Ethylene-vinyl alcohol copolymer resin and particle producing method thereof, the resin particle

A copolymer and vinyl alcohol technology, applied to the preparation of ethylene-vinyl alcohol copolymer resin and its pellets, can solve the problems of thermal stability decline, easy adhesion, poor quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

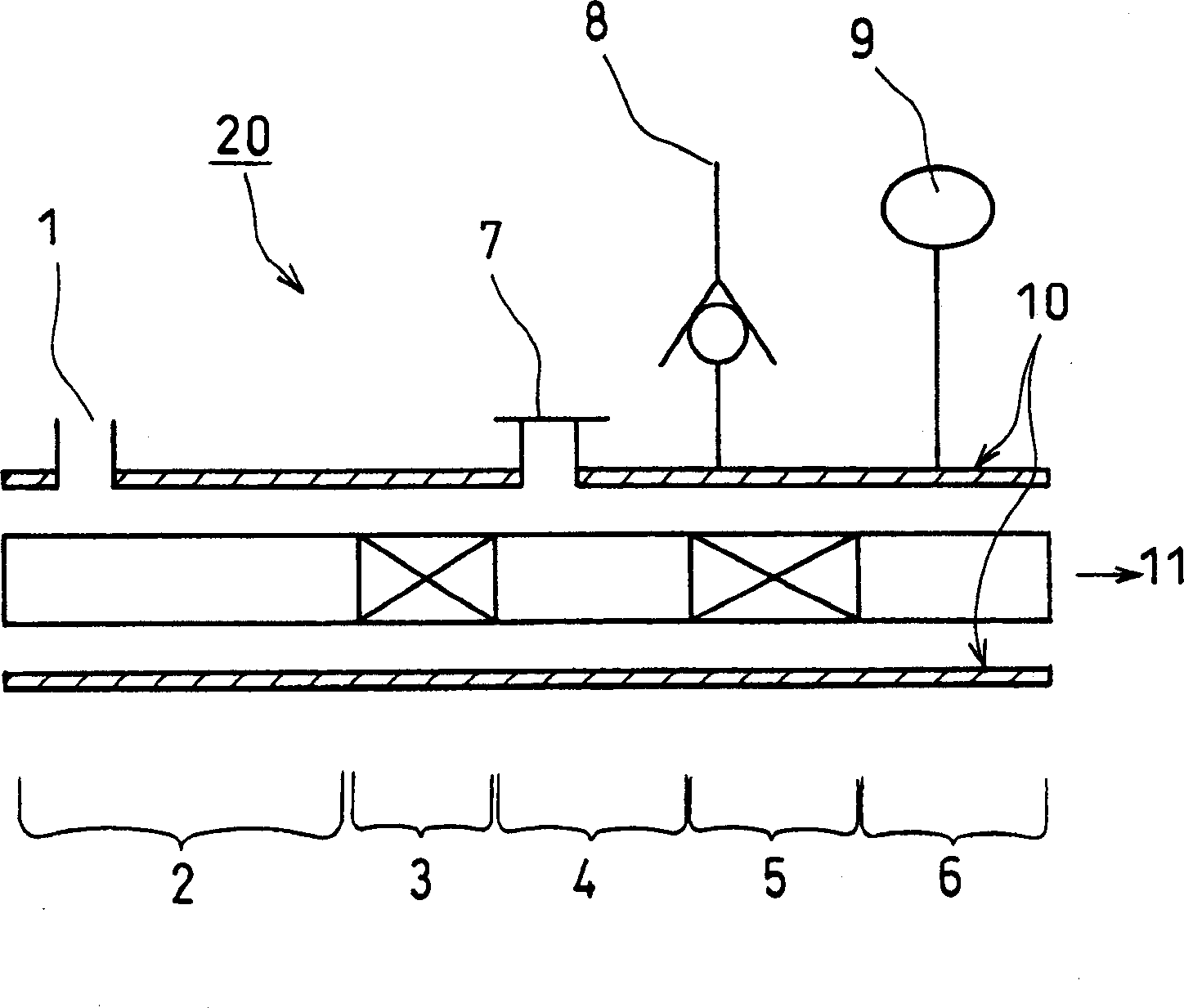

[0221] The EVOH with ethylene content 32 mol%, saponification degree 99.5 mol%, water content 35% by weight is dropped into such as figure 1 In the recorded twin-screw extruder, set the resin temperature at the outlet to 100°C, from figure 1 In the trace component addition portion at the front end portion on the discharge port side shown, a treatment liquid composed of acetic acid / boric acid / sodium acetate / magnesium acetate / potassium dihydrogen phosphate aqueous solution is added. The input amount of EVOH per unit time is 10kg / hr (including the weight of water contained therein), the input amount of treatment liquid per unit time is 0.65L / hr, and the composition of the treatment liquid is 4.3g / L acetic acid, 15g / L Aqueous solution of boric acid, 4.6g / L sodium acetate, 3.0g / L magnesium acetate, 1.4g / L potassium dihydrogen phosphate. The specifications of the twin-screw extruder are as follows (details are described in figure 1 middle).

[0222] Form Twin-screw extruder

[0...

Embodiment 2-4

[0252] In addition to changes in the ethylene content in EVOH, degree of saponification, resin temperature in the extruder, moisture content before feeding into the extruder, and moisture content immediately after discharge from the extruder as summarized in Table 1, Except that the addition amount of EVOH per unit time and the addition amount per unit time of at least one solution selected from carboxylic acid, boron compound, phosphoric acid compound, alkali metal salt and alkaline earth metal salt and its composition are changed as shown in Table 2, EVOH pellets were produced in the same manner as in Example 1. The extrusion conditions are shown in Table 1, the composition of the treatment liquid is shown in Table 2, the composition of the obtained EVOH pellets is shown in Table 3, and the evaluation results are shown in Table 4.

Embodiment 5

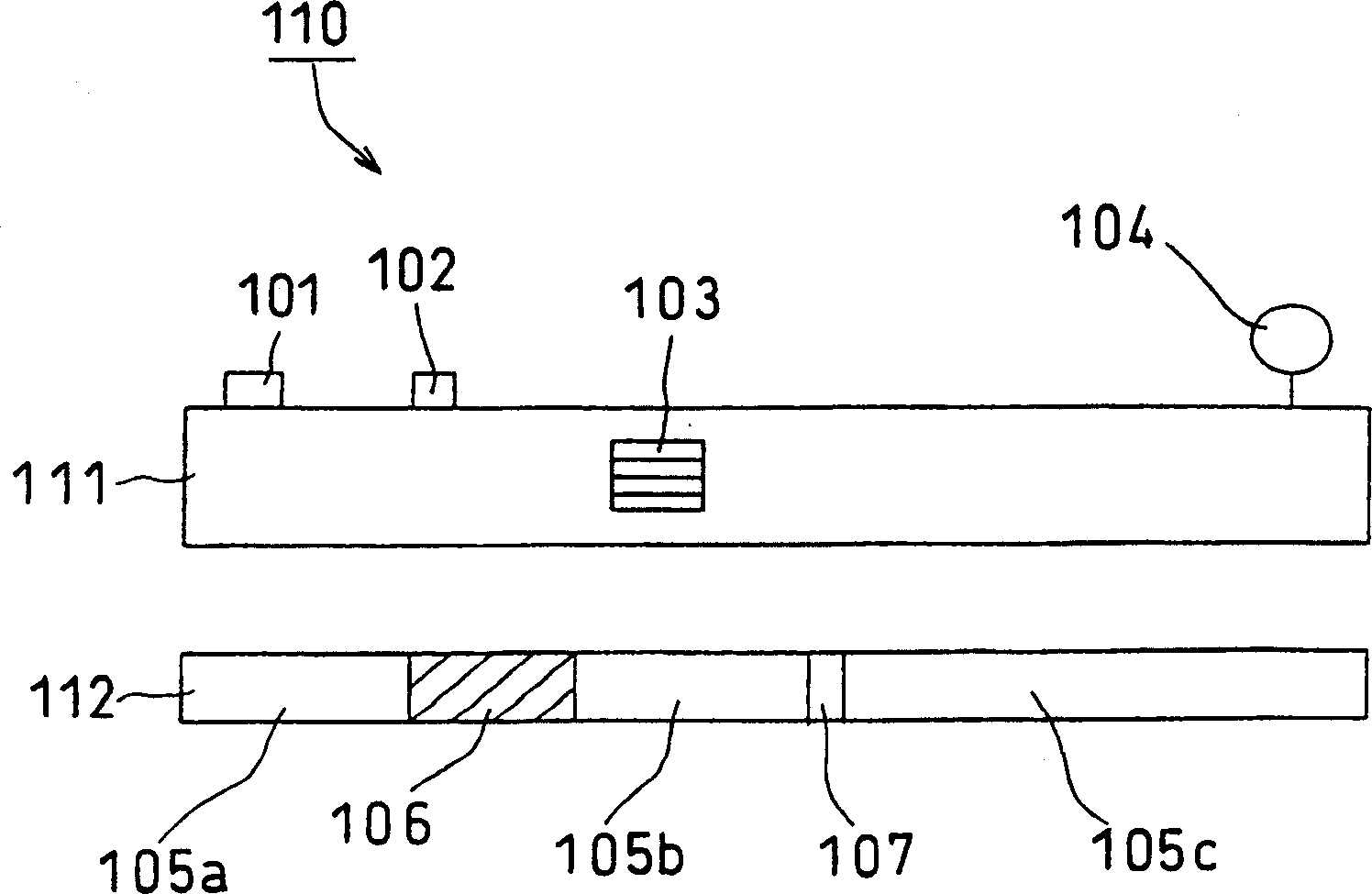

[0294] EVOH having an ethylene content of 32 mol%, a degree of saponification of 99.5 mol%, a water content of 40% by weight, and a sodium ion content of 1.5% by weight in terms of metals is supplied to such as image 3 Inside the twin-screw extruder shown. The twin-screw extruder consists of a raw material supply part, a cleaning liquid addition part, and a dehydration part, and a wedge-shaped wire-shaped dehydration slit is arranged at the dehydration part. Add 0.5g / L acetic acid aqueous solution from the cleaning solution addition site. The unit time input amount of EVOH is 50kg / hr (including the weight of contained water), the unit time input amount of acetic acid aqueous solution is 600L / hr, and the EVOH residence time is 5 minutes. The EVOH discharged from the wire die installed at the front end of the extruder was cut into pellets with a pelletizer. The specifications of the twin-screw extruder are shown below.

[0295] Form Twin-screw extruder

[0296] L / D 42

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com