Vacuum induction sintering furnace gas strong circulation stirring device

A vacuum induction furnace and vacuum induction technology are applied in the directions of stirring devices, furnaces, and furnace components to achieve the effects of improving productivity, reducing energy consumption, and improving firing qualification rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

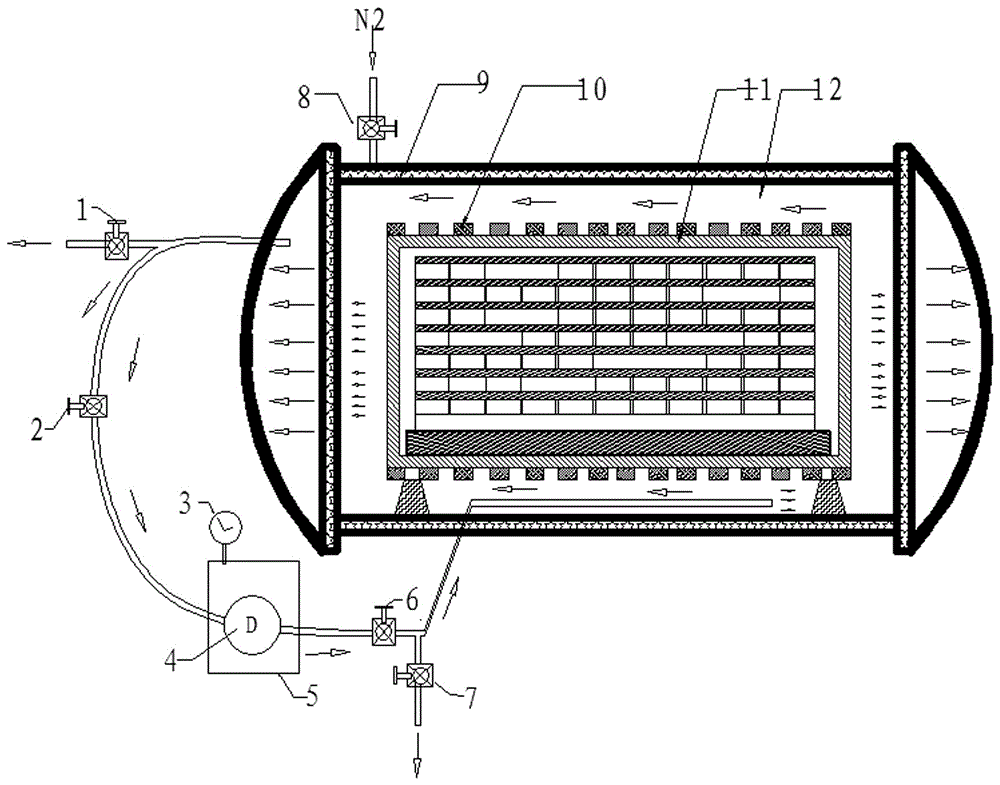

[0012] Vacuum induction sintering furnace gas strong circulation stirring device, including vacuum induction furnace body 9, induction heating element 11 set in the vacuum induction furnace body, induction coil 10 wrapped around the induction heating element, vacuum vortex fan 4, closed box 5 and vacuum valve. The vacuum induction furnace body 9 is equipped with a vacuum vortex blower 4 that strongly stirs the gas, and is connected to the rear and front of the vacuum induction furnace body 9 by connecting the inlet pipeline and the outlet pipeline of the vacuum vortex blower 4 respectively, and is connected to the chamber Body 12 communicates. The inlet pipeline of the vacuum vortex fan is equipped with a first vacuum valve 1 for exhaust and a second vacuum valve 2 for suction control, and the outlet pipeline is equipped with a third vacuum valve 6 for air intake control and a fourth vacuum valve for venting 7 and the fifth vacuum valve 8 on the nitrogen filling pipeline. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com