Electric field type polymer extruder head

A technology of polymers and extruders, which is applied in the field of improvement of screw extruder heads, and can solve the problems of reduced stability of extrusion products extruded by extruders, increased manufacturing costs of extruders, and high prices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

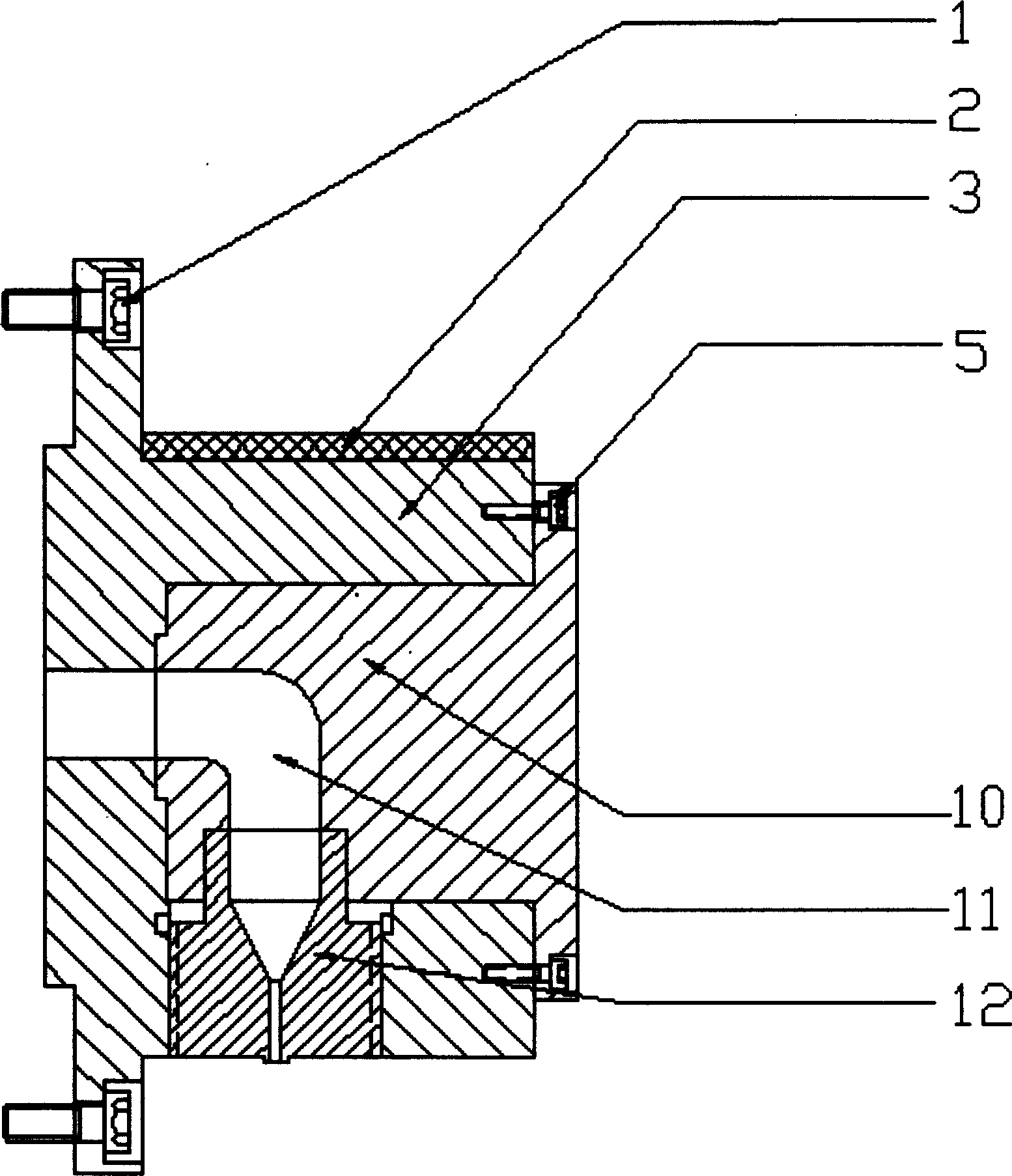

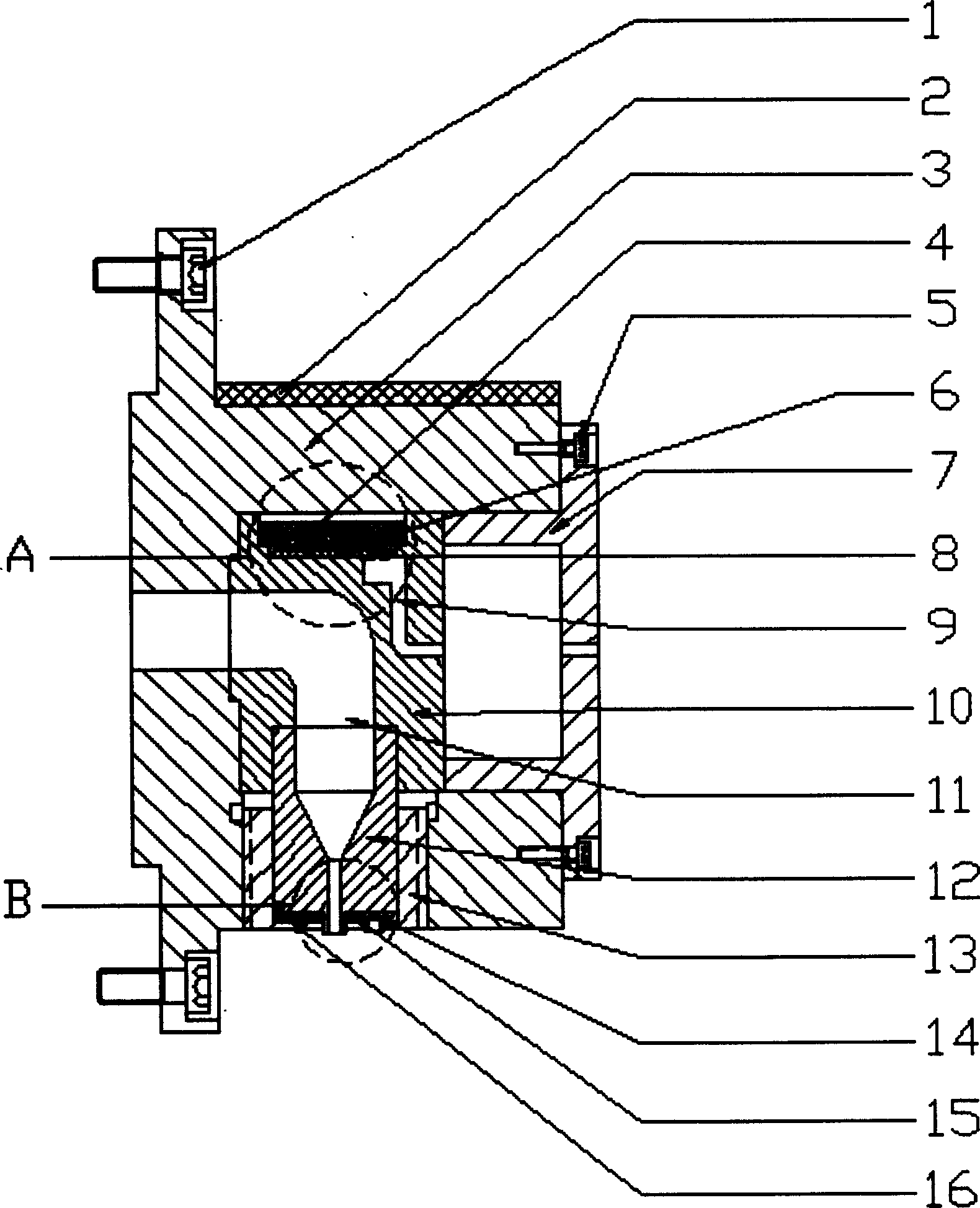

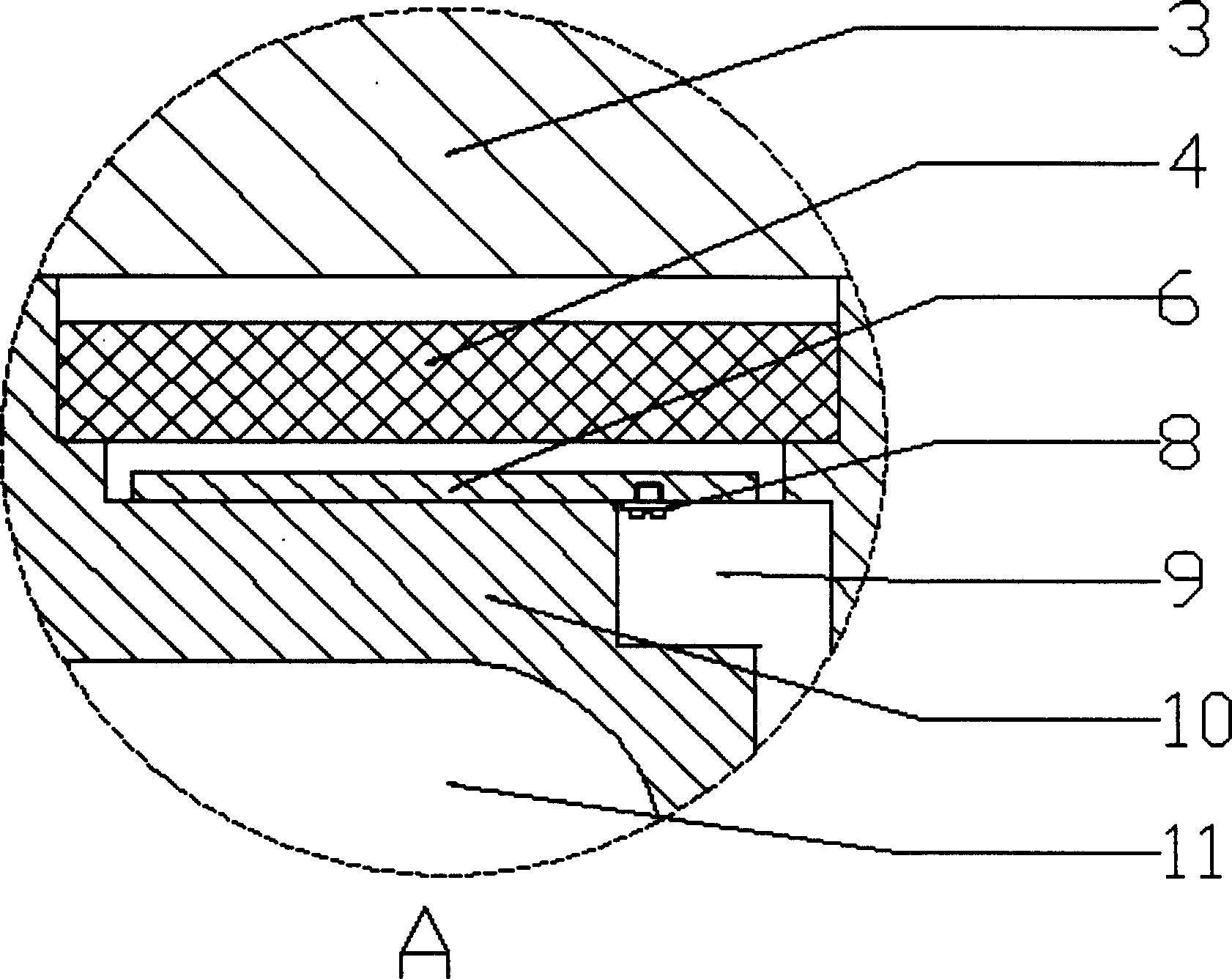

[0019] The head of an electric field polymer extruder proposed by the present invention has a connecting flange 3 and its external heating jacket 2 and a stopper 10 embedded in the inner wall of the connecting flange 3, and the connecting flange 3 and the stopper 10 1. The melt channel 11 formed by the smooth connection of the die core 12 and the die seat 13 are composed of an electrode plate 6 and an electrode plate 15 for applying a voltage around the melt channel 11 .

[0020] An electric field type polymer extruder head, the electrode plate 6 is located between the upper insulating pad 4 and the stopper 10 connecting the inner wall of the flange 3, and the other electrode plate 15 is located in the die core forming the melt flow channel 11 12 between the lower end and the lower insulating pad 16; the die core 12 is placed in the die seat 13, which is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com