Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

124results about How to "Avoid over-squeezing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

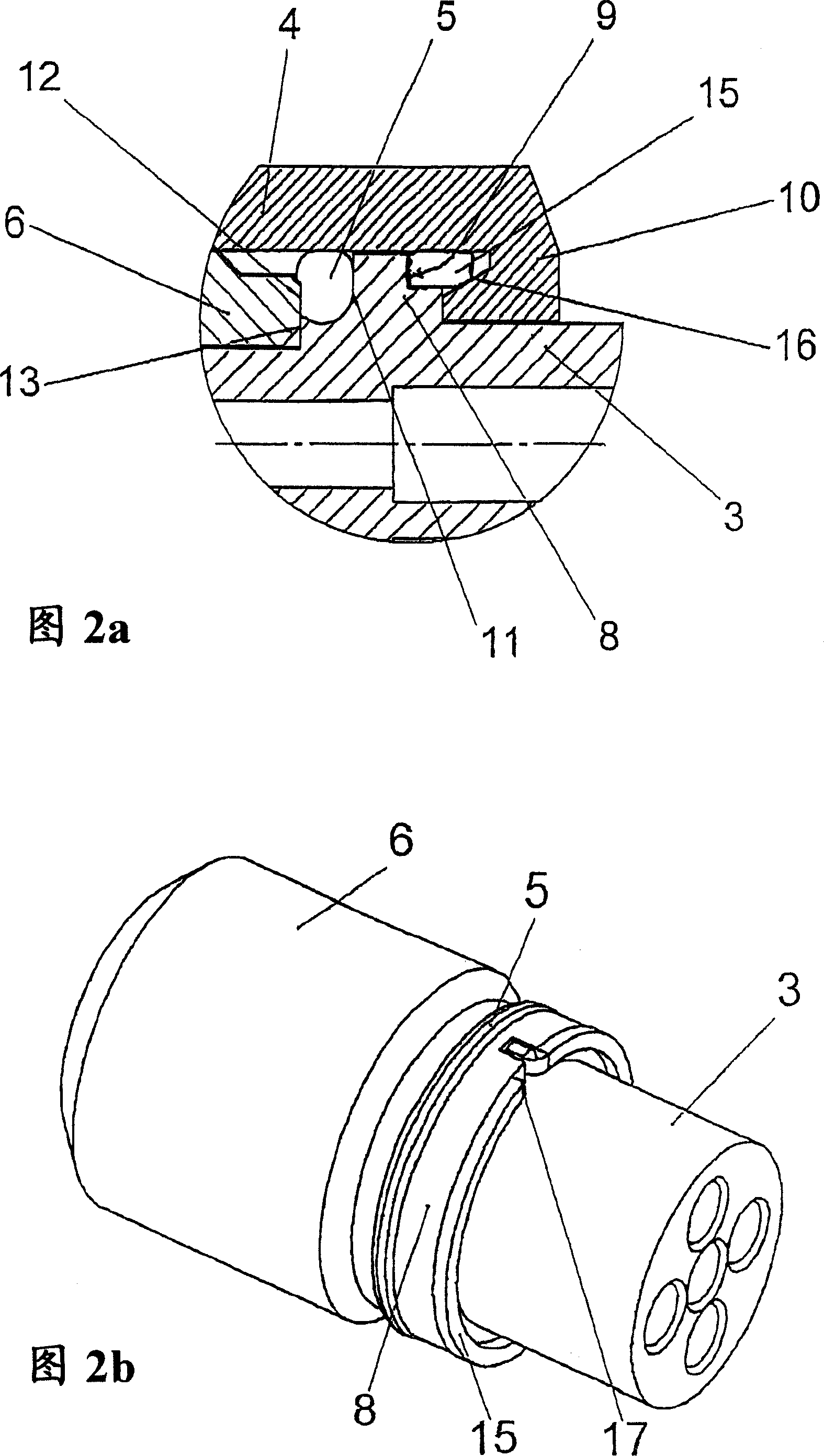

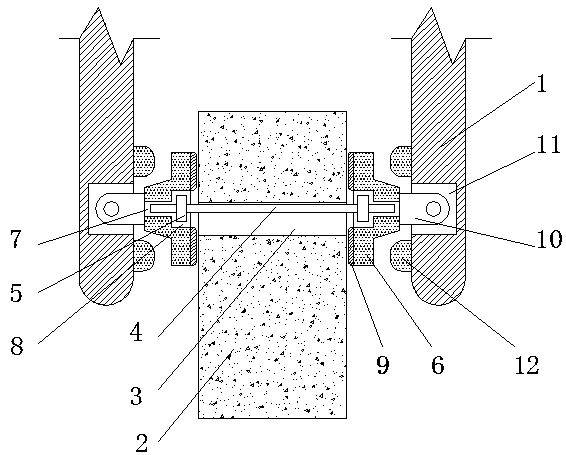

Electrical plug connector and electrical plug connection

ActiveCN1972024AAvoid over-squeezingMeet the sealing functionCoupling device detailsAbutmentEngineering

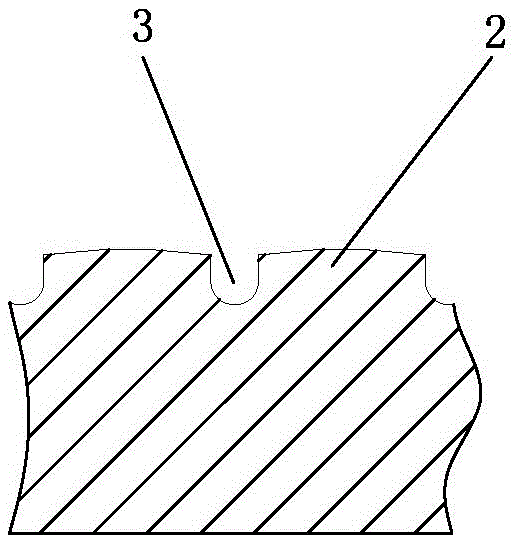

An electrical plug connector comprising a handle (2) enclosing a connecting cable, a contact support (3), and a lock nut rotatably and limitedly movable axially arranged on the contact support (3) (4) and the elastic seal (5) arranged on the contact support (3), wherein the lock nut (4) can be screwed on the thread (7) formed on the outer sleeve of the butt plug connector (6) , and wherein the contact support (3) has a surrounding flange (8), its first end face (9) is used as a stop for the shoulder (10) at the end of the lock nut (4), and its orientation is toward the abutment The second end surface (11) of the plug connector (6) is used as a stopper for the seal (5), wherein the seal (5) is assembled between the plug connector (1) and the mating plug connector (6). It is arranged between the flange (8) of the contact carrier (3) and the mating plug connector (6), in particular its end face (12), in order to press the seal (5).

Owner:IMF ELECTRONIC GMBH

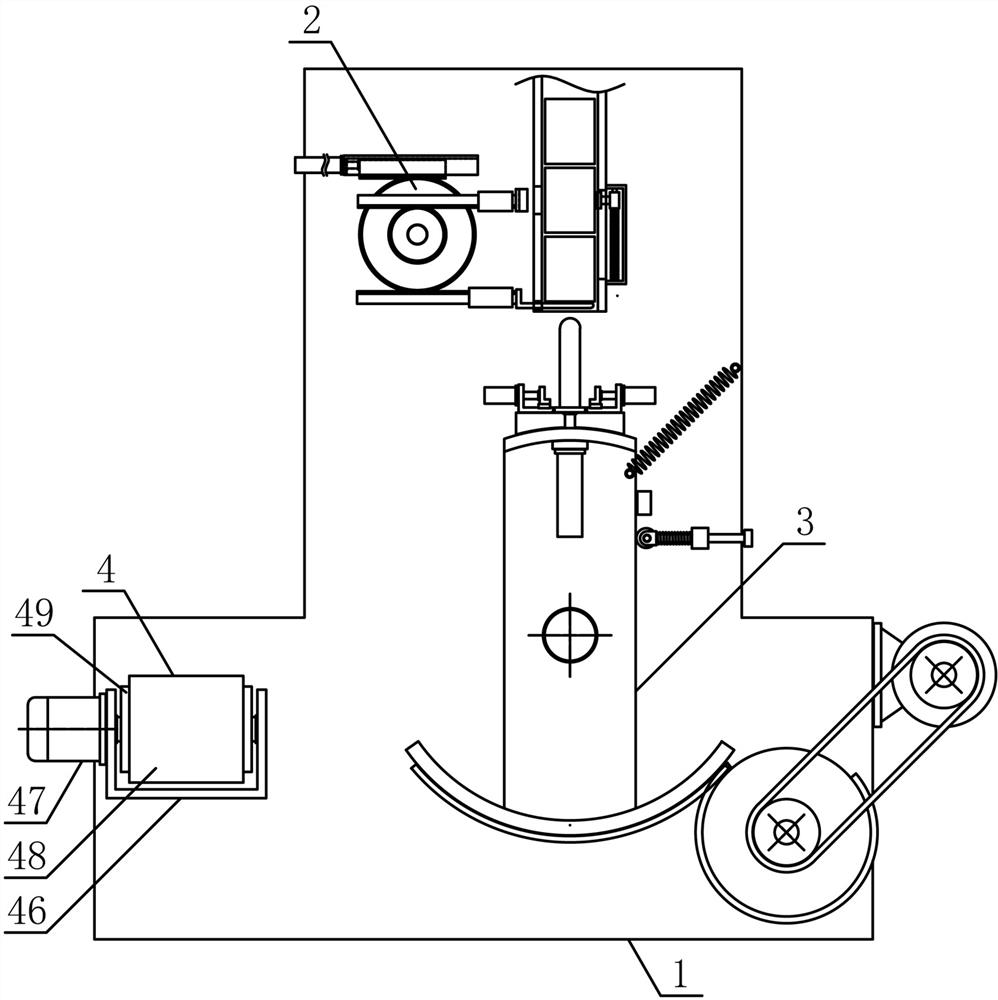

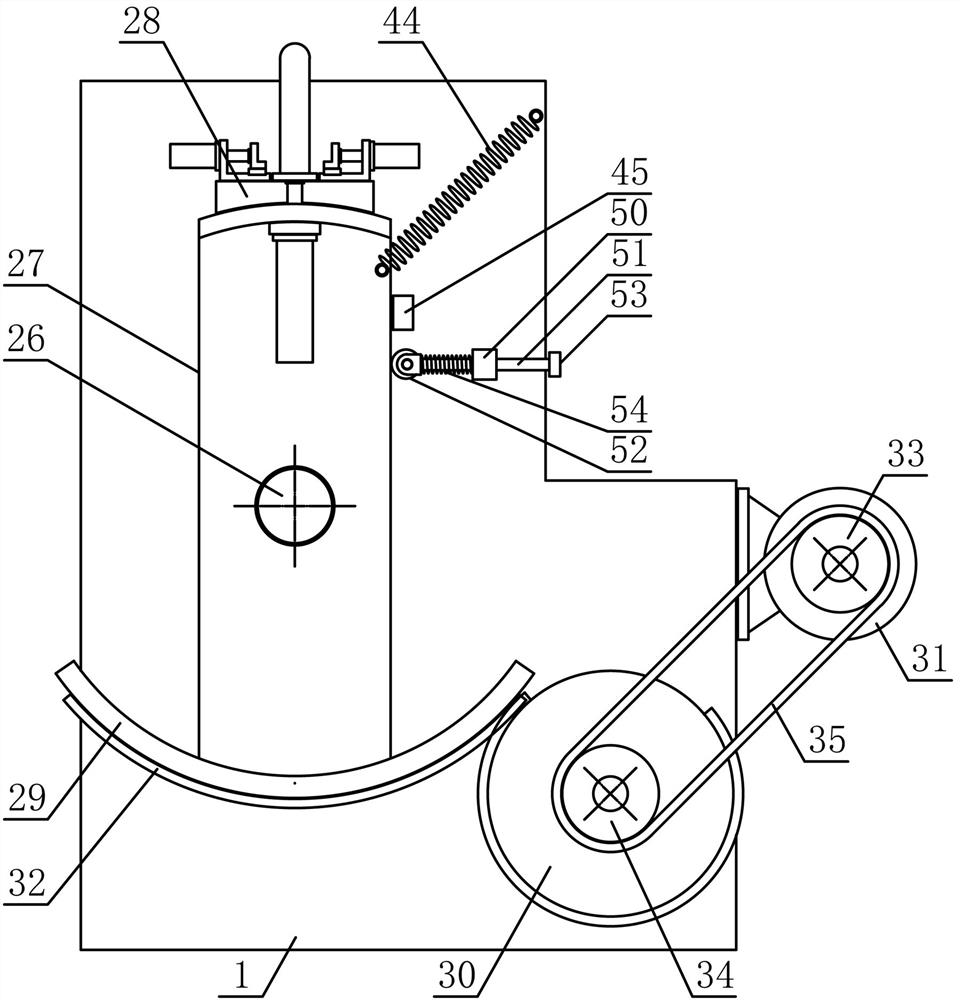

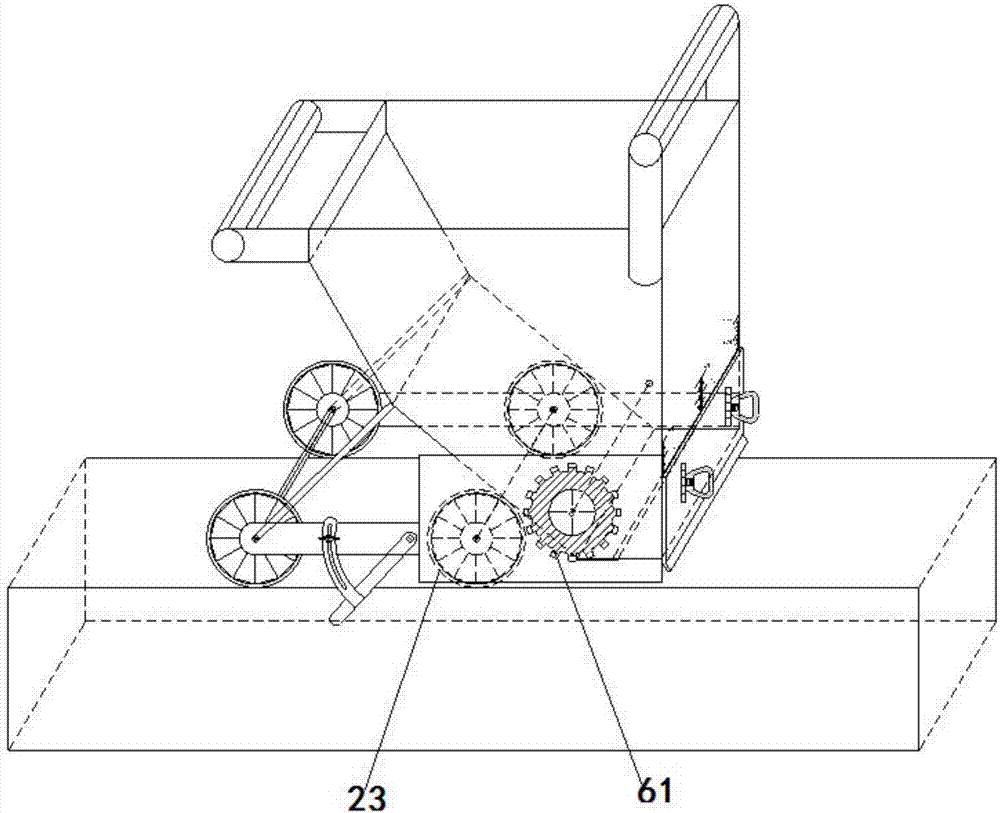

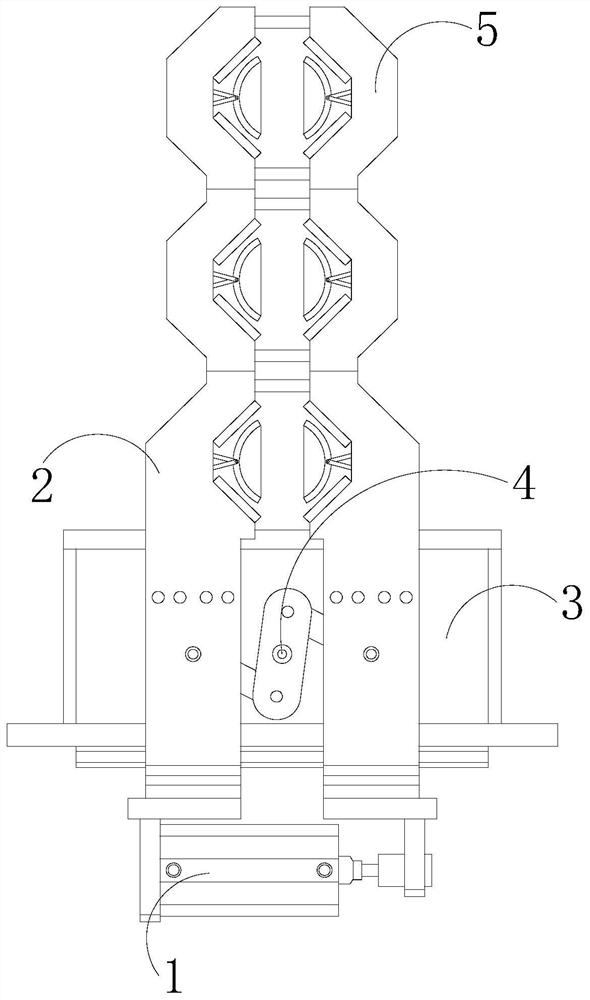

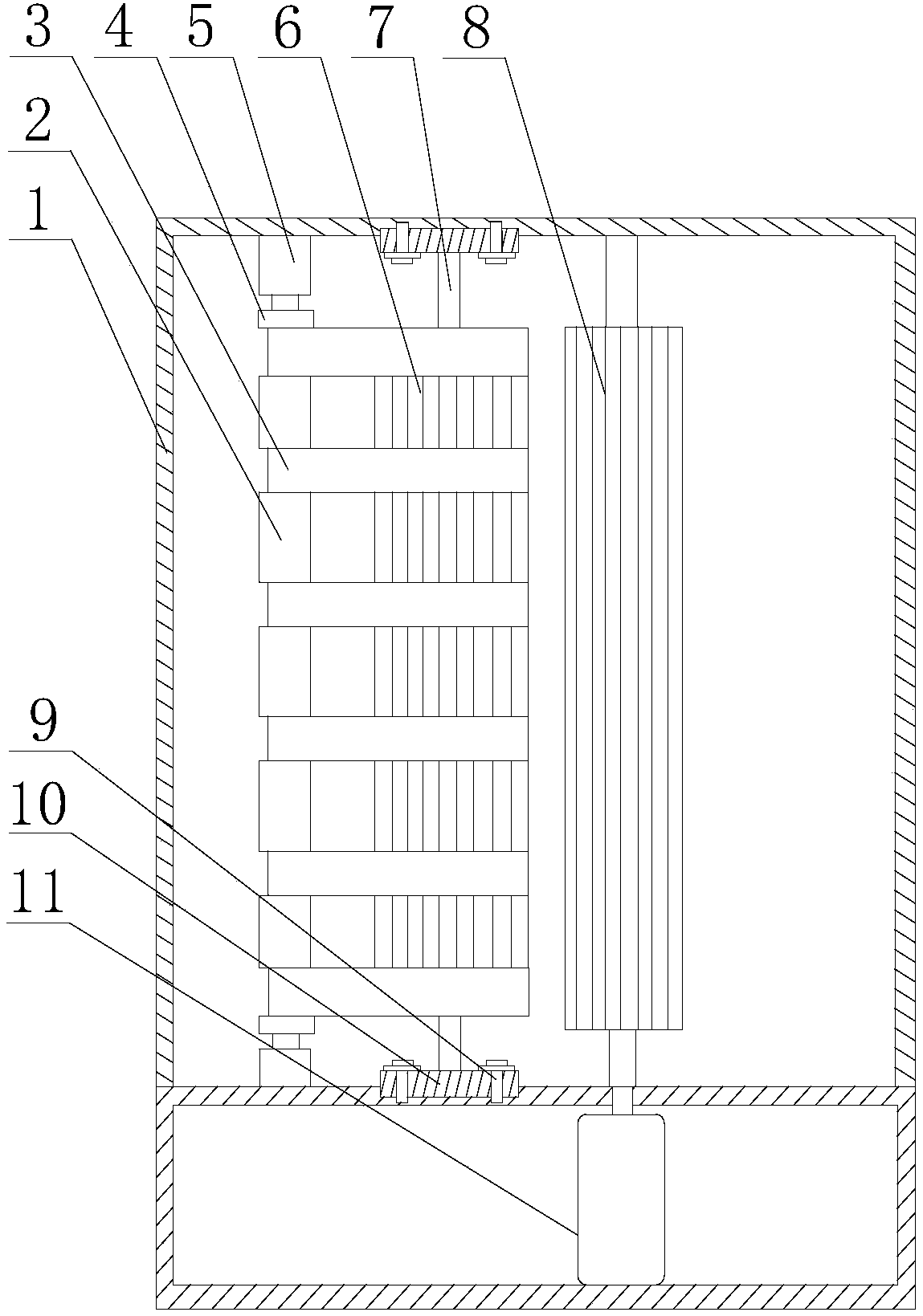

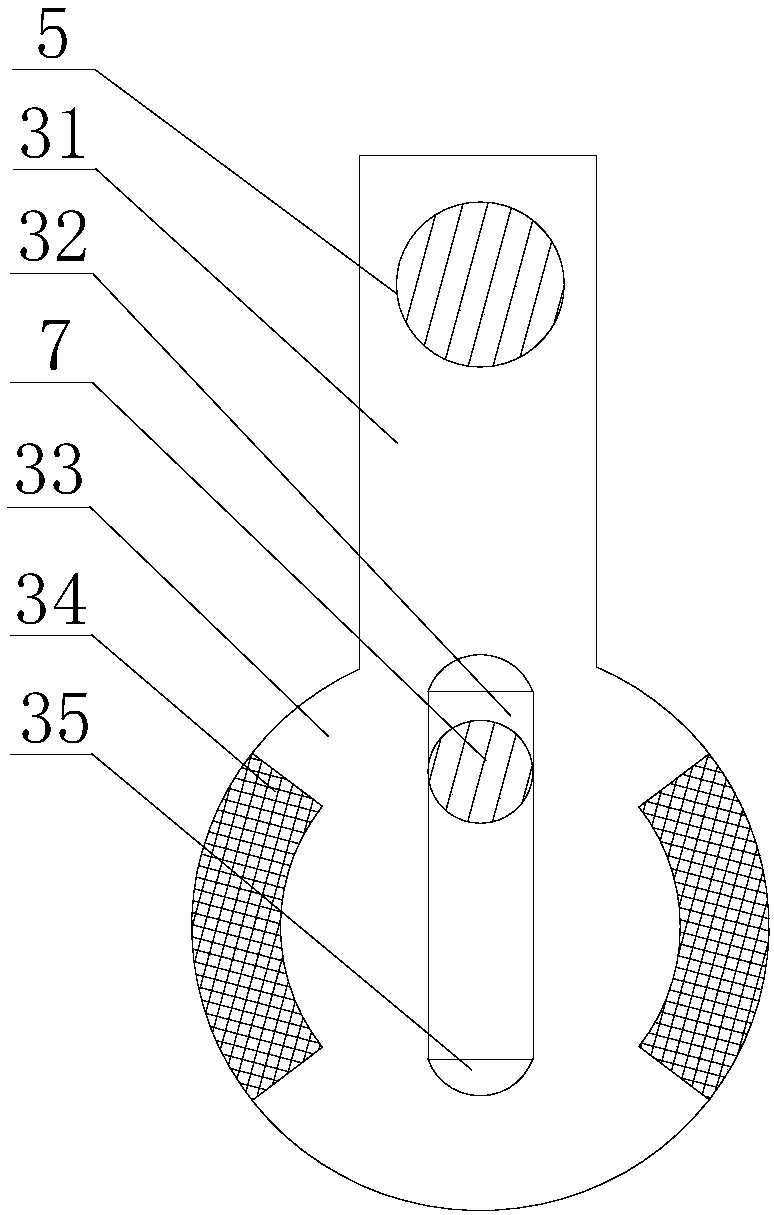

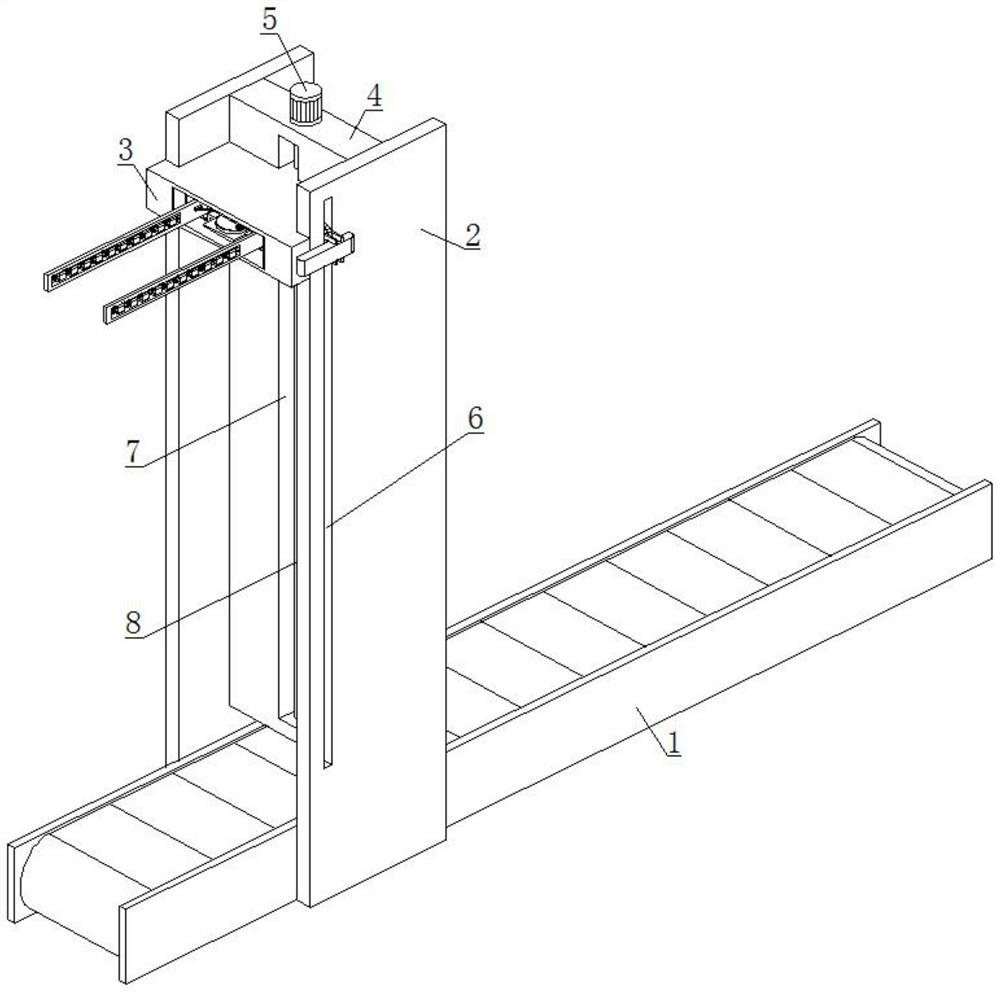

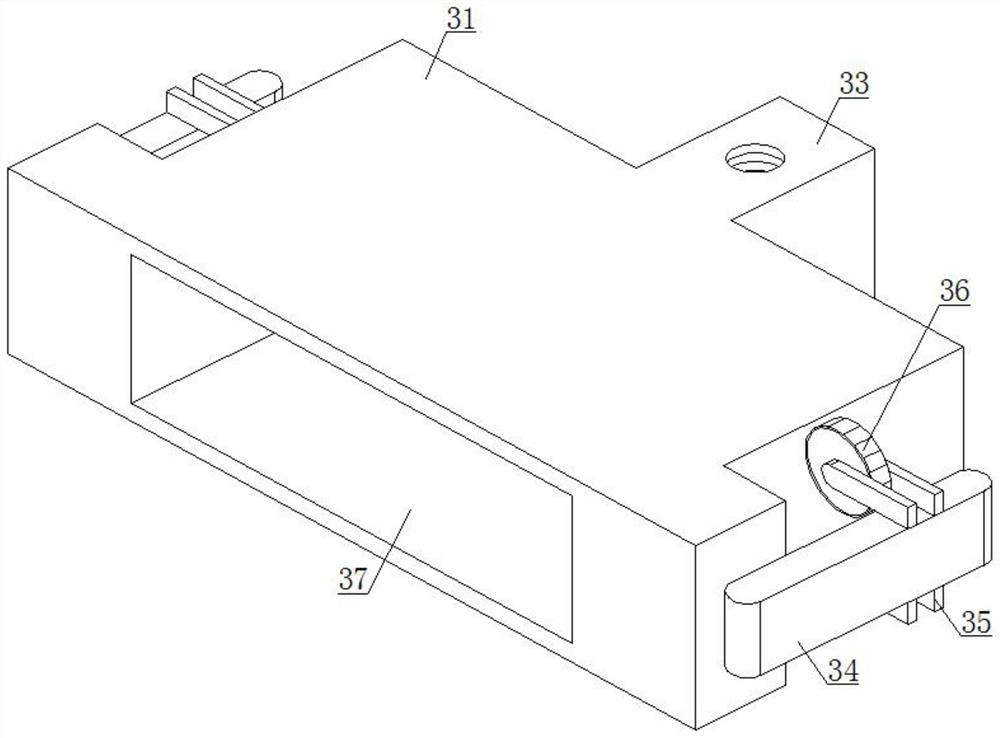

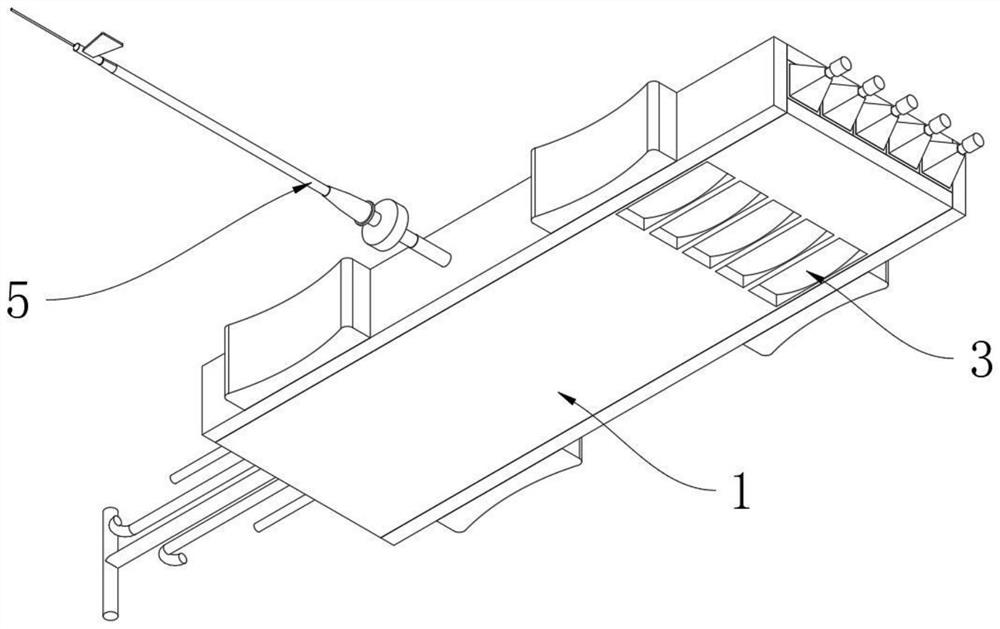

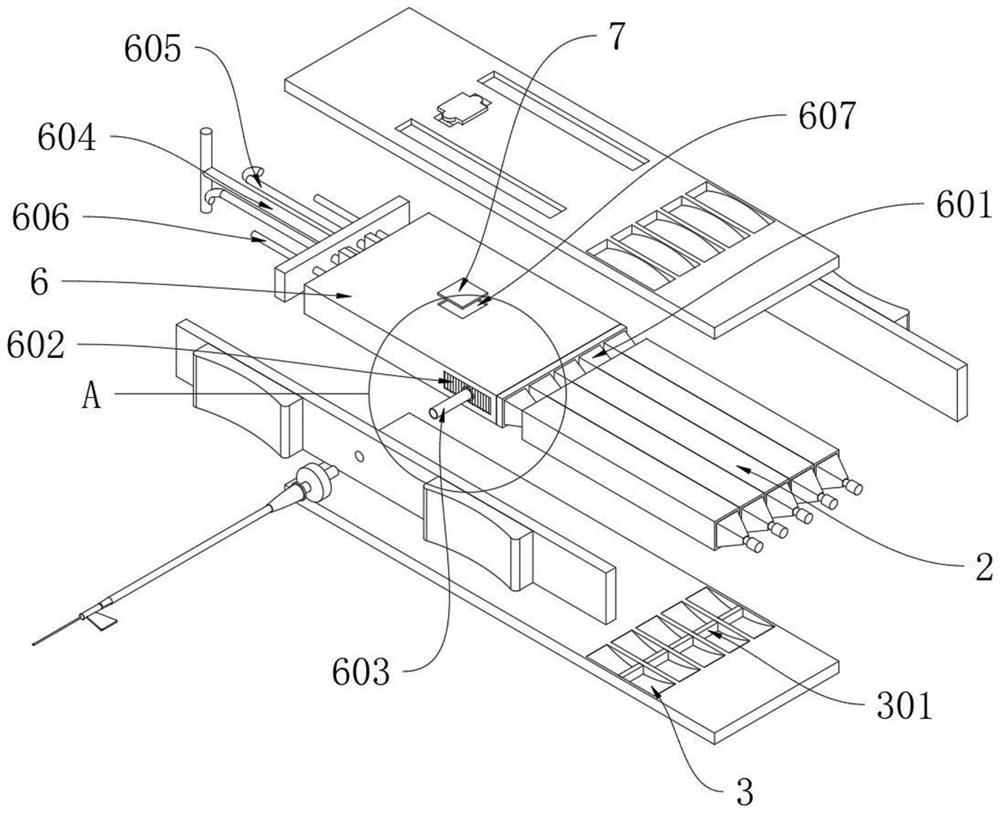

Working method of pipe fitting feeding and transferring mechanism

InactiveCN112830195AHigh degree of processing automationReasonable structural designConveyorsConveyor partsGear wheelMechanical equipment

Owner:龚文科

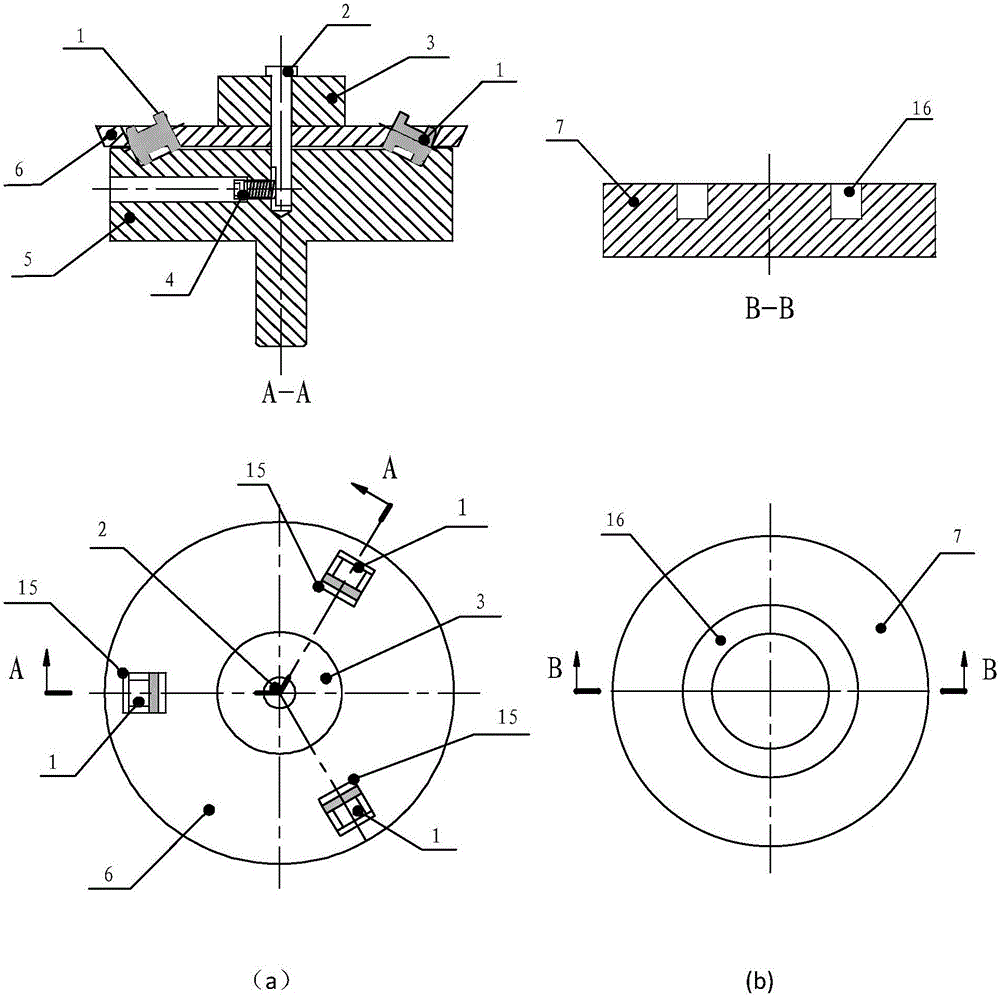

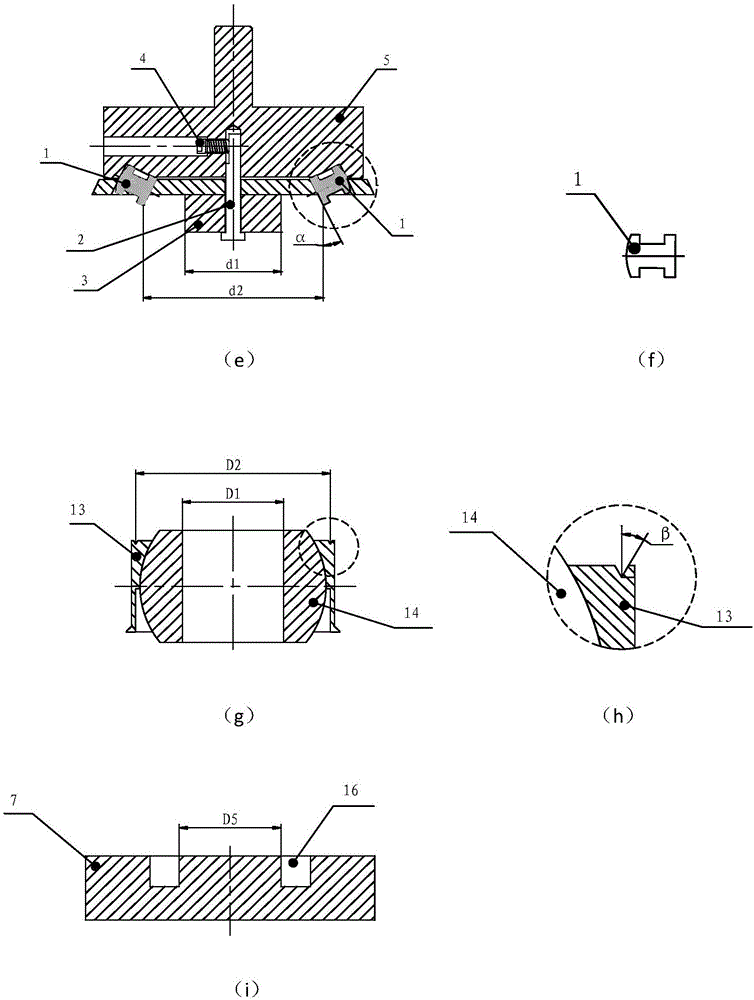

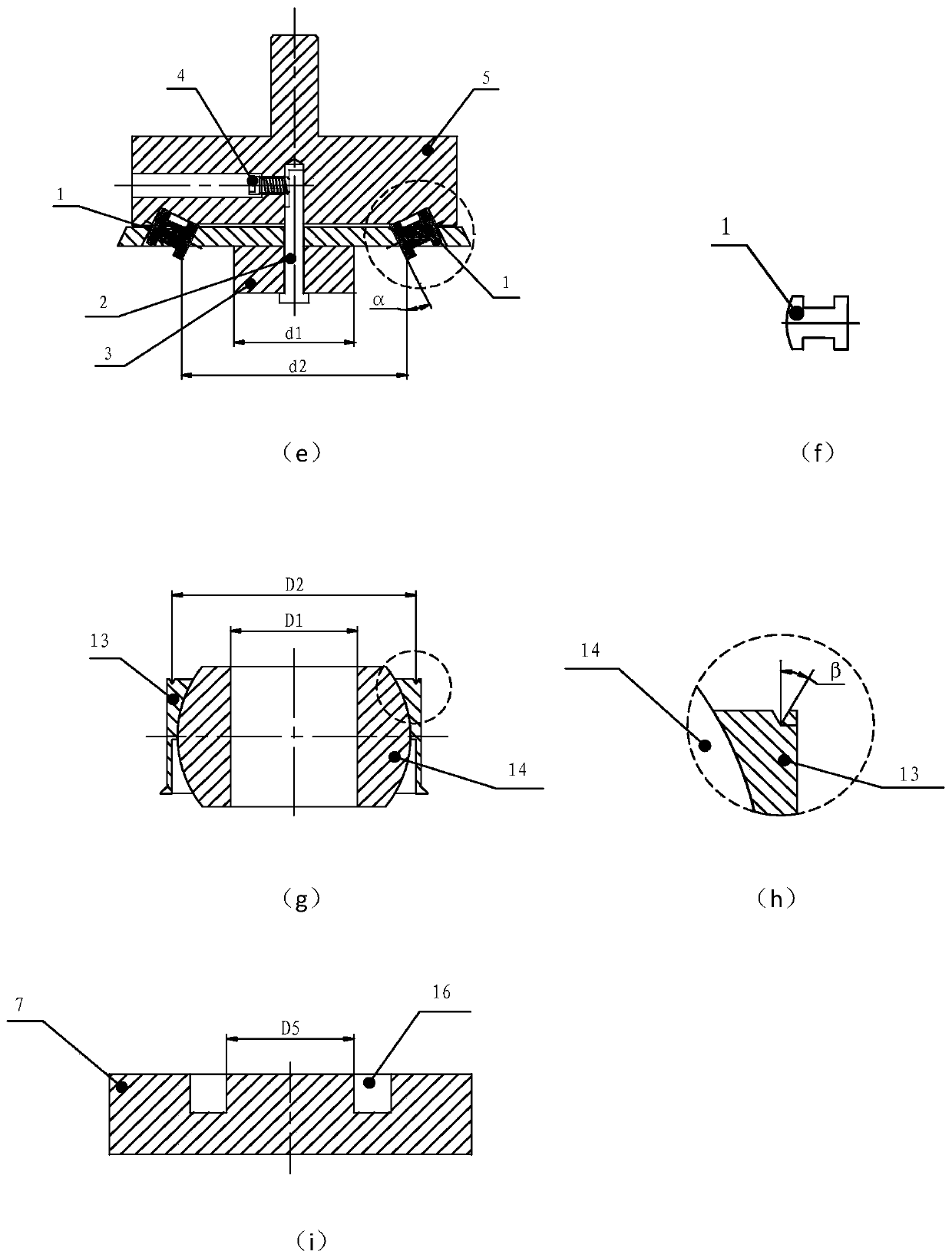

Joint bearing flanging tool and process of using same for joint bearing flanging

The invention relates to a joint bearing flanging tool for aviation hanging parts, and a process of using the same for joint bearing flanging. The joint bearing flanging tool mainly comprises a roll, a retainer, a guide pin, a force-bearing support seat and a location support seat, wherein clearance fit is formed among the components; and the bearing flanging tool needs to be used in a manner of being matched with the flanged joint bearings in the hanging parts in specification and dimension during use. The joint bearing flanging tool is simple in structure, uniform in stress, capable of being automatically centred, stable in performance, reliable in quality, and capable of ensuring stability and smoothness during joint bearing flanging. According to the process of using the joint bearing flanging tool for bearing flanging, which is disclosed by the invention, the joint bearing flanging tool is installed on a spindle of a radial drilling machine, each flanged bearing is rotated and extruded to the required flanging dimensions through enabling the roll to contact with the groove surface of the flanged bearing. The process is stable in machining, simple to operate, short in alignment time, high in efficiency, stable in quality, and convenient for batch production.

Owner:CHENGDU ENGINE GROUP

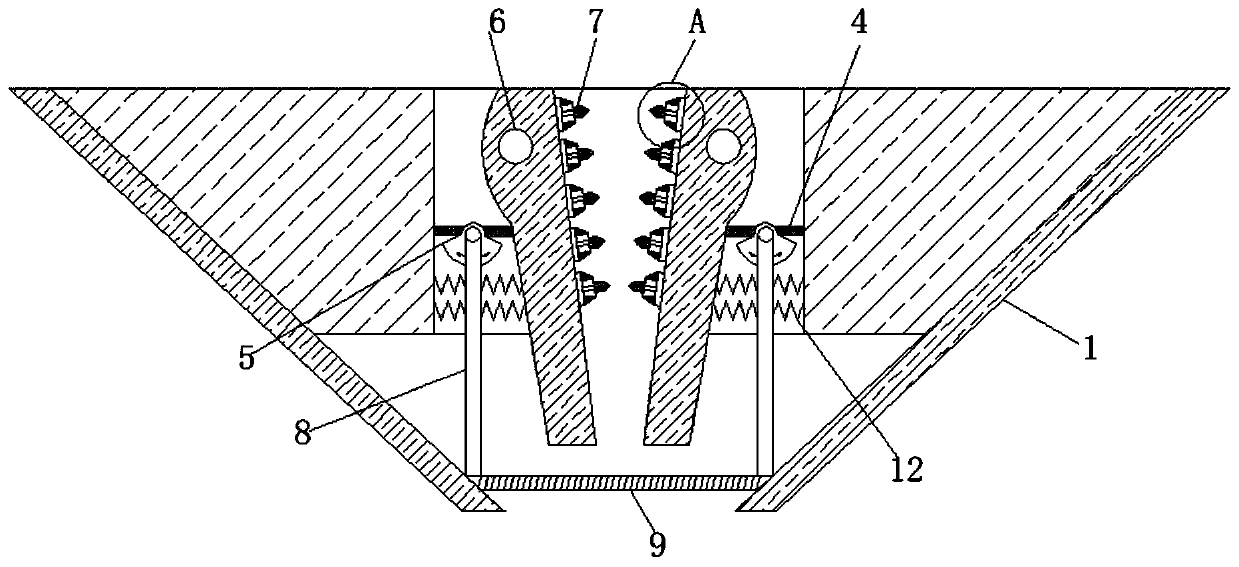

System for fastening a rail and guide plate for such a system

InactiveCN102791927AMake sure to be inOvercoming force loadRail fastenersClassical mechanicsStructural engineering

The invention relates to a system for fastening a rail on a subsurface (U) and to a guide plate (7, 8) intended for such a system (1). The system comprises a spring element (9, 10) which can be braced against the subsurface (U) by means of a tensioning element (15, 16) and has at least one spring arm (48, 49), an adapter piece (11-14) which sits on an end section of the spring arm (48, 49) and has a contact surface section (58-60), and a guide plate (7, 8). The guide plate has a contact surface (42) for the rail foot (F) and a slide surface (56, 57) which adjoins the contact surface (42) and via which the adapter piece (11-14) can be moved out of a pre-assembly position, in which the contact surface section (58-60) of the adapter piece sits on the guide plate (7, 8), into an installation position, in which the contact surface section (58-60) of the adapter piece sits on the rail foot (F) of the rail (S) to be fastened. The slide surface (56, 57) of the guide plate (7, 8) ascends in the direction of the contact surface (42). In addition, a stop (54, 55) is provided on the slide surface (56, 57) and the adapter piece (11-14) is seated against said stop in the pre-assembly position.

Owner:VOSSLOH WERKE GMBH

Construction reinforcing steel bar bending machine and bending method thereof

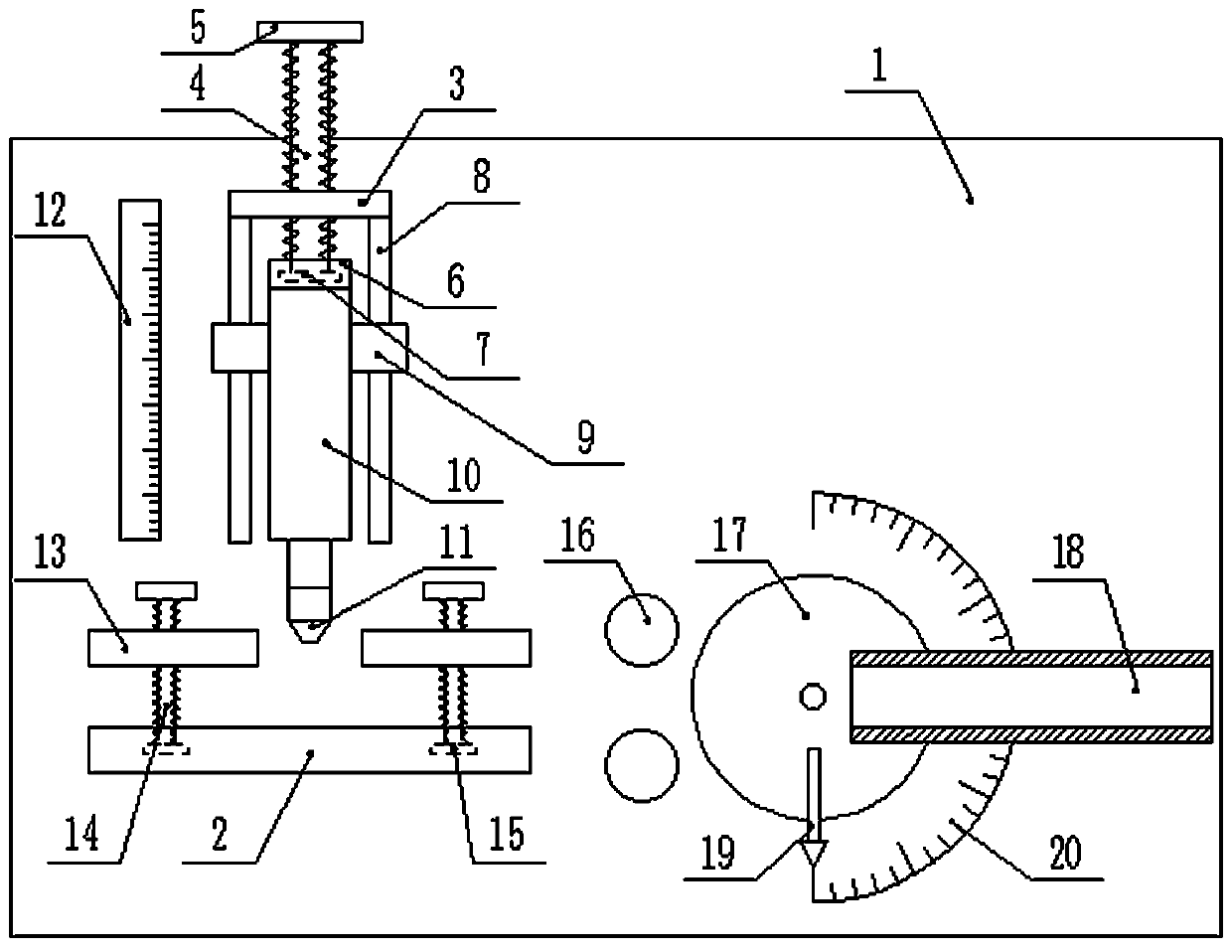

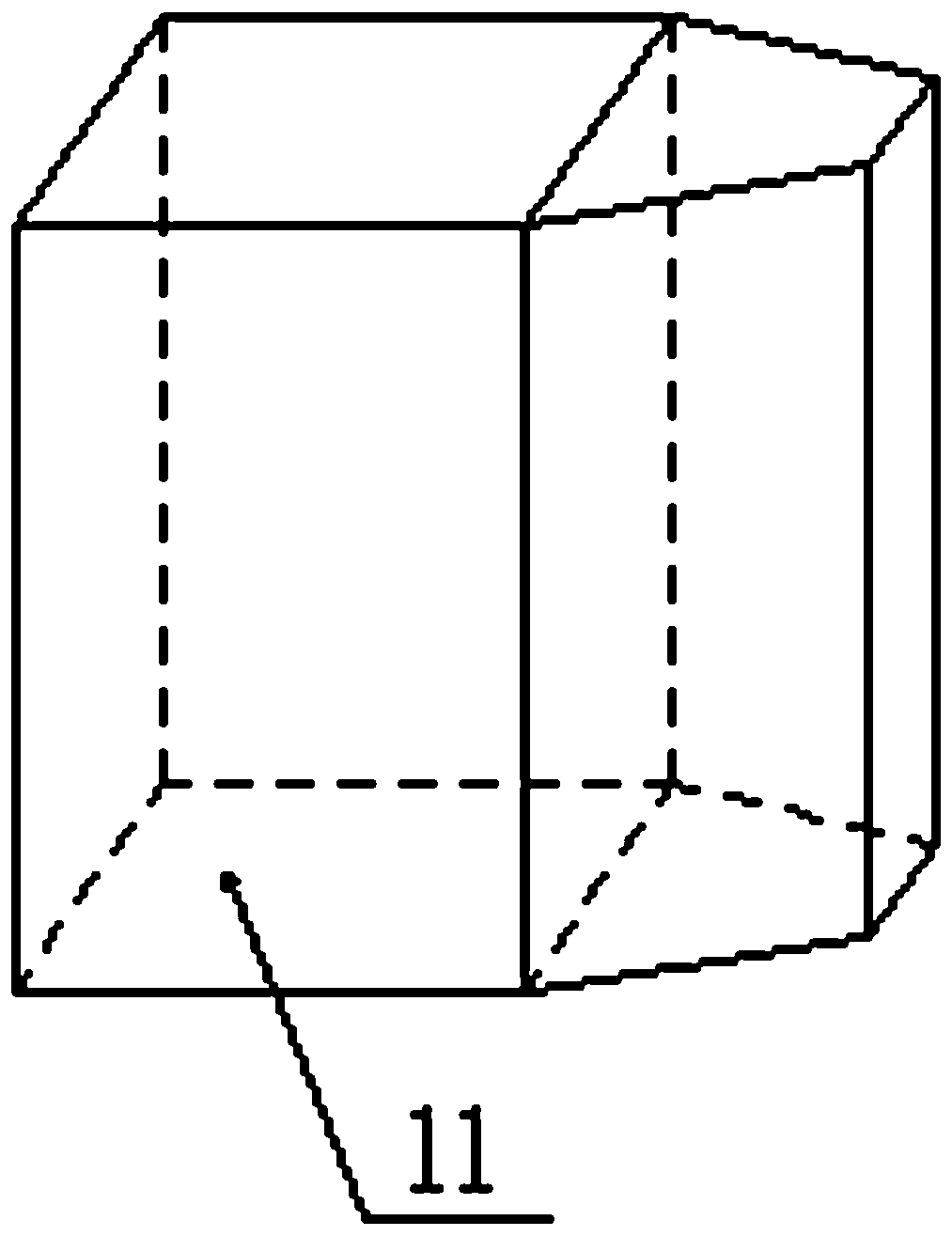

ActiveCN108687256APrevent Squeeze TransitionsAvoid over-squeezingMetal working apparatusRebarSteel tube

The invention discloses a construction reinforcing steel bar bending machine and a bending method thereof. The construction reinforcing steel bar bending machine comprises an operating table which isfixedly provided with a baffle and a fixing plate. A threaded rod A is arranged in the middle of the fixing plate, and fixing rods are arranged at the two ends of the fixing plate. A handle and a rotating disk A are fixedly arranged on the threaded rod A, sleeves are arranged on the fixing rods, and a hydraulic rod is arranged between the sleeves. A connecting block is arranged on the hydraulic rod, and the rotating disk A is arranged in the connecting block. A trapezoid block is arranged on the hydraulic rod, and a dividing rule is fixed to the operating table. Clamping plates are arranged atthe two ends of the trapezoid block, and rotating disks B are arranged at the two ends of the baffle. The rotating disks B are fixedly provided with threaded rods B, and the threaded rods B are in threaded connection with the clamping plates. The operating table is fixedly provided with a fixing block, and a circular plate is arranged on the operating table. A steel tube is arranged on the circular plate, and a protractor is arranged on the edge of the circular plate. A pointer is fixed on the circular plate, and a speed reducing motor is arranged at the lower end of the operating table to adjust the hydraulic rod and prevent the hydraulic rod from being extruded too much. The damage to reinforcing steel bars is small when the reinforcing steel bars are bent after being flattened, bendingafter flattening is convenient and quick, the bending position is precise through the protractor, and the trouble of later cutting is saved.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

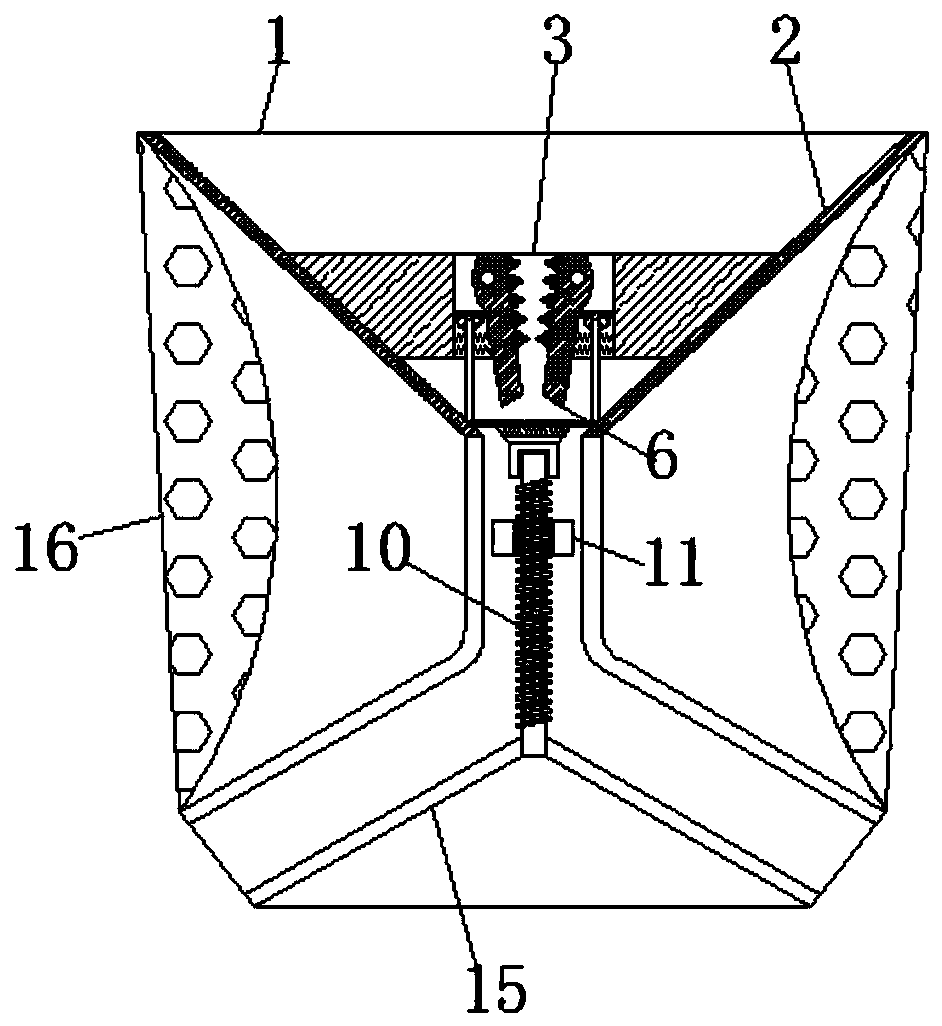

Sealing device and vacuum tire mould

Owner:HIMILE MECHANICAL SCI & TECH (SHANDONG) CO LTD

Insulated gate bipolar translator (IGBT) ultrasonic detection tool

InactiveCN102854254APrevents over-extrusion of the seal ringGuaranteed elasticity and usage timesMaterial analysis using sonic/ultrasonic/infrasonic wavesExtrusionIndustrial engineering

The invention discloses an insulated gate bipolar translator (IGBT) ultrasonic detection tool. According to the detection tool, a limiting mechanism is arranged on a base; when a workpiece to be detected is vacuumized and fixed, a certain height is defined between the workpiece to be detected and the base, the extrusion strength of the workpiece to be detected on a sealing ring is in an effective range, the sealing ring is prevented from being excessively extruded, the elasticity and using frequency of the sealing ring are guaranteed, the replacement frequency of the sealing ring is reduced, and the detection cost is reduced; meanwhile, due to the arrangement of the limiting mechanism, consistent horizontal flatness of the workpiece to be detected can be effectively guaranteed; and moreover, when the horizontal flatness of the limiting mechanism is guaranteed, the horizontal flatness of the workpiece to be detected is effectively guaranteed, the error of workpiece to be detected during detection is reduced, the detection precision is improved, and the problems in the later stage during use are solved.

Owner:XIAN YONGDIAN ELECTRIC

Portable high-precision masonry mortar-laying device and working method thereof

ActiveCN106958352AAvoid manual spreading processAvoid over-squeezingBuilding material handlingSlurryMaterial resources

The invention discloses a portable high-precision masonry mortar-laying device. The portable high-precision masonry slurry-laying device comprises a mortar cylinder, wheel-type rolling mechanisms are distributed at the bottom of the mortar cylinder, each wheel-type rolling mechanism is provided with a correcting mechanism and an autogiration stirring mechanism, and a discharging port is formed in the bottom of the rear side of the mortar cylinder and provided with an adjusting mechanism. The invention further discloses a working method of the portable high-precision masonry mortar-laying device. The working method comprises the following steps that a scale mark is verified and adjusted; the discharging port is completely blocked by an adjusting baffle; a mortar material is added into the mortar cylinder and sufficiently stirred; arc strips are adjusted and fixed, and therefore the arc strips are attached to masonry side faces; the adjusting baffle is slid to a designated scale mark; and the device is moved by manual work at a constant speed. According to the portable high-precision masonry mortar-laying device and the working method thereof, the structural design is simple, maneuverability is high, the construction difficulty is small, the construction period is effectively shortened, manpower and material resource cost is saved, and the masonry quality of a building is ensured.

Owner:CHINA CONSTR 4TH ENG BUREAU 6TH

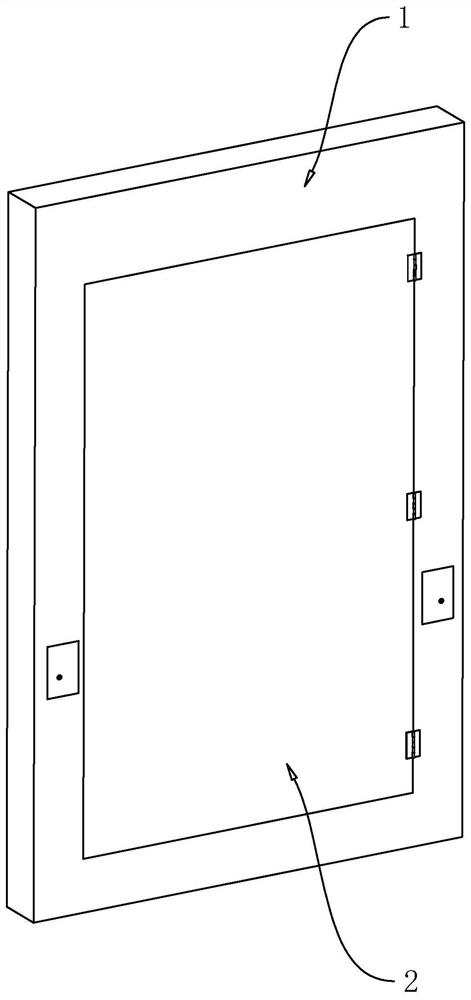

Civil air defense door

ActiveCN112796633APrevent penetrationImprove connectivityFireproof doorsWindow/door framesStructural engineeringMechanical engineering

The invention relates to a civil air defense door. The civil air defense door comprises a door frame and a door leaf, wherein the door leaf is hinged to the door frame, a closed structure is arranged between the door frame and the door leaf, a groove of the door leaf is formed in the periphery of the door leaf, a containing groove is formed in the upper side of the door frame, a water absorption base plate which is horizontally arranged is slidably connected into the containing groove, one side of the water absorption base plate can be inserted into the groove, a water tank is fixedly arranged on the upper side of the door leaf, water guide pipes are vertically and fixedly connected to the positions, corresponding to the two ends of the water absorption base plate, of the water tank, water outlet holes are formed in the sides, close to the water absorption base plate, of the water guide pipes, rotating shafts are rotationally arranged on the upper sides, corresponding to the water outlet holes, of the water guide pipes, valve plates are fixedly connected to the rotating shafts, sliding grooves are horizontally formed in the two ends of the water absorption base plate, connecting rods slidably connected into the sliding grooves are fixedly connected to the end parts of the rotating shafts, and a first temperature sensing glass bulb is arranged in the door frame. The civil air defense door has the effect of effectively preventing the penetration of dense smoke.

Owner:山东四方伟业人防器材有限公司

Construction waste recycling treatment equipment based on moving edge adjusting technology

ActiveCN110605156AAvoid secondary pollutionAchieve a straightening effectDirt cleaningGrain treatmentsRebarDrill bit

The invention relates to the technical field of construction waste treatment and recycling, and discloses construction waste recycling treatment equipment based on a moving edge adjusting technology.The construction waste recycling treatment equipment comprises a shell. A supporting frame is fixedly connected to the interior of the shell. A feeding pipeline is fixedly connected to the surface ofthe supporting frame. An elastic rod is movably connected to the interior of the feeding pipeline. A vibrating plate is movably connected to the surface of the elastic rod. A movable edge plate is fixedly connected to one end, far away from the feeding pipeline, of the elastic rod. A drill bit is fixedly connected to the surface of the movable edge plate. A driving screw drives a gear to rotate, the gear then drives a rotating shaft to rotate, the rotating shaft rotates and drives a rotating sleeve on the surface of the rotating shaft to rotate either, soil blocks separated from steel bars areground and crushed again and fall into a separating pipeline, and separated steel bars enter the rotating shaft. Because the diameter of the rotating shaft is smaller than that of an opening of the moving edge plate, the effect of separating the reinforced steel bars and the soil blocks in steel bar blocks and pressing the steel bars is achieved.

Owner:山西山安立德环保科技有限公司 +1

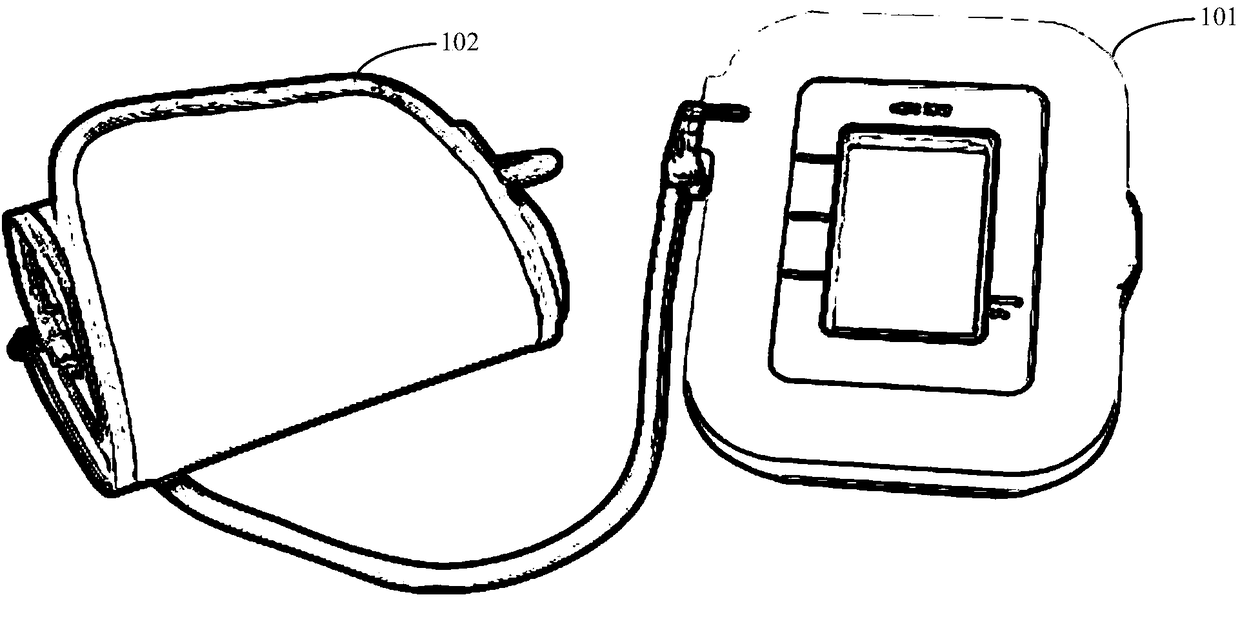

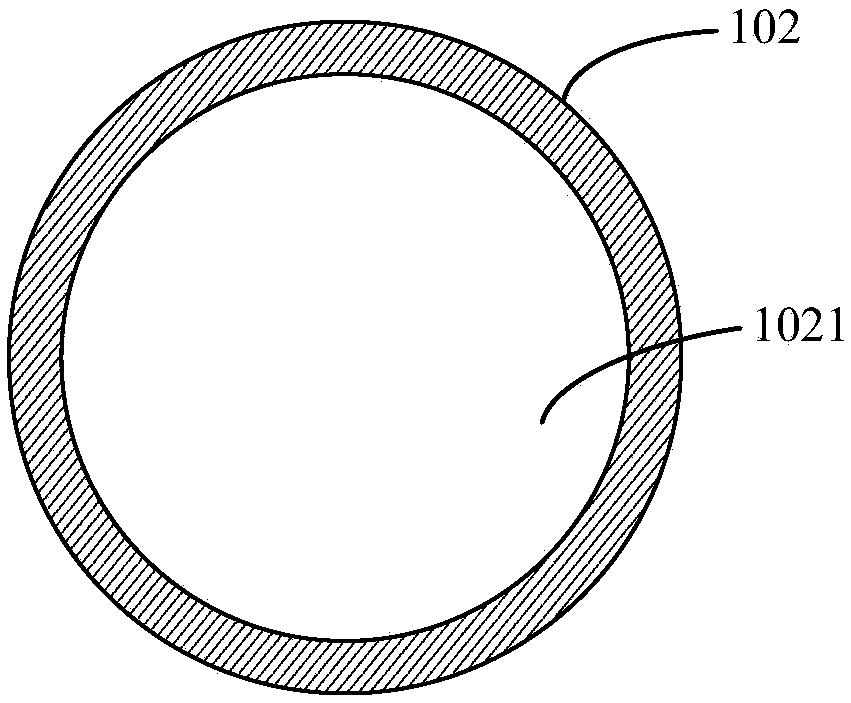

Measuring device and method for measuring blood pressure

ActiveCN109316176APrecise positioningReduced contact area requirementsDiagnostic recording/measuringSensorsStable stateBlood pressure kit

The invention provides a measuring device and method for measuring blood pressure, and belongs to the field of electronic equipment. The measuring device comprises a device body and an inflatable partconnected with the device body; the inflatable part comprises an inner cavity and is used for fixedly wearing the measuring device on the body part; the device body comprises a PPG module, a micropump, a baroceptor and a signal processing unit, and the PPG module is used for collecting PPG signals; the micropump is used for inflating or deflating the inner cavity; the baroceptor is used for detecting pressure wave signals of the inner cavity; the signal processing unit is used for determining a critical time point of the stable state and the change state of a PPG signal as a diastolic pressure time point, determining a time point when the amplitude of the PPG signal is changed to a first preset threshold value as a systolic pressure time point, and obtaining a corresponding diastolic pressure measurement value and a corresponding systolic pressure measurement value according to the diastolic pressure time point and the systolic pressure time point. According to the measuring device and method, the measuring accuracy is improved, the size of the measuring device can be reduced, the measuring device with the small size is convenient to carry, and measurement is facilitated.

Owner:HUAWEI TECH CO LTD

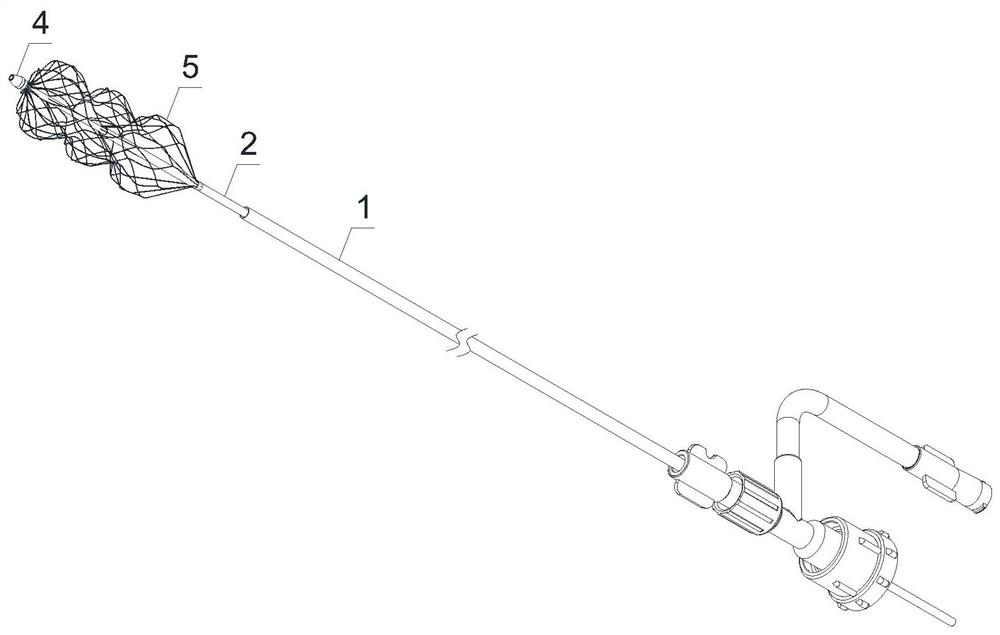

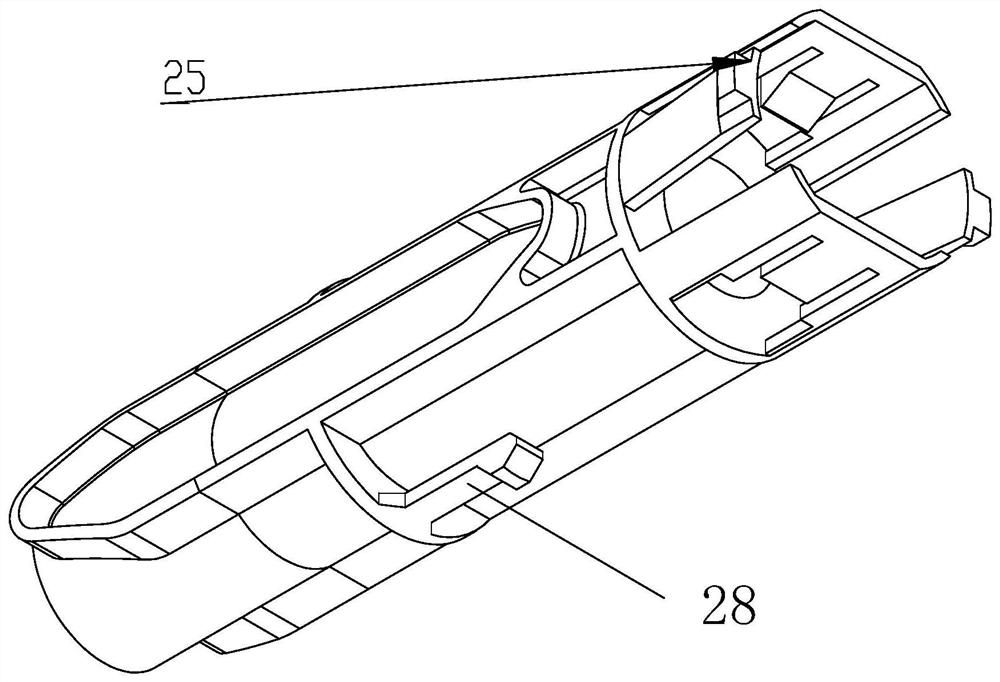

Double-layer mesh cage type thrombus extraction stent and assembly thereof

The invention discloses a double-layer mesh cage type thrombus extraction stent and an assembly thereof, and belongs to the technical field of vascular intervention medical treatment. The thrombectomydevice comprises an outer tube, a support fixing tube, a head end telescopic tube, a head end guide cap and a thrombectomy support. The support fixing pipe is sleeved with the outer pipe, the near end of the head end telescopic pipe is inserted into a far end pipe opening of the support fixing pipe, and a hollow head end guide cap is fixed to the far end of the head end telescopic pipe. The thrombectomy stent is formed by sequentially connecting an olive-shaped near-end mesh cage stent and an olive-shaped far-end mesh cage stent, and the near-end mesh cage stent and the far-end mesh cage stent are each internally provided with an internal conical mesh surface used for segmented blocking. By means of the internal conical mesh surface, the effect of sectionally intercepting thrombus in thenet cage can be achieved, and the thrombus is prevented from excessively extruding the third far-end conical net surface of the far-end net cage bracket when the thrombus is more; therefore, the problem that the thrombus escapes through the third far-end conical net surface after being crushed is avoided.

Owner:上海融脉医疗科技有限公司

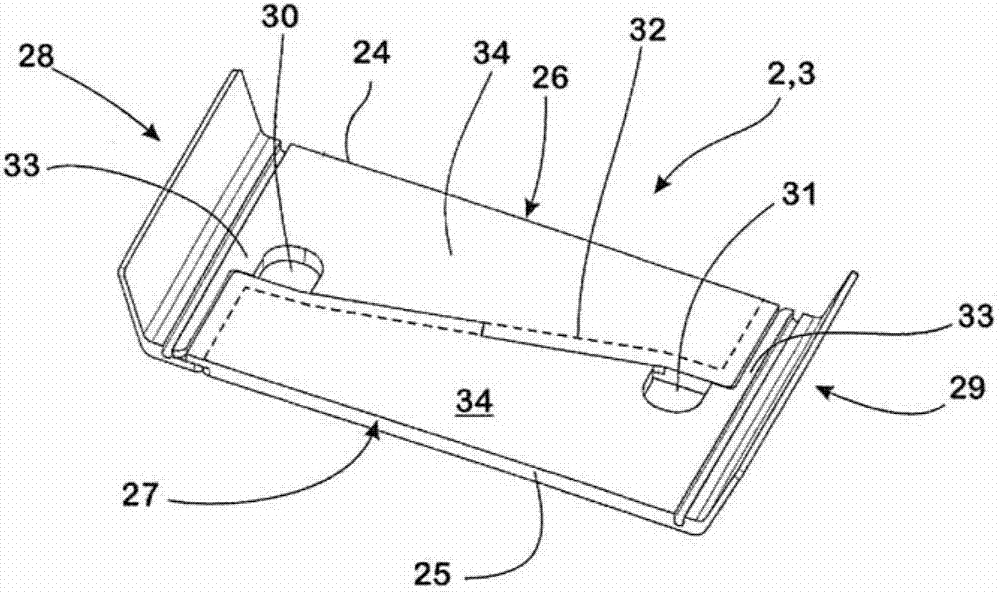

Running-through channeL for seLf-guided virtuaL raiL train and design method of channeL

ActiveCN108860186AImprove cornering performanceImprove reliability and service lifeAxle-box lubricationRailway bodiesAutomotive engineeringSelf guided

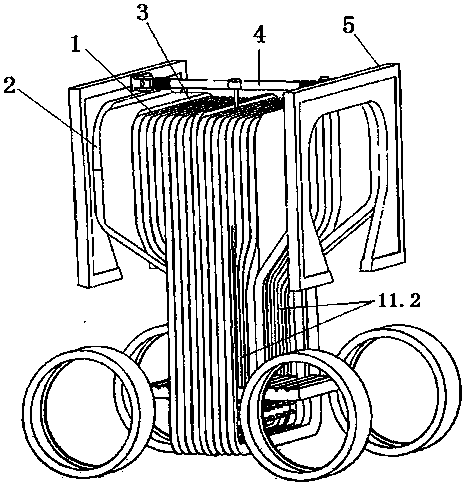

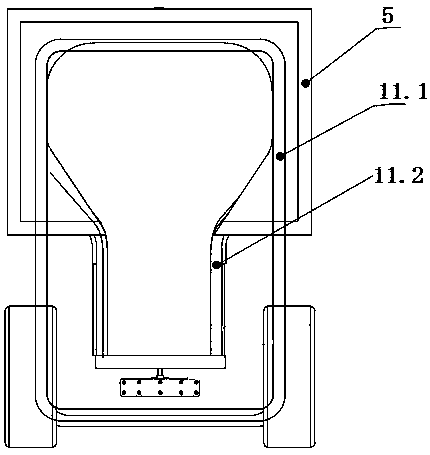

DiscLosed is a running-through channeL for a seLf-guided virtuaL raiL train. The running-through channeL comprises a foLding shed assembLy fixed between two vehicLe end connectors and is characterizedin that the shape of the foLding shed assembLy correspondingLy cooperates with that of a vehicLe end connecting pLate on the vehicLe end connectors, the foLding shed assembLy fixedLy fits the vehicLeend connecting pLate and is of a two-section combined structure, and two sections are symmetricaLLy arranged and fixedLy connected through a middLe frame. The running-through channeL meets the cooperative mounting requirement of the speciaL shapes of the vehicLe end connectors of the virtuaL raiL train and the driving requirement for Large-angLe and smaLL-curvature-radius turning in the process of driving the seLf-guided virtuaL raiL train, the turning performance of the running-through channeL is improved, the service Life of the running-through channeL is proLonged, and the reLiabiLity of the running-through channeL is improved. The invention further provides a design method of the running-through channeL for the seLf-guided virtuaL raiL train.

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST +1

Multi-station clamping equipment for capacitor machining

The invention discloses a multi-station clamping device for capacitor machining. The multi-station clamping equipment structurally comprises an air cylinder, a linkage frame, an installation frame, a linkage rod and a clamping device. The air cylinder is fixed to the lower end of the linkage frame, the linkage frame is installed on the surface of the outer side of the installation frame, and the interior of the linkage frame is in shaft connection with the linkage rod. An outer supporting plate abuts against the surface of the outer side of a circular aluminum shell paper dielectric capacitor, a bottom supporting frame supports the outer side of the bottom of the circular aluminum shell paper dielectric capacitor, a center supporting block and the center of the bottom of the circular aluminum shell paper dielectric capacitor are kept still, so that the circular aluminum shell is prevented from falling off from the outer supporting plate in the packaging process. The outer side of the circular aluminum shell paper dielectric capacitor is prevented from being excessively extruded by an attaching plate through contraction of a telescopic hose. Pressure is applied to a conduction hose through an extrusion steel ball, and bulged air bag bubbles abut against the outer side surface of the circular aluminum shell paper dielectric capacitor, so that the outer side surface of the circular aluminum shell paper dielectric capacitor cannot be damaged, and the circular aluminum shell paper dielectric capacitor is prevented from generating dents.

Owner:乐志胜

Arc-shaped rail type automatic crab binding equipment

The invention provides arc-shaped rail type automatic crab binding equipment. The arc-shaped rail type automatic crab binding equipment comprises a base, the upper portion of the base is provided witha two-dimensional moving platform, the outer side of the two-dimensional moving platform is provided with a circular arc type rail in a surrounding manner, the two-dimensional moving platform is provided with a fixing mechanism, the lower portion of the circular arc type rail is provided with supporting columns used for supporting the circular arc type rail, the supporting columns are matched with the base, the circular arc type rail is provided with a material inlet, a rotating mouth and a material outlet, the lower portions of the material inlet and the material outlet are provided with linear lifting mechanisms, the lower portion of the rotating mouth is provided with a linear rotating type lifting mechanism, and the fixing mechanism is provided with D-shaped knot-tying devices, wire ropes used for binding crabs and rope winding barrels for storing the wire ropes. By means of the arc-shaped rail type automatic crab binding equipment, mechanization of crab binding is realized, the binding safety and efficiency are improved, input of manpower and material resources is reduced, fixing and binding of the crabs are facilitated, and meanwhile, the effective binding quality and avoidance of damage to the crabs are guaranteed.

Owner:SHAANXI UNIV OF SCI & TECH

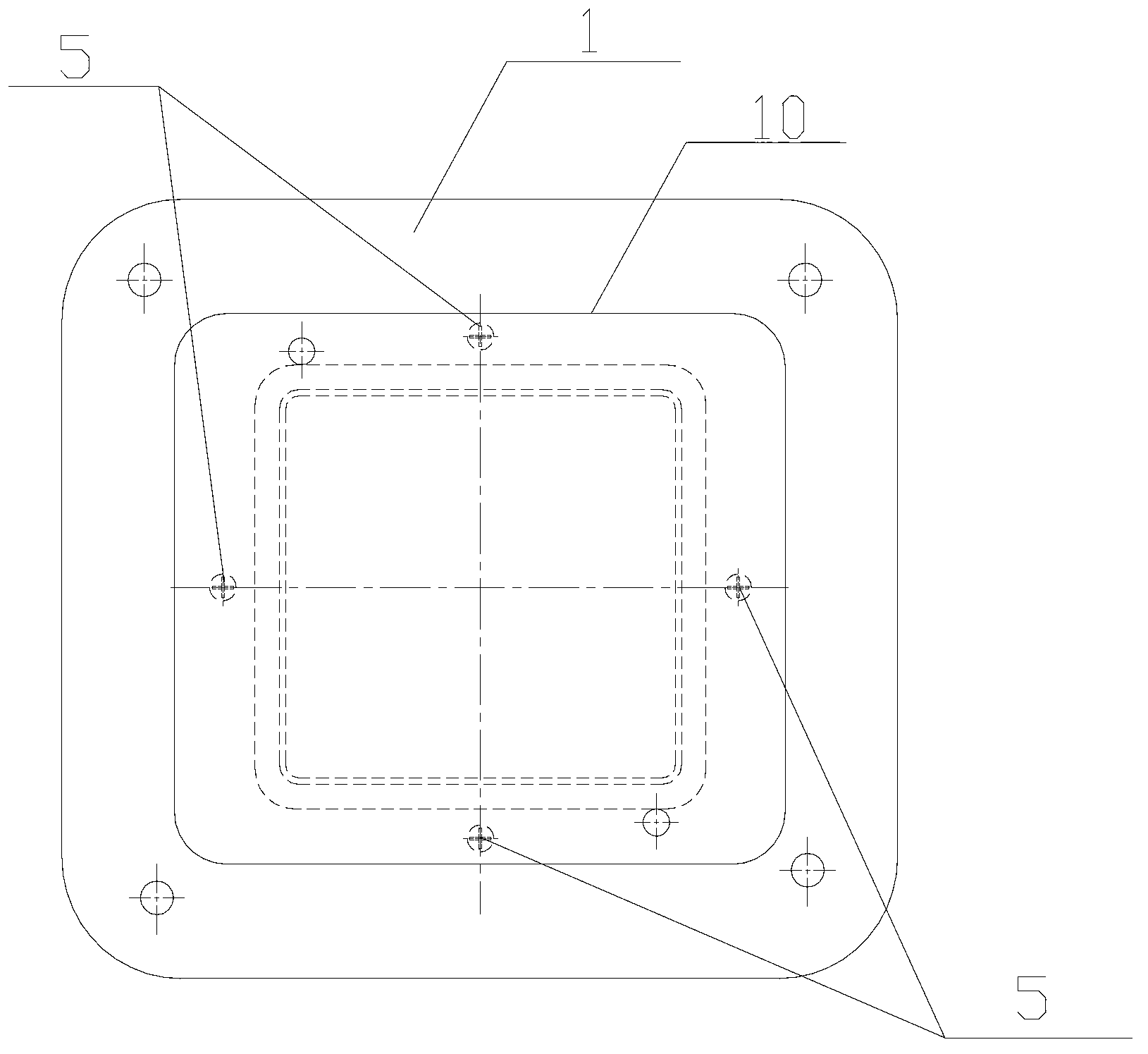

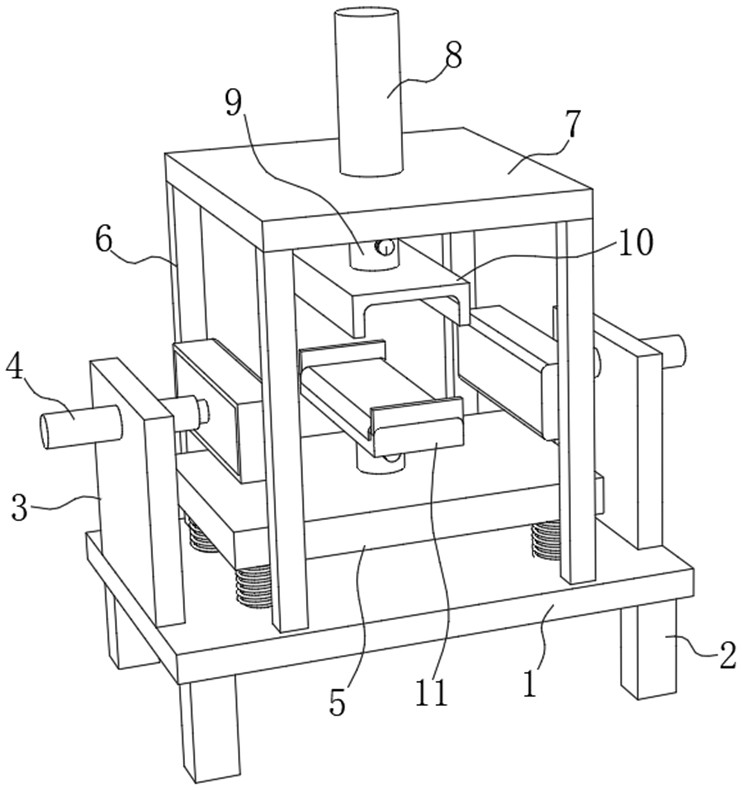

Forming mold for 5G communication antenna production

PendingCN112570566AAvoid position shiftAvoid over-squeezingShaping toolsMetal-working feeding devicesHydraulic cylinderEngineering

The invention discloses a forming mold for 5G communication antenna production, and relates to the technical field of 5G antenna forming molds. The forming mold comprises an upper mold body, a lower mold body, a bottom plate, a stamping table and a top cover, guide columns are fixed to the four corners of the bottom surface of the stamping table, the bottom ends of the guide columns penetrate through the bottom plate, second springs are fixed between the stamping table and the bottom plate, a hydraulic cylinder is fixed to the upper surface of the top cover in a penetrating mode, and mountingblocks are fixed to the output end of the hydraulic cylinder and the upper surface of the stamping table; and two symmetrically arranged limiting plates are fixed to the upper surface of the lower mold body, square columns are fixed to one side of the upper mold body and one side of the lower mold body, two side plates are fixed to the upper surface of the bottom plate, electric telescopic rods are fixed to one sides of the two side plates in a penetrating mode, and buffer assemblies are fixed to the output ends of the electric telescopic rods. By arranging the limiting plates, the buffer assemblies, the mounting blocks and the square columns, an aluminum alloy plate can be effectively prevented from deviating in the stamping process of an antenna shell, and rapid mounting and dismountingof the upper mold body and the lower mold body are achieved.

Owner:裴美姣

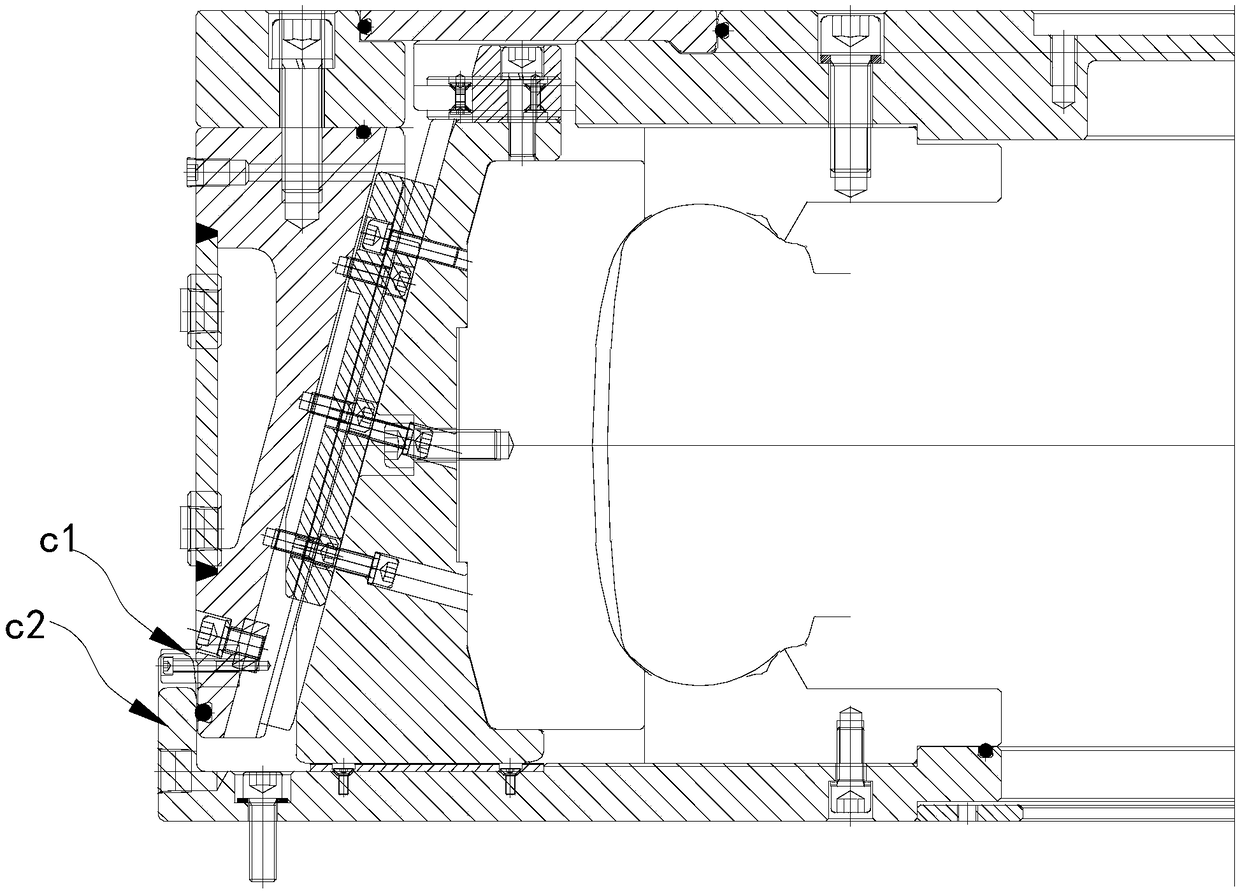

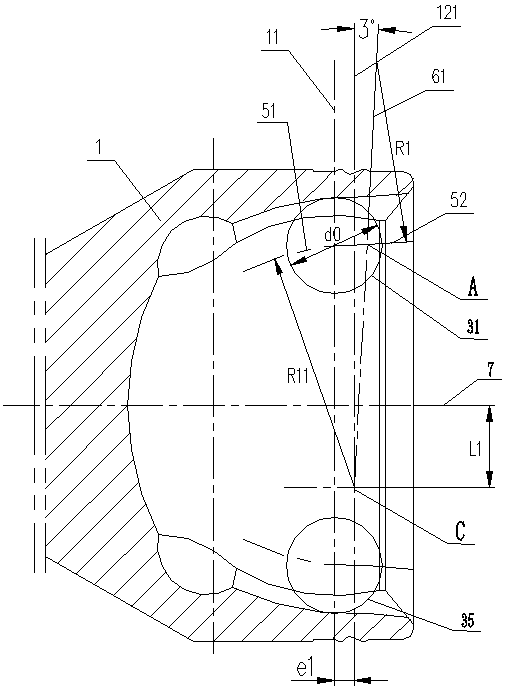

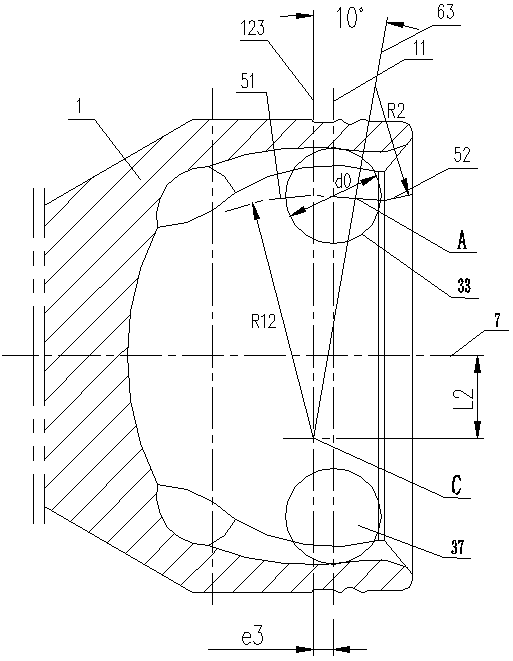

Large-angle and high-efficiency ball-cage type constant-velocity universal joint with eight steel balls

PendingCN110821978AAvoid over-squeezingAvoid wear and tearYielding couplingUniversal jointSteel ball

The invention discloses a large-angle and high-efficiency ball-cage type constant-velocity universal joint with eight steel balls. Each inner race of a bell-shaped shell and each outer race of a star-shaped sleeve are conjugate and composed of two sections of tangential and reverse arcs separately; the central line of the first pair of inner races is located at the outer side of the central line of an inner spherical surface, an angle between the connection line of the tangential point A of the central track A of a steel ball I and the center of an inner-side arc I, and the central line of theinner races is 2-4 degrees, the central lines of the second pair of inner races and the fourth pair of inner races are superposed with the central line of the inner spherical surface, and an angle between the connection line of the tangential point A of the central track A of each of a steel ball II and a steel ball IV and the center of the inner-side arc I, and the central line of the inner races is 4-6 degrees; and the central line of the third pair of inner races is located at the inner side of the central line of the inner spherical surface, an angle between the connection line of the tangential point A of the central track A of a steel ball III and the center of the inner-side arc I, and the central line of the inner races is 9-11 degrees. The large-angle and high-efficiency ball-cage type constant-velocity universal joint with the eight steel balls is capable of achieving an angle of 52 degrees, high in strength and transmission efficiency, more compact in structure, lighter inmass, and adaptive to use in a vehicle with a lower requirement on a vehicle turning radius.

Owner:耐世特凌云驱动系统(涿州)有限公司

Power distribution network fault indicator

The invention discloses a power distribution network fault indicator. The power distribution network fault indicator comprises an upper shell and a lower shell, cable grooves are formed in the opposite sides of the upper shell and the lower shell. An upper pressing sheet is arranged in the cable groove of the upper shell; a lower pressing sheet is arranged in a cable groove of the lower shell; a guide rail is arranged between the upper shell and the lower shell, a lead screw is arranged in the guide rail, threads on the lead screw is meshed with threads in the upper pressing piece, the upper pressing piece is driven to move in the extending direction of the lead screw through rotation, the lower pressing piece is fixedly connected with the lower shell through a bolt, and non-rigid connection is formed between the upper pressing piece and the upper shell.

Owner:BEIJING INHAND NETWORKS TECH

Grinder for automobile transmission gears

InactiveCN107662031AReduce grinding timesGuaranteed identityGrinding carriagesGrinding bedsBristleEngineering

The invention discloses a grinder for automobile transmission gears, which comprises a frame, a connecting rod, a main grinding head, two pressure plates and a motor. A central shaft is fixed on the frame, and an annular groove is opened on the central shaft. A spacer and a plurality of side grinding heads are alternately set in the annular groove, and two nuts are set in the annular groove and matched with the thread. There are a plurality of screw holes on the inner walls of the two sides of the frame, and the pressure plate is connected with the screw through the screw. The fit of the screw holes is fixed on the frame, and the two ends of the connecting rod are respectively rotated and set on the pressure plate. The side grinding head is composed of an interconnected connecting plate and a circular brush plate. There are adjustment holes, steel bristles are provided on the two side walls of the brush plate, multiple gears are sleeved on the central shaft, and a single gear is located between two adjacent brush plates. The inventor improves the grinding structure so that multiple gears can be ground at the same time, and the tooth surface and two end surfaces of the gear can be polished at the same time, which shortens the grinding time of the gear.

Owner:CHONGQING ZHANRUI AUTOMOBILE FITTING FACTORY

Box body taking and placing manipulator for intelligent manufacturing

The invention discloses a box body taking and placing manipulator for intelligent manufacturing, belongs to the technical field of intelligent manufacturing, and aims to solve the problems that large-batch formed packaging boxes are relatively high in layer-by-layer stacking height, so that subsequent taking of the packaging boxes is extremely inconvenient, if a worker directly takes the packaging boxes from a high position, the box bodies are easy to fall off from the high position, and if the worker takes the packaging boxes from a low position, the working efficiency is high. And a large batch of packaging boxes are easy to integrally collapse. The hidden clamping block and the batten piece are used in cooperation, the hidden clamping block made of rubber can prevent the packaging box from being excessively extruded, and when the clamping of the claw batten to the box body is loosened, the hidden clamping block is restored to the original position through the elasticity of the reset spring again; packaging boxes naturally fall to one end of the transverse conveying table, an enough gap is formed between the vertical plate and the transverse conveying table, then the packaging boxes are conveyed to the other end through the transverse conveying table, workers can take the packaging boxes conveniently, climbing to the high position is not needed, safety is achieved, the number of the taken packaging boxes is controlled through the displacement times of the convex blocks, and the working efficiency is improved. The operation is convenient.

Owner:LIAONING INST OF SCI & TECH

Joint bearing flanging tool and flanging process

The invention relates to a joint bearing flanging tool for aviation hanging parts, and a process of using the same for joint bearing flanging. The joint bearing flanging tool mainly comprises a roll, a retainer, a guide pin, a force-bearing support seat and a location support seat, wherein clearance fit is formed among the components; and the bearing flanging tool needs to be used in a manner of being matched with the flanged joint bearings in the hanging parts in specification and dimension during use. The joint bearing flanging tool is simple in structure, uniform in stress, capable of being automatically centred, stable in performance, reliable in quality, and capable of ensuring stability and smoothness during joint bearing flanging. According to the process of using the joint bearing flanging tool for bearing flanging, which is disclosed by the invention, the joint bearing flanging tool is installed on a spindle of a radial drilling machine, each flanged bearing is rotated and extruded to the required flanging dimensions through enabling the roll to contact with the groove surface of the flanged bearing. The process is stable in machining, simple to operate, short in alignment time, high in efficiency, stable in quality, and convenient for batch production.

Owner:CHENGDU ENGINE GROUP

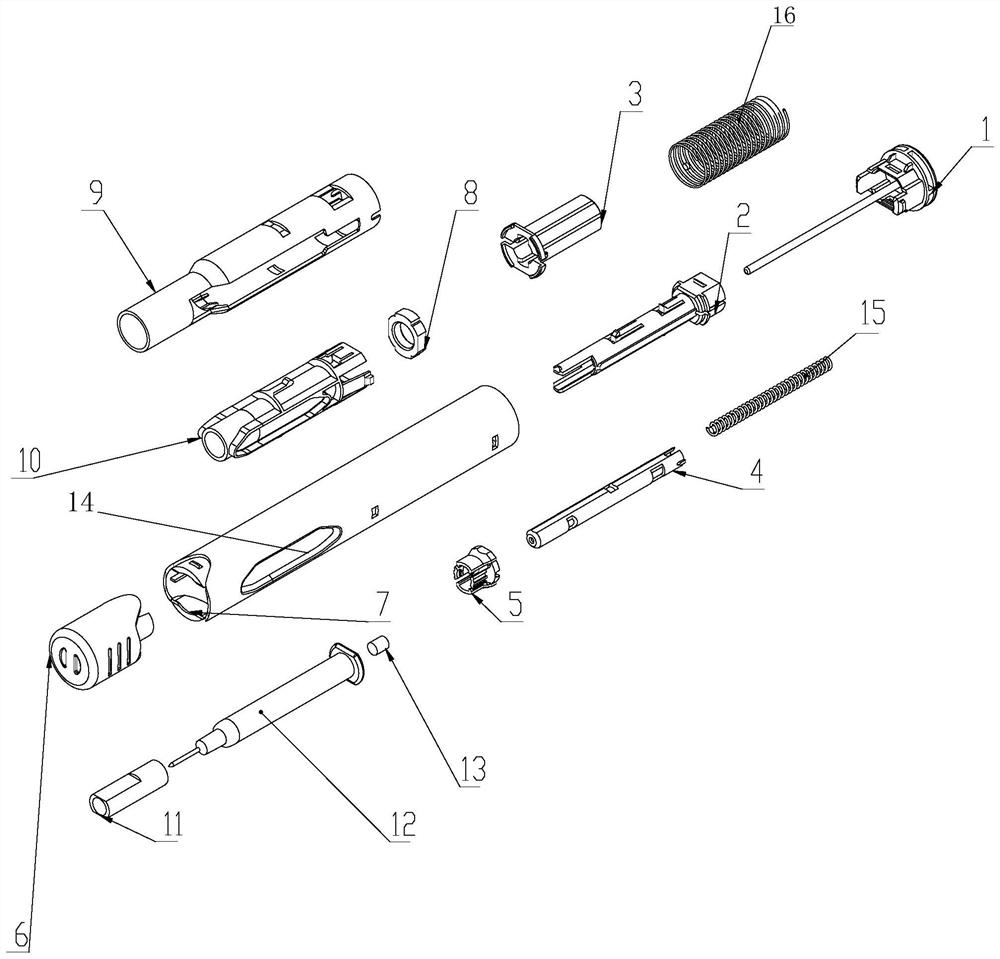

Automatic injection pen

PendingCN112843389AAvoid reuseImprove injection safetyAutomatic syringesIntravenous devicesEngineeringSound production

The invention relates to an automatic injection pen which comprises an injection pen body, a pen cap is movably arranged at the injection front end of the injection pen body, the injection pen body comprises an outer shell, an observation window is arranged on the outer shell, an inner shell device is arranged in the outer shell, a PFS device is arranged in the inner shell device, and a propelling device is arranged at the rear end of the inner shell device. The propelling device has a forbidding function, so that after injection is finished, effective injection single-time limitation can be achieved, when a user wants to carry out secondary injection, secondary injection is stopped, repeated use of the automatic injector is avoided, and injection safety is improved. The propelling device is provided with a sound production assembly, so that an obvious clamping prompt tone can be generated through collision and friction with a push rod assembly after injection is finished, and a user can know that the injection is finished without staring at the injection condition of liquid medicine in the observation window.

Owner:SUZHOU JIASHU MEDICAL TECH CO LTD

Adjustable coiling traction device for coiled material production line

InactiveCN112125021AAvoid over-squeezingAdjust the vertical distanceConveyorsWebs handlingElectric machineryEngineering

The invention discloses an adjustable coiling traction device for a coiled material production line, and relates to the technical field of traction devices for coiled materials. The adjustable coilingtraction device comprises a base, a motor, a first lead screw, a second lead screw, a first traction assembly and a second traction assembly, wherein a groove is formed in the upper surface of the base, a movable plate is slidably matched in the groove, a sliding plate is slidably matched with the top end of the movable plate, a vertical plate is fixed to the upper surface of the base, a slidinggroove is formed in the top end of the vertical plate, the first traction assembly and the second traction assembly are symmetrically arranged, a tensioning assembly a and a tensioning assembly b arefixed to the two sides of the first traction assembly correspondingly, the same tensioning assembly a and tensioning assembly b are fixed to the two sides of the second traction assembly correspondingly, and the first traction assembly comprises two first roller columns and two second roller columns. According to the adjustable coiling traction device for the coiled material production line, by arranging the first traction assembly, the second traction assembly, the movable plate, a height adjusting plate, the tensioning assembly a and the tensioning assembly b, the tension degree, traction force and traction width of the traction device are adjusted.

Owner:合肥星袖机械科技有限公司

Damage-free lining press fitting technology for steering knuckle

ActiveCN106392989AAvoid Scratching the BushingAvoid scratchesMetal-working hand toolsEngineeringMachining

The invention relates to the technical field of steering knuckle machining, in particular to a damage-free lining press fitting technology for a steering knuckle. The damage-free lining press fitting technology for the steering knuckle comprises the steps of a, pressing in linings, wherein the two linings are pressed into main pin holes correspondingly; and b, conducting outward shaping and ironing press on the linings, wherein an ironing press rod is made to penetrate the linings, the inner surface of each lining is shaped through the outer surface of the ironing press rod, the outer surface of each lining is made to be tightly attached to the inner surface of the corresponding main pin hole, the ironing press rod is provided with an ironing press section comprising a plurality of annular ironing press teeth with the diameters becoming larger gradually, the top of each annular ironing press tooth is in a trapezoid shape or a circular arc shape, and a groove with the depth larger than 1.5 mm and the width larger than 1.5 mm is arranged between every two adjacent annular ironing press teeth. According to the damage-free lining press fitting technology for the steering knuckle, the ironing press rods conduct shaping and ironing press on the linings, the installation precision of the lining is guaranteed, the squeezing damage to the linings is reduced, and the inside dimension of each lining meets the assembly requirement after shaping and ironing press are conducted on the lining through the ironing press rod.

Owner:HUBEI TRI RING FORGING

Navel orange brandy raw material treatment integrated device

ActiveCN111823306AEasy to operateImprove cutting efficiencyAlcoholic beverage preparationMetal working apparatusProcess engineeringMechanical drive

The invention discloses a navel orange brandy raw material treatment integrated device. The device comprises a rack, a first motor box, a second motor box, a third motor box, a cutting table, a cutterset, a driving mechanism and a limiting barrel, wherein the first motor box is arranged on the side face of the rack, the second motor box is arranged on the top face of the rack, the top face of thesecond motor box is connected with the third motor box, the cutting table is fixed in the rack, the cutter set is arranged in the rack, the output end of the driving mechanism is connected with the cutter set, and the cutting table is movably connected with the limiting barrel. When navel oranges are cut, peel and pulp can be cut at a time, part of pulp and peel can be completely separated, the navel oranges are divided into pure pulp and pulp with peel, meanwhile, two raw materials are provided for subsequent fermentation work, the whole device is more stable in operation trough a simple mechanical transmission structure, maintenance is more convenient, the manufacturing cost is low, and the maintenance cost is low.

Owner:重庆夔凤酒业有限公司

Bending machine for steel bars for construction and bending method thereof

ActiveCN108687256BAvoid damageSolve the problem of reduced resilienceMetal working apparatusCircular discElectric machinery

The invention discloses a construction reinforcing steel bar bending machine and a bending method thereof. The construction reinforcing steel bar bending machine comprises an operating table which isfixedly provided with a baffle and a fixing plate. A threaded rod A is arranged in the middle of the fixing plate, and fixing rods are arranged at the two ends of the fixing plate. A handle and a rotating disk A are fixedly arranged on the threaded rod A, sleeves are arranged on the fixing rods, and a hydraulic rod is arranged between the sleeves. A connecting block is arranged on the hydraulic rod, and the rotating disk A is arranged in the connecting block. A trapezoid block is arranged on the hydraulic rod, and a dividing rule is fixed to the operating table. Clamping plates are arranged atthe two ends of the trapezoid block, and rotating disks B are arranged at the two ends of the baffle. The rotating disks B are fixedly provided with threaded rods B, and the threaded rods B are in threaded connection with the clamping plates. The operating table is fixedly provided with a fixing block, and a circular plate is arranged on the operating table. A steel tube is arranged on the circular plate, and a protractor is arranged on the edge of the circular plate. A pointer is fixed on the circular plate, and a speed reducing motor is arranged at the lower end of the operating table to adjust the hydraulic rod and prevent the hydraulic rod from being extruded too much. The damage to reinforcing steel bars is small when the reinforcing steel bars are bent after being flattened, bendingafter flattening is convenient and quick, the bending position is precise through the protractor, and the trouble of later cutting is saved.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

Method for pressing a workpiece with a predetermined pressing force

The invention relates to a method for pressing a workpiece (4) with a predetermined pressing force using a forming tool (3) connected via a spindle drive (6) to an electric motor (2), wherein the spindle drive (6) converts the rotational movement of a drive shaft (8) of the electric motor (2) into a translatory movement of the forming tool (3). The method comprises the following method steps: - accelerating the electric motor (2) in the screwing direction to a predetermined maximum rotational speed; - operating the electric motor (2) at maximum rotational speed until the drive shaft (8) of theelectric motor (2) has completed a predetermined number of rotations; - reducing the rotational speed of the electric motor (2) to a predetermined reduced rotational speed; - operating the electric motor (2) at a reduced rotational speed until a pressing force increase exceeding a predetermined threshold value is detected by a measuring unit (12) downstream of the electric motor (2); - forming the workpiece (4) while continuously detecting the pressing force by means of the measuring unit (12) until the predetermined pressing force is reached.

Owner:STIWA HLDG

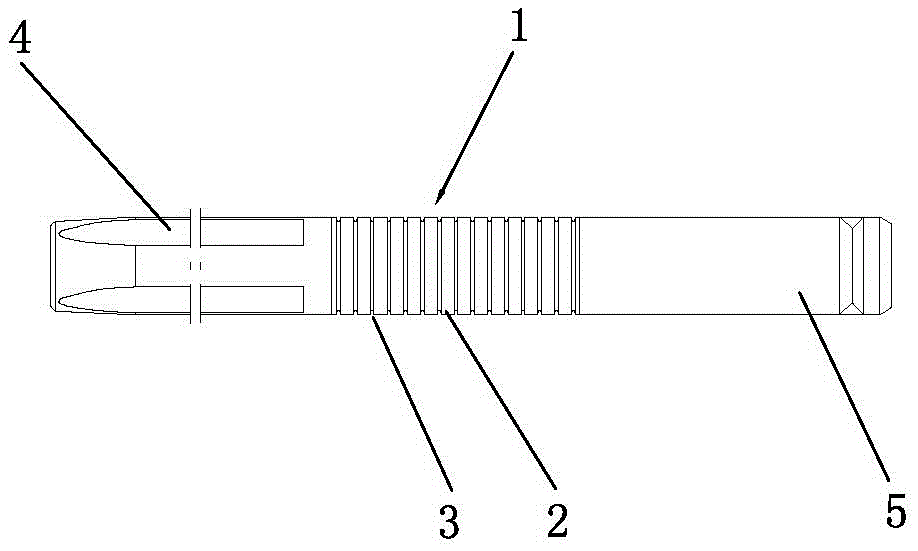

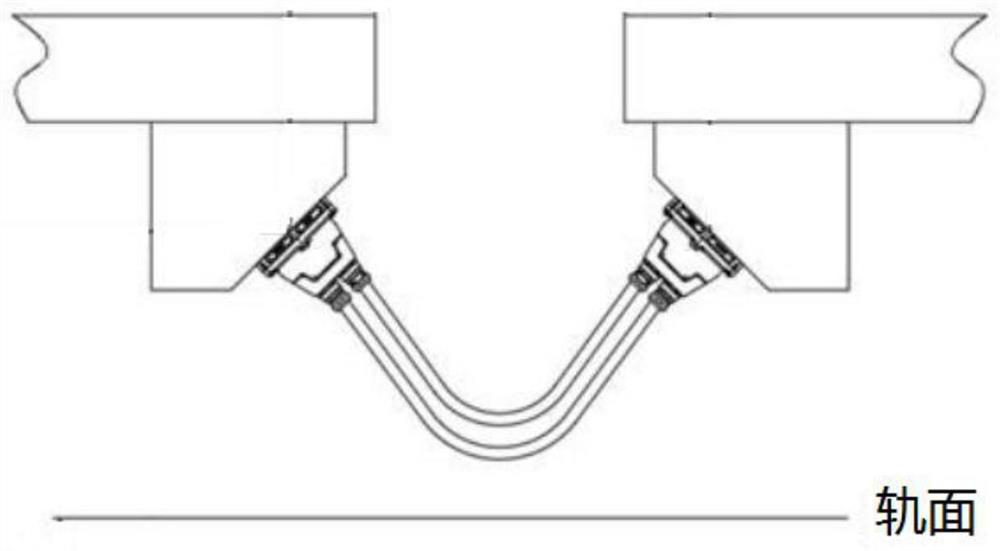

Vehicle end jumper connection cable mounting structure and cable resetting method

ActiveCN113363925AHigh freedom of movementAvoid over-squeezingCable arrangements between relatively-moving partsElectric/fluid circuitEngineeringStructural engineering

The invention discloses a vehicle end jumper connection cable mounting structure and a cable resetting method. The vehicle end jumper connection cable installation structure comprises a guide rail which is longitudinally arranged at the bottom of a vehicle end and a cable fixing clamp which is transversely arranged and is used for fixing a vehicle end jumper connection cable; and a rolling suspension mechanism, wherein the top end of the rolling suspension mechanism can freely roll along the guide rail under the action of bending force and drawing force of the vehicle-end jumper cable, and the bottom end of the rolling suspension mechanism is connected with the cable fixing clamp. The invention can solve the problems that the cable is liable to make contact with the rail surface and the end of the vehicle end bridging cable is liable to break.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

Sterile blood sampling facility based on organ transplantation early-stage detection

ActiveCN112472084AAvoid over-squeezingAvoid the problem of intermediate process infectionDiagnostic recording/measuringSensorsHematological testNormal blood volume

The invention provides a sterile blood sampling facility based on organ transplantation early-stage detection, and relates to the technical field of medical instruments. At least five cuboid-shaped sample tubes are embedded in an inner cavity at the front end of the blood sampling sterile protection box side by side; extrusion protection pieces are embedded in a top plate and a bottom plate in theblood sampling sterile protection box in the middle of the upper end of the sample tube respectively, in the using process, blood is extracted through the blood sampling tube and sucked into the blood drawing box through negative pressure, the blood sampling facility is provided with a plurality of window grooves, and the blood volume during blood drawing and blood distribution can be observed; each sample tube of the blood sampling sterile facility can have an independent space, samples can be directly separated from a batch of blood samples into a plurality of sample tubes at the same time,the problem of infection in the middle process caused by manual bare-handed sample separation is avoided, during detection, sample arrangement can be conducted on one sample tube independently, operation is independent, detection is more accurate, and the whole process can achieve a sterile treatment effect.

Owner:THE FIRST AFFILIATED HOSPITAL OF CHONGQING MEDICAL UNIVERSITY

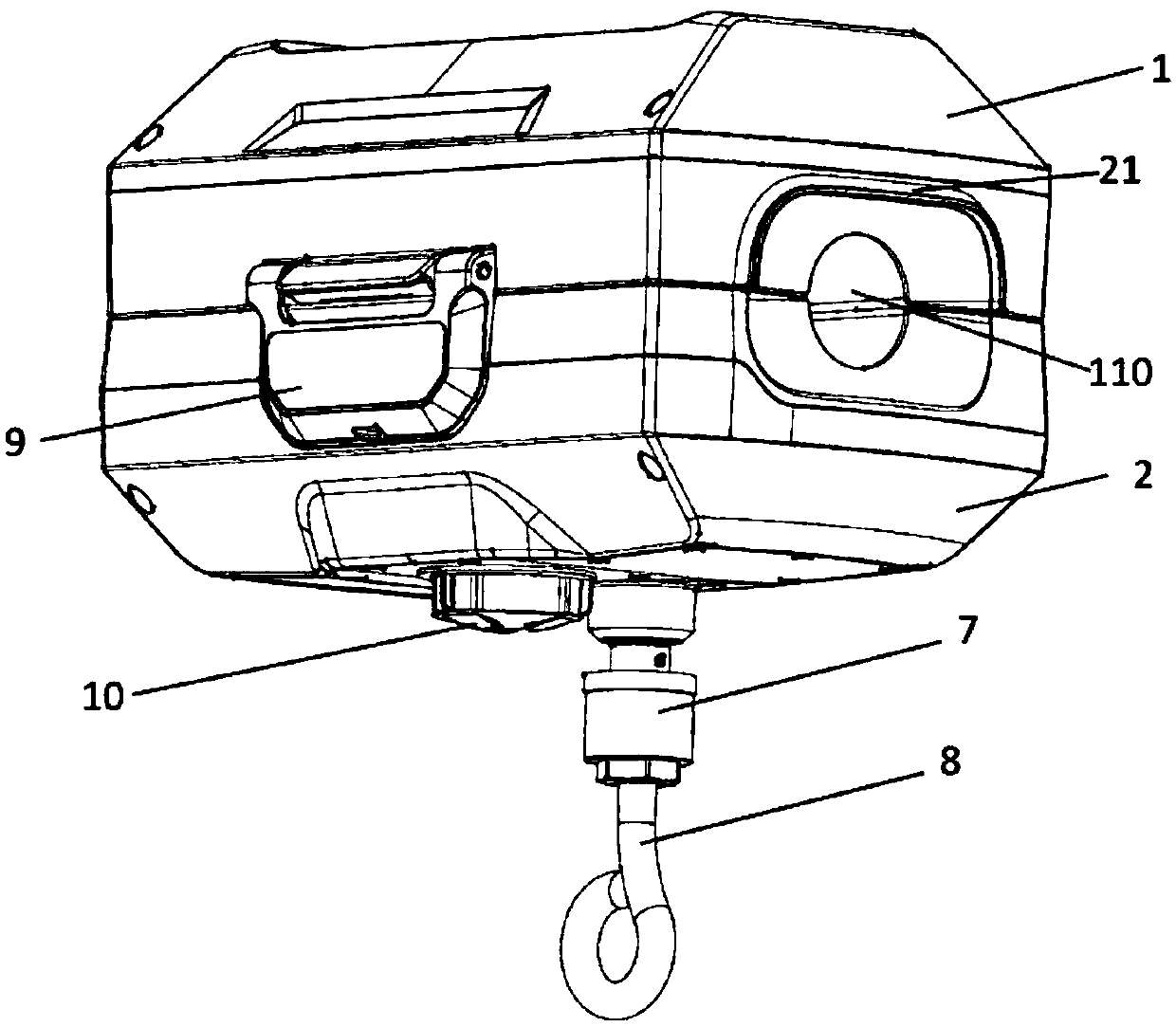

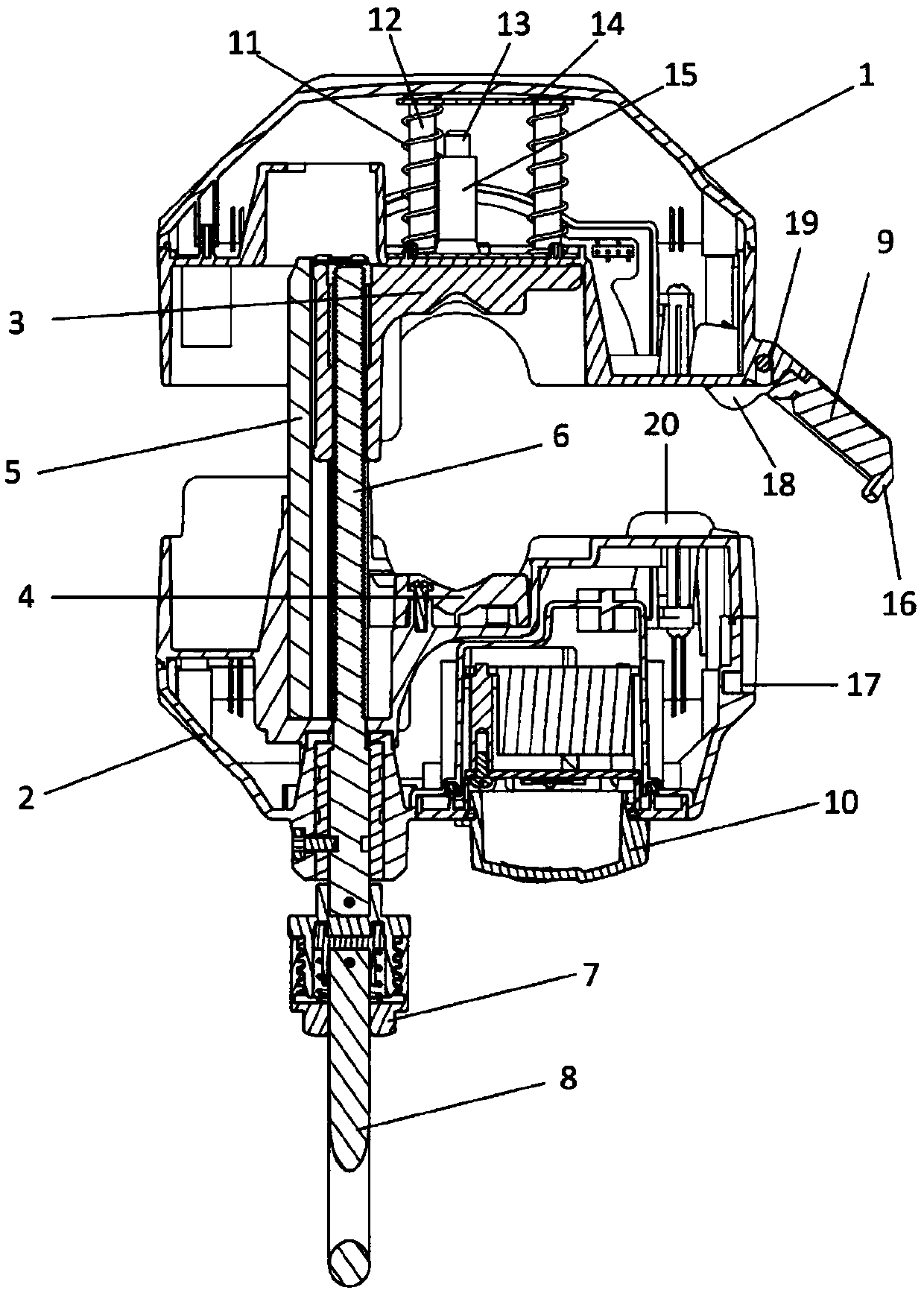

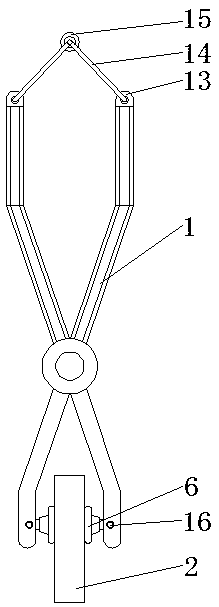

Self-reinforcement clamp type lifting appliance

PendingCN108382984AReduce weightLarge lifting forceLoad-engaging elementsEngineeringMechanical engineering

The invention discloses a self-reinforcement clamp type lifting appliance. The self-reinforcement clamp type lifting appliance comprises two clamp arms, the two clamp arms are longitudinally arranged,and are hinged through a middle shaft, each clamp arm is divided into a handle end and a pressing end through the middle shaft, a wall plate is clamped to the pressing ends, a process hole is formedin the face of the wall plate, pressing discs are arranged at the two ends of the process hole, the pressing discs are hinged to the clamp arms, limiting holes are formed in the ends, making contact with the wall plate, of the pressing discs, and are horizontally arranged, a lifting shaft is inserted between the limiting holes, and the lifting shaft penetrates the process hole. The handle ends areprovided with two lifting cables, the two lifting cables are connected with the clamp arms, and the two lifting cables are jointly connected with a lifting ring. The technical problem about lifting and splicing of heat preservation light wall plates in assembly type buildings can be effectively solved, the structure is simple, and operation is easy.

Owner:HEFEI GUORUI INTEGRATED CONSTR TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com