Device and process for purification and preparation of polysilicon by controlling heating temperature field

A technology of polysilicon and temperature field, applied in the direction of polycrystalline material growth, silicon compound, crystal growth, etc., can solve the problems of discontinuous control of temperature field, unfavorable growth of columnar crystals, etc., achieve good cooling effect, ensure cooling effect, and ensure flat straight or slightly convex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

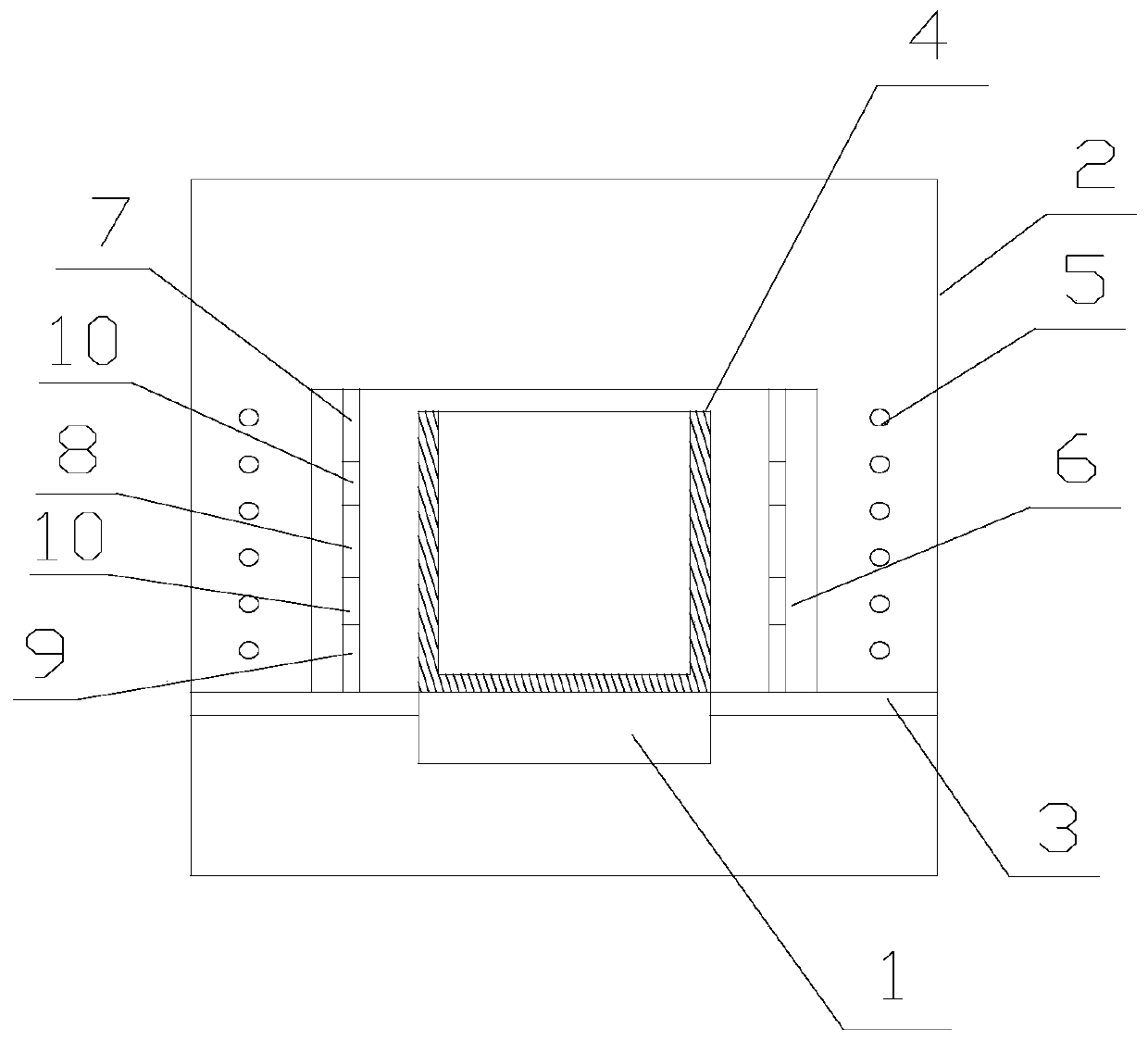

[0049] This embodiment provides a device for purifying and preparing polysilicon by controlling a heating temperature field, including a furnace body 2, wherein a heat insulating plate 3 is provided in the furnace body 2, and a through hole is formed in the middle of the heat insulating plate 3 for accommodating the cooling plate 1, The crucible 4 is placed on the cooling plate 1. The crucible 4 is provided with a heating induction coil 5 and a heat preservation cylinder 6. The heat preservation cylinder 6 is provided with an upper section graphite heating ring 7, a middle section graphite heating ring 8 and a lower section graphite heating ring 9, and the upper section is provided with a graphite heating ring 7. A connecting ring 10 is provided between the graphite heating ring 7 and the middle graphite heating ring 8, and between the middle graphite heating ring 8 and the lower graphite heating ring 9. The connecting ring 10 adopts a thermal conductivity of 10 to 50 W / m·k. Ma...

Embodiment 2

[0051] Further improvement is made on the basis of Embodiment 1. The connecting ring is made of zirconia ceramics or alumina ceramics, and a plurality of through holes 11 are provided on the side walls of the connecting ring 10 . The inner bottom of the heat preservation cylinder 6 is provided with a limit ring plate 12, and the inner diameter of the limit ring plate 12 is smaller than the inner diameter of the upper graphite heating ring 7, the middle graphite heating ring 8, the lower graphite heating ring 9 and the connecting ring 10.

Embodiment 3

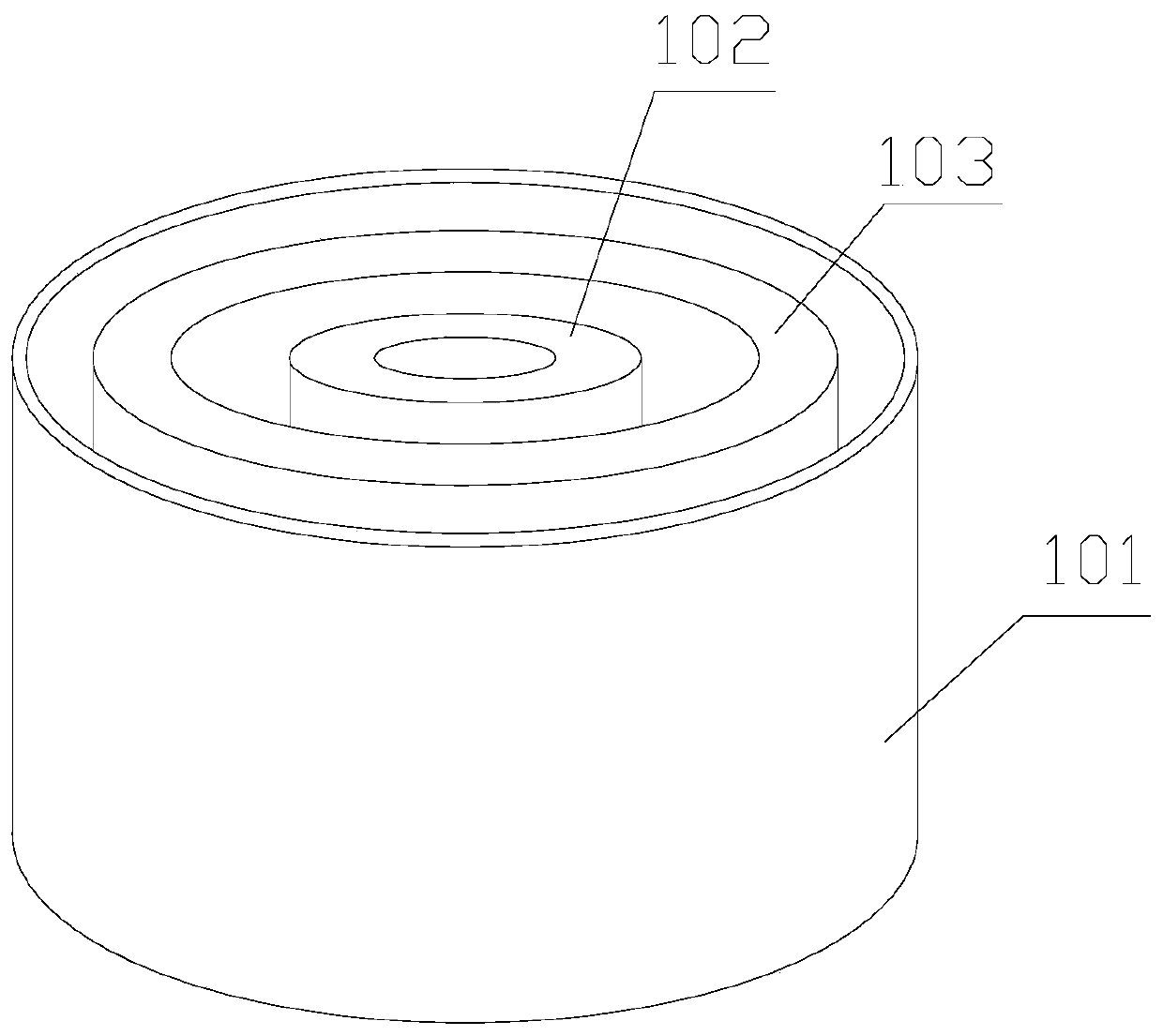

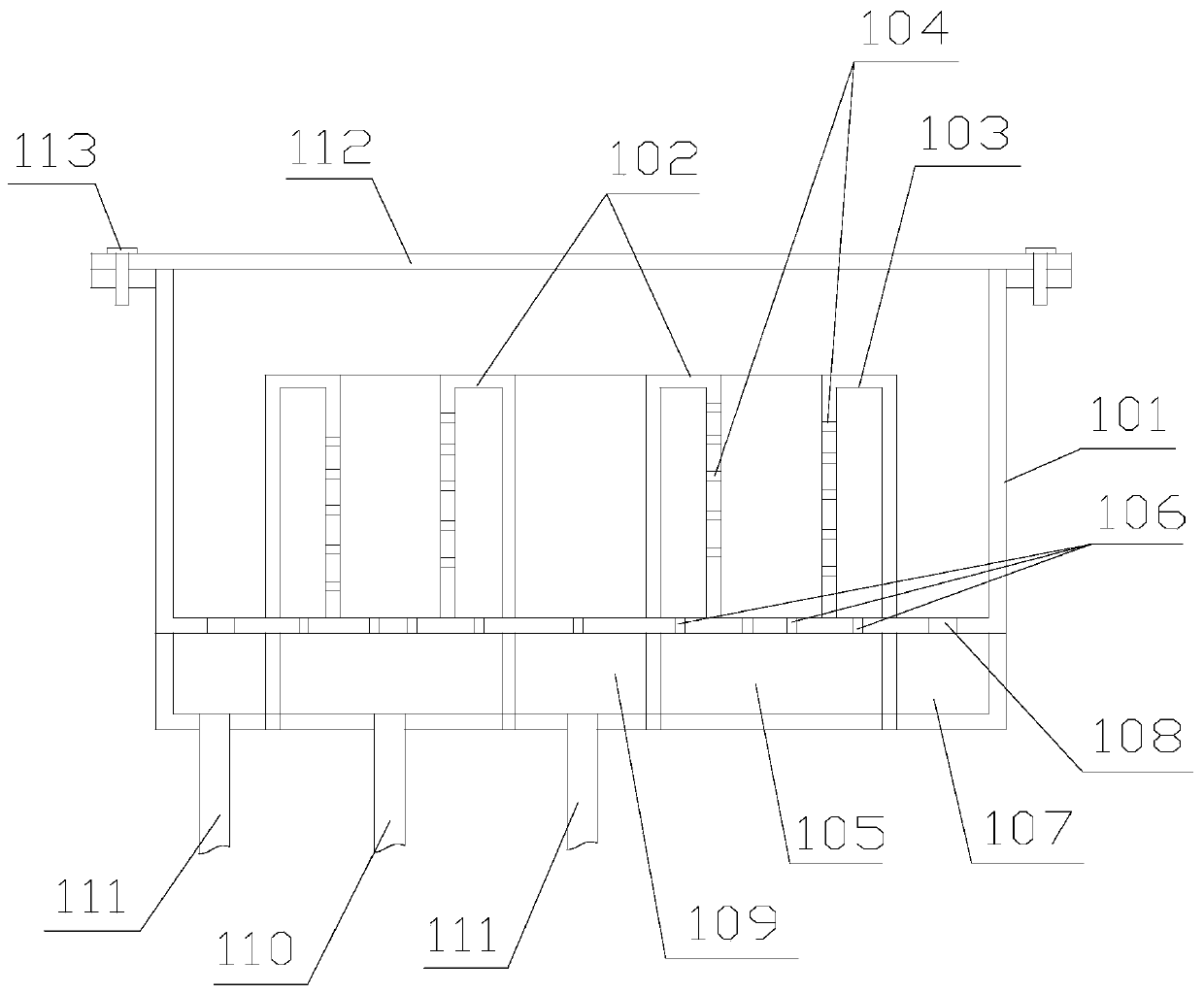

[0053] Further improvement on the basis of Embodiment 2, the cooling plate 1 includes a cylindrical casing 101, and a gas distribution sleeve I102 and a gas distribution sleeve P103 with a coaxial line are arranged in the casing 101. The sleeve П103 is sleeved outside the gas distribution sleeve I102; the outer diameter of the gas distribution sleeve П103 is smaller than the inner diameter of the housing 101, and the inner diameter of the gas distribution sleeve П103 is larger than the gas distribution sleeve I102 The outer diameter of;

[0054] The inside of the gas distribution sleeve I102 and the side wall of the gas distribution sleeve П103 are annular hollow chamber structures, and the inner sidewall of the gas distribution sleeve П103 and the outer sidewall of the gas distribution sleeve I102 are provided with ventilation holes 104;

[0055] The bottom of the casing 101 is provided with an annular air inlet chamber 105 along the circumferential direction, the air inlet ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com