Low-expansion high-strength thin-wall cordierite honeycomb ceramic and preparation method thereof

A cordierite honeycomb and honeycomb ceramic technology, applied in ceramic products, other household appliances, applications, etc., can solve the problems of reducing the qualified rate of the sintering process of the products, increasing the production cost, reducing the strength of the products, etc. The effect of reducing cracking and reducing CTE

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] To further illustrate the present invention, the following examples are provided to provide those skilled in the art with a complete illustration and description of the honeycomb ceramic articles and preparation methods that constitute the requirements herein. These examples are only used to illustrate the present invention, and do not limit the scope of the present invention that the inventors consider.

[0052] Percentages refer to mass percent unless otherwise indicated.

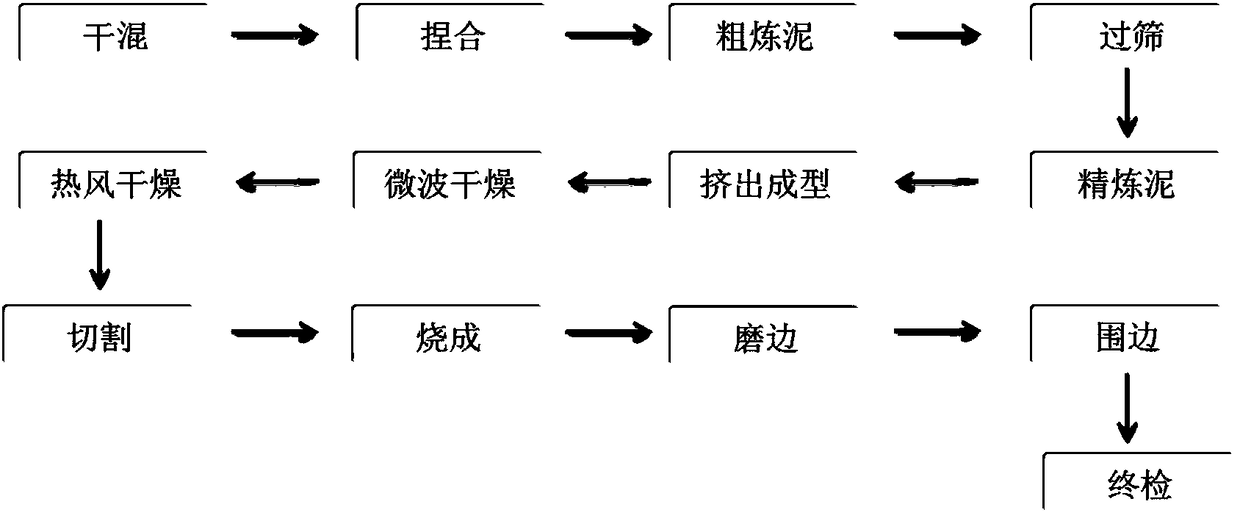

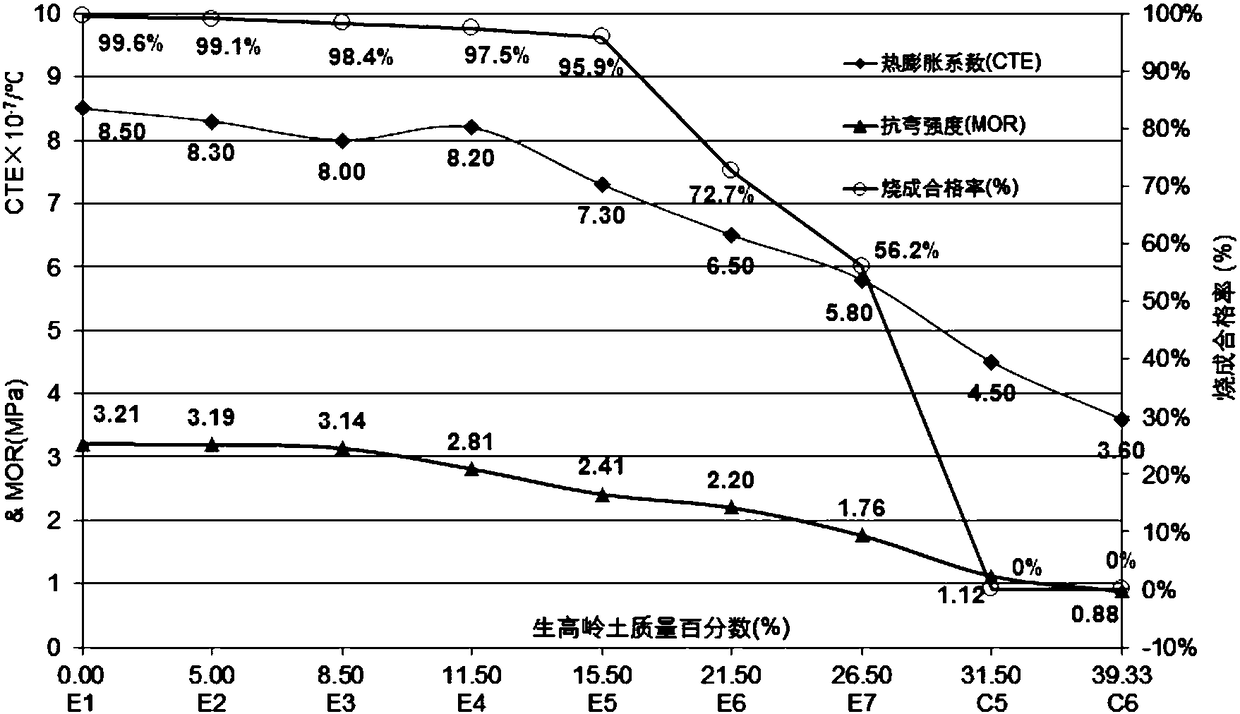

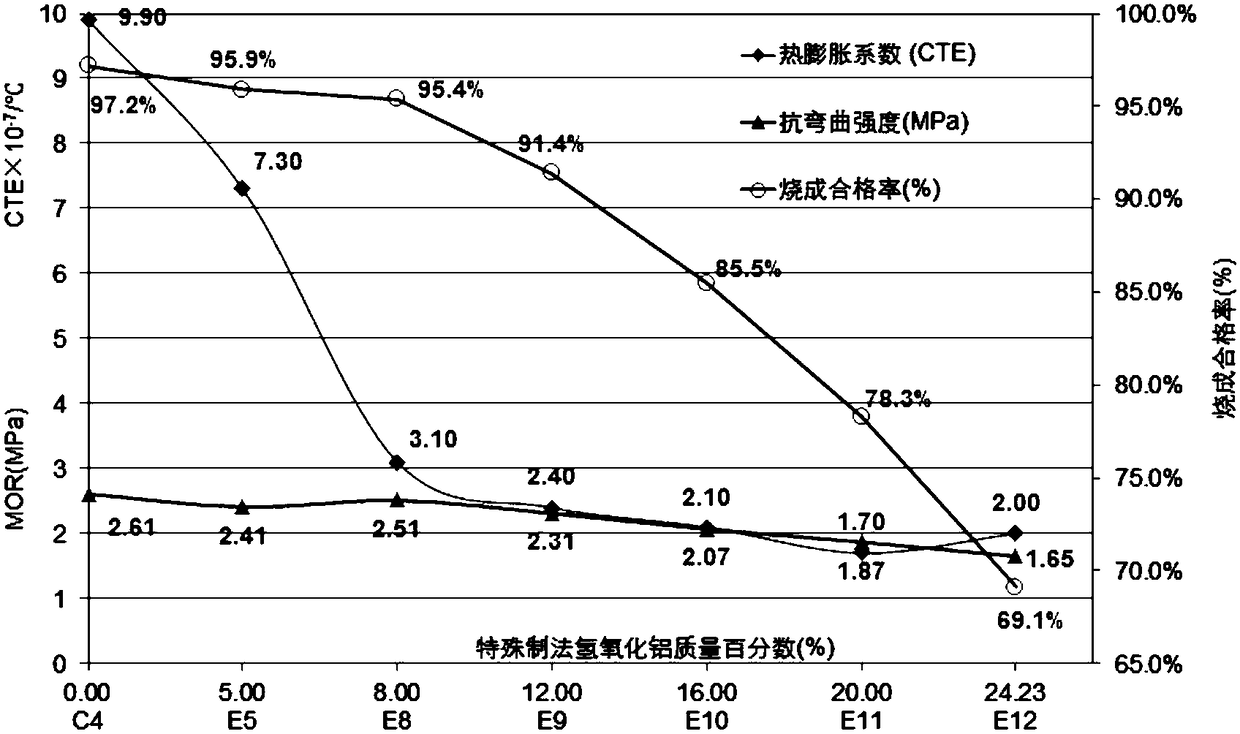

[0053] The embodiments of the present invention and their specific properties are listed in Table 1, numbered E1-E25, and the comparative examples of the present invention and their specific properties are listed in Table 2, numbered C1-C8. The preparation method of embodiment and comparative example all is that inorganic raw material and 5 mass % hydroxypropyl cellulose ethers are mixed homogeneously, then add 1 mass % lubricant polyether polyol, 2 mass % surfactant stearic acid and 25 mass % Mas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com