Power-type laser fiber plug-in

A power type, optical fiber technology, applied in the field of power type laser optical fiber plug-in, can solve the problems of side stress damage of optical fiber input window, decrease of effective light transmittance, optical fiber burning, etc., so as to improve the stability of effective pass rate ratio and avoid heat generation. Spontaneous combustion, the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and embodiment the present invention will be further described

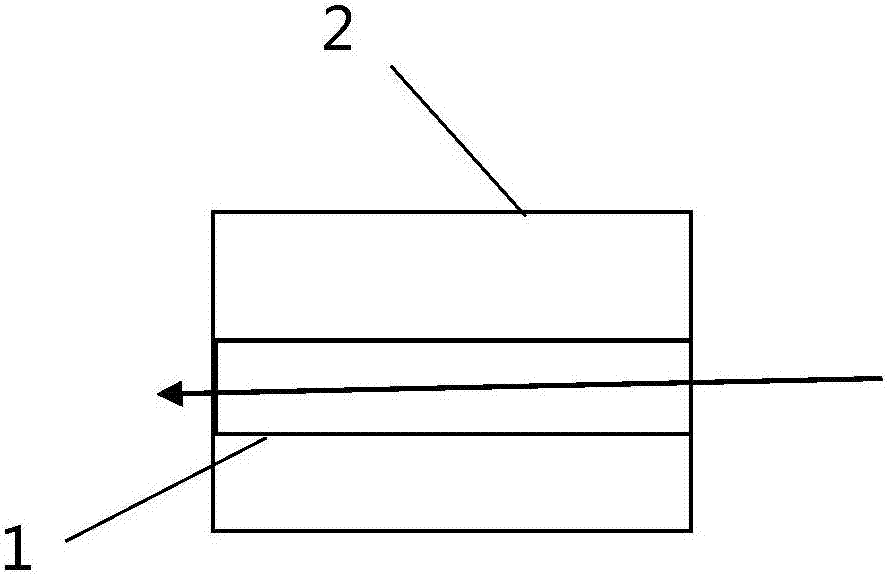

[0012] A power type laser fiber plug-in of the present invention (as attached figure 2 As shown), its characteristics are composed of a deep micro-hole inclined-plane ferrule 1 and a concentric metal bushing 2 in an embedded manner.

[0013] The slope angle of the deep micro-hole slope ferrule 1 is 5-10°, which is a material with a low expansion coefficient.

[0014] Further, the material with low expansion coefficient is zirconia ceramics.

[0015] The concentric metal bushing 2 is a metal jacket with um-level precision.

[0016] The central positioning of the oblique ferrule 1 with deep micro-holes matches the optical fiber with an outer diameter of 125um-1200um.

[0017] Further, the inclined surface of the deep micro-hole inclined ferrule 1 is a conical surface.

[0018] As mentioned above, the power-type laser fiber plug-in of the present invention, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com