Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Improve firing pass rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Agate-containing dark green glaze for ru-porcelain, processing method of glaze as well as ru-porcelain and firing method thereof

The invention relates to agate-containing dark green glaze for ru-porcelain, a processing method of the glaze as well as the ru-porcelain and a firing method thereof and relates to the technical field of silicate ceramics. The agate-containing dark green glaze for the ru-porcelain is prepared from components in parts by weight as follows: 6-20 parts of ru jade, 1-15 parts of agate, 10-70 parts of feldspar, 2-8 parts of calcite, 1-20 parts of wollastonite, 0-2 parts of talc, 0-15 parts of chest wood ash, 1-8 parts of ammolite and 1-20 parts of black bluestone. The enamel of the ru-porcelain fired with the adoption of the agate-containing dark green glaze for the ru-porcelain takes dark green as a base, can present the deep and full sky blue, azure, light greenish blue, bluish white, pale blue and bright green and can present bright and transparent pea green and onion green color. The ru-porcelain adopting the agate-containing dark green glaze for the ru-porcelain has good jade sense and opalescence effects and has a smoother glaze surface, higher mechanical strength, lower water absorption rate and high firing qualification rate.

Owner:郭秀贞

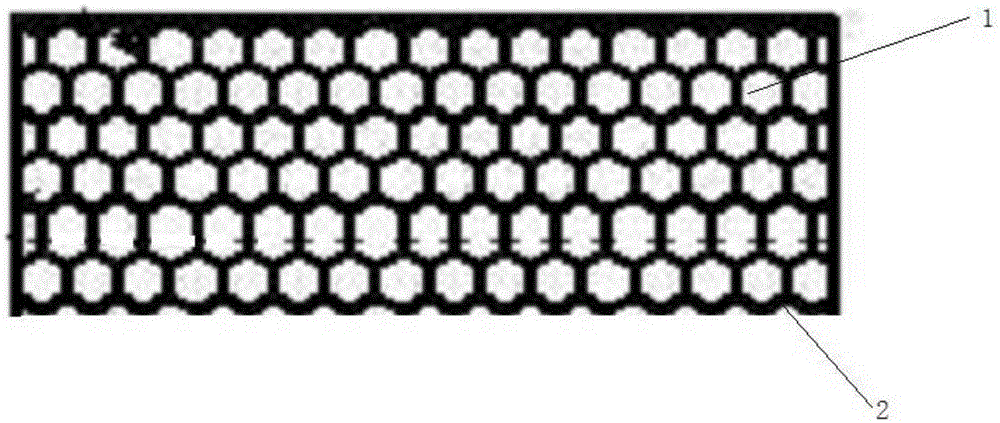

Zero-firing-shrinkage cordierite honeycomb ceramic carrier and preparation method thereof

ActiveCN104030720AFiring shrinkage zeroImprove firing pass rateCeramicwareCordieriteMaterials science

The invention relates to a zero-firing-shrinkage cordierite honeycomb ceramic carrier and a preparation method thereof. The carrier comprises the following raw materials in percentage by weight: 20-32 wt% of tabular alumina, 4-11 wt% of magnesium oxide, 15-45 wt% of electroquartz, 7-30 wt% of talcum and 10-35 wt% of kaolin, totaling 100%. The carrier also comprises an organic assistant and water. The preparation method comprises the following steps: by using alumina, magnesium oxide, electroquartz, talcum and kaolin as inorganic powder, adding the organic assistant and water, mixing, slurrying, extruding, drying, cutting and firing. The cordierite honeycomb ceramic carrier has the advantages of zero firing shrinkage, high firing qualification rate and low production cost.

Owner:SHANDONG AOFU ENVIRONMENTAL PROTECTION SCI & TECH

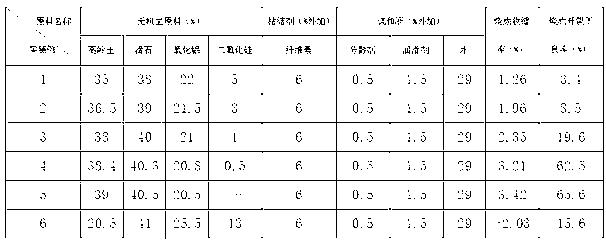

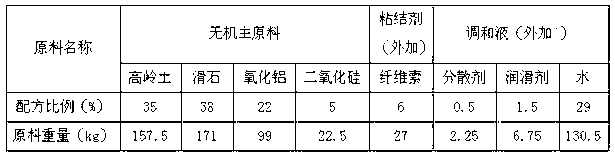

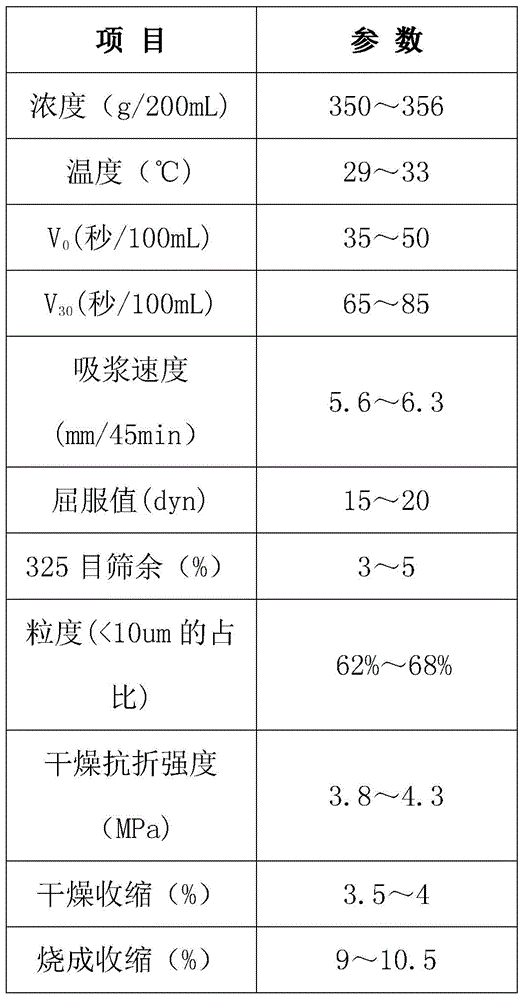

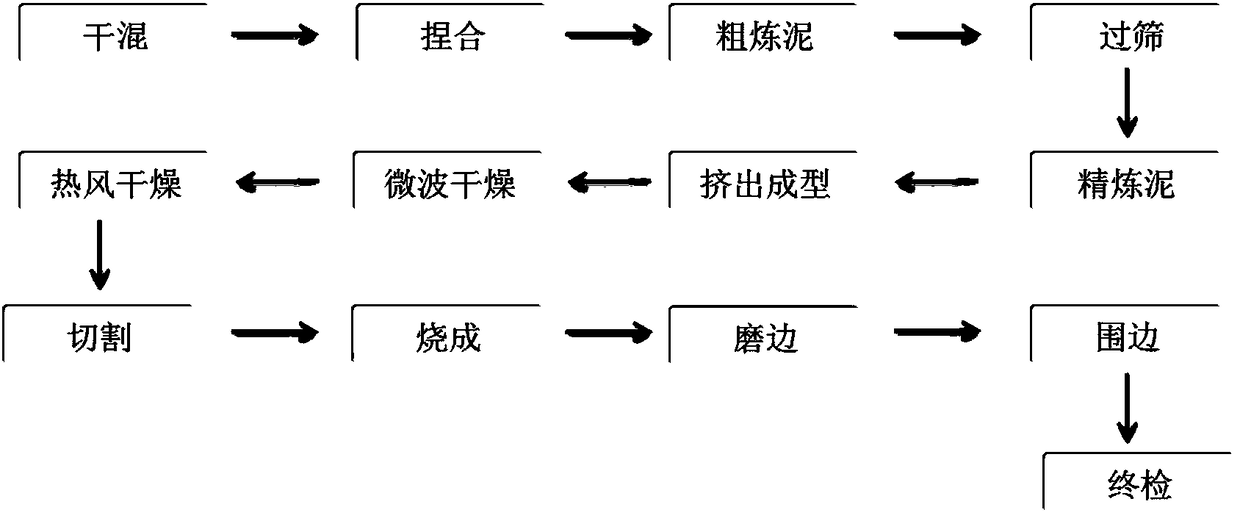

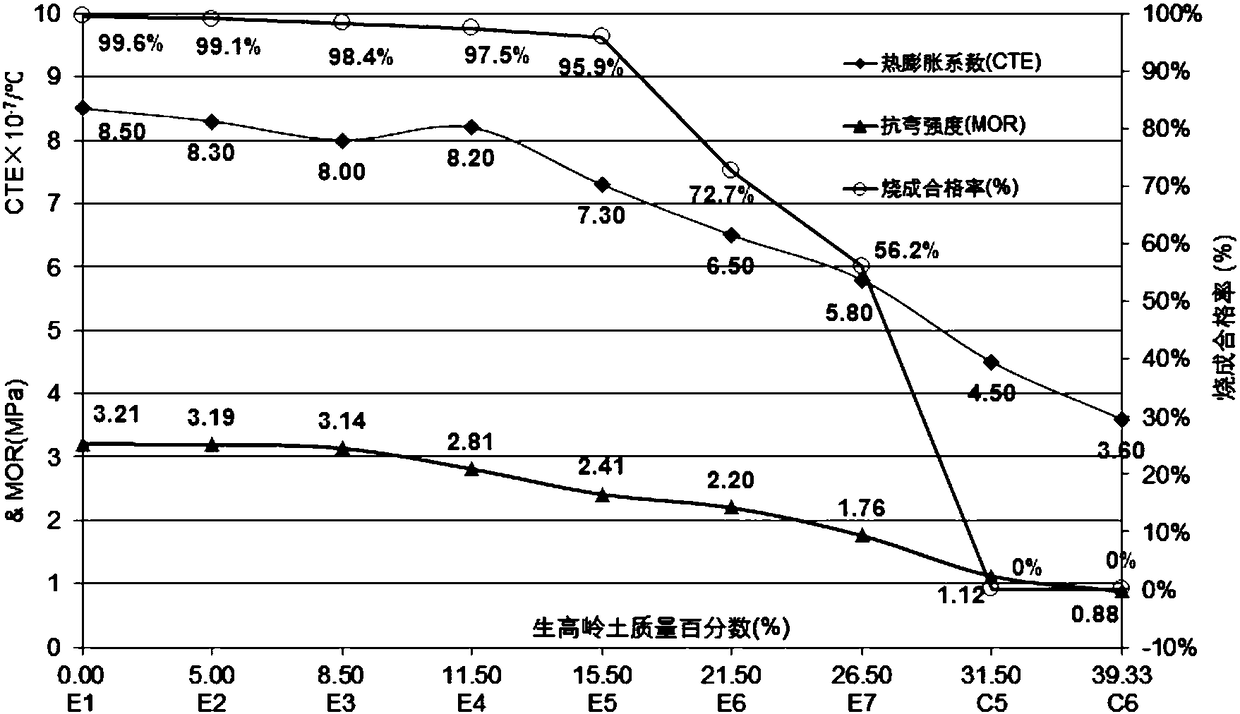

Method for adjusting firing shrinkage of cordierite honeycomb ceramics by using amorphous silicon micropowder

InactiveCN102815932AAlleviate the problem of burning shrinkageImprove firing pass rateAdhesiveHoneycomb

The invention relates to a method for adjusting firing shrinkage of cordierite honeycomb ceramics by using amorphous silicon micropowder. Natural amorphous silicon dioxide used as a raw material is introduced into the production formula of cordierite honeycomb ceramics. The method comprises the following steps: adding an adhesive and a blending solution into kaolin, talcum, aluminum oxide and silicon dioxide which are used as inorganic main raw materials; and proportioning, mixing, kneading, sludging, forming, drying, processing and firing to adjust the firing shrinkage of the cordierite honeycomb ceramics. A certain amount of natural amorphous silicon dioxide raw material is introduced into the production formula of cordierite honeycomb ceramics to well solve the problem of firing shrinkage of the product in the firing process, thereby greatly enhancing the firing qualification rate of the product.

Owner:李少荣

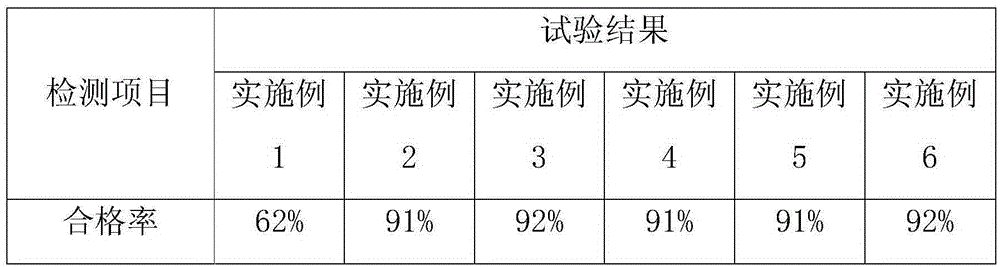

Sanitary ceramics slip and preparation technology thereof

The invention discloses sanitary ceramics slip and a preparation technology thereof. The sanitary ceramics slip mainly comprises, by weight, 30-70 parts of illite-structure clay, 5-15 parts of kaolin, 6-14 parts of ball clay, 8-13 parts of potassium feldspar, 5-10 parts of pyrophyllite, 5-10 parts of sericite, 0.1-3 parts of dolomite and 40-45 parts of water. Sanitary ceramics prepared from the sanitary ceramics slip are low in firing temperature, little in energy consumption and high in strength, and slip casting qualified rate, semi-finished product qualified rate and firing qualified rate can reach 98%, 96% and 92% respectively.

Owner:福建科福材料有限公司

Low-temperature stoneware formula

The invention relates provides a low-temperature stoneware formula, relating to stoneware. The low-temperature stoneware formula provided by the invention has the advantages that the firing temperature and energy consumption can be obviously reduced and the firing pass rate can be increased. The low-temperature stoneware formula comprises grouting mud and raw glaze, wherein the grouting mud is prepared from potash feldspar, lithium porcelain stone, quartz powder, kaolin, black clay, pyrophyllite powder and ceramic powder; the raw glaze is transparent glaze or matte glaze; the transparent glaze is prepared from potash feldspar, lithium porcelain stone, quartz powder, strontium carbonate, barium carbonate, calcined talc, light calcium carbonate, kaolin and ceramic powder; and the matte glaze is prepared from potash feldspar, lithium porcelain stone, quartz powder, strontium carbonate, alumina, calcined talc, light calcium carbonate, kaolin, calcined zinc oxide and barium carbonate.

Owner:漳州汇宜陶瓷有限公司

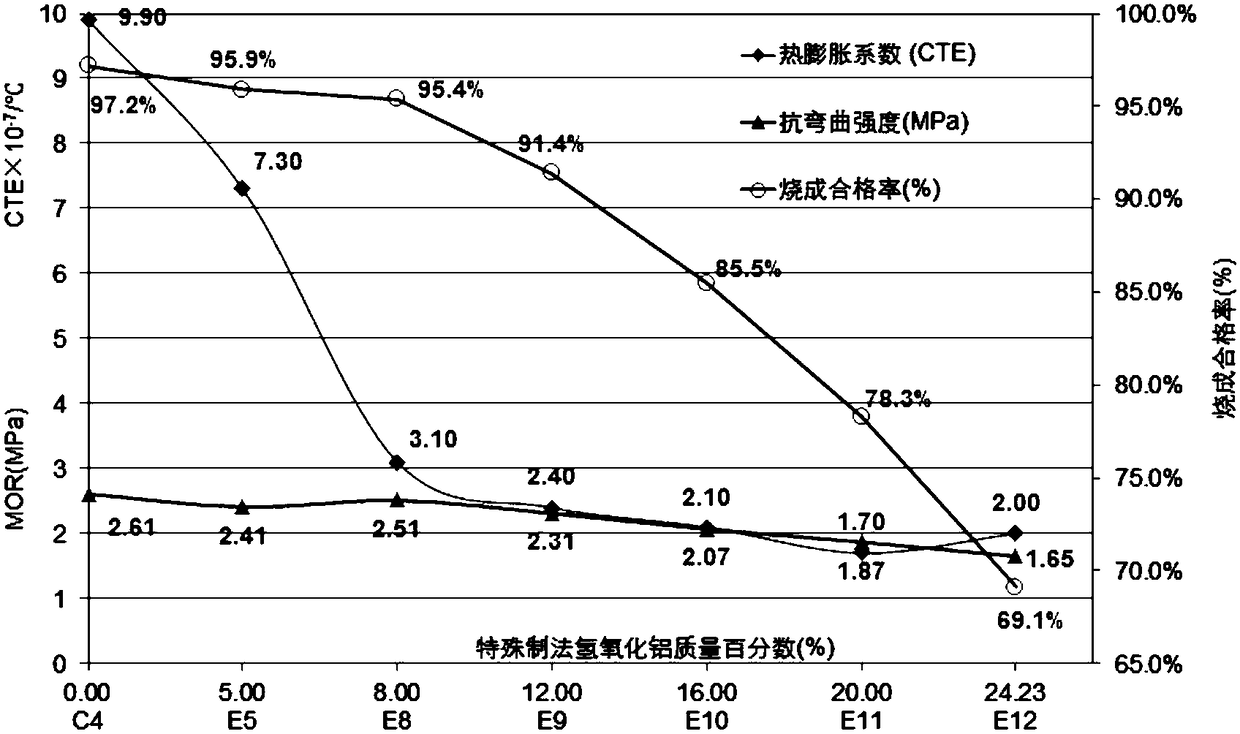

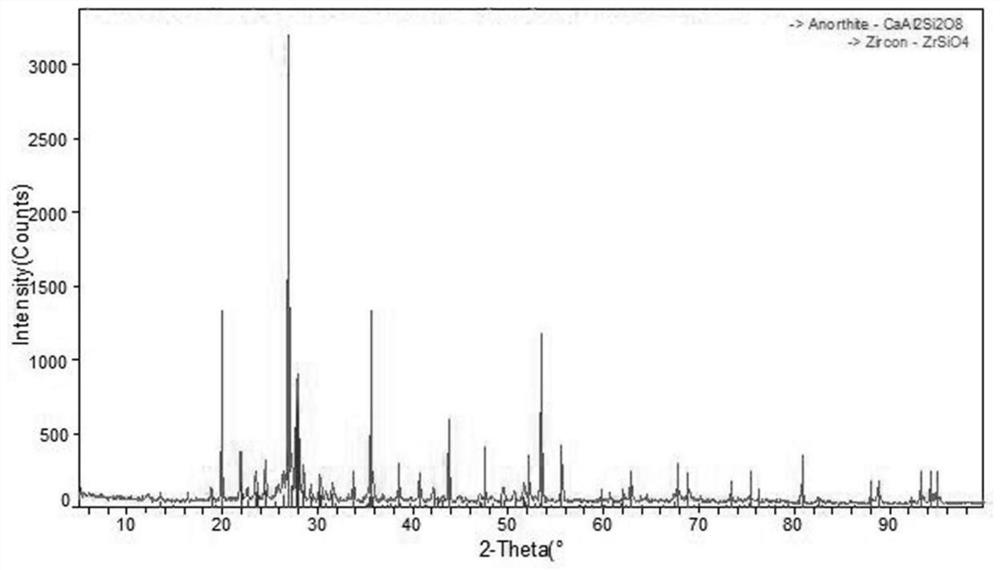

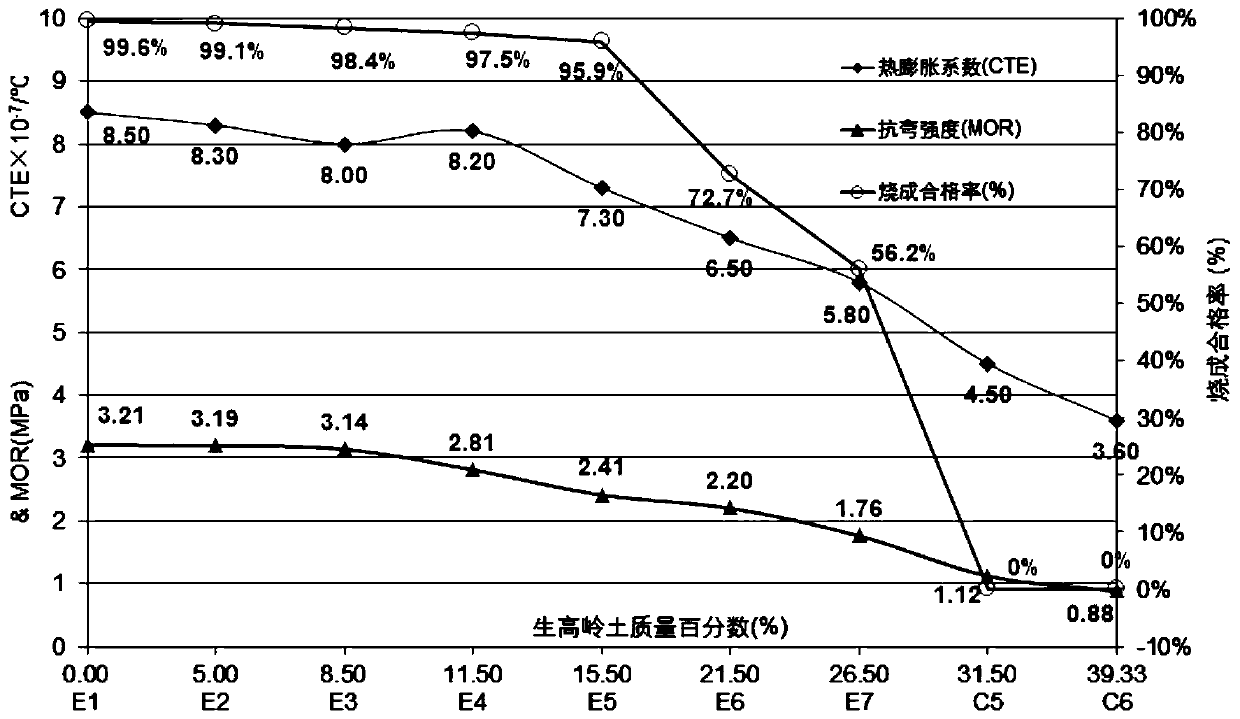

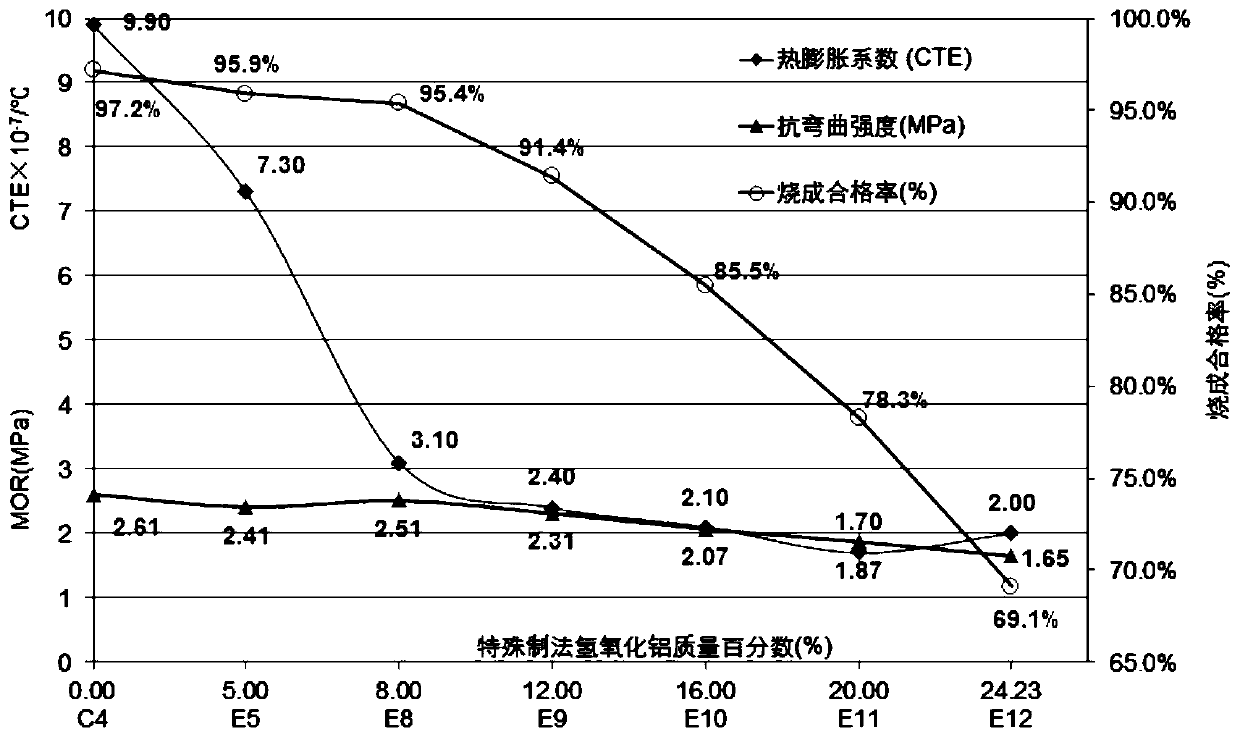

Low-expansion high-strength thin-wall cordierite honeycomb ceramic and preparation method thereof

The invention discloses low-expansion high-strength thin-wall cordierite honeycomb ceramic and a preparation method thereof. Content of cordierite in ceramic is greater than 95%, and the ceramic is prepared from the following chemical components in percentage by mass: 47.5-52.5% of SiO2, 32.7-37.7% of Al2O3 and 11.5-15.5% of MgO; porosity of honeycomb ceramic is greater than or equal to 16%, and awater absorption rate is 14%-30%; bending strength of the honeycomb ceramic is greater than or equal to 1.6 MPa; and a thermal expansion coefficient at the room temperature of 800 DEG C is smaller than or equal to 5*10<-7> / DEG C. According to the preparation method, aluminum hydroxide prepared by a special preparation method is led, so that the product has low CTE (Coefficient of Thermal Expansion), high strength and low cost.

Owner:SHANDONG AOFU ENVIRONMENTAL PROTECTION SCI & TECH

Process for heating foam ceramic

InactiveCN1793051AMeet the process needs of heatingNo pollution in the processCeramicwareHeating timeMicrowave

The invention relates to a heating method for bubble ceramic. According to the method, the bubble ceramic blank is set into the microwave heating device to take heating, under the condition of 300MHz-300GHz, 25-2000 degree centigrade heating time for 30-60 minutes, cooling. The method has simple technology, short producing cycle high production efficiency and high economic benefits.

Owner:长沙隆泰科技有限公司

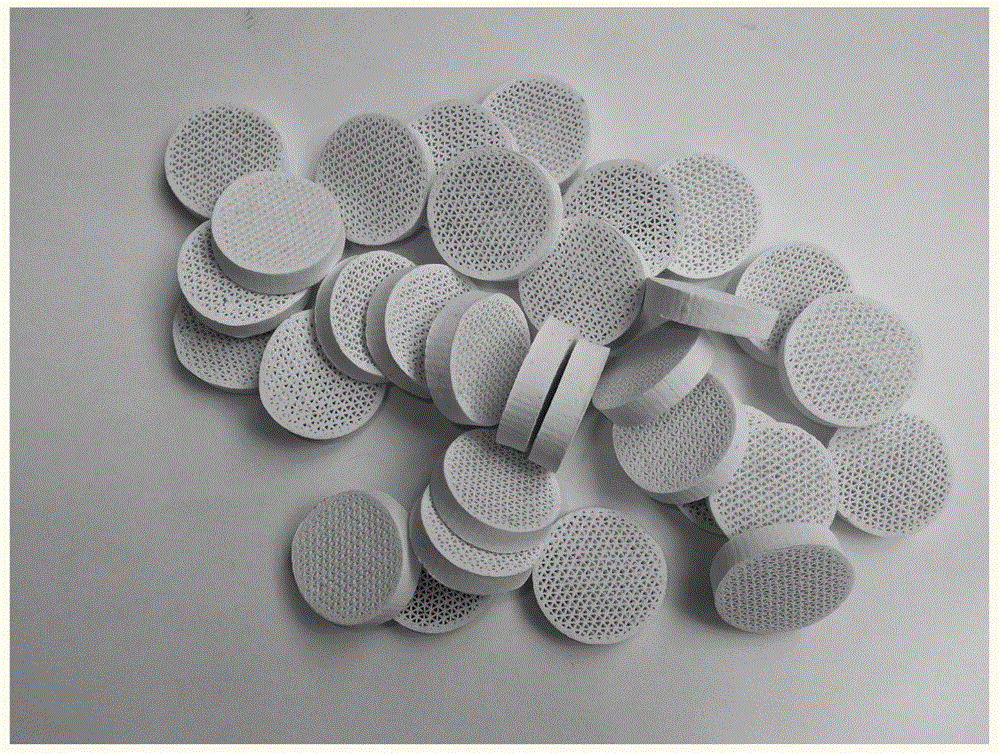

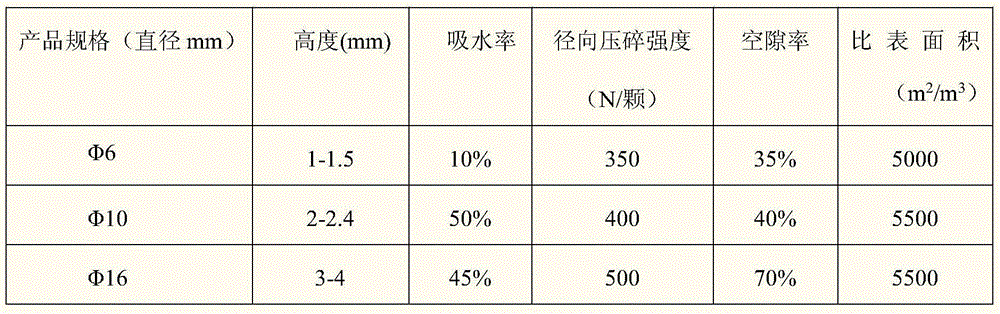

Honeycomb nest hydrogenation protecting agent

ActiveCN104888864AImprove firing pass rateExcellent extrusion formabilityCatalyst carriersHoneycombSolvent

A honeycomb nest hydrogenation protecting agent is prepared from 1-60% of alumina powder, 5-50% of kaolin, 0.1-15% of talcum powder, 5-60% of clay, 0.5-10% of an alkaline solvent, and 0.1-5% of an auxiliary material. The unit cross section area of the above product has more and denser through holes, so the external specific surface area of the product is greatly increased and reaches above 5000m<2> / m<3>, so a reaction raw material and the protecting agent have a larger contact and reaction area. The void fraction of the product reaches 30-70%, the water absorption rate reaches 10-50%, and the appropriate water absorption rate makes the protecting agent adsorb more active substances, so the absorption rate of adsorbed impurities is improved, and the catalysis effect is improved; and the radial crushing strength of the product is 50-500N / granule of the product, the product cannot be fragmented when 50-500N is applied to the two axial ends of the product, and maintains integrity, so the strength is improved, and the service life is prolonged.

Owner:JIANGXI ACICHEMSHUN IND

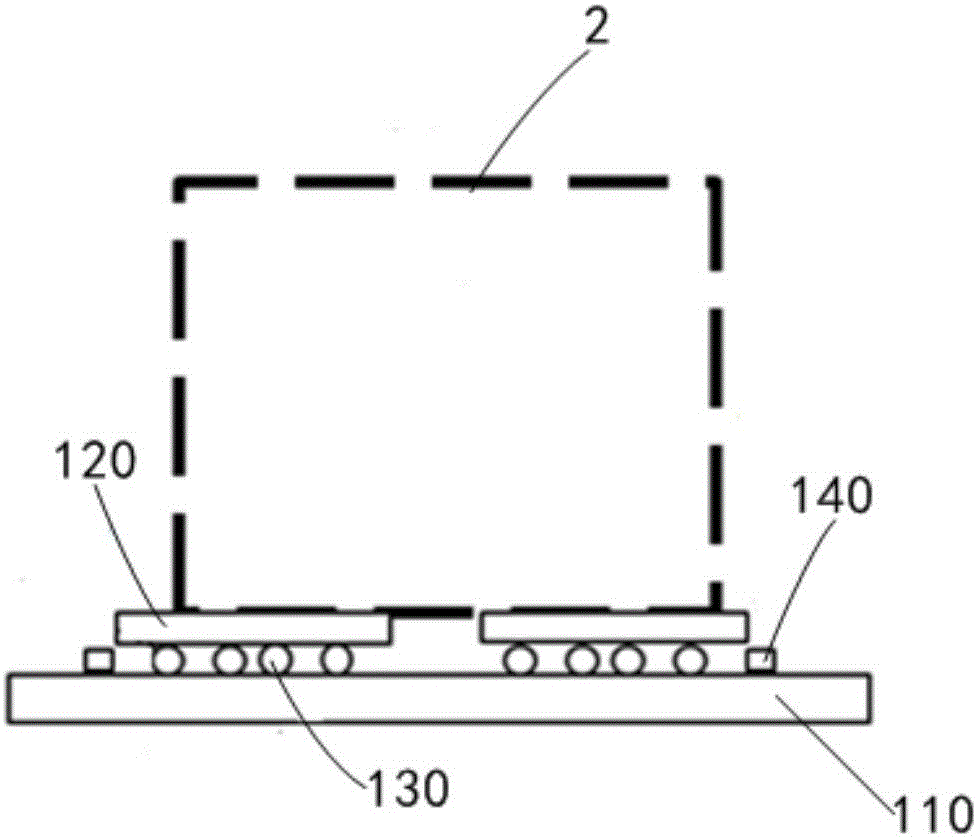

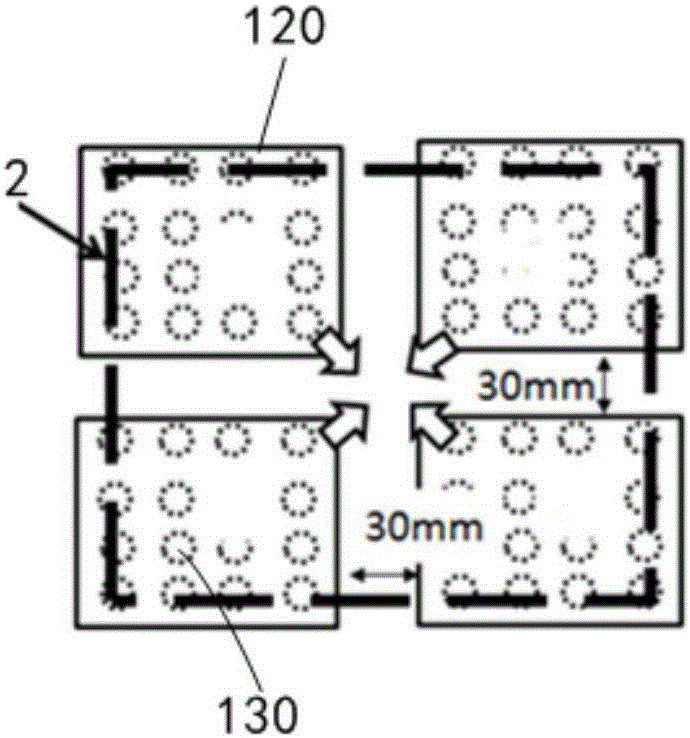

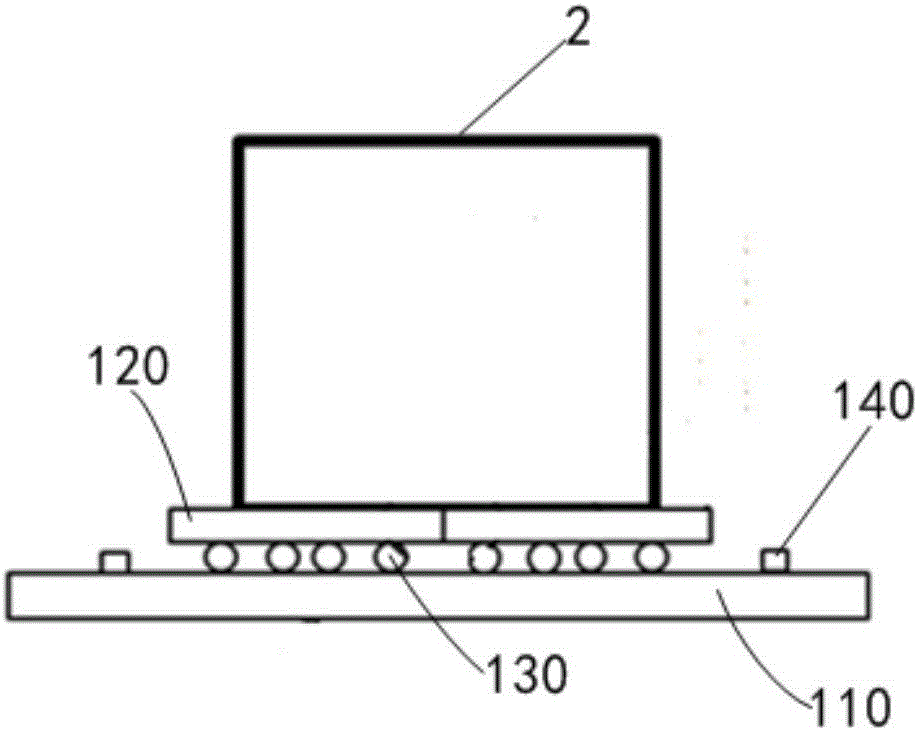

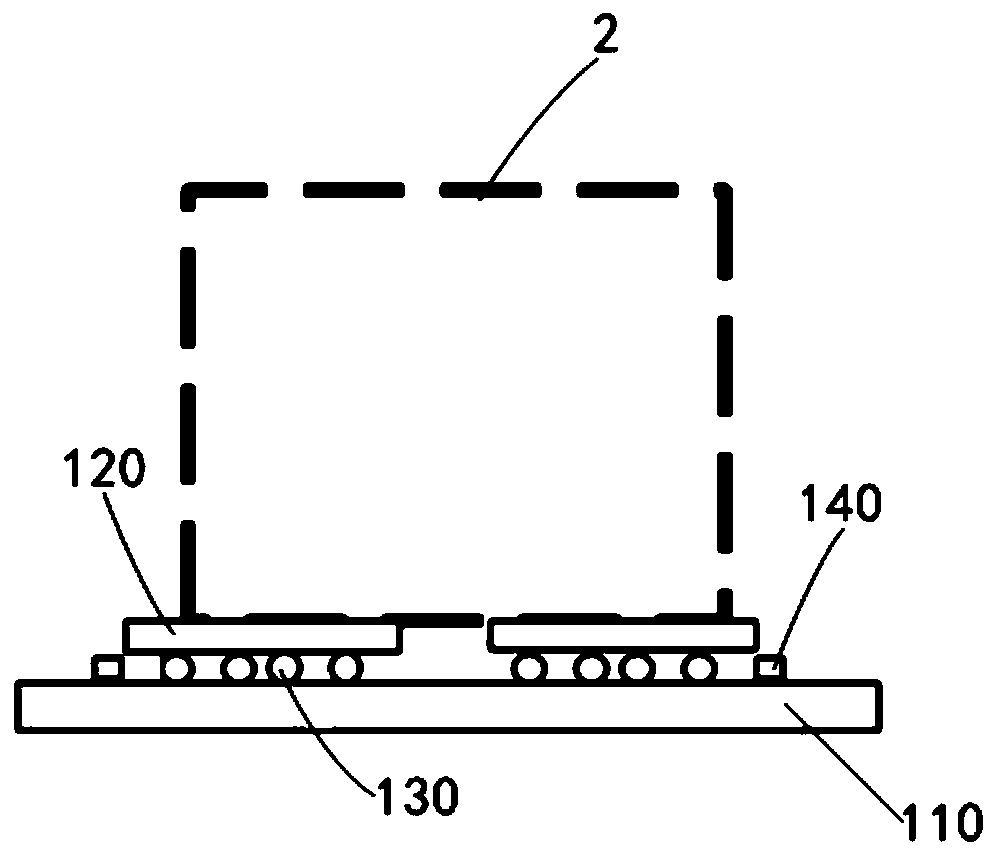

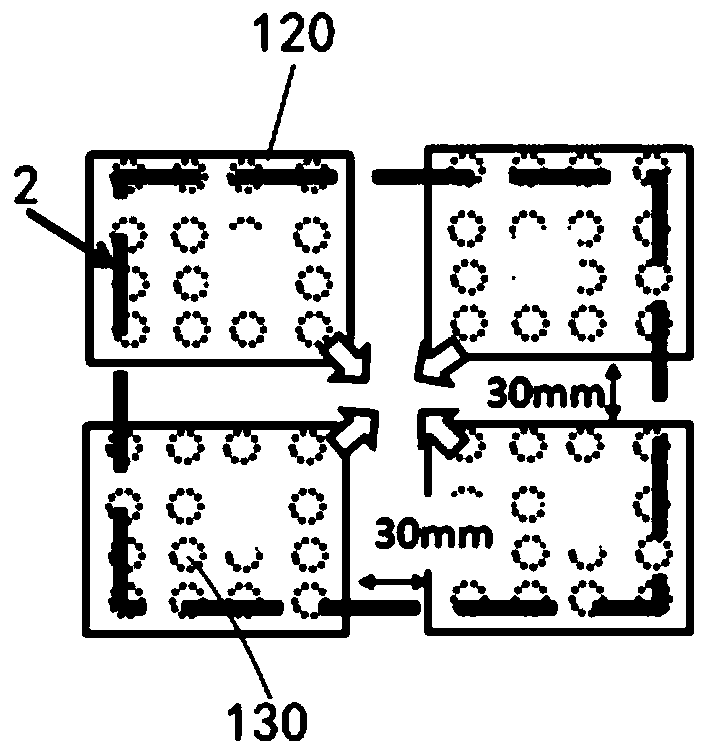

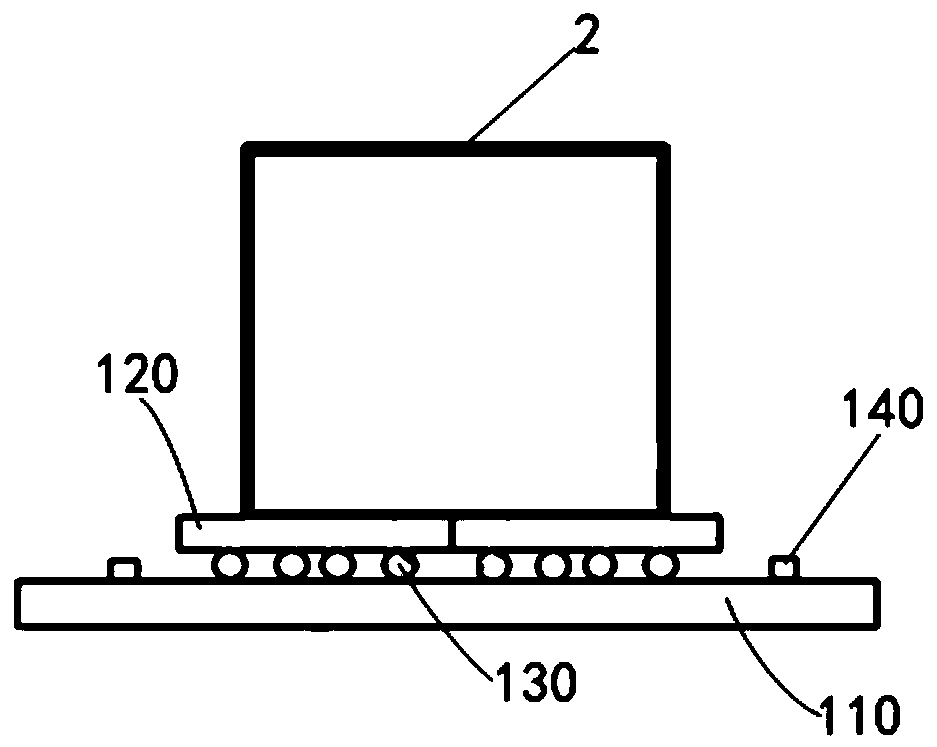

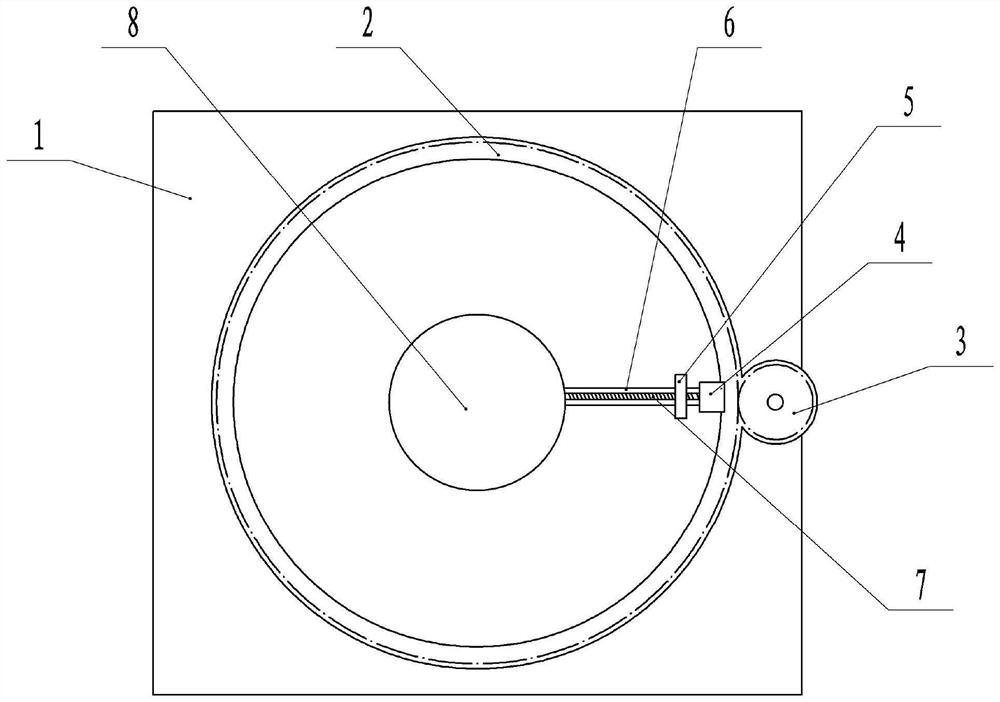

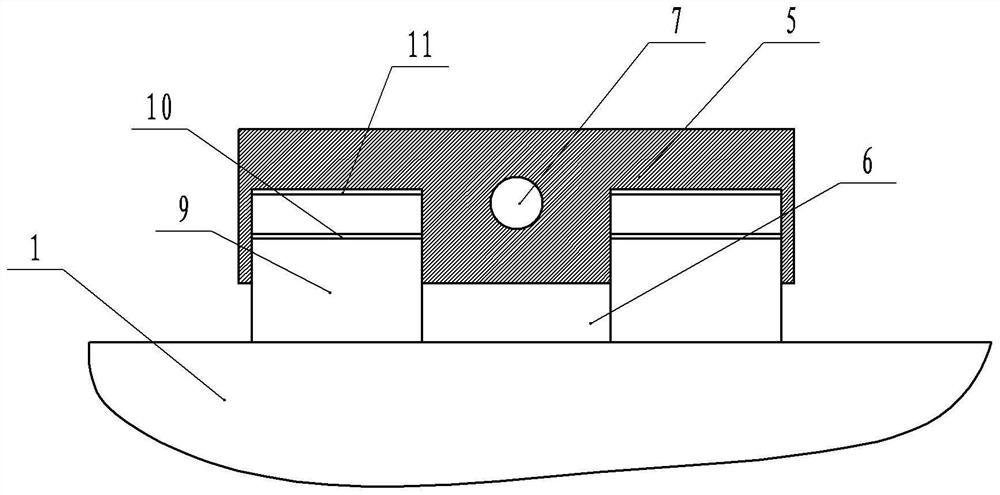

Ceramic firing method

ActiveCN106830949ASolve the deformationImprove firing pass rateCharge supportsDeformation ProblemStart up

A ceramic firing method includes the steps: a first kiln plate is horizontally arranged in a kiln; a plurality of high-temperature-resistant balls are laid on the first kiln plate; at least two second kiln plates for uniformly supporting at the bottom of a ceramic green body are laid on the plurality of high-temperature-resistant balls, and a gap exists between each adjacent second kiln plates; the ceramic green body is placed on the second kiln plates, and the bottom of the ceramic green body is uniformly supported by the at least two second kiln plates; and the kiln is started up for firing the ceramic green body with the firing temperature of 1100-1300 DEG C for 6-8 hours. According to the method, in the process of firing the ceramic green body, the second kiln plates can relatively move along with the green body shrinkage stress traction, so that the shrinkage stress of the product is released, the deformation problem of a high-end straight-edge product is completely solved, the firing qualified rate of the product is improved, the quality of the product is improved, and the costs are reduced.

Owner:LIXIL AS SANITARY MFG (SHANGHAI) CO LTD

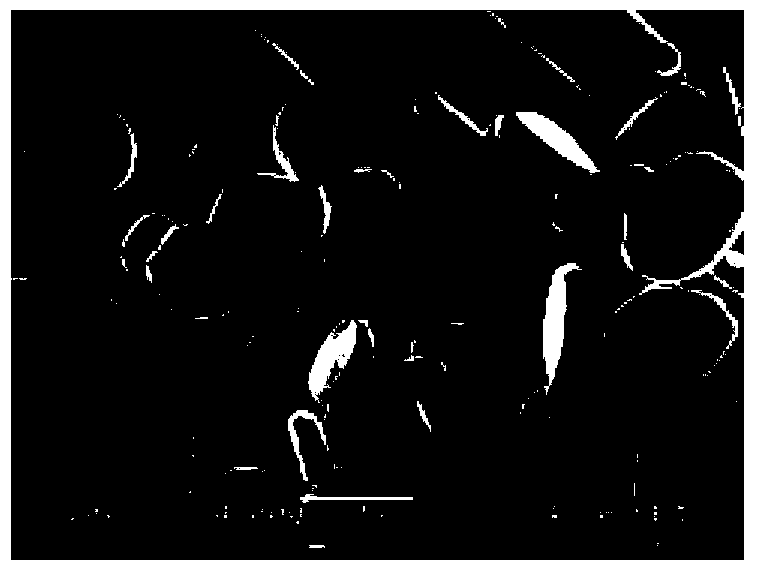

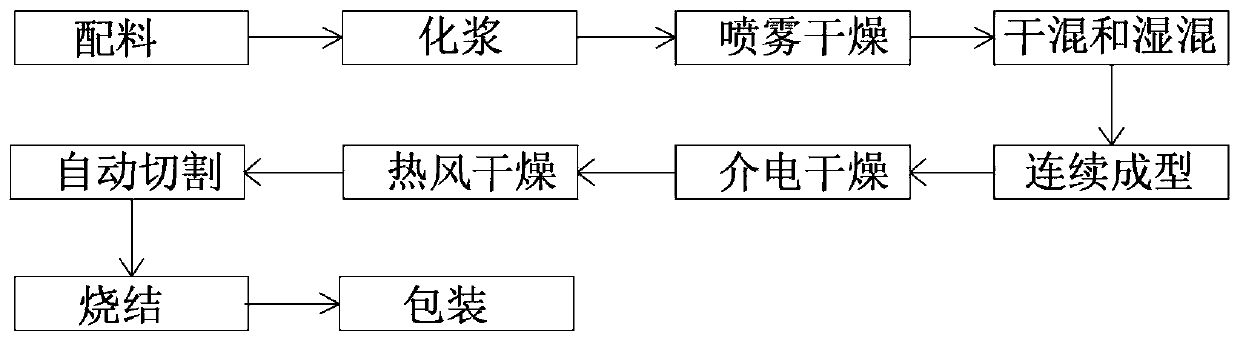

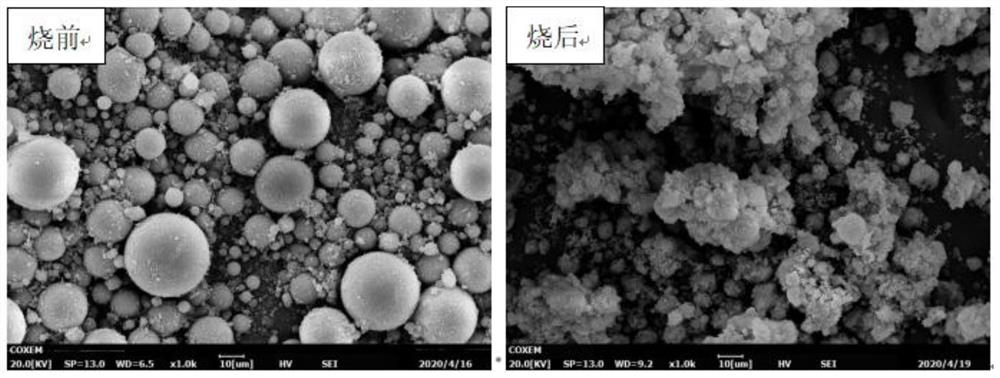

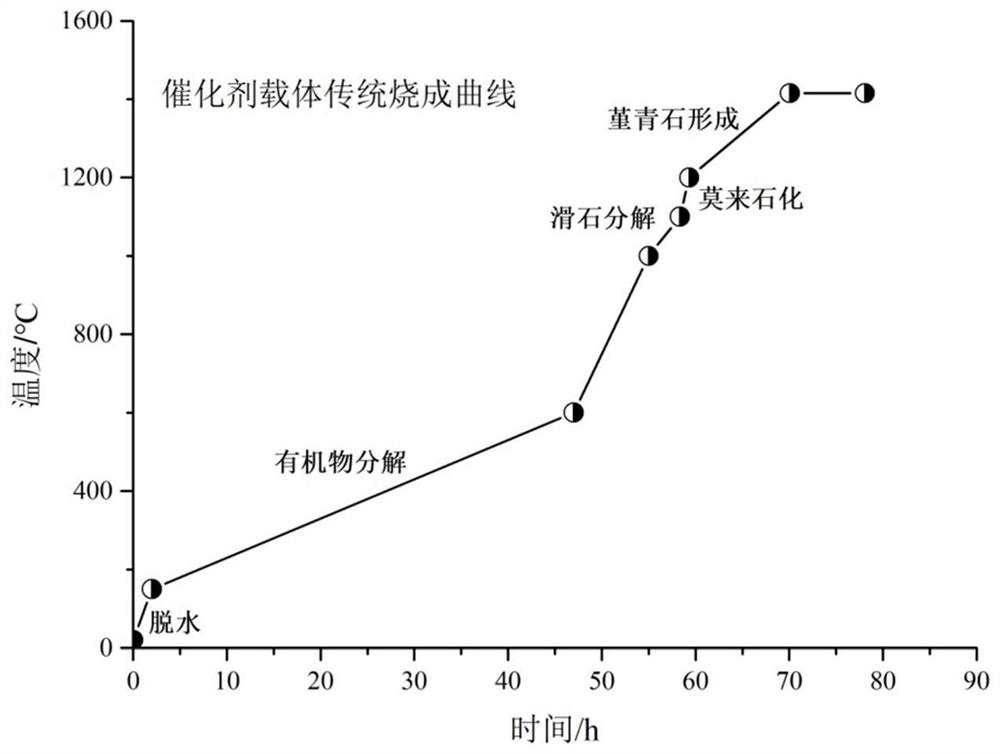

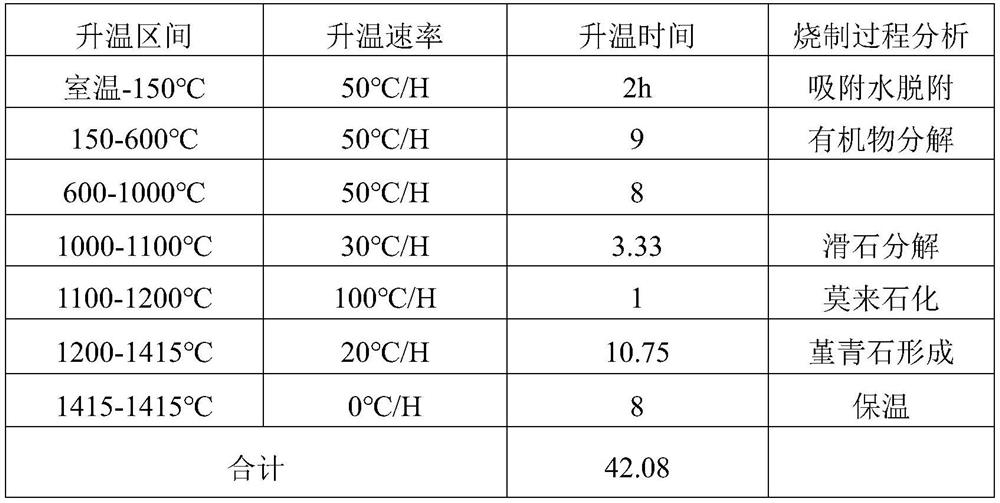

High-pore-density ultrathin-wall cordierite honeycomb ceramic carrier for TWC, and preparation method thereof

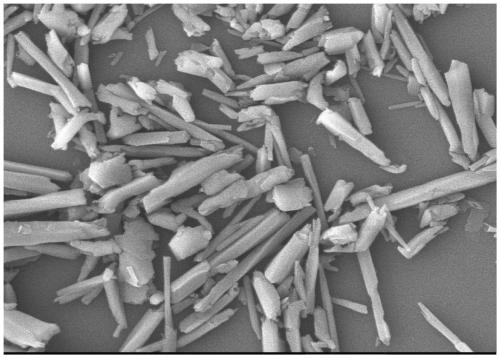

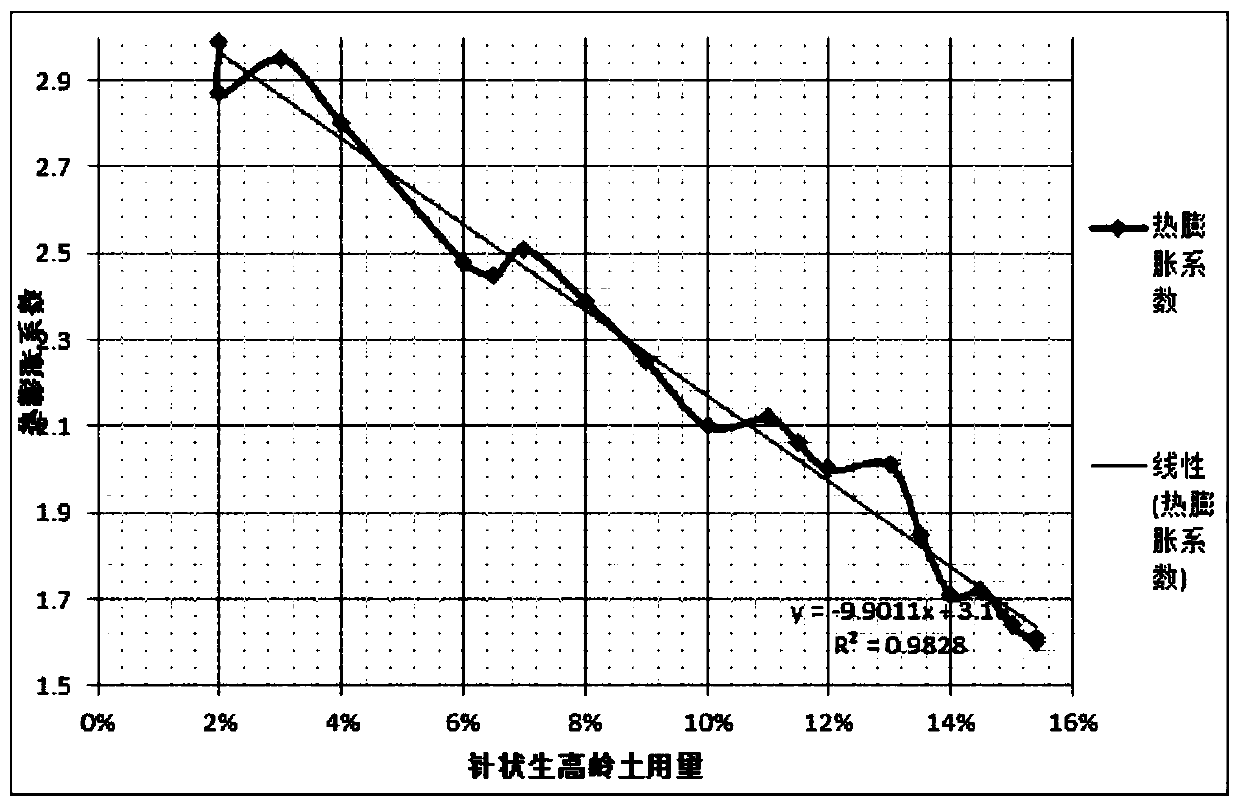

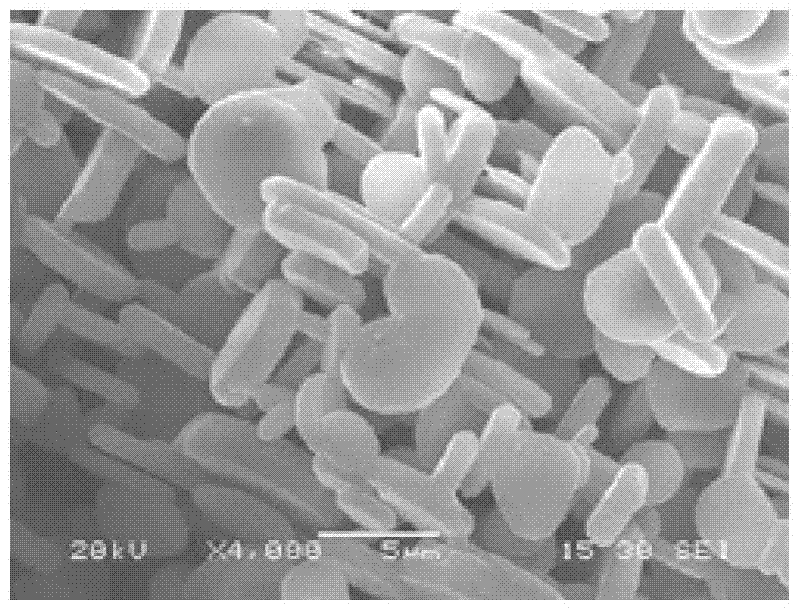

InactiveCN111205073AEasy OrientationPromotes directional growthCatalyst carriersCeramicwareKaolin clayCordierite

The invention discloses a preparation method of a high-pore-density ultrathin-wall cordierite honeycomb ceramic carrier for a gasoline engine three-way catalytic converter. The preparation method comprises the following steps: (1) stirring an inorganic material, an organic dispersant and purified water to form a slurry, and carrying out spray drying on an inorganic powder by using a spray drying device to form a powder with excellent flowability; (2) carrying out dry mixing on the powder and an organic binder, then adding a lubricant and a dispersion medium, and carrying out wet mixing to enable the mixture to form plastic mud pellets; and (3) carrying out extrusion molding on the mud pellets obtained in step (2) to form a green body, and carrying out dielectric drying, hot air drying, cutting and firing on the green body to finally prepare the honeycomb ceramic product, wherein the inorganic material comprises acicular raw kaolin. According to the preparation method provided by the invention, the acicular raw kaolin is introduced, so that the prepared product has ultralow CTE, high yield and low cost.

Owner:CHONGQING AOFU FINE CERAMICS CO LTD

Large-size diesel oil particulate filter with low pressure drop and low expansion coefficient and preparation method thereof

ActiveCN108439967ASmall pressure dropSmall expansion coefficientGas treatmentDispersed particle filtrationAdhesiveThermal expansion

The invention discloses a large-size diesel oil particulate filter with low pressure drop and a low expansion coefficient and a preparation method thereof. The filter is prepared from the following raw materials: an inorganic component, a graphene precursor, starch, polymer resin and an adhesive, wherein the inorganic component is prepared from the following components by mass: 30 to 50 percent oftalcum, 5 to 30 percent of kaolin, 10 to 25 percent of aluminum oxide, 5 to 30 percent of hydrated alumina and 5 to 25 percent of silicon dioxide; the amounts of the graphene precursor, the starch and the polymer resin respectively account for 2 to 15 percent, 5 to 10 percent and 5 to 15 percent of the mass of the inorganic component; the amount of the adhesive is 2 to 10 percent of the total mass of the inorganic component, the graphene precursor, the starch and the polymer resin. The filter provided by the invention can be used for purifying automobile tail gases, in particular to particulate matters in tail gases of diesel vehicles, so that the problems of high pressure drop and high thermal expansion coefficient in an existing filter are solved; meanwhile, the problem of lower qualification rate in the preparation process of the filter is solved, the production cost is reduced, and the production efficiency is improved.

Owner:SHANDONG AOFU ENVIRONMENTAL PROTECTION SCI & TECH

A kind of sanitary ceramic mud and its preparation process

The invention discloses sanitary ceramics slip and a preparation technology thereof. The sanitary ceramics slip mainly comprises, by weight, 30-70 parts of illite-structure clay, 5-15 parts of kaolin, 6-14 parts of ball clay, 8-13 parts of potassium feldspar, 5-10 parts of pyrophyllite, 5-10 parts of sericite, 0.1-3 parts of dolomite and 40-45 parts of water. Sanitary ceramics prepared from the sanitary ceramics slip are low in firing temperature, little in energy consumption and high in strength, and slip casting qualified rate, semi-finished product qualified rate and firing qualified rate can reach 98%, 96% and 92% respectively.

Owner:福建科福材料有限公司

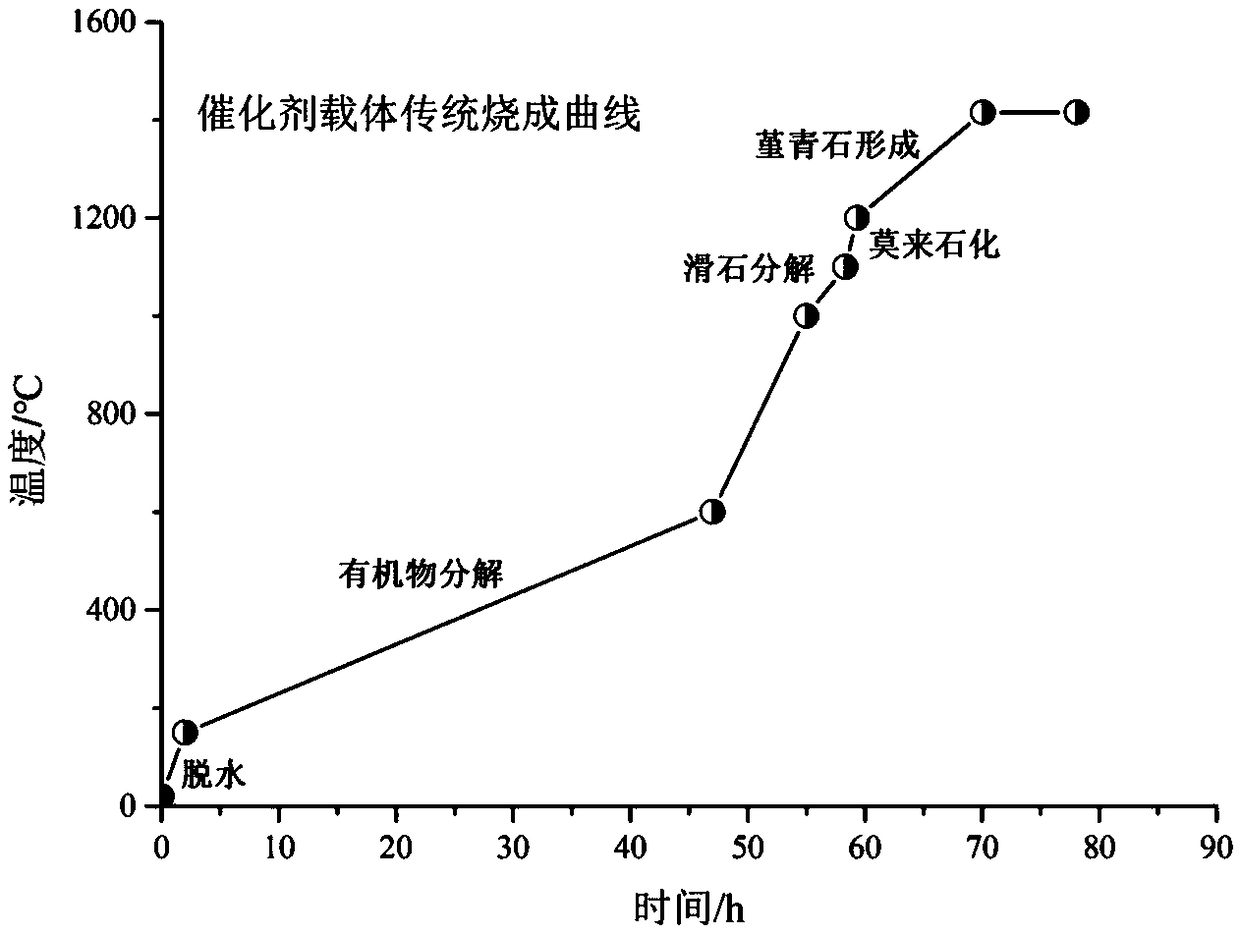

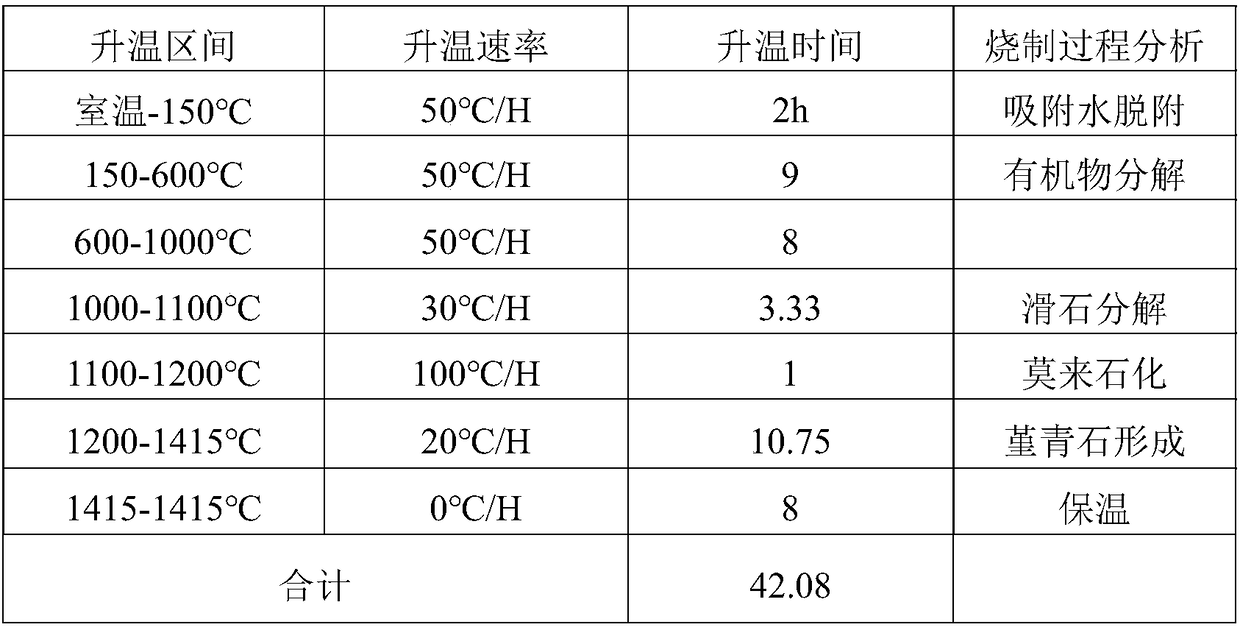

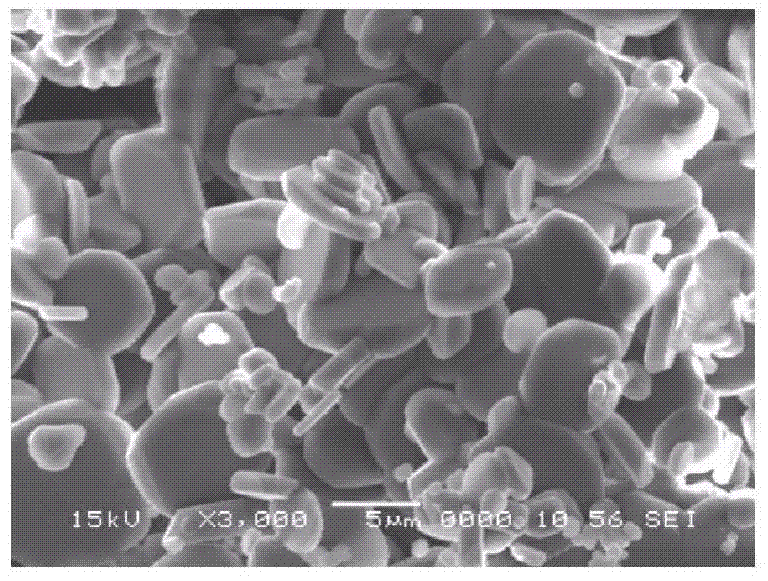

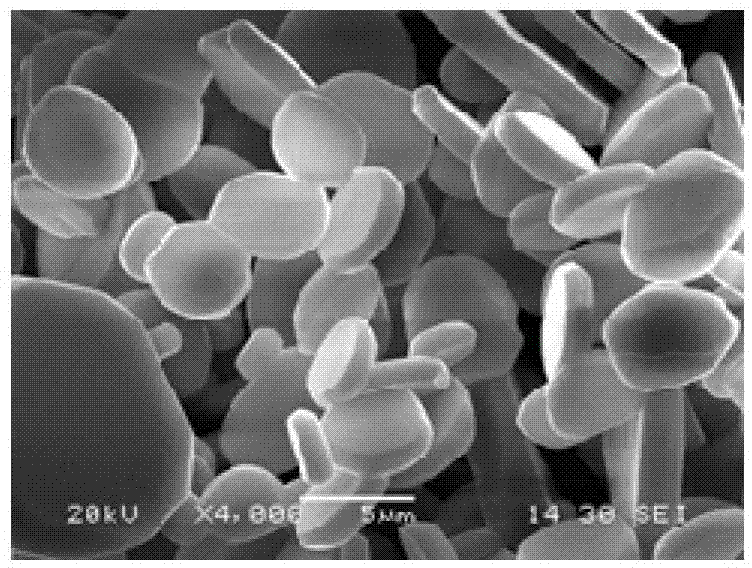

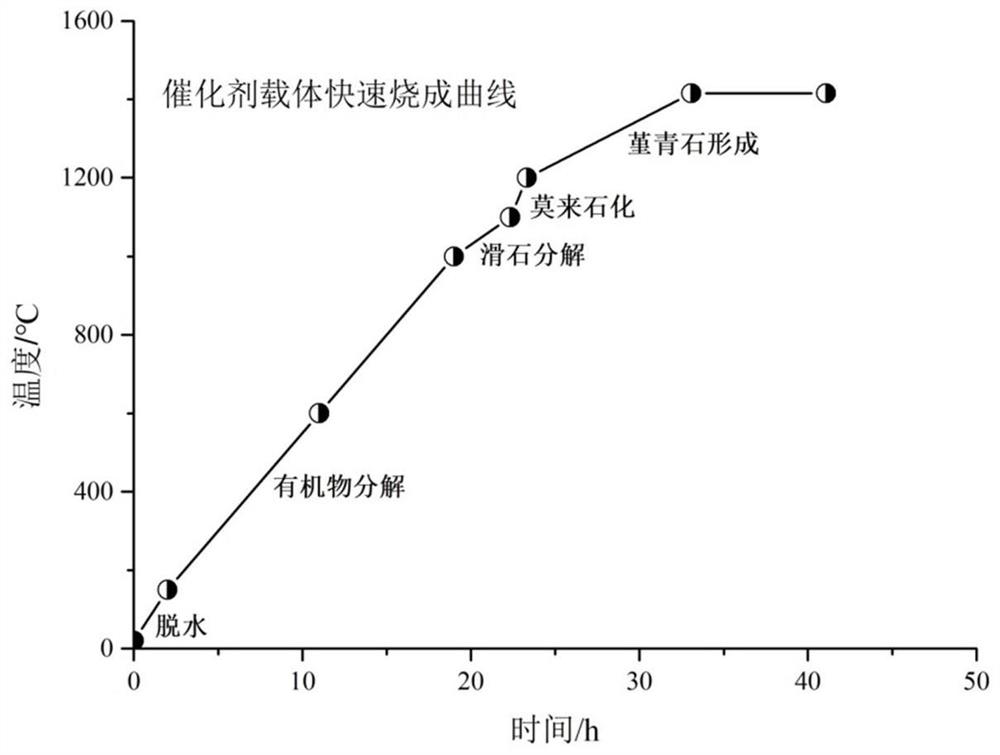

Honeycomb ceramic catalyst carrier and preparation method thereof

ActiveCN109133860AHeating up fastAvoid burnsCatalyst carriersCatalyst activation/preparationCopolymerEnergy conservation

The invention belongs to the technical field of honeycomb ceramic materials, and particularly relates to a honeycomb ceramic catalyst carrier and a preparation method of the catalyst carrier. The honeycomb ceramic catalyst carrier takes aluminum oxide, magnesium oxide, electroquartz, talcum and raw kaoline as inorganic main materials; methylcellulose, a bromobenzene fire retardant, an organosilicon polyether copolymer, bean oil and water are added as catalysts; particularly, the halogen-free, low-smoke and low-toxicity bromobenzene fire retardant is added, and is a functional assistant endowing a flammable polymer with flame retardance; the flame retardance can be provided for a high polymer material; combustion of organic matter in the honeycomb ceramic carrier can be effectively inhibited; a temperature difference inside and outside the carrier is avoided; a qualified rate of firing is increased; at the same time, due to an inhibiting effect of the fire retardant, the temperature ofthe honeycomb ceramic carrier rises quickly in a firing process to contribute to improving production efficiency; and the carrier has the advantages of energy conservation and environmental protection.

Owner:SHANDONG AOFU ENVIRONMENTAL PROTECTION SCI & TECH

Nitrogen oxide sensor

ActiveCN113075278AGuaranteed symmetric distributionReduce distanceMaterial analysis by electric/magnetic meansNitrogen oxidesReference electrode

The invention discloses a nitrogen oxide sensor which comprises a first structural layer with the same thickness as a second structural layer, and the first structural layer and the second structural layer are symmetrically arranged relative to a solid electrolyte layer group; a common electrode is arranged on the side, facing the first structural layer, of the first solid electrolyte layer, and a first main pump electrode and a first auxiliary pump electrode are arranged on the side, facing the second solid electrolyte layer, of the first solid electrolyte layer. A second main pump electrode, a second auxiliary pump electrode and a measuring pump electrode are arranged on the side, facing the first solid electrolyte layer, of the second solid electrolyte layer, a reference electrode is arranged on the side, facing the third solid electrolyte layer, of the second solid electrolyte layer, and a heater is arranged on the side, facing the second structural layer, of the third solid electrolyte layer. According to the nitrogen oxide sensor, the power consumption of the nitrogen oxide sensor in a working state is reduced, the service life of the nitrogen oxide sensor can be prolonged, and meanwhile, the firing qualification rate is improved.

Owner:INST OF ADVANCED TECH UNIV OF SCI & TECH OF CHINA

Zero-firing-shrinkage cordierite honeycomb ceramic carrier and preparation method thereof

ActiveCN104030720BFiring shrinkage zeroImprove firing pass rateCeramicwareCordieriteMaterials science

The invention relates to a zero-firing-shrinkage cordierite honeycomb ceramic carrier and a preparation method thereof. The carrier comprises the following raw materials in percentage by weight: 20-32 wt% of tabular alumina, 4-11 wt% of magnesium oxide, 15-45 wt% of electroquartz, 7-30 wt% of talcum and 10-35 wt% of kaolin, totaling 100%. The carrier also comprises an organic assistant and water. The preparation method comprises the following steps: by using alumina, magnesium oxide, electroquartz, talcum and kaolin as inorganic powder, adding the organic assistant and water, mixing, slurrying, extruding, drying, cutting and firing. The cordierite honeycomb ceramic carrier has the advantages of zero firing shrinkage, high firing qualification rate and low production cost.

Owner:SHANDONG AOFU ENVIRONMENTAL PROTECTION SCI & TECH

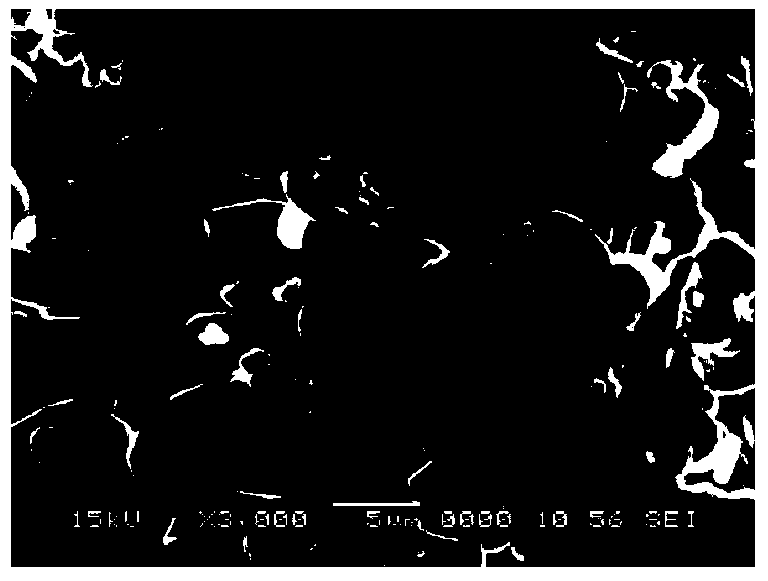

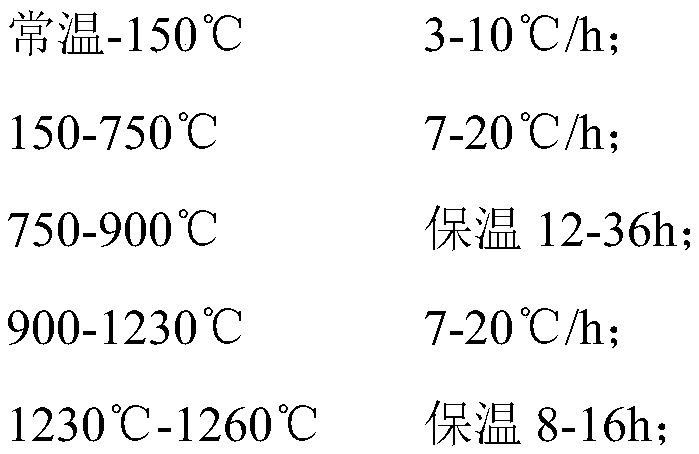

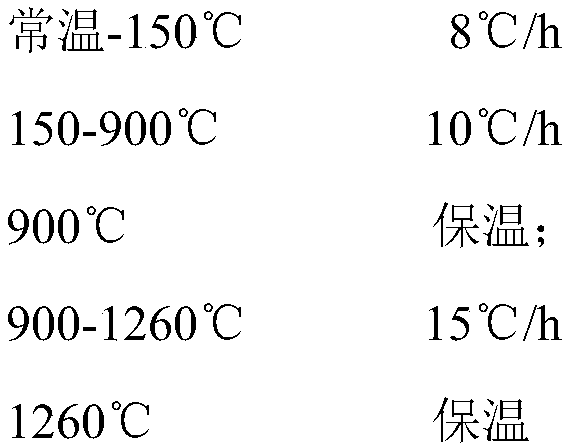

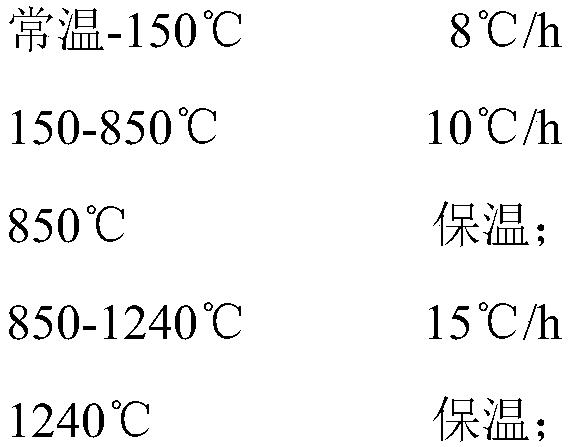

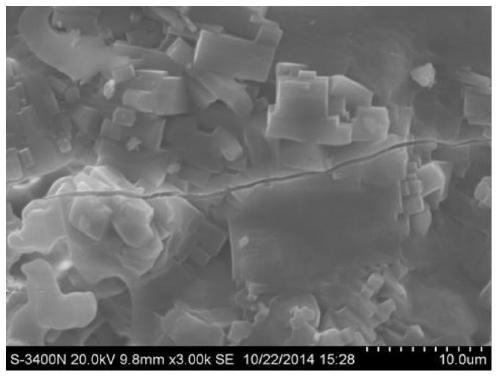

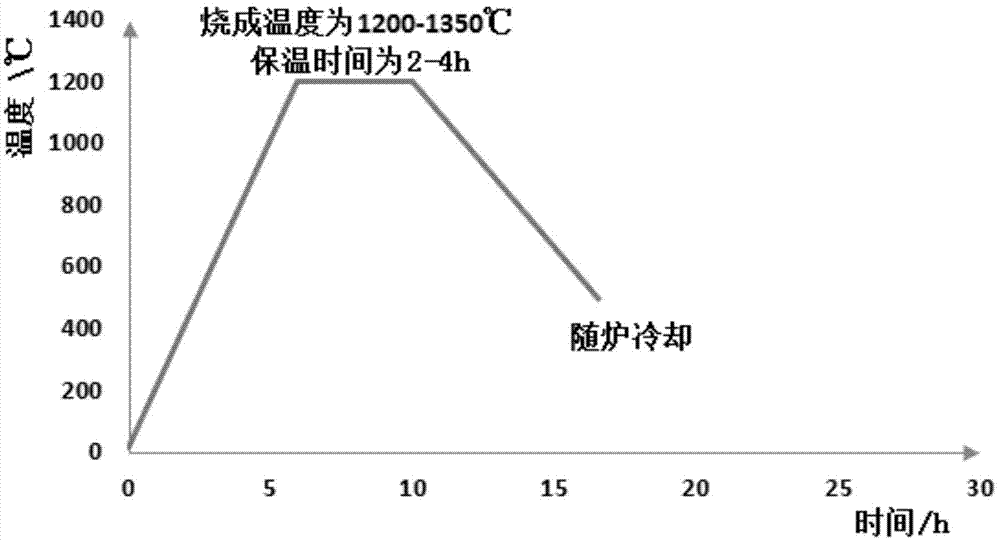

Preparation method of large solid quartz ceramic material

ActiveCN109369163AImprove firing pass rateImprove medium temperature strengthPorosityRoom temperature

The invention relates to a preparation method of a large solid quartz ceramic material and belongs to the technical field of quartz ceramic products. The preparation method comprises the following steps: preparing a mixed material: weighing the following substances in percent by mass: 15-35% of quartz coarse particles, 20-40% of quartz fine particles, 0.99-5.66% of a bonding agent, 15-30% of quartz fine powder, 8-20% of quartz micropowder and 8-15% of spherical quartz micropowder, and mixing the substances uniformly to form the mixed material; isostatic compaction: filling a rubber mold with the mixed material and vacuumizing the mold, and carrying out compression moulding at an isostatic press of 80-150 MPa to form a blank; and sintering process: sintering the blank in the step 2 according to a firing system, and carrying out furnace cooling to room temperature after fire stopping. The preparation method is scientific and reasonable and simple and feasible and the prepared quartz ceramic material is good in microstructure uniformity and has the characteristics of low porosity, high volume density and high constant temperature pressure resistance.

Owner:ZIBO GT INDAL CERAMICS

Low-cost high-strength light-weight ceramic body and preparation method thereof

ActiveCN109678461ALow costWide firing temperature rangeCeramic materials productionClaywaresLithiumPyrophyllite

The invention discloses a low-cost high-strength light-weight ceramic body and a preparation method thereof. The low-cost high-strength light-weight ceramic body is prepared by firing a base materialand an additive in a multi-element compound flux system, wherein the additive is an organosilicon nanometer fluid, and the base material comprises the following raw materials by weight percentage: 28-30 wt% of elutriating mud, 12-14 wt% of smolmitza, 0-1 wt% of bentonite, 5-6 wt% of pyrophyllite, 12-18 wt% of low-temperature sand, 4-5 wt% of lithium chinastone, 6-10 wt% of dolomite, 6-8 wt% of black talc, 7-8 wt% of limestone, 8-10 wt% of diopside, 0-2 wt% of Yongchun coarse soil and 0-3 wt% of waste porcelain powder. A multi-element compound flux is added, particularly that the lithium element and the organosilicon nanometer fluid are added, so that the firing temperature is reduced substantially, the organosilicon nanometer fluid forms a mullite crystal at low temperature, and the lithium element forms a high-strength glass phase easily when being fired at the low temperature, so that the strength of the ceramic body is improved, and the ceramic body is easy to degrade.

Owner:FUJIAN DEHUA FIVE CONTINENTS CERAMIC MFG CO LTD

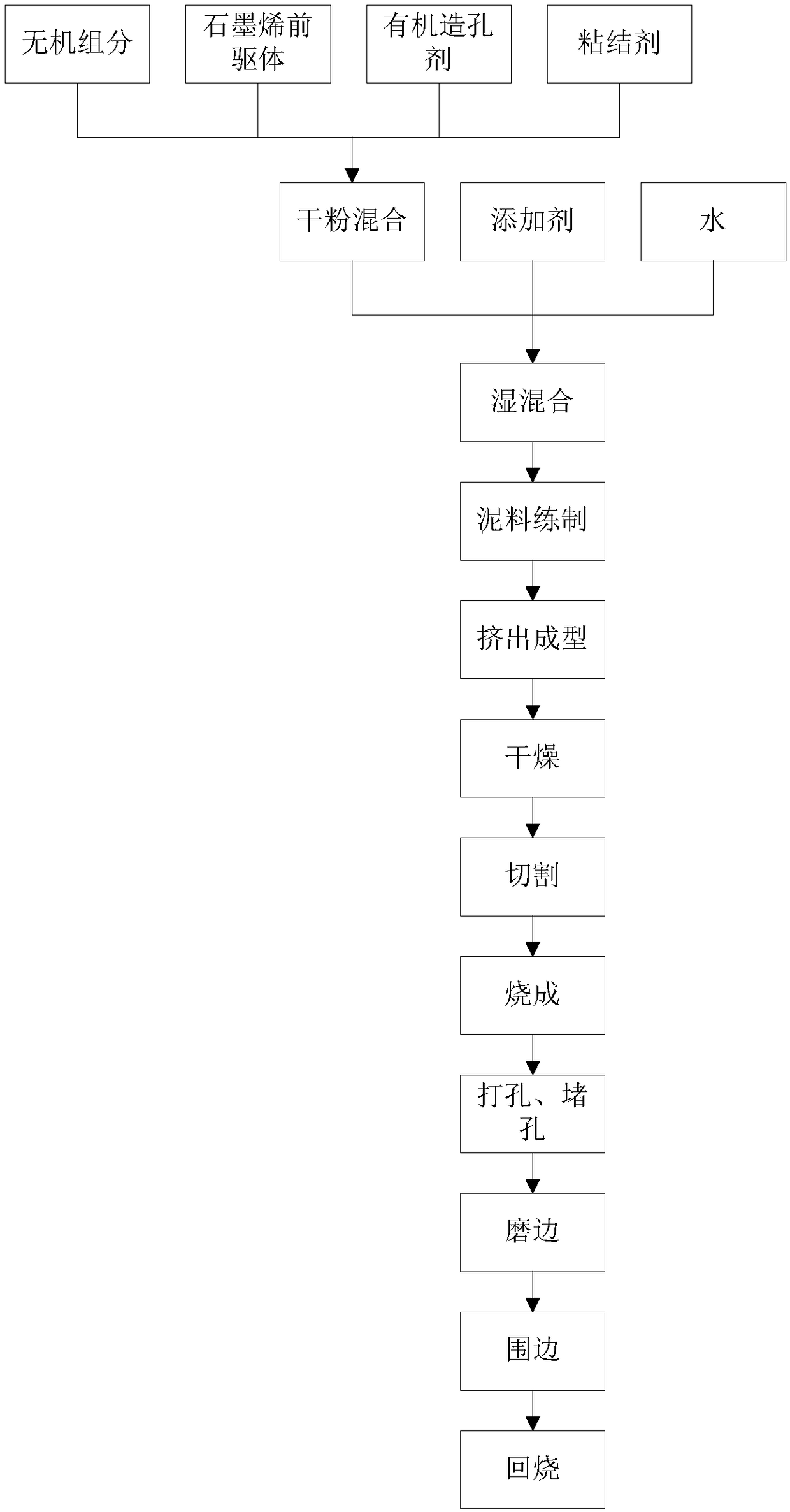

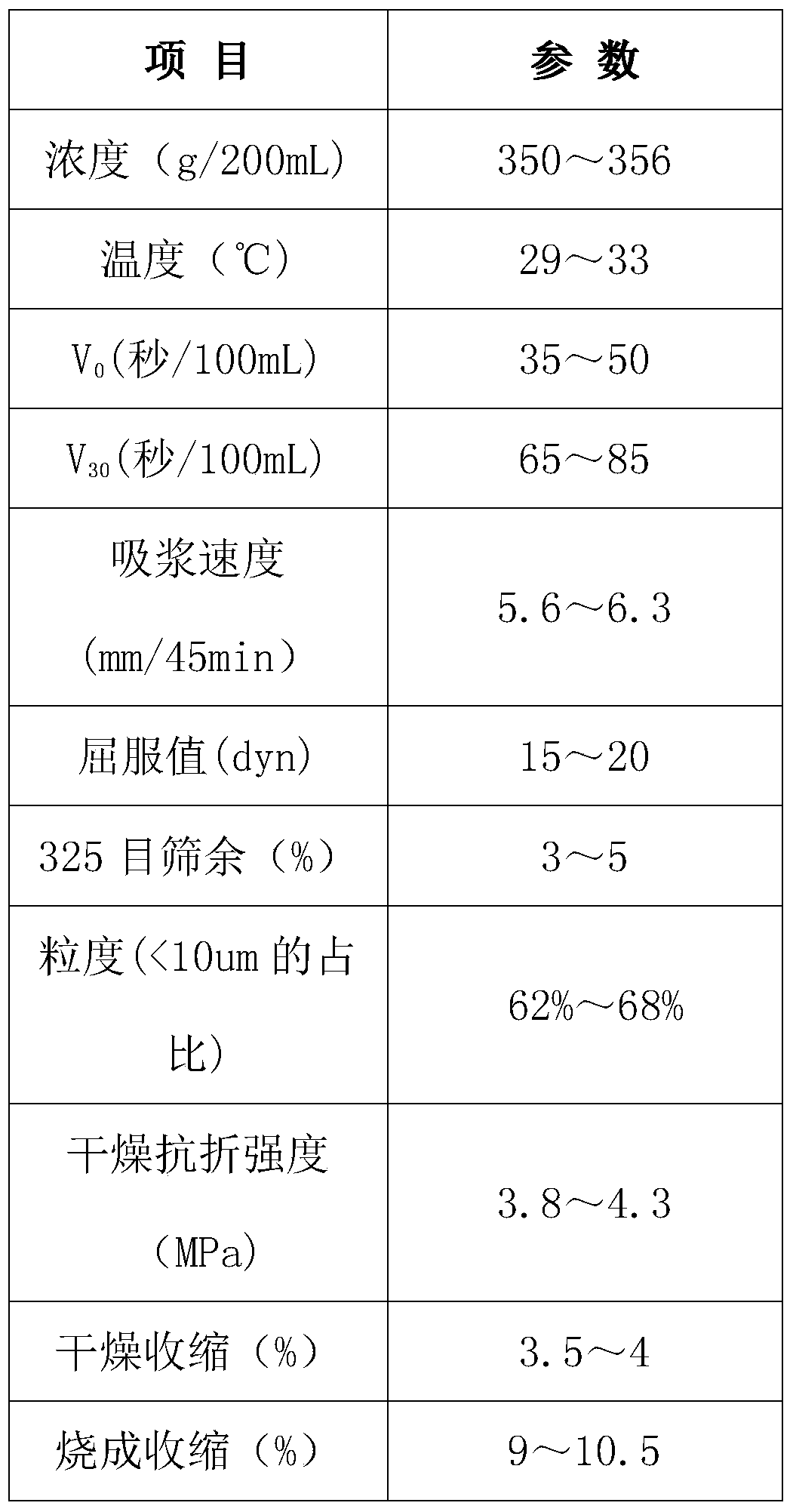

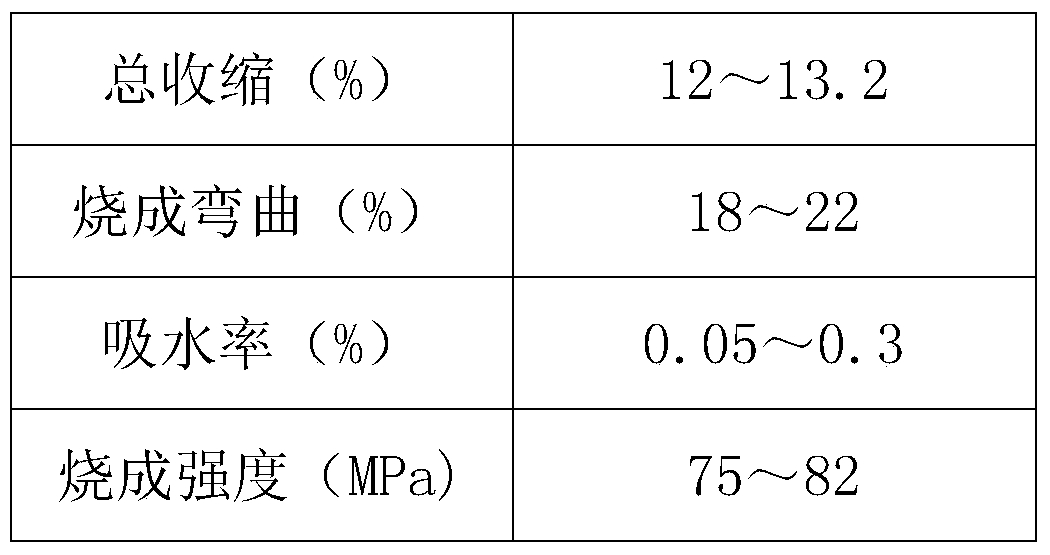

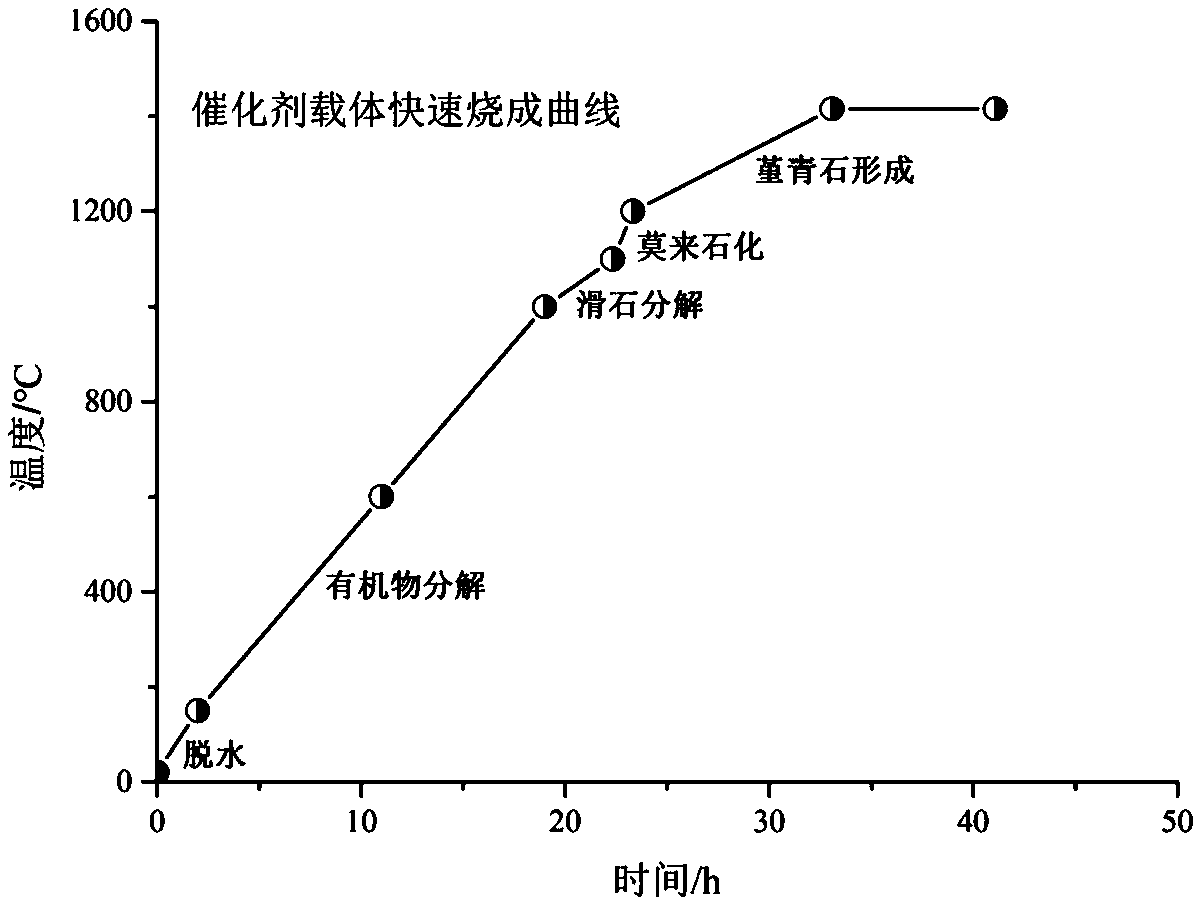

Preparation method of large-size diesel particle filter

PendingCN111892385AImprove firing pass rateReduce manufacturing costDispersed particle filtrationExhaust apparatusMicrospherePolyamide

The invention discloses a preparation method of a large-size diesel particle filter. The method comprises the following steps: (1) uniformly mixing inorganic powder and organic silicon microspheres, and continuing to add polyamide powder, starch and a binder to obtain mixed powder; (2) adding the mixed powder into a kneading machine, continuously adding a lubricating agent into the kneading machine, and kneading to obtain pug; (3) preparing the pug into a pug section; (4) extruding the mud section with plasticity into a honeycomb structure; (5) cutting the dried green body to a fixed height, and sintering in a high-temperature furnace; and (6) punching the sintered green body, plugging the hole, putting the green body into a kiln, carrying out re-sintering, and finally surrounding the skinto obtain the large-size diesel particle filter. According to the preparation method of the large-size and high-porosity diesel particle filter, the product porosity is high, the micropore connectivity is good, the quality is excellent, the production cost is low, and the production efficiency is high.

Owner:CHONGQING AOFU FINE CERAMICS CO LTD

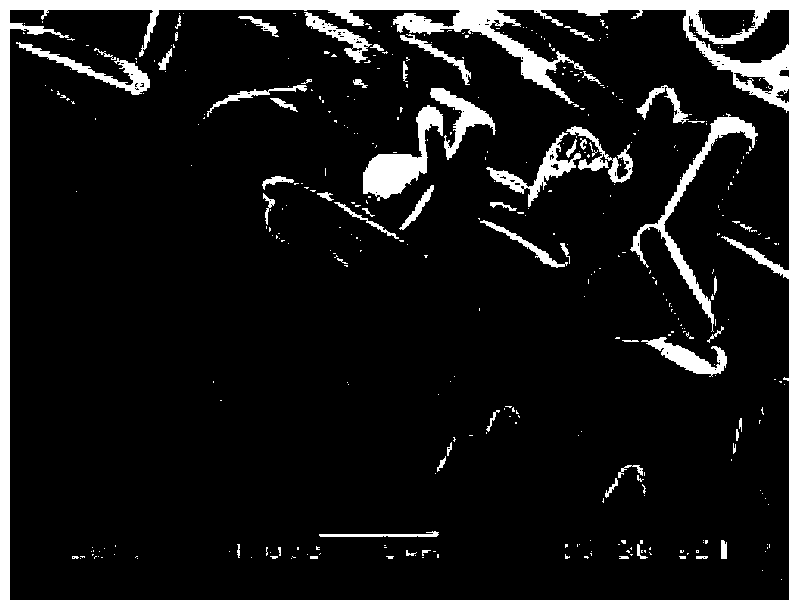

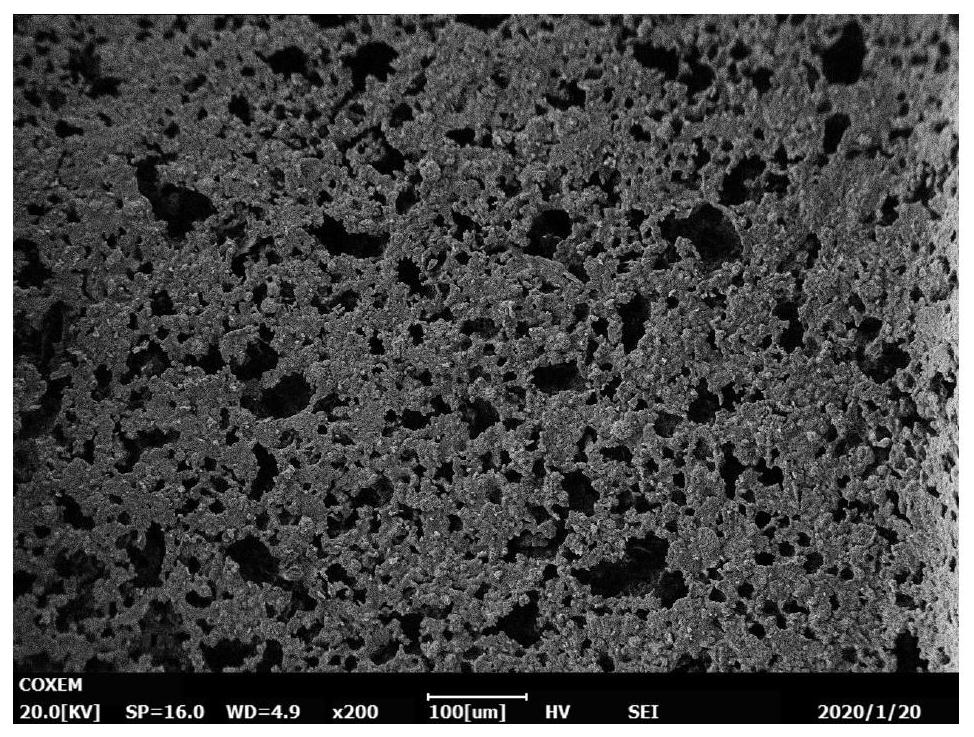

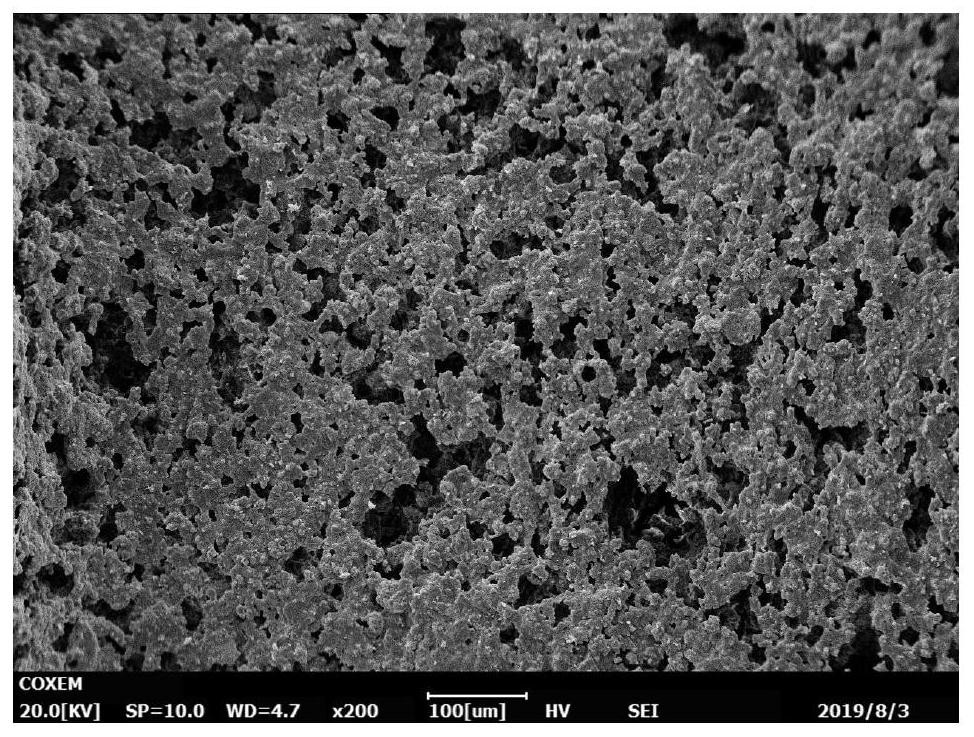

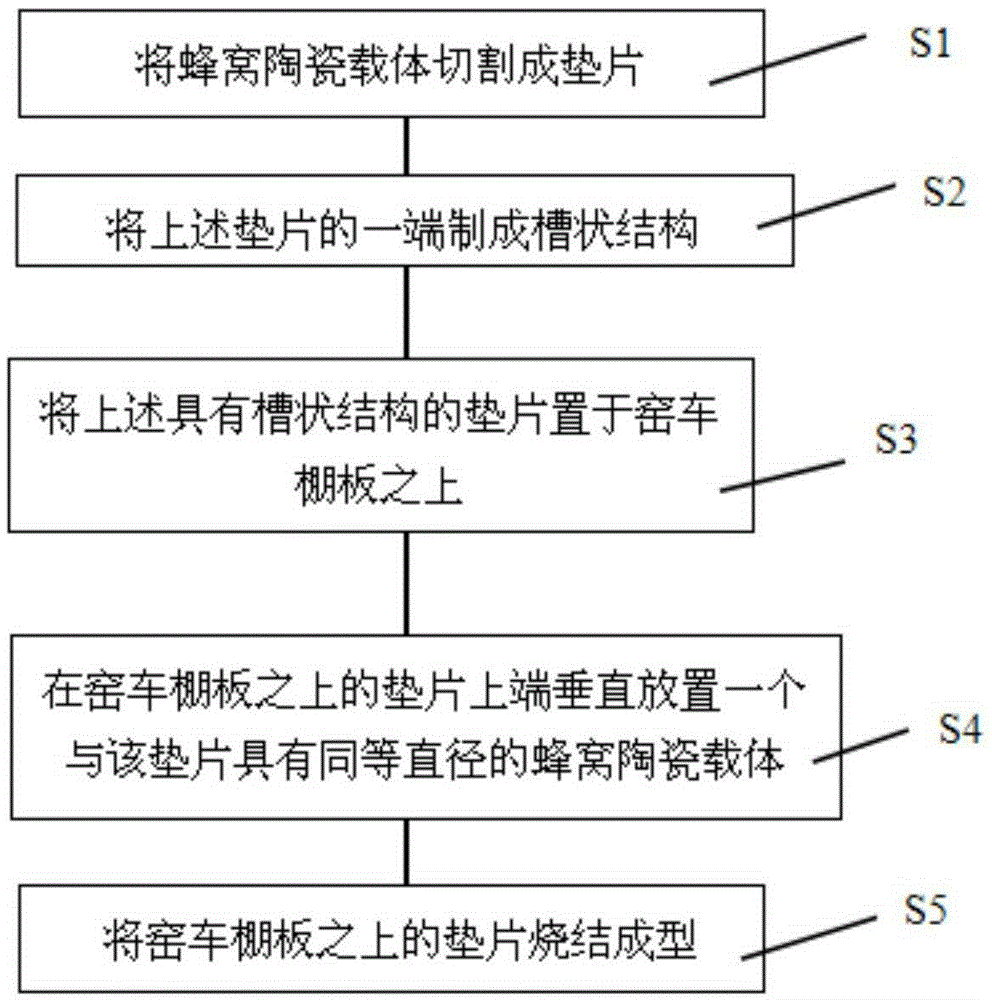

Manufacturing method for honeycomb ceramic carrier seat cushion

InactiveCN105315001AControl the speed of defocusingImprove firing pass rateCeramicwareEngineeringKiln

The invention provides a manufacturing method for a honeycomb ceramic carrier seat cushion. The manufacturing method comprises the following steps that a honeycomb ceramic carrier is cut into a spacer; one end of the spacer is manufactured into a groove structure; the spacer with the groove structure is arranged on a shed plate of a kiln car; a honeycomb ceramic carrier with the same diameter as that of the spacer is perpendicularly arranged at the upper end of the spacer on the shed plate of the kiln car; the spacer on the shed plate of the kiln car is sintered for formation. The method is especially suitable for manufacturing large-specification honeycomb ceramic carrier seat cushions, the coke exhaust speed of the honeycomb ceramic carrier is controlled, and the sintering qualified rate of the carrier is increased; in addition, the kiln loading procedure is simplified, and production cost is reduced.

Owner:凯龙蓝烽新材料科技有限公司

Low-temperature stoneware formula

Owner:漳州汇宜陶瓷有限公司

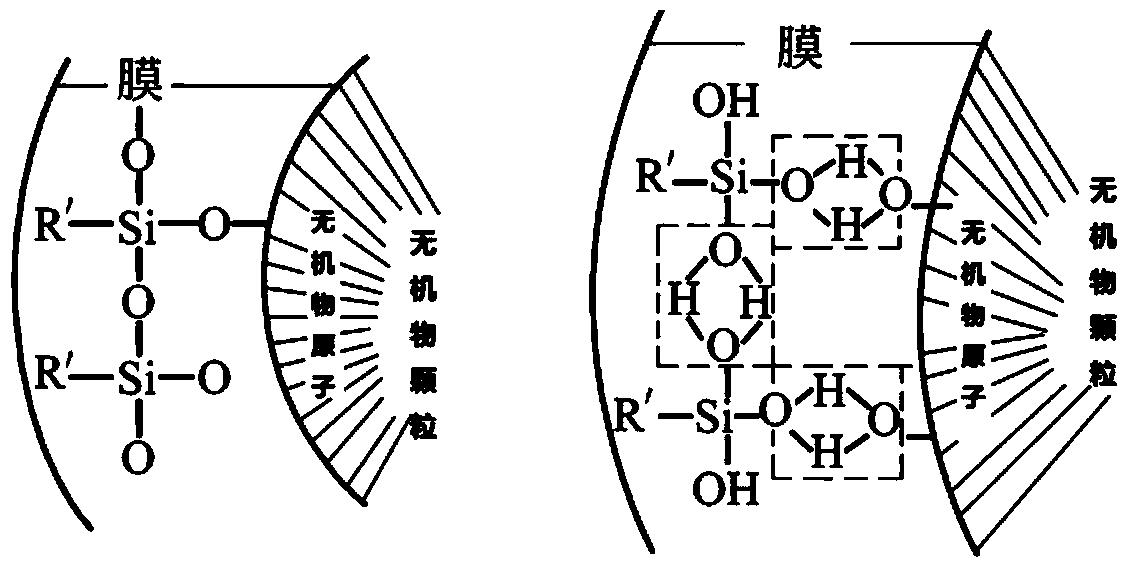

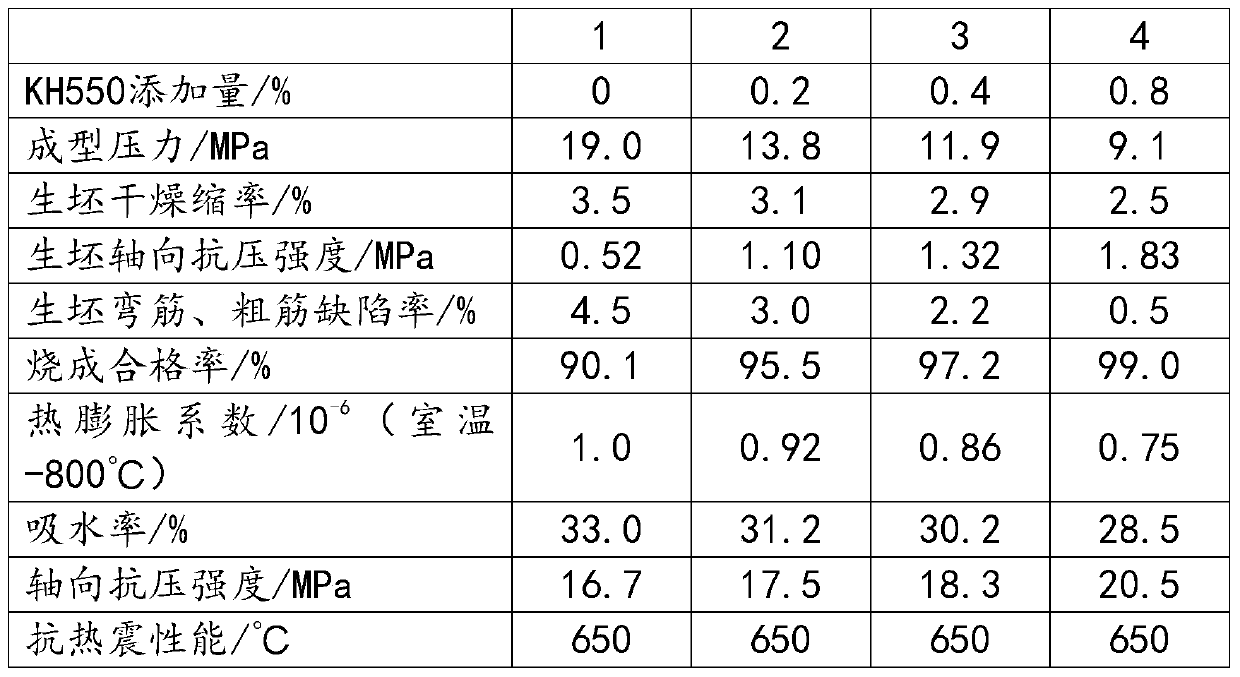

A large-scale thin-walled cordierite honeycomb ceramic carrier mud and its preparation method

The invention discloses large-size thin-wall cordierite honeycomb ceramics carrier mud, which is prepared from inorganic raw materials, an organic binder, water and a silane coupling agent, wherein the inorganic raw materials consist of flake-like talc, flake-like washed kaolin, flake-like aluminium oxide and electroquartz. The silane coupling agent is used for carrying out surface modification on the inorganic raw materials including the flake-like talc, the flake-like washed kaolin, the flake-like aluminium oxide and the electroquartz, and the silane coupling agent forms a substituent group-OSi(CH3)2- on the surface of the raw materials to enable the inorganic raw materials to have hydrophobicity. The large-size cordierite honeycomb ceramics carrier mud prepared from the surface-modified inorganic raw materials has the advantages of small hydration shell thickness and small drying shrinkage and can effectively lower a coefficient of thermal expansion; since the mud has good liquidity, forming pressure is low, the abrasion degrees of forming equipment and moulds can be effectively lowered, meanwhile, the surface substituent group-OSi(CH3)2- can form an -O-Si-O-Si-three-dimensional network in a carrier, green body strength is improved, sintering cracks are reduced, and a high sintering yield can be obtained.

Owner:CHONGQING AOFU FINE CERAMICS CO LTD

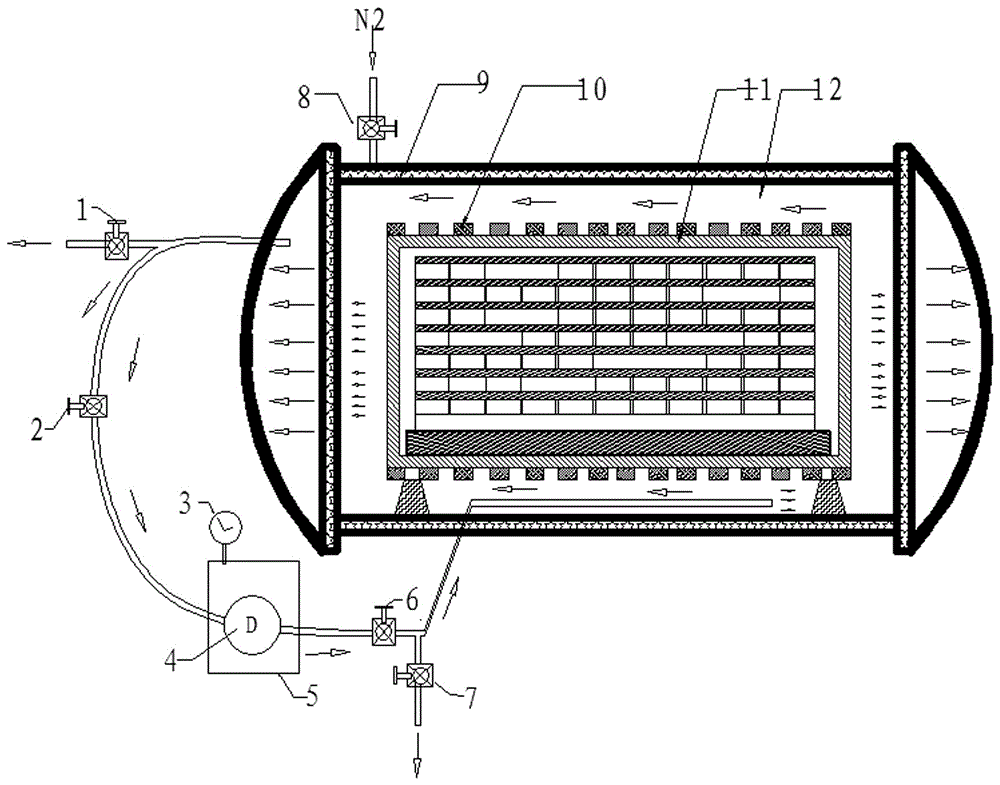

Vacuum induction sintering furnace gas strong circulation stirring device

ActiveCN103542733BImproving Participation Response EffectsShorten heating and cooling timeStirring devicesProduction rateMetallurgy

A powerful gas circulating and stirring device of a vacuum induction sintering furnace. The powerful gas circulating and stirring device comprises a vacuum induction furnace body, an induction heating body arranged in the vacuum induction furnace body, an induction coil wound and sleeved on the induction heating body, a vacuum vortex fan, a closed box and a vacuum valve, and the vacuum vortex fan powerfully stirring gas arranged outside the vacuum induction furnace body is connected with the rear end and the front end of the vacuum induction furnace body by connecting an inlet pipeline and an outlet pipeline of the vacuum vortex fan and communicated with a cavity. The powerful gas circulating and stirring device has quite obvious effect of improving gas participation in reaction, sintering yield is increased, energy consumption is effectively lowered, loading rate is increased, pit furnace cooling time is shortened, and productivity is greatly improved.

Owner:SHENYANG STARLIGHT ADVANCED CERAMICS

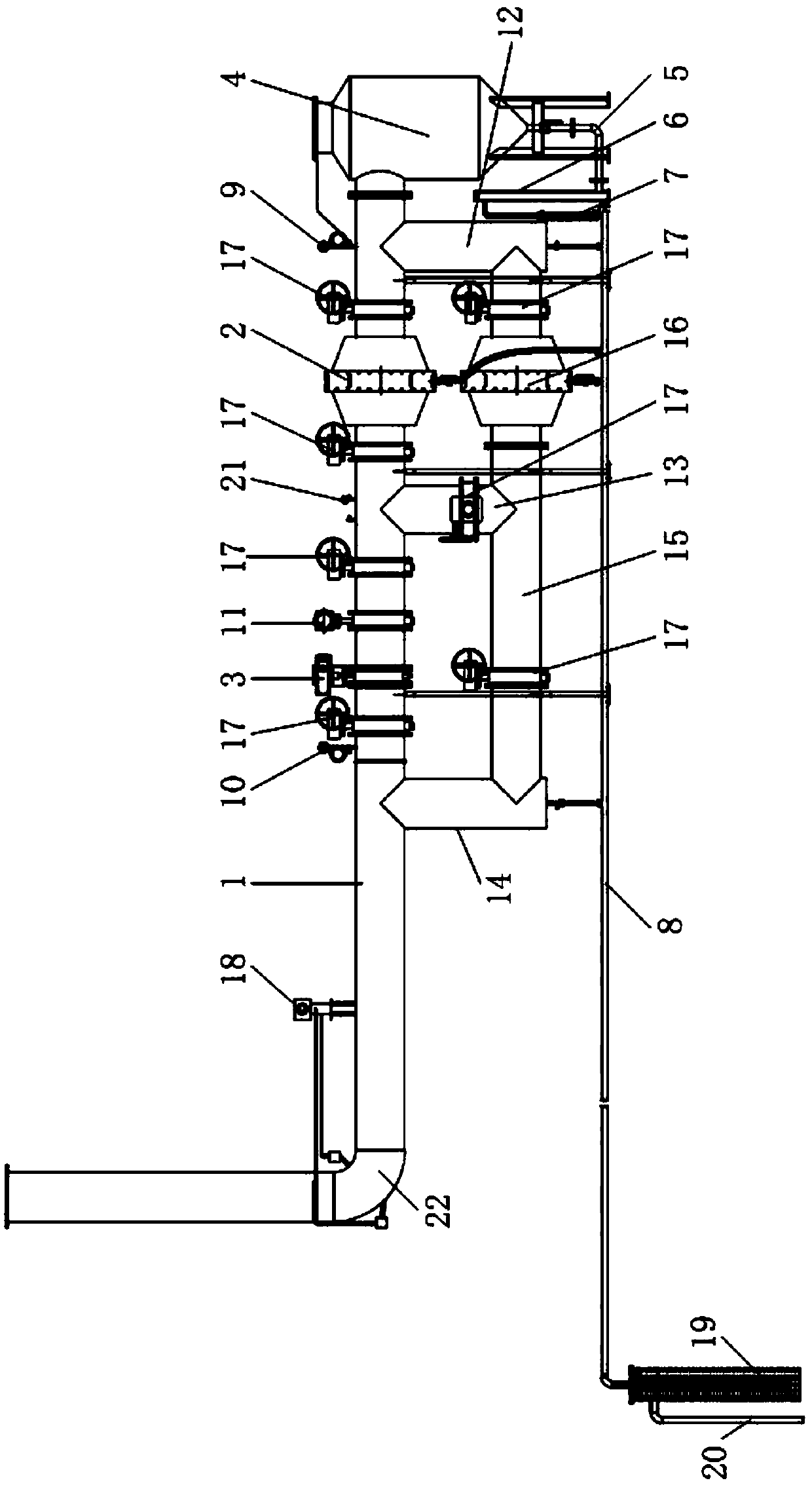

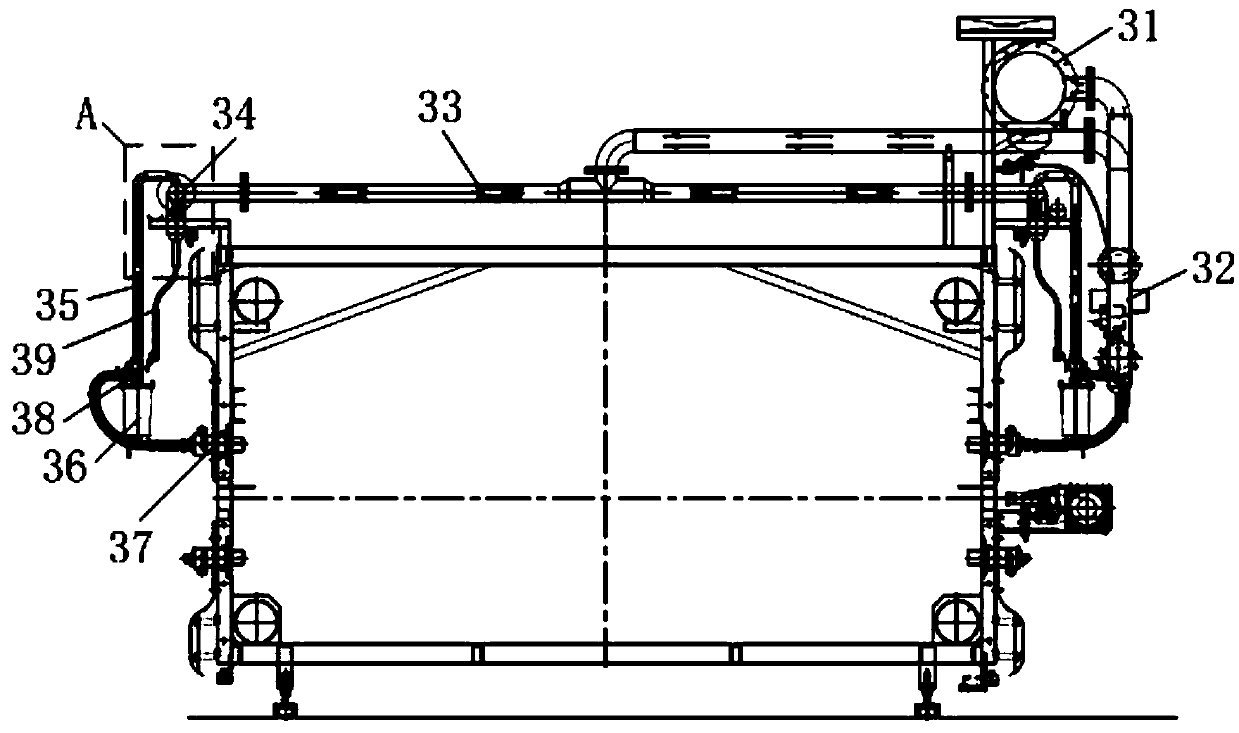

Water gas combustion pipeline structure

PendingCN109681901AEasy to useStable pressureGaseous fuel feeder/distributionGas contaminants removalTemperature controlEngineering

The embodiment of the invention discloses a water gas combustion pipeline structure. The structure comprises a pressure stabilizing and filtering pipe set and a gas distribution pipe set; the pressurestabilizing and filtering pipe set is used for carrying out pressure stabilizing and filtering on water gas supplied by a gas station, the gas distribution pipe set is used for distributing the watergas treated through the pressure stabilizing and filtering pipe set to nozzles of a kiln, through the structure, the pressure stabilizing and filtering pipe set can carry out rapid pressure reducing,pressure stabilizing, water removal and dust removal on the water gas from the gas station and then feeds the water gas to the kiln to be combusted, the gas distribution pipe set can further removalwater in the water gas, finally, the water gas is fed to nozzles in the upper portion and the lower portion of the kiln, and the aim that the nozzles in the upper layer and the lower layer in each combustion pipe set can be subjected to independent temperature control is achieved.

Owner:DLT TECH CO LTD

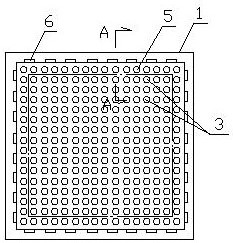

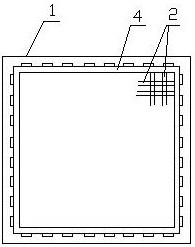

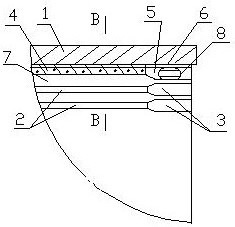

Preparation method of a honeycomb ceramic regenerator with ultra-thick outer wall

ActiveCN110696152BStored heat increasedReduced inner wall thicknessCeramic extrusion diesClay processing apparatusMolding machineRaw material

Owner:JIANGXI BOCENT TEC CO LTD

A kind of ceramic firing method

ActiveCN106830949BSolve the deformationImprove firing pass rateCharge supportsDeformation ProblemStart up

A ceramic firing method includes the steps: a first kiln plate is horizontally arranged in a kiln; a plurality of high-temperature-resistant balls are laid on the first kiln plate; at least two second kiln plates for uniformly supporting at the bottom of a ceramic green body are laid on the plurality of high-temperature-resistant balls, and a gap exists between each adjacent second kiln plates; the ceramic green body is placed on the second kiln plates, and the bottom of the ceramic green body is uniformly supported by the at least two second kiln plates; and the kiln is started up for firing the ceramic green body with the firing temperature of 1100-1300 DEG C for 6-8 hours. According to the method, in the process of firing the ceramic green body, the second kiln plates can relatively move along with the green body shrinkage stress traction, so that the shrinkage stress of the product is released, the deformation problem of a high-end straight-edge product is completely solved, the firing qualified rate of the product is improved, the quality of the product is improved, and the costs are reduced.

Owner:LIXIL AS SANITARY MFG (SHANGHAI) CO LTD

A kind of honeycomb ceramic catalyst carrier and preparation method thereof

ActiveCN109133860BAvoid temperature difference between inside and outsideImprove firing pass rateCatalyst carriersCatalyst activation/preparationCellulosePtru catalyst

The invention belongs to the technical field of honeycomb ceramic materials, and in particular relates to a honeycomb ceramic catalyst carrier and a preparation method thereof. The honeycomb ceramic catalyst carrier of the present invention uses alumina, magnesia, fused quartz, talc, and raw kaolin as inorganic main materials, and adds methyl cellulose, bromobenzene flame retardant, organosilicon polyether copolymer, soybean oil And water as a catalyst, especially the addition of low-smoke, low-toxic bromobenzene flame retardant, is a functional additive that imparts flame retardancy to flammable polymers. It can provide flame retardancy of polymer materials and can effectively inhibit The organic matter in the honeycomb ceramic carrier burns, avoiding the temperature difference between the inside and outside of the carrier, and improving the firing pass rate; at the same time, the inhibitory effect of the flame retardant can make the honeycomb ceramic carrier heat up rapidly during the firing process, which helps to improve production efficiency, and has the advantages of energy saving and environmental protection. Advantage.

Owner:SHANDONG AOFU ENVIRONMENTAL PROTECTION SCI & TECH

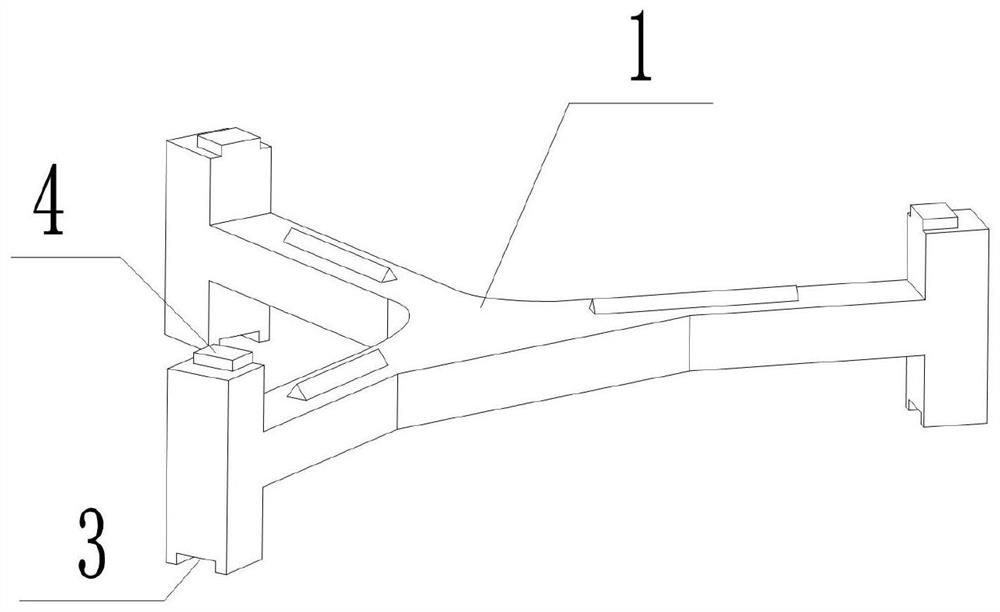

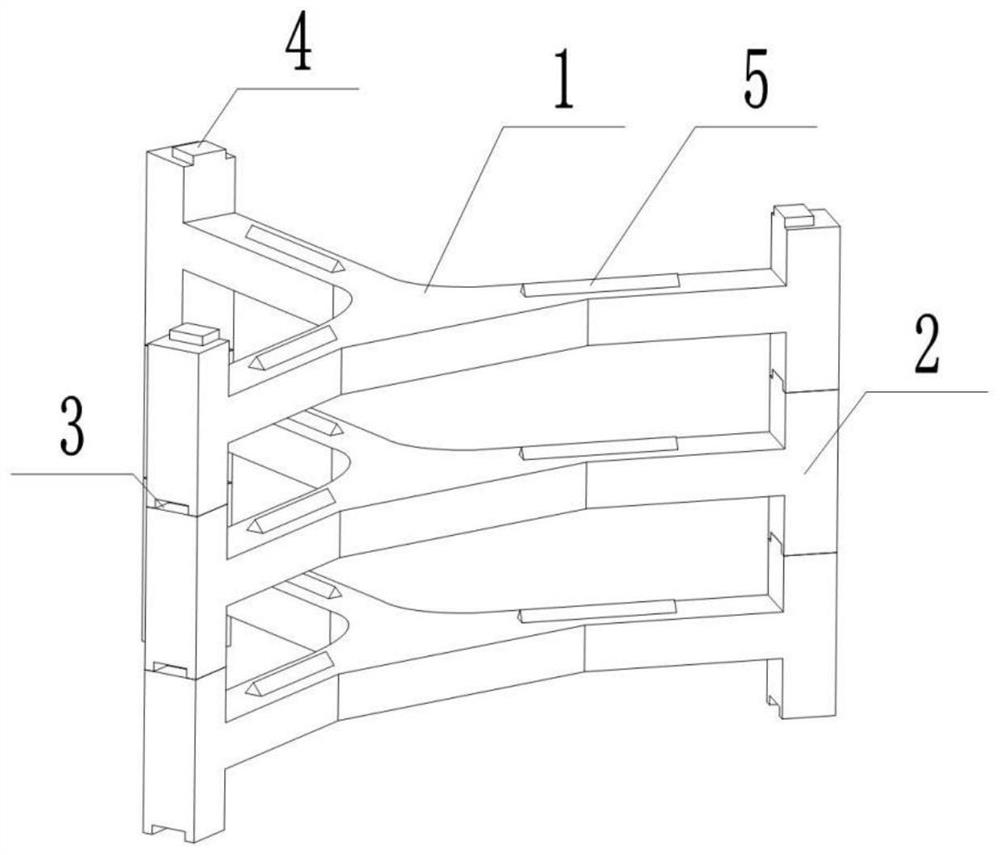

Energy-saving supporting piece for domestic ceramic firing and preparation method of supporting piece

ActiveCN112611226AImproved thermal shock stabilityImprove corrosion resistanceCharge supportsCeramic materials productionCeramicKiln

The invention relates to an energy-saving supporting piece for domestic ceramic firing and a preparation method of the supporting piece. The supporting piece comprises a plurality of Y-shaped brackets which are stacked together up and down. The preparation method of the supporting piece comprises the following steps: a, preparation of raw materials; b, mixing and grinding; c, ageing; d, manufacturing of bracket blanks; e, drying; and f firing. The Y-shaped brackets are provided with supporting legs, can independently support domestic ceramic, and are light in weight and low in self heat absorption energy consumption, heat exchange in a kiln is uniform, the ceramic firing percent of pass is high, energy-saving fast firing is realized, loading and stacking are stable, the domestic ceramic loading amount in the same space is large, workers can load and unload the domestic ceramic conveniently and quickly, three protruding edges are used for supporting to-be-fired ceramic products, the contact area is small, and meanwhile, the supporting piece contains zircon sand, and the zircon sand can prevent glaze adhesion, so that glaze adhesion damage is reduced, and the overall attractiveness of the ceramic is improved. In the using process, the supporting piece is not prone to deformation and protects to-be-fired ceramic pieces against deformation and damage.

Owner:天津创导热材料有限公司

Low-expansion high-strength thin-walled cordierite honeycomb ceramics and preparation method thereof

ActiveCN108178652BLarge specific surface areaHigh activityCeramicwareThermal dilatationAluminium hydroxide

The invention discloses low-expansion high-strength thin-wall cordierite honeycomb ceramic and a preparation method thereof. Content of cordierite in ceramic is greater than 95%, and the ceramic is prepared from the following chemical components in percentage by mass: 47.5-52.5% of SiO2, 32.7-37.7% of Al2O3 and 11.5-15.5% of MgO; porosity of honeycomb ceramic is greater than or equal to 16%, and awater absorption rate is 14%-30%; bending strength of the honeycomb ceramic is greater than or equal to 1.6 MPa; and a thermal expansion coefficient at the room temperature of 800 DEG C is smaller than or equal to 5*10<-7> / DEG C. According to the preparation method, aluminum hydroxide prepared by a special preparation method is led, so that the product has low CTE (Coefficient of Thermal Expansion), high strength and low cost.

Owner:SHANDONG AOFU ENVIRONMENTAL PROTECTION SCI & TECH

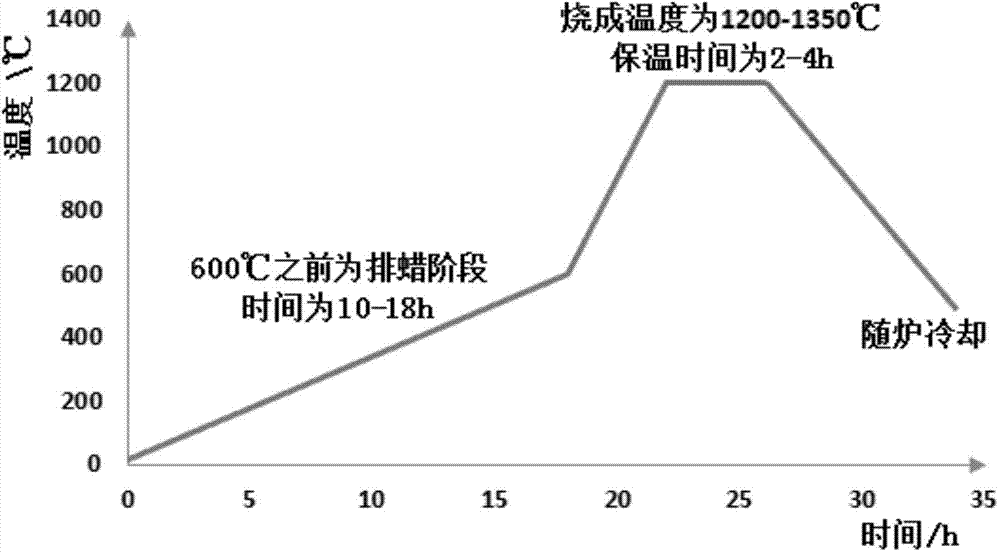

Improved ceramic core firing method

The invention discloses an improved ceramic core firing method. The technical problems of long time, high possibility of bulging, cracking and trace formation and the like of the conventional ceramic core in a wax removal stage are mainly solved. According to the method, n-heptane is used for dissolving and removing a part of a plasticizer in a ceramic core green body, and an open passage facilitating discharging of the plasticizer is formed on the premise of ensuring sufficient green body strength; in a later firing process, the plasticizer can be easily discharged from the formed open passage, so that the aims of shortening firing time and reducing the defects of a wax removal process are fulfilled; the firing cycle can be remarkably shortened, the firing time can be shortened to be within 10 hours, the firing qualified rate of the product can be increased, and the method has an important promotion effect on energy resource saving, cost reduction and expansion of the application range of the ceramic core.

Owner:辽宁航安型芯科技股份有限公司

Light brick and production method thereof

InactiveCN114477955AAchieve recyclingSave resourcesCeramic materials productionClaywaresBrickMold removal

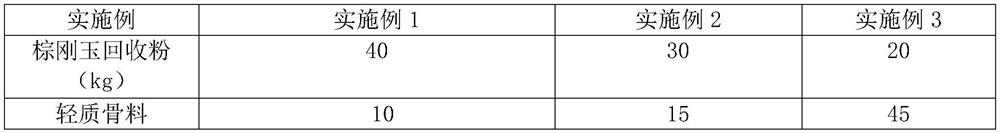

The invention relates to the field of light bricks, in particular to a light brick and a production method thereof.The light brick comprises 20-40 parts of brown fused alumina recycled powder, 10-45 parts of light aggregate, 30-50 parts of dry ash and 5-15 parts of light aggregate; the brown fused alumina recovery powder is prepared from the following components in parts by weight: 29 to 31 parts of Al2O3, 38 to 39 parts of SiO2, 16 to 17 parts of K2O, 3 to 4 parts of Fe2O3, 0.5 to 1 part of TiO2, 0.5 to 1 part of MgO, 0.1 to 0.2 part of CaO and 0.5 to 1 part of Na2O; the light brick production method comprises the following steps of A, feeding, B, stirring, C, pouring, D, demolding, E, cutting, F, stacking and G, sintering. According to the scheme, the brown fused alumina powder is recycled, and meanwhile, the performance of the light brick is improved.

Owner:重庆市赛特刚玉有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com