Welding manipulator with protection function for automobile parts

A technology for welding manipulators and auto parts, applied in mechanical equipment, welding equipment, auxiliary welding equipment, etc., can solve problems such as eye injuries of construction workers, and achieve the effects of ensuring normal use, good practical value, and good protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

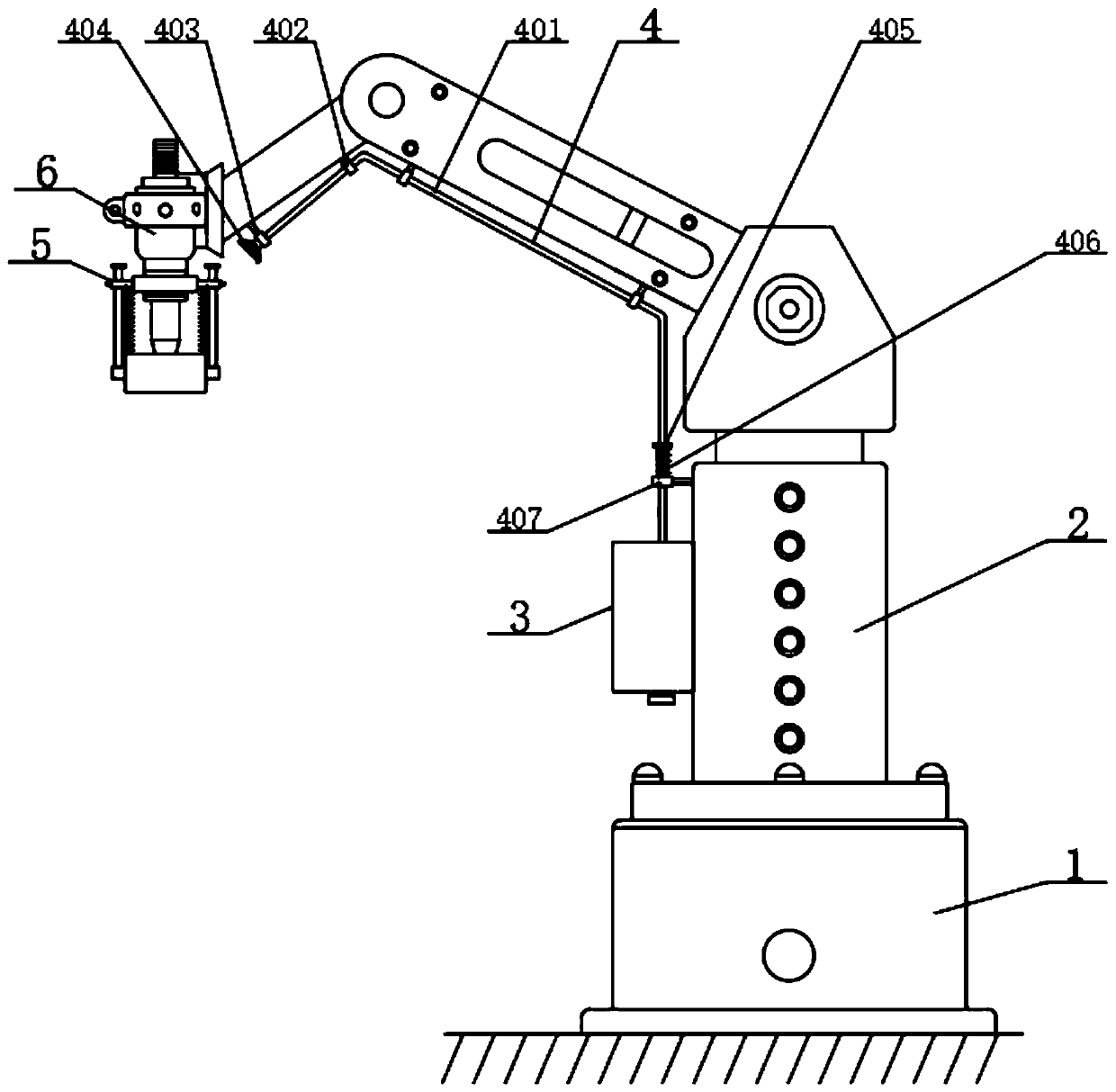

[0024] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , the present invention provides a technical solution:

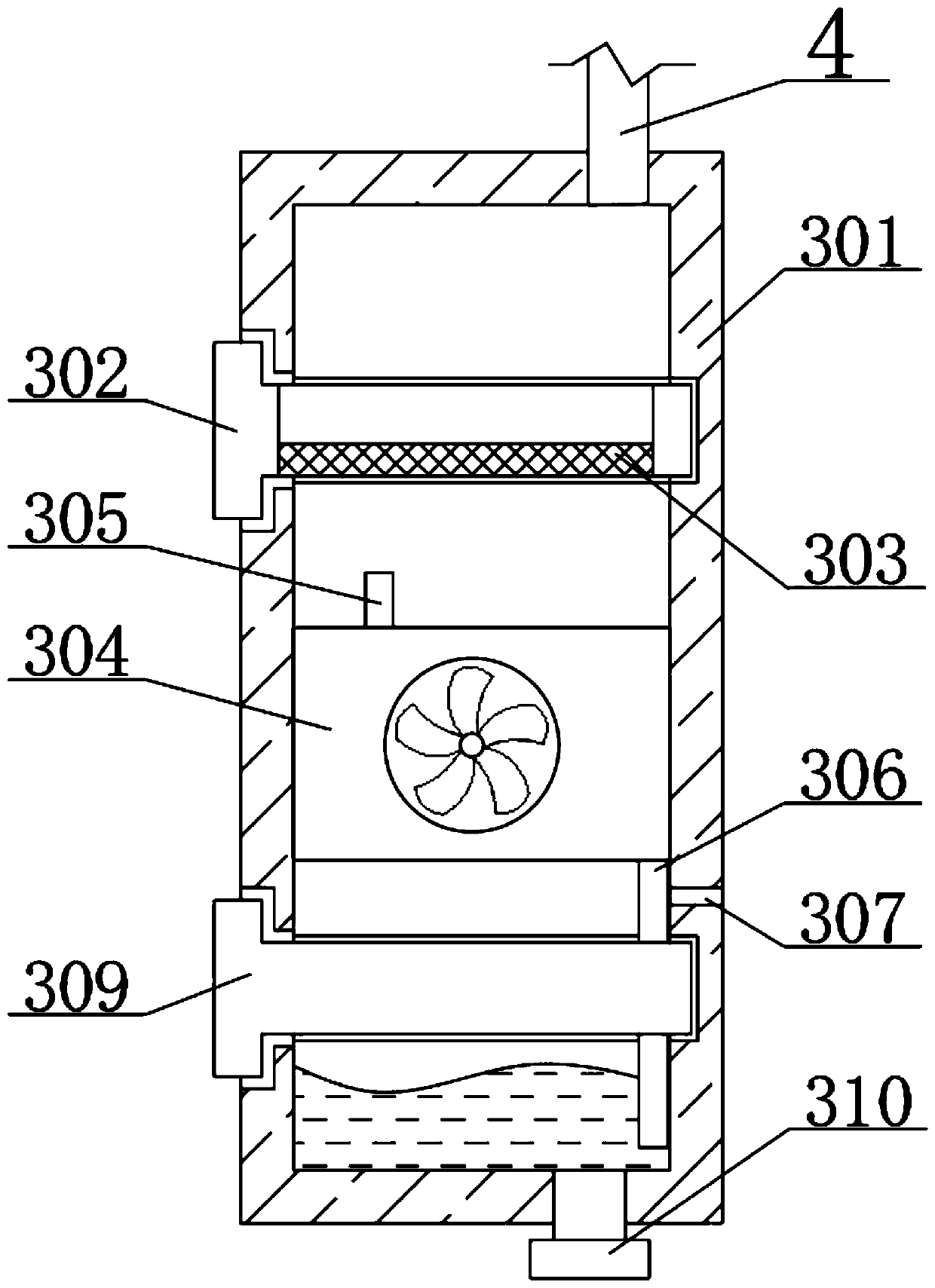

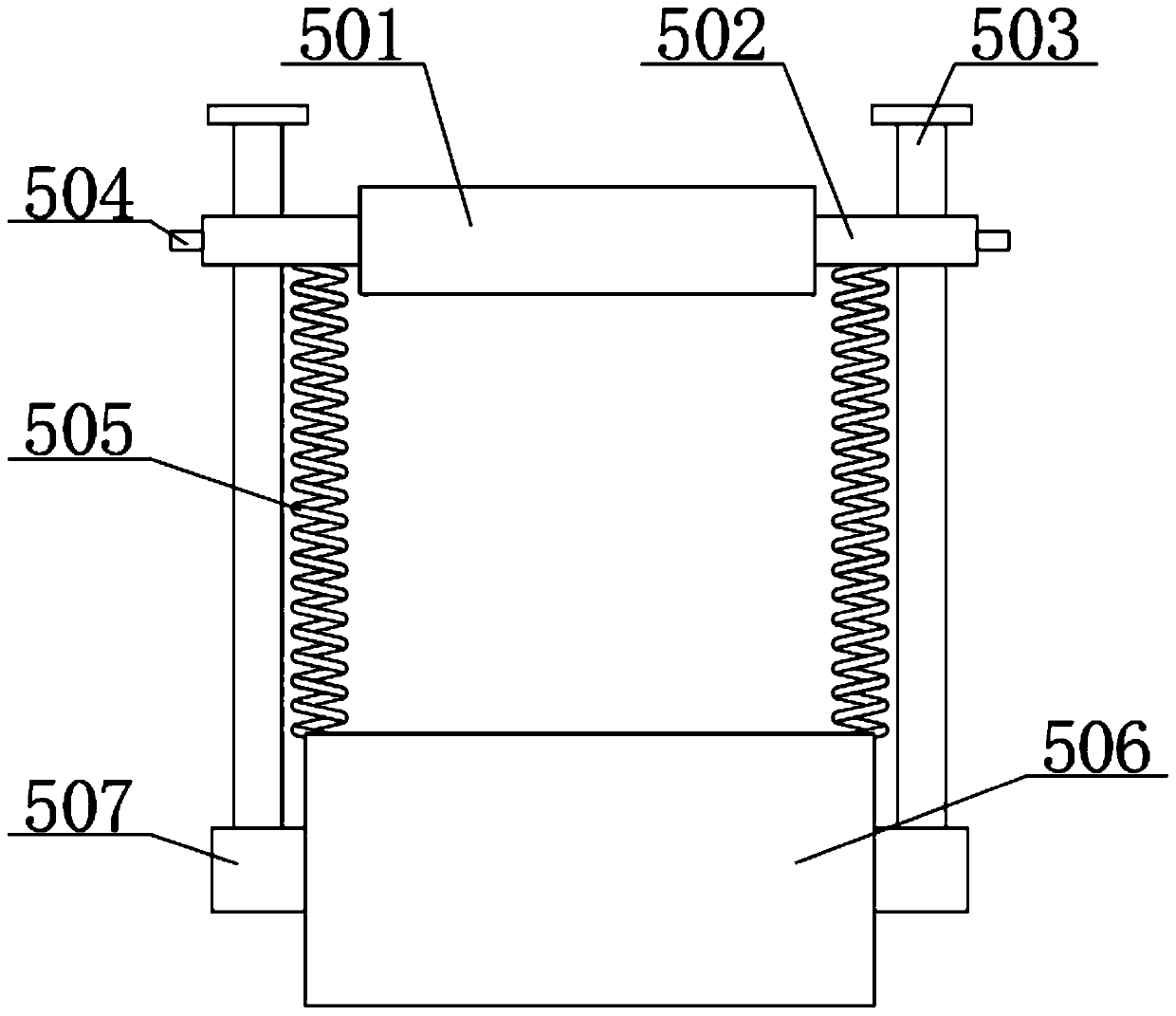

[0025]A welding manipulator for auto parts with a protective function, comprising a base 1 and a mechanical arm 2, the upper end of the base 1 is fixedly connected with a mechanical arm 2, and the left side of the mechanical arm 2 is fixedly connected with an exhaust gas treatment device 3, the The exhaust gas treatment device 3 includes a treatment box 301 and a filter frame 302. The right end surface of the treatment box 301 is fixedly connected with the mechanical arm 2. The upper end surface of the treatment box 301 is fixedly connected with a tensioning device 4. The tensioning device 4 includes a Trachea 401 and fixed frame 402, one end of the ventilation pipe 401 is fixedly connected with the suction cover 404, and the outside of the suction cover 404 is fixedly connected with a fixed plate 403, and the fixed plate 403 can fix the suction cov...

Embodiment 2

[0028] In embodiment 2, the same part as embodiment 1 will not be described again, the difference is that when the equipment failure needs to observe the contact position between the welding head 6 and the welding workpiece, in order to determine the cause of the failure, by manually moving the sliding rod 503 upward Slide to make it drive the fixed block 507 and the protective cover 506 to move upwards, and then when the welding head 6 is located below the lower end surface of the protective cover 506, the connecting plate 502 and the sliding rod 503 are continued to be fixed by the clamping block 504 through the limiting hole 508, It is convenient for the staff to observe with the mask in hand, the solid impurities on the surface of the filter plate 303 can be cleaned by sliding the filter frame 302, and the activated carbon plate 309 can be replaced by sliding the activated carbon plate 309 to ensure its adsorption effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com