Silane cross-linking semi-conductive inner shielding material and production process thereof

A technology of silane crosslinking and production process, which is applied in the field of cable materials, can solve the problems of resin crosslinking, high temperature control of equipment, high reaction temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

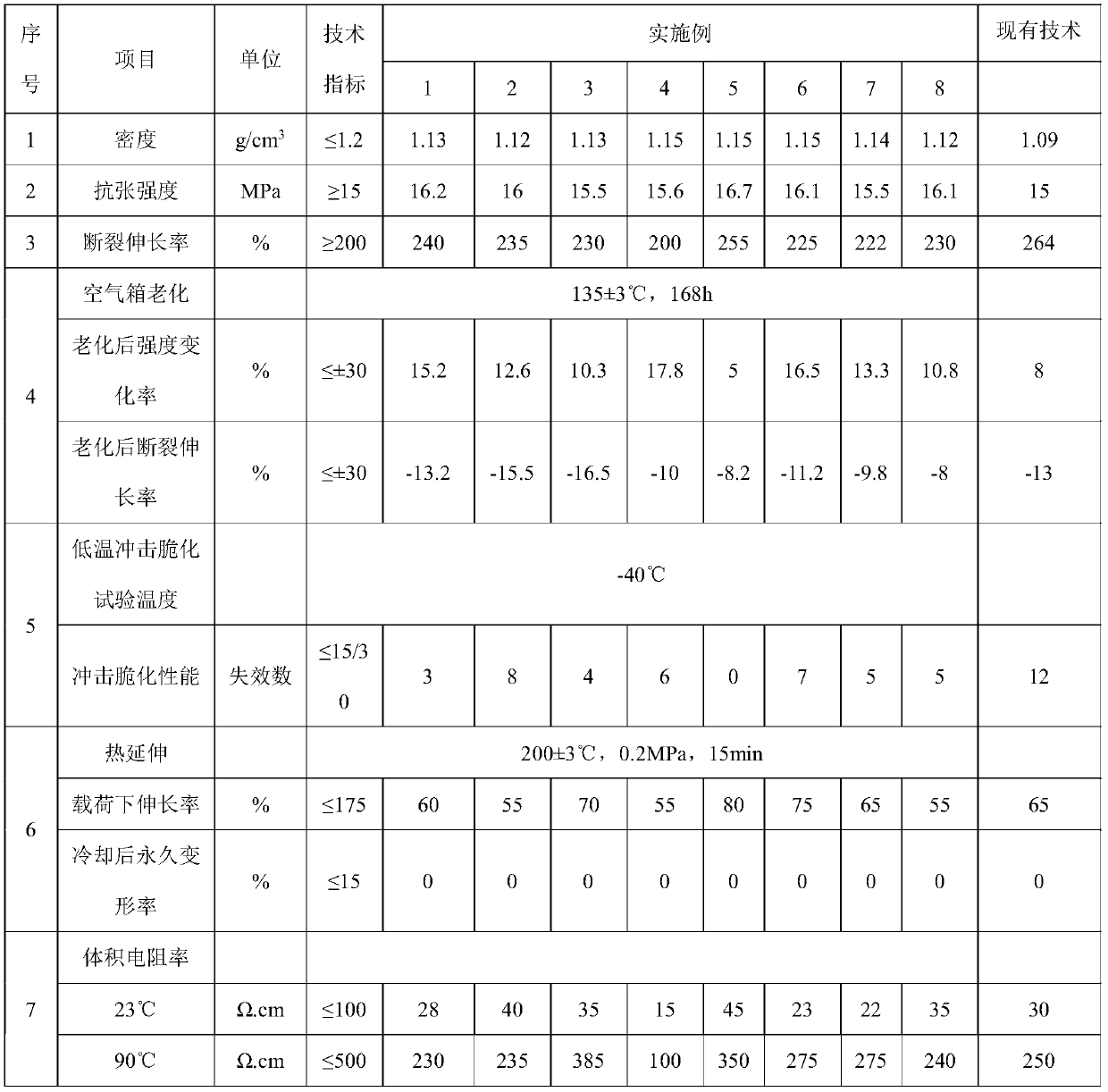

Examples

Embodiment 1

[0025] The production process of the silane cross-linked semi-conductive inner shielding material in this embodiment adopts high-conductivity A material and catalytic B material to be mixed and co-extruded and then cross-linked in warm water.

[0026] In parts by weight, 40 parts of ethylene-vinyl acetate copolymer, 60 parts of ethylene-vinyl silane copolymer, 60 parts of high-conductivity carbon black, 2 parts of EBS, 10 parts of white oil and 1 part of antioxidant 1010 are automatically metered The device automatically feeds the material into the single screw of the reciprocating machine to extrude and granulate to prepare high-conductivity A material. The temperature of the reciprocating machine shaft is 50°C, the first zone is 70°C, the second zone is 90°C, the third zone is 115°C, the temperature of the single screw mandrel is 40°C, the first zone is 90°C, the second zone is 120°C, and the head is 140°C.

[0027] In parts by weight, 100 parts of ethylene-vinyl acetate cop...

Embodiment 2

[0030] The silane cross-linked semiconductive inner shielding material of the present embodiment and its production process steps are as follows: in parts by weight, 50 parts of ethylene-vinyl acetate copolymer, 50 parts of ethylene-vinyl silane copolymer, and 55 parts of high-conductivity carbon black , 1 part of EBS, 8 parts of white oil and 0.8 part of antioxidant 1010 are passed through the automatic metering device, and the materials are automatically fed into the single screw of the reciprocating machine for extrusion and granulation to prepare high-conductivity A material. The temperature of the reciprocating machine shaft is 50°C, the first zone is 70°C, the second zone is 90°C, the third zone is 115°C, the temperature of the single screw mandrel is 40°C, the first zone is 90°C, the second zone is 120°C, and the head is 140°C.

[0031] In parts by weight, 100 parts of ethylene-vinyl acetate copolymer, 1 part of dibutyltin dilaurate, and 10101 parts of antioxidant are pa...

Embodiment 3

[0034] The production process steps of the silane cross-linked semiconductive inner shielding material of the present embodiment are as follows: in parts by weight, 50 parts of ethylene-vinyl acetate copolymer, 40 parts of ethylene-vinylsilane copolymer, and 70 parts of high-conductivity carbon black , 2 parts of EBS, 12 parts of white oil and 1.2 parts of antioxidant 1010 are passed through the automatic metering device, and the materials are automatically fed into the single screw of the reciprocating machine for extrusion and granulation to prepare high-conductivity A material. The temperature of the reciprocating machine shaft is 50°C, the first zone is 70°C, the second zone is 90°C, the third zone is 115°C, the temperature of the single screw mandrel is 40°C, the first zone is 90°C, the second zone is 120°C, and the head is 140°C.

[0035] In parts by weight, 100 parts of ethylene-vinyl acetate copolymer, 3 parts of dibutyltin dilaurate, and 10100.5 parts of antioxidant ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com