Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Improve extrusion stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

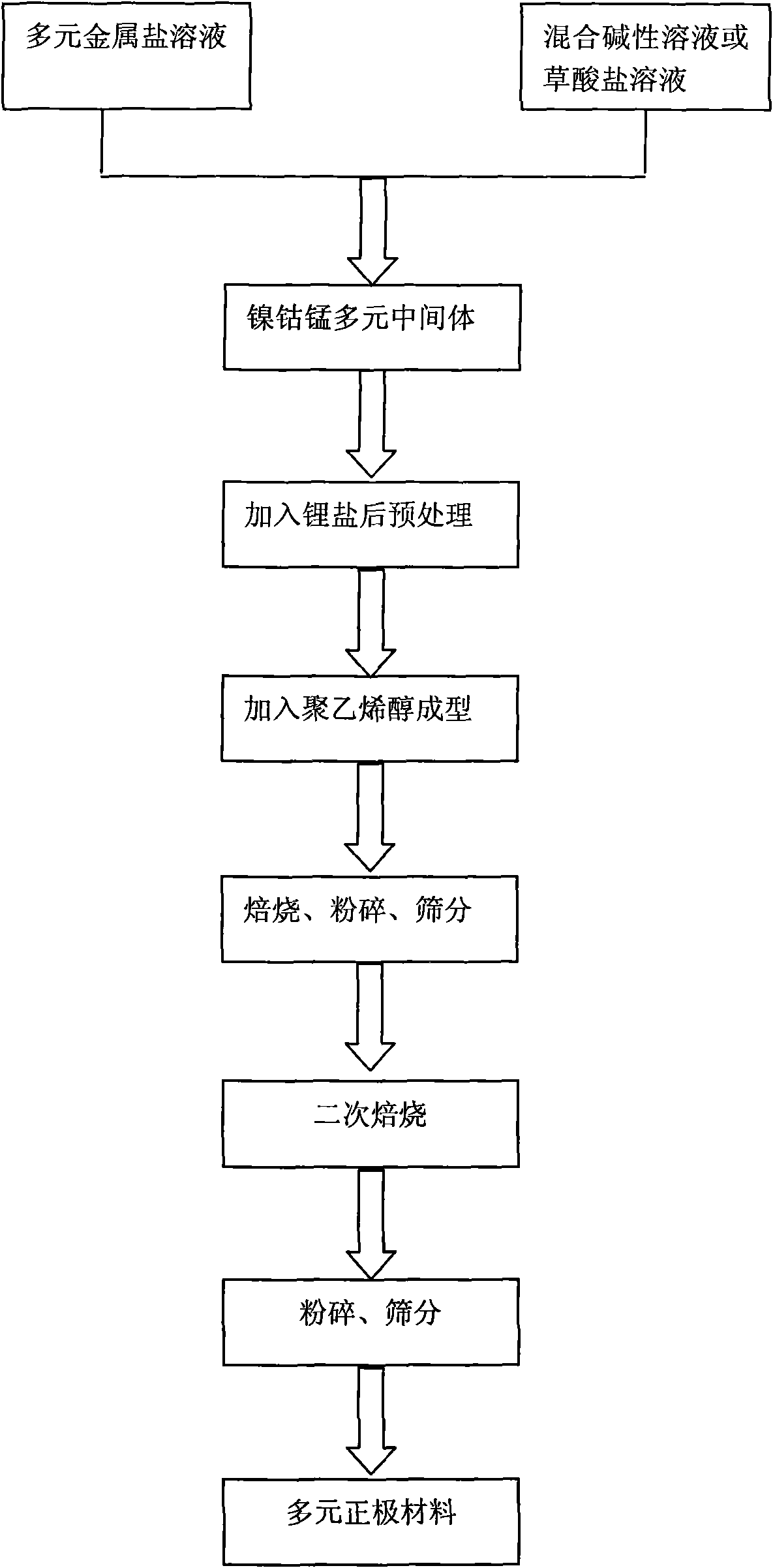

Nickel-cobalt-manganese multi-doped lithium ion battery cathode material and preparation method thereof

InactiveCN101621125AIncrease compaction densityLow hygroscopicityElectrode manufacturing processesSecondary cellsChemical synthesisPolyvinyl alcohol

The invention discloses a nickel-cobalt-manganese multi-doped lithium ion battery cathode material with high compacted density and a preparation method thereof, belonging to the technical field of energy materials. The preparation method of the battery cathode material comprises the following steps: preparing a nickel-cobalt-manganese multi-doped intermediate by a coprecipitation method or a chemical synthesis method; mixing the multi-doped intermediate with lithium salts; after pretreatment, adding polyvinyl alcohol to the obtained mixture; uniformly mixing the polyvinyl alcohol and the mixture and then pressing the mixture into a cake; roasting the cake at 800-950 DEG C; taking the roasted cake out and carrying out cooling, pulverization and 400 meshes of sieving on the cake; then roasting obtained powder at 700-800 DEG C, taking the powder out and carrying out cooling, pulverization and sieving on the powder to obtain the battery cathode material. Granules of the battery cathode material are non-agglomerated single-crystal grains with a grain diameter of 0.6-30 microns, a chemical formula of LiNixCoyMnzM[(1-x-y-z)]O2, a degree of compaction of 3.5-3.7g / cm<3> and a primary discharge capacity of 150-165mAh / g, thus the battery cathode material has good cycle performance and higher safety performance.

Owner:CHENGDU JINGYUAN NEW MATERIALS TECH

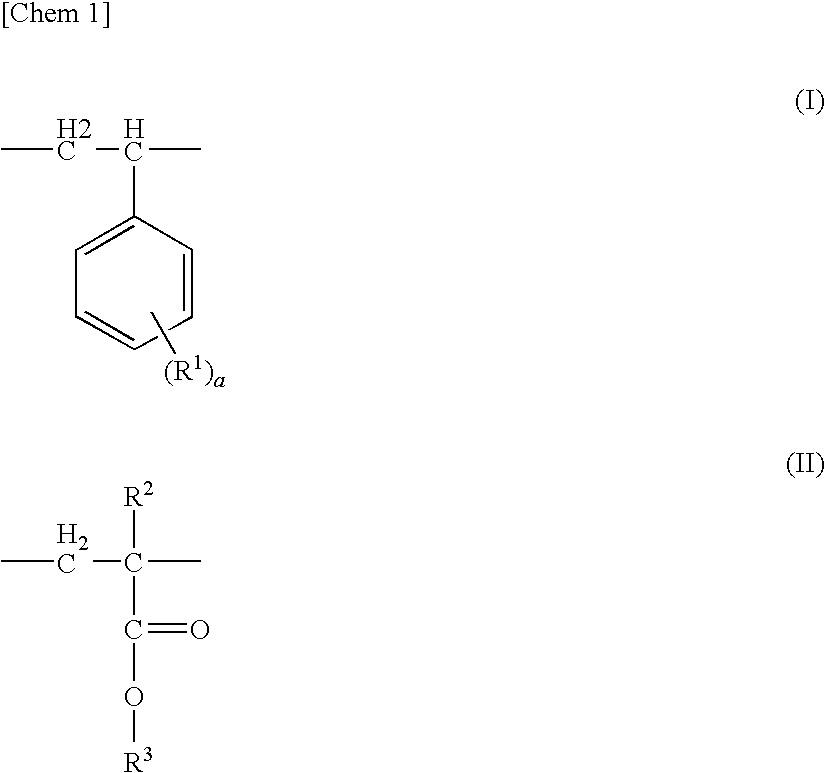

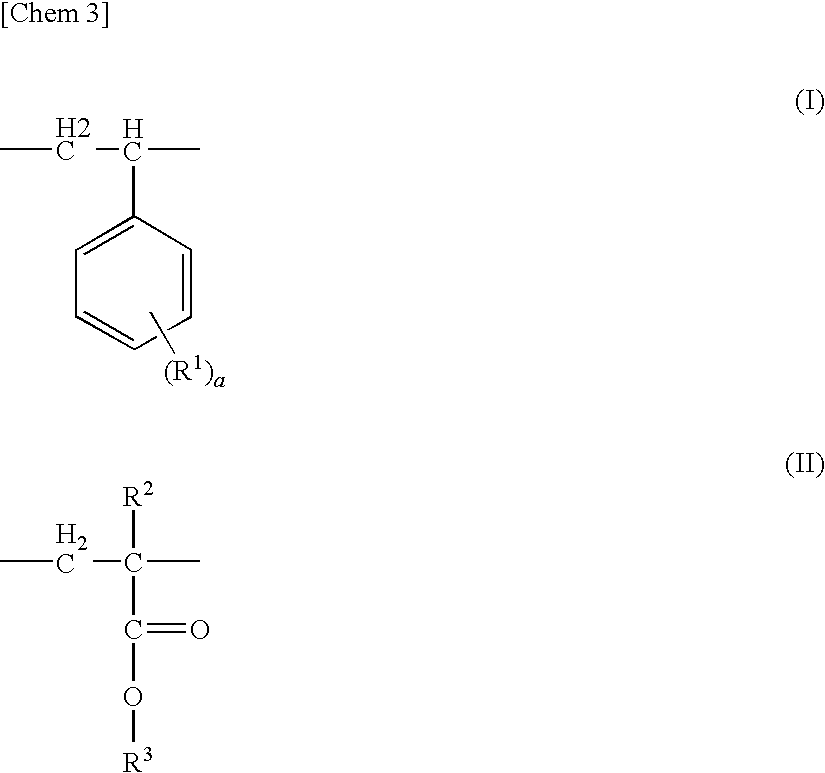

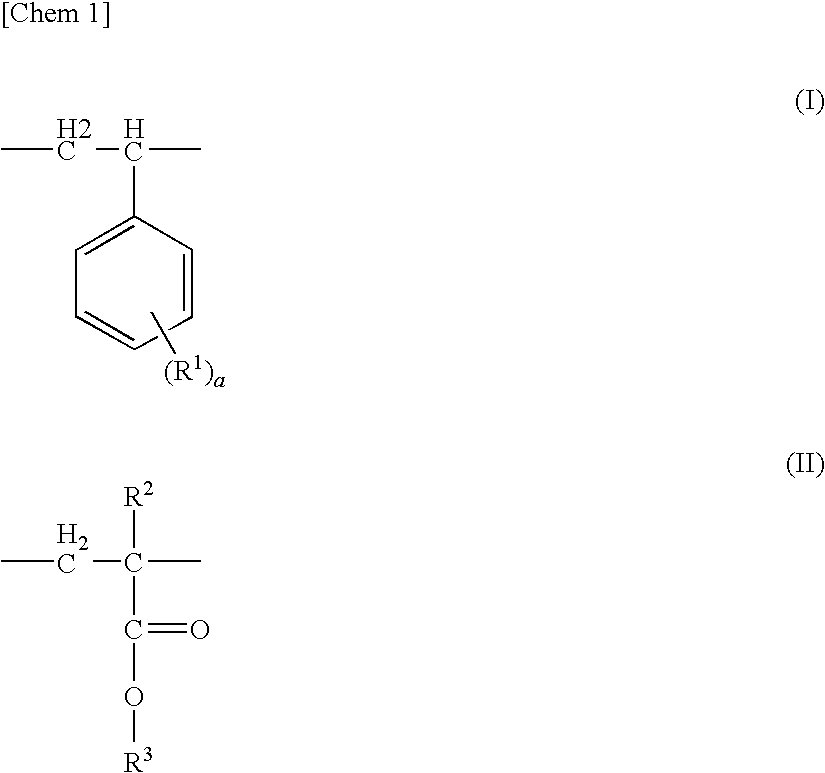

Method for producing ethylene-vinyl alcohol copolymer resin

InactiveUS6838029B2Good effectWell mixedColloidal chemistry detailsOrganic chemistryEthylene vinyl alcohol copolymer

Owner:KURARAY CO LTD

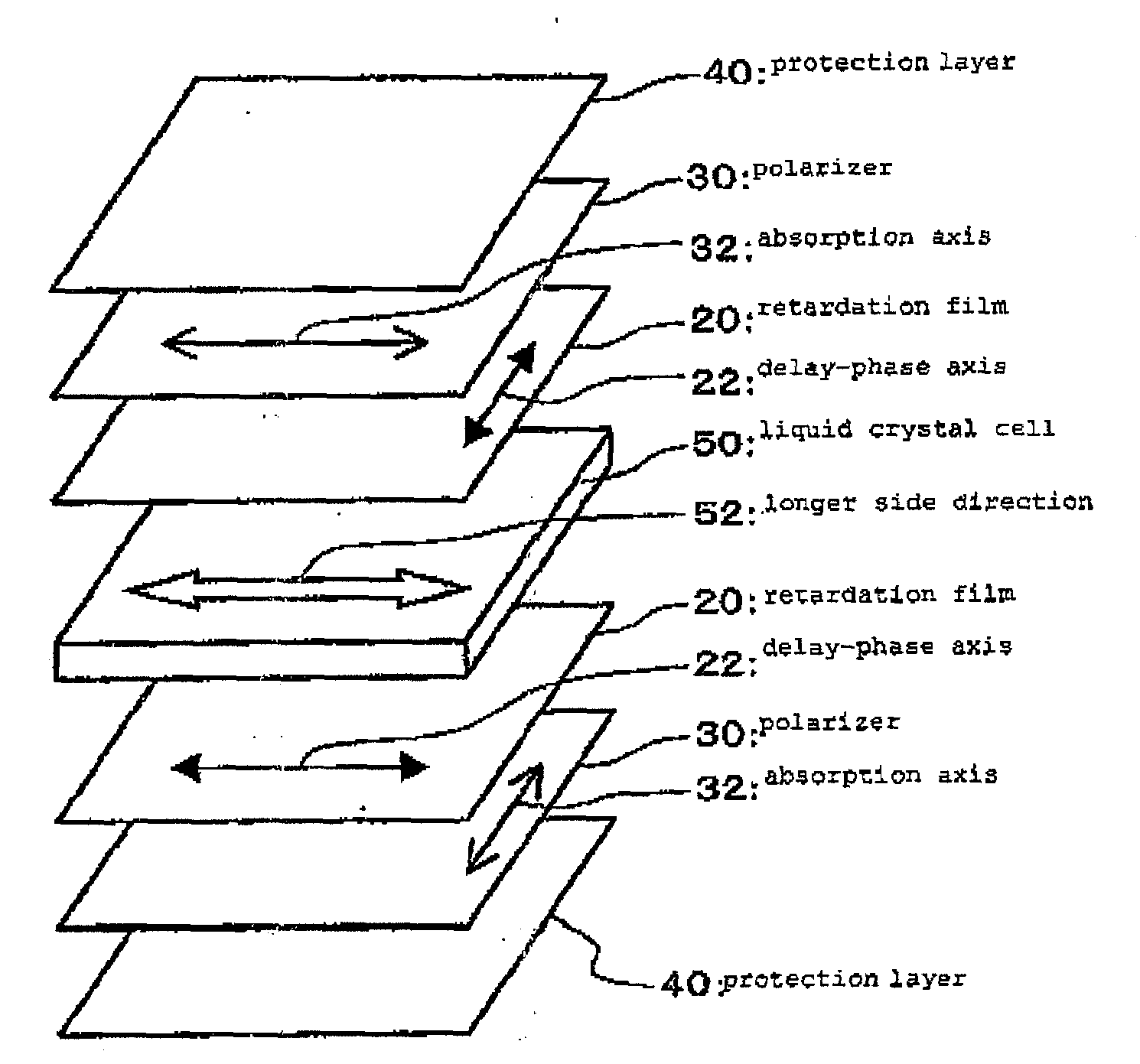

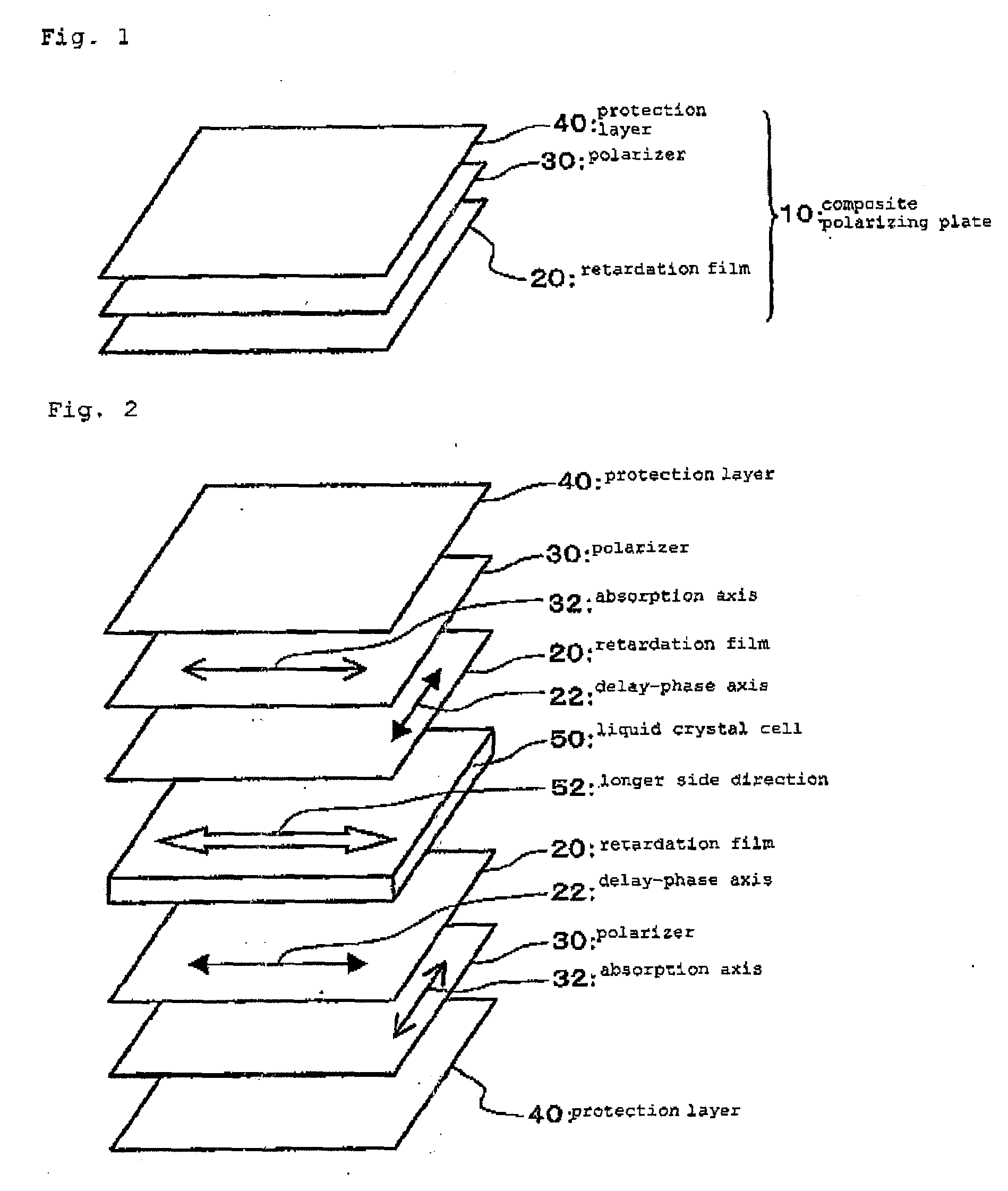

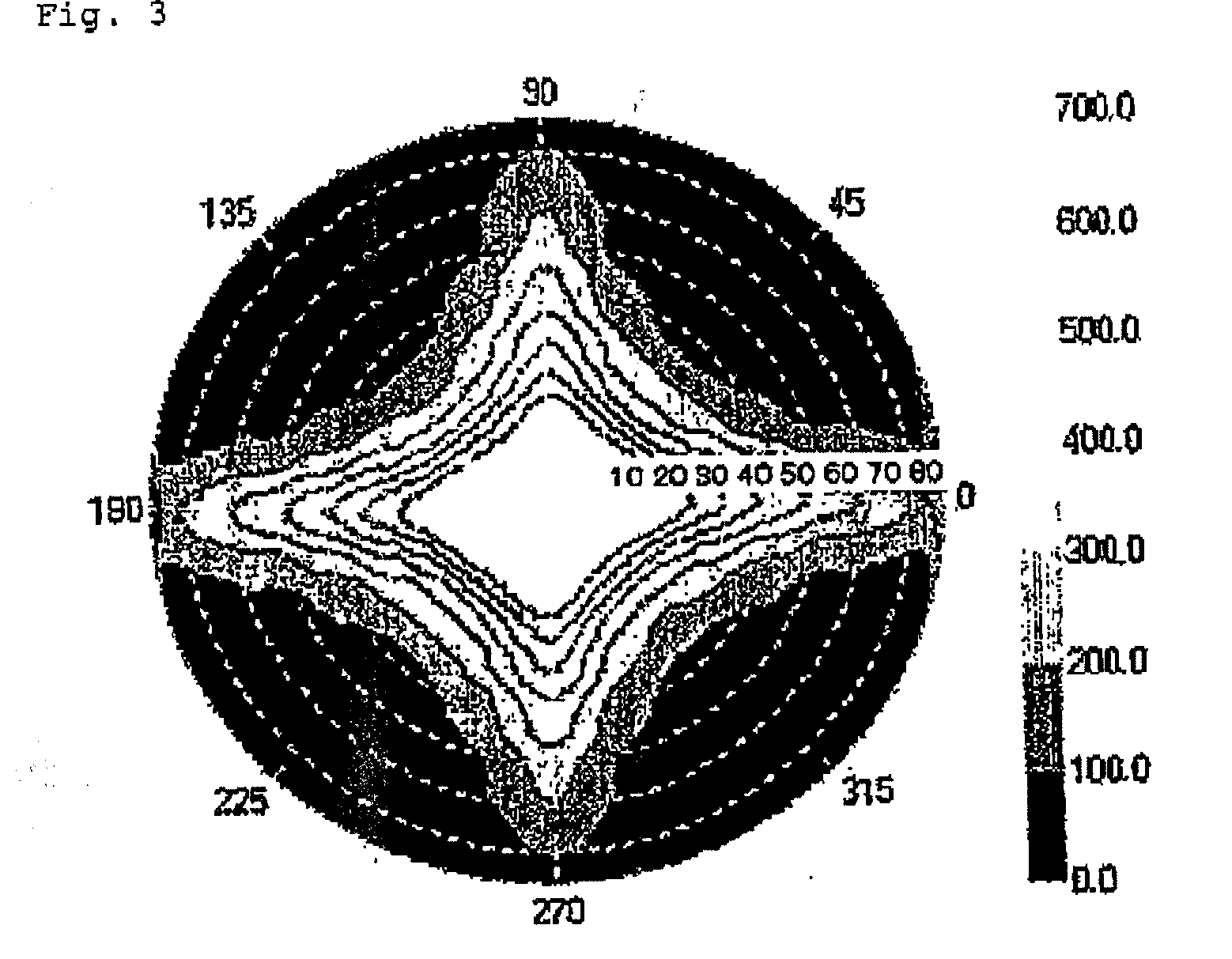

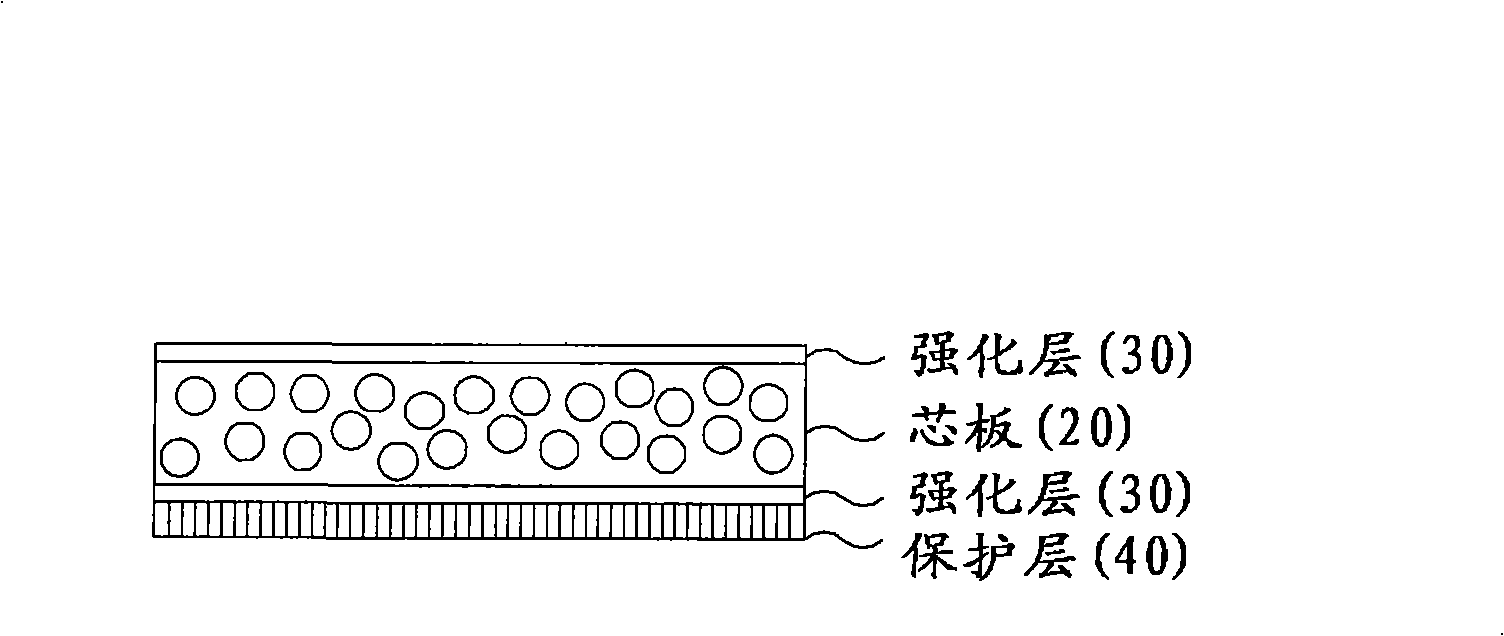

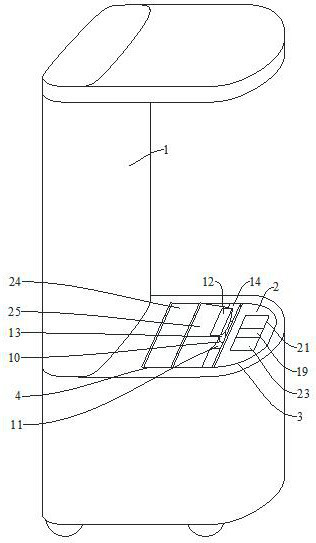

Composite polarizing plate and liquid crystal display using the same

InactiveUS20090066888A1Suppression of deteriorationSuppression of decompositionPolarising elementsNon-linear opticsPolyvinyl alcoholPolarizer

Disclosed is a composite polarizing plate wherein a transparent protection layer (40) is formed on one side of a polarizer (30) which is composed of a polyvinyl alcohol resin and a retardation film (20) composed of a polypropylene resin is bonded to the other side of the polarizer (30), which is opposite to the side on which the transparent protection layer (40) is formed. The retardation film (20) composed of a polypropylene resin may be made of a homopolymer of propylene, or alternatively made of a copolymer with another monomer which mainly consists of propylene. A liquid crystal display is obtained by arranging this composite polarizing plate on at least one side of a liquid crystal cell (50).

Owner:SUMITOMO CHEM CO LTD

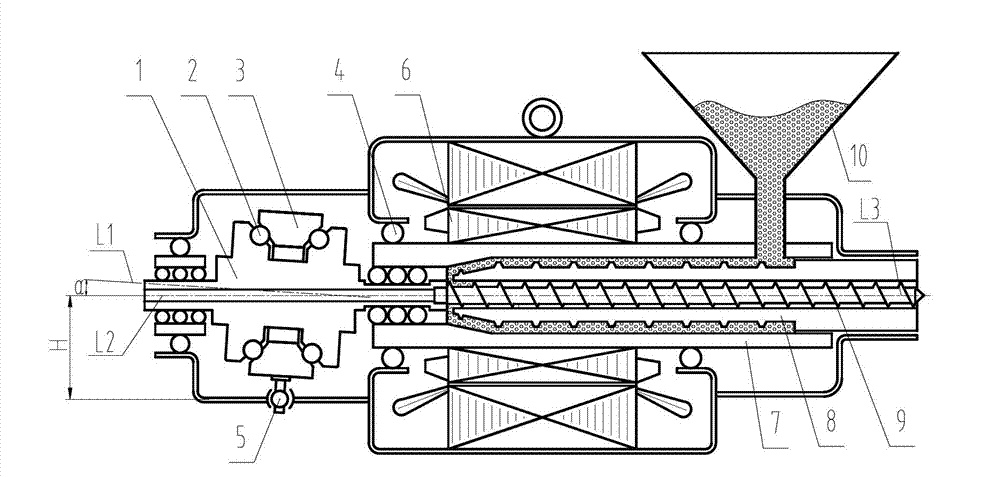

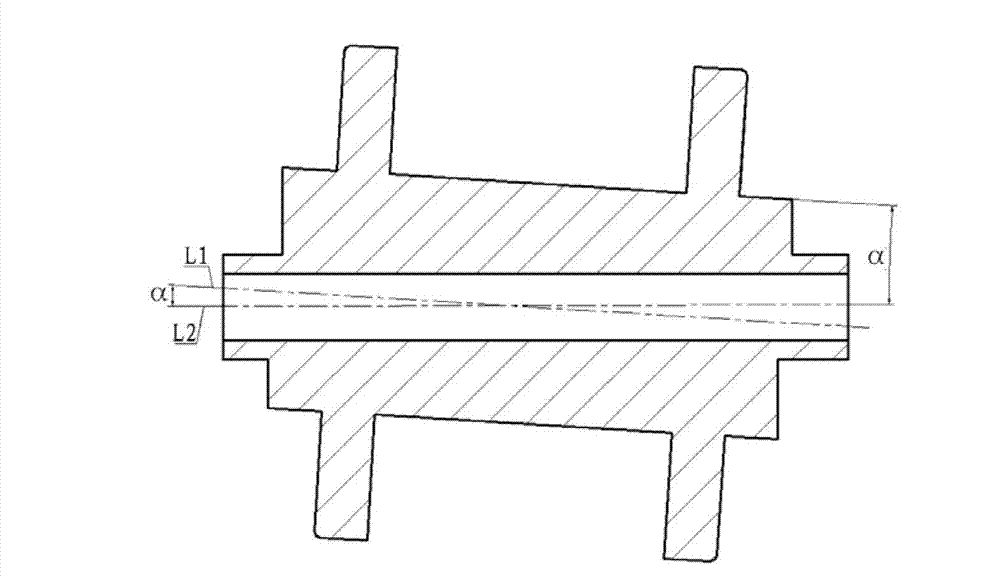

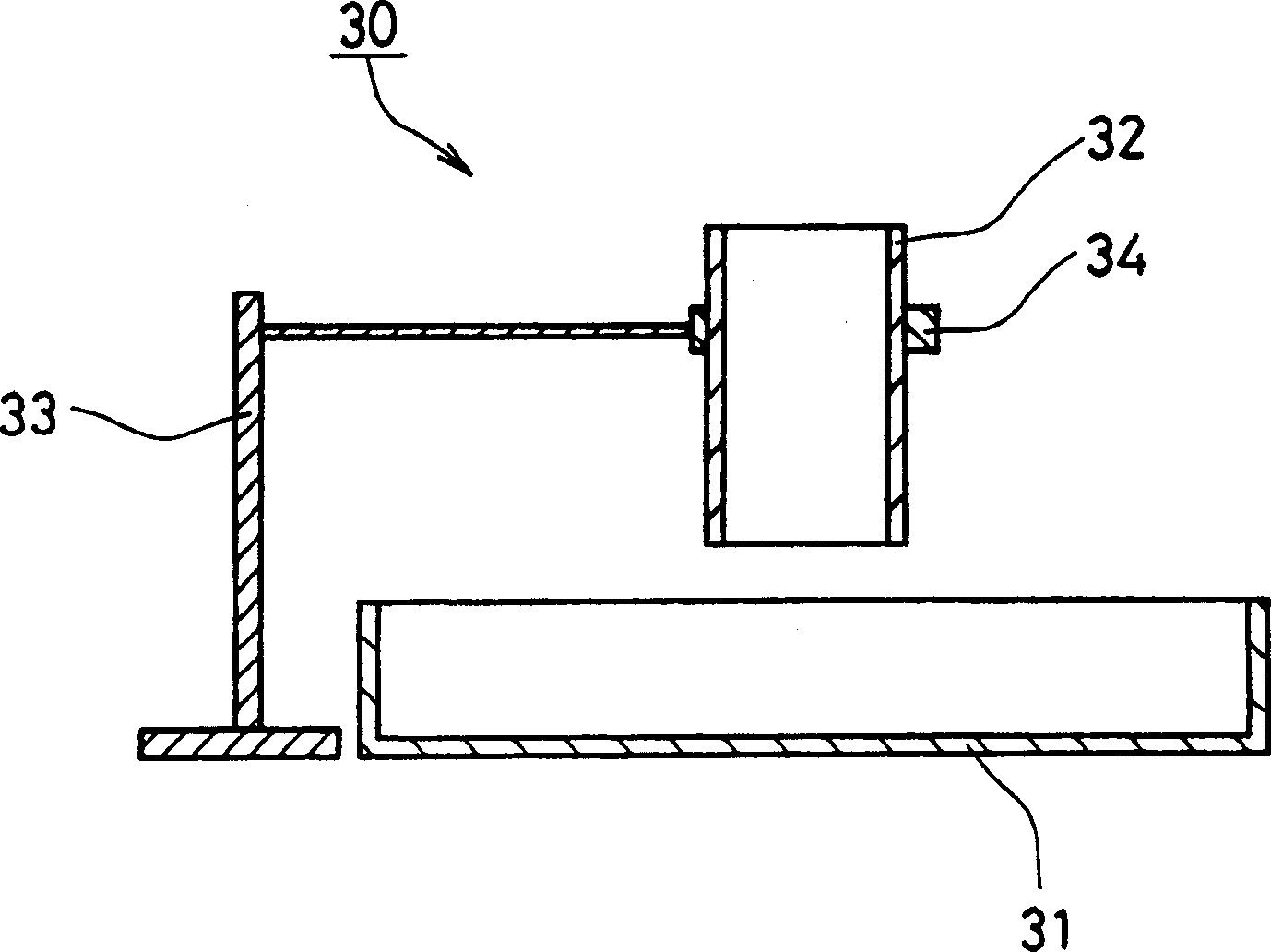

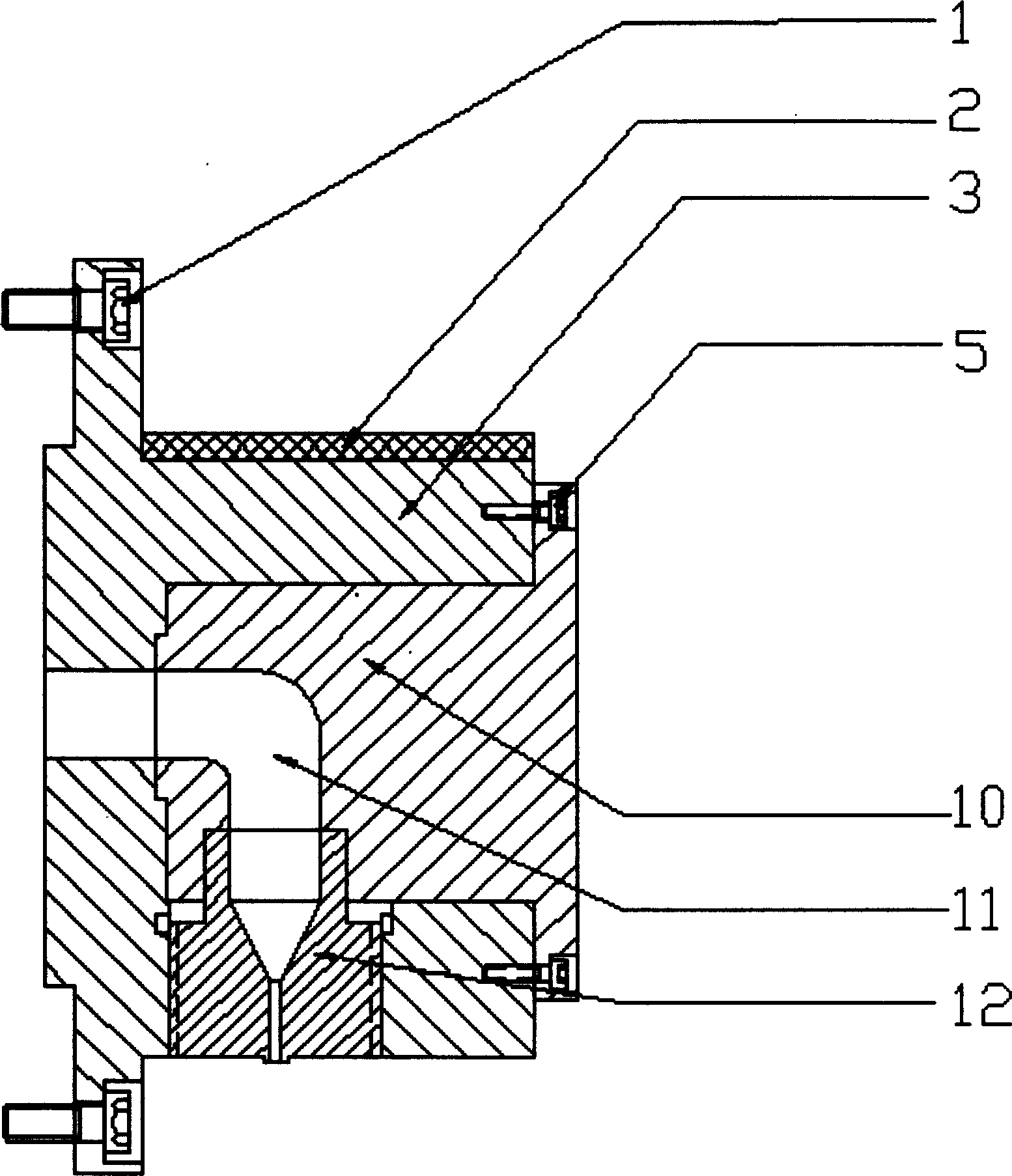

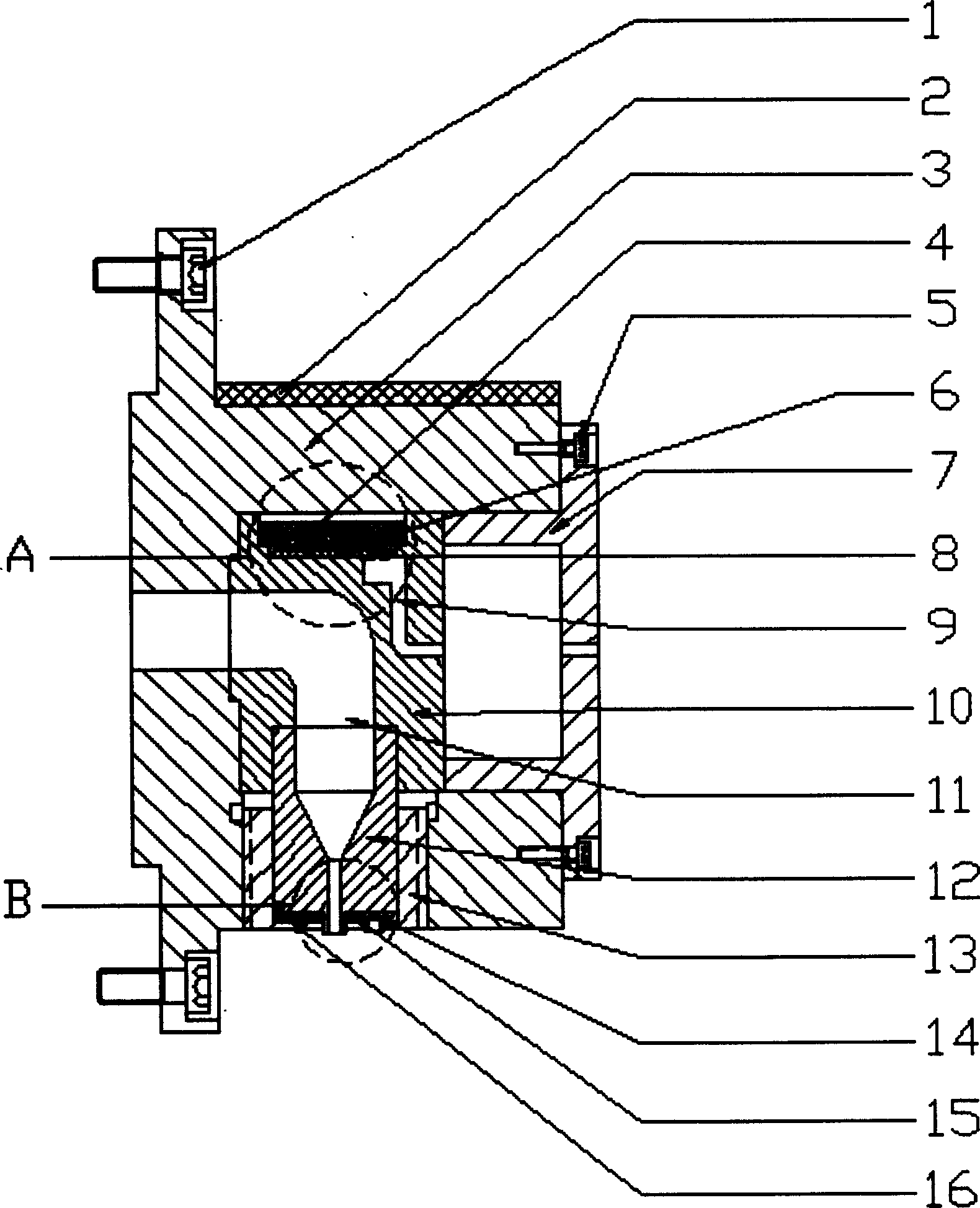

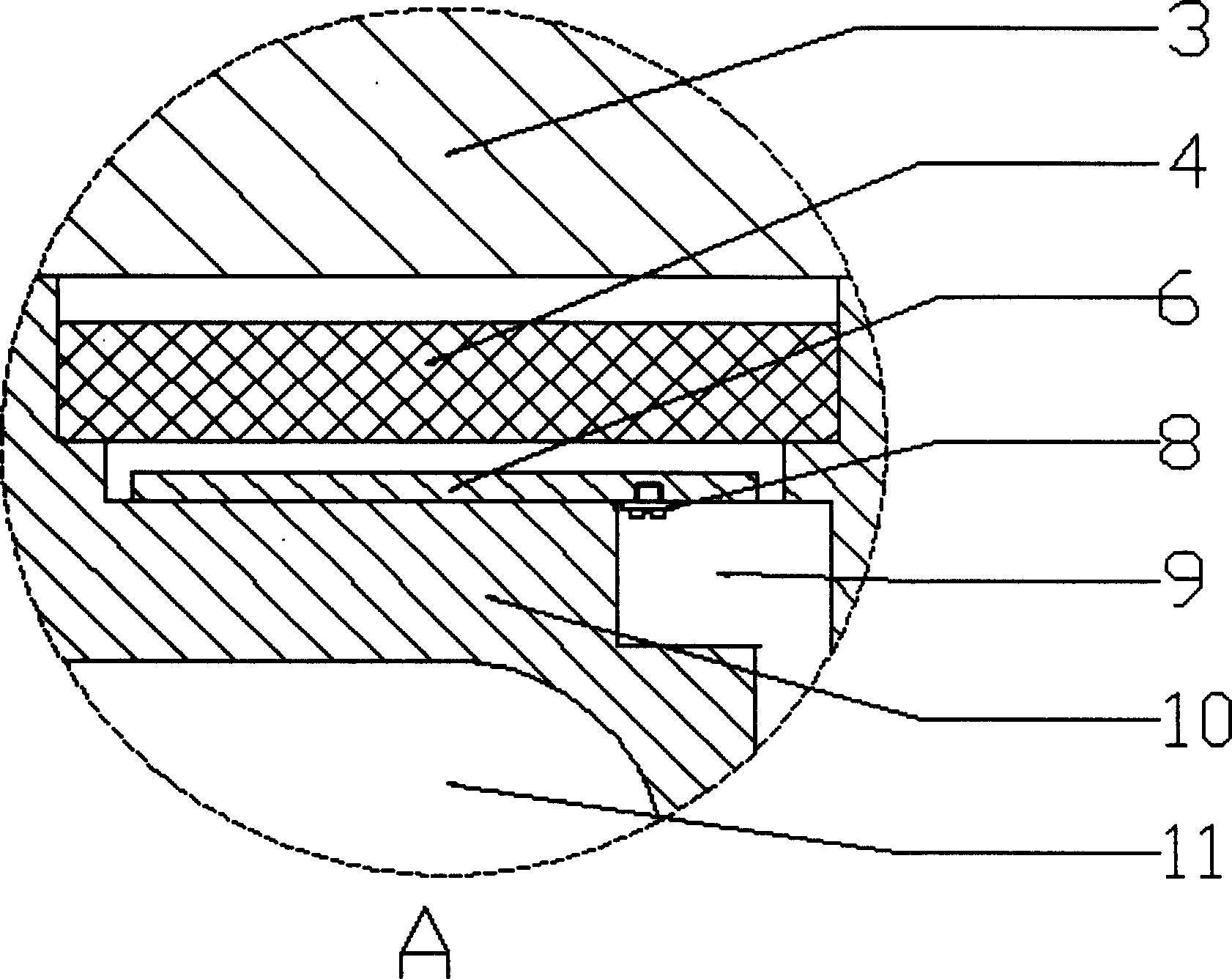

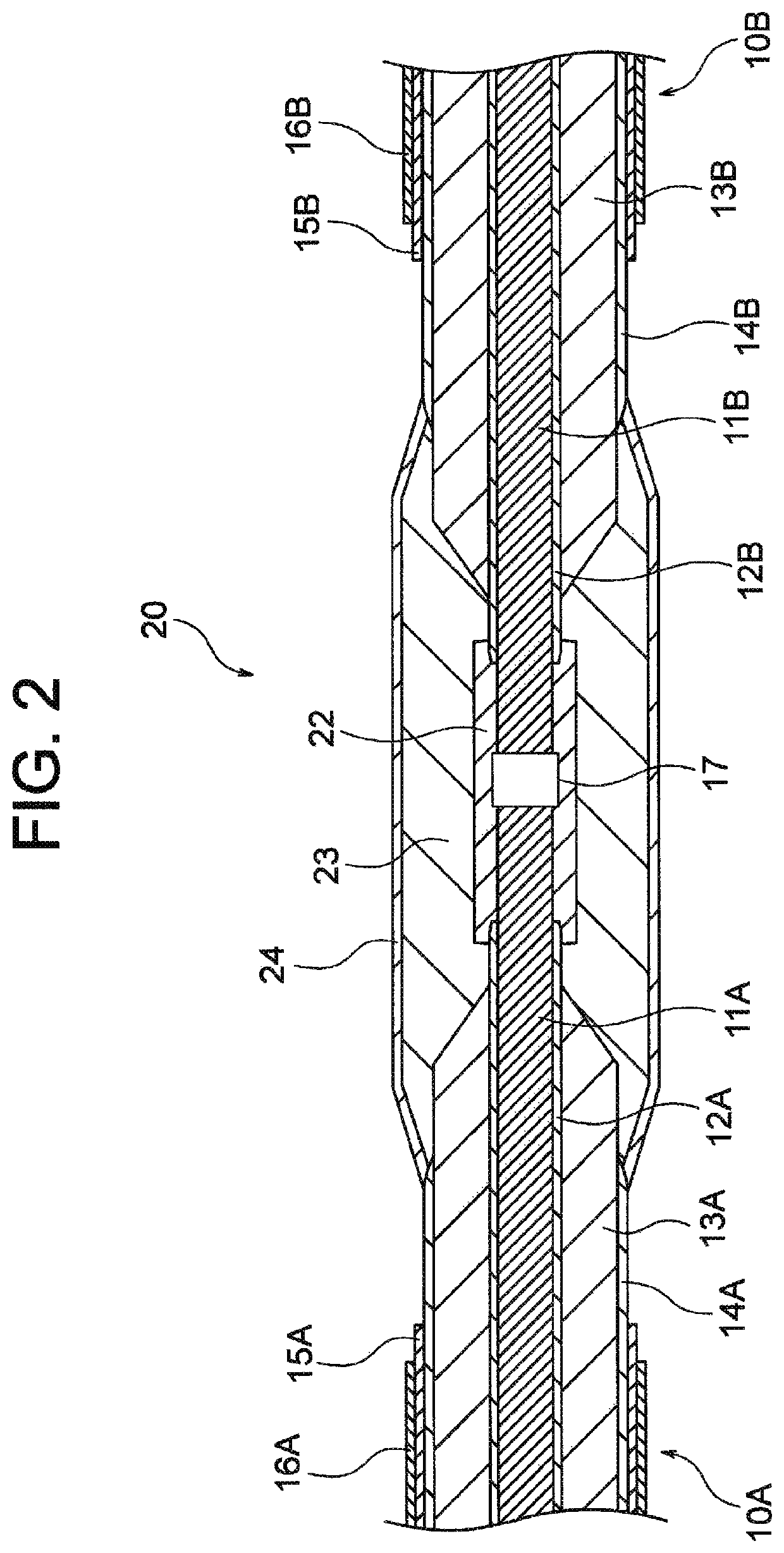

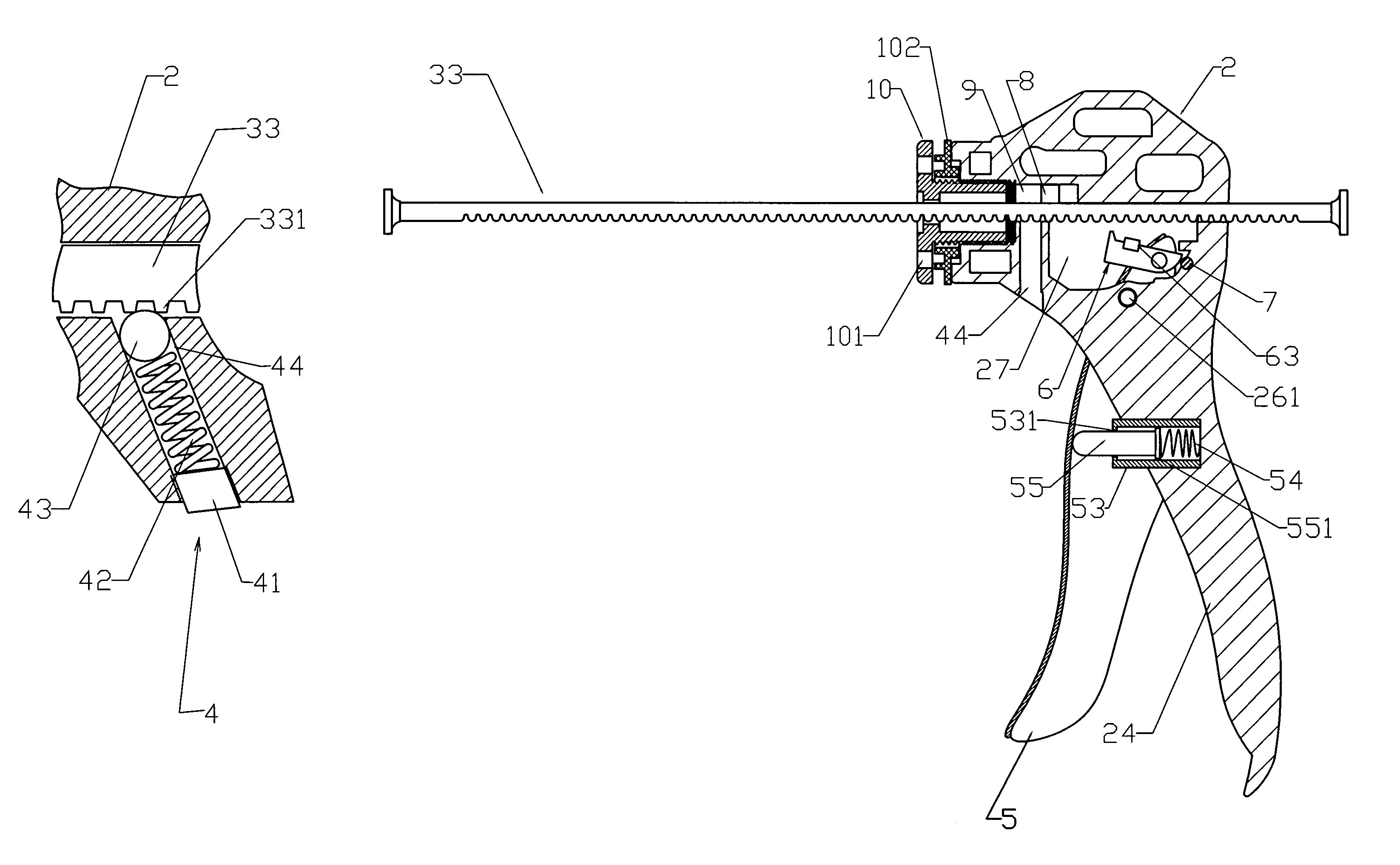

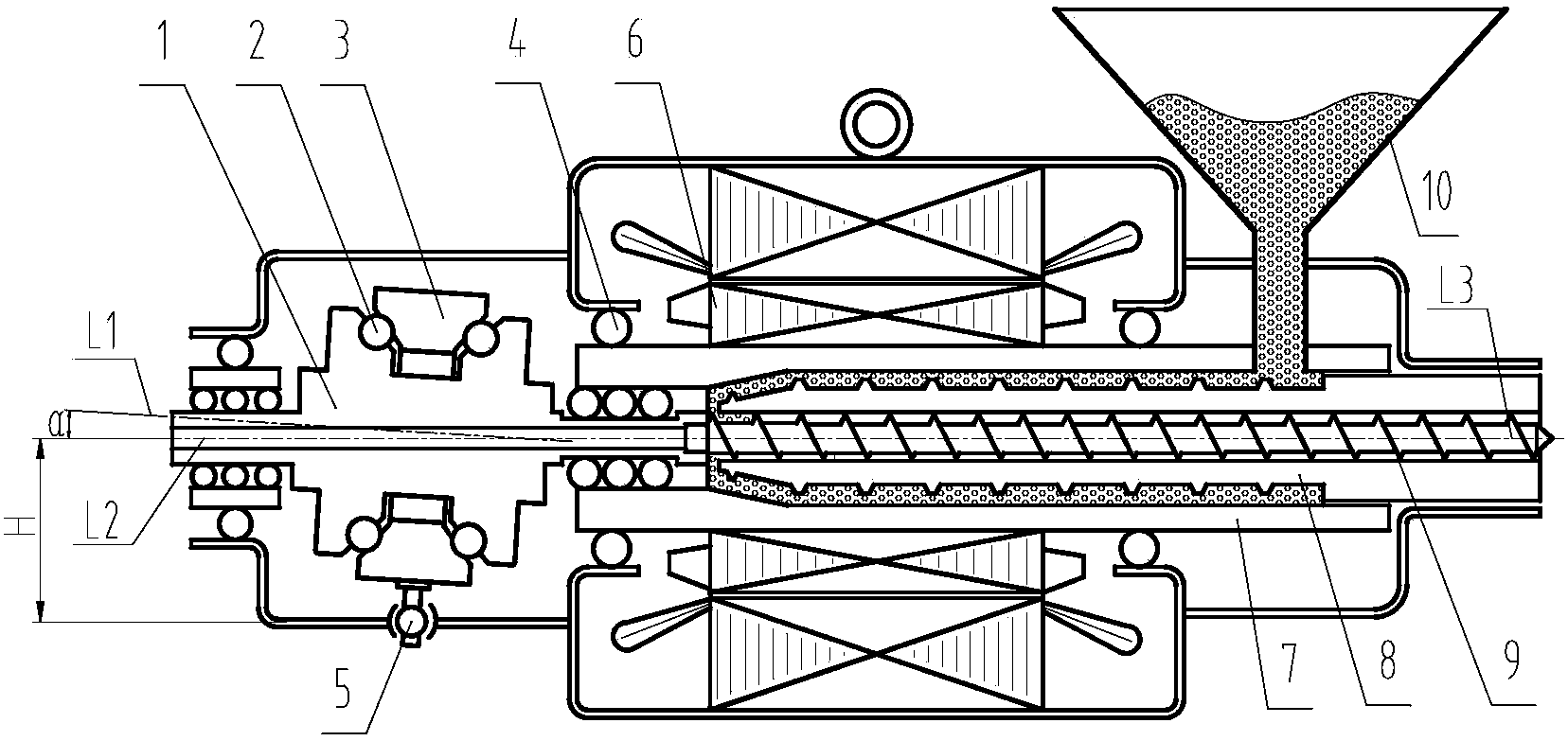

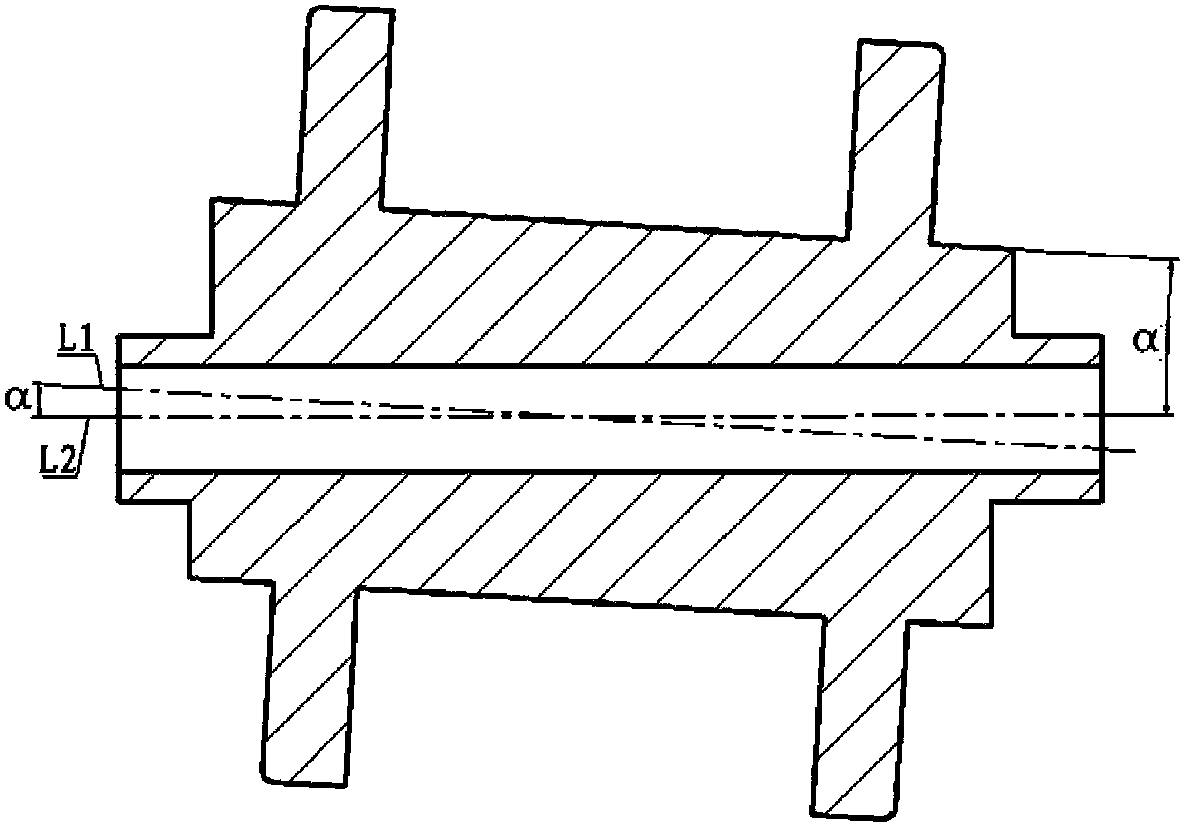

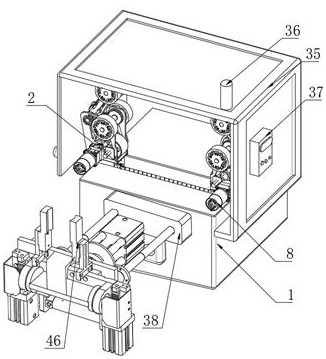

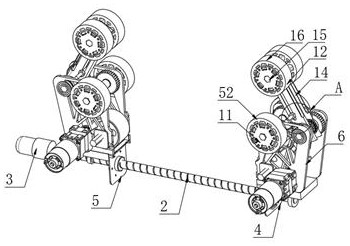

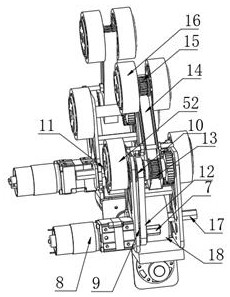

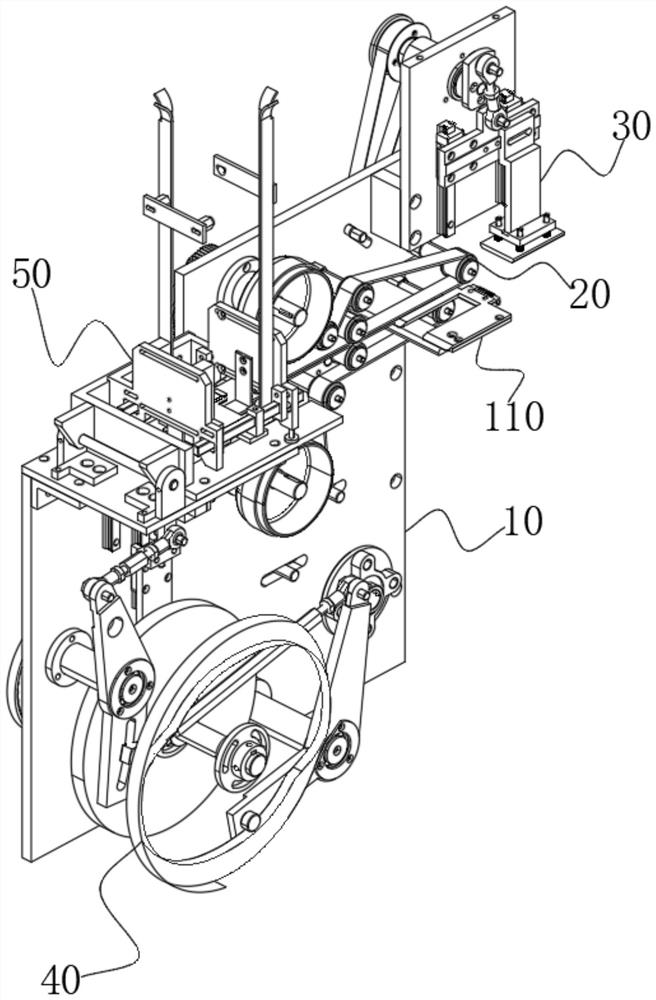

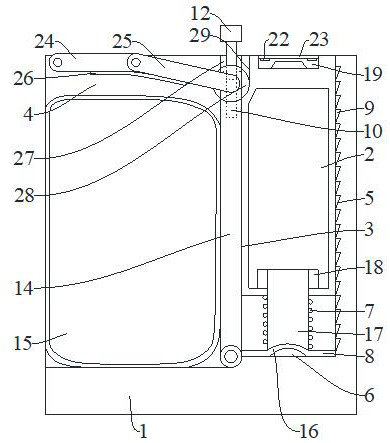

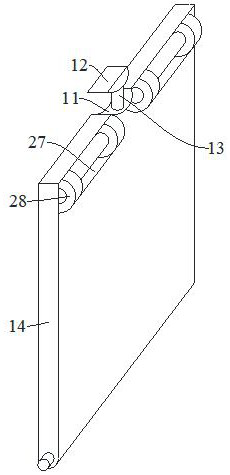

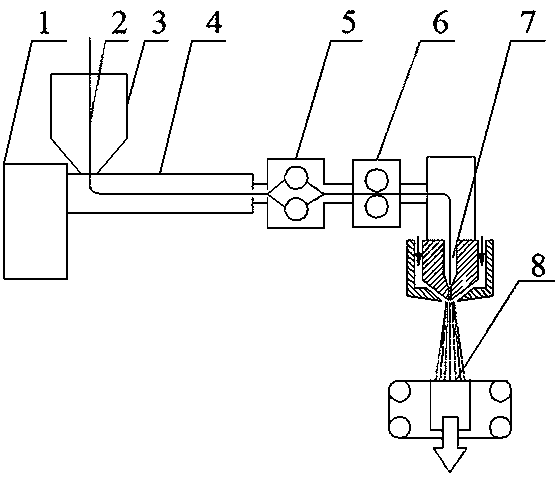

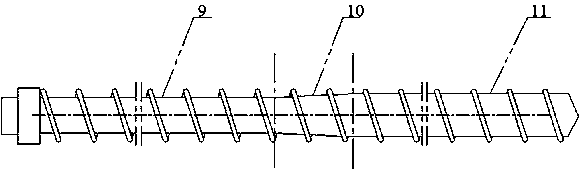

Rotation and axial vibration synergic driving method and device for screw rod of directly-driven dynamic extruder

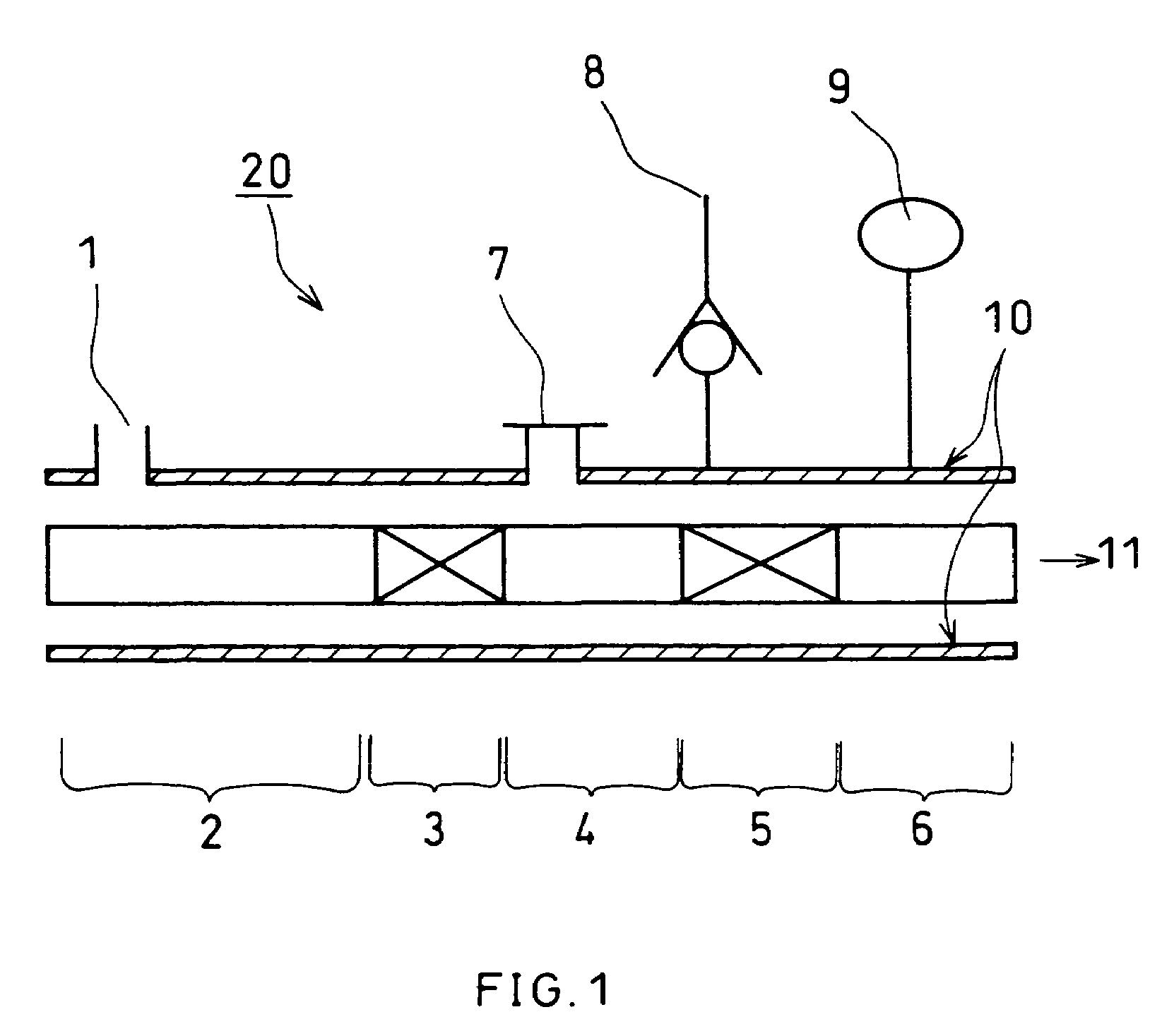

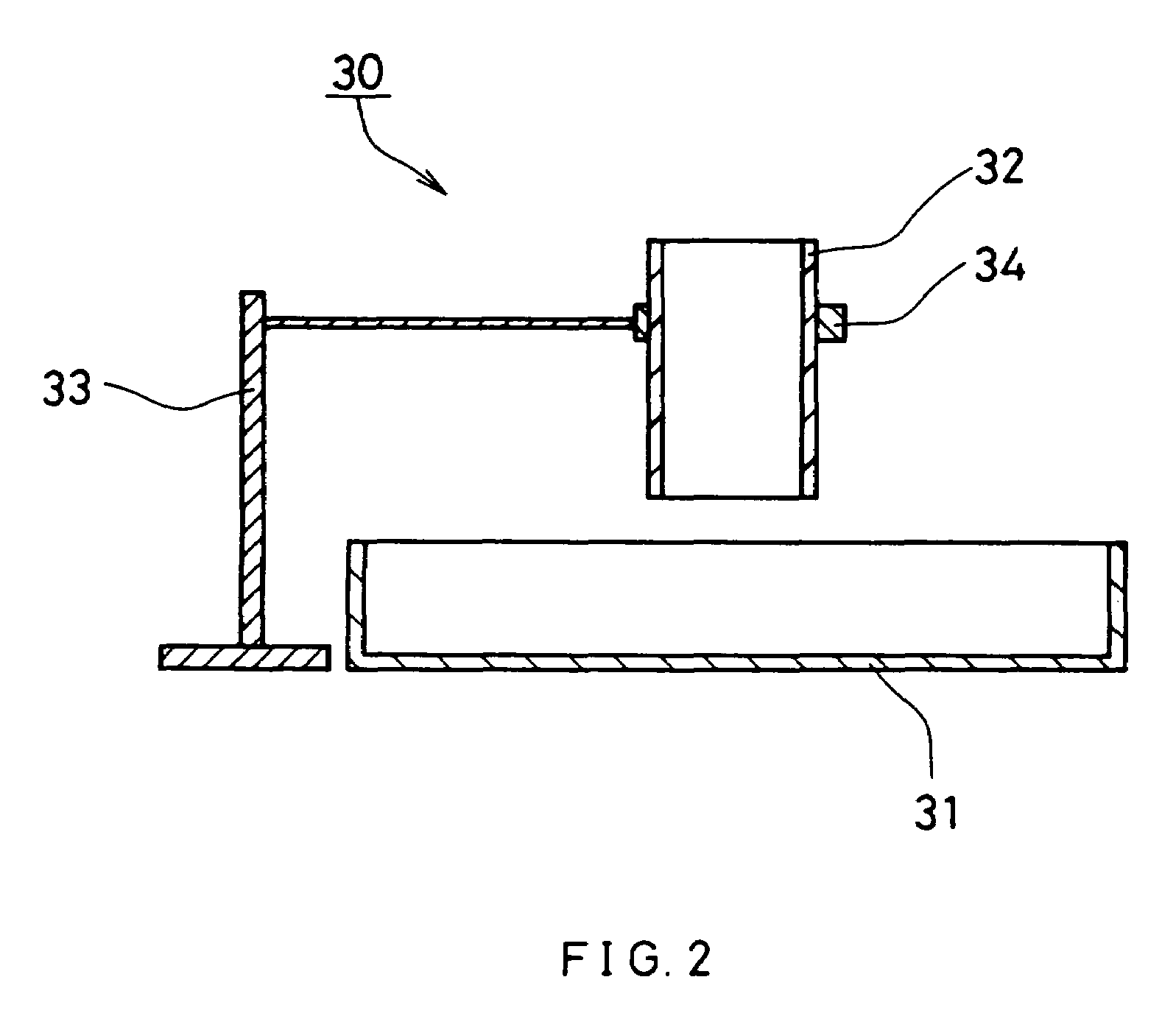

The invention relates to a rotation and axial vibration synergic driving method and a rotation and axial vibration synergic driving device for a plasticized transport screw rod of a directly-driven dynamic extruder. A swinging driving sleeve of the device is connected with a motor hollow shaft through a linear rolling bearing; the swinging driving sleeve is connected with a shaking ring through aligning thrust roller bearings which are symmetrically arranged on both sides of the shaking ring; the swinging driving sleeve is fixedly connected with the plasticized transport screw rod; the inner hole central line of the swinging driving sleeve is coincided with the central line of the motor hollow shaft; meanwhile, the shaking ring is connected with a joint bearing; the shaking ring is restrained by using the joint bearing, and swings by taking the joint bearing as a supporting point; the swinging driving sleeve has a cylindrical structure; the middle part of a cylinder is provided with a cylindrical through hole; and the central line of the outer cylindrical surface of the swinging driving sleeve intersects with the central line of the inner hole cylindrical surface, so that an angle alpha is formed. The swinging driving sleeve is used for driving the plasticized transport screw rod to vibrate axially during rotating, so that homologous synergic driving of the rotation and axial vibration of the screw rod are realized. The device has the characteristics of large axial vibrating amplitude of the plasticized transport screw rod, high stability, high reliability and the like.

Owner:SOUTH CHINA UNIV OF TECH +1

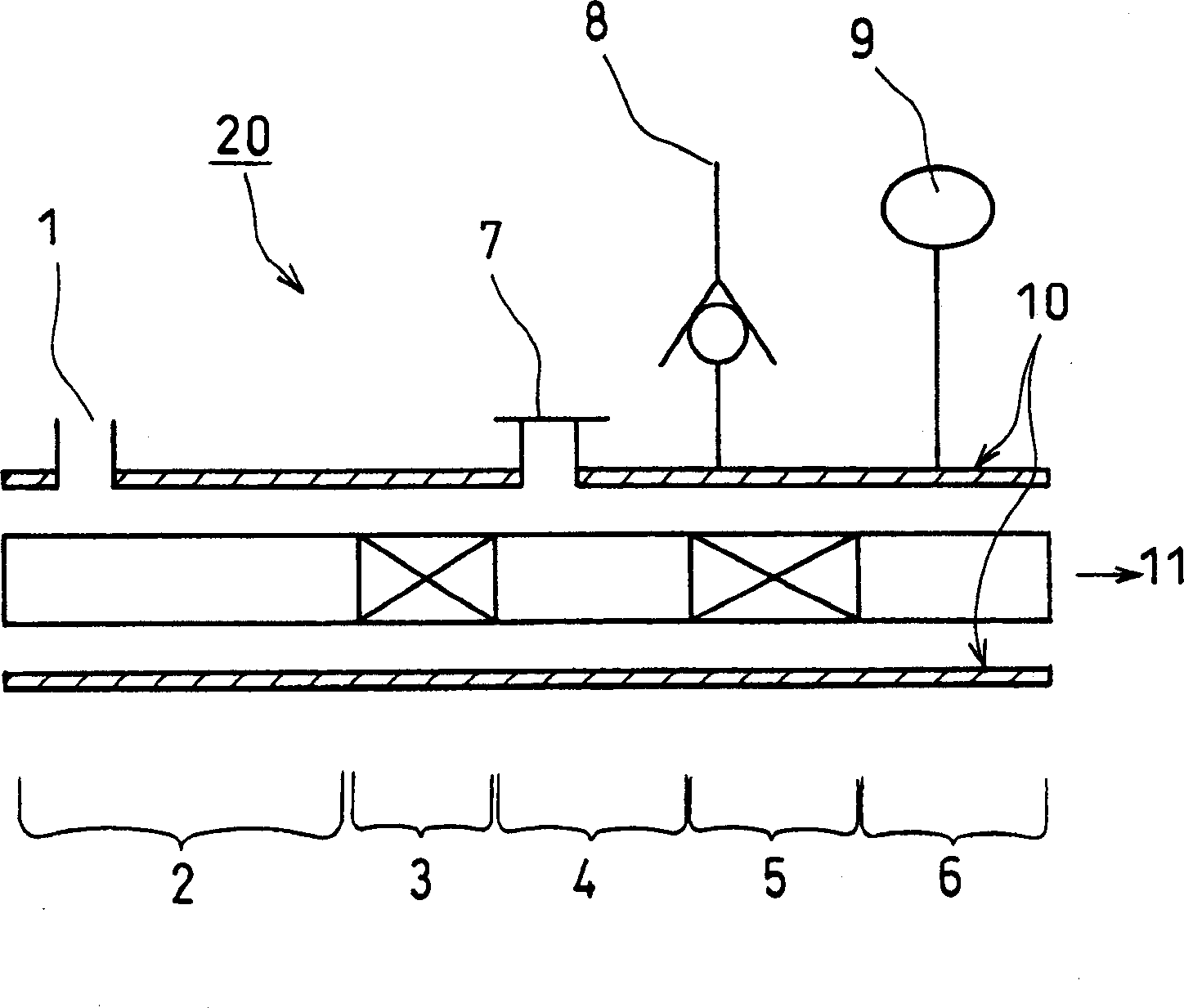

Ethylene-vinyl alcohol copolymer resin and particle producing method thereof, the resin particle

A process for producing an ethylene-vinyl alcohol copolymer resin, including feeding EVOH into an extruder, keeping the temperature of the melting resin in the extruder at 70 to 170 DEG C, adjusting the amount of water in the extruder so that the water content right after being discharged from the extruder is 5 to 40 weight %, and extruding out the EVOH resin. The extruded EVOH resin is cut into EVOH pellets. Thereby, it is possible to obtain resin pellets in which no spherocrystals are observed in the center of the cross section of the resin when the cross section is observed by the use of a polarization microscope, or no lubricant is contained in the resin pellets, and the angle of repose is 23 DEG or less when the resin pellets are laminated. Thus, it is possible to provide an ethylene-vinyl alcohol copolymer (EVOH) resin pellet having a reduced discharging load to the environment and capable of being fed into an extruder smoothly without being blocked, extruding stability, and thermal stability (long-run property).

Owner:KURARAY CO LTD

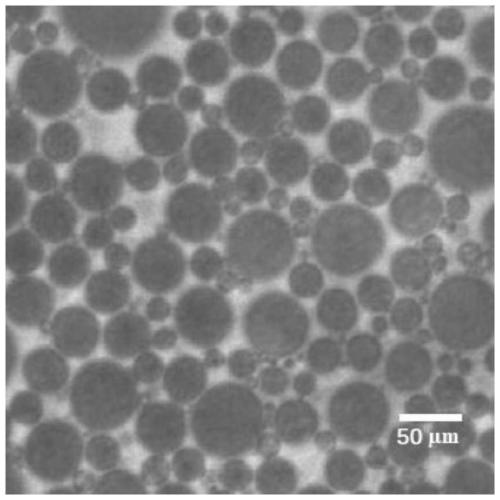

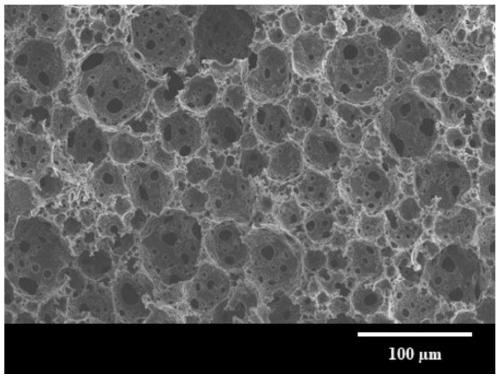

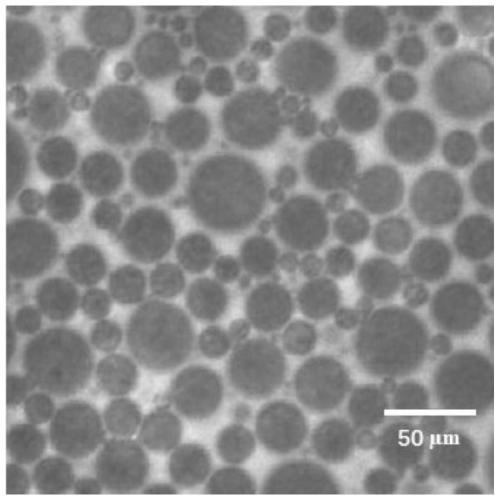

Method for continuously preparing water-in-oil type high internal phase emulsion and polymer porous material

The invention relates to a method for continuously preparing a water-in-oil high internal phase emulsion and a polymer porous material. The method for preparing the polymer porous material comprises the steps of dissolving an emulsifier in a hydrophobic monomer to obtain a solution as an oil phase; taking an aqueous solution containing an electrolyte and an initiator as a water phase; continuouslyadding the oil phase and the water phase into a twin-screw extruder respectively, and fully emulsifying the oil phase and the water phase to form an emulsion through a twin-screw shearing effect; andafter the oil phase and the water phase are fully emulsified to form the emulsion, initiating the hydrophobic monomer in the emulsion by the initiator to obtain the polymer porous material with a pore structure and adjustable pore structure morphology. Compared with the prior art, the method is simple and easy to implement, can be used for continuously producing the high internal phase emulsion,and can be used for obtaining the porous material with the special pore structure.

Owner:EAST CHINA UNIV OF SCI & TECH

Preparation method of polylactic acid transparent straw

InactiveCN108976731AImprove extrusion stabilityDiameter stableTubular articlesStraight tubeDiameter ratio

The invention discloses a preparation method of a polylactic acid transparent straw. According to the preparation method, 94-96% of PLA, 2-3% of PEO, 1-2% of ParaloidKM-355P, 0.4-0.8% of VINNEX*2525 and 0.1-0.2% of EBS. The preparation method comprises the following steps of: adding the PLA into a double-screw extruder, adding the PEO, the ParaloidKM-355P, the VINNEX*2525 and the EBS into the double-screw extruder from a side feeding port, and carrying out extrusion, bracing, cooling, drying and slicing to obtain a modified resin for PLA straws, wherein a barrel temperature is 160 DEG C, a diehead temperature is 165 DEG C and a screw length-diameter ratio of the extruder is 52: 1; adding the obtained modified resin for PLA straws into a beverage straw manufacturing machine to carry out extrusion, traction, cooling and trimming so as to obtain a transparent a polylactic acid straight tube, wherein the barrel temperature is 160 DEG C, the die head is additionally provided with a melt pump, the die head temperature is 165 DEG C, and a cooling water temperature is 40-50 DEG C; and putting the transparent a polylactic acid straight tube into a full-automatic bendable straw forming machine to obtain a PLA high-transparency straw. According to the preparation method, the PLA application field is extended, traditional PP straws can be replaced so that the white pollution can be decreased, and the PLA is a natural bacteriostasis material and is beneficial for human health.

Owner:ANHUI JUMEI BIOLOGICAL TECH

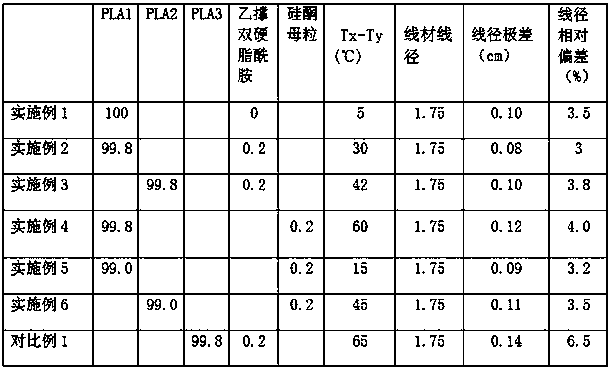

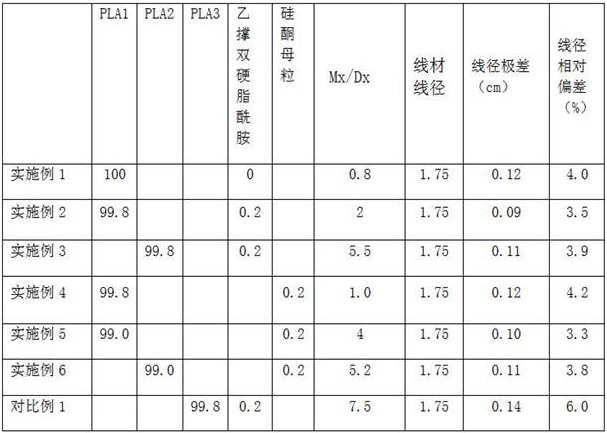

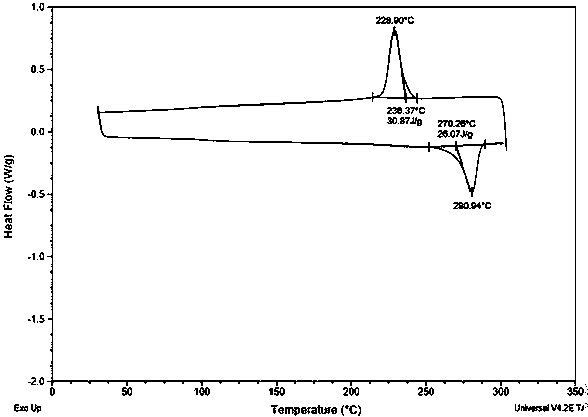

Polylactic acid 3D printing material and wire prepared from polylactic acid 3D printing material

InactiveCN107936502AImprove extrusion stabilityAdditive manufacturing apparatusDecompositionPolymer chemistry

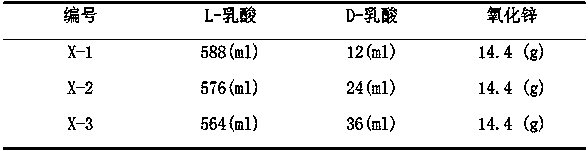

The invention discloses a polylactic acid 3D printing material and a wire prepared from the polylactic acid 3D printing material. The polylactic acid 3D printing material comprises: (a) 98.0-100 partsof polylactic acid and (b) 0-2.0 parts of a processing auxiliary agent. With respect to the total weight of polylactic acid, the weight of D-polylactic acid is 0.3-5%. The structure of the polylacticacid 3D printing material satisfies the following relation: 0 DEG C<=Tx-Ty<=60 DEG C, wherein Tx is the maximum weight loss rate temperature of the polylactic acid 3D printing material, and Ty is theextrapolated initial decomposition temperature of the polylactic acid 3D printing material. It is found through research that when the structure of the polylactic acid 3D printing material satisfiesthe following relation: 0 DEG C<=Tx-Ty<=60 DEG C, and when the wire drawing extrusion speed of the polylactic acid 3D printing material is 45 Kg / h, and the diameter of the extruded wire is 1.75 cm, the wire diameter range is no more than 0.12 cm, and the relative deviation of the wire diameter is less than 5%. Therefore, the wire extrusion stability is well developed.

Owner:KINGFA SCI & TECH CO LTD +2

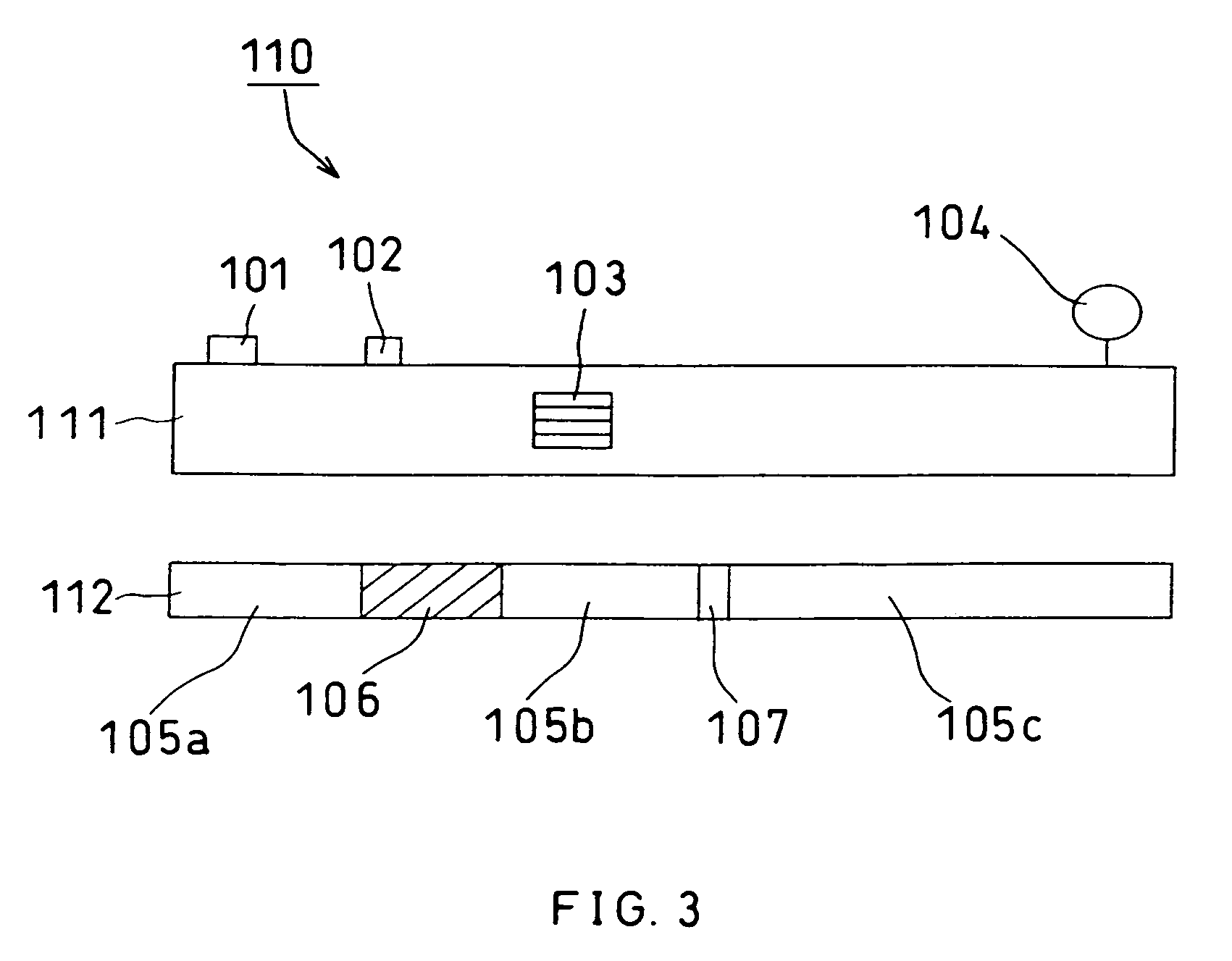

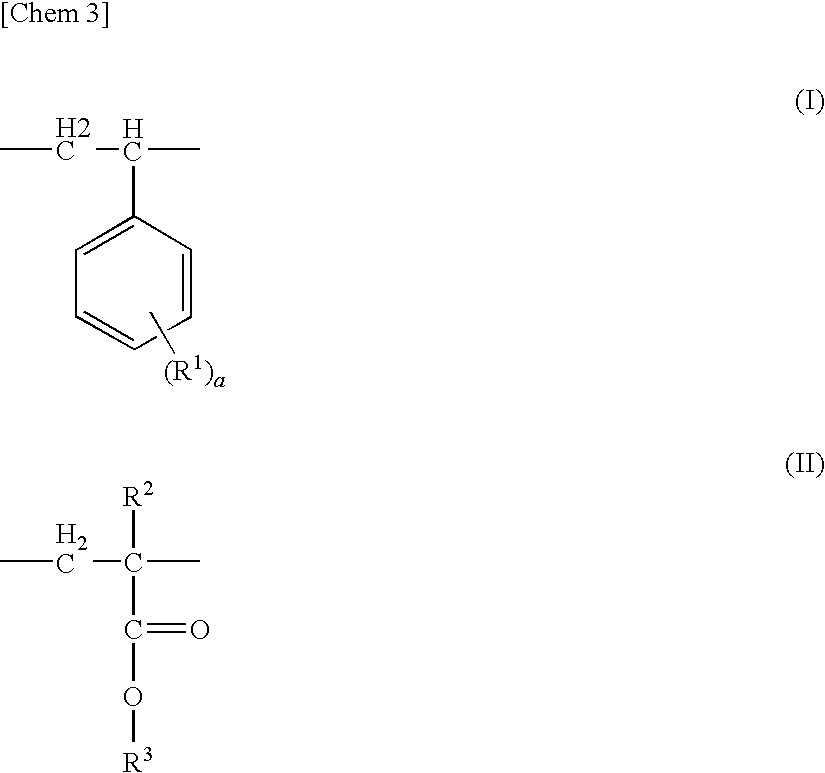

Process for producing ethylene-vinyl alcohol copolymer resin, process for producing pellets and resin pellets

InactiveUS7323503B2Reduce discharge loadImprove extrusion stabilityNon-fibrous pulp additionWorking-up pitch/asphalt/bitumen by chemical meansThermal stabilityPolyresin

A process for producing an ethylene-vinyl alcohol copolymer resin, including feeding EVOH into an extruder, keeping the temperature of the melting resin in the extruder at 70 to 170° C., adjusting the amount of water in the extruder so that the water content right after being discharged from the extruder is 5 to 40 weight %, and extruding out the EVOH resin. The extruded EVOH resin is cut into EVOH pellets. Thereby, it is possible to obtain resin pellets in which no spherocrystals are observed in the center of the cross section of the resin when the cross section is observed by the use of a polarization microscope, or no lubricant is contained in the resin pellets, and the angle of repose is 23° or less when the resin pellets are laminated. Thus, it is possible to provide an ethylene-vinyl alcohol copolymer (EVOH) resin pellet having a reduced discharging load to the environment and capable of being fed into an extruder smoothly without being blocked, extruding stability, and thermal stability (long-run property).

Owner:KURARAY CO LTD

Aromatic polycarbonate resin composition, molded body thereof for optical use, and light diffusion film

InactiveUS20100105846A1High transparencyImprove extrusion stabilitySynthetic resin layered productsThin material handlingPolycarbonatePolyresin

Provided is an aromatic polycarbonate resin composition containing, with respect to 100 parts by mass of a resin mixture including 60 to 99 mass % of (A) an aromatic polycarbonate resin and 1 to 40 mass % of (B) a styrene-based resin, 1 to 30 parts by mass of a compatibilizer, the compatibilizer being formed of a block or random copolymer constituted of an aromatic vinyl monomer unit and an acrylate-based monomer unit. This aromatic polycarbonate resin composition has improved transparency and improved extrusion stability.

Owner:IDEMITSU KOSAN CO LTD

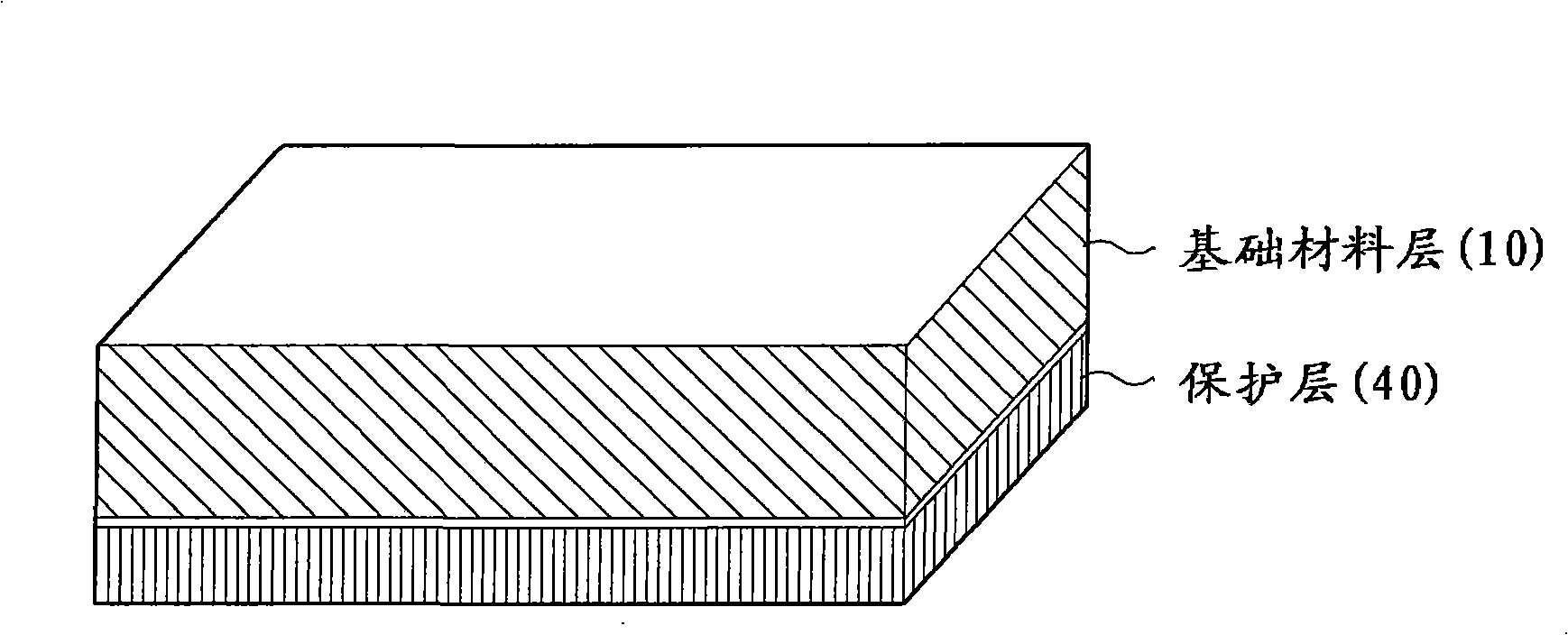

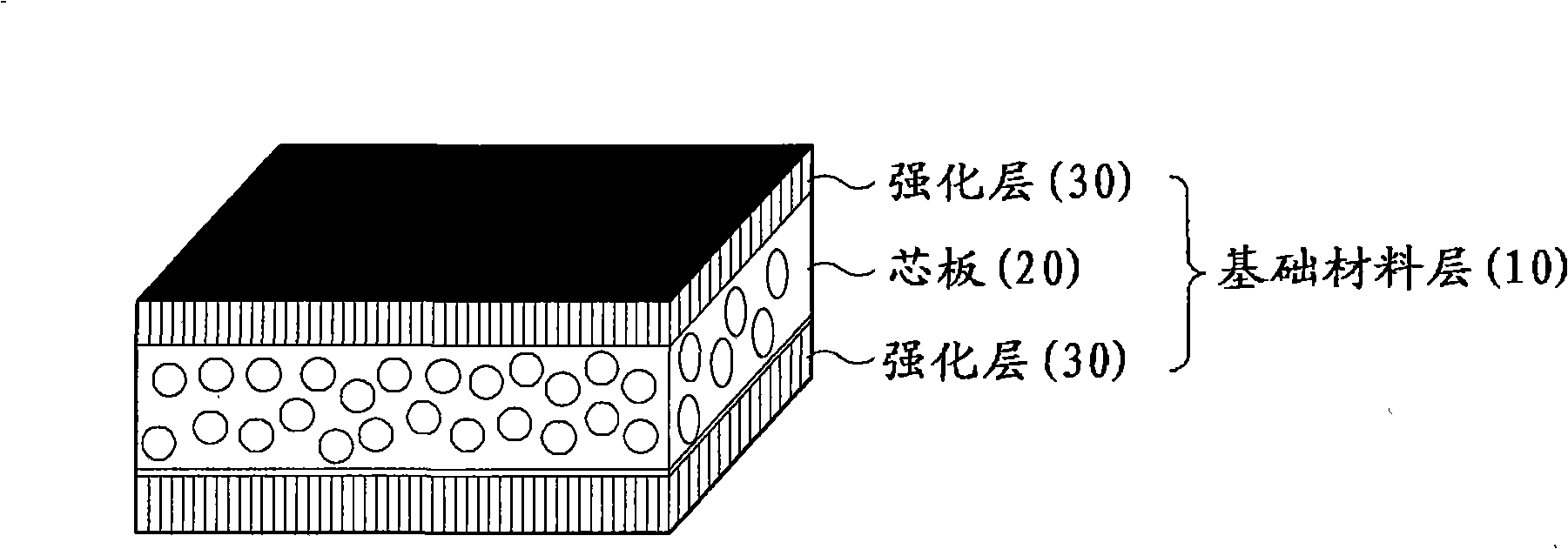

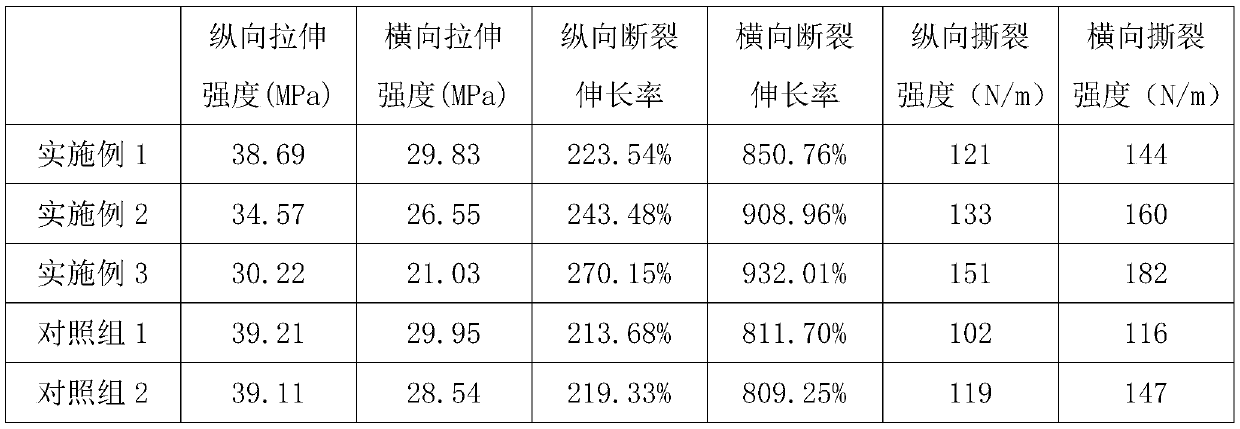

Base material for vehicle head liner

InactiveCN101348022AImprove extrusion stabilityEasy to makeSynthetic resin layered productsThin material handlingHeat resistanceEngineering

Owner:DOO YANG IND

Thermoplastic elastomer and preparation method

The invention discloses a thermoplastic elastomer. The thermoplastic elastomer is prepared from, by weight, 60-85 parts of matrix, 1-10 parts of foaming agent, 5-20 parts of rubber oil A, 1-3 parts of lubricant, 1-3 parts of cross-linking agent A and 1-2 parts of light stabilizer. Compared with the prior art, the thermoplastic elastomer has the advantages that the prepared elastomer is low in density, good in elasticity, high in tensile strength, uniform in foaming, convenient and fast to process and stable in extrusion.

Owner:中广核三角洲集团(苏州)特威塑胶有限公司

Electric field type polymer extruder head

InactiveCN1555974ARelieve pressureReduce melt viscosityEnergy based chemical/physical/physico-chemical processesEngineeringViscosity

An electric field type extruding head of polymer extruder features that a pair of plate electrodes are arranged on the ordinary extruding head for applying pulse or DC voltage across them to generate an electric field, which can orient the macro-molecular chains and molecular chains in fused polymer, lowering the viscosity of fused polymer and decreasing the extruding pressure.

Owner:DONGHUA UNIV

Extrusion-grade polycarbonate alloy material as well as preparation method and application thereof

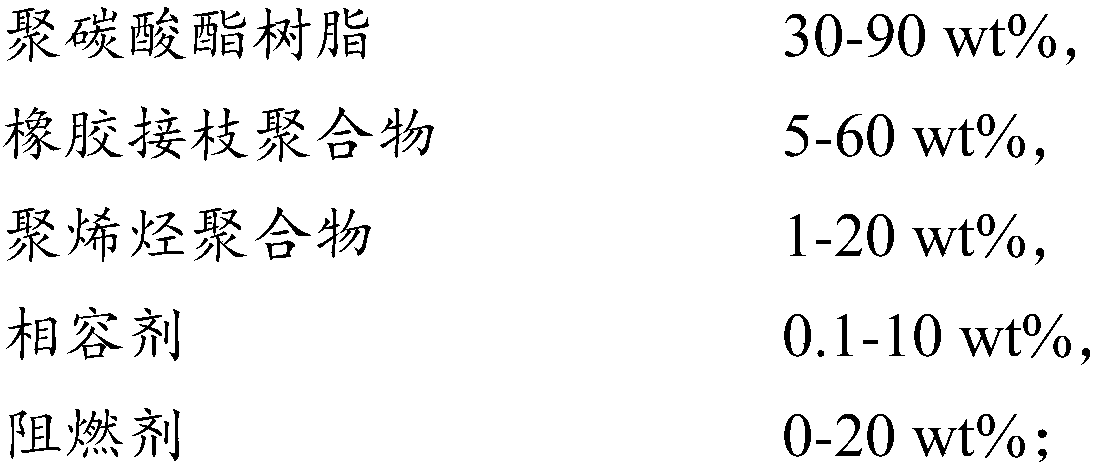

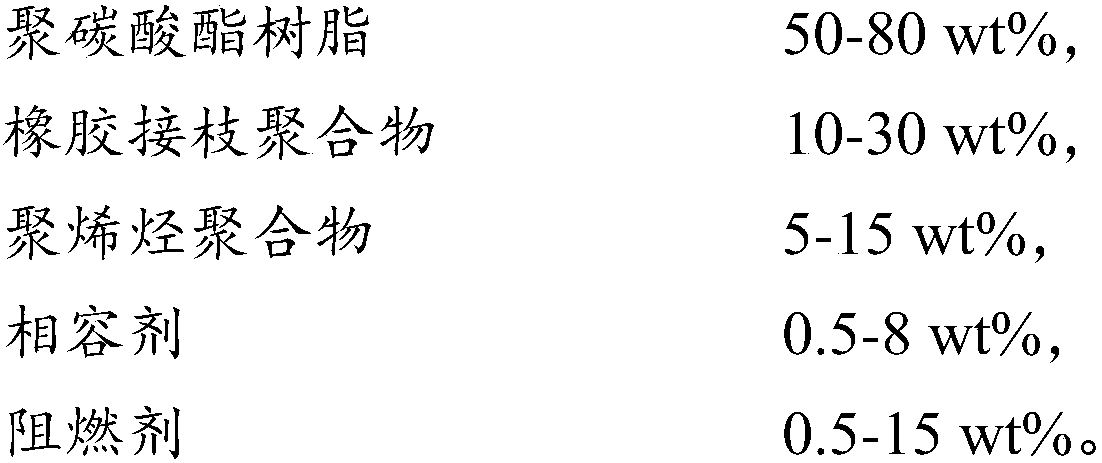

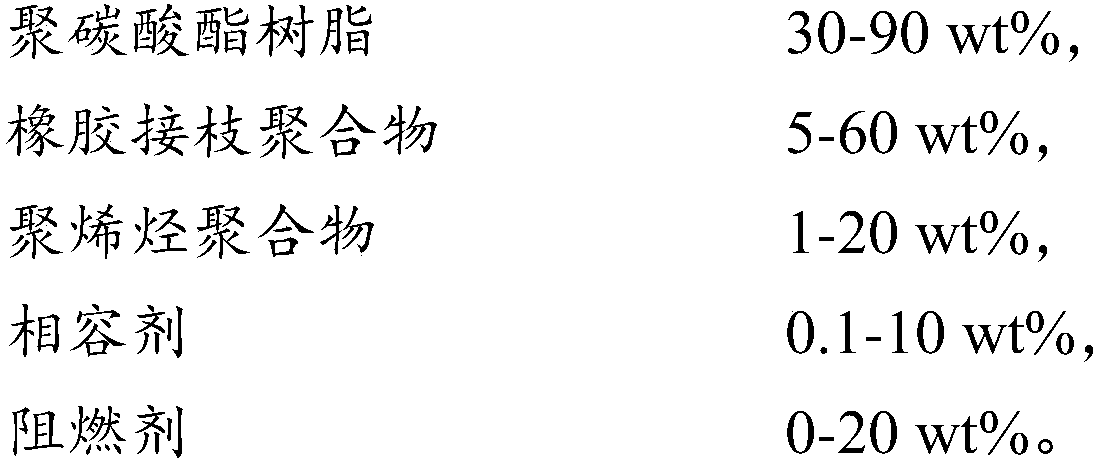

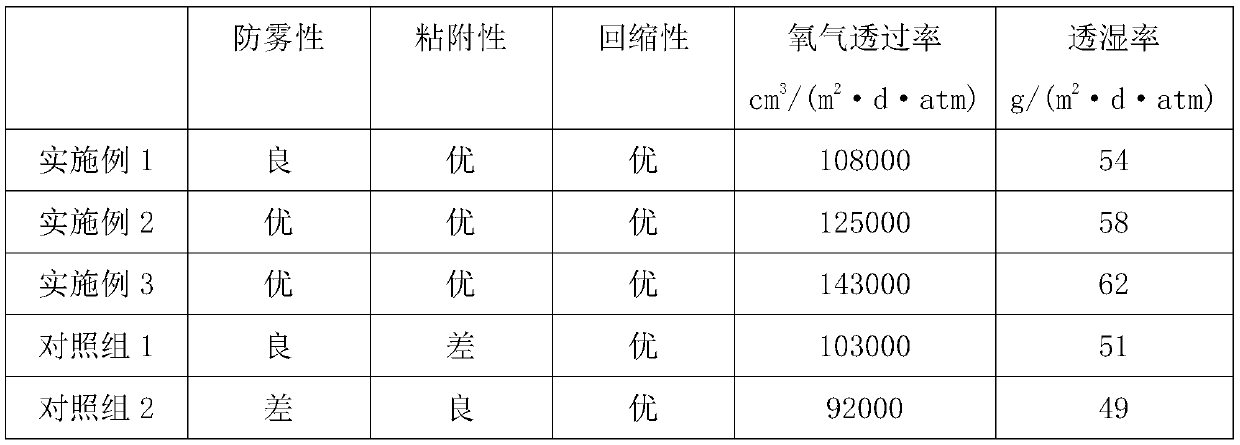

The invention belongs to the technical field of macromolecule commixing and molding processing and provides an extrusion-grade polycarbonate alloy material as well as a preparation method and application thereof. The extrusion-grade polycarbonate alloy material is prepared from the following components in percentage by weight: 30-90wt% of a polycarbonate resin, 5-60wt% of a rubber grafted polymer,1-20wt% of a polyolefin polymer, 0.1-10wt% of a compatilizer and 0-20wt% of a flame retardant, wherein the total weight of the components in percentage by mass is 100wt%. The preparation method comprises the following steps: (1) mixing the components; (2) putting the mixture of the step (1) into a double-screw extruder, melting and extruding materials, and carrying out bar drawing and pelletizing. Due to addition of the polyolefin polymer, the strength of a melt of the obtained polycarbonate alloy material can be remarkably improved while good physical and mechanical properties are ensured.

Owner:WANHUA CHEM GRP CO LTD

Preparation method of high-transparency self-adhesive PBAT preservative film

The invention discloses a preparation method of a high-transparency self-adhesive PBAT preservative film. The high-transparency self-adhesive PBAT preservative film comprises the following raw materials: PBAT, ACR, glycerin and glycerin fatty acid ester. The preparation method comprises the steps of material mixing, material particle manufacturing, film blowing and film rolling. According to the invention, the ACR is added into PBAT resin, so the ductility, the retractility and the winding smoothness of the PBAT preservative film are improved; the glycerin can improve the extrusion stability,the softness and the adhesion of the PBAT preservative film; the glycerin fatty acid ester can improve the antifogging property of the PBAT preservative film; and meanwhile, the glycerin and glycerinfatty acid can achieve a synergistic effect, so the anti-fog effect of the PBAT preservative film is further enhanced. The prepared PBAT preservative film is excellent in physical property, high in transparency, high in adhesion, high in retractility, smooth in winding, free of wrinkles and good in air permeability.

Owner:ANHUI JUMEI BIOLOGICAL TECH

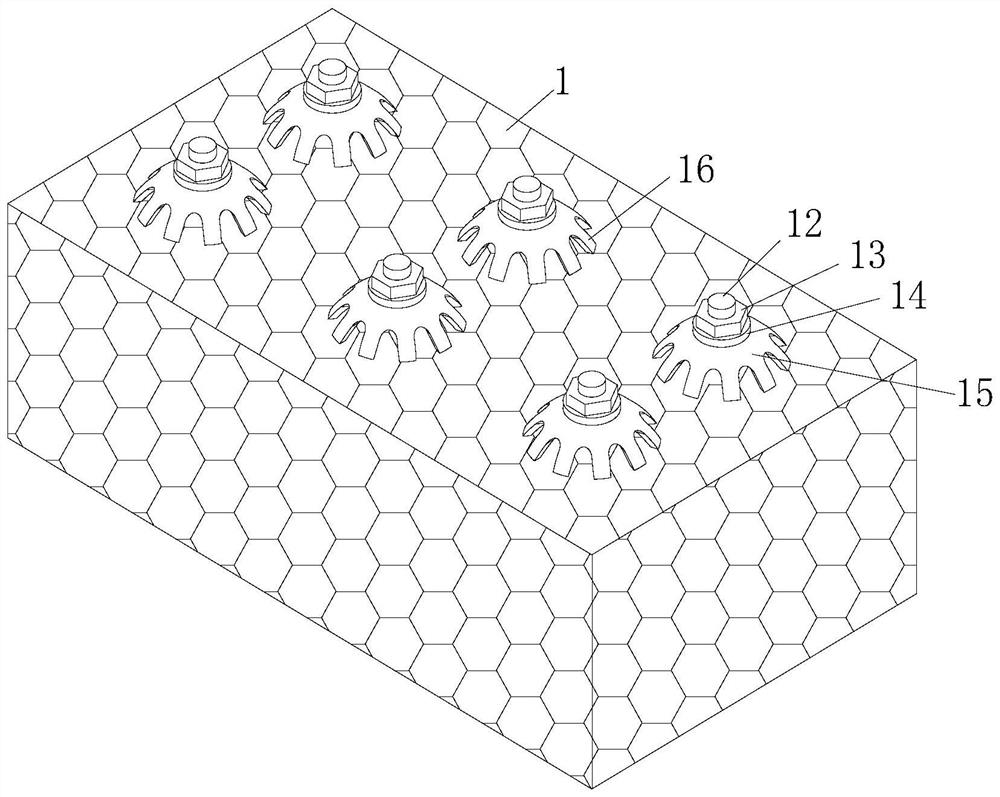

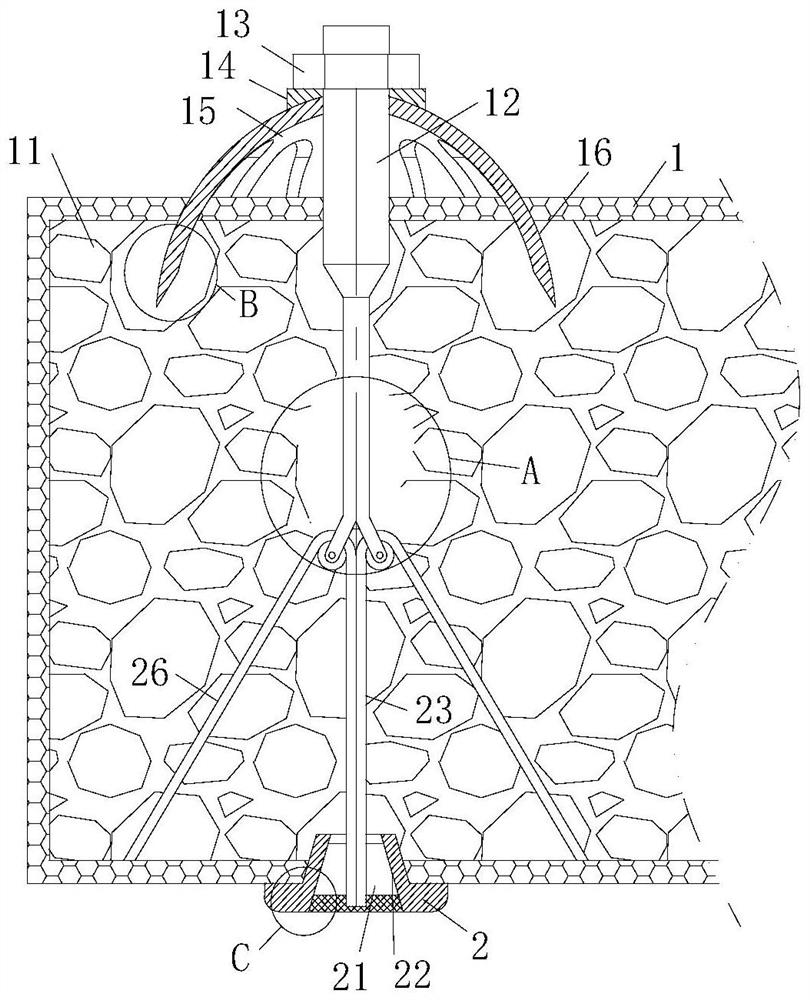

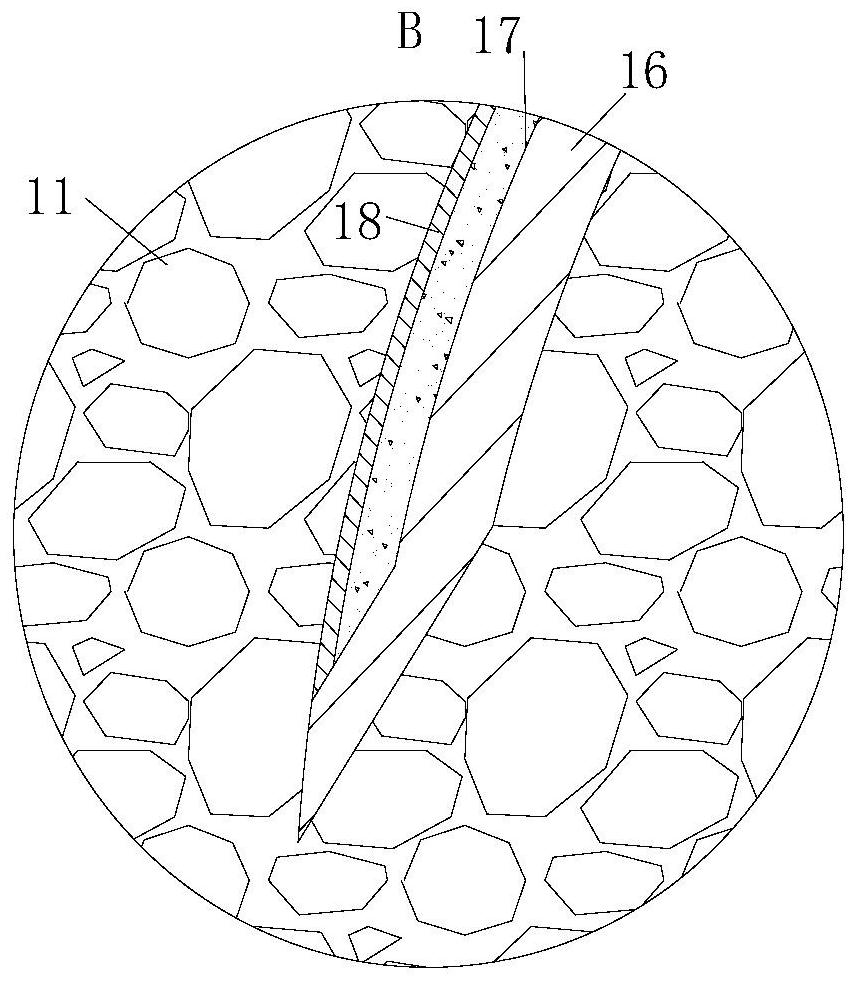

Gabion protective net

The invention belongs to the technical field of engineering protection, and particularly relates to a gabion protective net which comprises a net body, the net body is filled with stones, a set of pull rods are arranged at the top of the net body, and one ends of the pull rods penetrate through the stones and then are connected with the net body through quick connecting units. A nut sleeves the other end of the pull rod and is in threaded connection with the pull rod; a round gasket is sleeved on the pull rod between the nut and the net body; after the net body is filled with stones, the two ends of each pull rod oppositely pull the net body through cooperation of the pull rods and the nuts, so that the net body locks the stones, looseness of the stones is reduced, the stones in the net body are mutually embedded due to extrusion of the net body, and the hardening and curing effects of the stones in the net body are further improved; the maintenance time of the net body shape is prolonged, the covering effect on the bottom of a riverbed is further improved, scouring of water flow to the riverbed is reduced, and the flood control quality of a river bank dam is improved.

Owner:安平县昊昌丝网制造有限公司

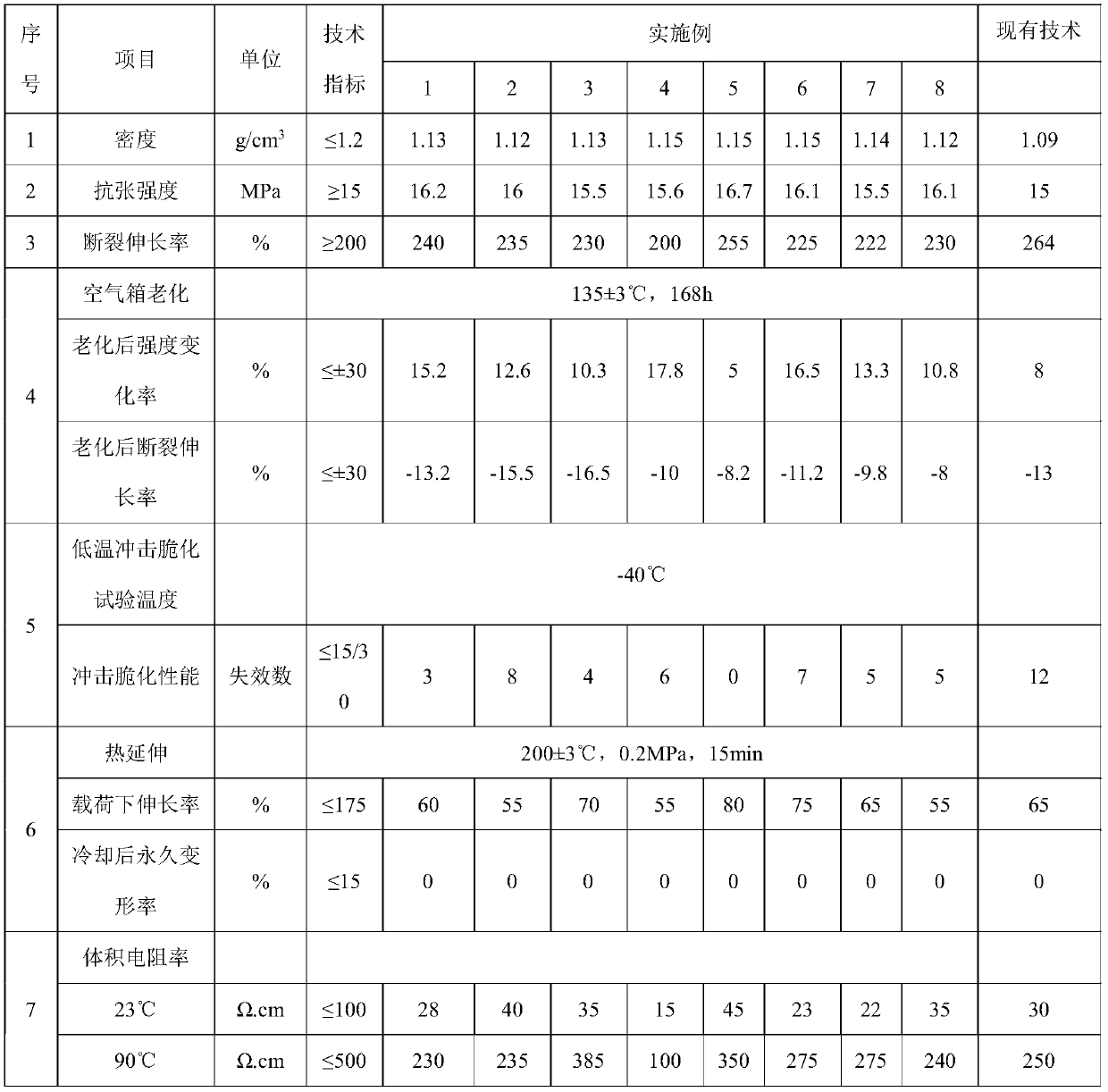

Silane cross-linking semi-conductive inner shielding material and production process thereof

The invention discloses a silane cross-linking semi-conductive inner shielding material and a production process thereof. The production process comprises the following steps: preparing a high-conductivity material A; preparing a catalytic material B; mixing and extruding the high-conductivity material A and the catalytic material B into a mixture; performing warm water crosslinking on the mixture to obtain a finished product. In a manufacturing process of the high-conductivety material A, an ethylene- vinyl silane copolymer is subjected to warm water cross-linking, so silane grafting reaction in a traditional process is avoided, the reaction temperature is within 140 DEG C, no coke is produced, the production continuity is good, the stability is high, the energy consumption is low, continuous production can be realized without stopping, periodically shutting down equipment to clear the coke in the equipment is not needed, a prepared cable material is excellent in mechanical and insulating properties and semi-conductivity, which is conducive to improving the transmission capacity of a power grid, improving the wind resistance of a line, and improving and enhancing the safety and reliability of a distribution system.

Owner:FAR EAST CABLE +2

Insulating resin composition for DC power cable, crosslinked resin body, DC power cable, member for forming reinforcing insulating layer of DC power joint, and DC power cable joint

ActiveUS10752758B2Improve the extrusion effectImproved scorch resistancePlastic/resin/waxes insulatorsPower cables with screens/conductive layersLow-density polyethylenePower cable

An insulating resin composition for a DC power cable improves DC electrical properties and extrusion stability, and includes (A) a low-density polyethylene having a complex viscosity η*100, which is measured at 130° C. and a frequency of 100 rad / s, of 600 to 1,300 Pa·s, wherein a ratio (η*0.1 / η*100) of a complex viscosity η*0.1, which is measured at 130° C. and a frequency of 0.1 rad / s, to the complex viscosity η*100 is 4 or more; (B) a modified polyethylene; and (C) a stabilizer including a mixture of a hindered phenol antioxidant and a thioether antioxidant. The amount of carbonyl groups introduced into the resin composition through the component (B) is 7×10−6 to 1.3×10−5 mol / g relative to the total mass of the component (A), the component (B), and the component (C).

Owner:NUC +1

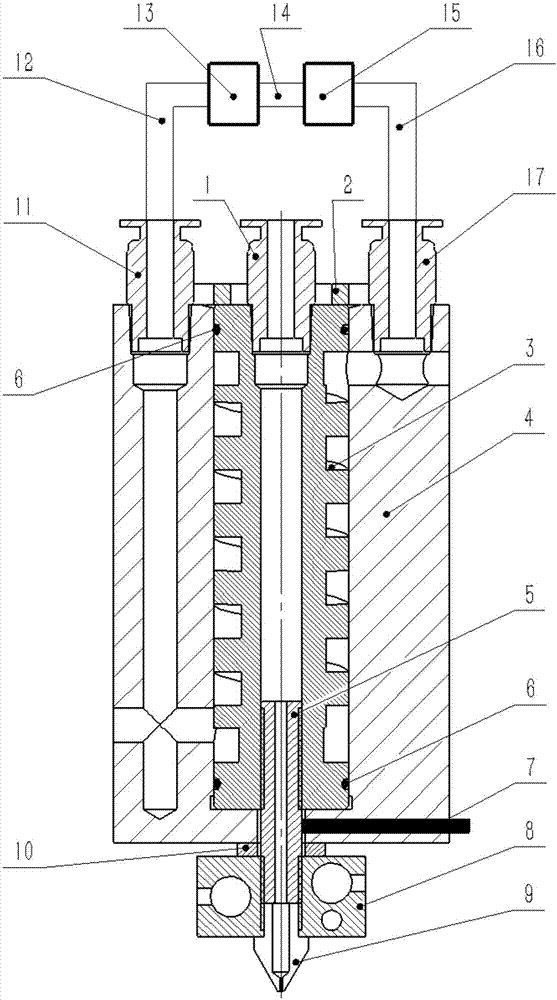

A fluid circulation temperature controlled fusion deposition forming print head

ActiveCN105666876BImprove gap backflowAvoid "plug" phenomenonAdditive manufacturing apparatus3D object support structuresTemperature controlThroat

A fluid circulation temperature-controlled fusion deposition forming print head, including a cooling pipe, a threaded pipe outside the cooling pipe, a cooling liquid inlet pipe and a cooling liquid outlet pipe inside the cooling body, the cooling liquid inlet pipe, the threaded pipe, and the cooling liquid outlet pipe are common Consists of the internal circulation pipe of the coolant in the print head, the coolant inlet pipe is connected to the outlet of the coolant inlet pipe through the coolant inlet pipe joint, the inlet of the coolant inlet pipe is connected to the outlet of the water pump, and the inlet of the water pump is outlet through the radiator The water pipe is connected to the outlet of the radiator, and the inlet of the radiator is connected through the coolant outlet pipe, the coolant outlet pipe joint and the coolant outlet pipeline to form a fluid circulation system. Reduce the throat temperature in time, improve the gap backflow during high-temperature printing, and maintain stable printing accuracy during long-term continuous printing.

Owner:XI AN JIAOTONG UNIV

Vinylidene chloride copolymer composition, its preparing method and its membrane or sheet material

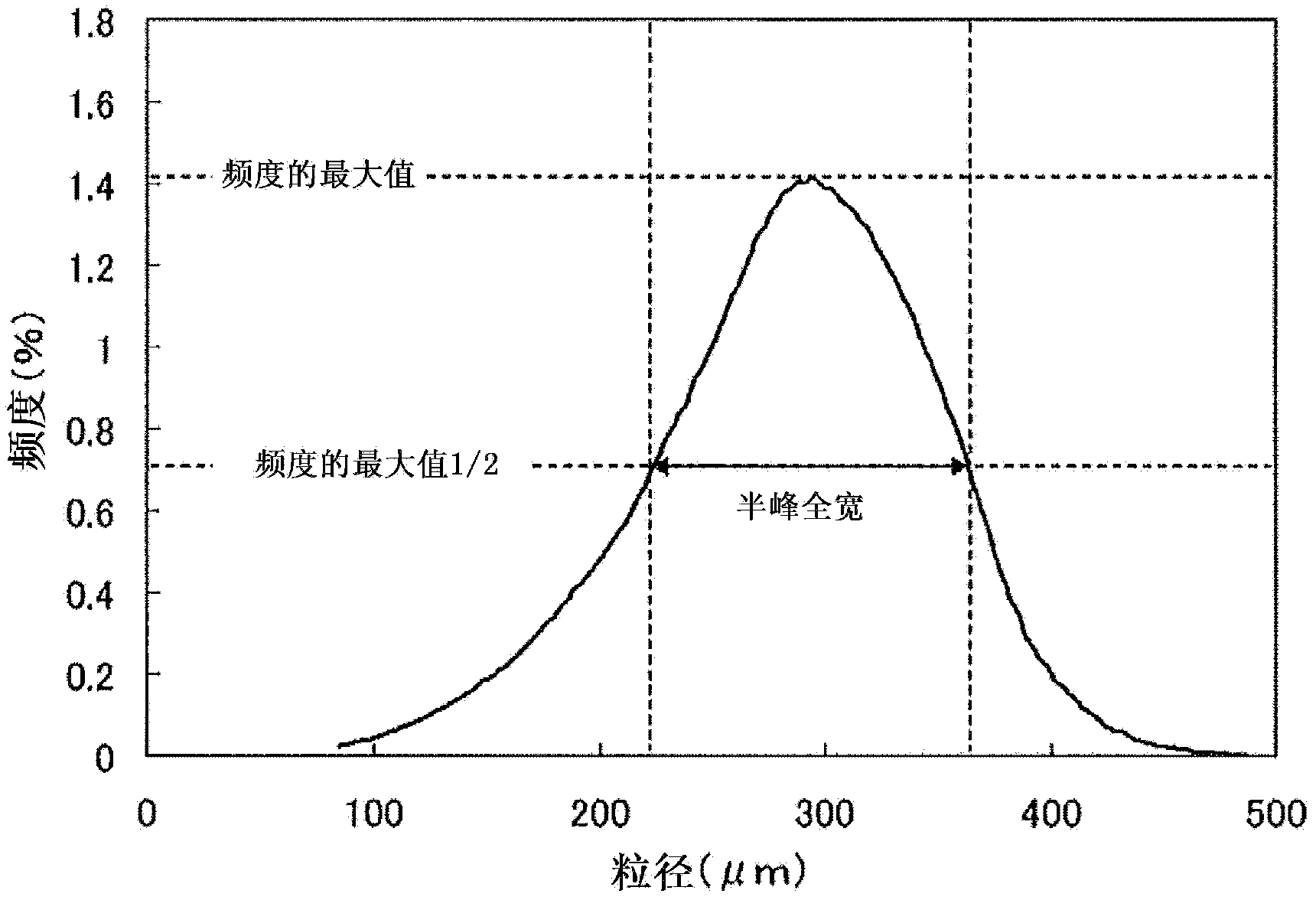

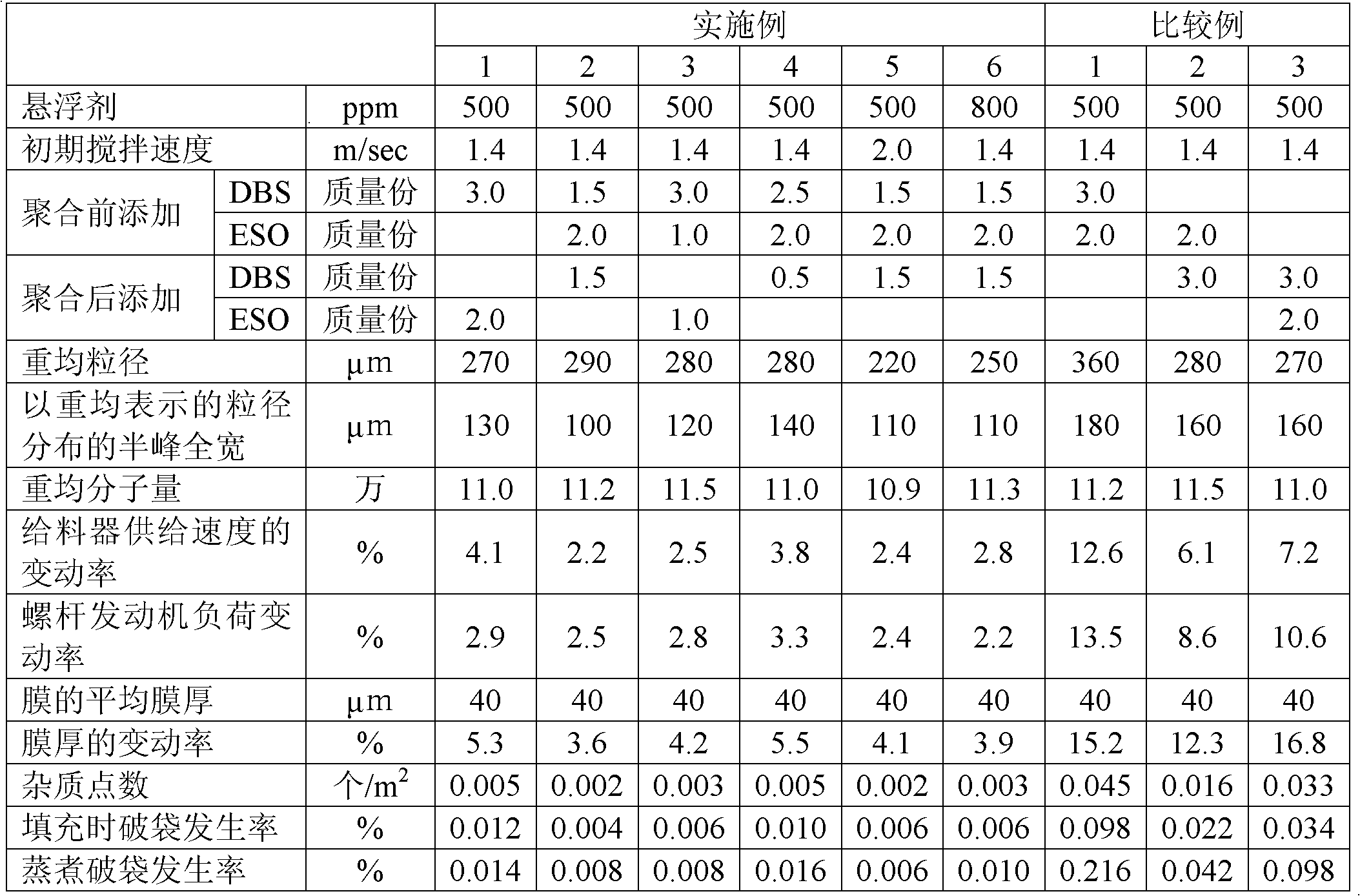

ActiveCN103224676AImprove extrusion stabilityImprove film thickness uniformityFlexible coversWrappersChlorideVolume average

The invention relates to a vinylidene chloride copolymer composition, its preparing method and its membrane or sheet material. The vinylidene chloride copolymer composition of the present invention is the copolymer composition formed by vinylidene chloride and a polymerism vinyl monomer, and is characterized in that the scope of the volume-average diameters of the particle of the copolymer composition is in 200mum-500mum, and the half-peak overall width of the particle size distribution by volume-average expression is below 150mum.

Owner:ASAHI KASEI KK

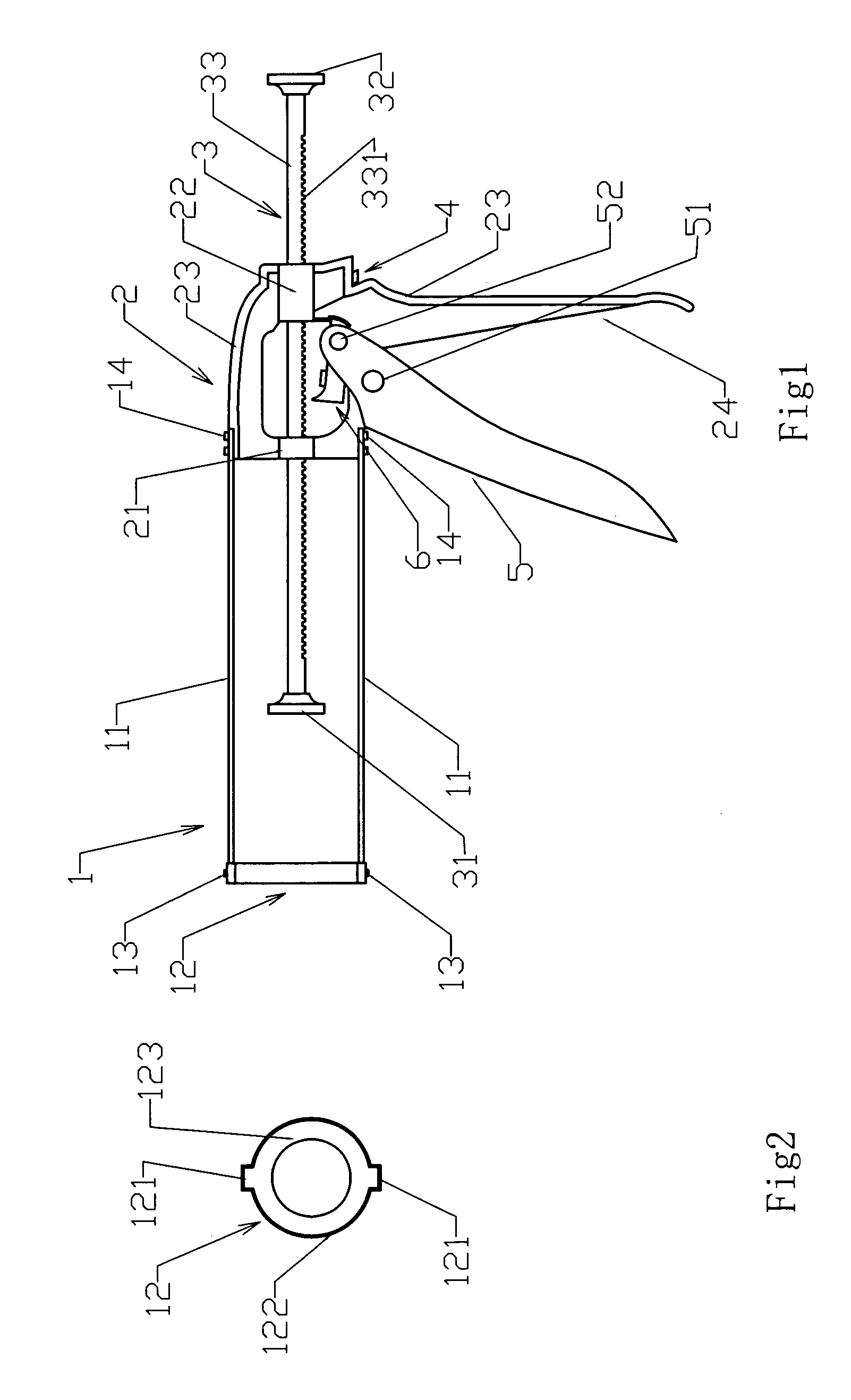

Extrusion apparatus for high viscosity liquid

InactiveUS7717305B2Effective controlHigh viscosityLiquid surface applicatorsLiquid transferring devicesEngineeringViscosity

The present invention discloses an extrusion apparatus for high viscosity liquid to address the problems that the existing extrusion apparatus tends to be abraded for long-time use and the high viscosity liquid could not be well extruded. The extrusion apparatus for high viscosity liquid of the invention comprises a gun body, a retainer fixedly connected to the gun body, a push rod slidably running through the gun body, a wrench hinged to the gun body and a handle connected to the gun body, characterized in that, a push block is hinged to one end of the wrench adjacent to the push rod, the push rod has a rod body provided with several teeth on the side facing the push block, a push tooth is provided on the push block, a permanent magnet is placed on the push block or the push rod, and the push tooth could be snapped to the teeth under action of the magnetic force of the permanent magnet.

Owner:LIANG HAIJUN

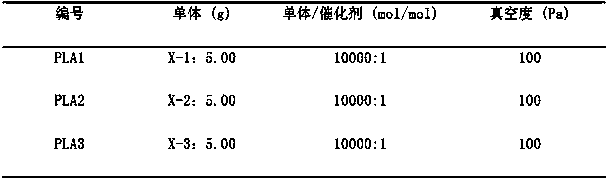

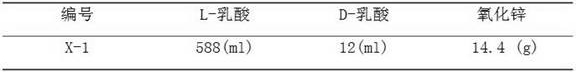

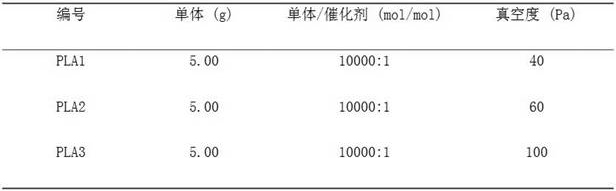

A polylactic acid 3D printing material and wire prepared therefrom

ActiveCN107974062BImprove extrusion stabilityAdditive manufacturing apparatusMonocomponent polyesters artificial filamentWire rodPolymer science

The invention discloses a polylactic acid 3D printing material and a wire prepared therefrom, comprising the following components: (a) 98.0-100 parts of polylactic acid; (b) 0-2.0 parts of a processing aid; wherein, based on the whole polylactic acid The total weight of the polylactic acid has a number average molecular weight Mn of 50,000 to 150,000. The structure of the polylactic acid 3D printing material satisfies the following relationship: 0.8≤Mx / Dx≤7, where Dx represents the polydispersity coefficient and is defined as Mw / Mn, where Mw is the weight average molecular weight of the polylactic acid 3D printing material, and Mn is The number average molecular weight of the polylactic acid 3D printing material, Mx represents the melt flow rate of the polylactic acid 3D printing material at a temperature of 190°C and a load of 2.16kg. The present invention finds through research that when the structure of the polylactic acid 3D printing material satisfies the following relational formula: 0.8≤Mx / Dx≤7, the extrusion speed of the polylactic acid 3D printing material is 45Kg / h, and the diameter of the extruded wire is When the wire diameter is 1.75cm, the extreme difference of the wire diameter is ≤0.12cm, and the relative deviation of the wire diameter is less than 5%, thus showing good wire extrusion stability.

Owner:KINGFA SCI & TECH CO LTD +2

Aromatic polycarbonate resin composition, molded body thereof for optical use, and light diffusion film

InactiveUS8221886B2High transparencyImprove extrusion stabilitySynthetic resin layered productsThin material handlingPolycarbonatePolyresin

Provided is an aromatic polycarbonate resin composition containing, with respect to 100 parts by mass of a resin mixture including 60 to 99 mass % of (A) an aromatic polycarbonate resin and 1 to 40 mass % of (B) a styrene-based resin, 1 to 30 parts by mass of a compatibilizer, the compatibilizer being formed of a block or random copolymer constituted of an aromatic vinyl monomer unit and an acrylate-based monomer unit. This aromatic polycarbonate resin composition has improved transparency and improved extrusion stability.

Owner:IDEMITSU KOSAN CO LTD

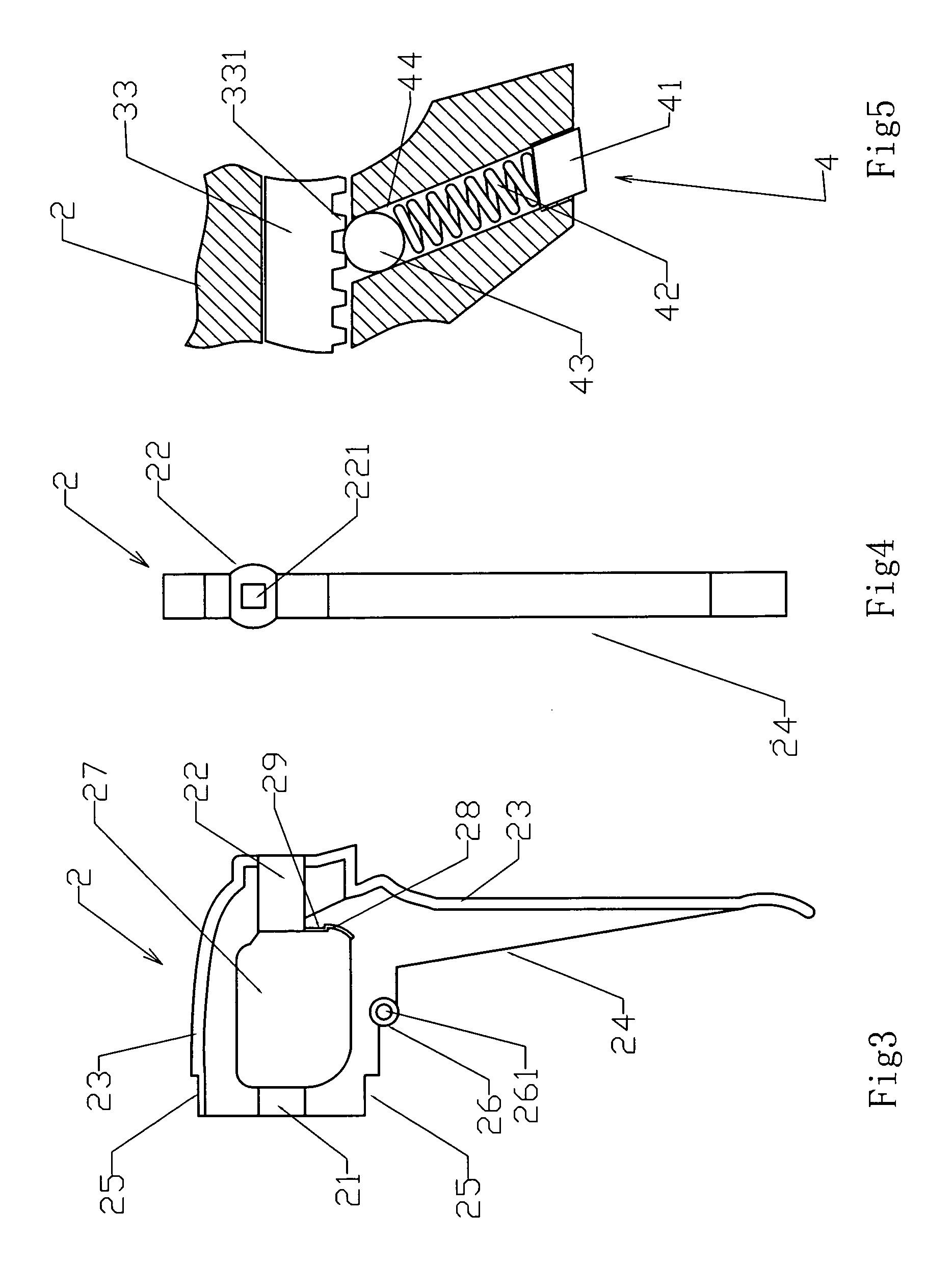

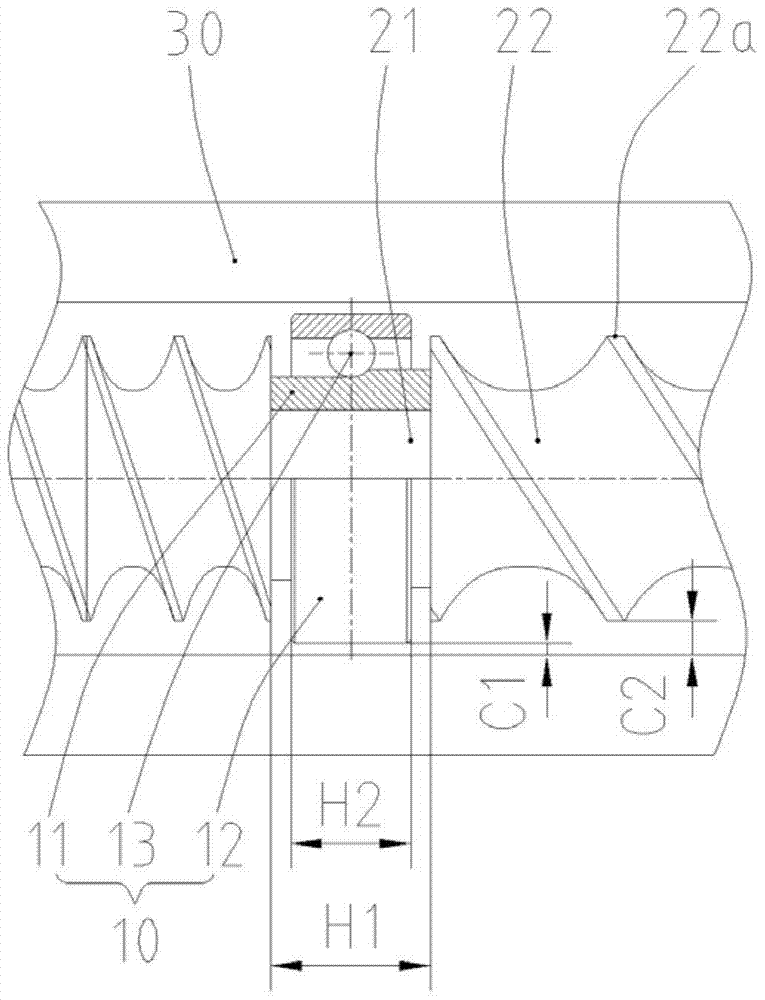

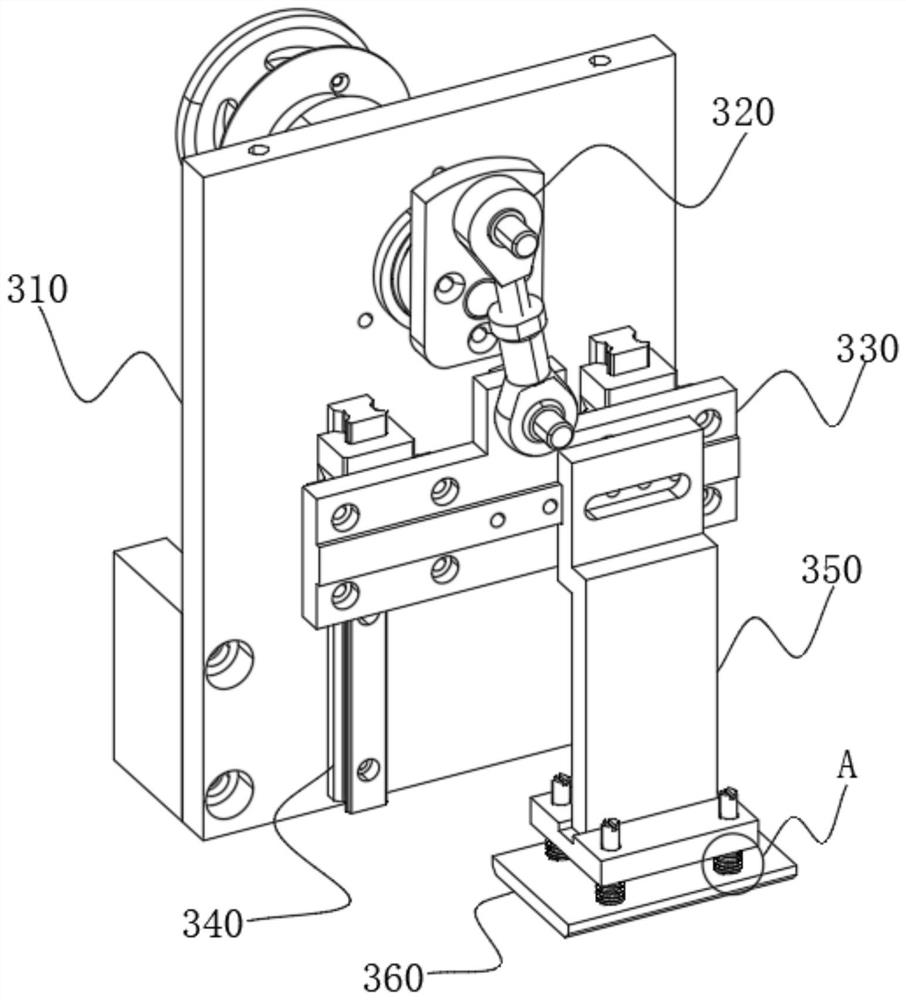

A screw support device and a twin-screw extruder with the same

ActiveCN104999646BDoes not affect normal disassemblyEliminate wear and tearEngineeringMechanical engineering

The invention provides a screw support device and a double-screw extruder provided with the screw support device. The screw support device comprises one pair or more pairs of screw support elements, wherein two screw support elements used in pairs are mounted at the same axial positions of two screw spindles; each screw support element comprises an inner ring, an outer ring and a rolling body; two outer rings are limited by each other; the axial length of each outer ring is smaller than that of each inner ring; the clearance between the radial direction of the outer ring and the inner wall of a machine barrel is smaller than the clearance between a screw flight and the inner wall of the machine barrel; the radial clearance between two outer rings is smaller than the radial clearance between two screws; structures capable of keeping certain distance between the rolling bodies and preventing the rolling bodies from moving in the axial direction relative to the inner rings or the outer rings are arranged on the screw support elements. The double-screw extruder provided with the screw support device supports one or more different positions of the screws so as to eliminate the abrasion between the screws and the machine barrel and the abrasion between the screws.

Owner:HUNAN KUANGWEI TECH CO LTD

Rotation and axial vibration synergic driving method and device for screw rod of directly-driven dynamic extruder

The invention relates to a rotation and axial vibration synergic driving method and a rotation and axial vibration synergic driving device for a plasticized transport screw rod of a directly-driven dynamic extruder. A swinging driving sleeve of the device is connected with a motor hollow shaft through a linear rolling bearing; the swinging driving sleeve is connected with a shaking ring through aligning thrust roller bearings which are symmetrically arranged on both sides of the shaking ring; the swinging driving sleeve is fixedly connected with the plasticized transport screw rod; the inner hole central line of the swinging driving sleeve is coincided with the central line of the motor hollow shaft; meanwhile, the shaking ring is connected with a joint bearing; the shaking ring is restrained by using the joint bearing, and swings by taking the joint bearing as a supporting point; the swinging driving sleeve has a cylindrical structure; the middle part of a cylinder is provided with a cylindrical through hole; and the central line of the outer cylindrical surface of the swinging driving sleeve intersects with the central line of the inner hole cylindrical surface, so that an angle alpha is formed. The swinging driving sleeve is used for driving the plasticized transport screw rod to vibrate axially during rotating, so that homologous synergic driving of the rotation and axial vibration of the screw rod are realized. The device has the characteristics of large axial vibrating amplitude of the plasticized transport screw rod, high stability, high reliability and the like.

Owner:SOUTH CHINA UNIV OF TECH +1

A convenient auxiliary device for precision sheet metal processing

ActiveCN113617956BReduce scrapImprove product qualityMetal-working feeding devicesWelding/cutting auxillary devicesGear wheelEngineering

The invention discloses an easy-to-operate auxiliary device for precision sheet metal processing, specifically relates to the technical field of precision sheet metal processing, including a device box, a clamping mechanism is arranged inside the device box, and a stable mechanism, the device box side is provided with a blanking mechanism; the clamping mechanism includes a drive screw arranged inside the device box. In the present invention, by setting the clamping mechanism, the first spiral ring socket plate and the second spiral ring socket plate are close to each other, the first transmission gear rotates, the adjustment is very simple, and the clamping has wide applicability. The pressing ring, the second rubber extrusion ring, and the third rubber extrusion ring are used for extrusion operation. Not only is the three-point extrusion more stable, it is not easy to shake during the processing, and even if a large force is applied during the extrusion process, the It will not cause strangle marks on the outside of the board, reduce the amount of scrapped boards, and improve the quality of board production.

Owner:南通恒华金属构件有限公司

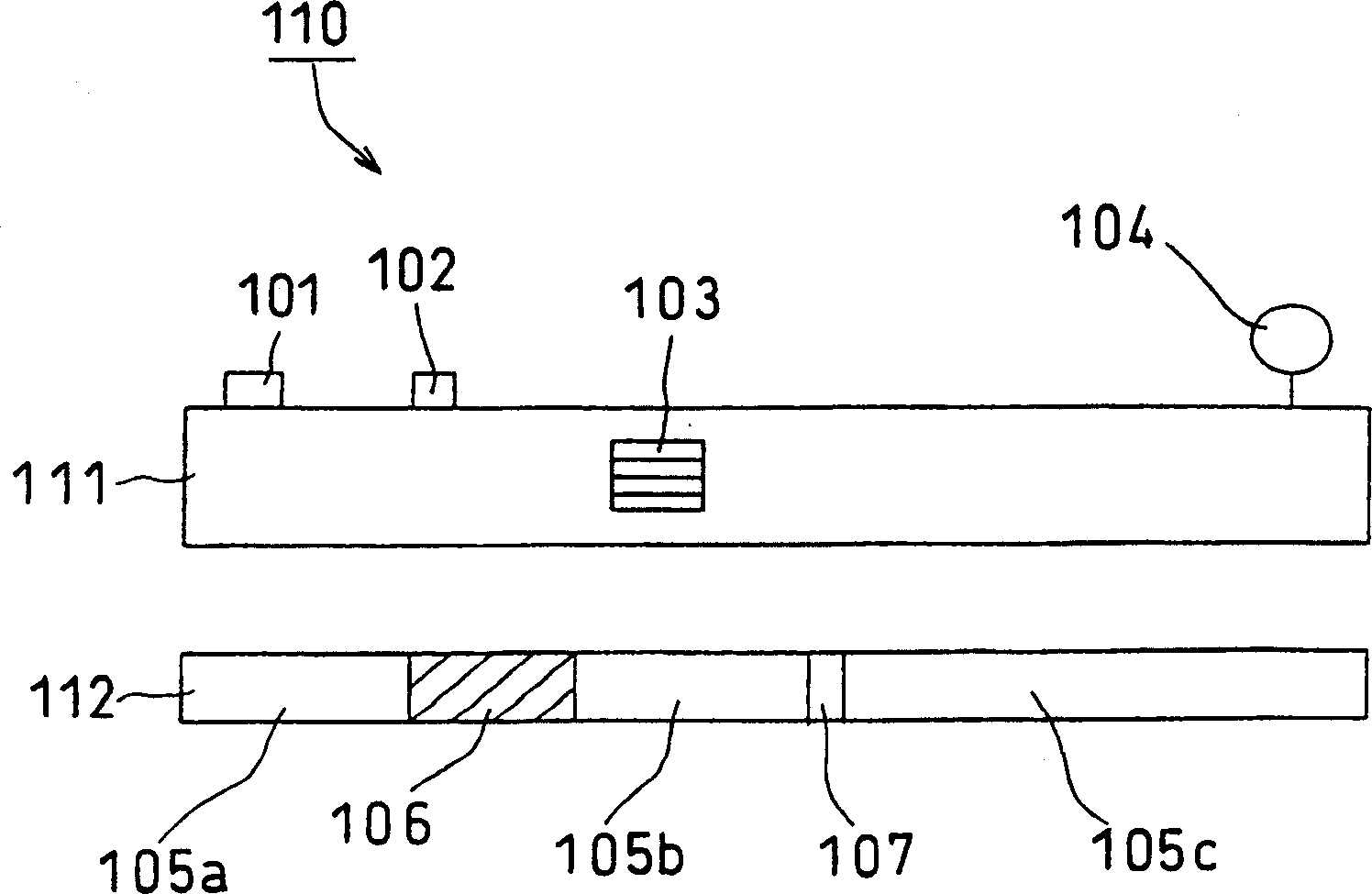

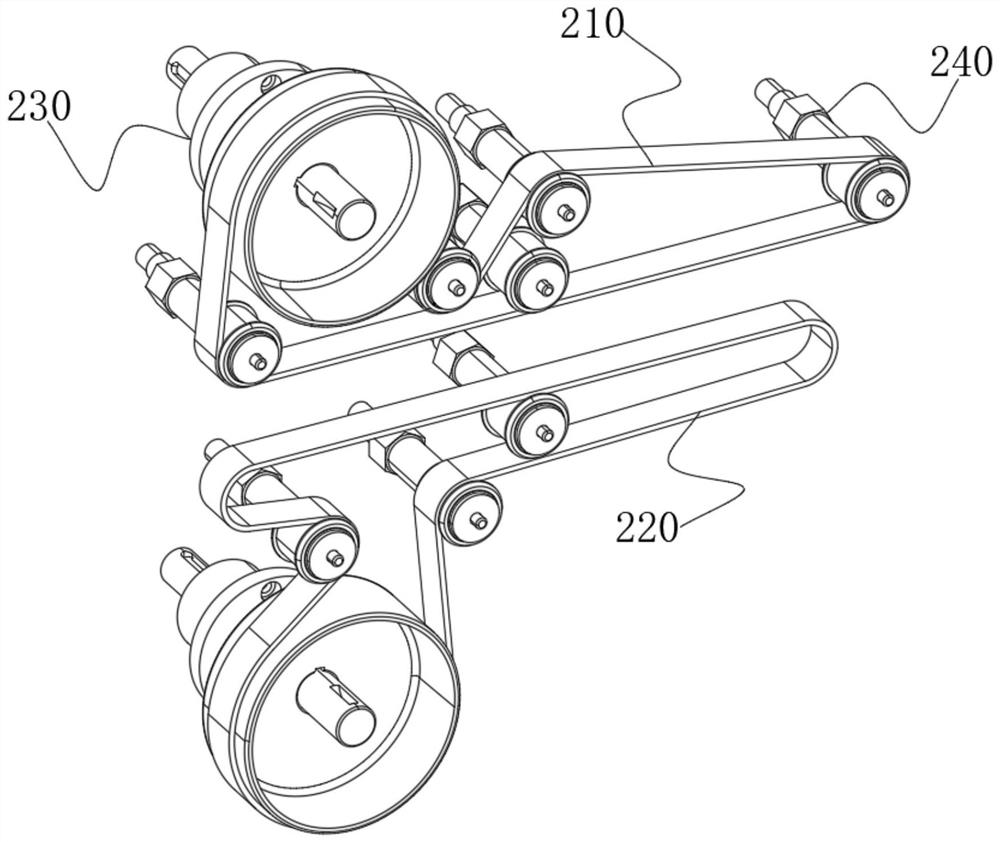

Distance-adjustable paper box conveying equipment

PendingCN113978027APosition remains constantEasy to processBox making operationsPaper-makingDrive shaftControl theory

The invention relates to conveying equipment, in particular to distance-adjustable paper box conveying equipment. The equipment comprises an operation panel and a conveying piece installed on the side face of the operation panel, the conveying piece comprises a driving belt, a driven belt is arranged at the top end of the driving belt, the driven belt is attached to the driving belt, driving shafts are arranged at the inner ends of the driving belt and the driven belt, and a plurality of driven shafts are arranged at the inner ends of the driving belt and the driven belt. The position of a paper box is adjusted through the arranged conveying piece, during specific use, the paper box is attached between the driving belt and the driven belt, the driving shaft drives the driving belt and the driven belt to move, and the driven belt and the driving belt clamp the paper box to move, so that the position distance of the paper box is adjusted, and meanwhile the stability in the sliding process is improved; and the position of the paper box is kept constant in the conveying process, paper box processing in the next stage is facilitated, and the paper box production efficiency is further improved.

Owner:天津树达科技发展有限公司

A quick release device for lifting and distributing modules of disinfection robots

The invention relates to the technical field of components of a medical disinfection robot, in particular to a quick disassembly device for a disinfection robot lifting power distribution module, which includes a disinfection robot body and a power distribution module body installed inside the disinfection robot body. A quick-disconnect device for lifting and distributing power distribution modules of disinfection robots adopts a quick-removal structure design, and inserts the power distribution module body in the upper lifting and lowering assembly groove into the lateral locking surface by using an elastic flipping limit plate. Connect the limit position, so that the power distribution module body is fixed in the upper lifting assembly groove, the operation is simple and convenient; install the elastic folding plate and the flexible liquid storage bag on the side wall of the elastic flip limit plate, and use the elastic flip to squeeze and fill and sterilize The liquid is used to squeeze and limit the elastic flip limit plate, thereby greatly improving the stability and firmness of the entire power distribution module body.

Owner:JIANGSU PANASIA MEDICAL TECH GRP CO LTD

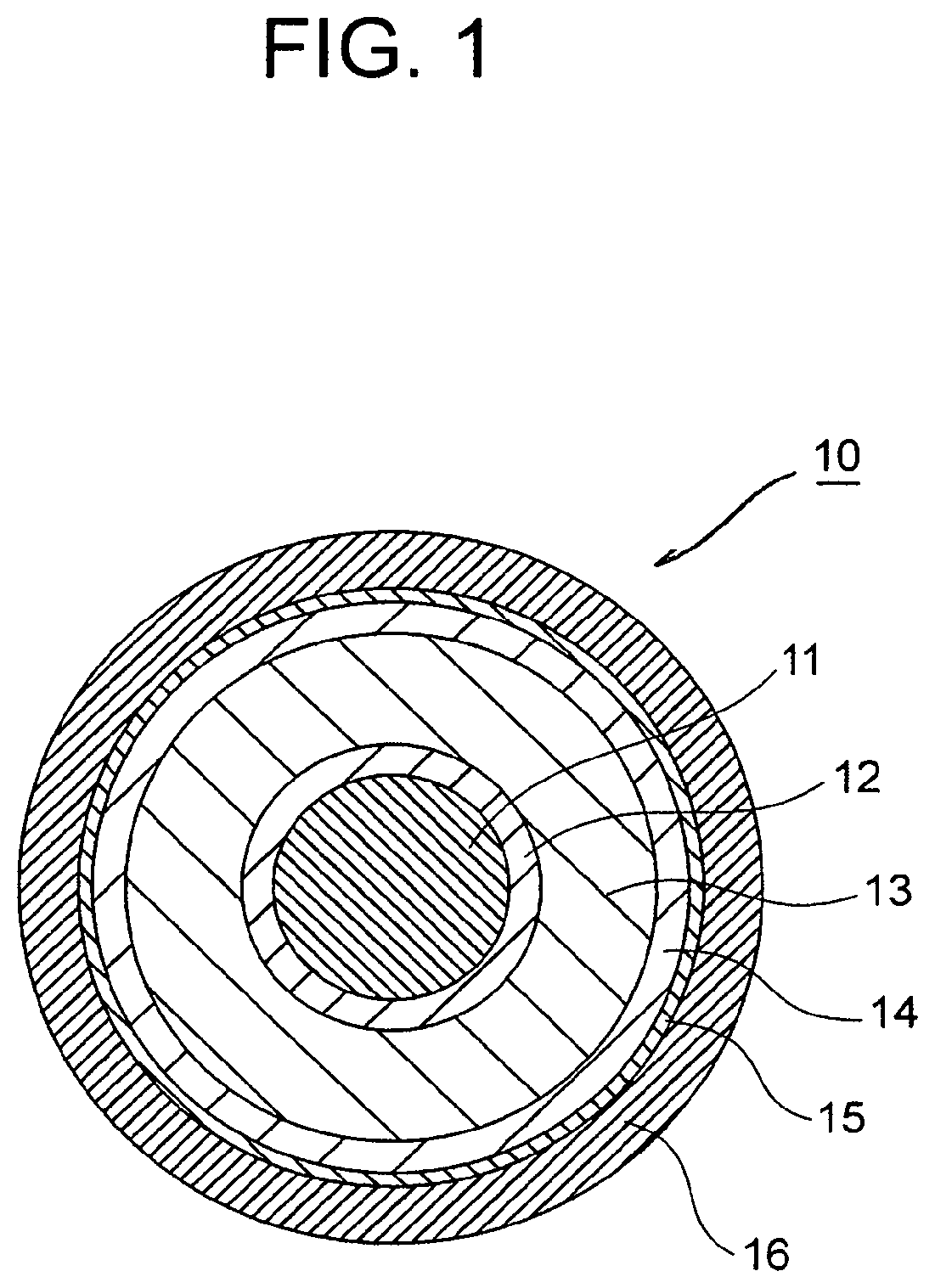

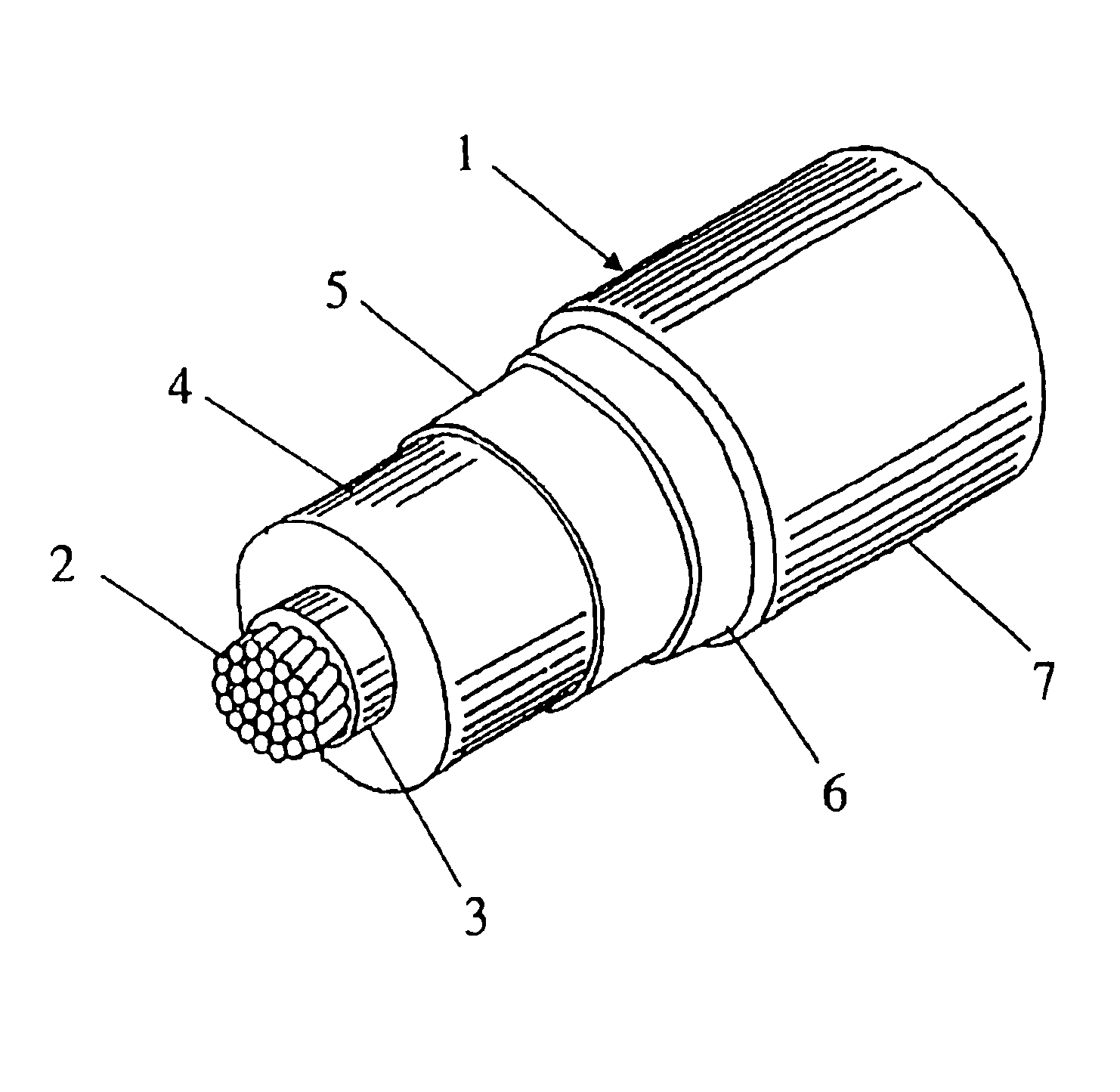

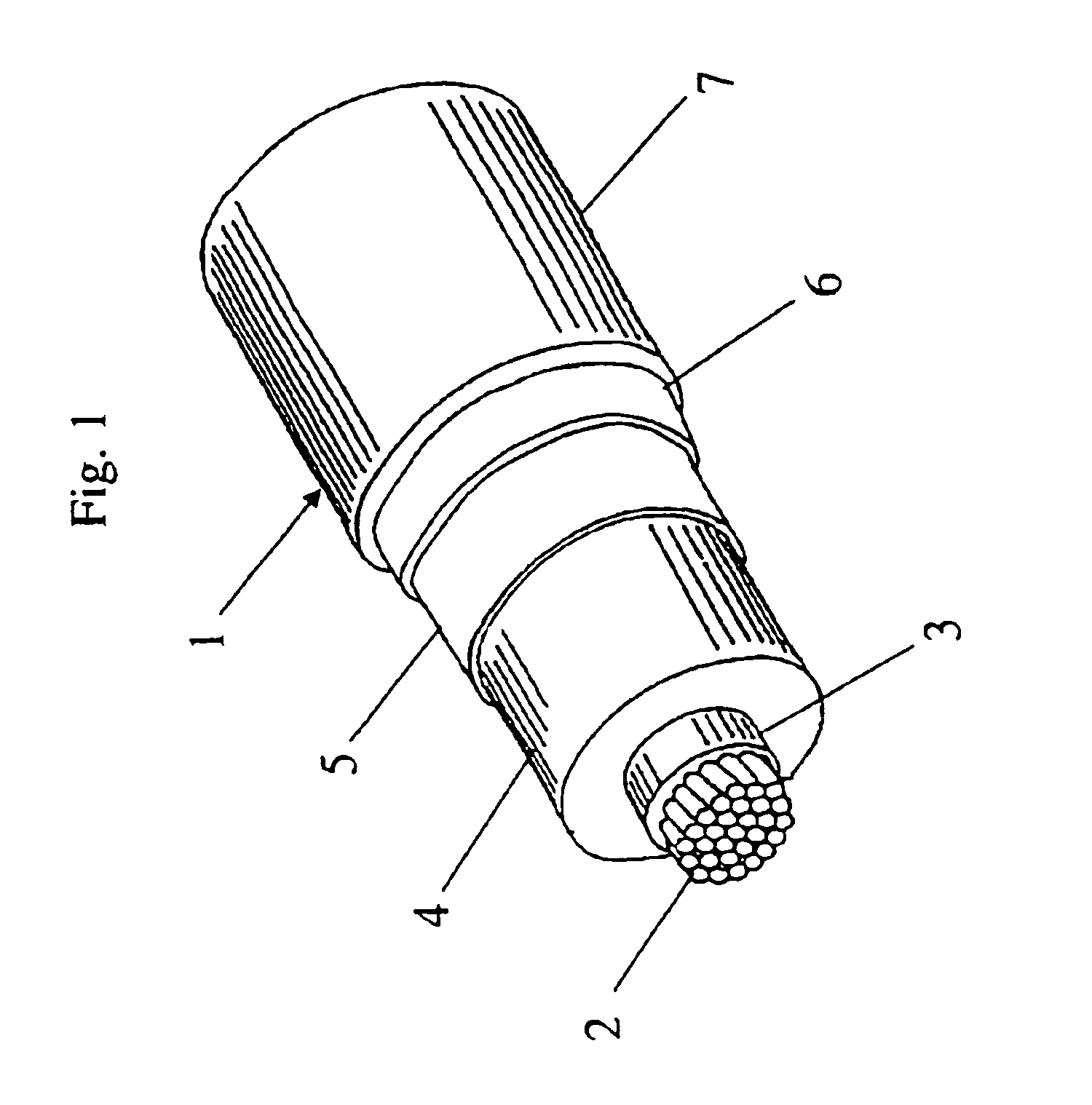

Electrical cable, particularly for high voltage direct current transmission or distribution

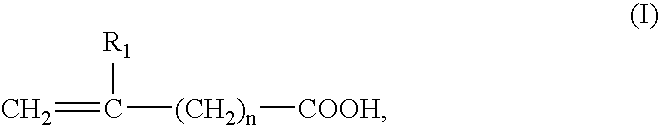

InactiveUS6960726B2Reduce accumulationGood grafting rateLamination ancillary operationsPlastic/resin/waxes insulatorsElectrical conductorFree form

An electrical cable having at least one conductor and at least one extruded insulating coating layer. The extruded insulating coating layer includes a polymeric composition having a polyethylene grafted with at least one unsaturated carboxylic acid of general formula (I): in which: R represents H or CH3; n represents 0 or 1. The grafted polyethylene is derived from polyethylene, a radical initiator and at least one unsaturated carboxylic acid of general formula (I) in free form; and the unsaturated carboxylic acid is present in an amount of between 0.0006% and 0.25% by weight. The amount is expressed as the weight content of —COOH groups relative to the total weight of the polymeric composition.

Owner:PRYSMIAN CAVI E SISTEMI ENERGIA

A kind of preparation method of polyamide superfine fiber net

ActiveCN106757771BWide range of usesImprove filtration efficiencyFilament forming substance formingMelt spinning methodsPolyamideEngineering

The invention provides a preparation method of a polyamide ultrafine fiber web. The preparation method includes the steps of drying, feeding, screw melt extruding, filtering, accurately metering with a metering pump, die spinning, high-temperature and high-speed air drawing and web forming. Compared with regular melt-blown materials, the melt-blown ultrafine fiber web has good corrosion resistance and high-temperature resistance and is widely applied for filtering corrosive liquid or oils. Besides, compared with regular products, PA66 melt-blown products have sound wear-resisting property and high filament strength. The filament strength of normal melt-blown PP fibers is about 1.5cN / dtex while the filament strength of PA66 fibers is 3.5cN / dtex. Thus, the strength of PA66 melt-blown non-woven fabric is much higher than that of polyamide melt-blown non-woven fabric.

Owner:山东滨州红叶网业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com