Method for continuously preparing water-in-oil type high internal phase emulsion and polymer porous material

A high internal phase emulsion, water-in-oil technology, which is applied in the fields of emulsion preparation and porous material preparation, can solve problems such as applications that have not yet been reported, and achieve the effects of simple and easy method, high quality and good temperature control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

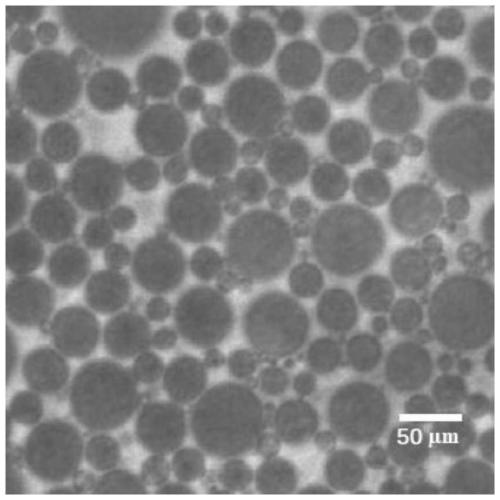

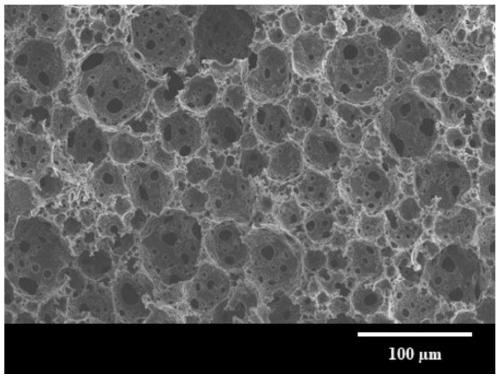

Embodiment 1

[0056] Take 100 grams of Span 80 by weighing, add in the mixture of 1600 grams of styrene and 400 grams of divinylbenzene, the obtained organic solution is an oil phase. 300 grams of sodium chloride and 100 grams of potassium persulfate were weighed and added to 8000 grams of distilled water, and the resulting solution was the water phase. Heat the oil phase and the water phase to 30°C respectively, and then add the oil phase and the water phase at a volume ratio of 1:3 to the cylinder temperature set at 30°C and the twin-screw speed at 350 rpm through a constant flow pump. in a twin-screw extruder. After the water phase and the oil phase are sheared by the twin-screw, the high internal phase emulsion comes out from the outlet of the extruder. Heat the obtained high internal phase emulsion to 70°C to initiate polymerization of the monomers in the high internal phase emulsion, and react to obtain a white solid. Wash the solid product with rinsing solvent water, ethanol or thei...

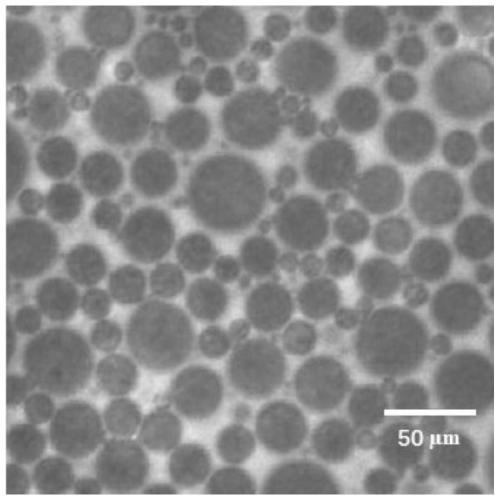

Embodiment 2

[0061] Weigh 600 grams of Span 60, add 1600 grams of 2-hydroxyethyl methacrylate and 400 grams of ethylene glycol dimethacrylate into the mixture, and the resulting organic solution is an oil phase. Weigh 300 grams of sodium chloride and 300 grams of potassium persulfate and add them to 10,000 grams of distilled water, and the resulting solution is the water phase. Heat the oil phase and the water phase to 30°C respectively, and then add the oil phase and the water phase at a volume ratio of 1:4 to the cylinder temperature set at 30°C and the twin-screw speed at 100 rpm through a constant flow pump. in a twin-screw extruder. After the water phase and the oil phase are sheared by the twin-screw, the high internal phase emulsion comes out from the outlet of the extruder. Heat the obtained high internal phase emulsion to 70°C to initiate polymerization of the monomers in the high internal phase emulsion, and react to obtain a white solid. Wash the solid product with rinsing solv...

Embodiment 3

[0066] Weigh 200 grams of polyglycerol alkenyl succinate and 100 grams of HypermerT96, add 1600 grams of 2-ethylhexyl acrylate and 400 grams of divinylbenzene into the mixture, the resulting organic solution is an oil phase. Weigh 200 grams of sodium chloride and 300 grams of potassium persulfate and add them to 10,000 grams of distilled water, and the resulting solution is the water phase. Heat the oil phase and the water phase to 30°C respectively, and then add the oil phase and the water phase according to the volume ratio of 1:40 into the cylinder temperature set at 30°C and the twin-screw speed at 150 rpm through a constant flow pump. in a twin-screw extruder. After the water phase and the oil phase are sheared by the twin-screw, the high internal phase emulsion comes out from the outlet of the extruder. Heat the obtained high internal phase emulsion to 70°C to initiate polymerization of the monomers in the high internal phase emulsion, and react to obtain a white solid....

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com