A polylactic acid 3D printing material and wire prepared therefrom

A 3D printing and polylactic acid technology, which is applied in the field of polylactic acid 3D printing materials and wires prepared from it, can solve the problems of wire extrusion stability that are not mentioned, and achieve good wire extrusion stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

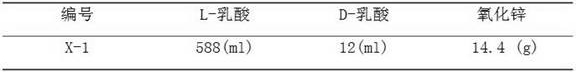

[0034] The preparation method of polylactic acid is as follows:

[0035] Add L-lactic acid, D-lactic acid monomer and ZnO in the ratio of Table 1 into the reaction vessel, stir evenly, react at 80-140°C and 4-10 KPa pressure for 6-12 h, distill off water, and form low Polymer. Add ZSM-5 molecular sieves to the reaction product in a vacuum distillation reaction vessel, stir evenly, and conduct vacuum distillation at 170-210°C and 102-103 Pa pressure until no product is distilled out. The time is 7-15 hours to obtain propane lactide products.

[0036] Table 1 Reactant Raw Material Composition Ratio

[0037]

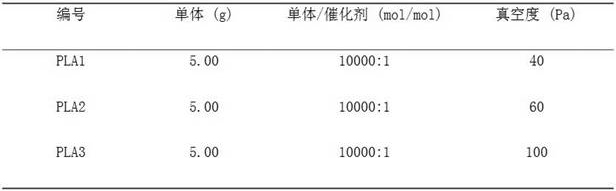

[0038] Accurately weigh a certain amount of the lactide product prepared in Table 1 into a sealed tube, then add a certain amount of stannous isooctanoate dichloromethane solution, and remove the solvent dichloromethane at room temperature. Place the sealed tube at room temperature, evacuate, inject high-purity nitrogen, and repeat three times. After evacuating for h...

Embodiment 1-6

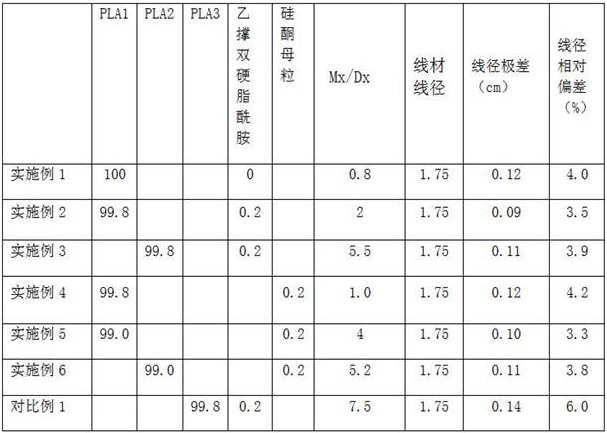

[0041] Example 1-6: Preparation of polylactic acid 3D printing materials

[0042] Mix PLA and processing aids according to the parts by weight shown in Table 3, put them into a twin-screw extruder, extrude and pelletize at 160°C-180°C, and obtain polylactic acid 3D printing materials;

[0043] Pull the polylactic acid 3D printing material on a single-screw extruder, control the extrusion temperature of the single screw to 160°C-210°C, and control the temperature of the water tank to be between 40°C and 60°C to obtain the polylactic acid 3D printing wire. Among them, The wire diameter of the extruded wire is 1.75cm, and the wire extrusion speed is 45Kg / h. The performance test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com