Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Guaranteed Straight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

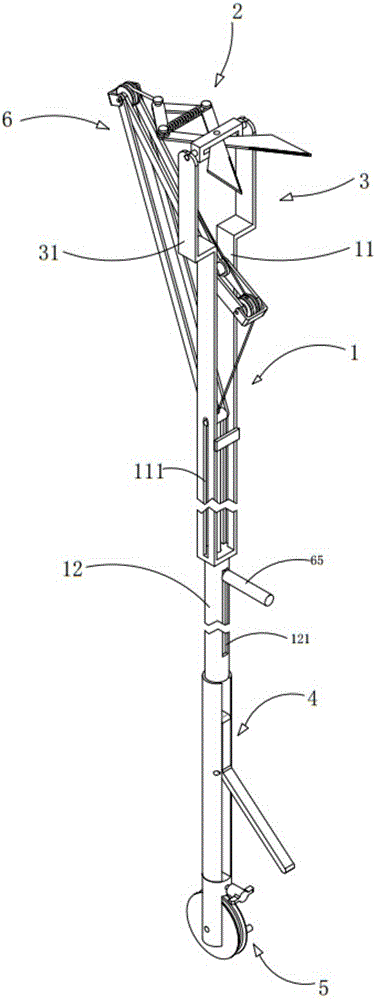

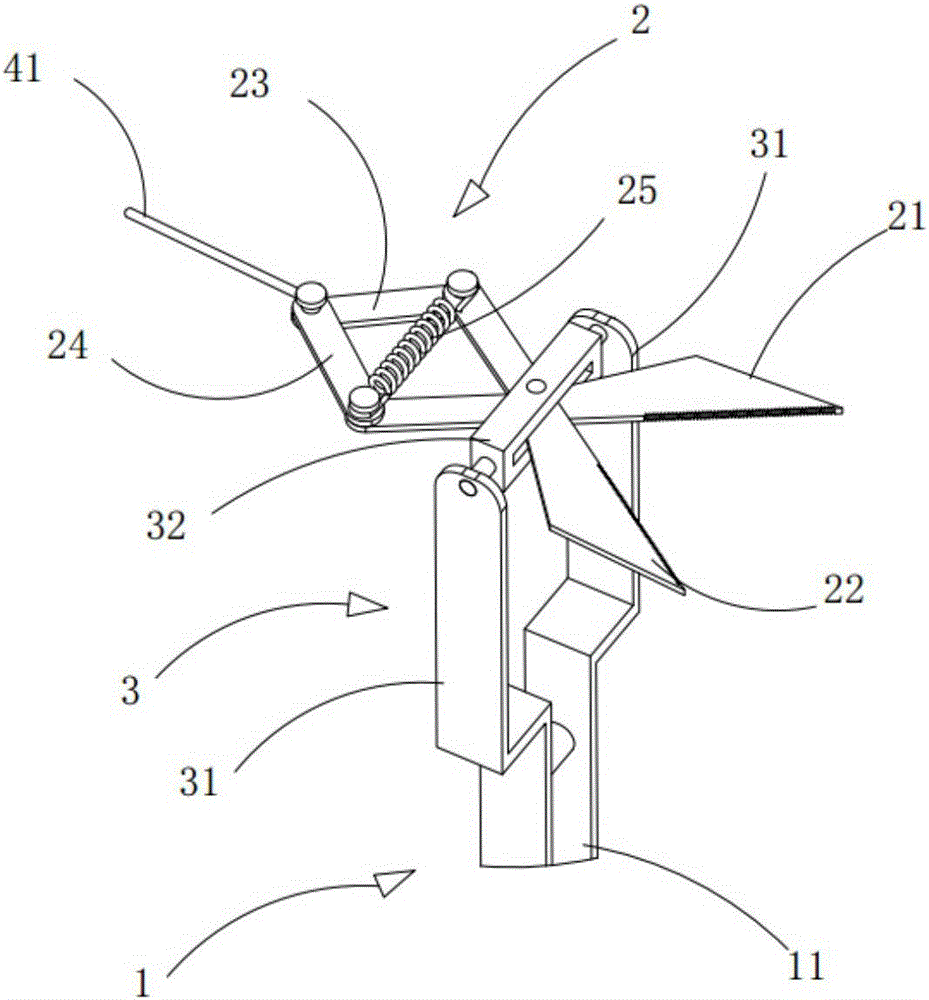

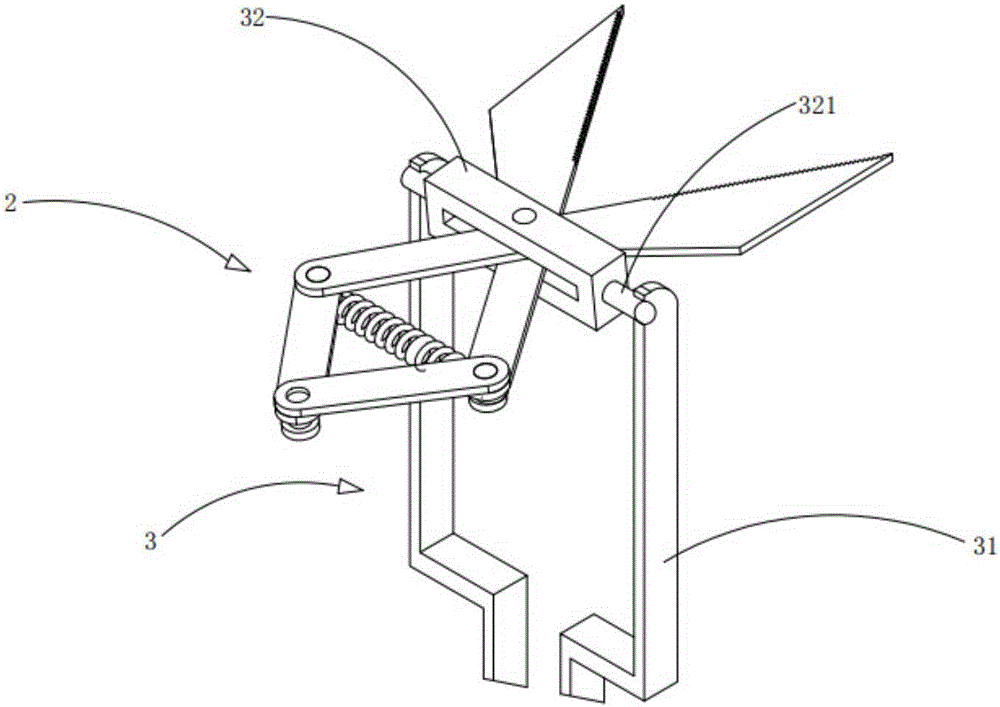

Angle-adjustable pruning and picking device

ActiveCN106613394ATo achieve the purpose of saving effortGuaranteed to be accurateCuttersCutting implementsMechanical engineeringLow altitude

The object of the invention is to solve the existing problems and provide an angle-adjustable pruning and picking device. The angle-adjustable pruning and picking device comprises a cutter head mechanism, a rotary mechanism, an operating mechanism and a taking-up mechanism, wherein the cutter head mechanism and the rotary mechanism are arranged at the front end of a cutter bar, and the operating mechanism and the taking-up mechanism are arranged at the rear end of the cutter bar; and a rotation auxiliary mechanism is arranged between the rotary mechanism and the operating mechanism. According to the angle-adjustable pruning and picking device, the angle of a cutter blade of the pruning device can be adjusted, the cutter blade and an object to be pruned can always be in a horizontal shearing state during pruning, branches and leaves of high-altitude or low-altitude flowers, plants and trees can be pruned smoothly, and the device can also be used for picking high-altitude fruits.

Owner:山东辛丁管理咨询有限公司

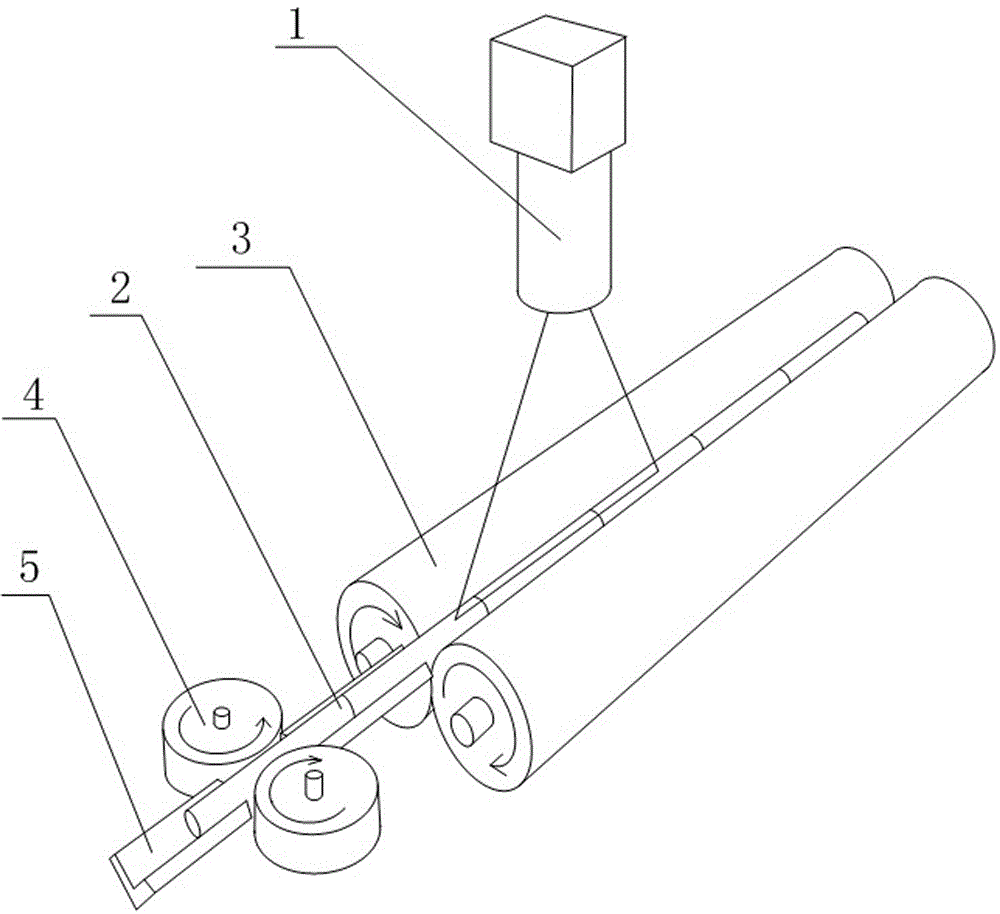

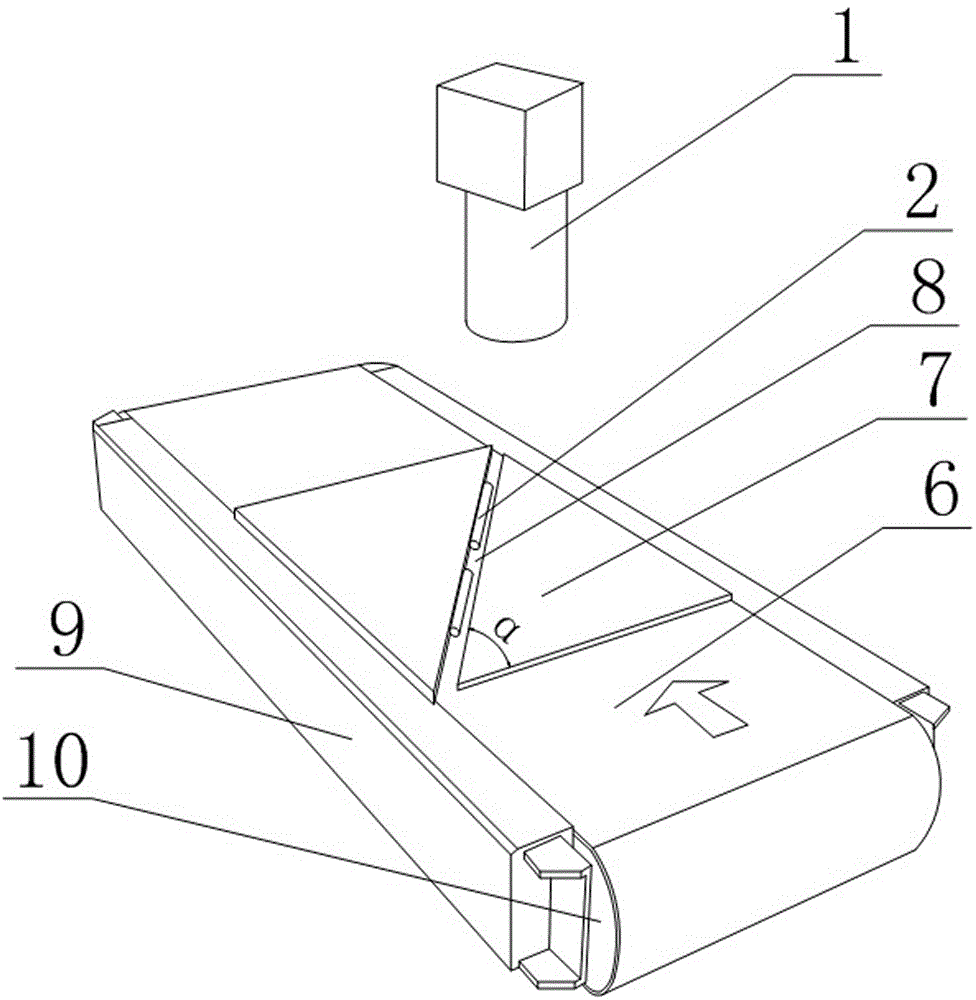

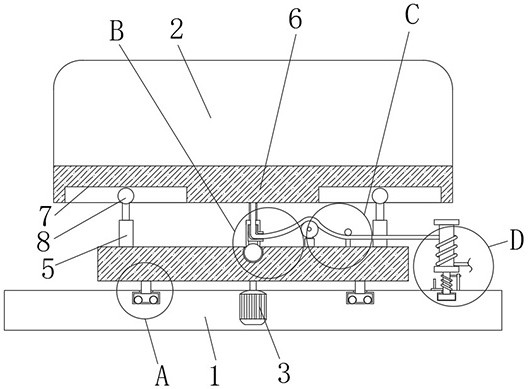

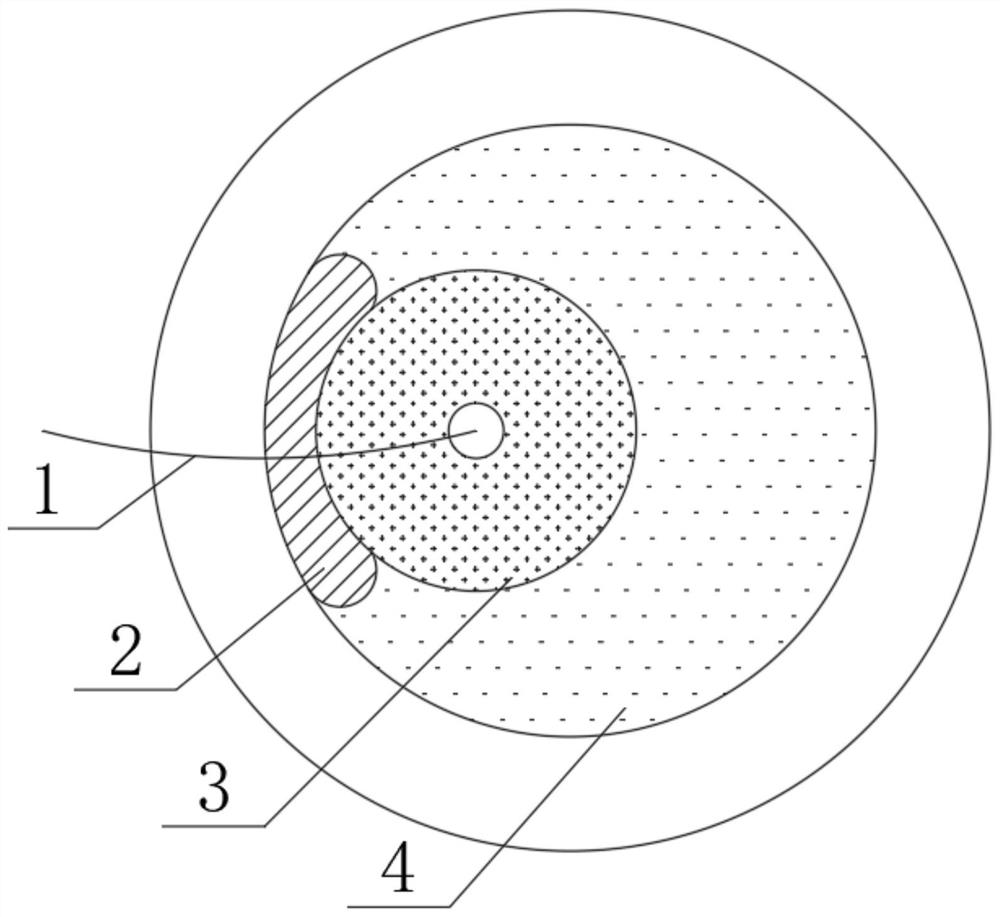

Appearance detection system for cylinder product

InactiveCN106093060AEnsure uniform motionGuaranteed StraightOptically investigating flaws/contaminationImaging processingStacking fault

The invention discloses an appearance detection system for a cylinder product. The appearance detection system comprises a line scanning camera and further comprises a conveyor belt, wherein two flat plates are fixed above the conveyor belt; a detection channel is formed between the two flat plates at an interval; an included angle alpha is formed between the detection channel and a movement direction of the conveyor belt, and alpha is more than 0 degree and smaller than 90 degrees; and the detection channel is located at a photographing region of the line scanning camera. The appearance detection system can ensure that constant-speed movement in the axial and peripheral directions is kept when a material passes through a view field of the line scanning camera, so that an acquired image is linear, the boundary of the material is clear when the image is acquired, and the image processing difficulty is reduced; the material is driven by the belt to continuously move, and after front-section material supply is stopped, the material is not left on the section; the driving of the material is not influenced by other materials and can be suitable for any length, diameter and weight; and once if the material is stacked, the material automatically moves, so that the front-section material supply is slowed down or the speed of the belt is improved, the material can move out of a stacked region, and a material stacking fault is automatically removed.

Owner:CHENGDU BEISEN WEIREN TECH CO LTD

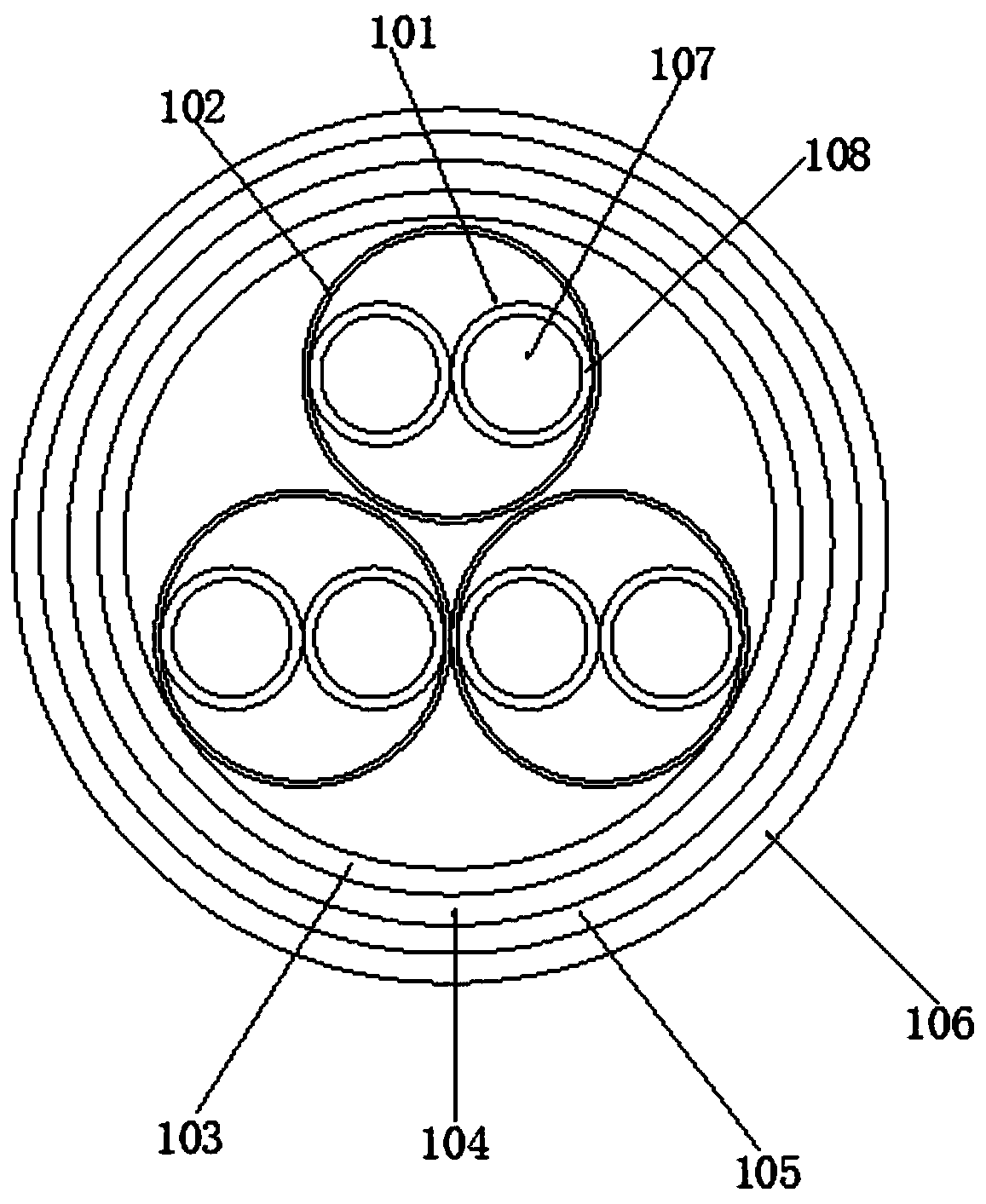

Flame-retardant and high-temperature-resistant computer cable and preparation process thereof

ActiveCN110364294AFlame retardantWith high temperature insulationInsulated cablesInsulated conductorsElectrical conductorCombustion

The invention discloses a flame-retardant and high-temperature-resistant computer cable. The cable comprises core wires, first wrapping layers, a second wrapping layer, a shielding layer, an armor layer and a sheath layer. Each core wire comprises tinned copper core conductors and insulating layers; the outer side of each tinned copper core conductor is wrapped with the corresponding insulating layer; every two core wires are twisted to form a pair wire set; and the outer side of each pair wire set is wrapped with the corresponding first wrapping layer. According to the invention, the quartz fiber maintenance sleeve layer on the outer side of the cable has the advantages of flame retardance, high-temperature resistance, insulationresistance, ablation resistance, corrosion resistance, heatinsulation ability, wave transmission ability, excellent dielectric property and the like; the cable can be protected from combustion in case of a fire; compared with polyethylene insulation, the performance of the the cross-linked polyethylene insulation is greatly improved after cross-linking modification; the comprehensive performance such as the mechanical performance, the environmental stresscracking resistance, the chemical corrosion resistance, the creep resistance and the electrical performance is remarkably improved; and the temperature resistance level is remarkably improved.

Owner:TIANCHANG HUILING ELECTRIC APPLIANCE METER FACTORY

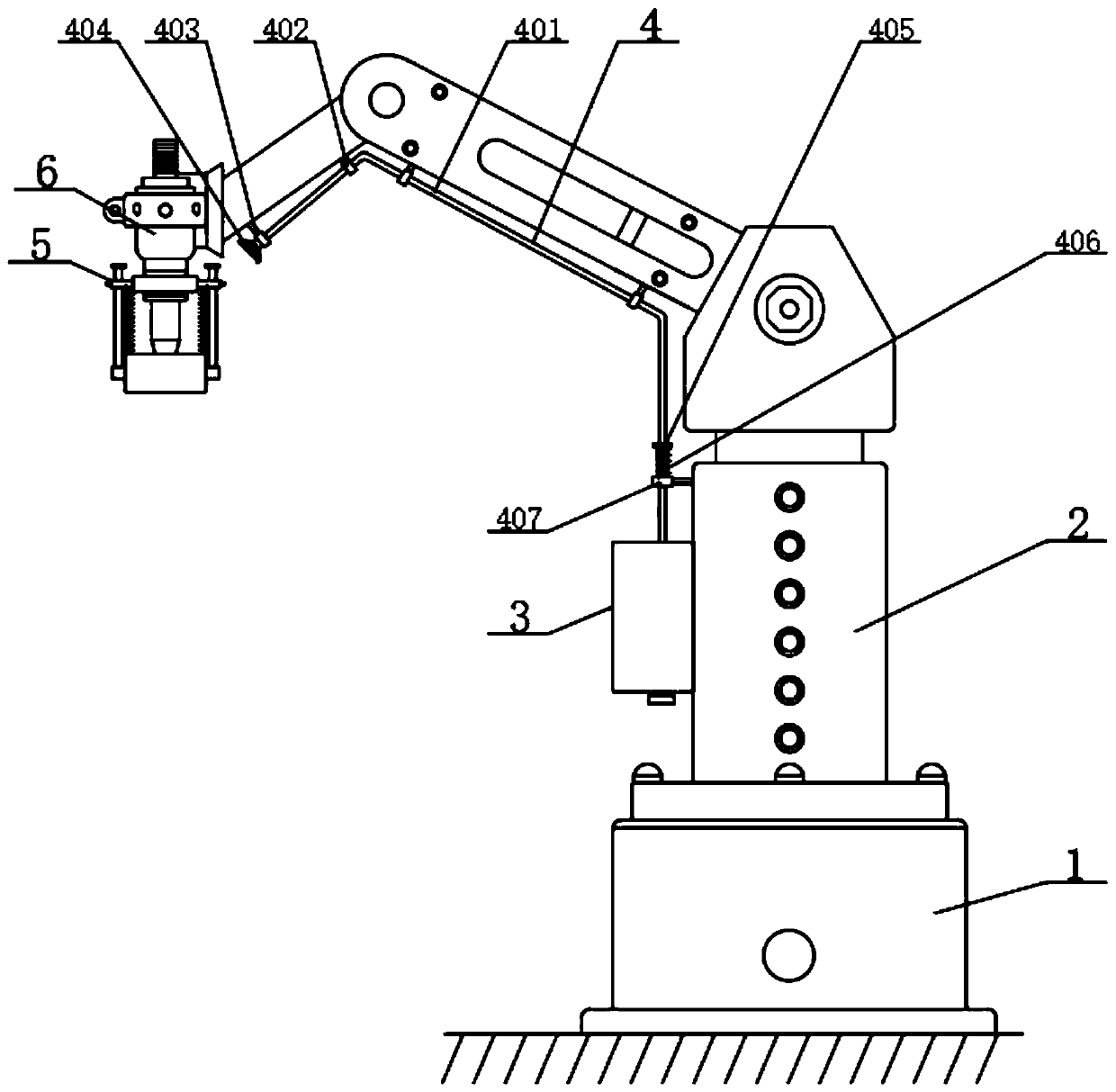

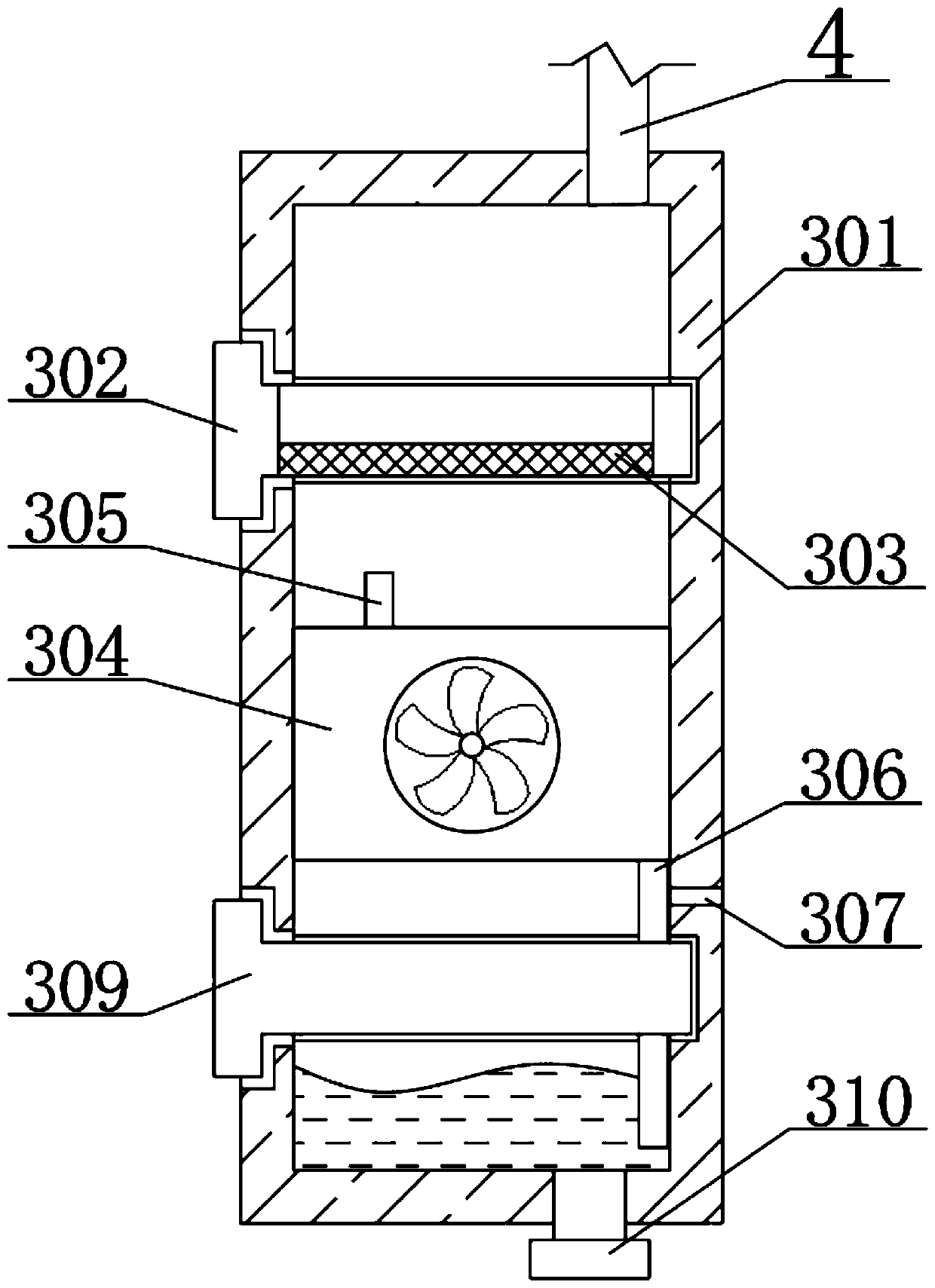

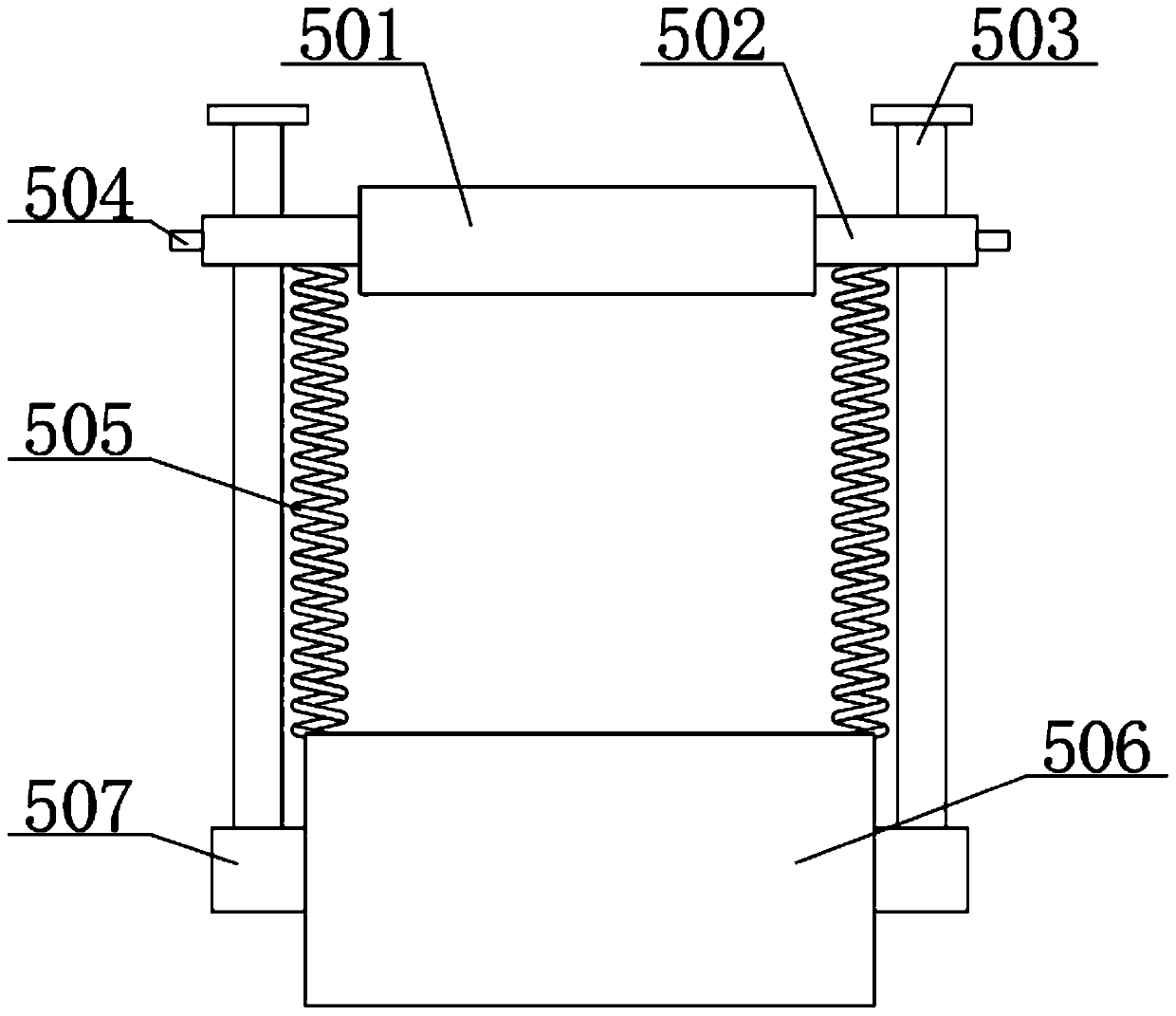

Welding manipulator with protection function for automobile parts

ActiveCN111015032AImprove the protective effectGuaranteed straightCombination devicesWelding/cutting auxillary devicesRobotic armStructural engineering

The invention relates to the technical field of automobile part processing, in particular to a welding manipulator with a protection function for automobile parts. The welding manipulator comprises abase and a mechanical arm, wherein the upper end face of the base is fixedly connected with the mechanical arm, the left side of the mechanical arm is fixedly connected with a waste gas treatment device, the upper end face of the waste gas treatment device is fixedly connected with a tensioning device, the upper end face of the tensioning device is fixedly connected with the mechanical arm, the left end face of the mechanical arm is fixedly connected with a welding head, the outer side of the welding head is rotationally connected with a protection device, and the protection device comprises arotating ring and a connecting plate. According to the welding manipulator with the protection function for the automobile parts, through the arranged rotating ring, the connecting plate, a limitingspring, a protective cover and a fixing block, when the welding head carries out welding work, the protective cover can shield the welding part, meanwhile, the protective cover can filter out infraredand ultraviolet rays harmful to human eyes and generated by electric welding, meanwhile, the strong light is reduced to the weak light which can be borne by the human eyes, the eyes of people are effectively protected, and a good protective effect is achieved.

Owner:安徽双骏智能科技有限公司

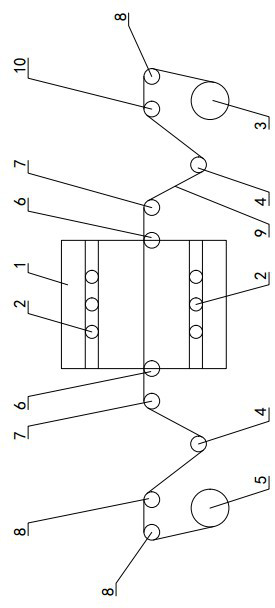

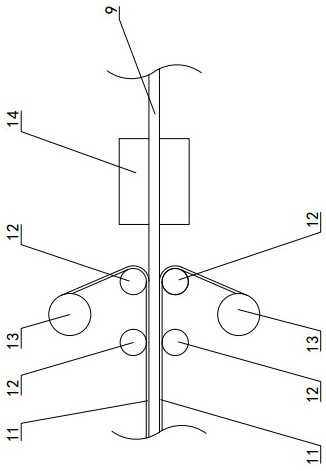

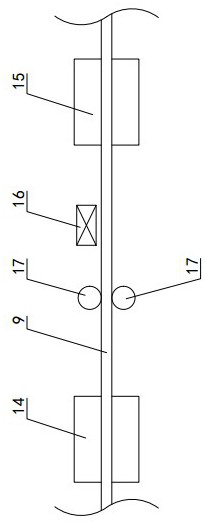

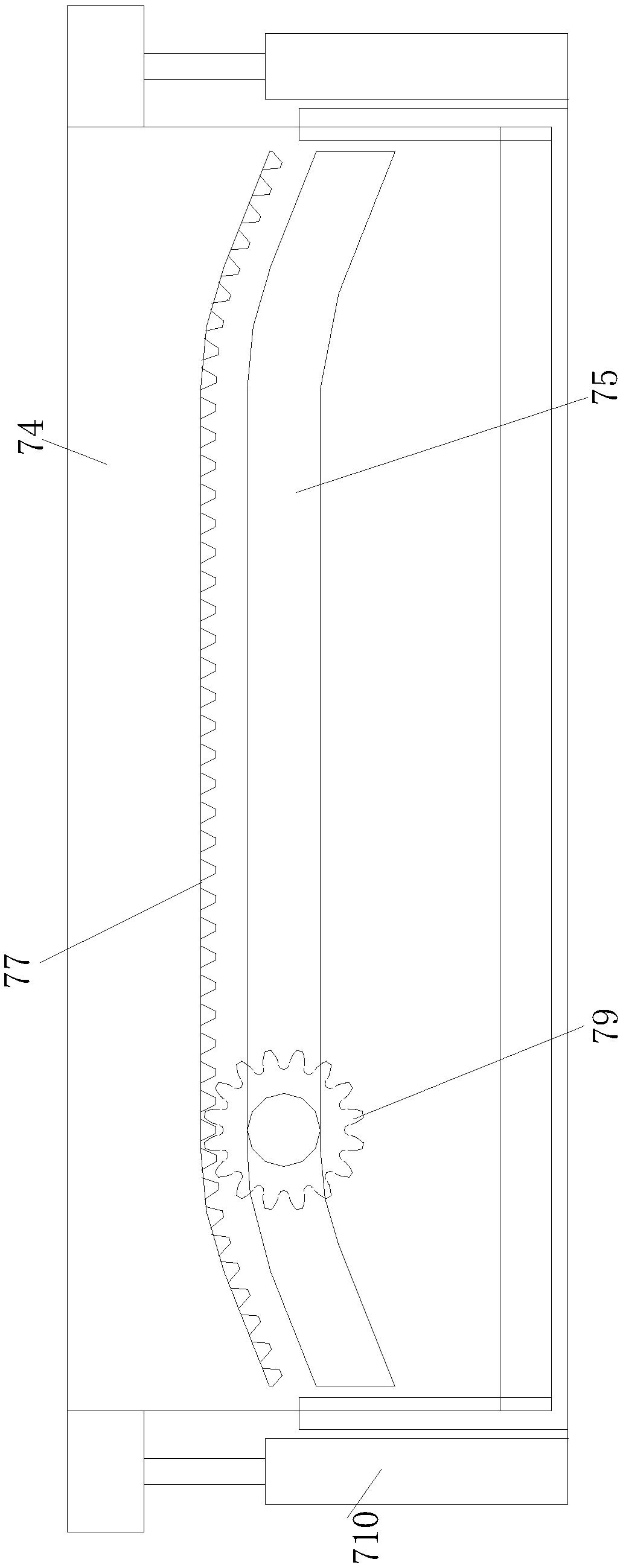

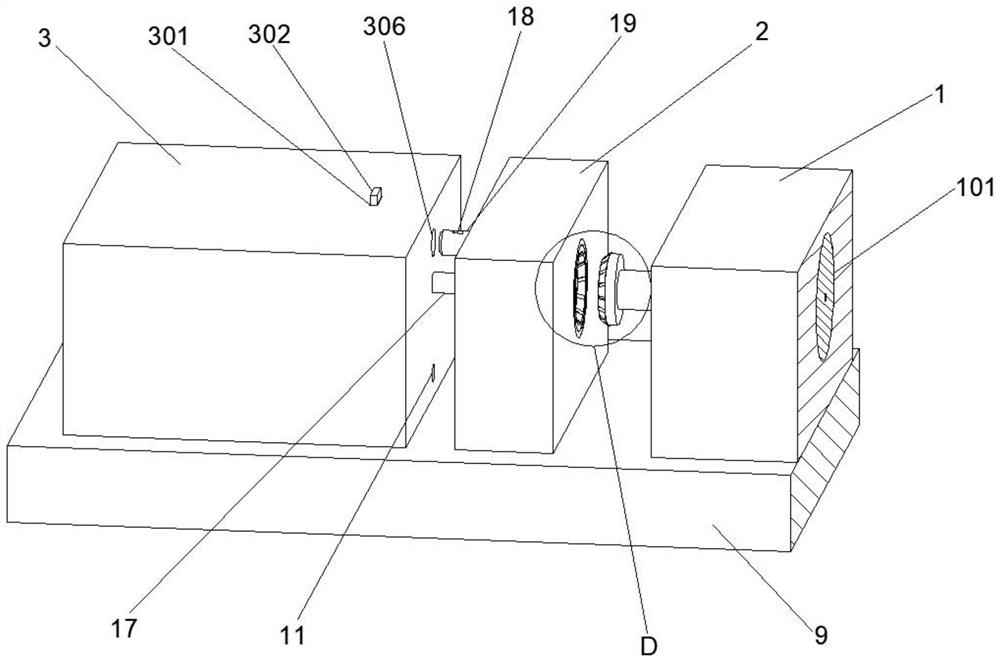

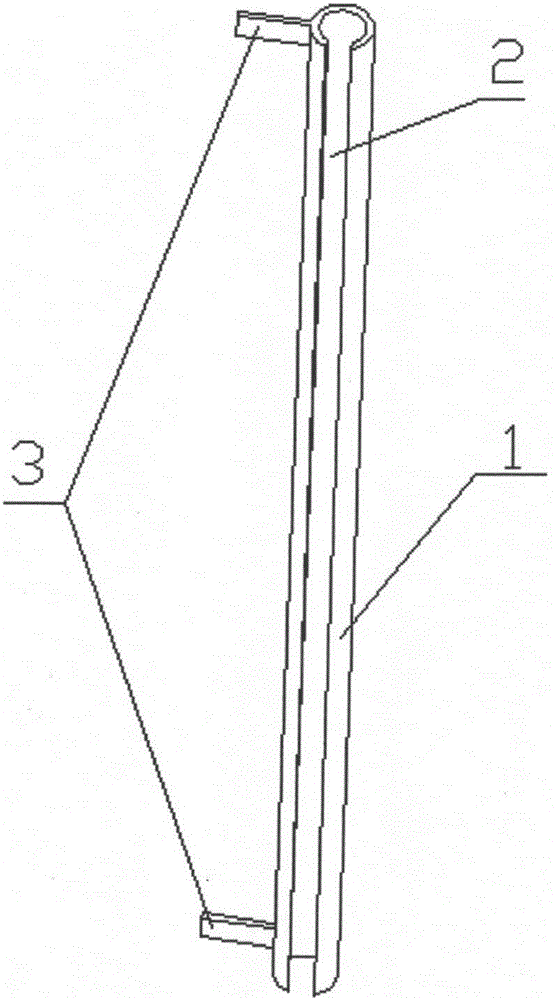

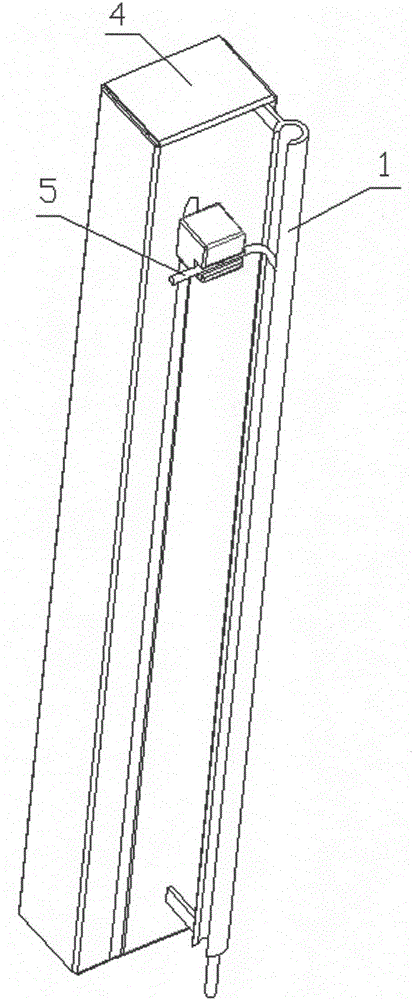

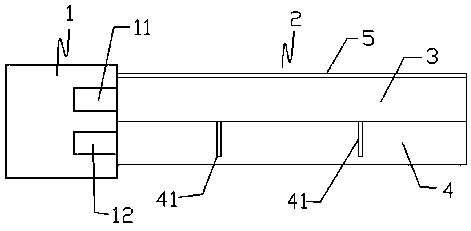

Laser exposure process for lead wire frame

PendingCN111640726AHigh exposure accuracyImprove pass rateSemiconductor/solid-state device detailsSolid-state devicesPhysicsWire frame

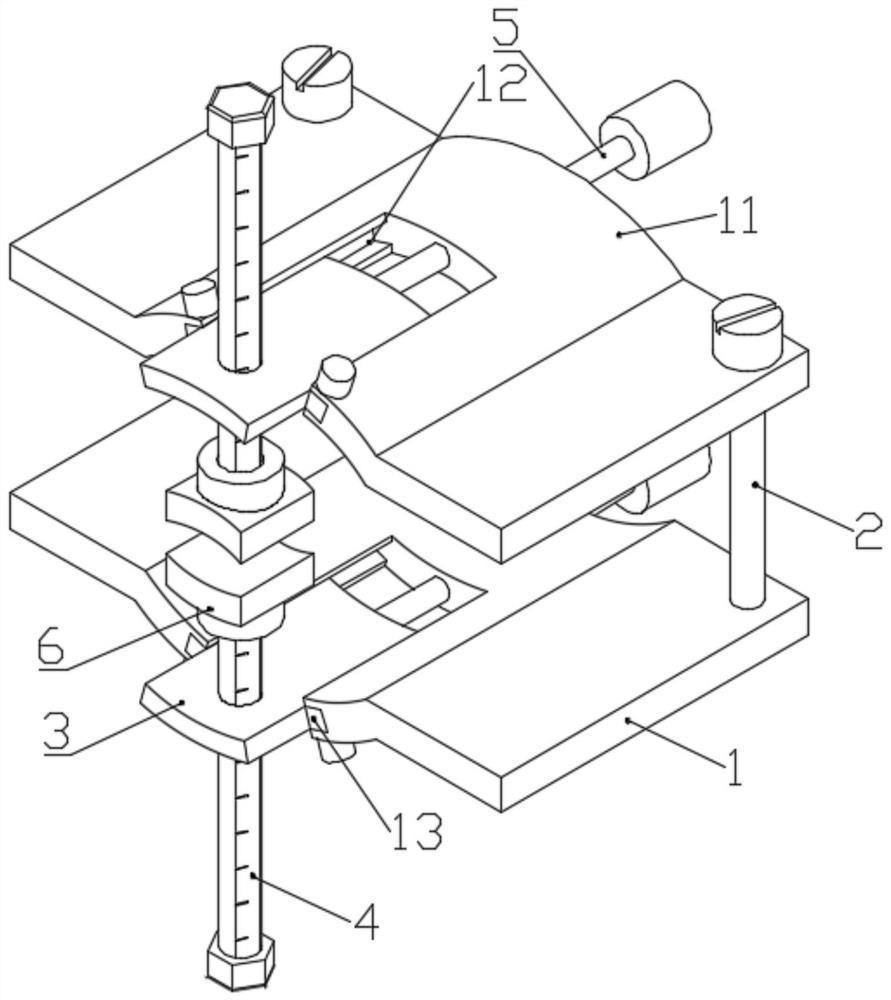

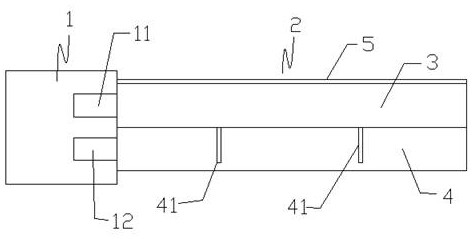

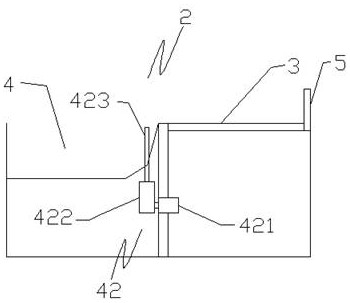

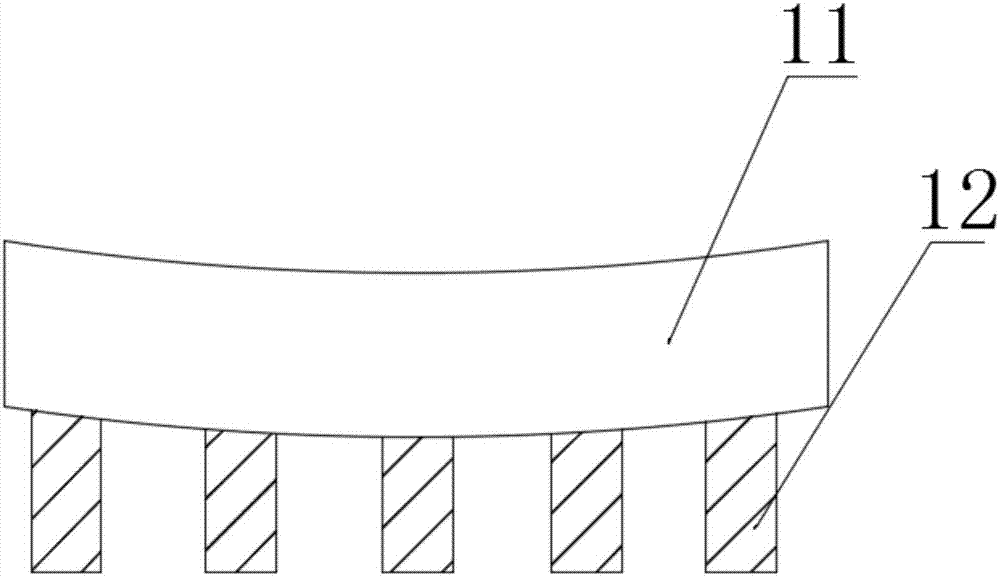

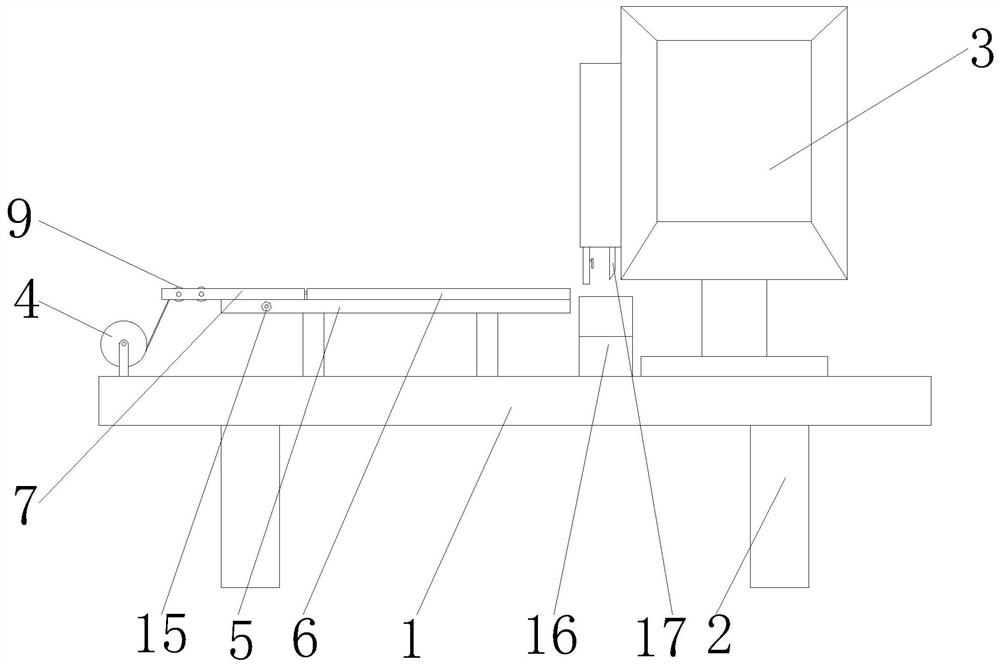

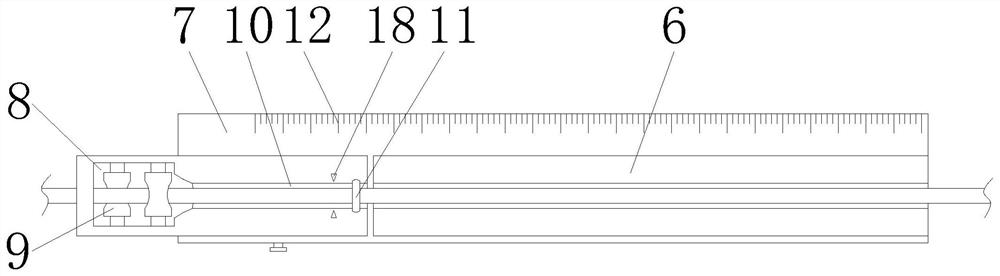

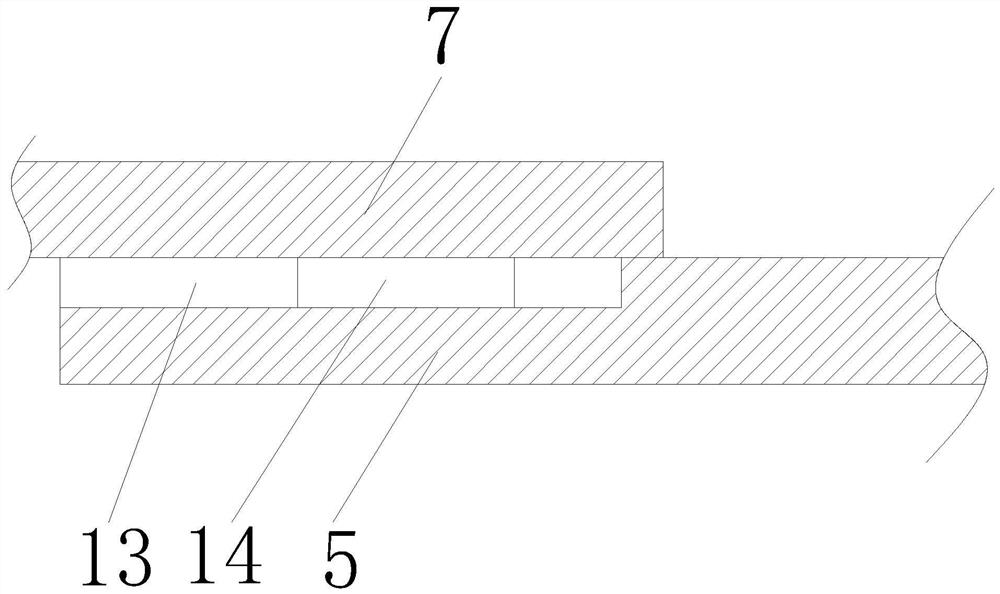

The invention discloses a lead wire frame laser exposure process, and belongs to the technical field of film pressing equipment. The process is characterized by comprising the following steps of: 1) pressing dry films (11) on two sides of a lead wire frame (9) through a film pressing device; 2) matching an input roller (3) with a winding roller (5) to enable the lead wire frame (9) to maintain tension of 10-20 kg, driving optical engines (2) on the two sides of the lead wire frame (9) to move by a translation device, and exposing the dry films (11) on the two sides of the lead wire frame (9);and 3) driving the optical engines (2) by the translation device to expose the next position of the lead wire frame (9) until the exposure of the whole roll of lead wire frame (9) is completed. According to the laser exposure process for the lead wire frame, the input roller is matched with the winding roller, so that the tension of the lead frame is maintained to be 10-20 kg, the lead wire framecan be ensured to be straightened, and the damage to the lead wire frame can be avoided.

Owner:新恒汇电子股份有限公司

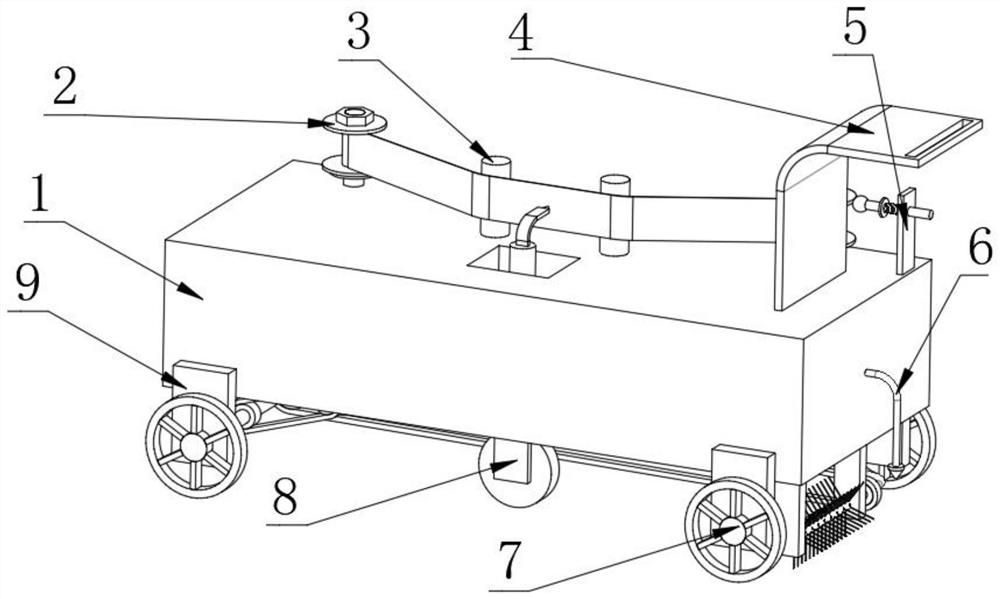

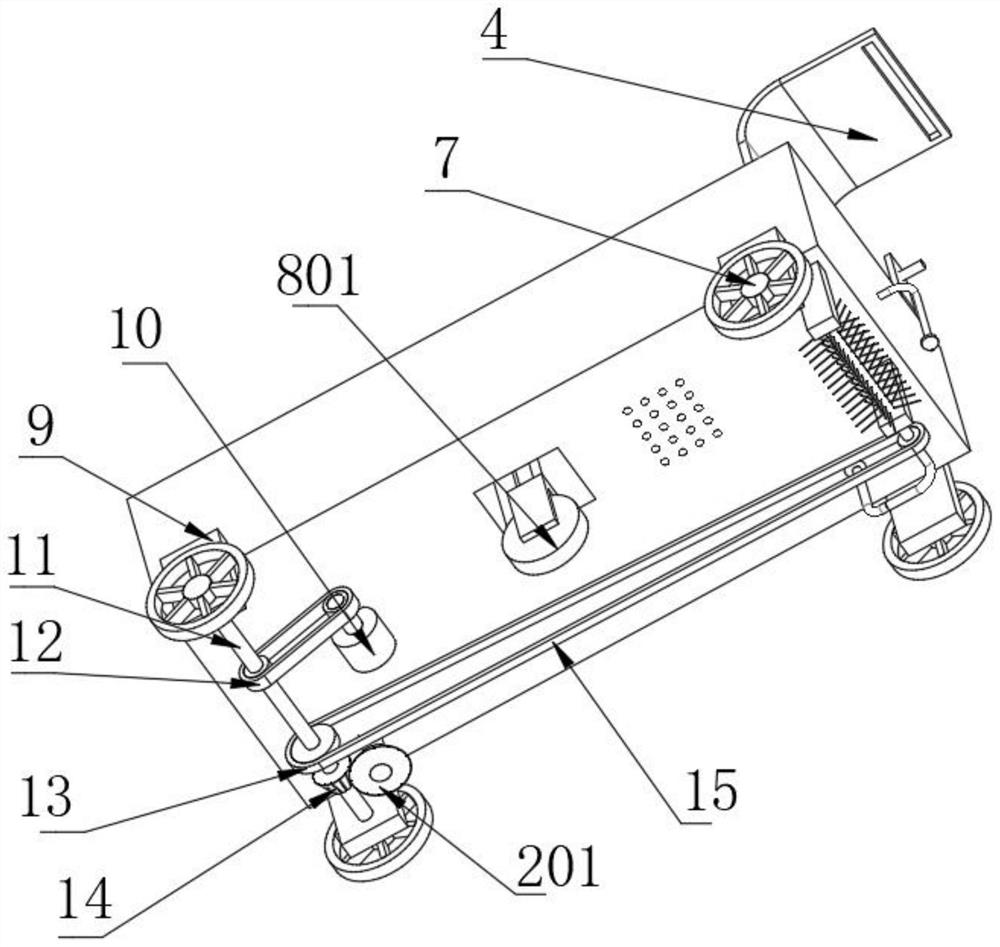

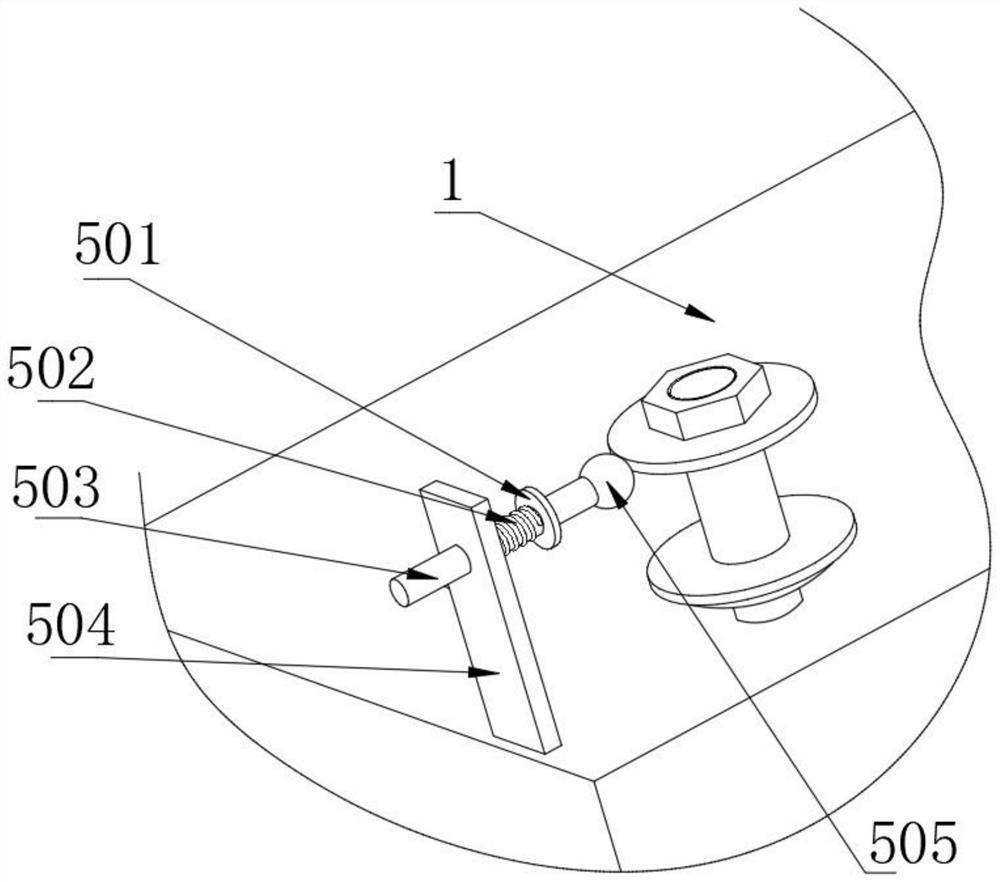

Building house flatness detection device

PendingCN113587888AEasy to install and disassembleEasy to operateMeasurement devicesRotational axisArchitectural engineering

The invention relates to the technical field of building houses, in particular to a building house flatness detection device, which comprises a mounting base, a winding mechanism, an extrusion mechanism and a detection mechanism, wherein mounting plates are mounted on the two sides of the outer walls of the two ends of the mounting base, and wheels are rotationally connected to the outer walls of one ends of the mounting plates; The outer walls of the opposite ends of the two mounting plates on one side are rotationally connected with a third rotating shaft; a motor is mounted on the bottom outer wall of the mounting base; the circumferential outer wall of the third rotating shaft is sleeved with a first belt pulley. By arranging the winding mechanism, the locking bolt is unscrewed; then, a second rotating shaft is sleeved with a paper winding wheel wound with empty white paper, a first rotating shaft is sleeved with an empty paper winding wheel, and then the empty paper winding wheel is fixed through a locking bolt, so that the paper winding wheels can be conveniently disassembled and assembled, and workers can conveniently operate the paper winding wheels; In addition, a rubber roller is arranged, so that the marking pen cannot break the blank paper when the paper winding wheel on the first rotating shaft becomes thick, and the line drawing effect is guaranteed.

Owner:广东中晟勘测科学研究有限公司

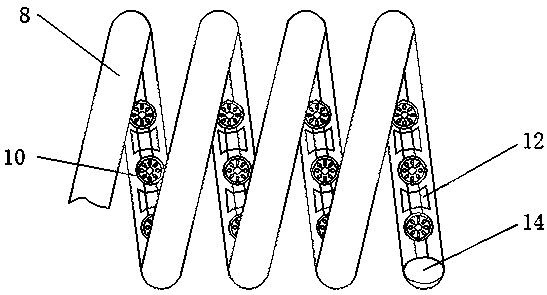

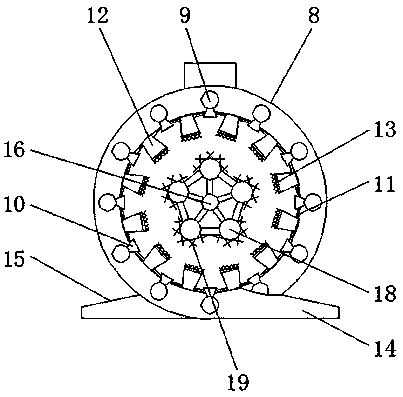

Annular spraying cleaning and conveying integrated device for mechanical production

InactiveCN108750538AGuaranteed support effectGuaranteed StraightConveyorsDrying gas arrangementsWater sourceWater flow

The invention discloses an annular spraying cleaning and conveying integrated device for mechanical production. The device comprises a base and conveying rollers; a transmission motor is arranged on the right side of the base, a driving belt is arranged above the transmission motor, a conveying belt is arranged on the outer sides of the conveying rollers, and the conveying rollers are located above the base. According to the annular spraying cleaning and conveying integrated device for mechanical production, through arranging of a cleaning ring frame, it is ensured that the device can clean the product, the cleaning ring frame is arranged to be of a spiral disc structure, the product can be circumferentially and rotatably driven to work, the product can be subject o comprehensive cleaningwork, a water passing pipe enables a cleaning water flow to pass, a spraying head is used for spraying atomized water fog, water sources are saved, it can be ensured that the cleaning water flow is disperse evenly, and evenly covers the outer side of the product, a soft brush on a brush plate makes contact with the product, and under friction resistance effect of the soft brush and the product, incombining with the penetrating structure, in the brush plate, of a fixed rod, the brush plate can finish angle deflection.

Owner:丽水市红日保洁服务有限公司

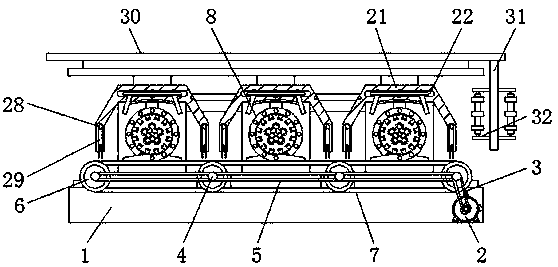

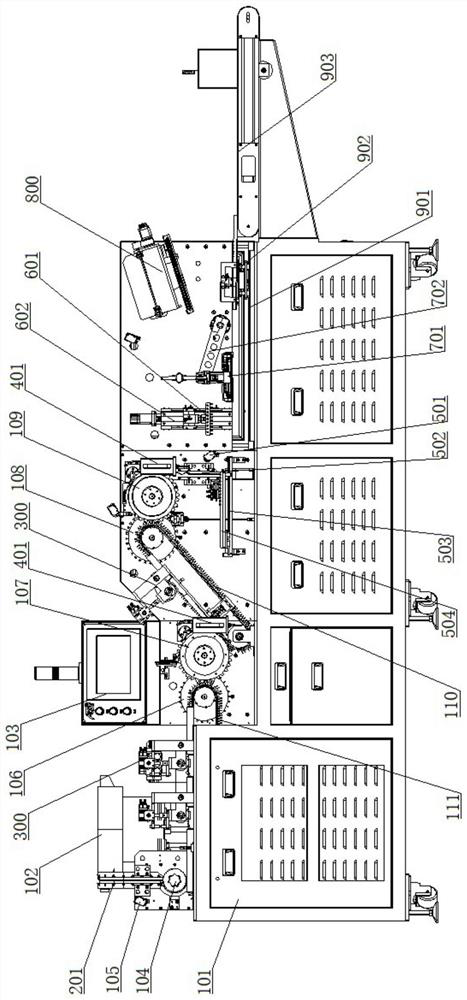

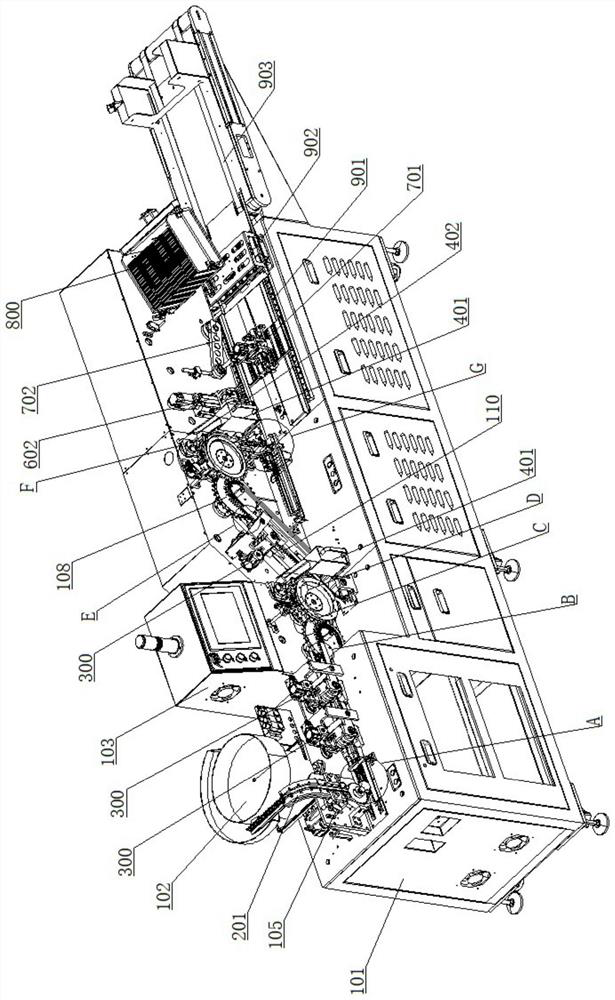

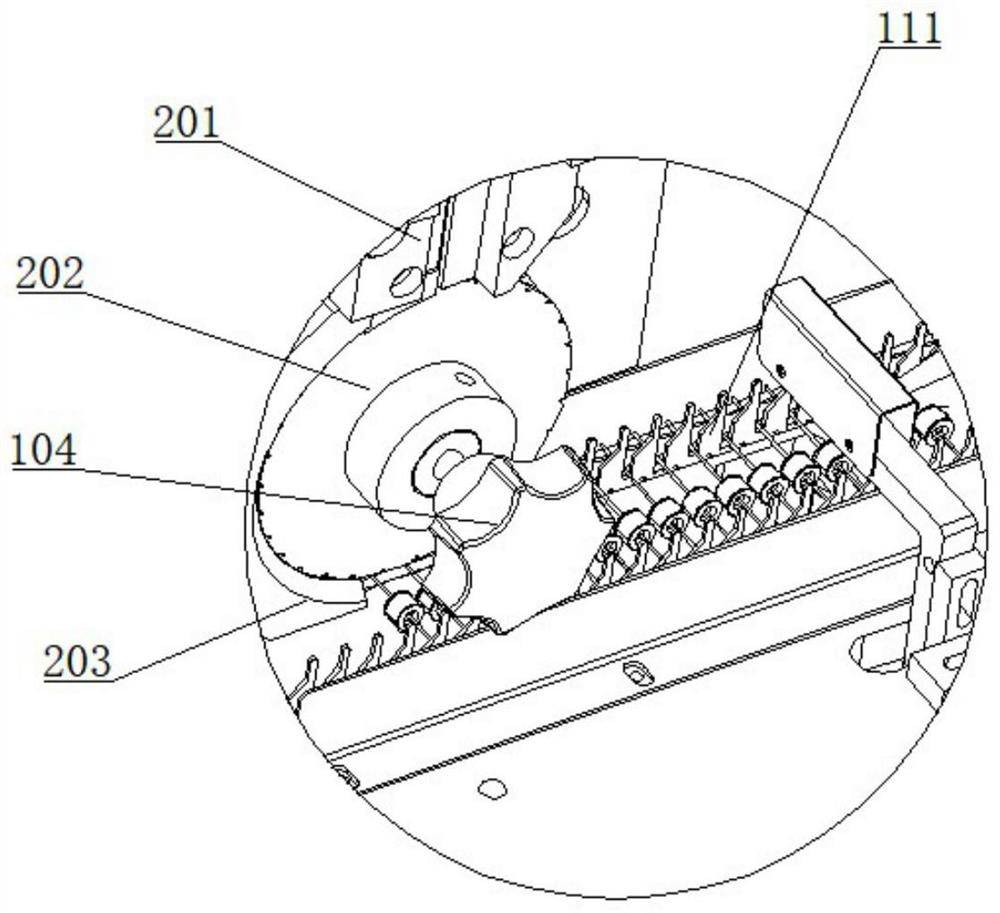

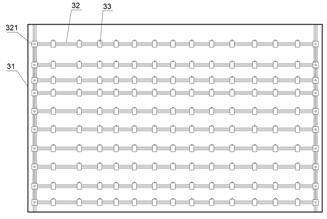

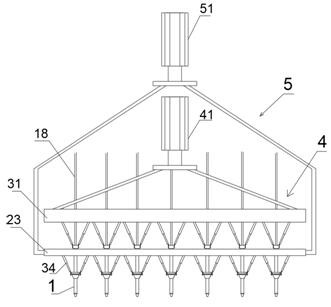

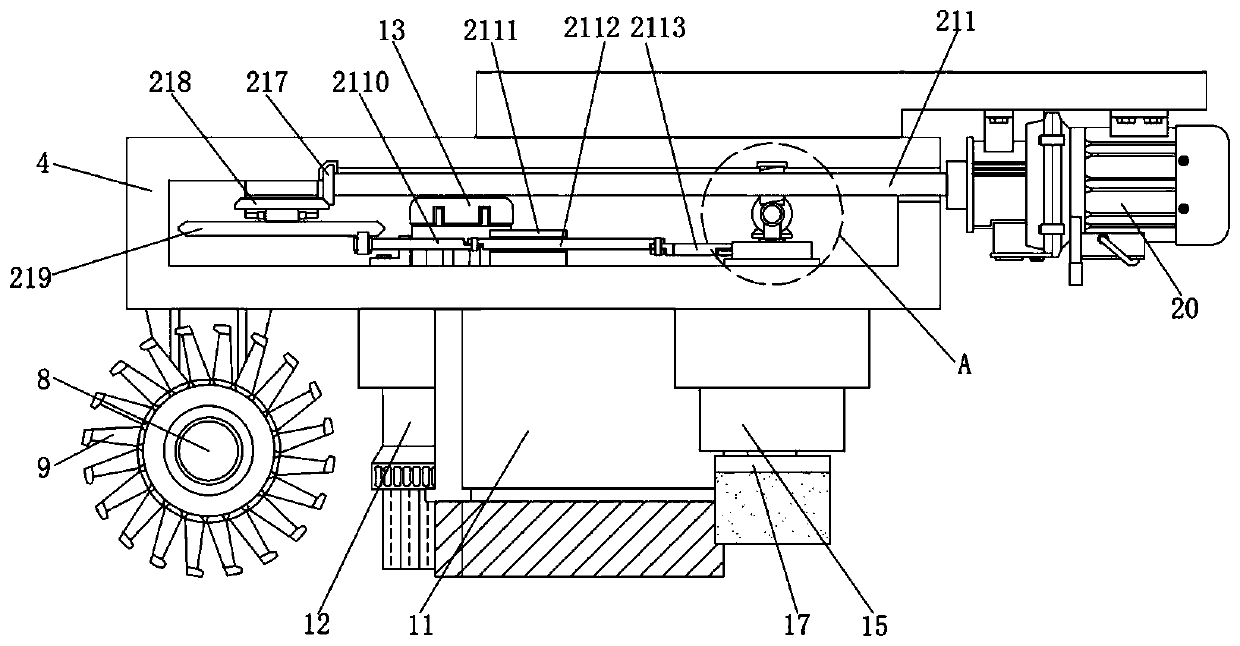

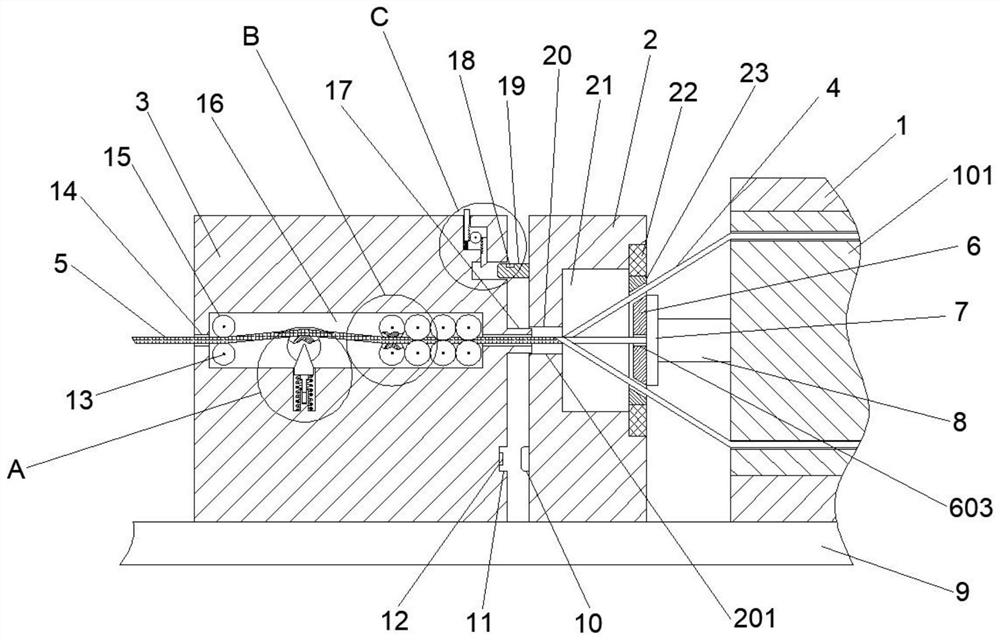

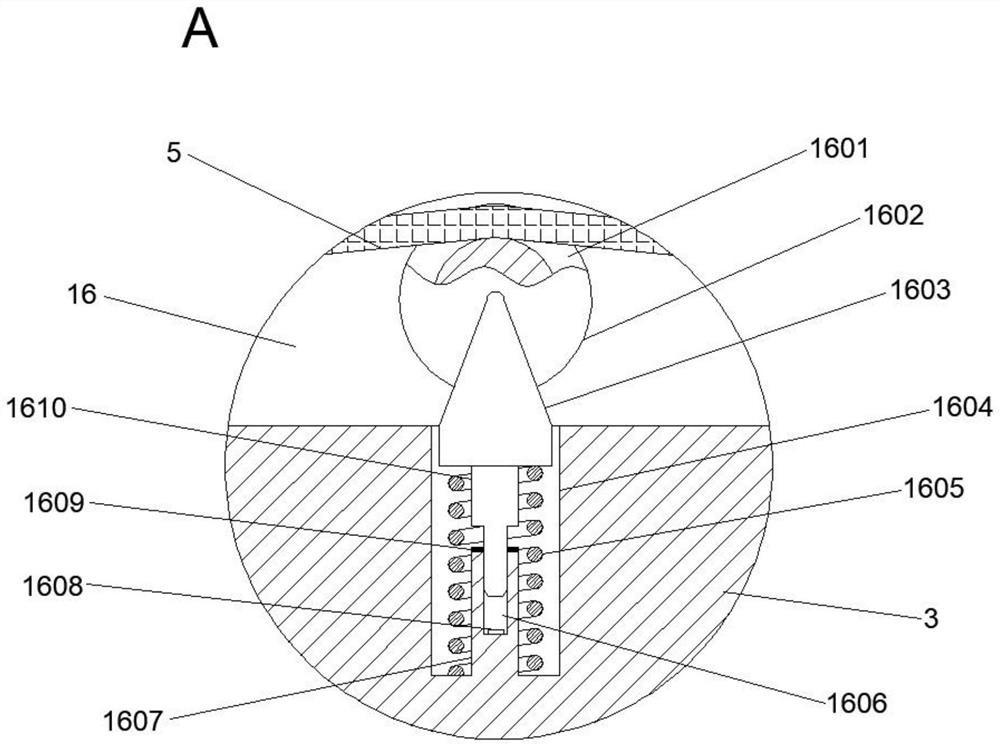

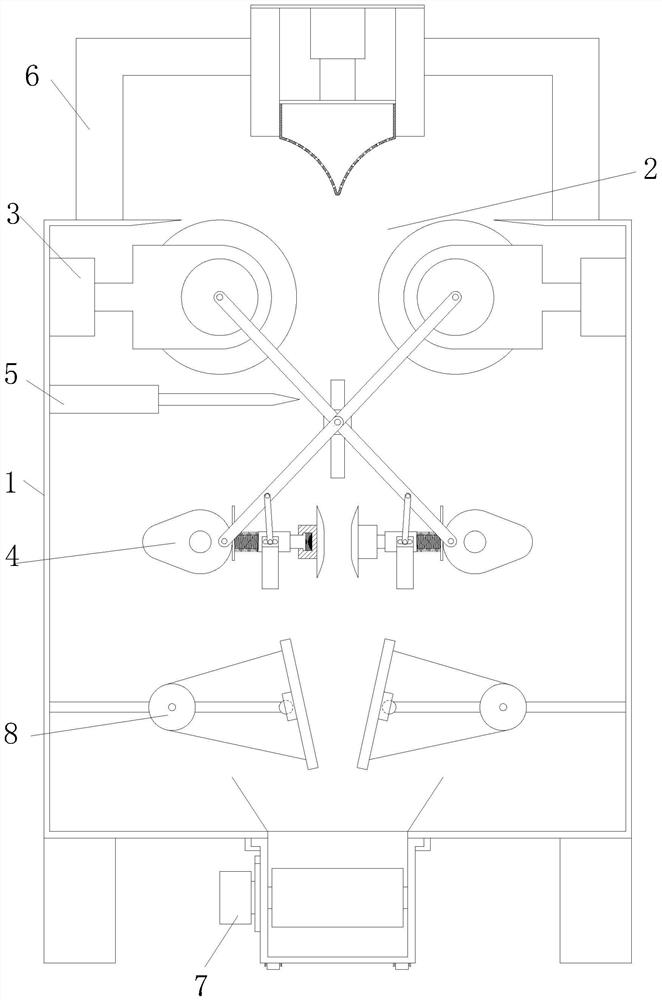

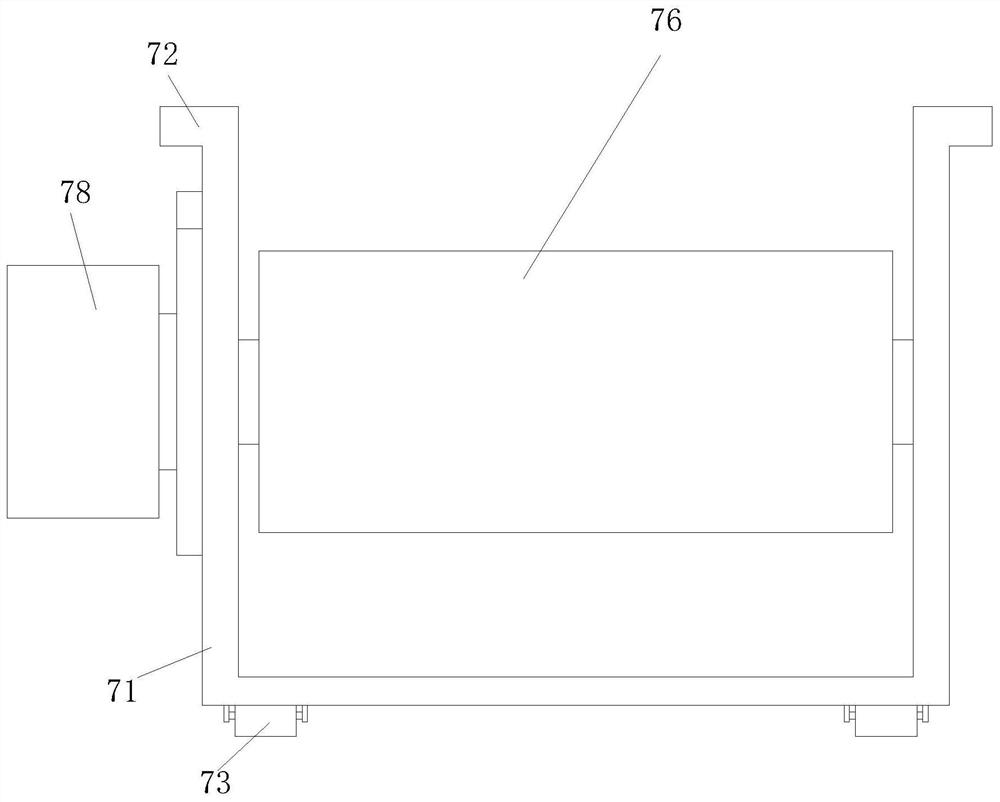

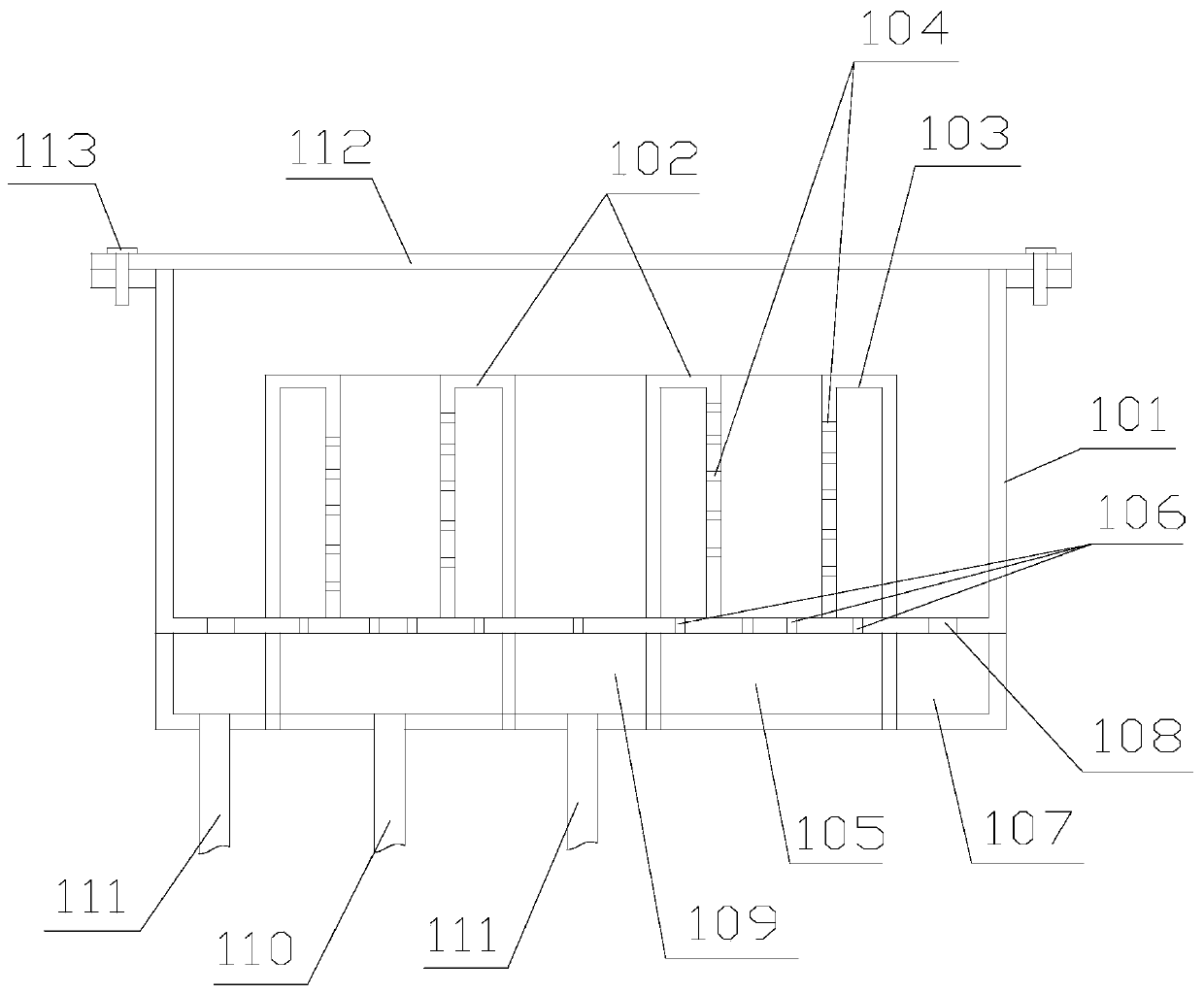

GDT array packaging machine

The invention belongs to the technical field of electronic component production equipment, and particularly relates to a GDT array packaging machine. Comprising a feeding assembly, a pair of transverse transmission chains, a pair of first transfer discs, a pair of first insulation discs and a pair of oblique transmission chains, wherein the feeding assembly, the pair of transverse transmission chains, the pair of first transfer discs, the pair of first insulation discs and the pair of oblique transmission chains are sequentially arranged on a rack and electrically connected with a control mechanism; the pair of second transfer discs are arranged in a spaced mode and rotate synchronously, and the pair of second insulation discs are arranged in a spaced mode and rotate synchronously. A straightening mechanism electrically connected with the control mechanism is arranged on one side of the transverse conveying chain and one side of the inclined conveying chain. A performance detection mechanism electrically connected with the control mechanism is arranged on the upper side of the first insulation disc. A label detection mechanism electrically connected with the control mechanism is arranged on the upper side of the second insulating disc. Hooking and removing mechanisms electrically connected with the control mechanism are arranged on the sides of the first insulating disc and the second insulating disc correspondingly.

Owner:华格电子(昆山)有限公司

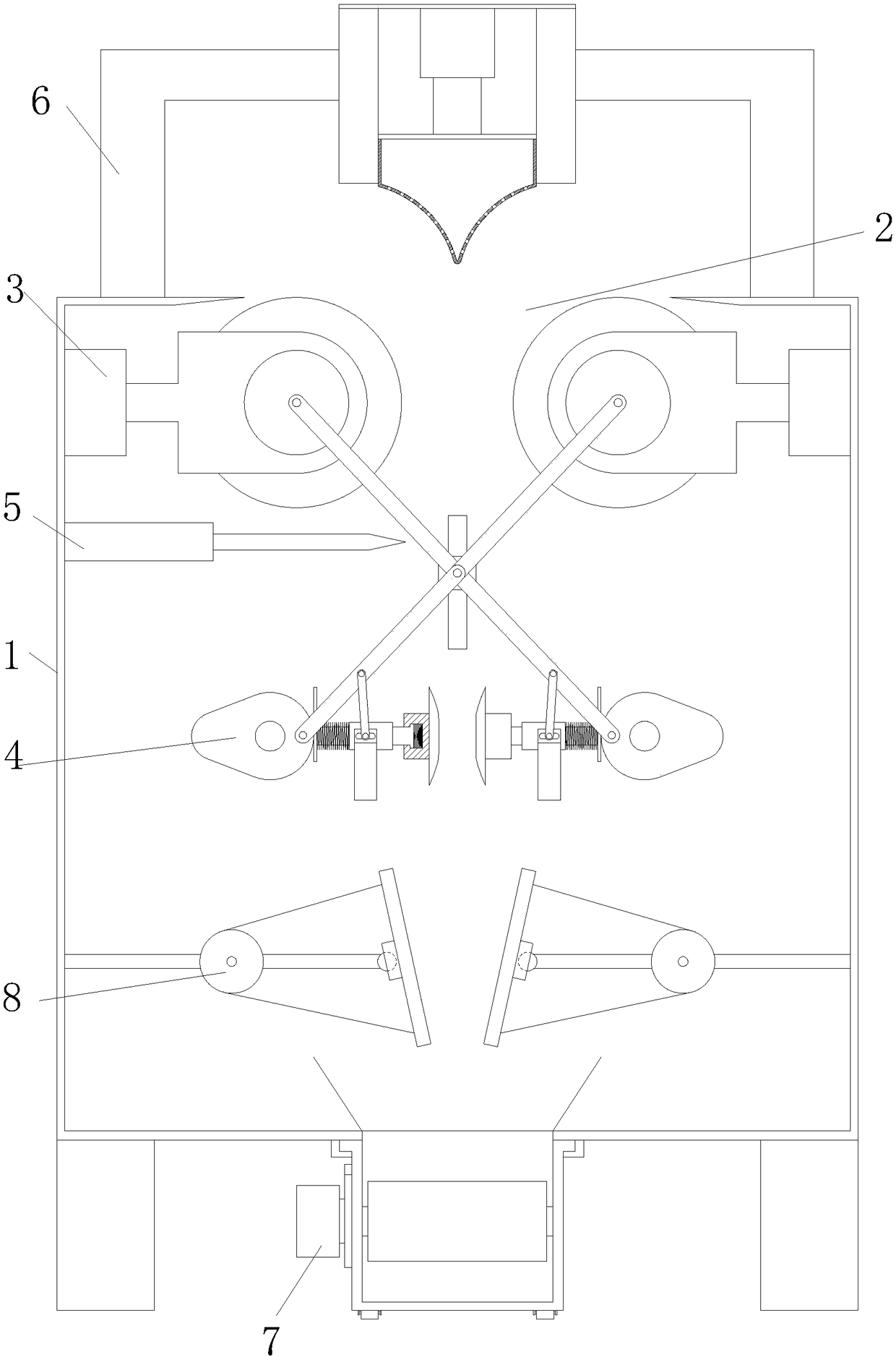

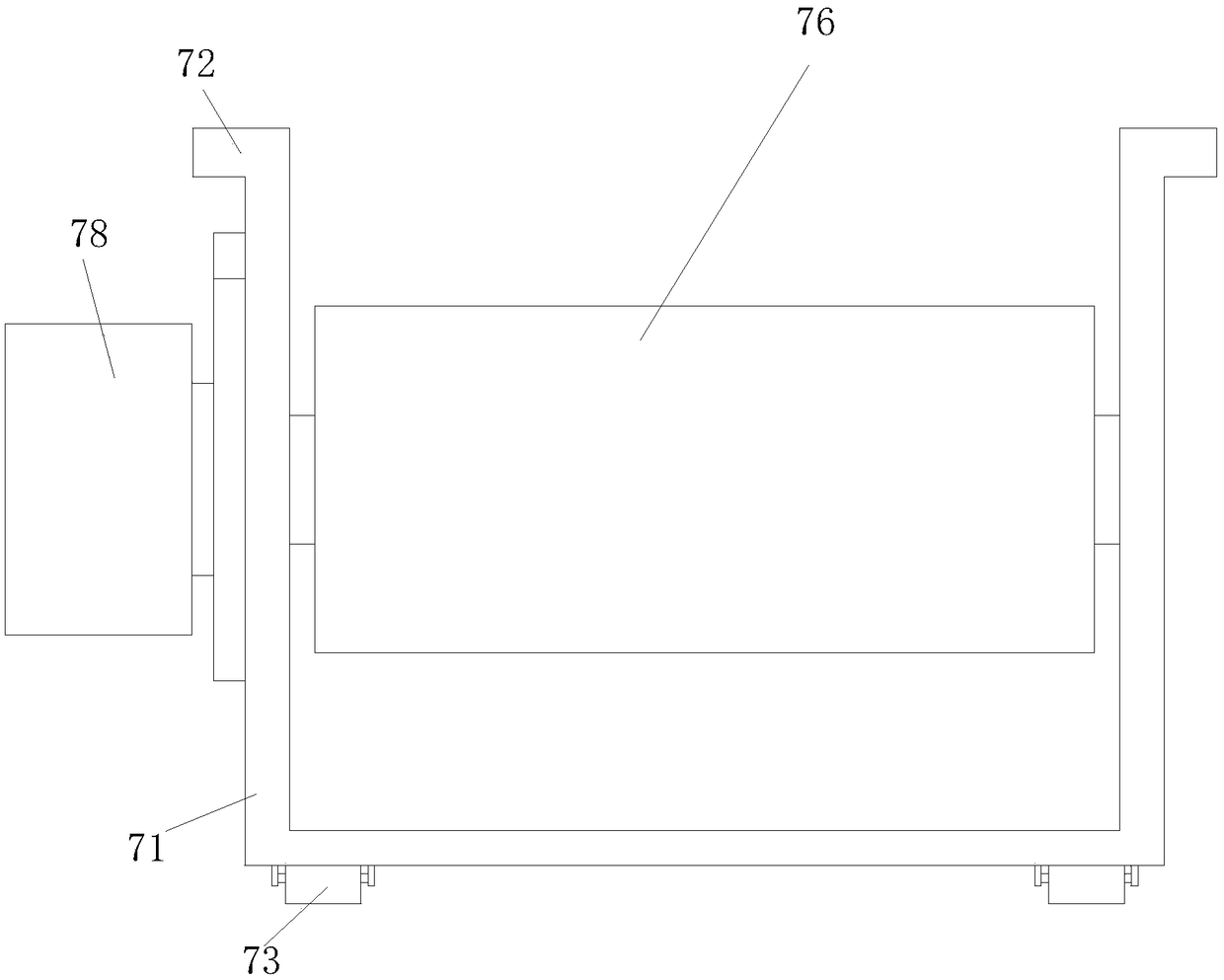

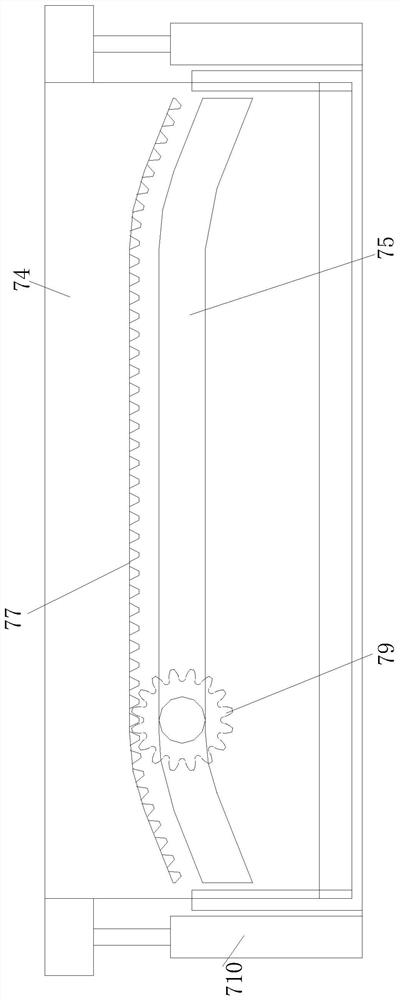

Film splicing device

ActiveCN109179031ASmall footprintLarge storage capacityArticle deliveryWebs handlingWorkloadLinkage concept

The invention discloses a film splicing device. The film splicing device comprises a box body, an opening is formed in the middle of the upper surface of the box body, the two ends of the opening aresymmetrically provided with pressing splicing assemblies, traction assemblies are installed below the pressing splicing assemblies, the pressing splicing assemblies drive the traction assemblies to work, a shearing assembly is installed between the pressing splicing assemblies and the traction assemblies, attraction assemblies are installed below the traction assemblies, adhesive tape sticking assemblies are installed above the opening, and a waste storage assembly is installed below the box body in a detachable mode. According to the film splicing device, through the arrangement of the wastestorage assembly, the occupied area of waste is reduced, the storage amount of a waste box is increased, the workload of operators is reduced, through the linkage arrangement between the pressing splicing assemblies and the traction assemblies, it is guaranteed that a thin film is kept in a straightened state during cutting, and then normal proceeding of cutting work is guaranteed.

Owner:安徽省临泉县康悦电子科技有限公司

Telescopic elevator key antibacterial film coating device

ActiveCN112722968AWith telescopic functionAvoid residueLiquid surface applicatorsCoatingsStructural engineeringAnti bacterial

The invention discloses a telescopic elevator key antibacterial film coating device. The telescopic elevator key antibacterial film coating device comprises an antibacterial film box body, a telescopic hollow frame body, an antibacterial agent applicator, a cutting positioning device and a fixing mechanism, wherein the antibacterial film box body can be used for rotatably placing an antibacterial film winding drum, the telescopic hollow frame body is provided with a guide channel and can be opened and closed, the antibacterial agent applicator is used for applying an antibacterial agent to an antibacterial film to improve the use frequency of the antibacterial film, the cutting positioning device is used for cutting and assisting in positioning the antibacterial film, and the fixing mechanism is used for fixing the telescopic elevator key antibacterial coating device to an elevator key panel. The telescopic hollow frame body comprises a surface frame and a bottom frame which are provided with hollow parts corresponding to a key area on the elevator key panel, the surface frame is connected with the left side of the bottom frame through a pivoting mechanism, the surface frame is connected with the right side of the bottom frame through a clamping column mechanism, and the device can quickly cover the antibacterial film on the key area on the elevator key panel. The telescopic elevator key antibacterial film coating device can be matched with elevator key panels of various models, antibacterial film roll materials can be saved, and cross infection caused by residual pathogens on elevator keys can be effectively avoided.

Owner:四川省特种设备检验研究院

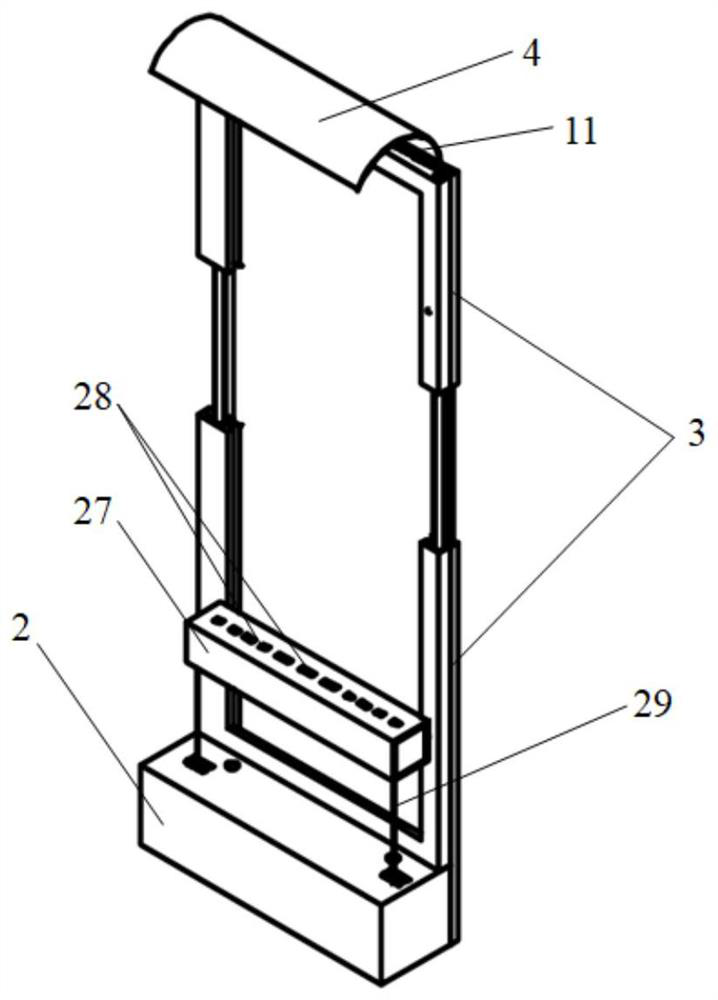

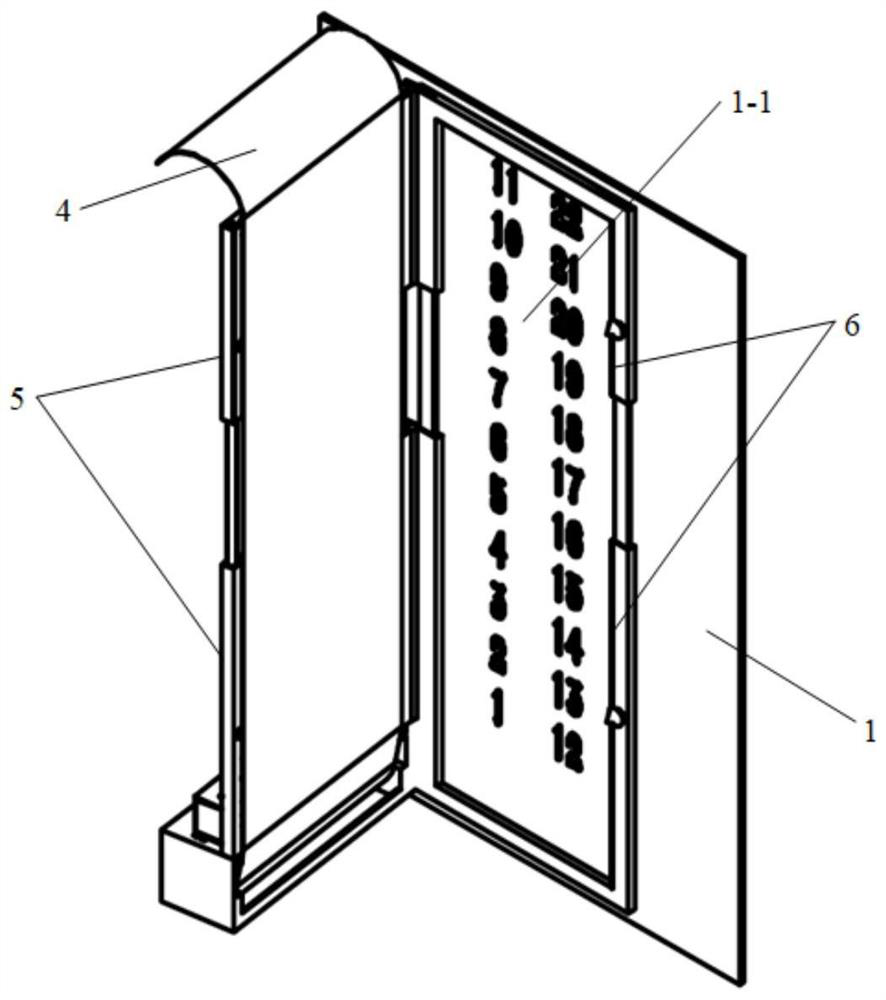

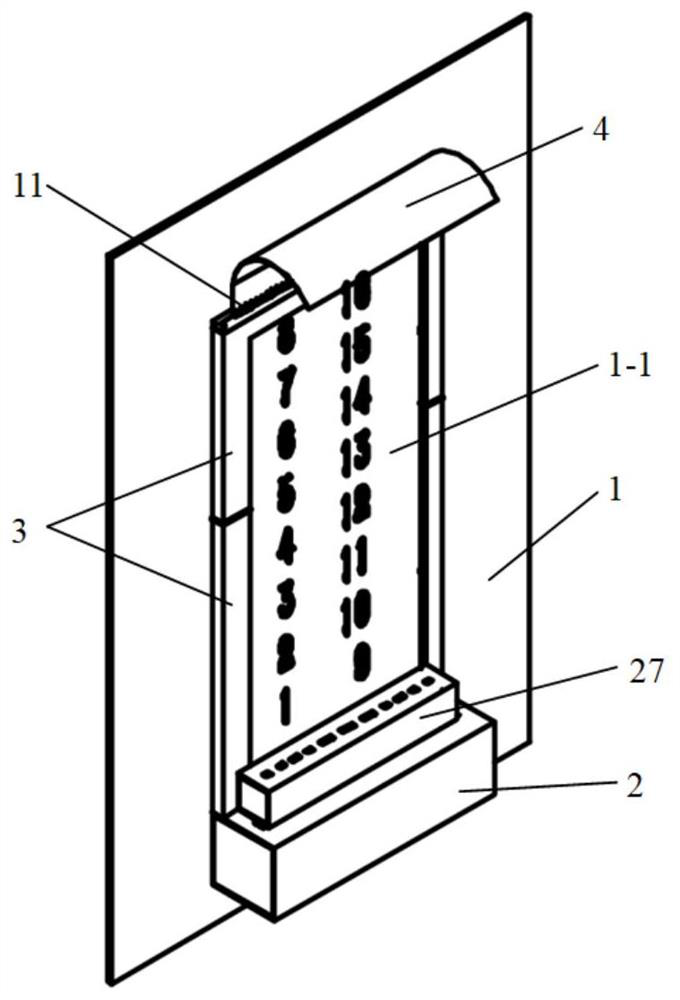

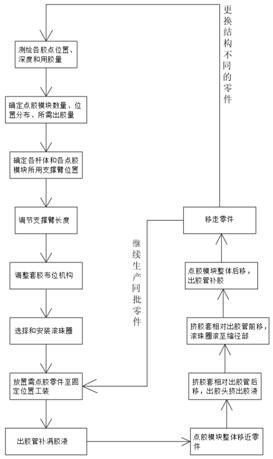

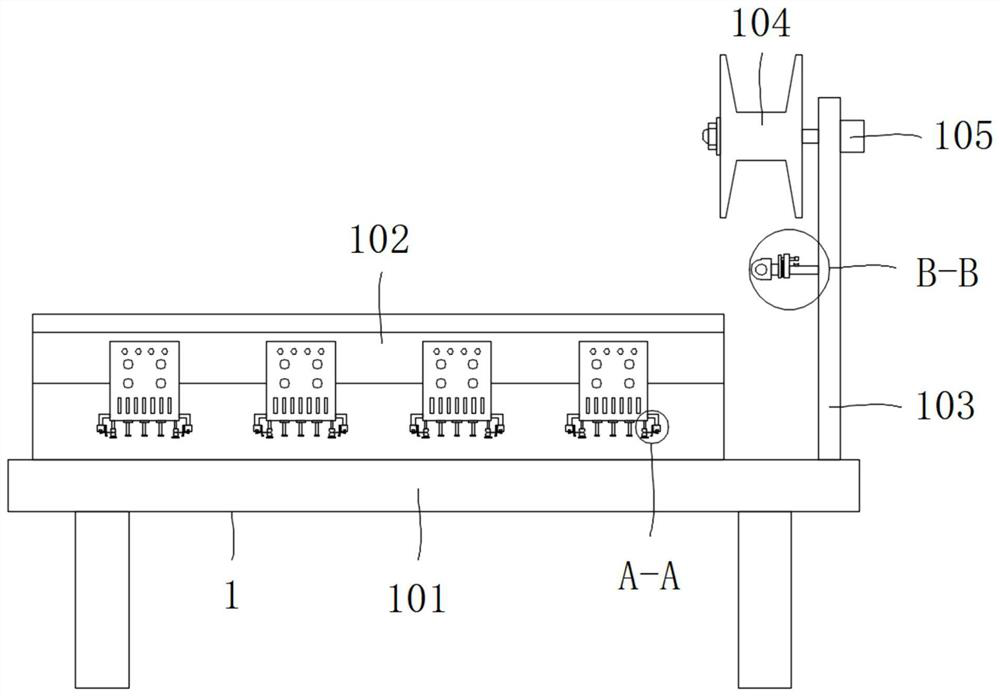

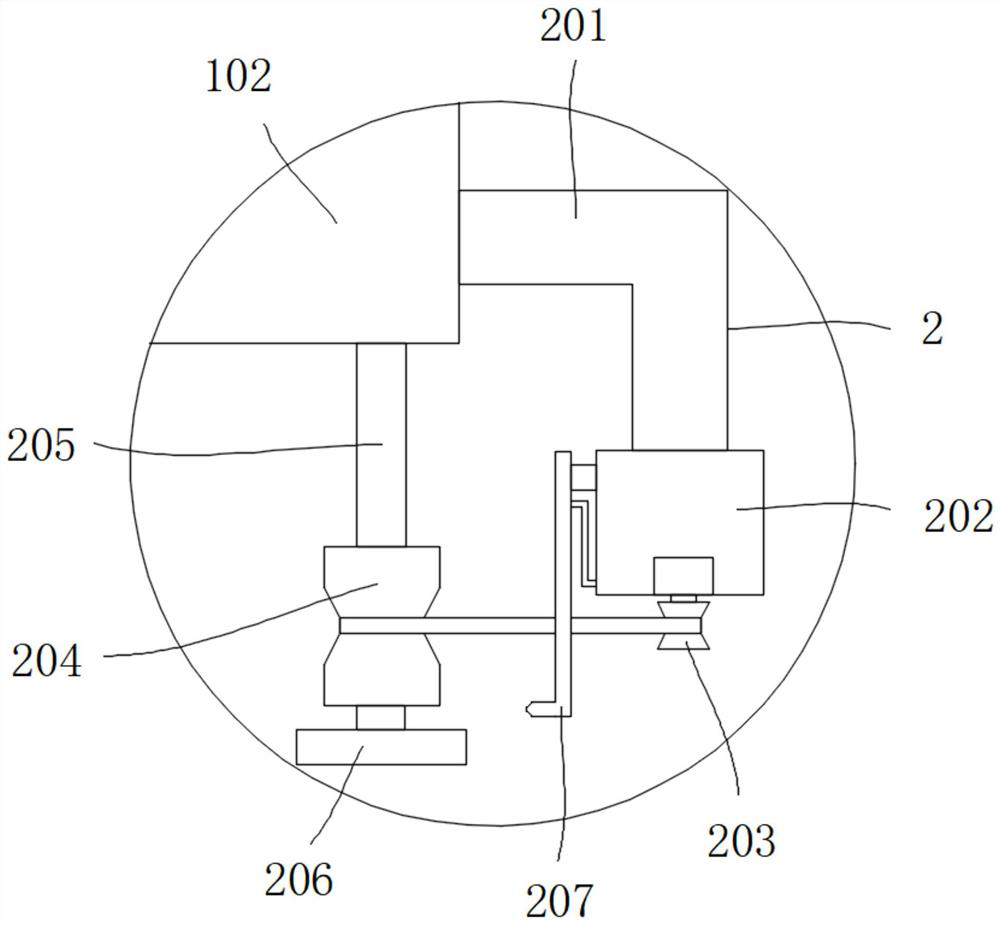

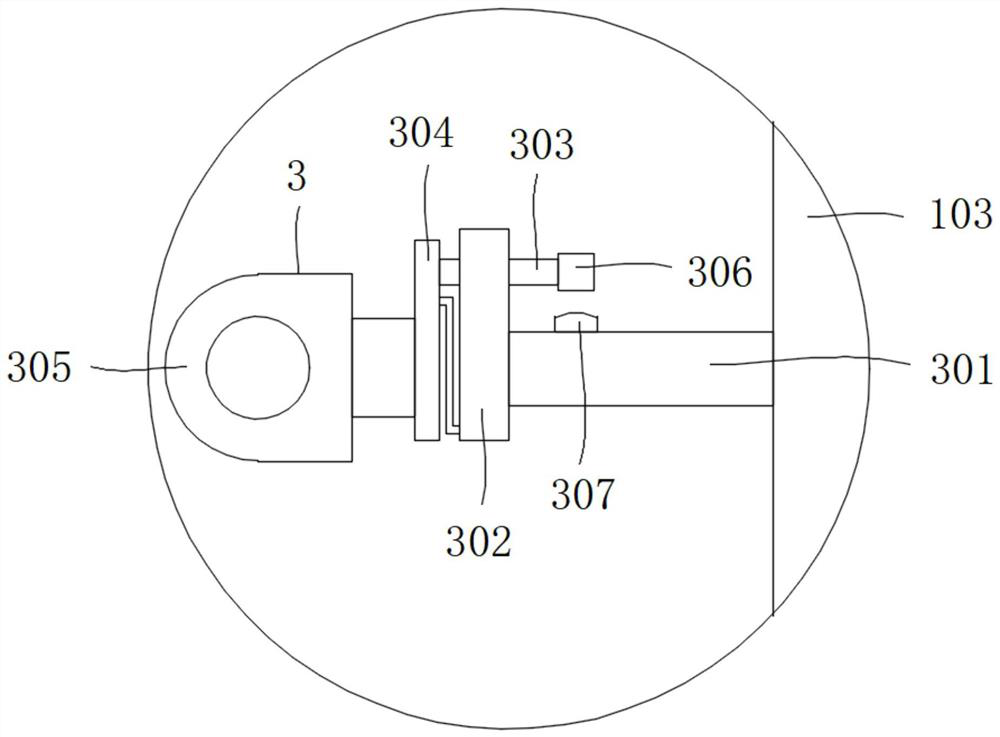

Multipoint synchronous dispensing machine and dispensing method

ActiveCN111632795ALarge structureEasy to adjustLiquid surface applicatorsCoatingsMachineIndustrial engineering

The invention relates to a multipoint synchronous dispensing machine and dispensing method. The dispensing machine comprises multiple dispensing modules achieving the dispensing function and a moduledistribution mechanism. The rear ends of the dispensing modules communicate with glue supplementary pipes. The module distribution mechanism is used for fixing the positions of the dispensing modulesand comprises a first frame and multiple parallel polygonal rods, and the rods are distributed in the first frame and are in sliding fit with the first frame in a locking and fixing manner. Multiple mounting blocks are in detachable sliding fit with the rods in a locking and fixing manner. According to the multipoint synchronous dispensing machine and dispensing method, dispensing can be subjectedto multiple points in a visual face of a part at the same time, the dispensing efficiency is greatly improved, and the dispensing machine and dispensing method are especially suitable for large-scalebatched production; the mechanical cooperation manner is mainly adopted, the number of needed electronic devices is small, work is extremely stable, the service life is long, and the maintenance costis low; dispensing control of different positions, depths and glue quantities can be achieved at the same time, and part structures which the dispensing machine and dispensing method can adapt to areextremely wide; and adjusting can be carried out rapidly and conveniently according parts of different structures, and the application range is wide.

Owner:XIAMEN XINAOGE AUTOMATION EQUIP CO LTD

Surface superfluous dimension machining removing mechanism adopted during installation of steel structure connecting piece

ActiveCN111331186AImprove riding performanceGuaranteed to be straightPlaning/slotting machinesOther manufacturing equipments/toolsMachined surfaceElectric machine

The invention discloses a surface superfluous dimension machining removing mechanism adopted during installation of a steel structure connecting piece. The mechanism comprises a beam, a first motor, asecond motor, a third motor and a control switch. A sliding rail is formed inside the beam. Two sets of connecting frames are embedded inside the sliding rail. An equipment box is welded to the bottoms of the two sets of connecting frames. A connecting rod is fixedly installed at the middle above the equipment box. A first screw is fixedly welded to the upper end of the connecting rod. The firstscrew is hinged to the portion above the beam through a support. A first rotating shaft is inserted at the left end of the bottom of the equipment box through a support. The connecting frame is installed in the sliding rail inside the beam, by means of a roller sleeving the connecting frame, the connecting frame can drive the equipment box to move straightly along the sliding rail, the machined surface removal smoothness of the device when in use is effectively improved, it is ensured that the removal plane is flat and straight, and the superfluous part of the connecting piece can be removed conveniently for butt-joint use.

Owner:杭州富阳东顺钢结构有限公司

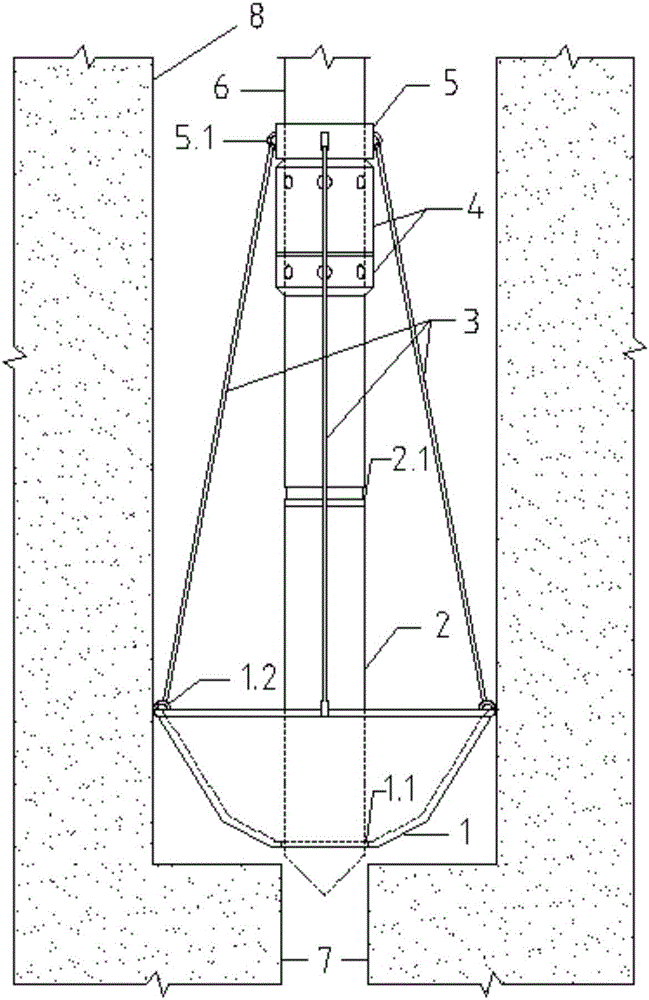

Aiding device for arranging probe in variable cross-section borehole

The present invention discloses an aiding device for arranging a probe in a variable cross-section borehole and belongs to the engineering survey in-situ testing technique field. The device is structured as the following manners: a drill pipe (6) and a probe (2) are connected with each other through a screw thread (2.1) from top to bottom along the central axes of a test hole (7) and a borehole (8) so as to form a test structure, the central axes of the test hole (7) and the borehole (8) being overlapped; the upper part of the drill pipe (6) is provided with a lock catch (4) and a hanging ring (5); the hanging ring (5), hanging ropes (3) and a basin-shaped guide groove (1) are connected with one another sequentially from top to bottom through hanging buckles (5.1) and pulling buckles (1.2) so as to form a guide structure; and one end of the probe (2) passes through a guide hole (1.1) of the basin-shaped guide groove (1) so as to be aligned with the test hole (7). With the aiding device adopted, the accurate arrangement of the probe in the variable cross-section borehole can be aided, and the probe can be arranged at an expected test depth; and disturbance on the borehole and the test hole can be avoided, and the integrity of the test hole can be ensured; and requirements of the arrangement of probes in boreholes and test holes of various kinds of diameters can be satisfied.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

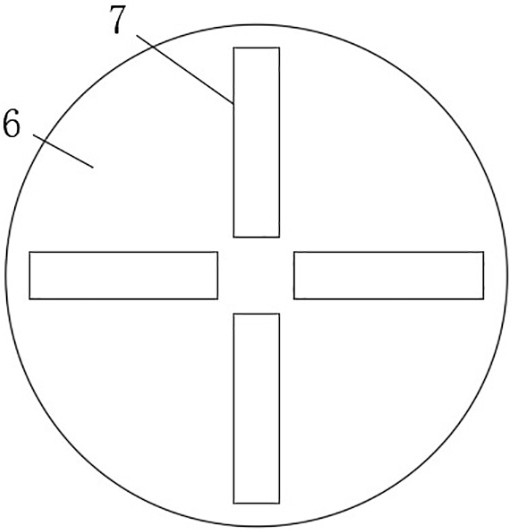

Environment-friendly wire processing system

PendingCN114783689AMeet electrical performanceFulfil requirementsCable/conductor manufactureWire rodEngineering

The invention relates to the technical field of wire manufacturing, in particular to an environment-friendly wire processing system which comprises a working platform, a rotor support is fixedly connected to the right top end face of the working platform, a rotor is rotatably mounted in the rotor support, and a plurality of threading through holes for wires to pass through are symmetrically formed in the rotor. A finished product discharging device is fixedly connected to the left top end face of the working platform, a second guide groove is formed in the right upper side face of the finished product discharging device, a first groove is formed in the right lower side face of the finished product discharging device, a first guide groove is formed in the top end face of the finished product discharging device, a push rod is movably installed in the first guide groove, and the push rod is matched with the first guide groove. According to the invention, through the arrangement of the wire rod limiting device, a plurality of single-wire wires are ensured to be twisted at a preset position, so that the twisted multi-wire wires are tight enough, and the requirements of electrical performance and mechanical performance are met.

Owner:何后飞

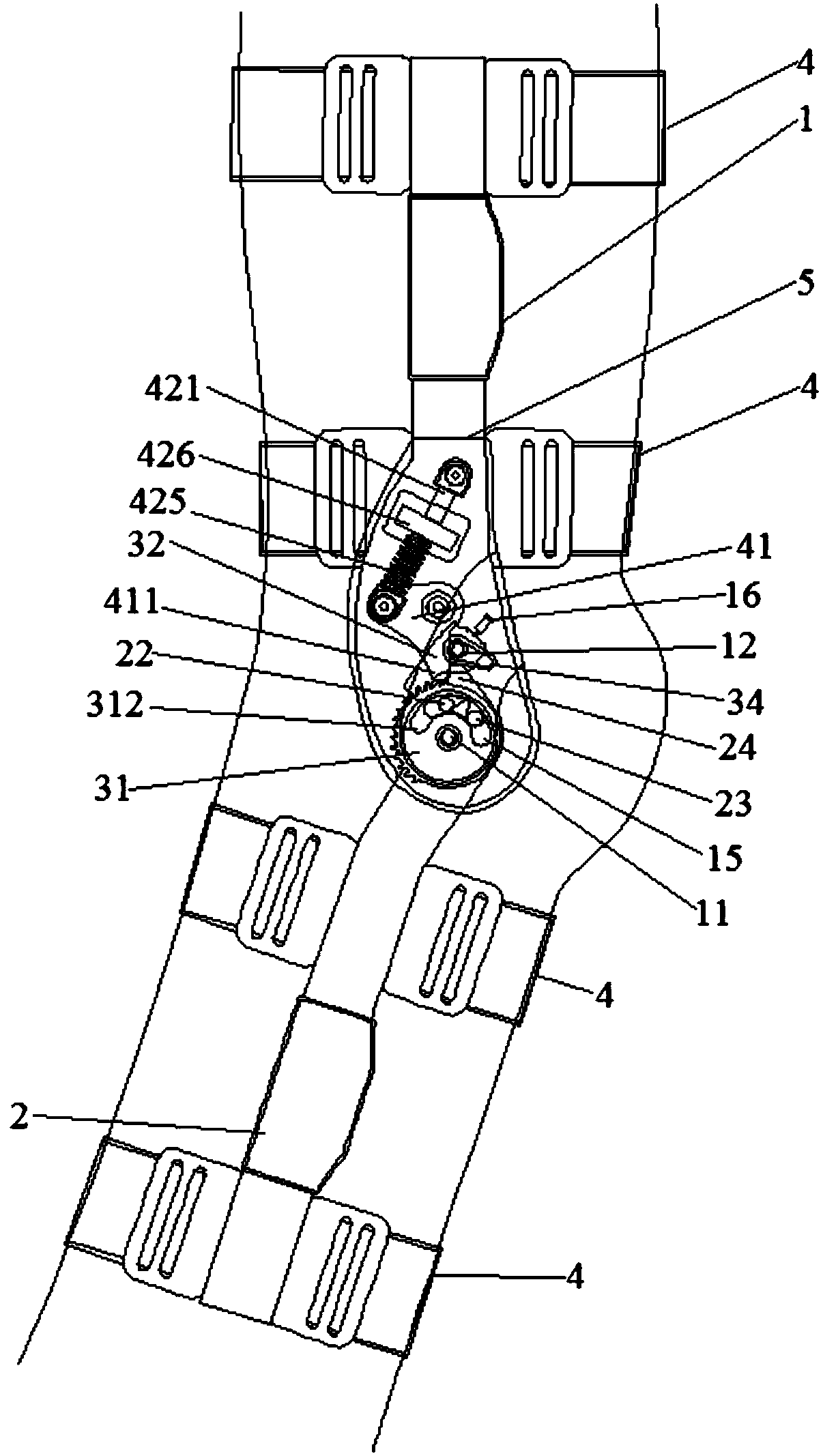

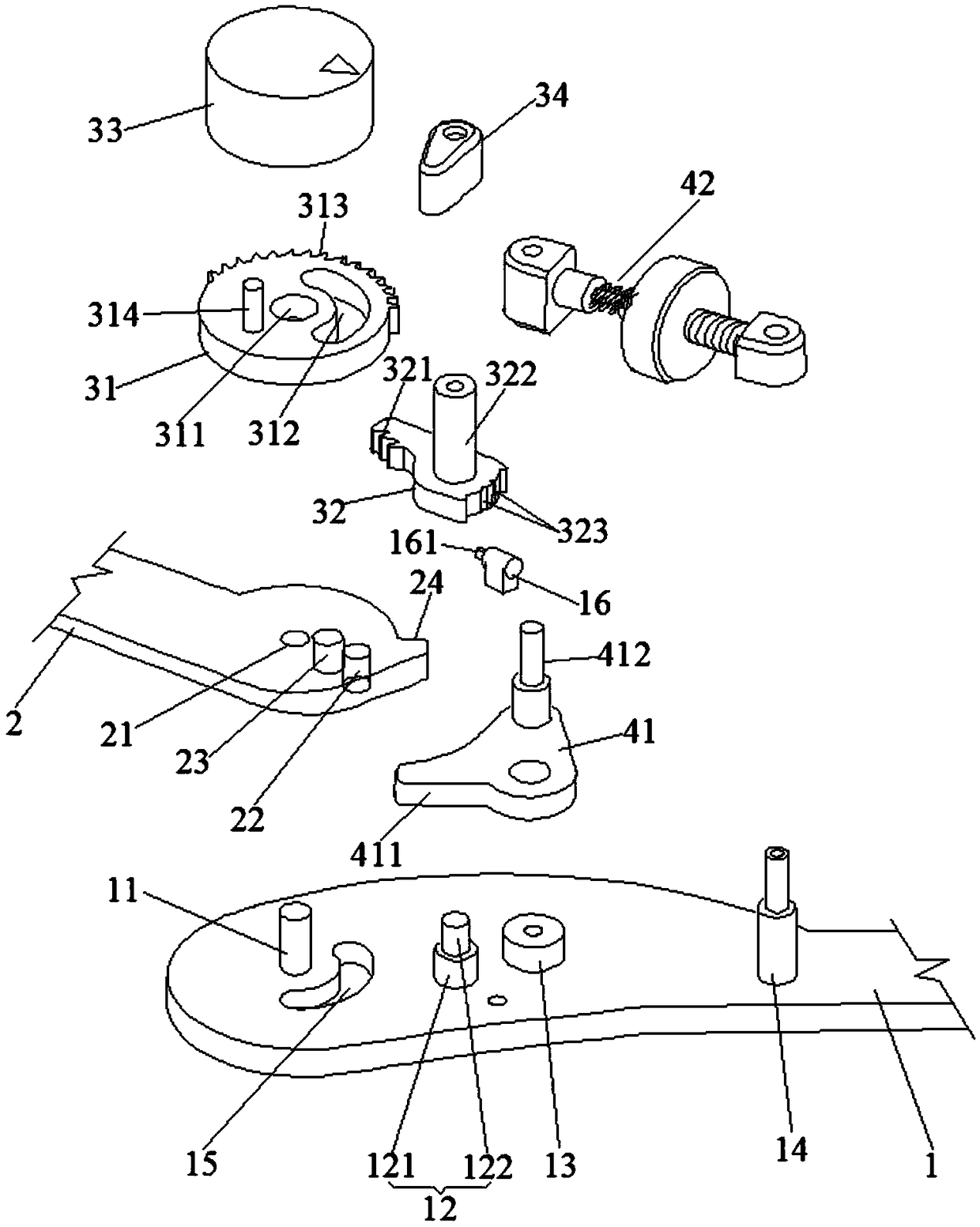

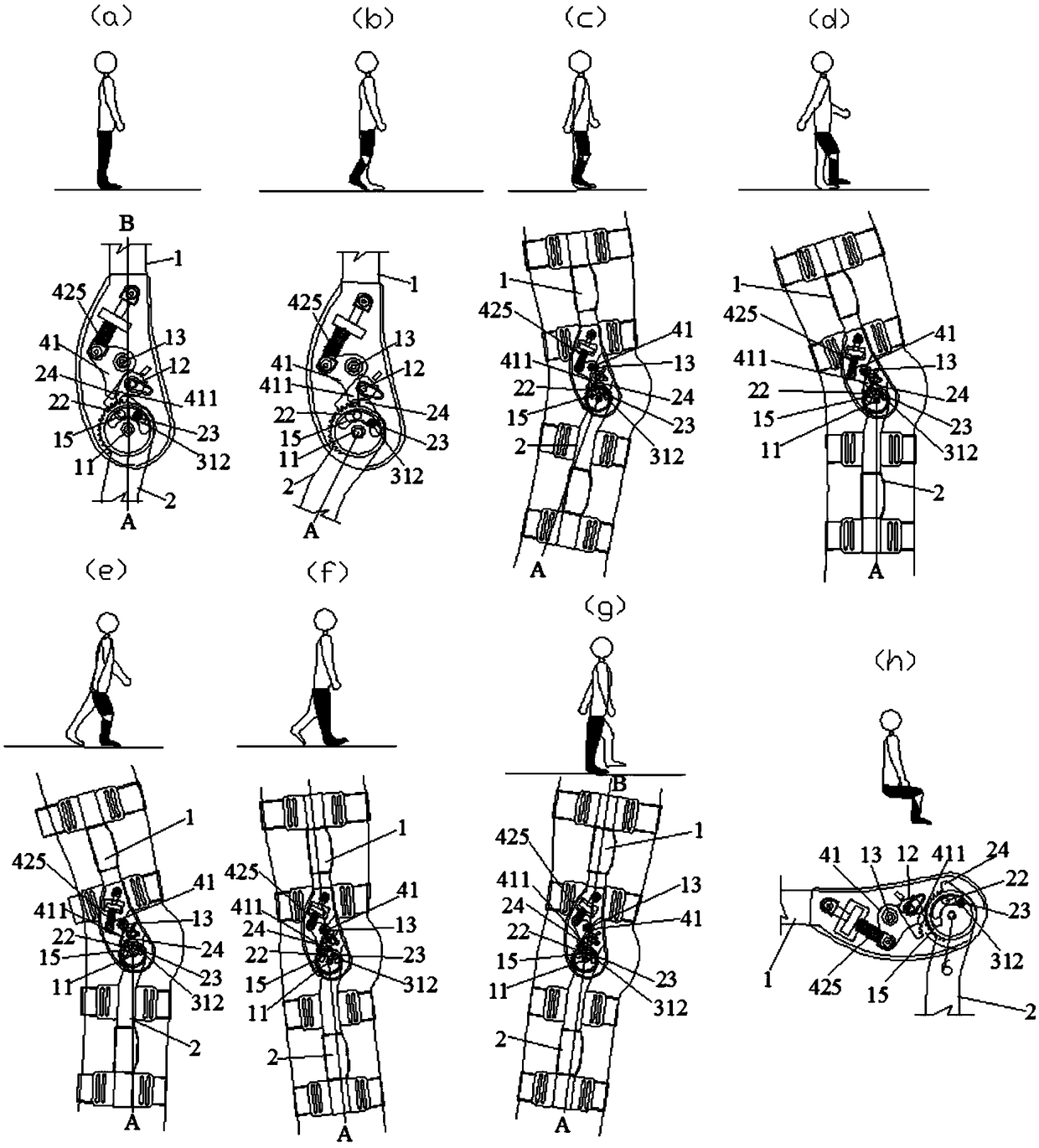

Auxiliary walking device

The invention discloses an auxiliary walking device, which comprises a first rotary plate mounted on thighs of a human body, a second rotary plate mounted on calves of the human body, an angle adjusting mechanism, driving machines and an outer shell, wherein a main shaft, a first supporting shaft, a second supporting shaft, a third supporting shaft, a first circular arc hole and a second rotary plate are formed in the surface of the first rotary plate; a first mounting hole, a first rotary shaft, a second rotary shaft and a pressing part are formed in the second rotary plate; the angle adjusting mechanism comprises a rotary disc, a locking plate; and the outer shell is used for accommodating the first rotary plate, the second rotary plate, the angle adjusting mechanism and the driving mechanism. The technical scheme simplifies the structure of the traditional auxiliary walking device, the cost is reduced, the use for users is facilitated, the comfort of the users to use is improved, and the use requirements of different users are met.

Owner:GULIN ELECTRICAL EQUIP CO LTD SHENZHEN

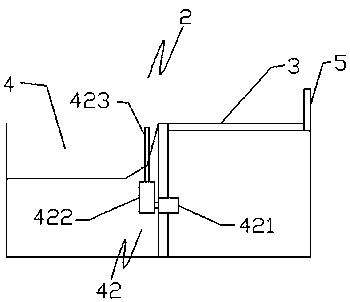

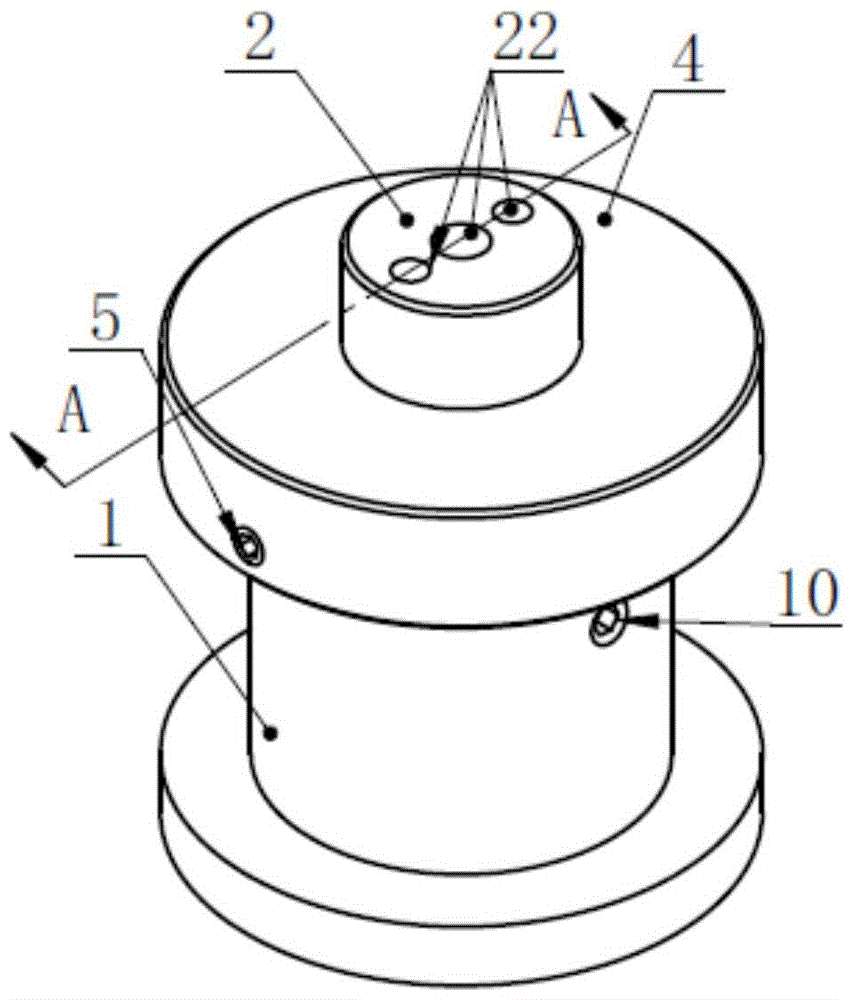

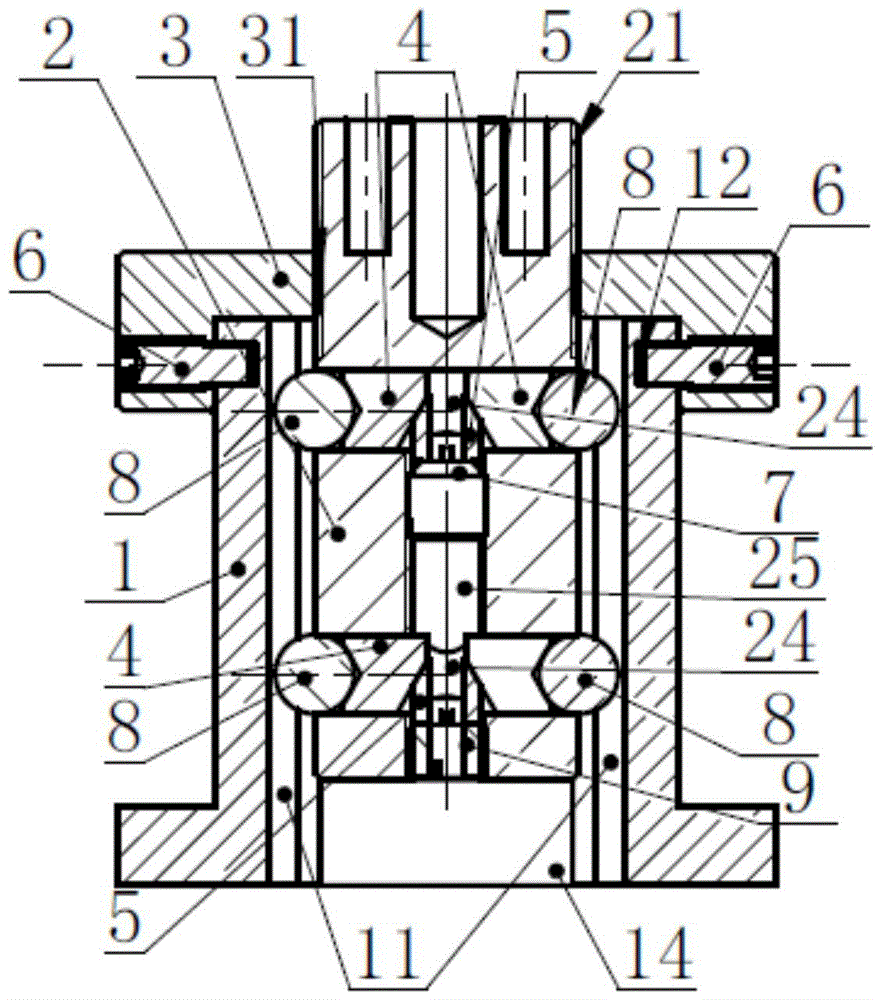

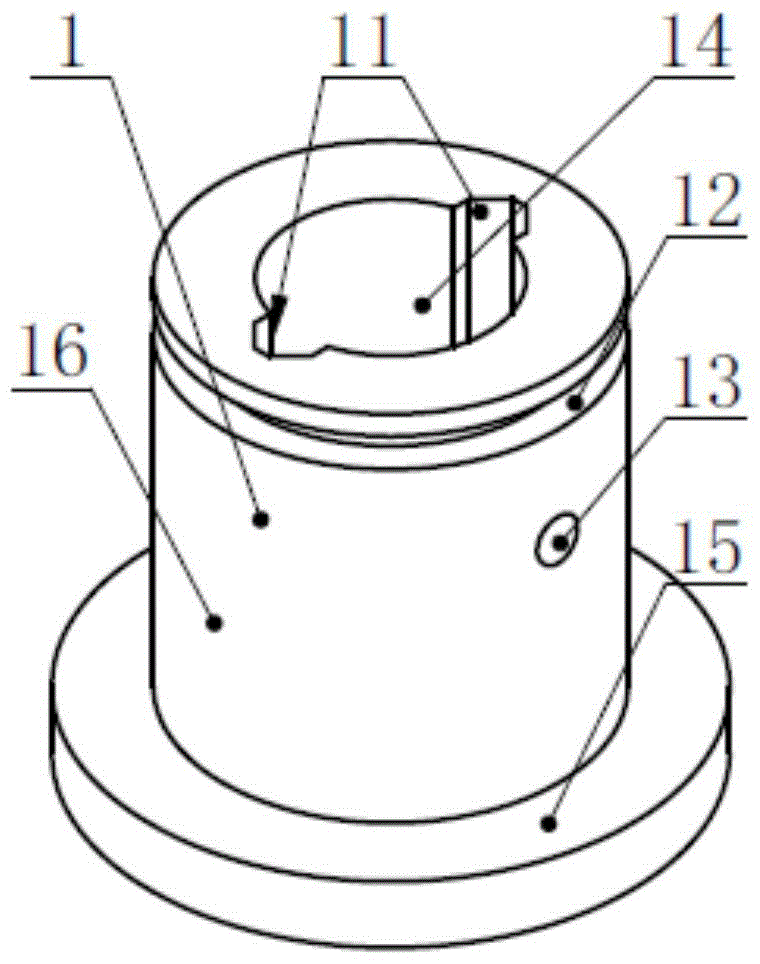

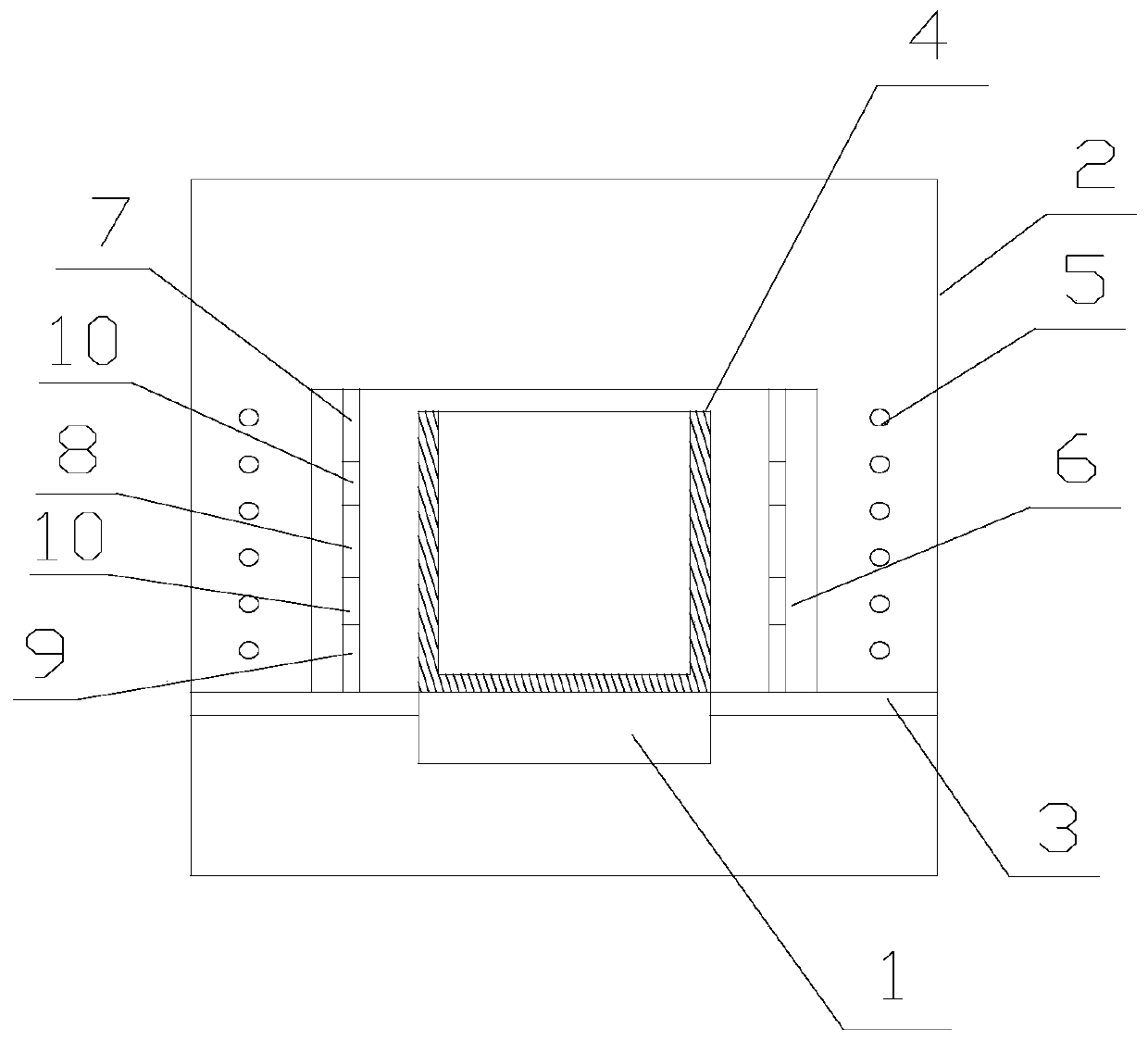

Central positioning mechanism, wire harness pouring device and wire harness pouring method

Owner:SUZHOU HUAZHAN SPACE APPLIANCE

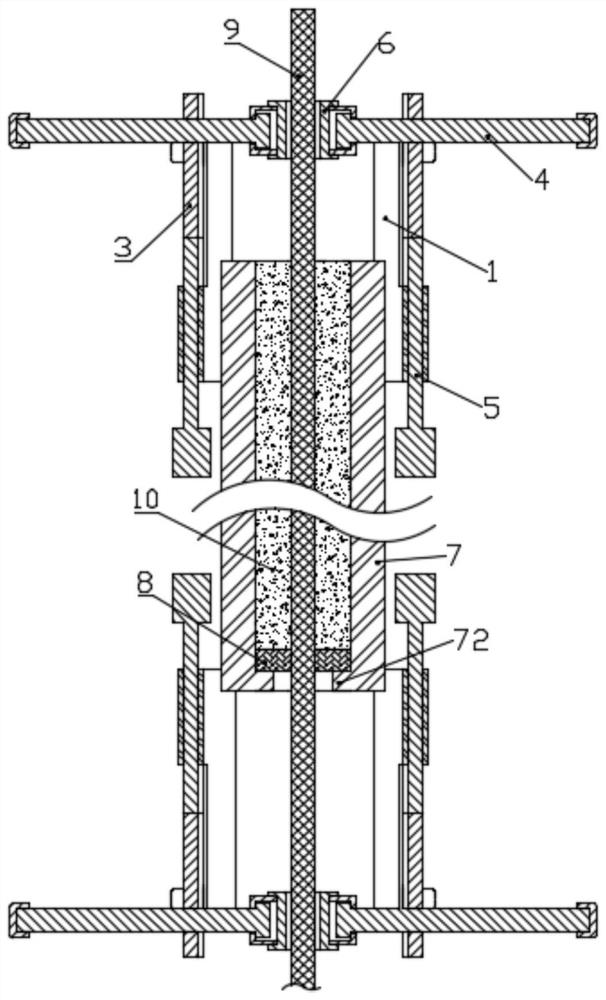

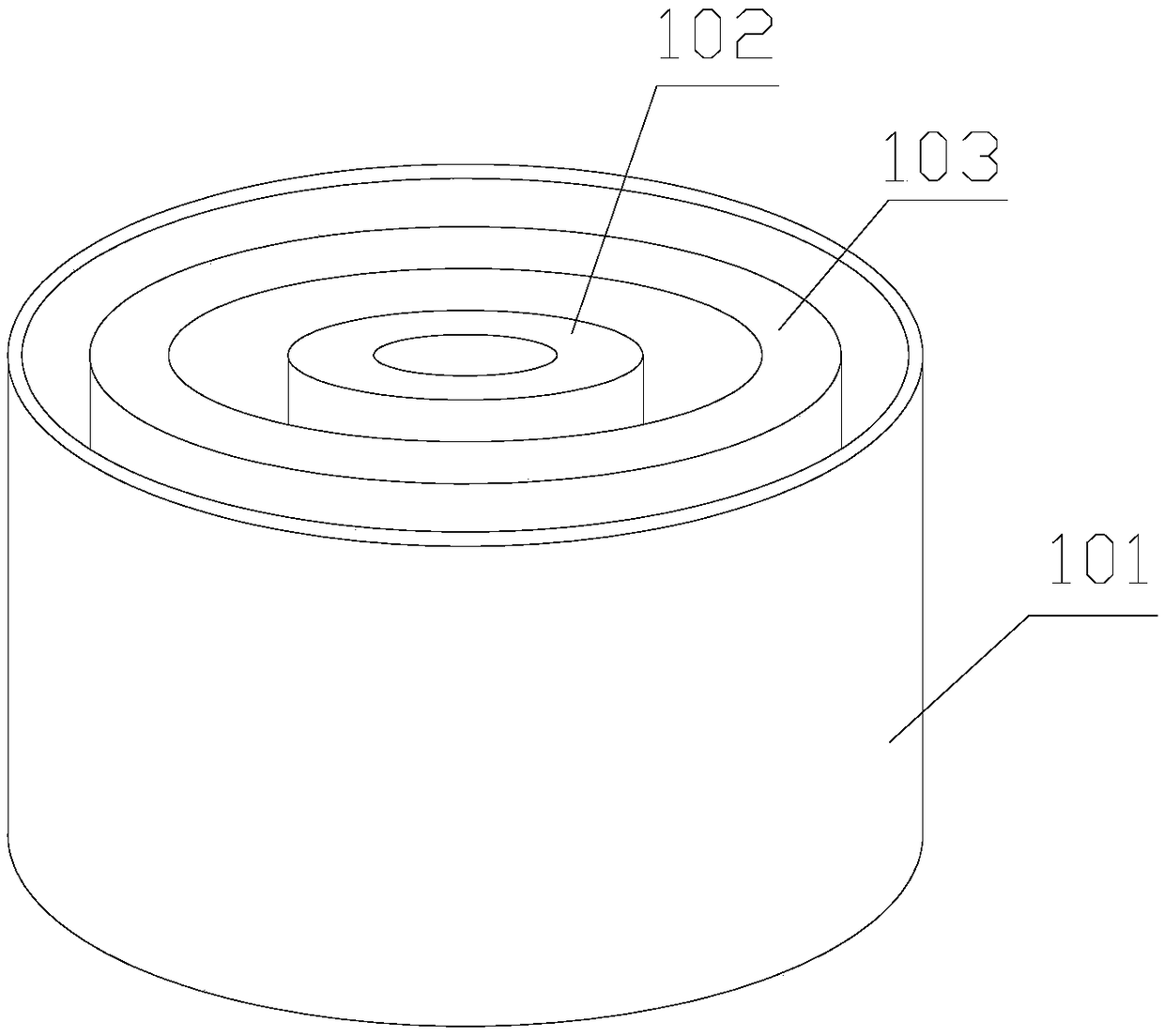

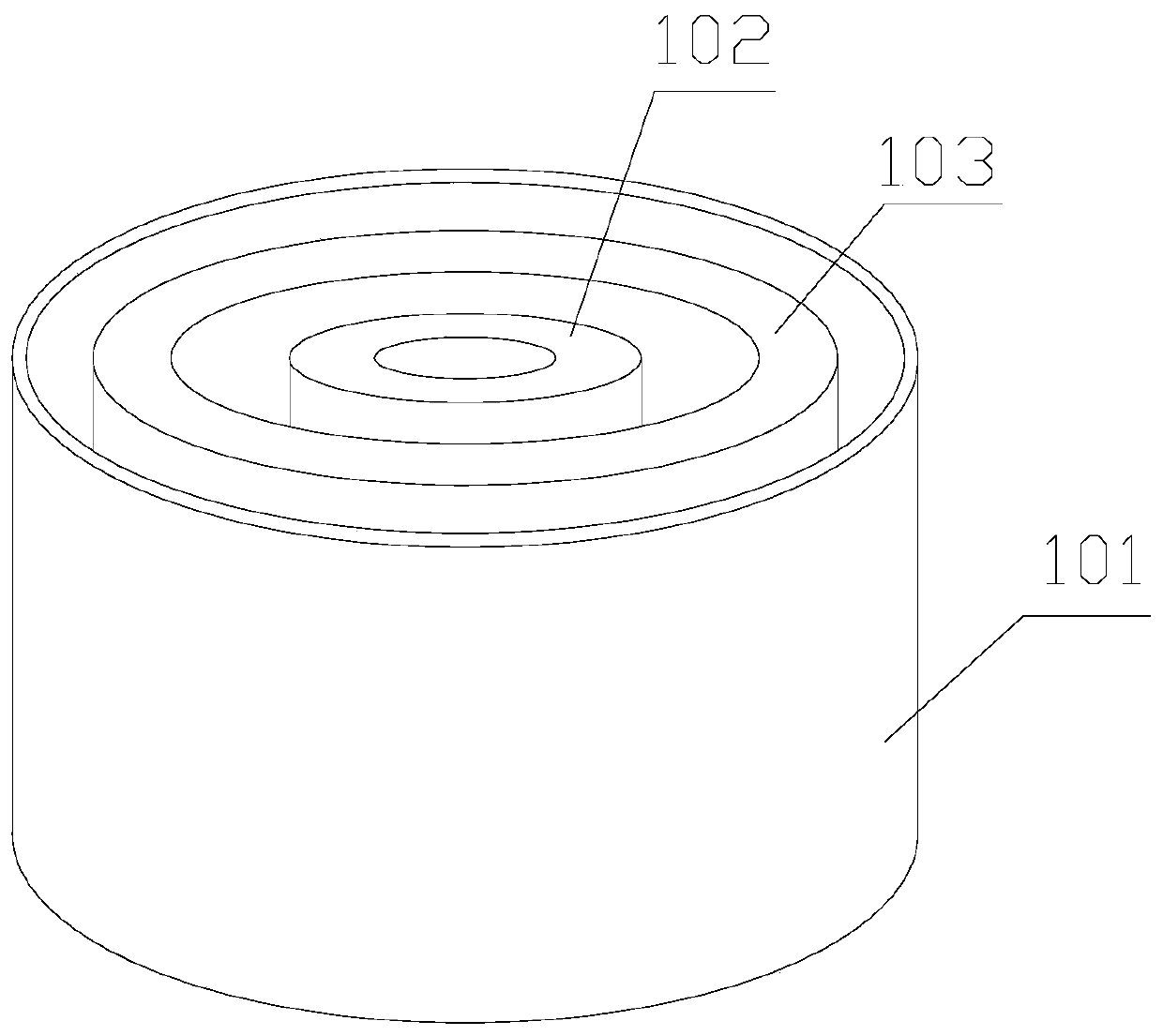

Device and process for controlling heating temperature field to purify and prepare polycrystalline silicon

ActiveCN109252216AIncreased air turbulenceGood for even distributionPolycrystalline material growthSilicon compoundsPolycrystalline siliconMetallurgy

The invention discloses a device for controlling a heating temperature field to purify and prepare polycrystalline silicon. The furnace body is provided therein with a heat insulation plate, a coolingplate, a crucible, a heating induction ring and a heat preservation tube. The heat preservation tube is provided therein with an upper graphite heating ring, a middle graphite heating ring and a lower graphite heating ring, connection rings are arranged between the upper graphite heating ring and the middle graphite heating ring, and between the middle graphite heating ring and the lower graphiteheating ring, respectively, and the connection rings are made from a high temperature resistant material with heat conduction coefficient of 10-50 W / m.k. A purification process comprises the steps: introducing a cooling gas into a cooling plate; introducing an inert gas into a furnace body, and meanwhile discharging through an exhaust pipe provided at the top of the furnace body to ensure a certain gas pressure existing in the furnace body; and controlling the upper graphite heating ring, the middle graphite heating ring, and the lower graphite heating ring to cool according to a certain procedure. The device and process for controlling heating temperature field to purify and prepare polycrystalline silicon facilitates the formation of a uniform temperature gradient, being favorable for crystal growth, and can effectively prevent the stepwise sudden change of a stepwise heat field from top down.

Owner:CHENGDU SILICON TECH CO LTD

Thermocouple guide pipe

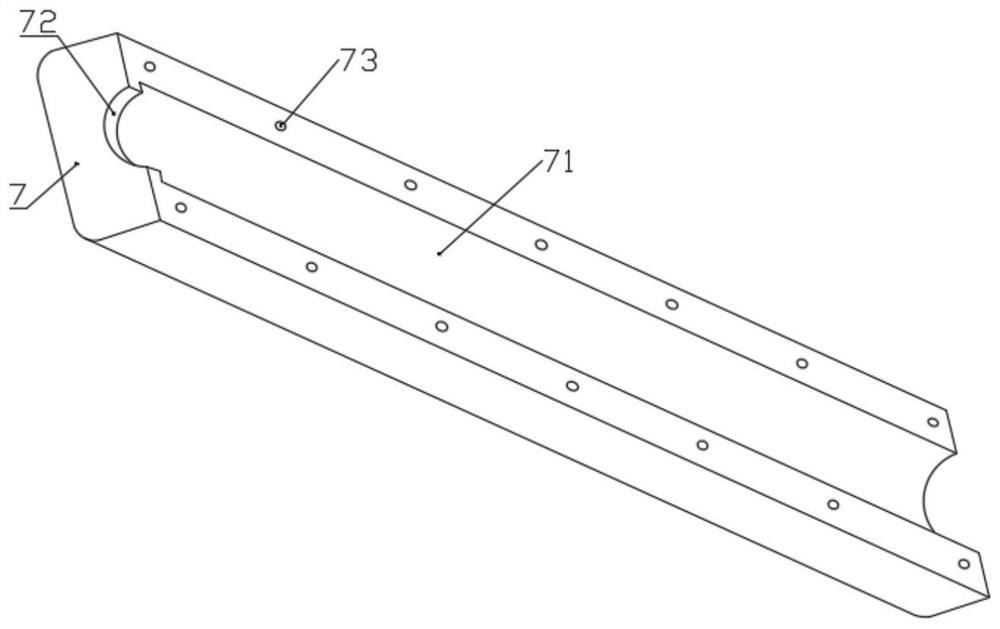

InactiveCN105675163AGuaranteed StraightControl deformationThermometer detailsThermometers using electric/magnetic elementsEngineeringPipe

The invention relates to a thermocouple guide pipe, and the guide pipe is characterized in that the guide pipe comprises a pipe body, a guide groove which is disposed in the length direction of the pipe body and is used for storing a thermocouple temperature measurement part, and a connection part which is disposed on an outer wall of the tube body and is connected with equipment main body. The guide pipe is advantageous in that the guide pipe is simple in structure, is easy to machine, is convenient to use, and is safe and reliable. The guide pipe can effectively guarantee the linearity of the movement of a thermocouple, effectively controls the deformation of the thermocouple, and prolongs the service life of the thermocouple.

Owner:迈瑞尔实验设备(上海)有限公司

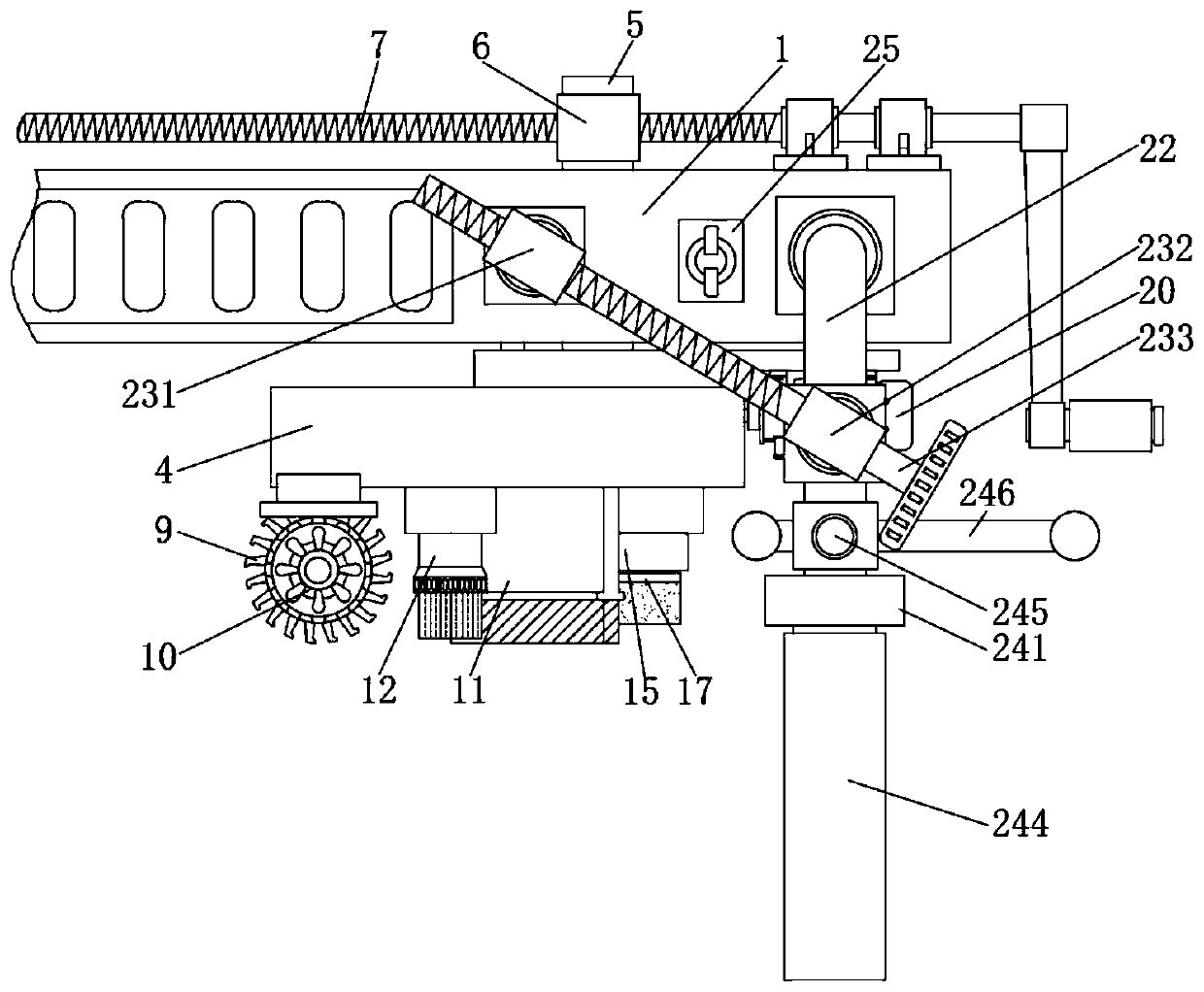

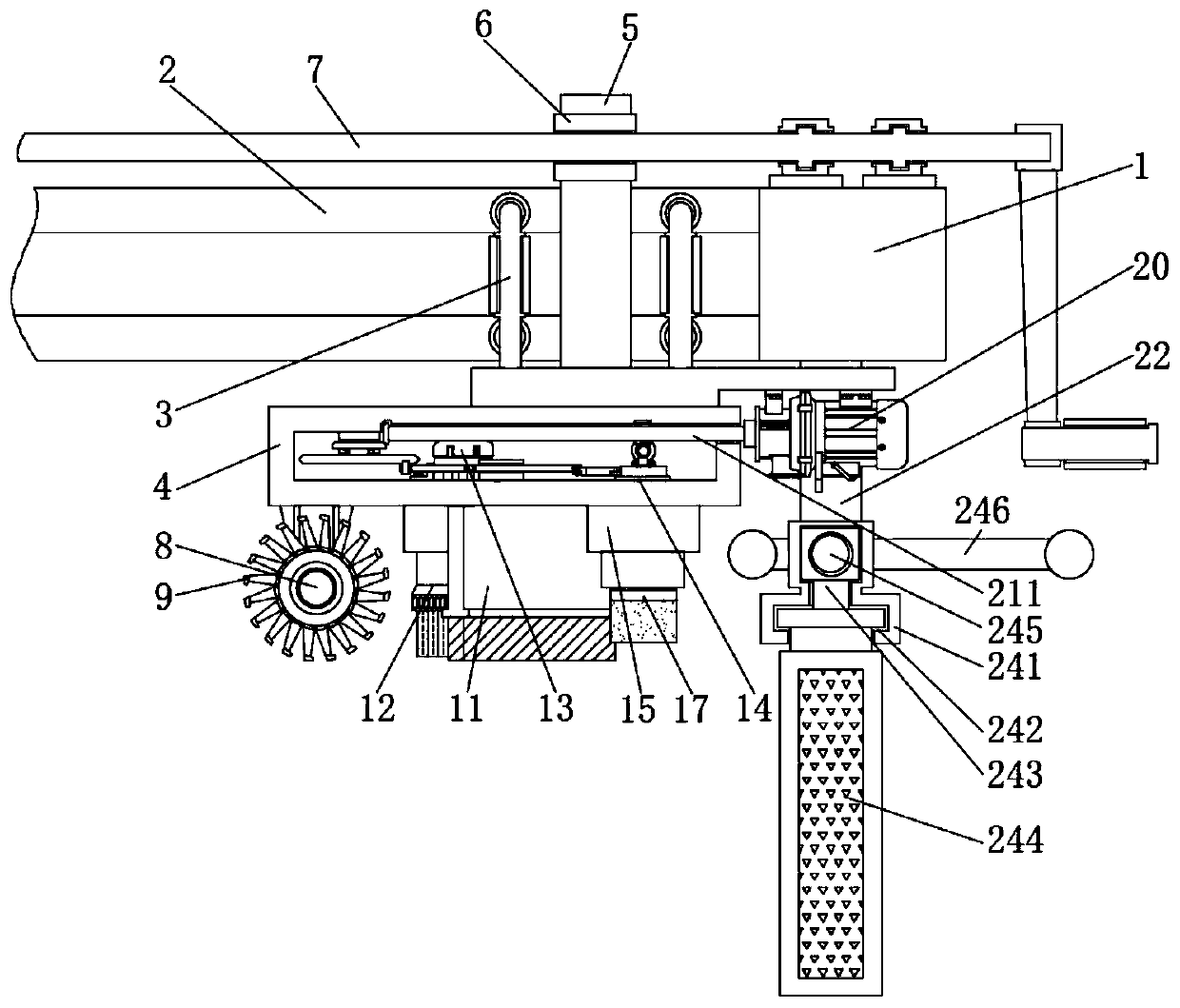

Full-automatic terminal pressure-welding device for super-long lead wire

ActiveCN107809047AScientific and reasonable designEasy to useConnection formation by deformationEngineeringTin

The invention belongs to the technical field of connector production, and particularly relates to a full-automatic terminal pressure-welding device for a super-long lead wire. The device comprises a full-automatic terminal machine and a lead wire guiding device, wherein the lead wire guiding device is connected with the full-automatic terminal machine and is arranged on one side of a product outlet of the full-automatic terminal machine; the lead wire guiding device comprises a conveying area and a finished product stacking area; the finished product stacking area is provided with at least twoguiding slots; guiding mechanisms are arranged under the guiding slots; the full-automatic terminal machine comprises a cutting station and a terminal pressure-welding station; the conveying area islocated on one side of the cutting station; the finished product stacking area is located on one side of the terminal pressure-welding station. According to the full-automatic terminal pressure-welding device for the super-long lead wire provided by the invention, a guiding device is arranged for guiding the lead wire so as to ensure the lead wire to be at a straight state, so that the super-longlead wire is cut and subjected to terminal pressure-welding and tinning; the guiding mechanism and the finished product stacking area are arranged in the guiding device, so that full-automatic production is realized.

Owner:惠州市米芯科技有限公司

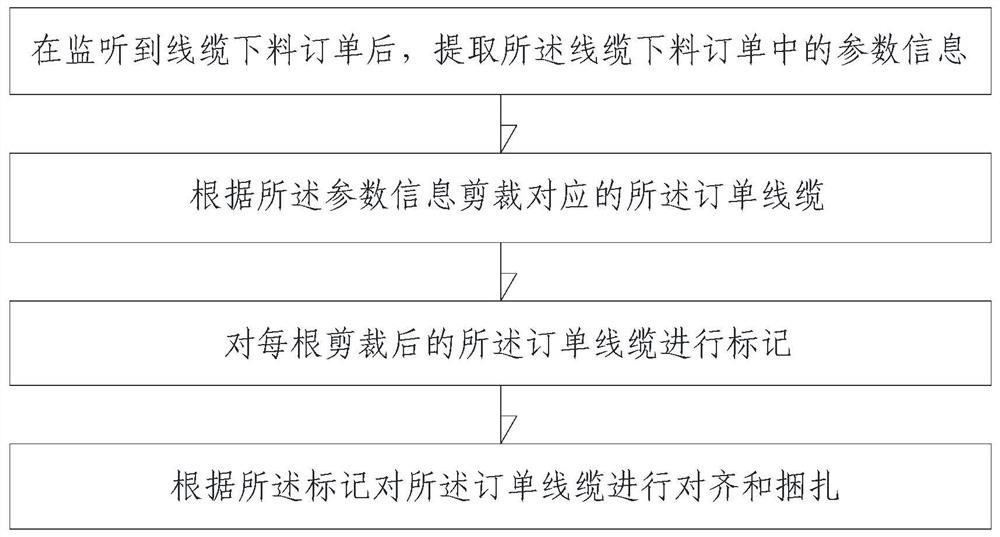

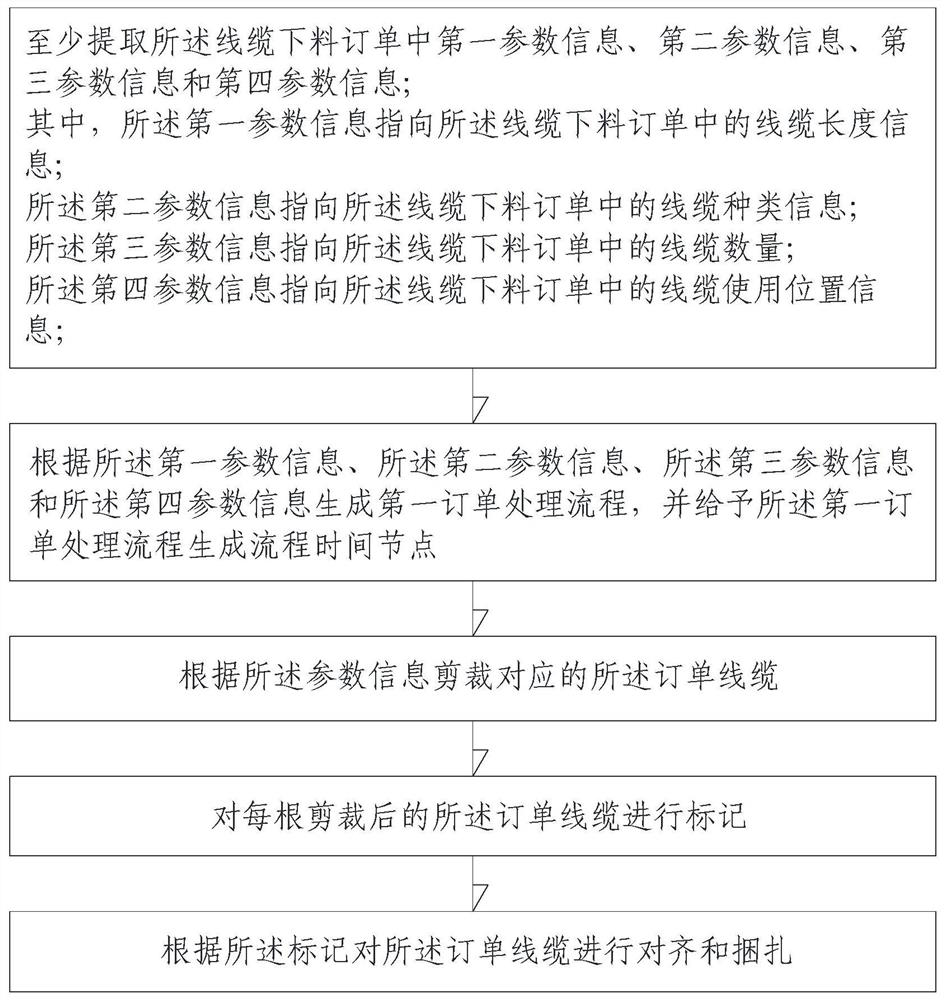

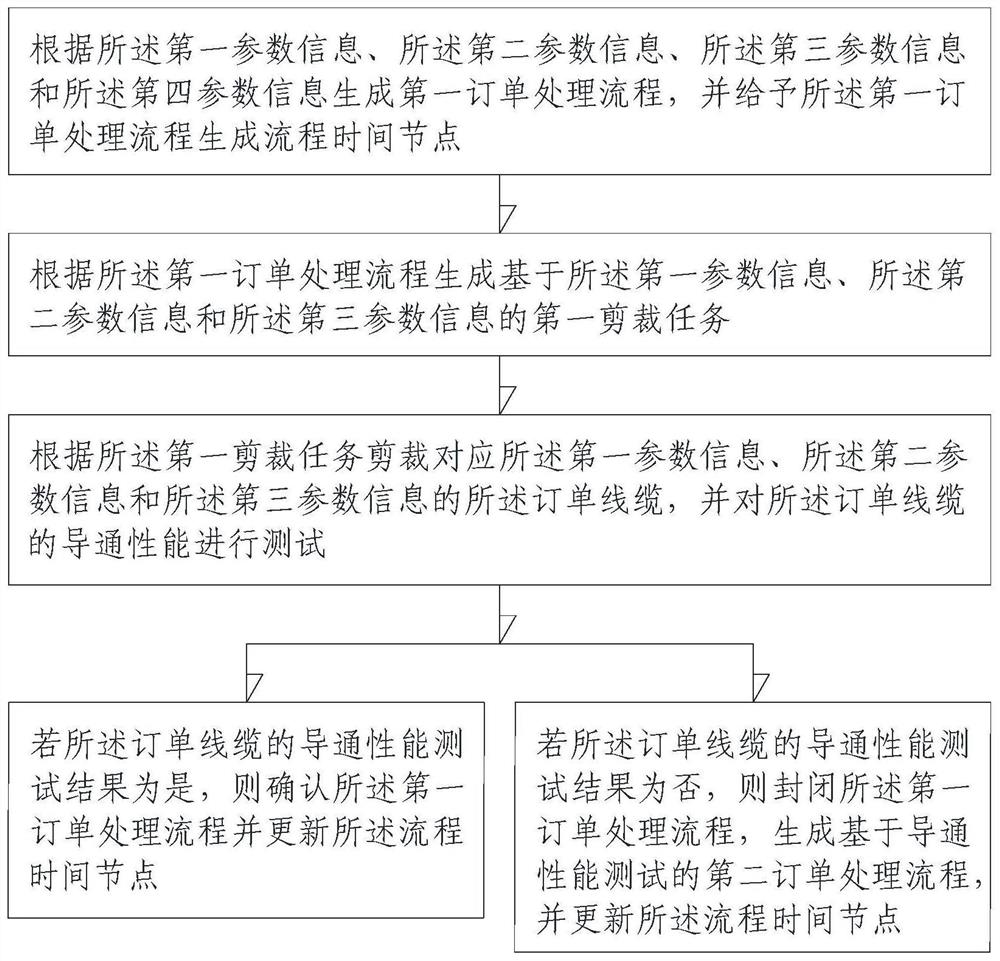

Cable discharging method and cable discharging system

ActiveCN112061517AConvenience guaranteedGuaranteed automationWrappingWrapper twisting/gatheringInformatizationControl theory

The embodiment of the invention provides a cable discharging method and a cable discharging system. The method comprises the following steps that after a cable discharging order is monitored, parameter information in the cable discharging order is extracted; corresponding order cables are tailored according to the parameter information; each tailored order cable is marked; and the order cables arealigned and tied according to marks. The cable discharging method and the cable discharging system in the embodiment are used for overcoming the defects that in the prior art, efficiency of the discharging working procedure is low, and a large number of workers are needed for participation, labor intensity of the workers is effectively reduced, the working efficiency is improved, and assistance is provided for automation, informatization and intelligence of production of enterprises.

Owner:CRRC IND INST CO LTD

A car built-in multi-directional self-adjusting integrated antenna

ActiveCN112133995BAdjust directionMultiple angle adjustment directionsAntenna adaptation in movable bodiesTelescopic elementsIn vehicleIntegrated antenna

The invention relates to the field of antennas, and discloses a built-in multi-directional self-adjusting integrated antenna in a car, which includes a fixing base and a vehicle-mounted integrated antenna. A driving motor is installed on the top of the fixing base, and the output shaft of the driving motor is fixedly connected to the There is a fixed plate, four evenly distributed miniature electric push rods are installed on the top of the fixed plate, and a mounting plate is installed on the bottom of the vehicle-mounted integrated antenna. The car has a built-in multi-directional self-adjusting integrated antenna. The control command output by the preset program in the car can control the independent expansion and contraction of four miniature electric actuators. When different miniature electric actuators are adjusted to different lengths, they can control The mounting plate is at different angles, so that the angle of the vehicle-mounted integrated antenna can be adjusted, and then the direction of the vehicle-mounted integrated antenna can be adjusted independently. Angle adjustment direction more.

Owner:赣州市硕源新能源电子科技有限公司

Threaded lift table

The invention relates to a thread lifting platform. The thread lifting platform comprises a lifting rod seat, a lifting screw rod, a lifting screw cover, a support pillar, an abutting block, a fixing rotating screw, a stopper screw, steel balls, a pressing ring and a tightening screw. According to the thread lifting platform, the lifting screw cover adjusts the lifting screw rod and achieves the up-and-down motion through the guide of the steel balls, the abutting block with elasticity enters a V-shaped sliding groove through the support pillar abutting against the steel balls, the elasticity of the abutting block makes up for the error of the V-shaped sliding groove, the steel ball is made to contact with the V-shaped sliding groove tightly, and the arrangement of the two pairs of up-and-down steel balls guarantee the movement stability of the lifting screw rod in the lifting rod seat. The probation shows that the screw lifting platform has the advantages that the structure is simple, adjustment is convenient, and stability and reliability are possessed.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

a strapping device

ActiveCN109179031BSmall footprintLarge storage capacityArticle deliveryWebs handlingClassical mechanicsThin membrane

The invention discloses a film splicing device. The film splicing device comprises a box body, an opening is formed in the middle of the upper surface of the box body, the two ends of the opening aresymmetrically provided with pressing splicing assemblies, traction assemblies are installed below the pressing splicing assemblies, the pressing splicing assemblies drive the traction assemblies to work, a shearing assembly is installed between the pressing splicing assemblies and the traction assemblies, attraction assemblies are installed below the traction assemblies, adhesive tape sticking assemblies are installed above the opening, and a waste storage assembly is installed below the box body in a detachable mode. According to the film splicing device, through the arrangement of the wastestorage assembly, the occupied area of waste is reduced, the storage amount of a waste box is increased, the workload of operators is reduced, through the linkage arrangement between the pressing splicing assemblies and the traction assemblies, it is guaranteed that a thin film is kept in a straightened state during cutting, and then normal proceeding of cutting work is guaranteed.

Owner:立昱电子(惠州)有限公司

Production and preparation method of luminescent fiber anti-counterfeiting mark fabric

The invention discloses a production and preparation method of luminescent fiber anti-counterfeiting mark fabric. The method adopts a spinning mechanism, wherein the spinning mechanism comprises a support, an embroidery machine body, a support rod, a pay-off roller and a servo motor. Through mutual cooperation of the spinning mechanism, a presser foot mechanism and a pay-off mechanism, productionequipment of the luminescent fiber anti-counterfeiting mark fabric is achieved, a presser foot plate is driven by the motor and a belt to rotate by 360 degrees or jump up and down, a yarn supply device can be controlled by a computer, the yarn supply length is preset, then through motor control and rocker induction, intelligent thread feeding and intelligent thread take-up are achieved, free take-up and pay-off are achieved, breakage caused by manual take-up and pay-off is avoided, during work, Z-shaped movement of the presser foot plate and sewing threads is achieved, thread trampling can beeffectively prevented, it is guaranteed that the sewing threads are straight and not bent, a rubber sleeve head is arranged at the contact position of a presser foot sleeve head and cloth, and the cloth is flattened and not liable to be scratched.

Owner:泉州市隐形盾鞋服科技有限公司

A fully automatic terminal crimping equipment for super long wires

ActiveCN107809047BScientific and reasonable designEasy to useConnection formation by deformationMechanical engineeringIndustrial engineering

Owner:惠州市米芯科技有限公司

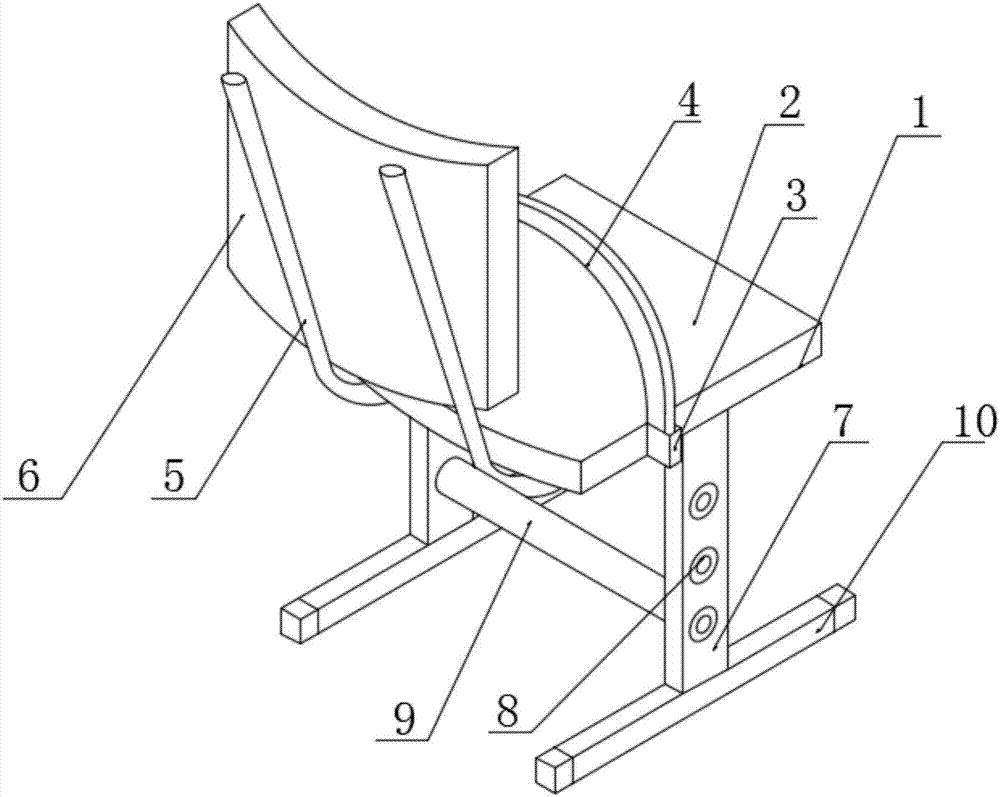

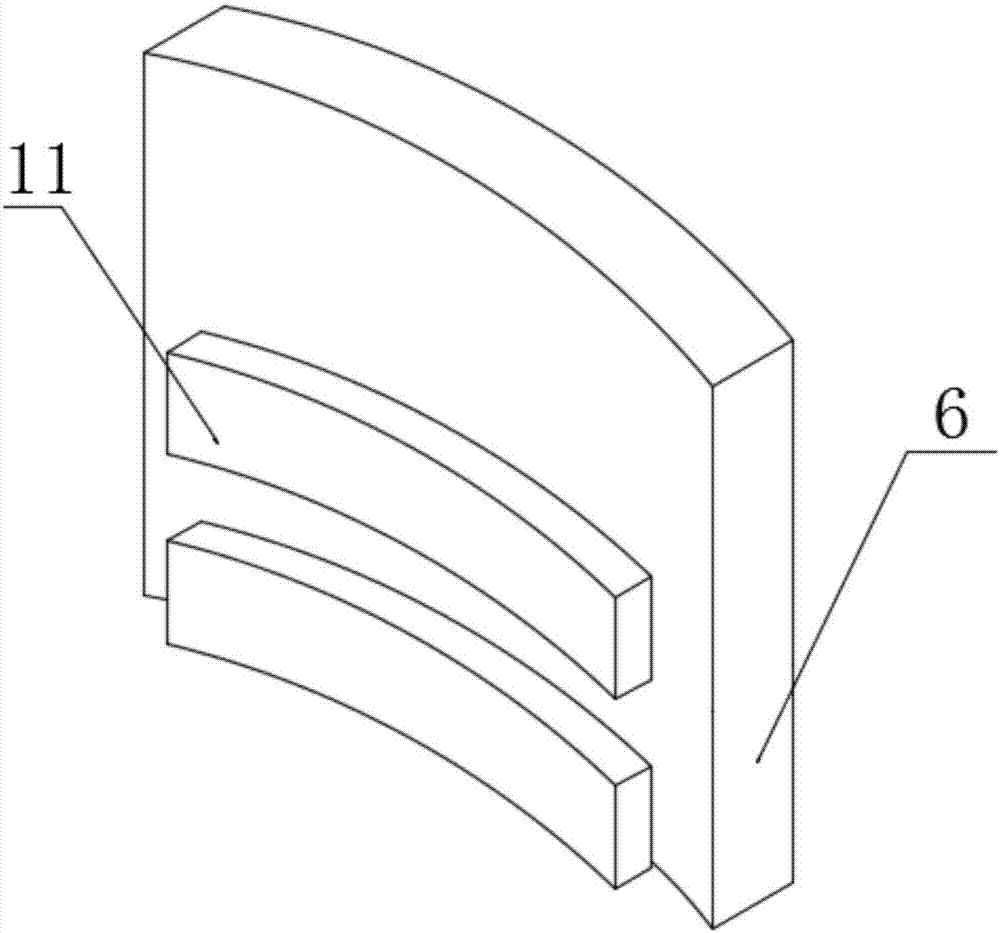

Student chair facilitating correction of sitting postures

InactiveCN107125991AThe correction effect is excellent and obviousReasonable designStoolsChairsEngineeringPoor posture

The invention discloses a student seat which is beneficial for correcting sitting posture, comprising a seat body, a seat board is arranged on the surface of the seat body, a fixing block is arranged on one side of the seat board, an elastic band is arranged on the surface of the fixing block, The back of the seat board is provided with a chair back bar, the surface of the chair back bar is provided with a chair back board, the bottom of the seat board is provided with a support seat, and the surface of the support seat is provided with several adjusting bolts, and an adjustment bolt is provided between the two support seats. There are connecting rods, the two ends of the connecting rods are provided with anti-skid sleeves, the surface of the chair back board is provided with a rectifying plate, and one side of the rectifying plate is provided with several springs. This kind of student seat solves the problem that the existing seat does not have the function of correcting the student's sitting posture. Since the student is in the stage of physical development, long-term bad sitting posture will lead to a series of bad habits such as the student's hunchback, which is not conducive to the student's Growth, causing the problem of inconvenient use.

Owner:WUXI NANCHANG EXPERIMENTAL MIDDLE SCHOOL

Earphone patch cord copper strip machine

The invention relates to the technical field of earphone patch cord processing, in particular to an earphone patch cord copper strip machine. Comprising a fixing plate, supporting legs arranged at the bottom of the fixing plate, a copper strip machine body arranged on the right side of the upper portion of the fixing plate and a pay-off reel arranged on the left side of the upper portion of a bottom plate, and a positioning mechanism is arranged between the pay-off reel and the copper strip machine body; a supporting plate located on the right side and an extension plate located on the left side are arranged on the fixing frame, a groove is formed in the left side of the extension plate, two rotating rollers are installed in an inner cavity of the groove, the rotating rollers are of a middle-sunken structure, and wire grooves matched with earphone wires for use are formed in the extension plate and the supporting plate. The upper part of the wire groove is provided with a limiting clamp which is of an arc-shaped structure and used for limiting the earphone wire. Precise machining can be conducted according to the length needed by a customer, the machining efficiency is high, and use is convenient.

Owner:安徽讴歌电子科技有限公司

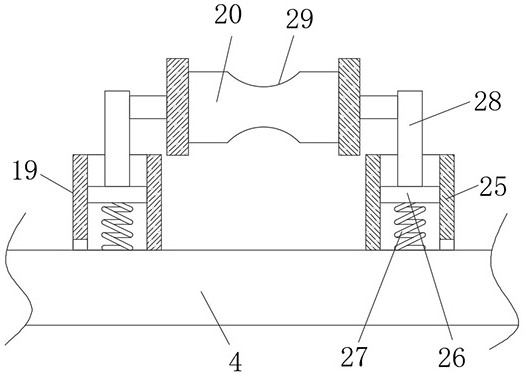

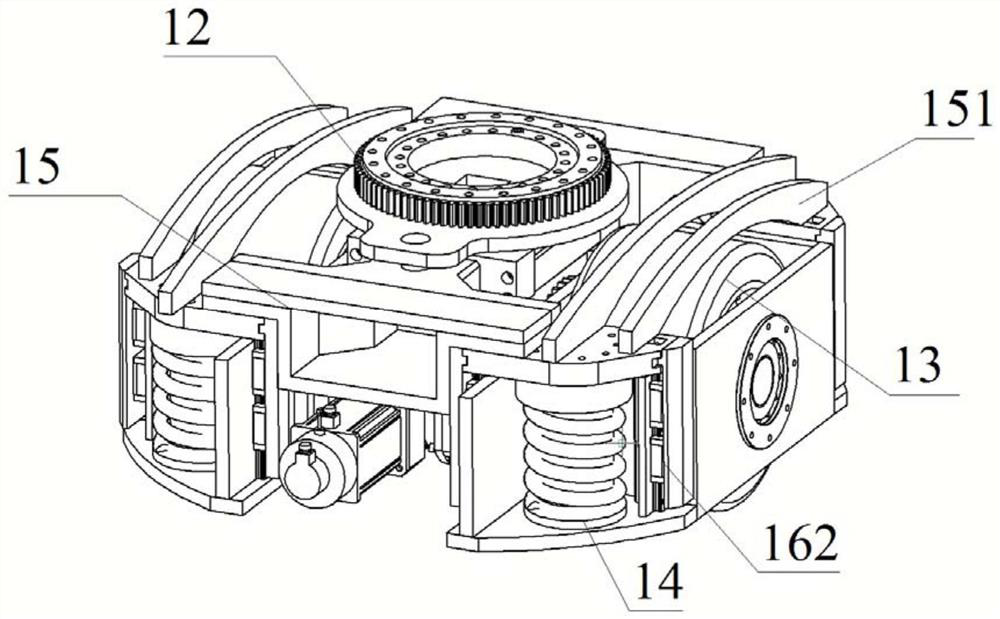

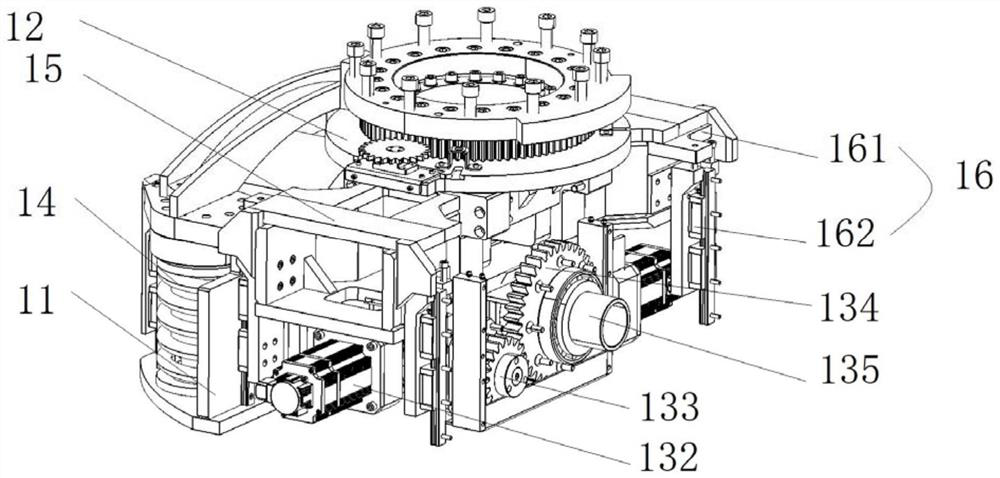

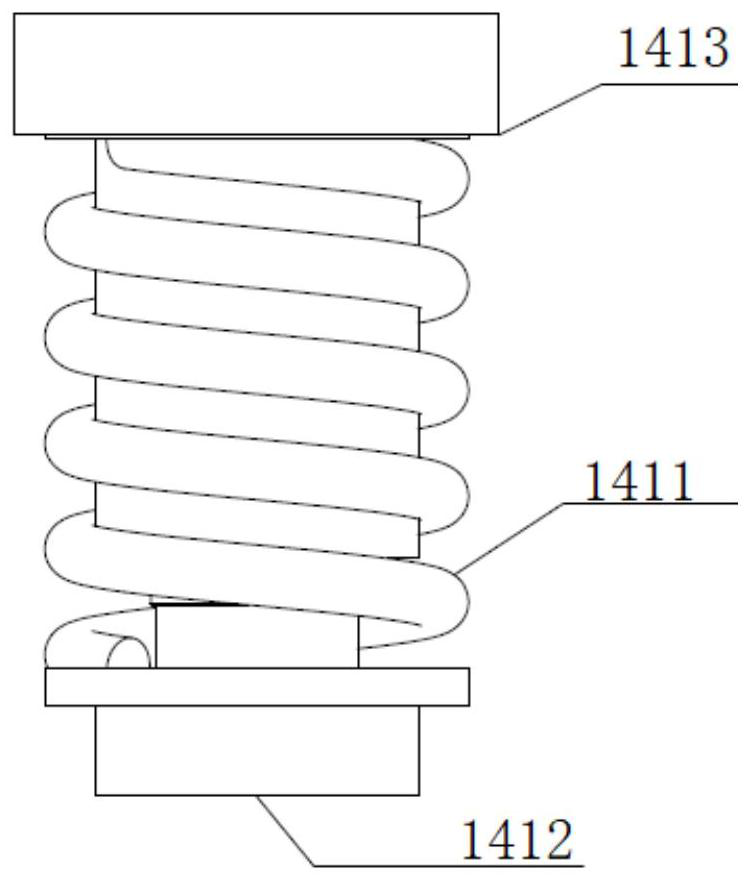

Transfer mechanism, blade root transferring trolley, blade tip transferring trolley and blade transfer system

ActiveCN113027694ALevel effectLevel does not affectWind energy generationWind motor transportStructural engineeringTransfer mechanism

The invention discloses a transfer mechanism, a blade root transferring trolley, a blade tip transferring trolley and a blade transfer system. The transfer mechanism comprises a transfer base frame, a bearing structure, rolling wheel assemblies, buffer assemblies and a swing bridge assembly. The bearing structure is provided with mounting portions which are arranged towards one side of the transfer base frame. The rolling wheel assemblies are provided with rolling wheel parts and rolling wheel drivers, the rolling wheel drivers are mounted on the transfer base frame, and the rolling wheel parts are driven by the rolling wheel drivers to rotate relative to the transfer base frame. Each buffer assembly is provided with at least one bias part, and one end of each bias part is mounted on the transfer base frame. The swing bridge assembly and the mounting portions rotate in a pivoted manner. The swing arm assembly is provided with a swing structure, and the swing structure is connected with the other ends, opposite to the transfer base frame, of the bias parts. According to the blade transfer system adopting the transfer mechanism of the structure, trafficability can be greatly improved, and the problem that the contact face of blades is worn due to wall face hard impact is solved.

Owner:SINOMATECH WIND POWER BLADE +1

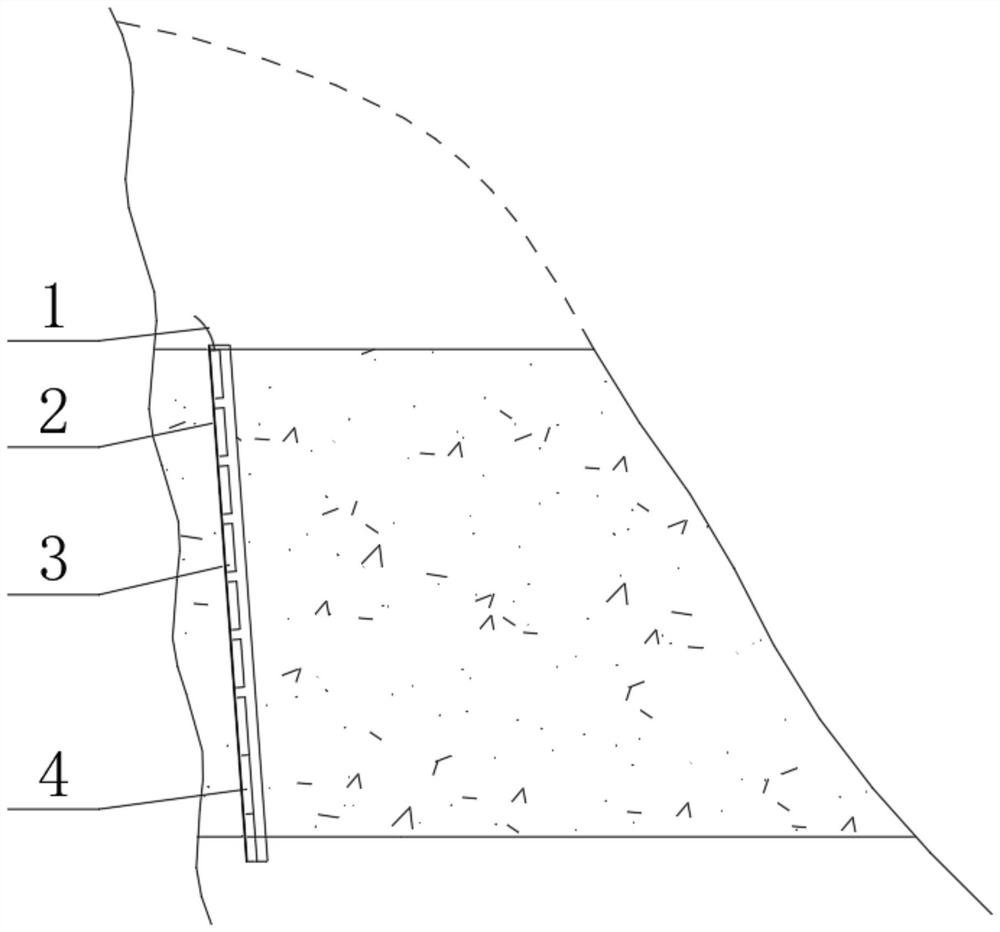

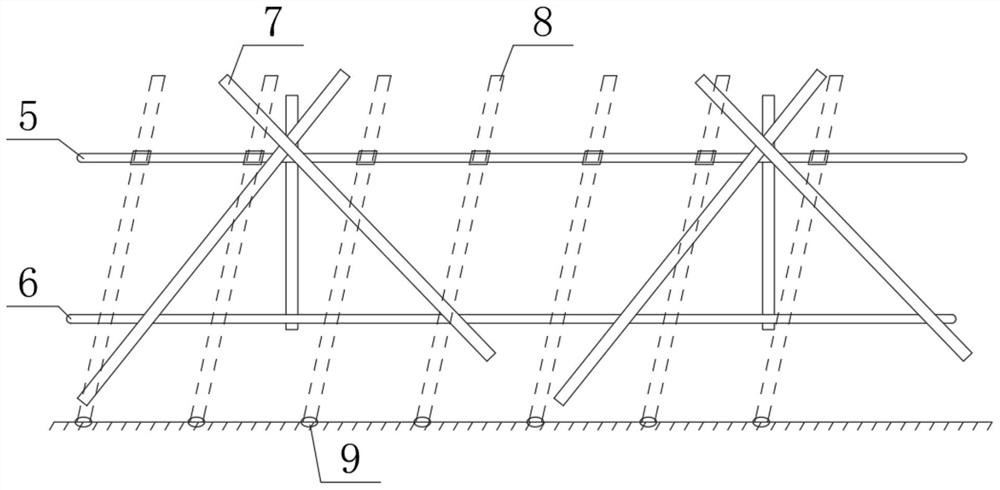

High slope presplitting blasting construction method

ActiveCN113340166AGuaranteed accuracyGuaranteed straightBlastingClimate change adaptationDrill holeVertical angle

The invention discloses a high slope presplitting blasting construction method which comprises the following steps of compiling a slope presplitting blasting construction scheme, manufacturing a guide frame, erecting the guide frame, drilling a presplitting hole and a main blasting hole, charging powder into the presplitting hole, connecting a detonating network, carrying out presplitting blasting, and measuring the gradient of a slope by using a slope measuring device. According to the high slope presplitting blasting construction method, by arranging the guide frame, auxiliary positioning can be conducted on a drill rod, the precision degree of the drilling angle is guaranteed, so that over-excavation and under-excavation are better controlled, excavation is made to be within the design requirement range, the hidden danger that a high slope is prone to landslide is effectively prevented, and meanwhile, the straightness of the slope is guaranteed; bamboo chips are arranged in the pre-splitting hole, and an explosive cartridge is isolated from the slope surface, so that the impact effect on the slope surface in the detonating process is reduced, and the stability of the slope is guaranteed; and the slope measuring device is arranged, so that the vertical angle of the slope can be conveniently measured.

Owner:包头市公路工程股份有限公司

Device and process for purification and preparation of polysilicon by controlling heating temperature field

ActiveCN109252216BPromote growthFast heating and cooling effectPolycrystalline material growthSilicon compoundsCrucibleGraphite

Owner:CHENGDU SILICON TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com