Extrusion-grade polycarbonate alloy material as well as preparation method and application thereof

A technology of polycarbonate and alloy materials, applied in the field of extrusion-grade polycarbonate alloy materials and their preparation, to achieve the effects of improving melt strength, improving system toughness, and improving extrusion molding stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

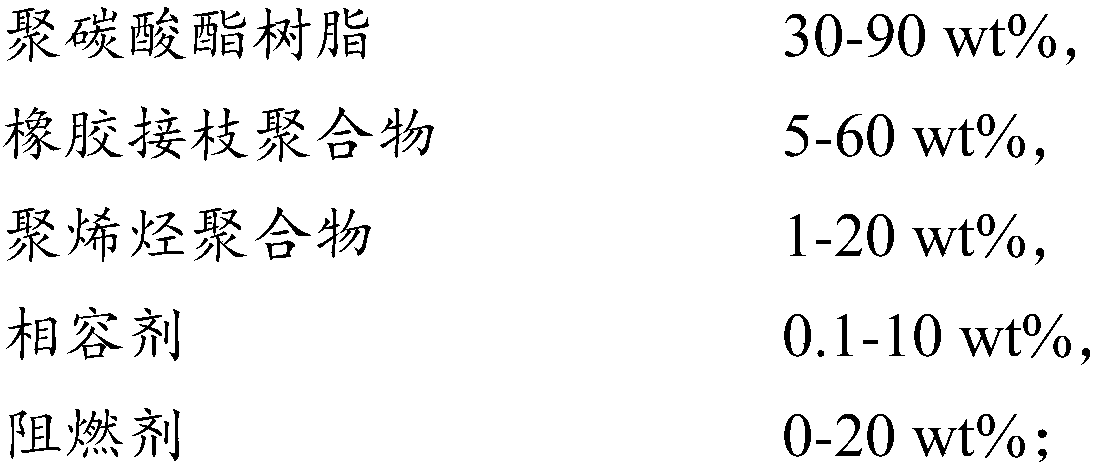

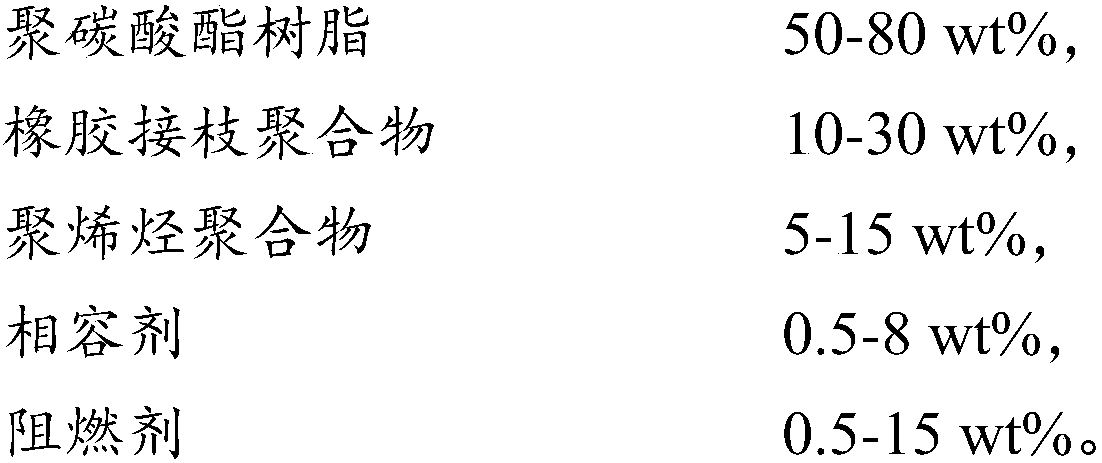

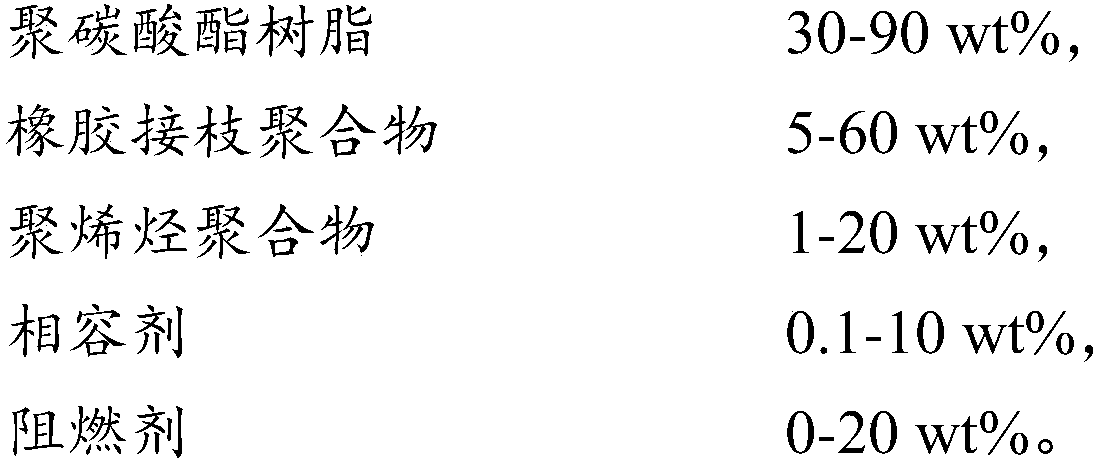

Method used

Image

Examples

Embodiment 1

[0079] (1) Weigh K-1300Y 7.5kg, 3513 1kg, WB260HMS 1kg, PO-003 0.5kg, B900 0.02kg, PETS 0.03kg;

[0080] (2) Mix the weighed material in the high mixer for 5 minutes before discharging;

[0081] (3) Add the mixed material into the twin-screw extruder, and set the temperature of each section of the extruder as follows (from the feeding port to the head): 80°C, 220°C, 250°C, 250°C, 250°C, 250°C, 250°C, 250°C, 245°C, 245°C; the die temperature is 245°C, the extrusion speed is 300RPM, the modified material is extruded from the die and granulated by water cooling to obtain the alloy material.

Embodiment 2

[0083] (1) Weigh K-1300Y 6kg, 3513 3kg, WB260HMS 0.8kg, PO-003 0.2kg, B900 0.02kg, PETS 0.03kg;

[0084] (2) Mix the weighed material in the high mixer for 5 minutes before discharging;

[0085] (3) Add the mixed material into the twin-screw extruder, and set the temperature of each section of the extruder as follows (from the feeding port to the head): 80°C, 220°C, 250°C, 250°C, 250°C, 250°C, 250°C, 250°C, 245°C, 245°C; the die temperature is 245°C, the extrusion speed is 300RPM, the modified material is extruded from the die and granulated by water cooling to obtain the alloy material.

Embodiment 3

[0087] (1) Weigh K-1300Y 9kg, 3513 0.5kg, WB260HMS 0.1kg, 1215HT 0.3kg, BDP 0.1kg, SN3300B3 0.03g, B900 0.02kg, PETS 0.03kg;

[0088] (2) Mix the weighed material in the high mixer for 5 minutes before discharging;

[0089] (3) Add the mixed material into the twin-screw extruder, and set the temperature of each section of the extruder as follows (from the feeding port to the head): 80°C, 220°C, 250°C, 280°C, 280°C, 280°C, 280°C, 280°C, 270°C, 270°C; the die temperature is 270°C, the extrusion speed is 100RPM, the modified material is extruded from the die and granulated by water cooling to obtain the alloy material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt strength | aaaaa | aaaaa |

| melt strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com