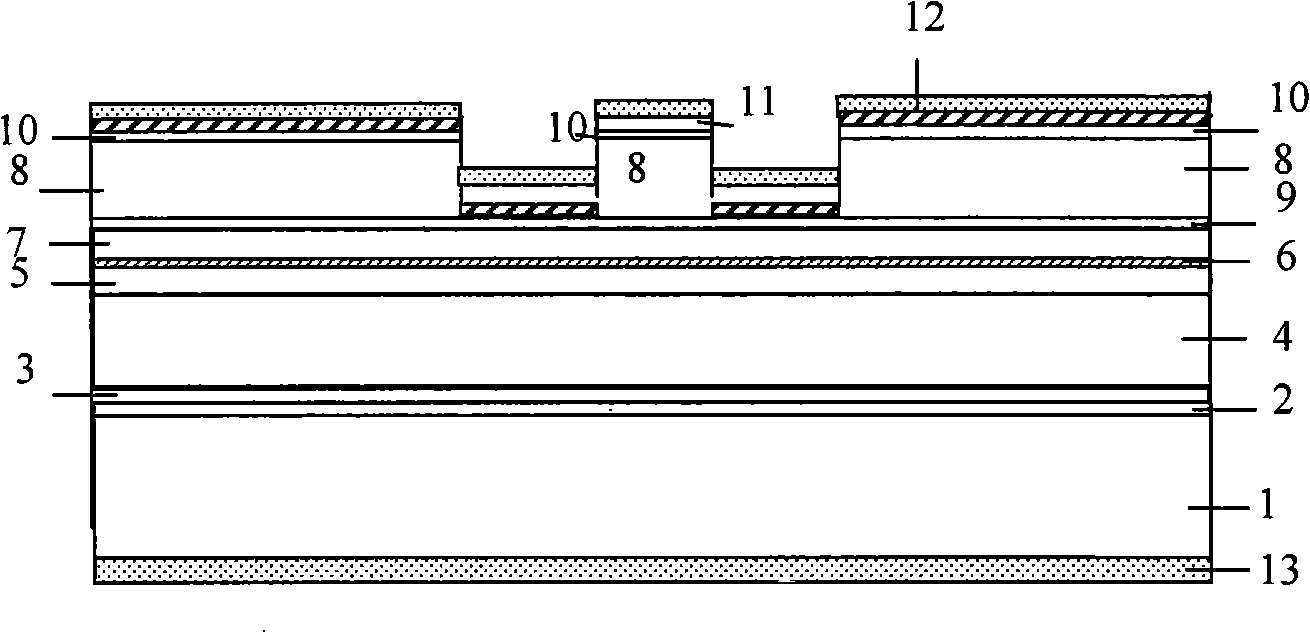

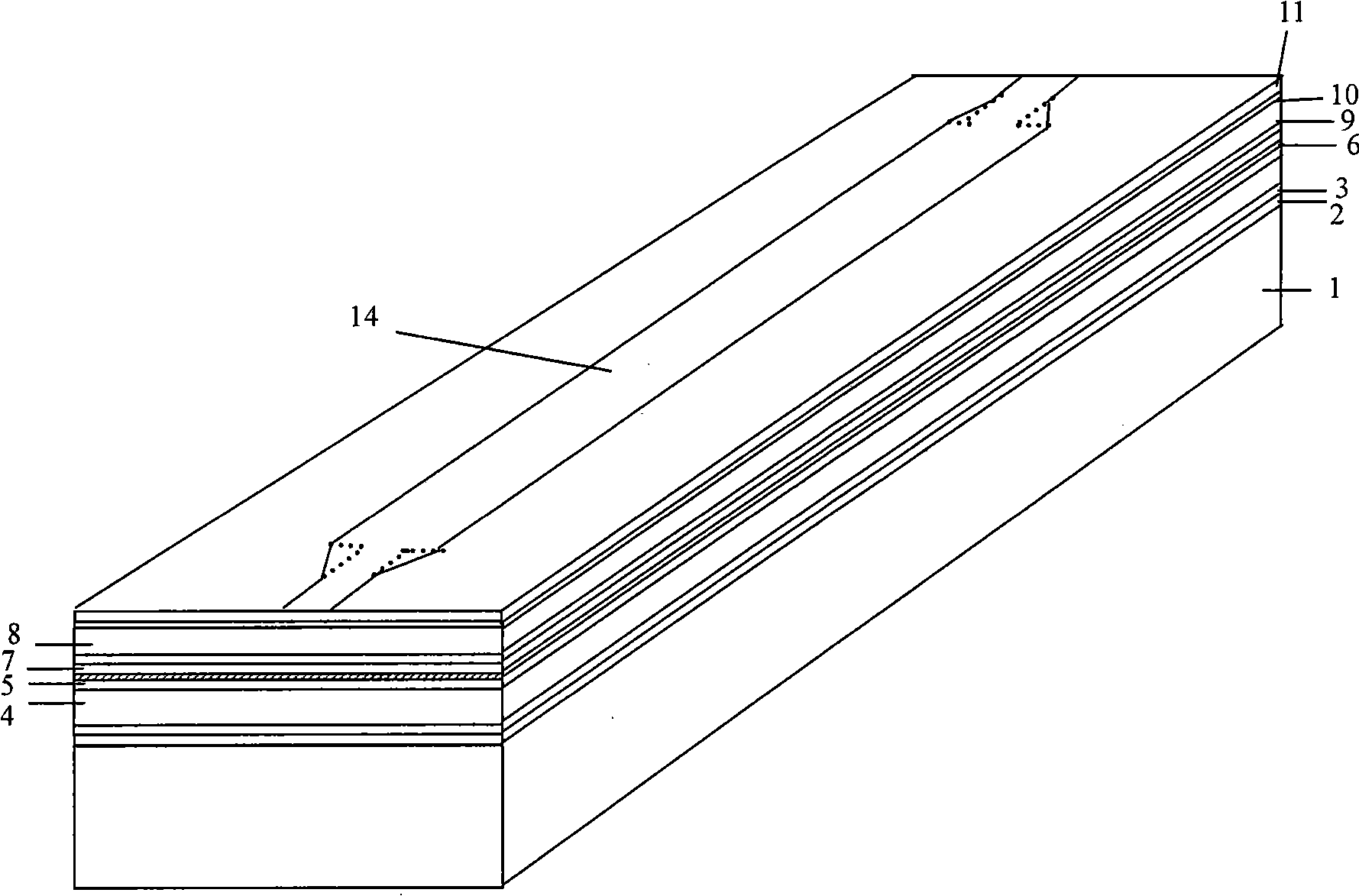

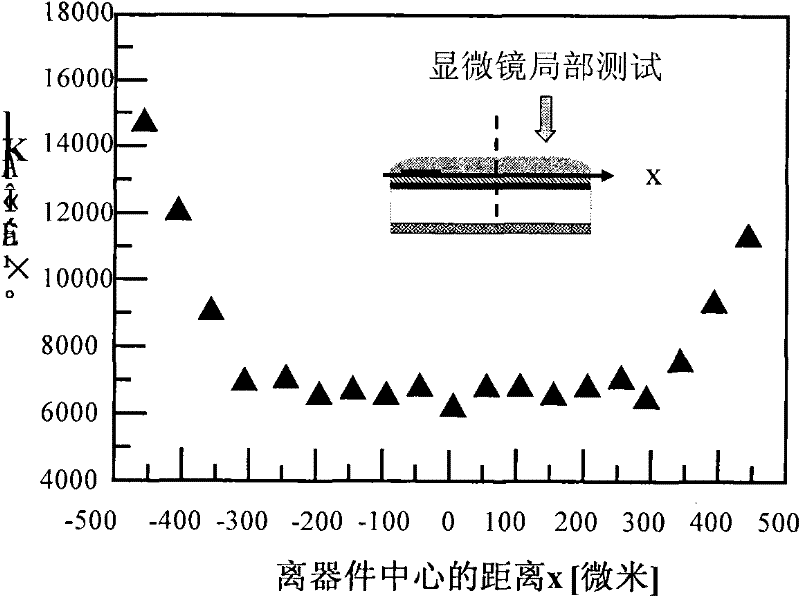

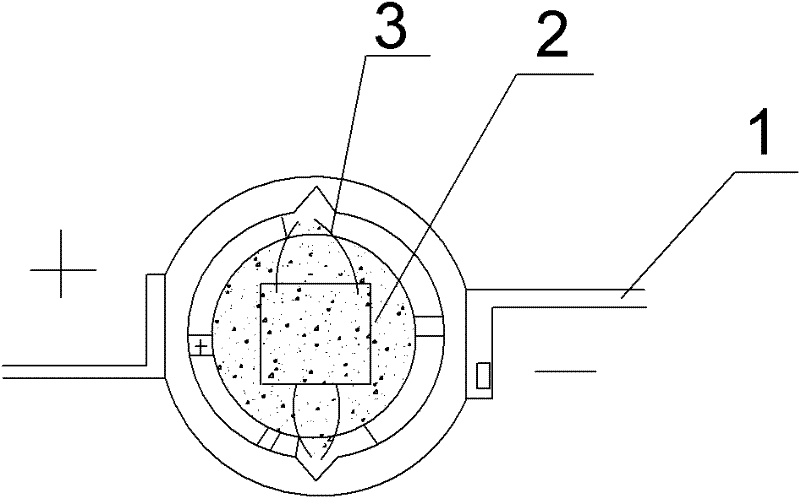

Production method of quantum well edge-emission semiconductor laser

InactiveCN101316027AImprove output spotOutput power is not affectedOptical wave guidanceLaser detailsFiberLight spot

The invention discloses a preparation method of a quantum well emitting semiconductor laser used for improving the output light spot, relating to the technical field of a semiconductor laser. The preparation method comprises the steps as follows: A. a Ga-As damping layer and a Ga-In-P damping layer are sequentially prepared on an N-typed Ga-As underlay; B. an Al-Ga-In-P limiting layer, a fibre waveguide layer and an active layer are sequentially prepared on the Ga-In-P damping layer and a structure which limits heterostructures is respectively formed; C. a dual-ridge waveguide is formed on an external extension sheet by etching twice; a ridge-shaped table is prepared to be taken as a light outlet surface; D. an electric insulation film is deposited on the ridge-shaped table; E. a P-surface electrode is prepared on the electric insulation film; F. an N-surface electrode is prepared after the N-typed underlay is thinned and polished. The preparation method of the invention ensures that the original output power and the photoelectric conversion efficiency of the ridge-shaped fibre wave guide laser are not affected basically, increases the parallel divergence angle and improves the output light spot of the laser.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

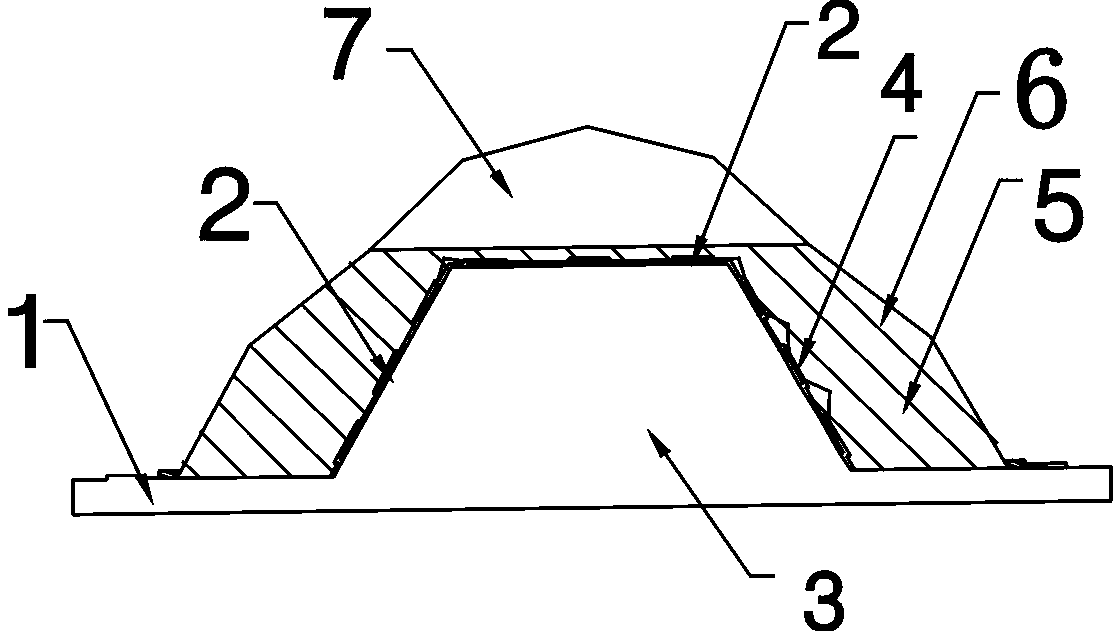

Optical pickup apparatus for optical disc

In an optical pickup apparatus, a collimator lens is rockably supported by edges of two protruding portions formed on opposing sides of a groove of an optical base. The collimator lens is urged against the edges of the two protruding portions by a leaf spring. The position in vertical direction of one end of the leaf spring is adjusted by a position adjustor. In this manner, a tilt angle of the collimator lens is adjusted. Therefore, astigmatism of the light spot can precisely be compensated for irrespective of variations among apparatuses to achieve an excellent light spot.

Owner:FUNAI ELECTRIC CO LTD

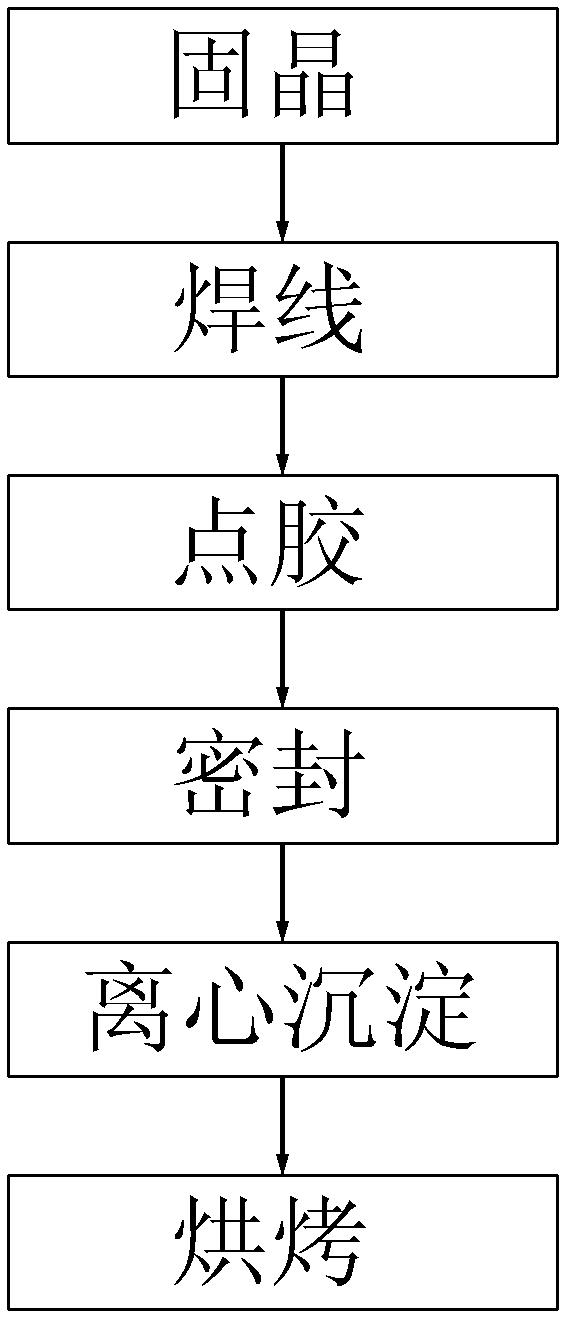

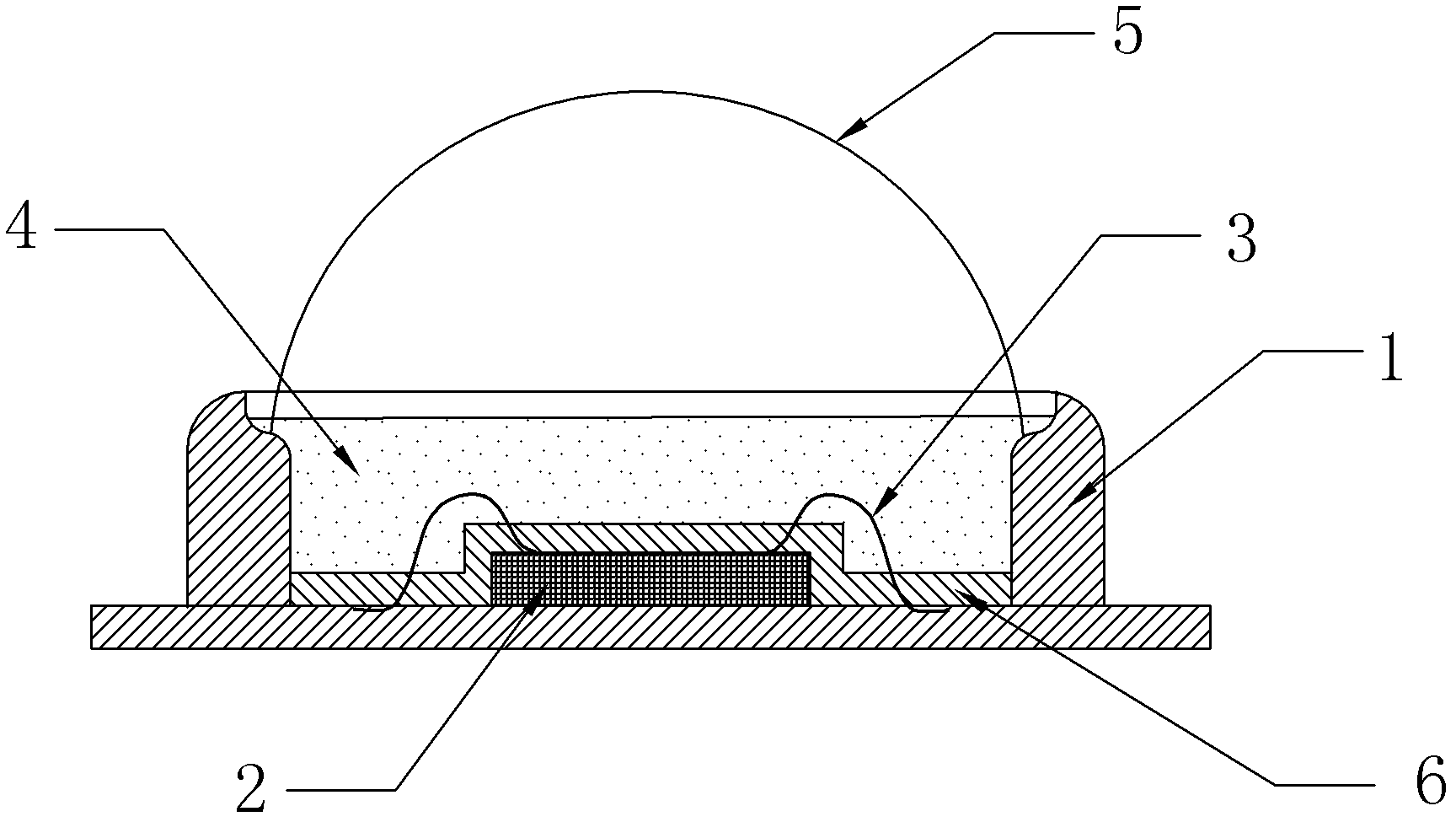

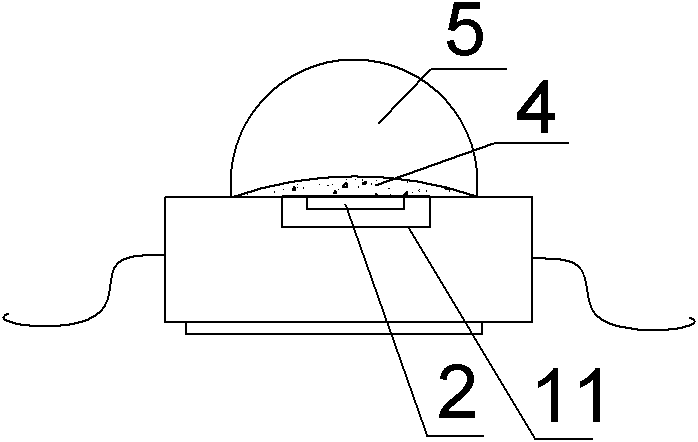

Packaging process of white light light-emitting diode (LED)

InactiveCN103178188AIncrease brightnessImprove spotSolid-state devicesSemiconductor devicesHigh concentrationFluorescence

The invention relates to a packaging process of a white light light-emitting diode (LED). The packaging process comprises the steps of providing a packaging support, a light-transmitting seal cover and a blue LED flip chip; performing crystal fixing, and fixing the blue LED flip chip on the packaging support; performing wire bonding, and enabling an anode and a cathode of the blue LED flip chip to be electrically connected with a first electrode and a second electrode on the packaging support respectively; dispensing gel, and filling the well made fluorescence gel in the packaging support; performing sealing, and assembling the light-transmitting seal cover at the top of the packaging support; performing centrifugal precipitation, enabling fluorescent powder in the fluorescence gel to be deposited on the surface of the bottom of the packaging support and the surface of the LED chip under the effect of centrifugal force, and forming a high-concentration fluorescent powder layer; performing baking, and enabling the LED undergoing centrifugal precipitation to be placed in a baking device to perform baking. By means of the uniform high-concentration fluorescent powder layer deposited on the surface of the blue LED flip chip, light spots can be greatly improved, and brightness of an LED lamp is improved.

Owner:BONSHINE OPTICAL ELECTRON TECH

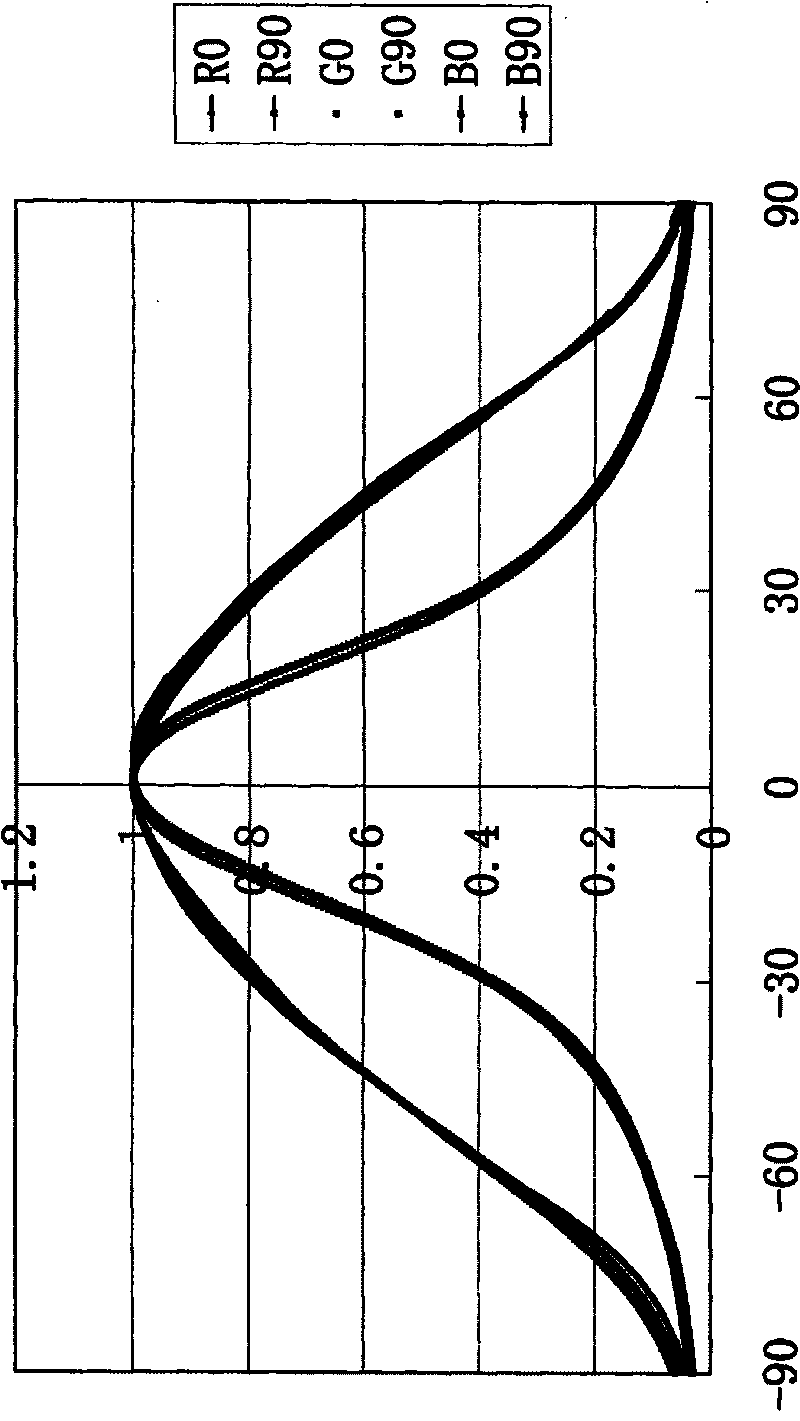

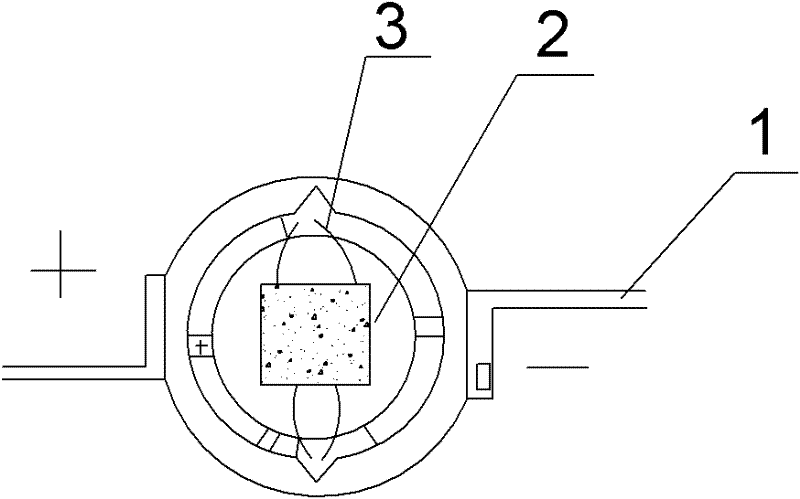

LED lamp and encapsulating method thereof

InactiveCN101701674AFull of lightImproved flare and light shapePoint-like light sourceElectric lightingEngineeringFacula

The invention discloses an LED lamp and an encapsulating method thereof. The size and appearance of an LED chip, a reflecting cup, and an illuminator of the LED lamp are designed according to a certain requirement, so that the light distribution curve of three rays of red, green and blue of the manufactured LED lamp can achieve the three lines-one effect; the light outgoing effect of the LED lamp is more flush; and the light spot and the light shape can be improved. The encapsulating method of the invention is simple, and the manufactured LED lamp can effectively improve the lighting effect of the LED lamp.

Owner:LEDMAN OPTOELECTRONICS

Illuminating system and method for improving asymmetric projection

InactiveUS7290886B2Improve spotMore light spotTelevision system detailsProjectorsLight spotLight beam

An illuminating system and method for improving asymmetric projection includes a light source producing a light beam to form a light path, a projection lens disposed in the light path, a light valve inserted in the light path between the light source and the projection lens, and at least one anamorphic surface unit placed in the light path between the light source and the light valve. The anamorphic surface unit offsets a distortion of a light spot resulted from obliquely incidence on the light valve, thus an asymmetric light spot can be improved as a more symmetric one to increase illuminating collection efficiency and uniformity.

Owner:YOUNG OPTICS

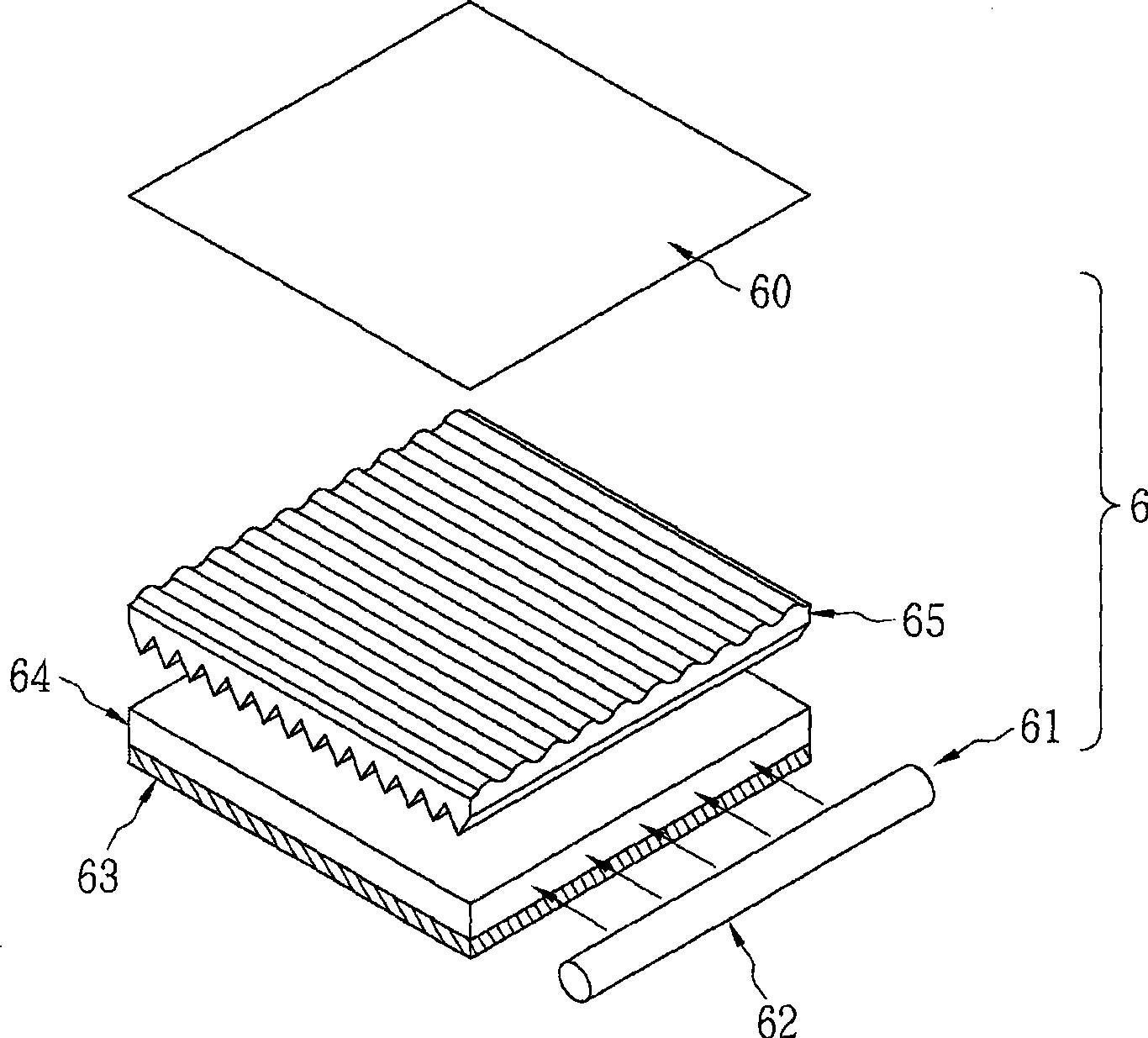

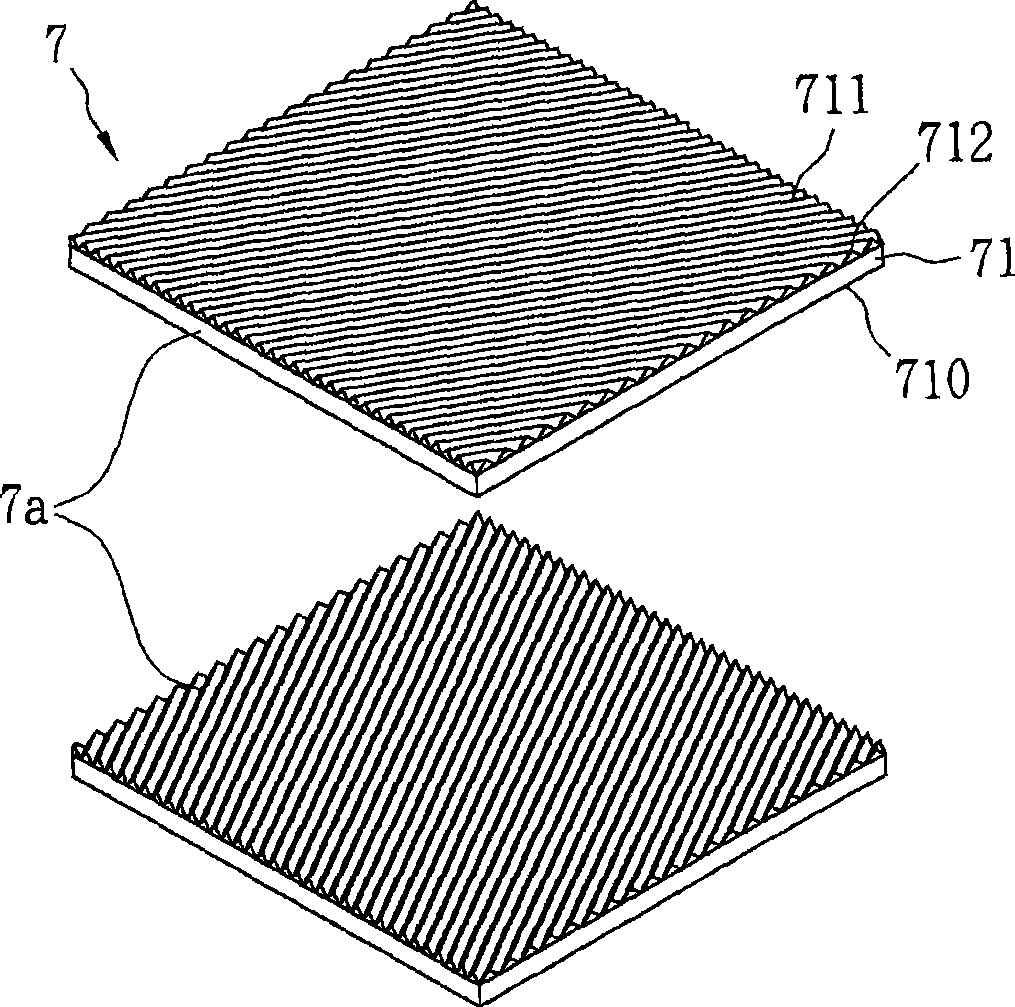

Prismatic lens, prism device and backlight module thereof

InactiveCN101546040AImprove spotExpand the scope of the designPrismsNon-linear opticsOptoelectronicsPrism

The invention relates to a prismatic lens, a prism device and a backlight module thereof, wherein the prism device comprises two prismatic lenses arranged in parallel; each prismatic lens comprises a rectangular substrate; the substrate is provided with an incident plane and an emergent plane which are opposite; and a plurality of parallel micro-prisms are arranged on the emergent plane. The corresponding micro-prisms on the two prismatic lenses are vertically arranged; the range of the included angle between the micro-prism of each prismatic lens and the long side of the substrate is between 1 and 89 degrees. The prism device and the backlight module thereof do not add components and cost and increase the range of the included angle between the micro-prism and the long side of the substrate, thereby improving the design elasticity of the system; and an even surface light source can be obtained to improve facula, interference and other problems.

Owner:ZHANJING TECH SHENZHEN +1

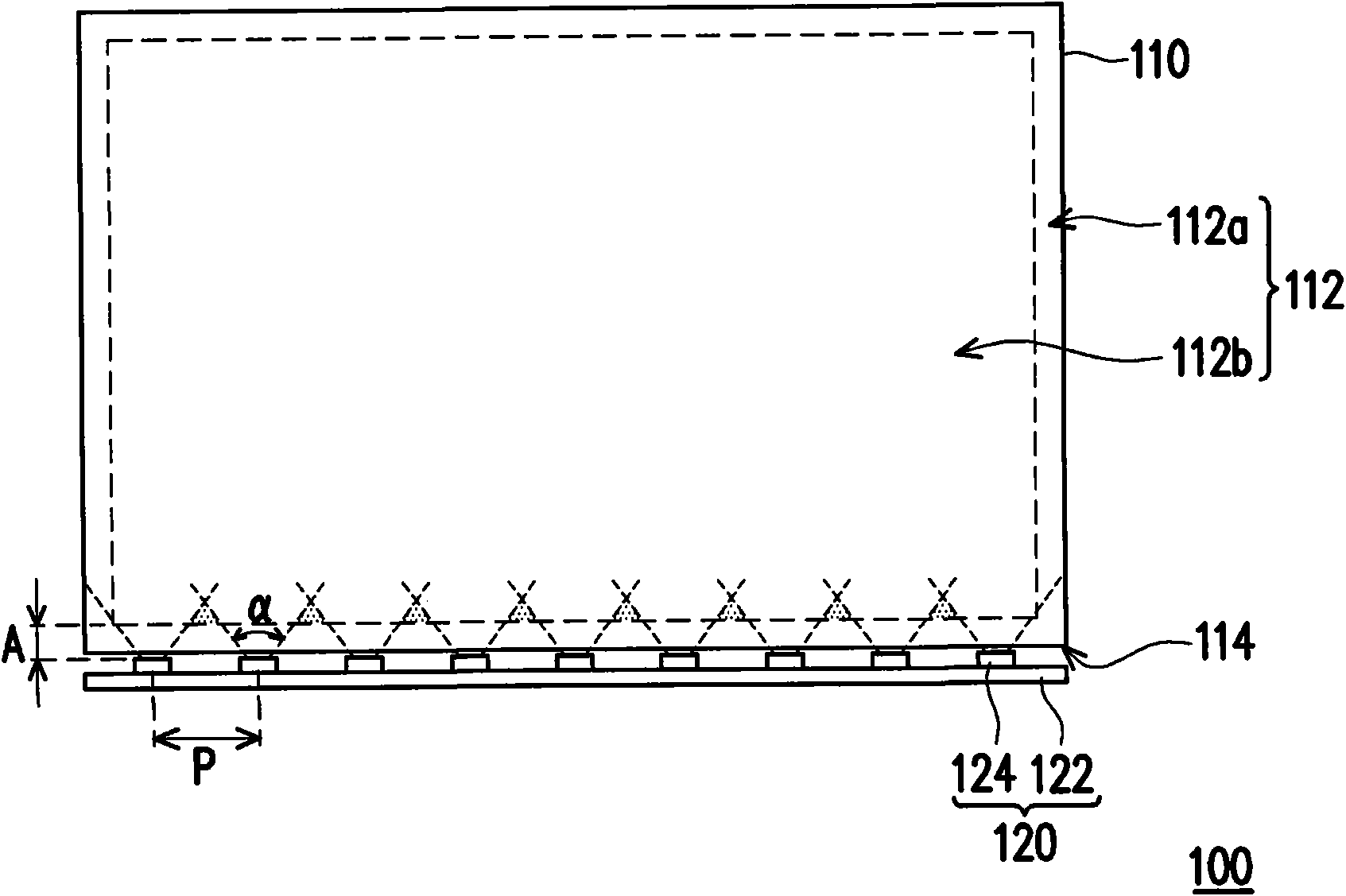

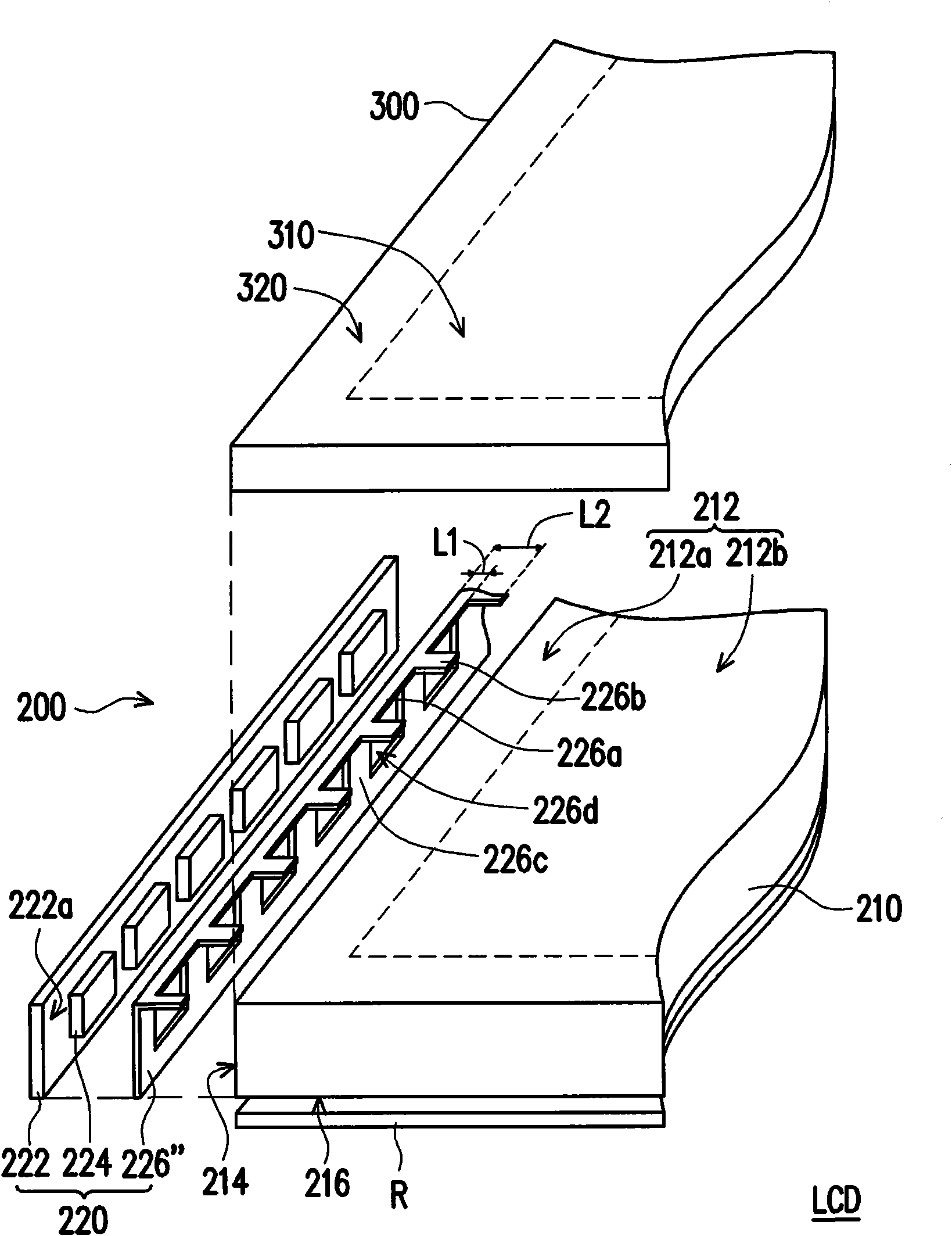

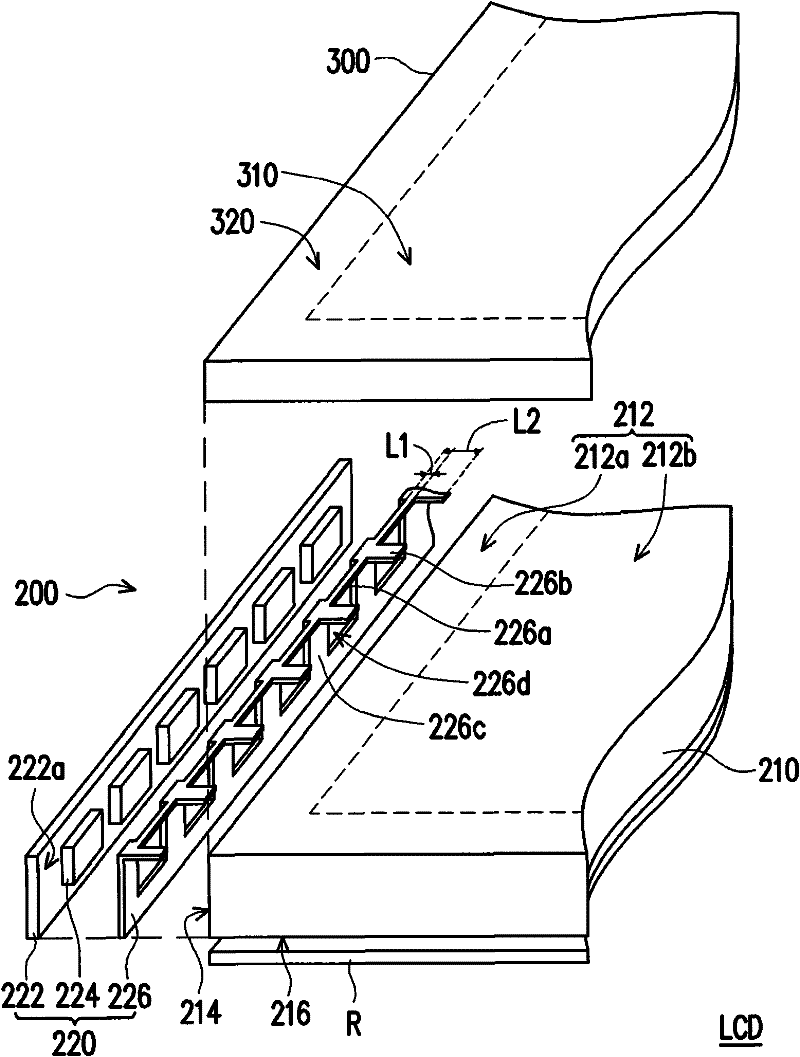

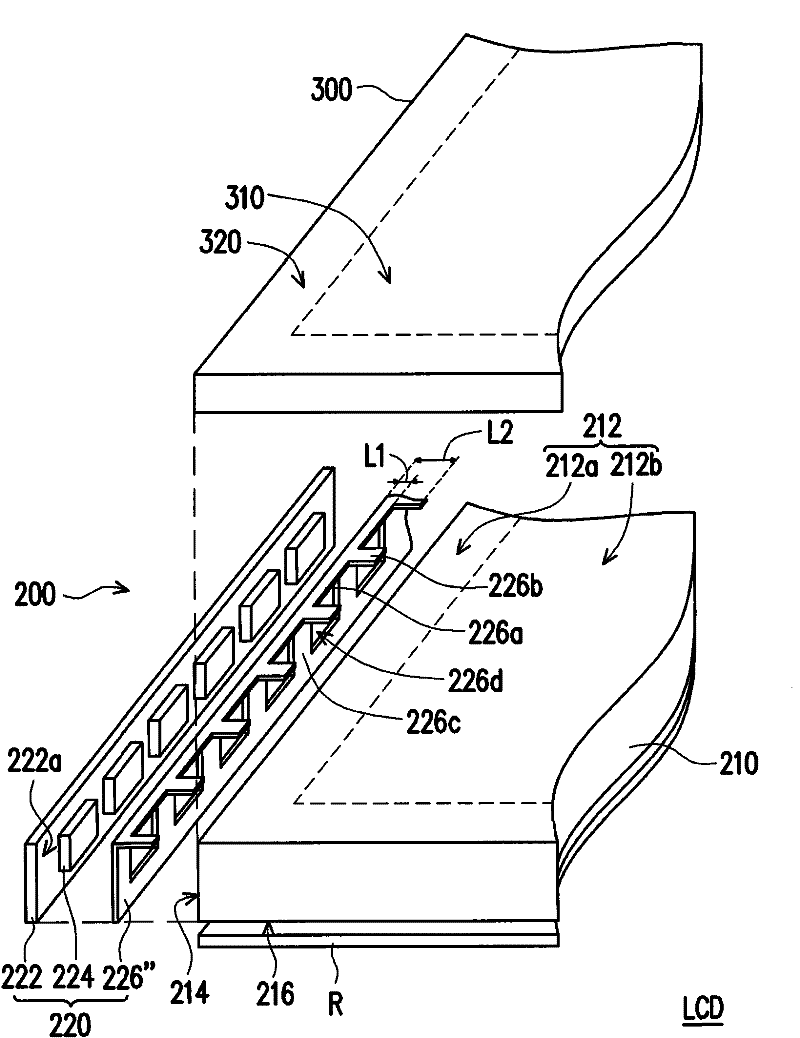

Liquid crystal display and backlight module thereof

ActiveCN102080789AImprove light distribution intensityImprove spotMechanical apparatusLight guides for lighting systemsLiquid-crystal displayLight guide

The invention discloses a liquid crystal display and a backlight module thereof. The backlight module comprises a light guide plate and a linear light source. The light guide plate has a top light leaving face and a lateral light incident face, wherein the top light leaving face comprises a peripheral area and an effective lighting area. The linear light source comprises a circuit board, a plurality of solid light emitting elements and a reflector. The solid light emitting elements are configured on the circuit board and are electrically connected with the circuit board, the light beams provided by the solid light emitting elements enter the light guide plate from the lateral light incident face, and the reflector covers part of the peripheral area. In addition, the reflector comprises a plurality of reflecting parts corresponding to the solid light emitting elements and a plurality of second reflecting parts connected between each two adjacent first reflecting parts, the first and second reflecting parts extend toward the direction of the effective lighting area from the edge of the top light leaving face, and the extended length of the first reflecting parts is smaller than that of the second reflecting parts. In the invention, the light spots generated by the backlight module can be effectively improved.

Owner:AU OPTRONICS CORP

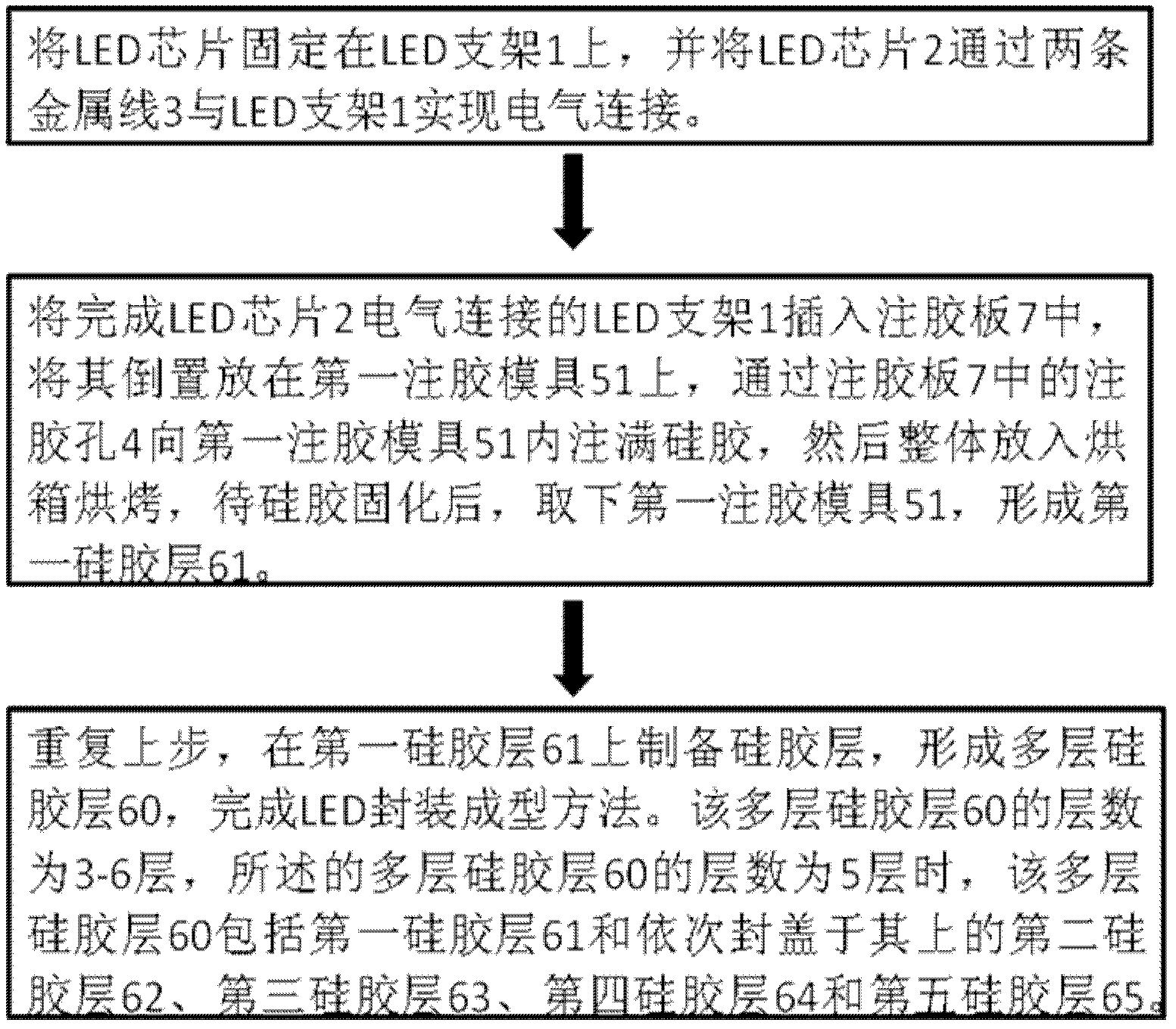

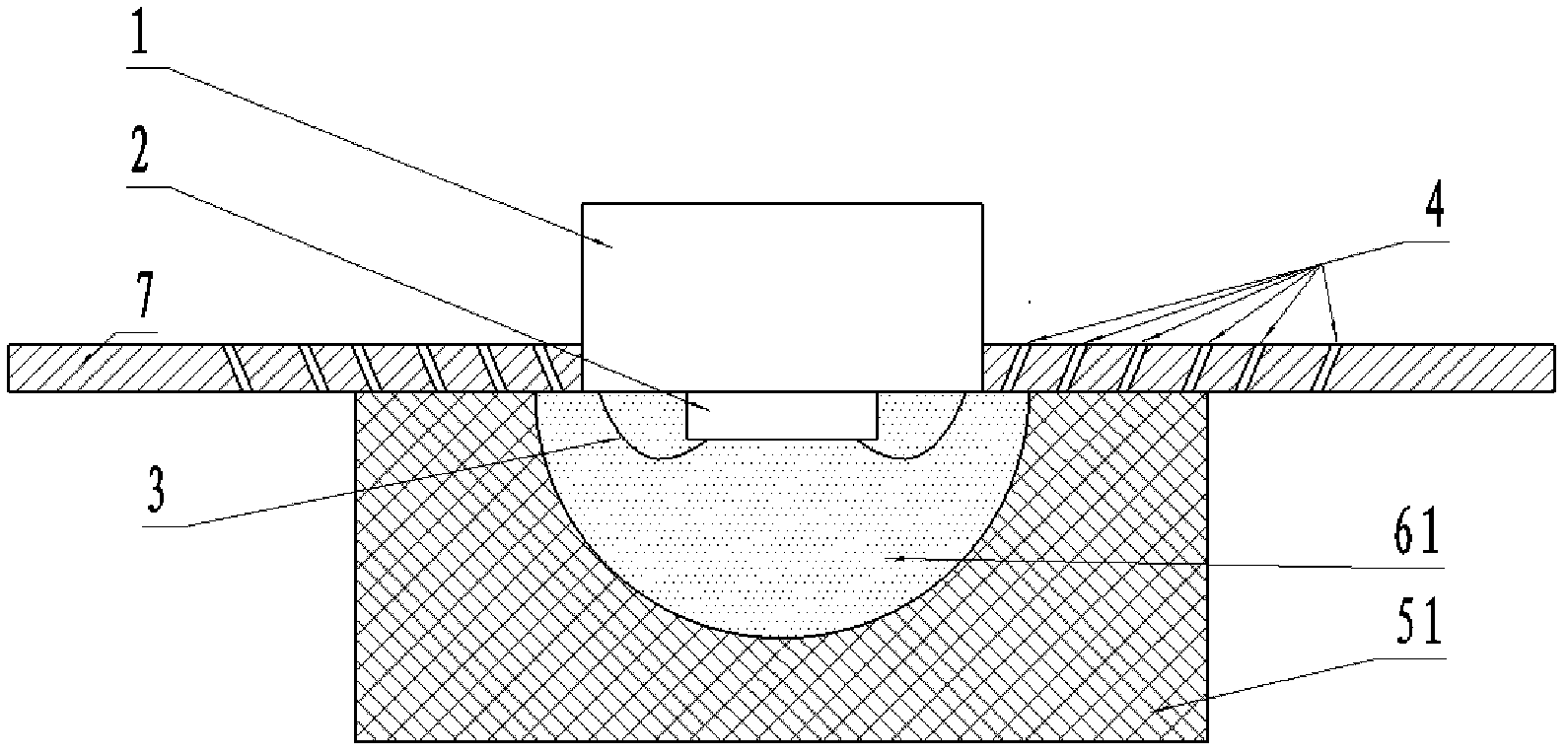

LED (light-emitting diode) packaging structure and packaging molding method

InactiveCN102637810AImprove spotConvenient lightingSemiconductor devicesQuantum efficiencyEngineering

The invention provides an LED (light-emitting diode) packaging structure and a packaging molding method. The LED packaging structure comprises an LED support, an LED chip, two metal wires and a multilayer silica gel layer, wherein the LED chip is fixed on the surface of the LED support, and the two metal wires are used for connecting the LED support with the LED chip; and the multilayer silica gel layer covers the LED support, the LED chip and the two metal wires. The packaging structure obtained by adopting the LED packaging method provided by the invention can effectively improve LED facula and light type, so that the LED sends out light uniformly, the light power loss is reduced, the external quantum efficiency and the LED reliability are improved, and light failure is reduced.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

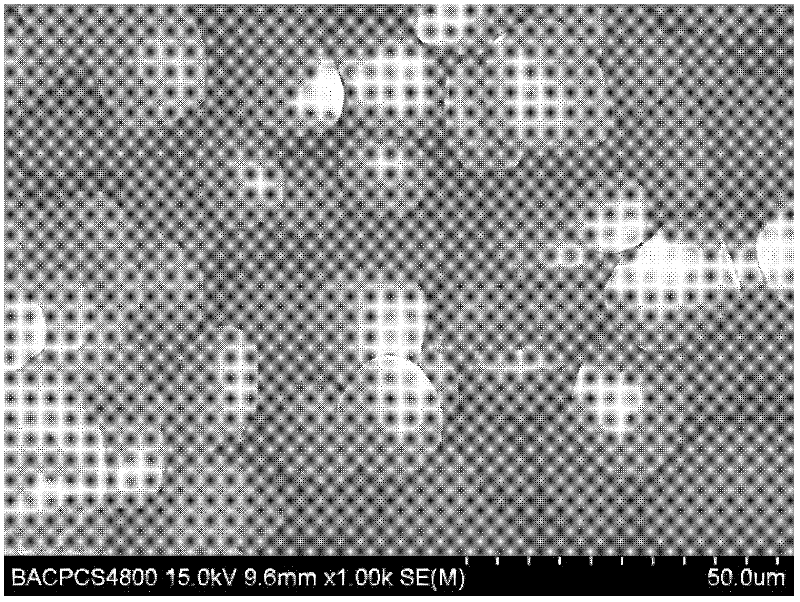

Method for preparing surface-coated yellow fluorescent powder

InactiveCN102337132AAvoid reunionMeet different requirementsLuminescent compositionsSemiconductor devicesCarboxymethyl cellulosePolyethylene glycol

The invention discloses a method for preparing surface-coated yellow fluorescent powder, which comprises the following steps of: mixing four compounds according to a molar ratio of Y2O3 to Al(OH)3 to BaCO3 to CeO4 of (3-x-y):5:x:y; then adding a fluxing agent of which the mass is 1 percent to 8 percent of the mass of the mixture and grinding for 30 to 40min to obtain a fluorescent powder precursor; carrying out ball milling and uniform mixing on the fluorescent powder precursor; then preserving heat for 1 to 1.5 hours at a temperature of 800 to 1,000 DEG C in the reducing condition; then heating the obtained product to a temperature of 1,300 DEG C to 1,550 DEG C, roasting for 5 to 10 hours and cooling in the air; after cooling, crushing the obtained product, collecting the crushed product and sufficiently washing the crushed product by water; filtering the obtained crushed product to obtain yellow fluorescent powder; coating the obtained yellow fluorescent powder with a mixture of carboxymethyl cellulose sodium, gelatin, polyethylene glycol and sodium silicate; and finally obtaining the surface-coated yellow fluorescent powder. Due to the adoption of the method disclosed by the invention, the aggregation between powder is effectively prevented, so that particles are small and are at the micron level.

Owner:IRICO

Apparatus for improving optical fiber output laser light spot homogenization

The invention relates to an apparatus for improving optical fiber output laser light spot homogenization. The apparatus comprises an optical fiber, an optical fiber protection pipe and a bended pipe. According to different light spot output requirements, different bended pipes are installed; the bended pipe is installed on the optical fiber or the optical fiber protection pipe to change light phase propagation mode distribution in a multimode fiber. Therefore, spatial distribution of light beams outputted from an optical fiber end surface is changed and a purpose of improving optical spots is reached.

Owner:Shandong Huaguang Optoelectronics Co. Ltd.

White light LED (Light Emitting Diode) fluorescent powder and preparation method thereof

InactiveCN102344809AAgglomerated particles are smallImprove spotGas discharge lamp usageLuminescent compositionsStrontium carbonateCrucible

The invention relates to white light LED (Light Emitting Diode) fluorescent powder with a chemical formula Sr(3-x)MgSiO7:xTb<3+>, wherein x is more than or equal to 0.01 and less than or equal to 0.25. The invention also provides a preparation method of the white light LED fluorescent powder. The preparation method comprises the following steps of: weighing silicon dioxide, magnesia, strontium carbonate and tetraterbium heptoxide; adding a charge compensator and a fusing assistant; mixing and grinding the raw materials; and feeding the mixture in a roasting crucible for roasting; cooling, crushing, washing and sieving to obtain the white light LED fluorescent powder. The white light LED fluorescent powder disclosed by the invention has the advantages of low price of raw materials, simple synthetic method, low loss of equipment, no need of special high-temperature equipment and the like.

Owner:IRICO

Preparation method for LED (Light Emitting Diode) fluorescent powder

InactiveCN102329614AAgglomerated particles are smallFully absorbedLuminescent compositionsSemiconductor devicesGadolinium oxideLight-emitting diode

The invention discloses a novel preparation method for LED (Light Emitting Diode) fluorescent powder. The method comprises the following steps of: based on a chemical formula of Y4-x-yGdGa5R1-2O16:Ce<3+>xEu<2+>y, weighing yttrium oxide, gallium oxide, gadolinium oxide, alkaline earth, cerium oxide and europium oxide according to a molar ratio respectively, wherein X is equal to 0.05-0.10; Y is equal to 0.01-0.10; adding 1-8 percent of mixed fluxing agent including barium fluoride, cerium fluoride and yttrium fluoride to obtain a mixture; uniformly mixing the mixture in a mixer; filling in a baked corundum crucible; placing in a high-temperature furnace to heat; introducing nitrogen and hydrogen mixed gas or pure hydrogen as a reducing atmosphere; preserving heat; heating to bake; cooling and then crushing; and washing and then screening to obtain the LED fluorescent powder. The fluorescent powder has a wide wave spectrum range; and emission spectrum of 530-630nm can be obtained when the fluorescent powder is excited by light of 440-460nm.

Owner:IRICO

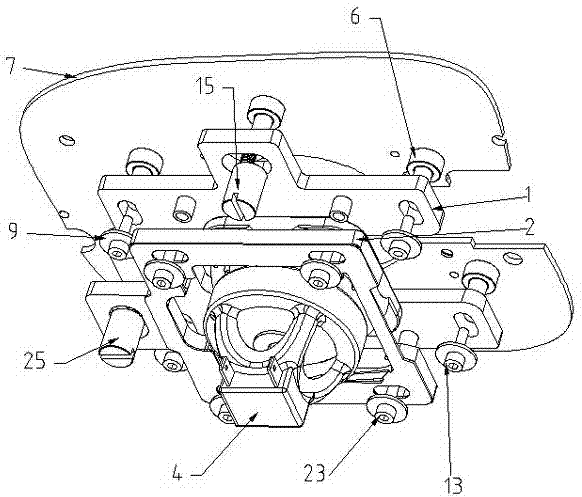

Stage lamp

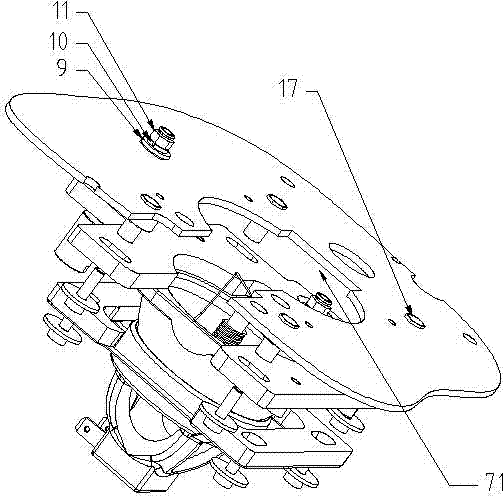

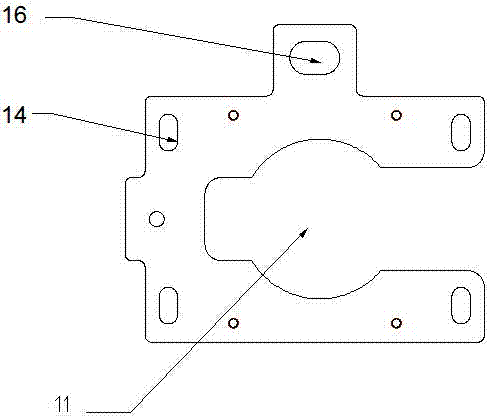

ActiveCN104501037AGood spot and beam output effectMeet the use requirementsLighting applicationsMechanical apparatusPhysicsEngineering

The invention discloses a stage lamp. The stage lamp comprises a lamp bulb assembly for emitting light, and further comprises a fixing plate and regulating devices, wherein the regulating devices comprise a first regulating device and a second regulating device; the lamp bulb assembly is mounted on the second regulating device; the first regulating device can move in parallel relative to the fixing plate in a first direction and is connected with the fixing plate; the second regulating device can move in parallel relative to the first regulating device in a second direction and is connected with the first regulating device; the first direction is perpendicular to the second direction. Through arrangement of the two regulating mechanisms, the positions of the lamp bulb assembly in two different directions on the same horizontal plane can be regulated, so that errors caused in the mounting and machining processes are overcome.

Owner:GUANGZHOU FINEART LIGHTING

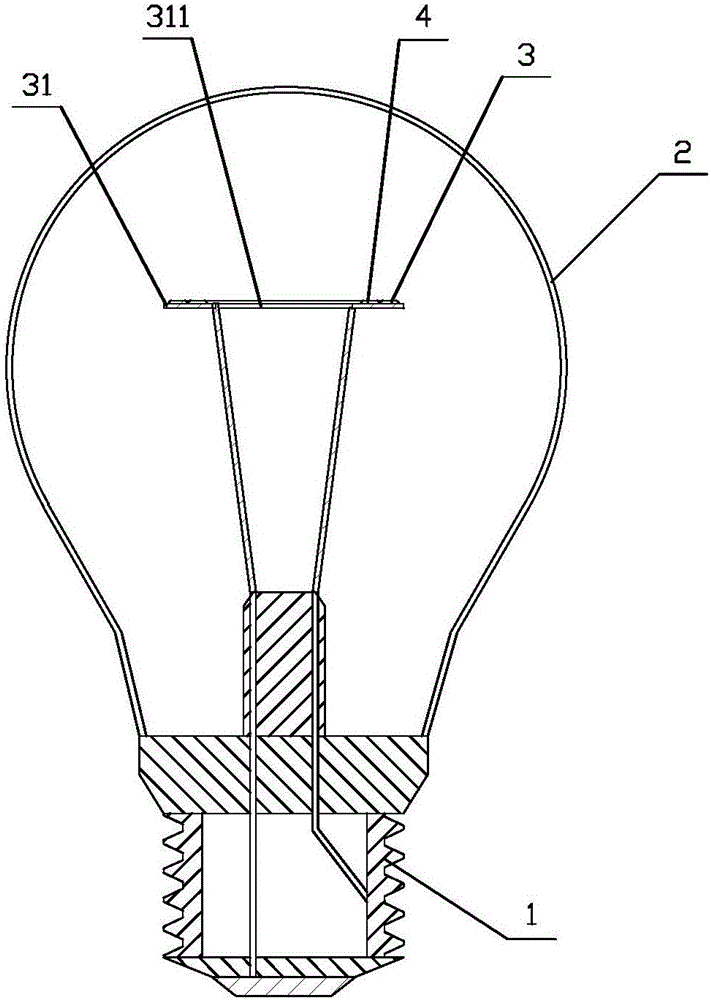

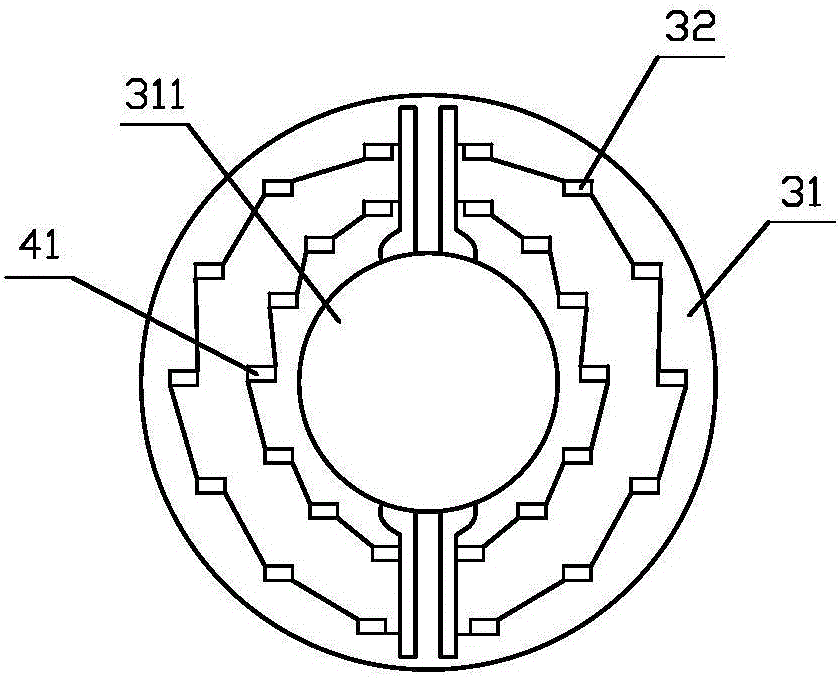

Color-temperature-adjustable LED bulb lamp

PendingCN105972462ARealize full lightColor temperature adjustment controlPlanar light sourcesLighting heating/cooling arrangementsAdhesiveFluorescence

The invention relates to a color-temperature-adjustable LED bulb lamp. The color-temperature-adjustable LED bulb lamp comprises a lamp cap, a bulb shell and an LED light source arranged in the bulb shell. The LED light source comprises a first light source body and a second light source body which are independent of each other and are separately controlled. The first light source body and the second light source body are parallel to each other or coplanar and are coaxial with the lamp cap. The first light source body comprises a first substrate. A first light-emitting chip set composed of multiple LED chips is arranged on the first substrate. The second light source body comprises a second light-emitting chip set composed of multiple LED chips. The surface of the first light-emitting chip set is wrapped with a first fluorescent adhesive layer, the surface of the second light-emitting chip set is wrapped with a second fluorescent adhesive layer, and the first fluorescent adhesive layer and the second fluorescent adhesive layer are different in color temperature. The luminous flux proportion of the light emitted by the first light source body and the light emitted by the second light source body is adjusted by changing the current across the first light source body and the current across the second light source body, light with different color temperatures is obtained through mixing, and adjustment of and control over the color temperature of the light emitted by the LED bulb lamp are achieved.

Owner:ZHEJIANG INTELED OPTOELECTRONICS TECH

Light source adopting LED chip packaging technology

InactiveCN103390716AHigh light efficiencyImprove cooling effectSolid-state devicesSemiconductor devicesEngineeringCopper substrate

The invention discloses a light source adopting an LED chip packaging technology. The light source comprises a copper substrate and LED chips, wherein a bulged part is formed in the center of the copper substrate; a plurality of LED chips are fixedly connected on the surface of the bulged part; a protective adhesive layer, a transparent filling adhesive layer and a fluorescent powder adhesive layer are sequentially arranged on each LED chip; the whole bulged part is covered with the three adhesive layers; and an optical lens is fixedly connected onto the top of the bulged part covered with the adhesive layers. According to the light source adopting the LED chip packaging technology, main center light rays are converged, so that the luminous efficiency is improved; and surrounding light rays are all reflected to provide illumination, and light spots are uniform.

Owner:江西量一光电科技有限公司

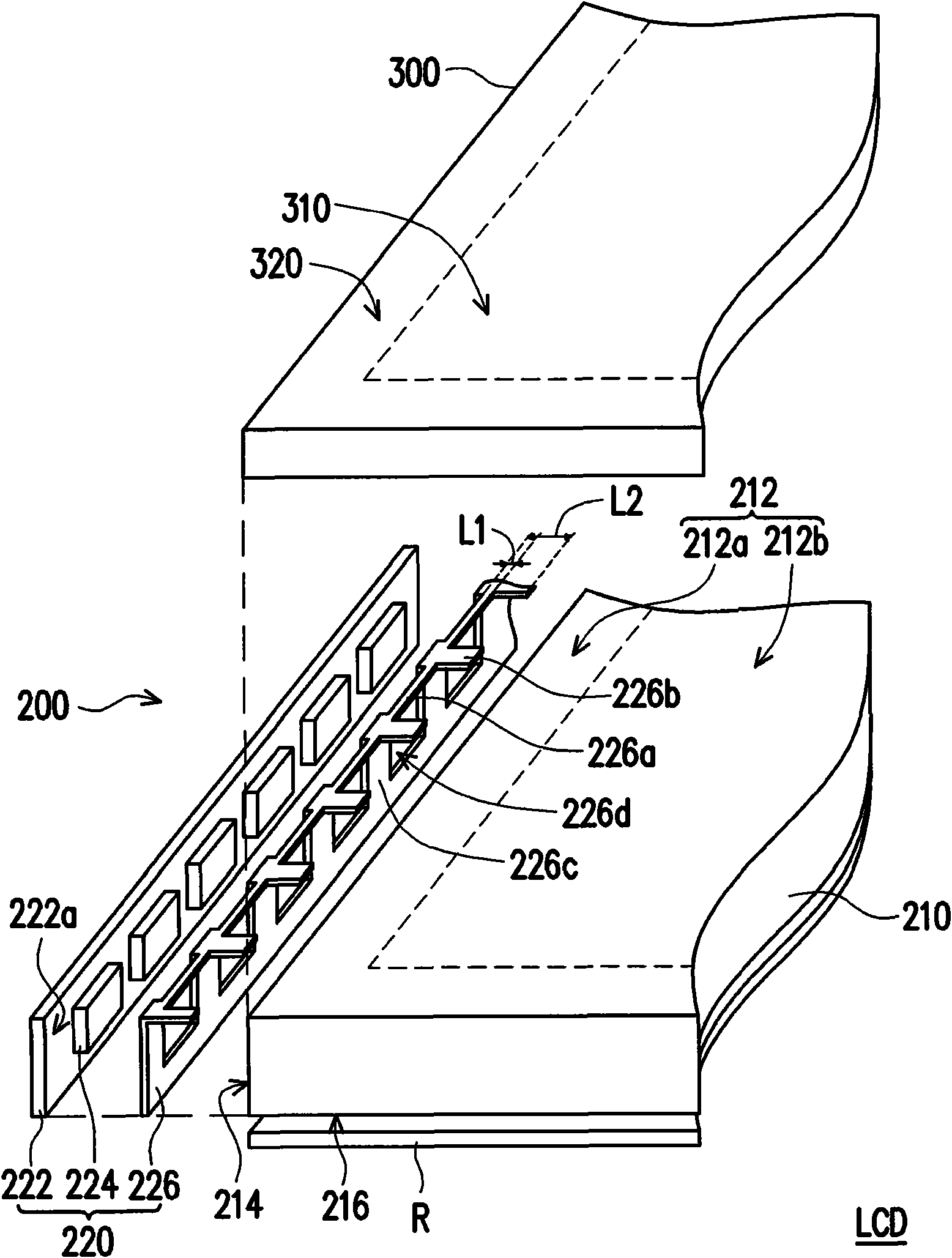

Optical scanning system with reduced spherical aberration and image forming apparatus using the same

InactiveUS7550712B2Improve spotEasy to produceInking apparatusBeam/ray focussing/reflecting arrangementsImage formationLight beam

An optical scanning system and an image forming apparatus having the same. The optical scanning system includes a light source, a deflector, an input optical system for directing a light beam from the light source to the deflector, and an imaging optical system for directing the light beam deflected by the deflector onto a surface to be scanned. The input optical system includes a first optical element having a power both in a main-scan sectional plane and in a sub-scan sectional plane, and a second optical element having a power in the sub-scan sectional plane. At least one surface of the first optical element has a shape being rotationally asymmetrical and, in the sub-scan sectional plane, being non-arcuate.

Owner:CANON KK

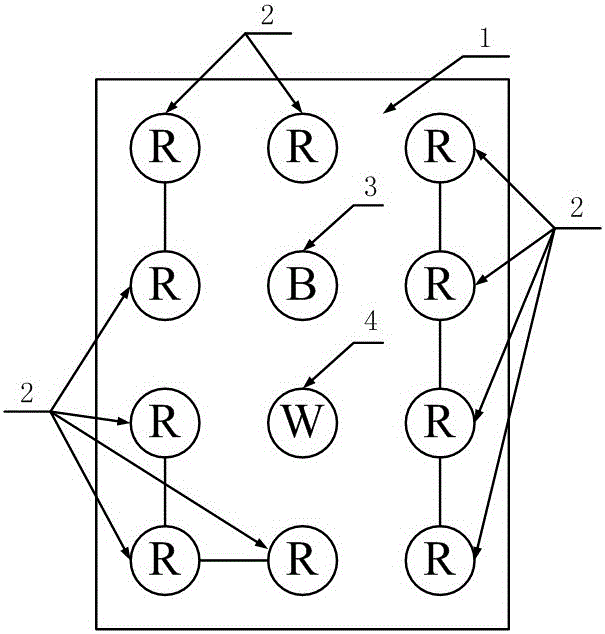

COB LED lamp for plant illumination

InactiveCN106287243AReduce areaImprove cooling efficiencyPlanar light sourcesLight source combinationsDriving currentPower flow

The invention discloses a COB LED lamp for plant illumination. The structure of the LED lamp comprises an aluminum substrate, wherein a blue LED chip, red LED chips and a white LED chip are packaged by COB. The LED lamp is characterized in that the quantity ratio of the red LED chips, the blue LED chip and the white LED chip is 10: 1: 1, and the red LED chips encircle the blue LED chip and the white LED chip. The COB LED lamp for plant illumination disclosed by the invention is small in area, high in heat dissipating efficiency, small in driving current and long in service life, and the proportion of red lights and blue lights can be randomly changed according to the demand.

Owner:FOSHAN CITY NANHAI DISTRICT LIANHE GUANGODNG XINGUANGYUAN IND INNOVATION CENT

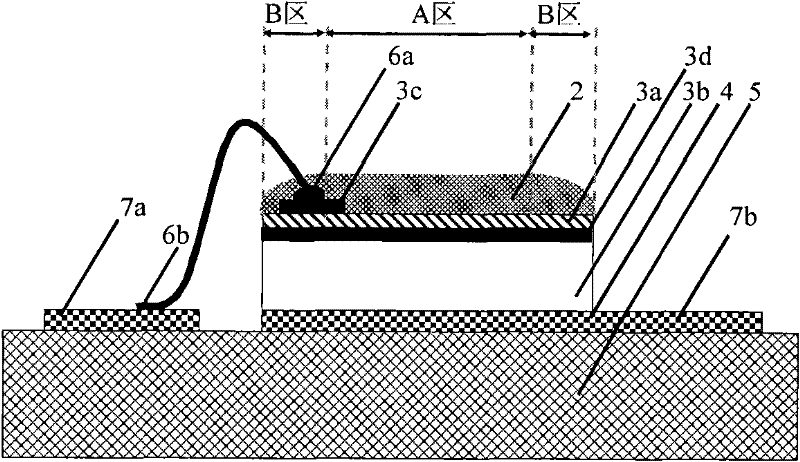

Semiconductor luminous device

InactiveCN102244177AAchieve color temperature uniformityImprove spotSolid-state devicesSemiconductor devicesAdhesiveFluorescence

The invention relates to a semiconductor luminous device, and belongs to the field of light-emitting diodes. In the semiconductor luminous device, a transparent glass sheet is arranged on the upper part of dispensed fluorescent adhesive, so that the thickness of a fluorescent adhesive membrane on the surface of a device is uniform; and a transparent support is positioned between the glass sheet and the luminous device, so the problem of large color temperature difference among different encapsulation devices is solved. By the semiconductor luminous device, the uniformity of the color temperature of the single encapsulation device can be realized in a simple mode, the light spots of the devices and the consistency of the color temperature among different devices are improved, and the production efficiency is improved.

Owner:北京宇极芯光光电技术有限公司

White-light LED (Light Emitting Diode) light source

ActiveCN102760820BOvercoming secondary absorptionImprove light extraction efficiencySemiconductor devicesAluminateColor rendering index

The invention relates to a white-light LED (Light Emitting Diode) light source. The white-light LED light source comprises a bowl cup, a blue-light LED chip arranged at the bottom of the bowl cup, yellow-green fluorescent powder and red fluorescent powder, wherein the yellow-green fluorescent powder and red fluorescent powder are arranged above the blue-light LED chip, and the yellow-green fluorescent powder is arranged above the red fluorescent powder. The white-light LED light source selects the yellow-green fluorescent powder with high luminous efficacy and a rare earth aluminate matrix, yellow-green silicate fluorescent powder and silica-based nitride red powder which are combined and matched with the blue-light LED chip, and through the reasonable design of the spatial layout of fluorescent powder with different systems inside an LED, the secondary absorption of yellow-green light by the nitride red fluorescent powder can be effectively overcome, and the relatively high emergent light efficiency also can be obtained simultaneously when a color rendering index is obviously promoted. A light-emitting system provided by the invention can realize white light with high luminous efficacy and a high color rendering index by adjusting the proportioning of fluorescent powder with different emission spectrums so as to meet the technical requirements of general lighting.

Owner:江西省兆驰光电有限公司

Liquid crystal display and backlight module thereof

ActiveCN102080789BImprove light distribution intensityImprove spotMechanical apparatusLight guides for lighting systemsSolid lightLiquid-crystal display

Owner:AU OPTRONICS CORP

Power-type laser fiber plug-in

PendingCN107544155AImprove the stability of the effective pass rate ratioImprove spotCoupling light guidesHigh power lasersLight source

The invention provides a power-type laser fiber plug-in and relates to the technical field of laser fiber plug-ins. The power-type laser fiber plug-in is composed of a deep micro-hole oblique-plane core insert (1) and a concentric metal shaft sleeve (2) in an embedded mode. The oblique-plane angle of the deep micro-hole oblique-plane core insert (1) is 5-10 degrees, and the core insert is made from a material low in dilatation coefficient. The center of the deep micro-hole oblique-plane core insert (1) is positioned to be matched with a fiber with the outer diameter of 125-1200 micros. The concentric metal shaft sleeve (2) is a metal sleeve having the um-level precision. The fiber large in core diameter is positioned to conduct high-power laser, so that laser beam spots output by the fiberare greatly improved. The heating spontaneous combustion phenomenon caused by fiber collimation and coupling structure factors and laser source damage caused by high-power laser reflection are avoided. A firm technical material basis is provided for laser cutting, welding, the safety of high-power laser conducting fiber in a medical minimally invasive technology and improvement of reliable and effective output powder.

Owner:SHANGHAI INST OF LASER TECH

Packaging method for flip LED chips

ActiveCN101872828BUniform coating thicknessPrevent collapseSemiconductor devicesScreen printingPhosphor

The invention relates to a packaging method for flip LED chips, which belongs to the field of LED fabrication. The packaging method at least includes the following steps that: (a) phosphor is coated on the surface of an LED chip by screen printing, and is baked to become solidified; (b) the LED chip is fixed on a chip substrate, so that the electrodes of the LED chip are bonded with the electrodes of the chip substrate; (c) the LED chip and the chip substrate are fixed on a support and the bottom of a reflective cup; (d) wires are utilized to respectively connect the positive and the negativeelectrodes of the fixed chip substrate with the positive and the negative electrodes of the support; (e) a sealing mould or a lens covers on the support on which the LED chip and the chip substrate are fixed, and silica gel is filled; and (f) the whole structure is backed to become solidified. Since the used LED chip is a flip chip and the phosphor is coated on the surface of the LED chip before the wires are soldered, the product yield can be increased, and the screen printing technique can ensure that the thickness of the coated phosphor is more uniform, so the distribution of phosphor powder particles is more uniform.

Owner:LEDMAN OPTOELECTRONICS CO LTD

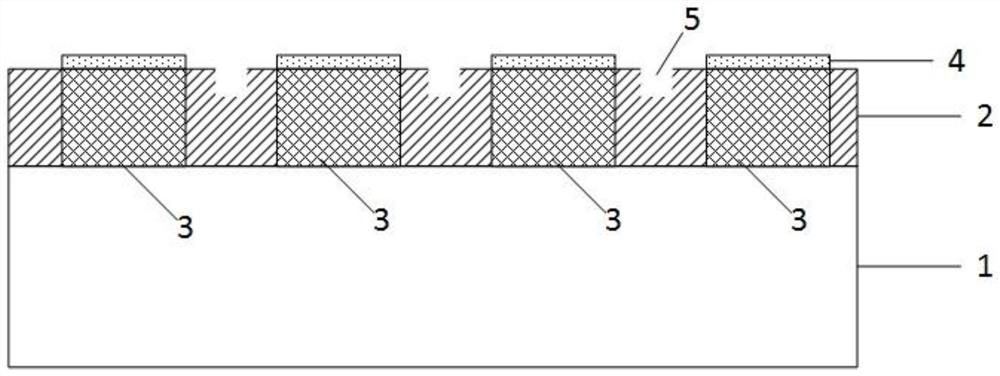

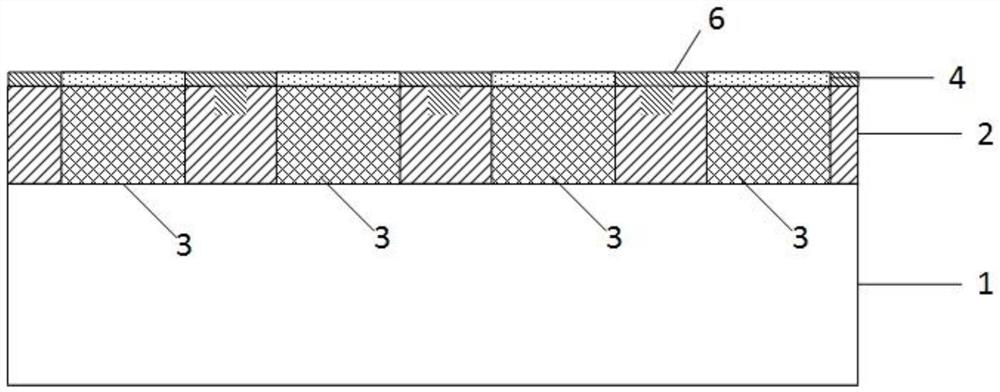

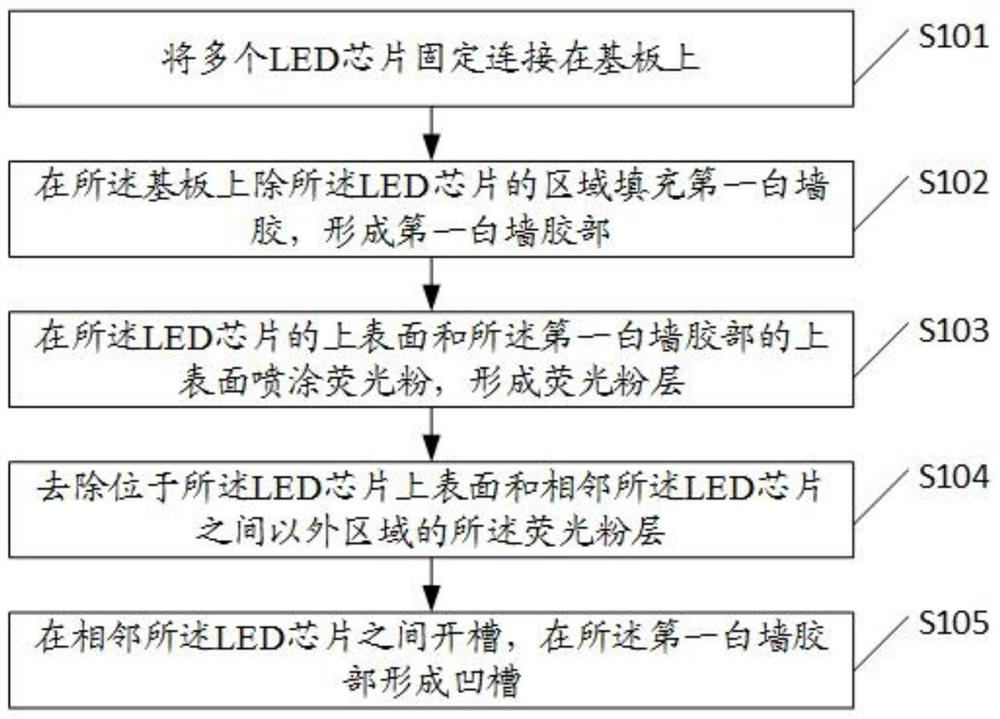

LED lamp and manufacturing method thereof

PendingCN113629176AImprove aestheticsPrevent spillageSolid-state devicesSemiconductor devicesLight spotFluorescence

The invention discloses an LED lamp. The LED lamp comprises a substrate; a plurality of LED chips which are arranged on the substrate and are electrically connected with the substrate; a fluorescent powder layer which is arranged on the upper surfaces of the LED chips; and a first white wall glue part which is arranged on the substrate and around the LED chips, and is provided with grooves distributed between the adjacent LED chips. The fluorescent powder layer is only arranged on the upper surfaces of the LED chips, so that invalid fluorescent powder areas are greatly reduced. The first white wall glue part is provided with the grooves between the adjacent LED chips, that is, there is no fluorescent powder layer between the adjacent LED chips, so that the boundaries of the light-emitting areas of the LED lamps are very obvious, and light spots are optimized. According to the LED lamp, the use of a fluorescent sheet patch is avoided, an adhesive and a steel mesh are not needed between the LED chips and the fluorescent powder layer, the manufacturing cost is reduced, the light emitting efficiency is improved, meanwhile, fluorescent glue is prevented from overflowing, and the attractiveness of the LED lamp is improved. The invention further provides a manufacturing method with the advantages.

Owner:NINGBO SUNPU OPTO SEMICON

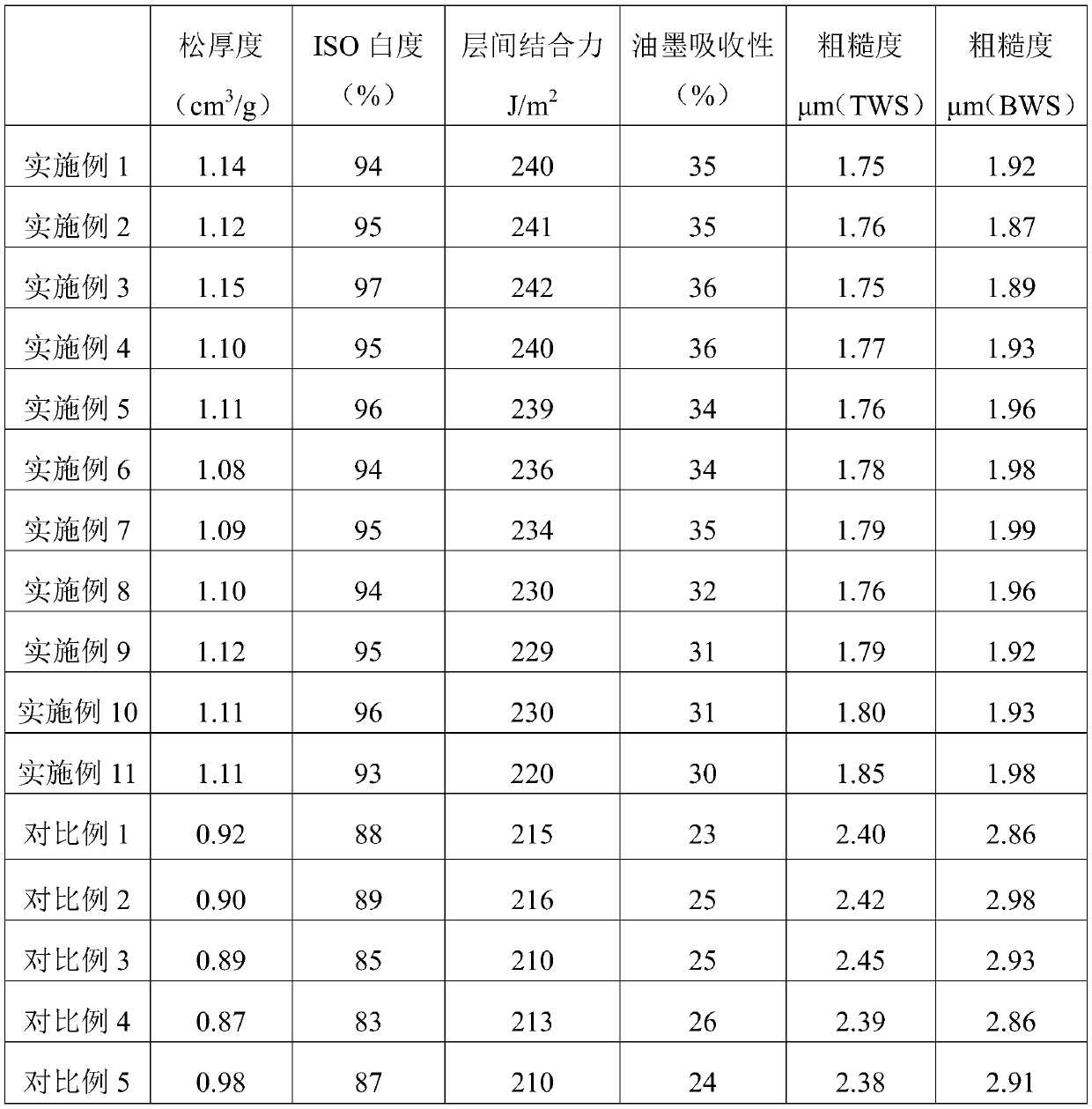

Matte coated paper with ultra-fine surface feeling and preparation method of matte coated paper

ActiveCN111321632AImprove flatnessImprove masking performanceFlexible coversWrappersFiberLatex rubber

The invention provides matte coated paper with an ultra-fine surface feeling and a preparation method of the matte coated paper. The matte coated paper comprises a raw paper layer, a pre-coating layerand a surface coating layer, wherein raw paper layer pulp comprises the following raw materials in parts by weight: 50-90 parts of short fiber pulp, 5-30 parts of long fiber pulp, 5-30 parts of mechanical pulp, 2-5 parts of a flow aid, 1-4 parts of a filter aid and 3-8 parts of cationic starch; the coating is prepared from the following raw materials in parts by weight: 70-90 parts of ground calcium carbonate, 60-80 parts of light calcium carbonate, 50-70 parts of latex, 20-26 parts of starch, 4-6 parts of a dispersing agent, 3-5 parts of a defoaming agent, 3-9 parts of a lubricating agent, 5-8 parts of a thickening agent and 3-5 parts of alkali liquor. The matte coated paper prepared by improving the flatness of the base paper and optimizing the formula of the coating is fine and smoothin paper surface, high in printing performance, small in flexibility and high in book strength, and can be suitable for a high-speed printing machine.

Owner:HAINAN JINHAI PULP & PAPER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com