Water gas combustion pipeline structure

A combustion tube, water gas technology, applied in combustion methods, combustion equipment, gaseous fuel supply/distribution, etc., can solve the problems of SIC combustion chamber rupture, pressure fluctuation, corrosion, etc., to ensure normal use, improve pass rate, and pressure stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

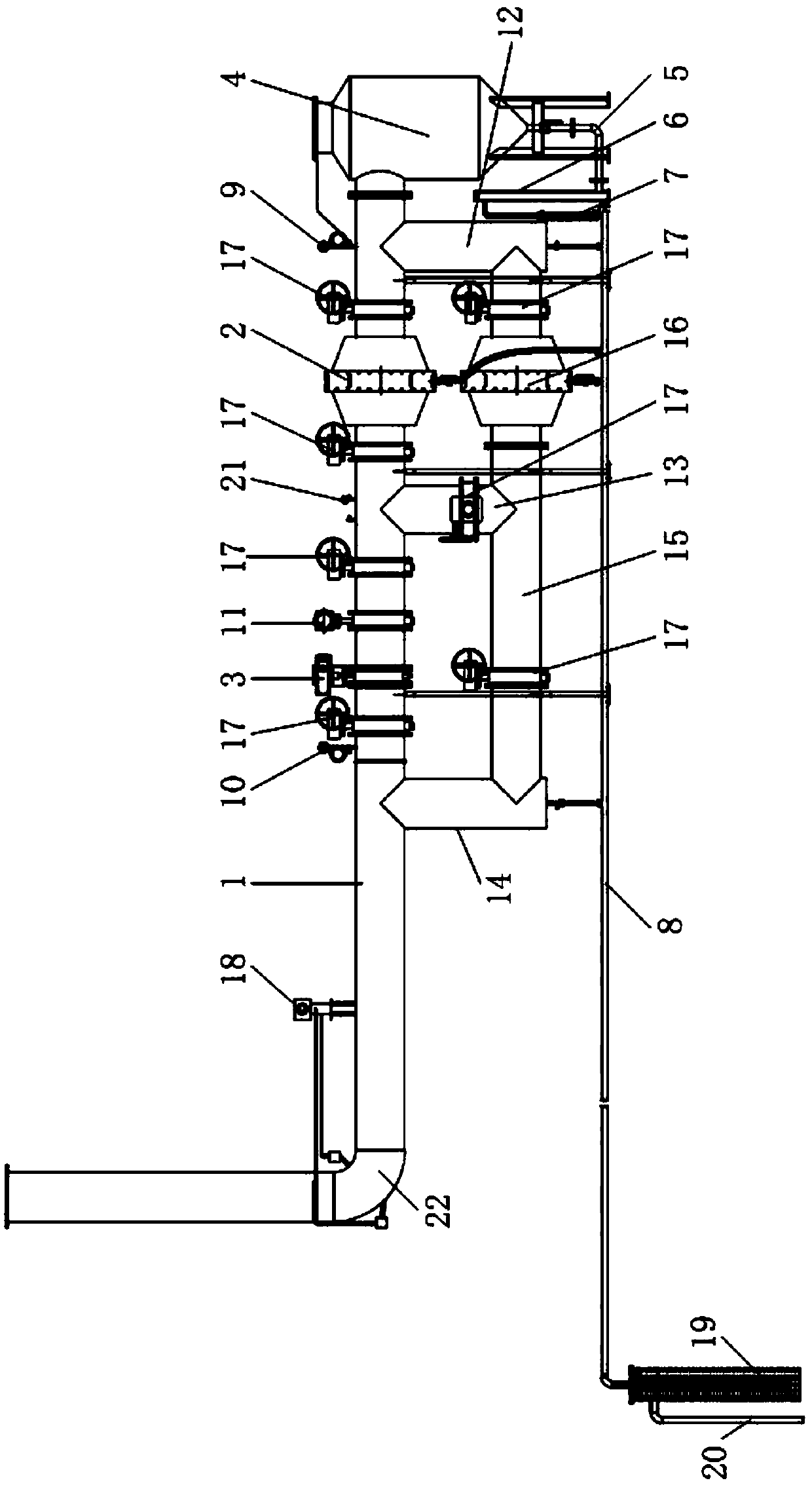

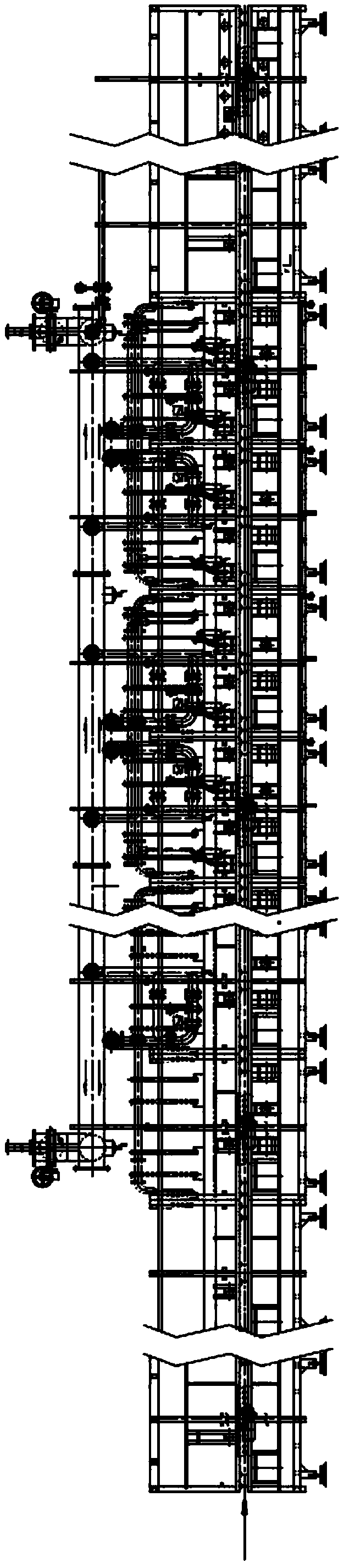

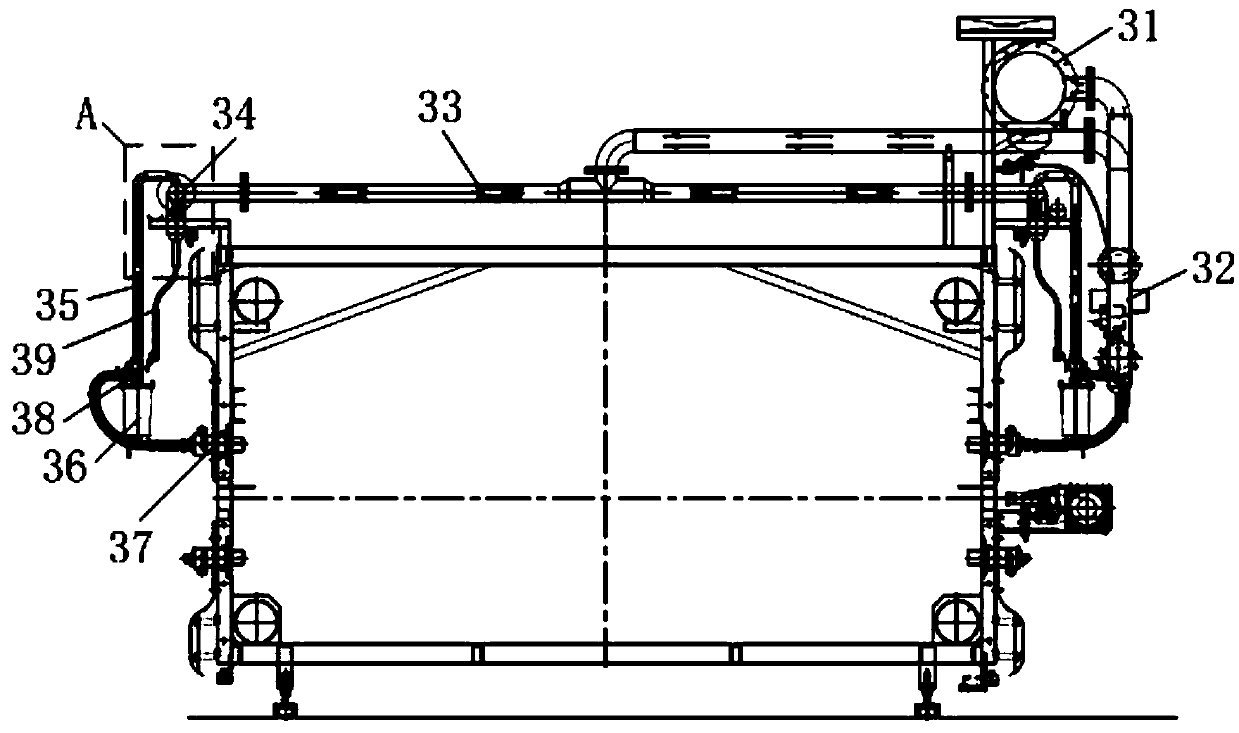

[0036] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings. It is only stated here that the words for directions such as up, down, left, right, front, back, inside, and outside that appear or will appear in the text of the present invention are only based on the accompanying drawings of the present invention, and are not specific to the present invention. limited.

[0037] Such as figure 2 As shown, the total length of the kiln in the present invention is composed of a plurality of modular sections (or single-section kilns), and the length of each modular section is 2.1m / section, and the inner width is determined according to product specifications, process characteristics or customer requirements. The upper and lower parts of each module section (the roller kiln structure can be called roller upper or lower; or the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com