Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

203results about How to "Meet the needs of processing and use" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

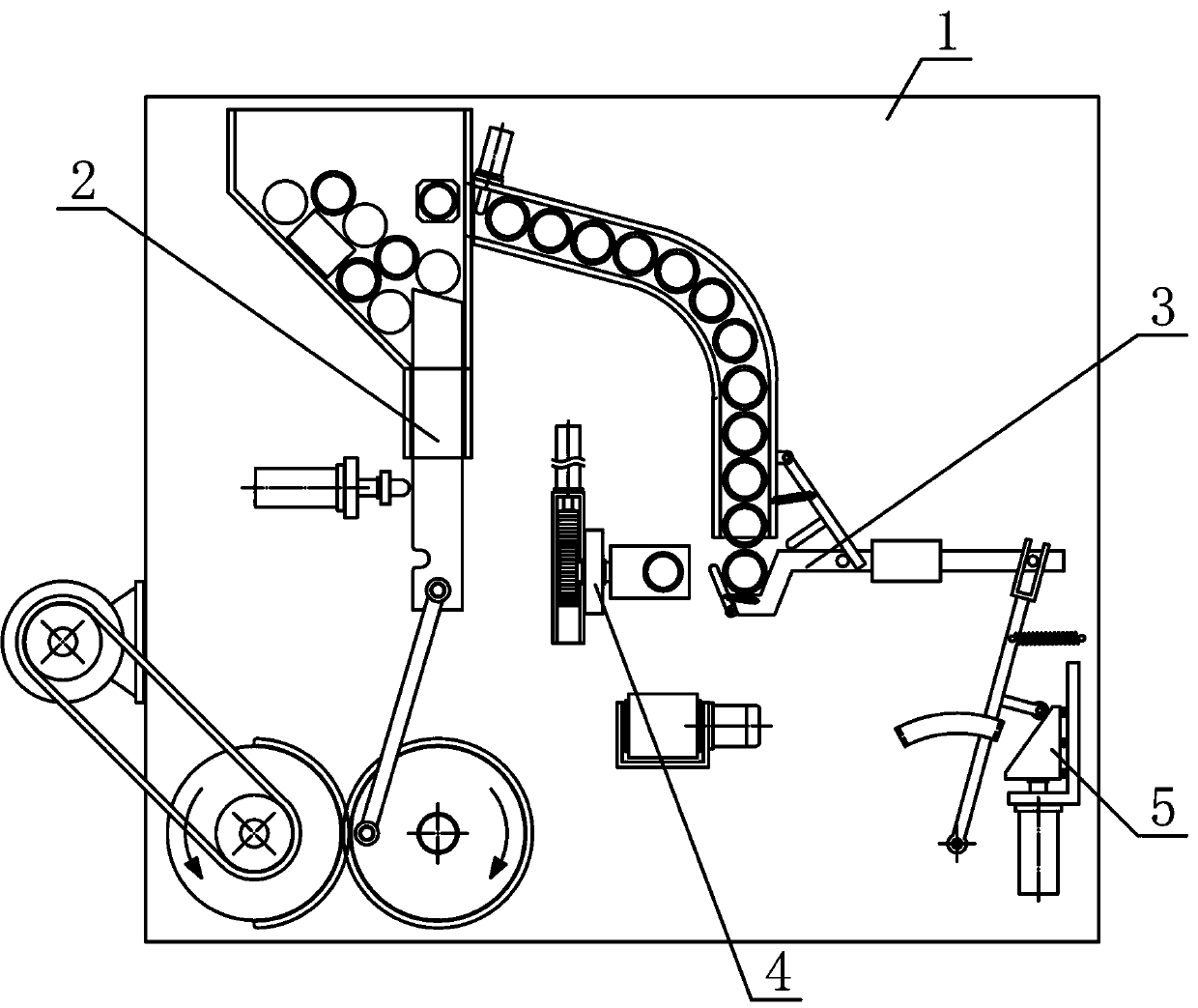

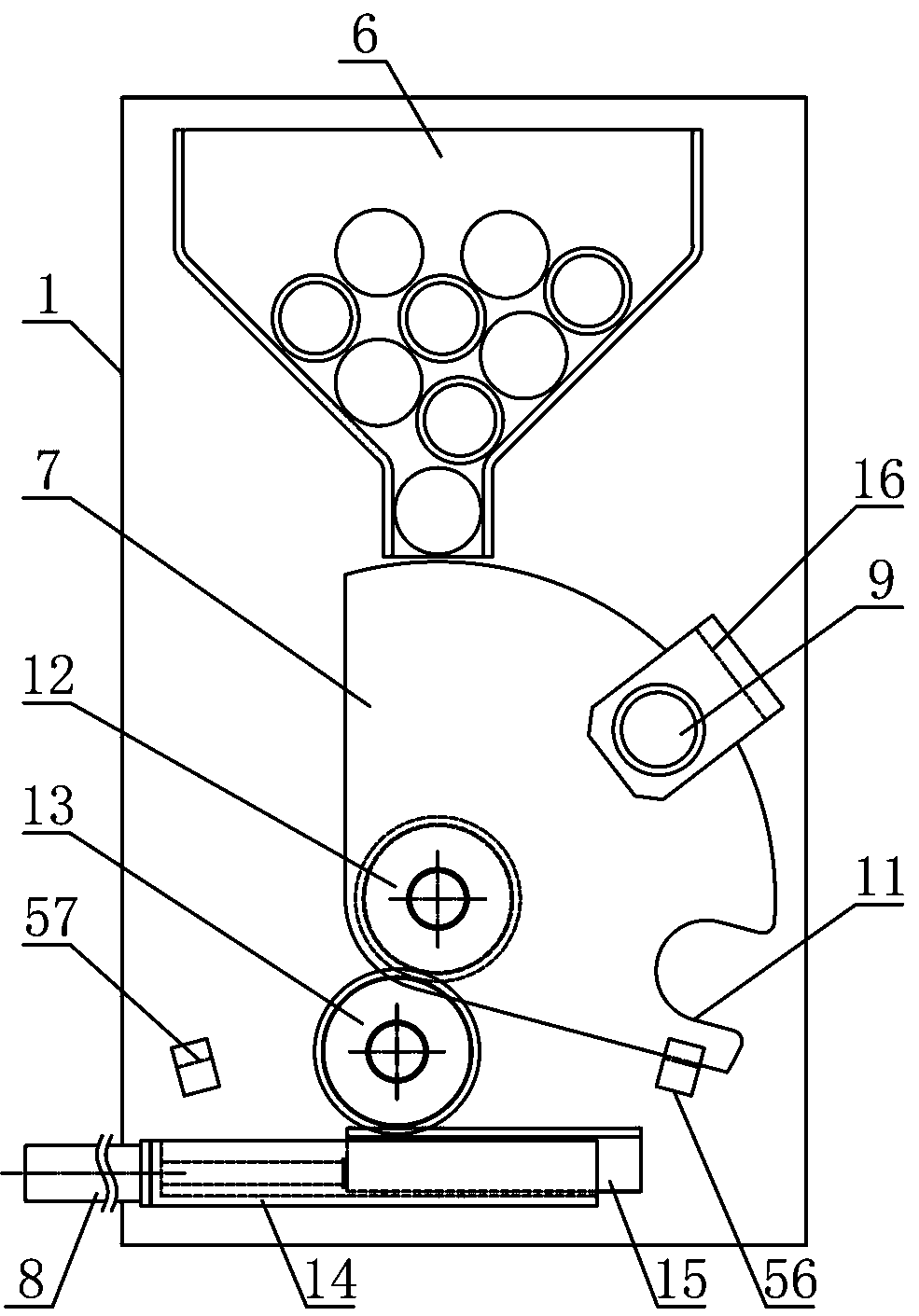

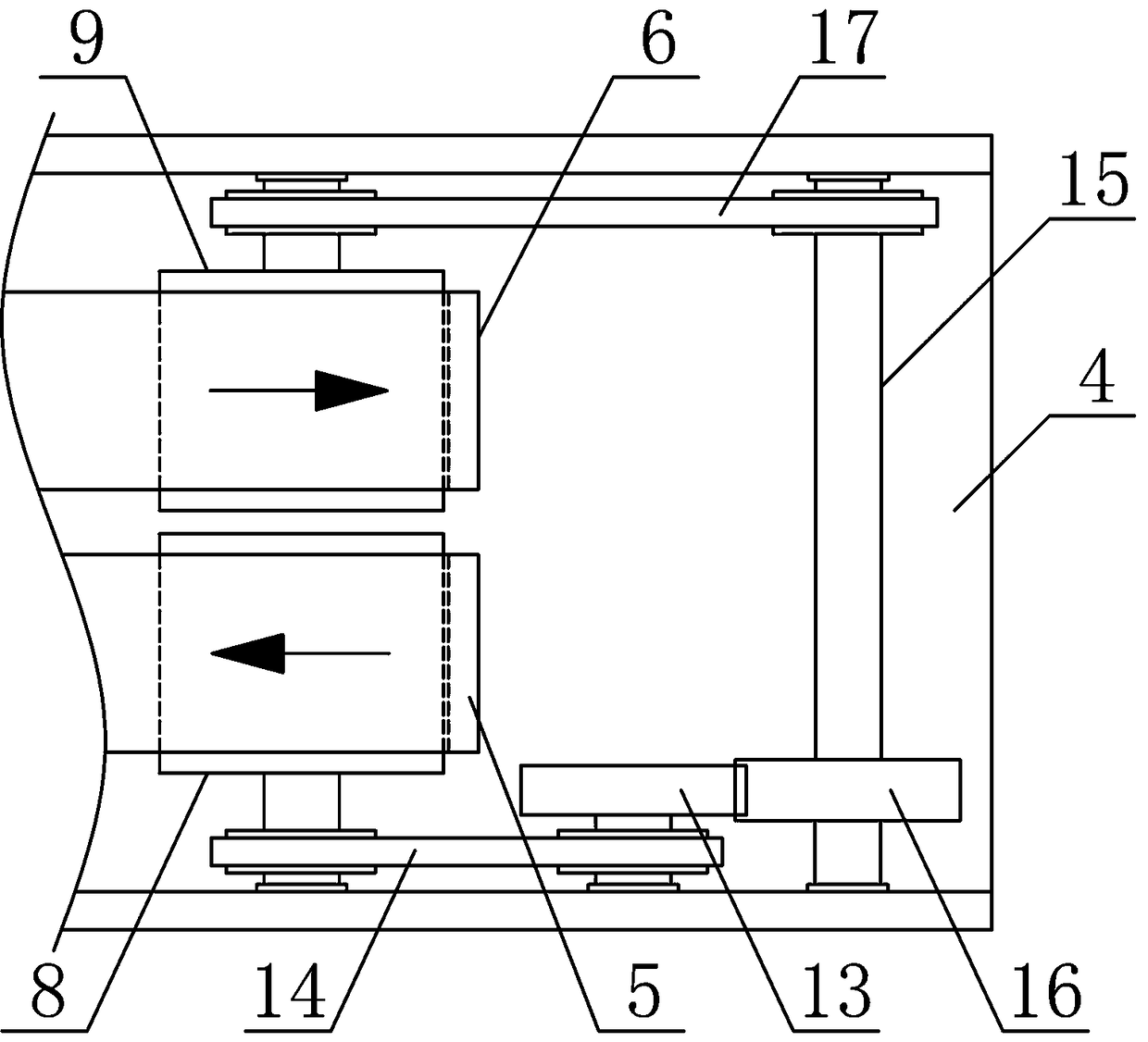

Feeding and transferring mechanism for pipe fittings with end portions closed

InactiveCN109704046AHigh degree of processing automationReasonable structural designConveyor partsMotor drivePipe fitting

The invention discloses a feeding and transferring mechanism for pipe fittings with end portions closed, and belongs to the field of workpiece machining mechanical equipment. A guide pipe through holeis formed in the upper end of a pipe storage hopper of the feeding and transferring mechanism. A lifting push plate is arranged on a push plate sleeve on the lower side of the pipe storage hopper ina sliding manner. A pipe movement guide plate is arranged on a guide pipe support on the lower side of a discharge guide pipe. A clamping rod limiting clamp is arranged at the upper end of a reciprocating swinging rod. A turnover gear is fixedly arranged on the end portion of one side of a fixed rotating shaft. The middle portion of one side of a turnover connection plate is fixedly arranged on the end portion, along the side of the pipe movement guide plate, of the fixed rotating shaft. The two sides of a pipe transferring belt are wound on and connected to pipe transferring rotation rollerson the two sides of a pipe transferring support correspondingly. A pipe transferring motor drives the pipe transferring rotation rollers to rotate. The feeding and transferring mechanism is reasonablein structural design, the pipe fittings can be conveniently and efficiently arranged and fed in an oriented manner one by one, the pipe fittings can be stably and accurately overturned vertically oneby one, and therefore the pipe fittings can be sequentially conveyed through vertical stations, the automation degree of pipe fitting feeding and processing can be improved, and requirements of machining and using can be met.

Owner:TONGXIANG TANGCHAO ADVERTISEMENT CO LTD

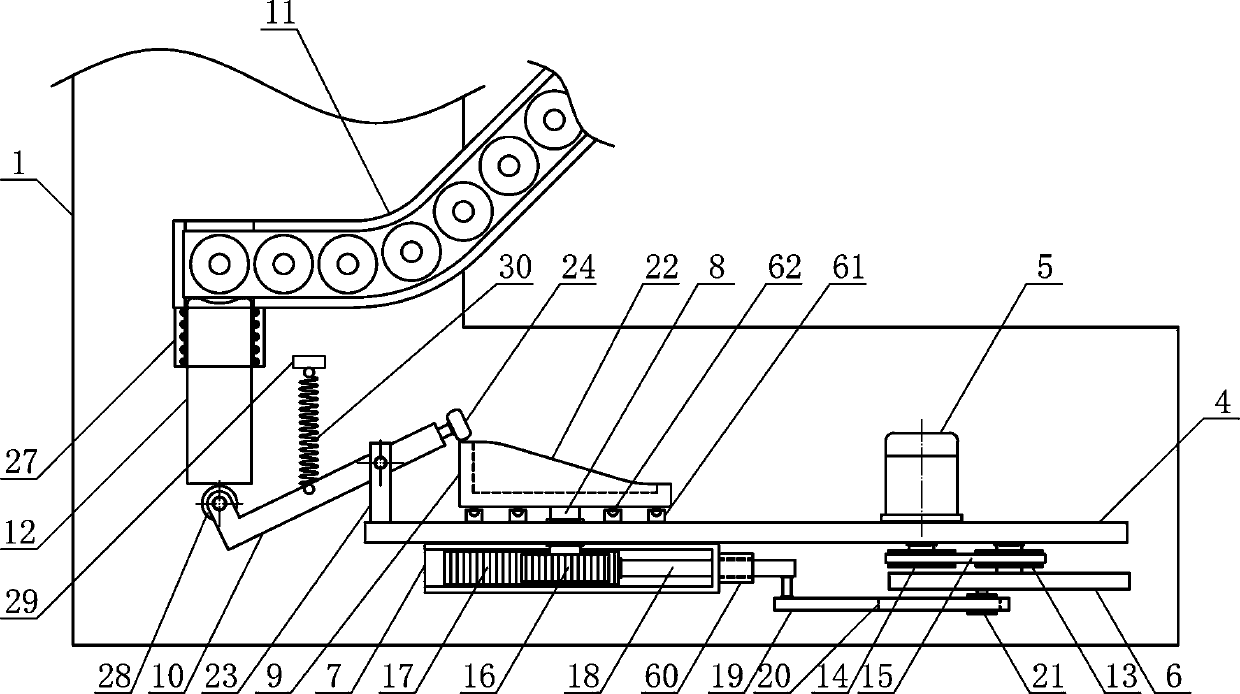

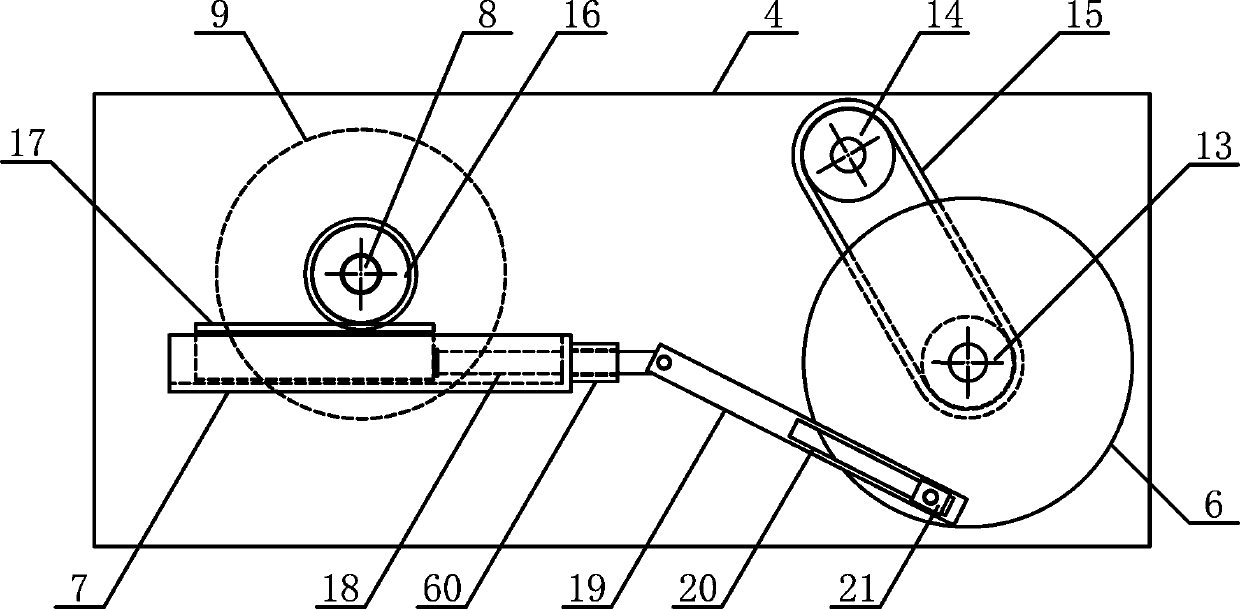

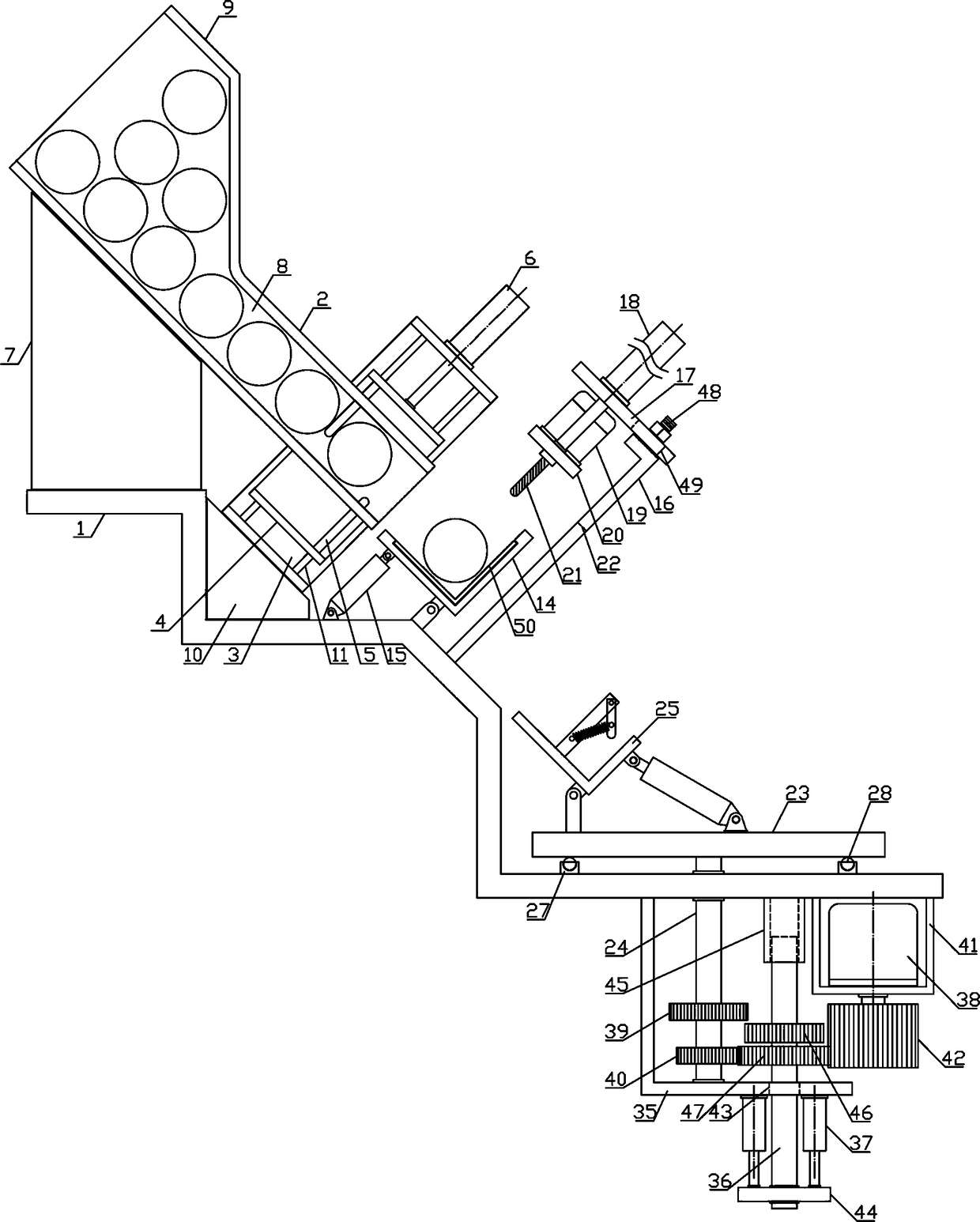

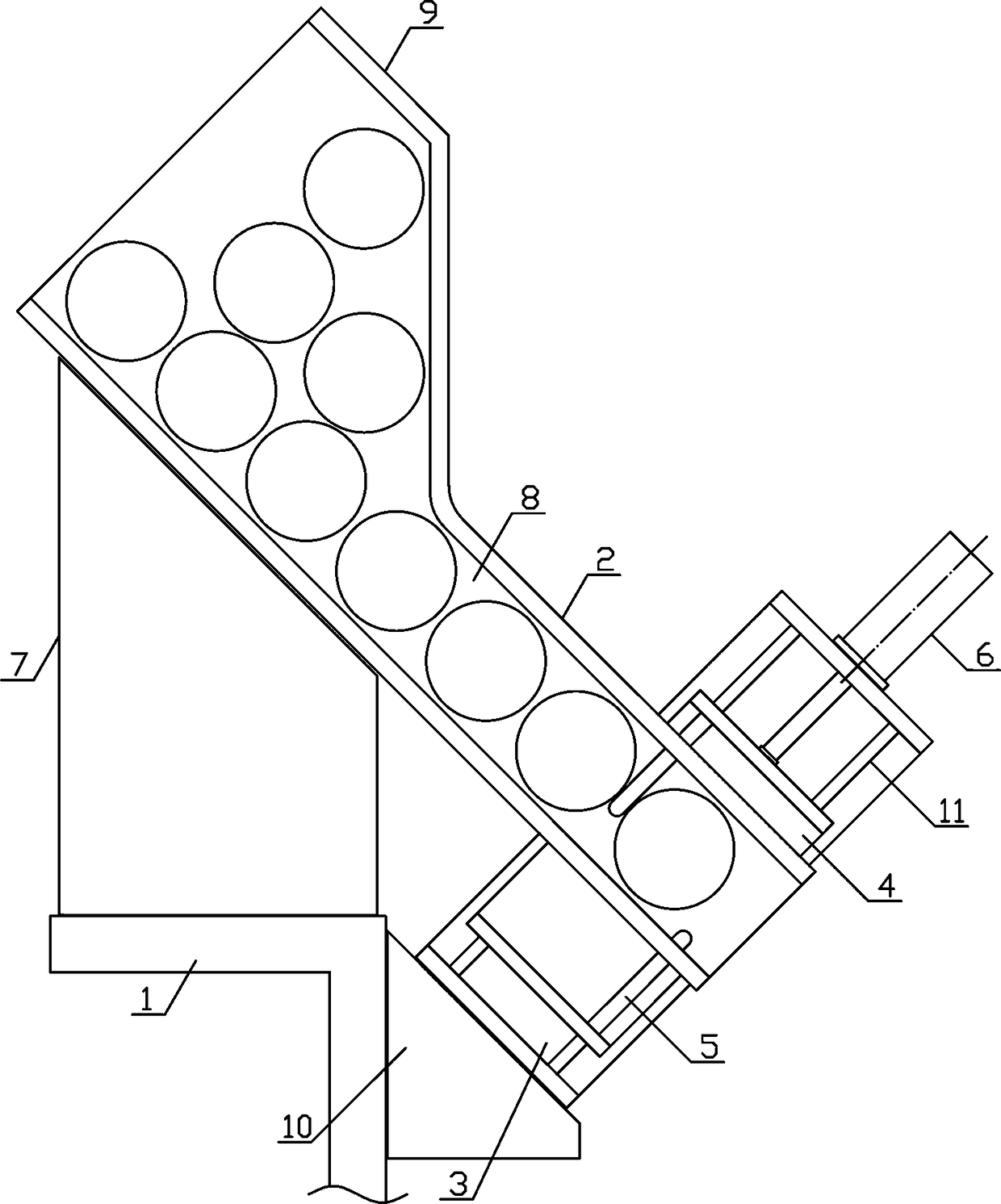

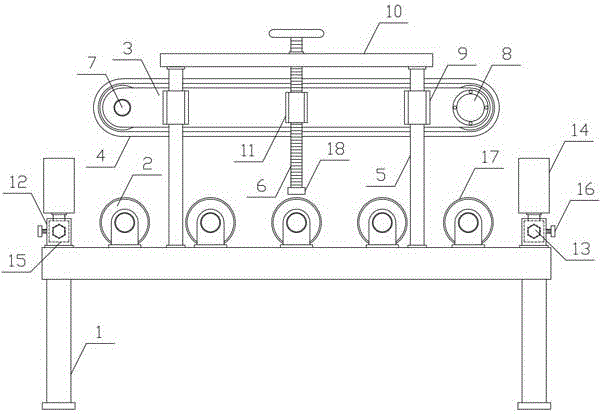

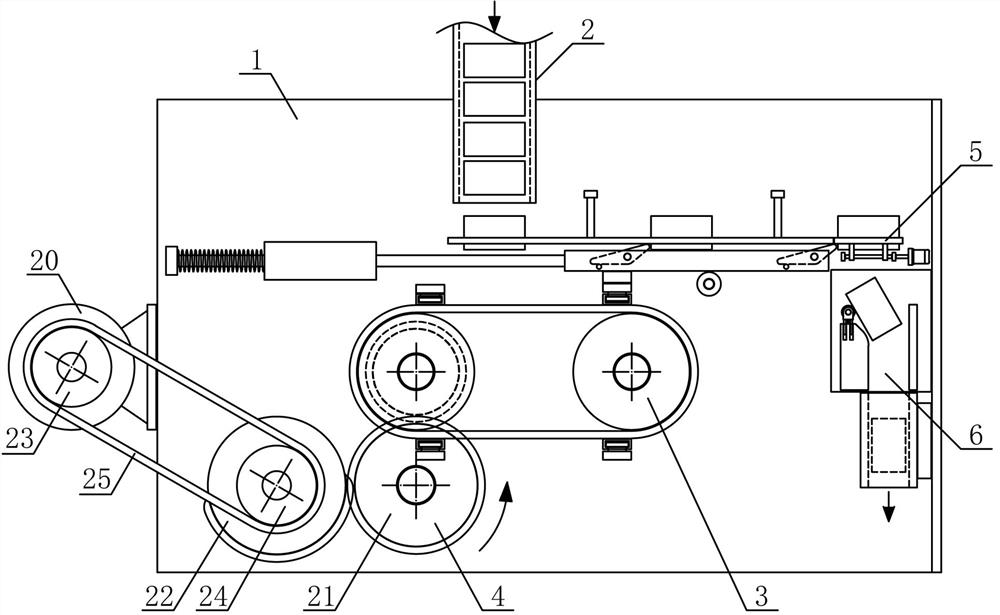

Intermittent pipe loading mechanism

InactiveCN108557448AAffect the normal and stable cuttingReasonable structural designConveyorsPackagingEngineeringMechanical equipment

The invention discloses an intermittent pipe loading mechanism, and belongs to the field of building material processing mechanical equipment. According to the mechanism, a limiting press board is obliquely arranged on the upper side of a pipe guiding oblique board downwards, pipe blanking air cylinders are symmetrically arranged on the lower side of the pipe guiding oblique board and the upper side of the limiting press board obliquely, a lifting bearing board at the output end of a pipe bearing air cylinder is arranged on a pipe bearing guiding rod in a sliding mode, a pipe blanking baffle is fixedly arranged at the output end of a baffle air cylinder on the upper side of the lifting bearing board obliquely, pipe guiding chain wheels of multiple pipe guiding rollers are in transmission connection with each other by adopting translation chains, an adjustment sleeve is arranged on a driving rotating shaft at the output end of a translation motor in a sliding mode, a material guiding rotating shaft is rotatably connected onto a connecting support on one side of the driving rotating shaft, and a damping mechanism is obliquely and fixedly arranged at the upper end of the material guiding rotating shaft. The intermittent pipe loading mechanism is reasonable in structural design, pipes of multiple kinds of dimensions can be subjected to steady blanking one by one and subjected to steady intermittent and accurate translation, so that the requirements of processing use are met.

Owner:桐乡市川泰纺织科技有限公司

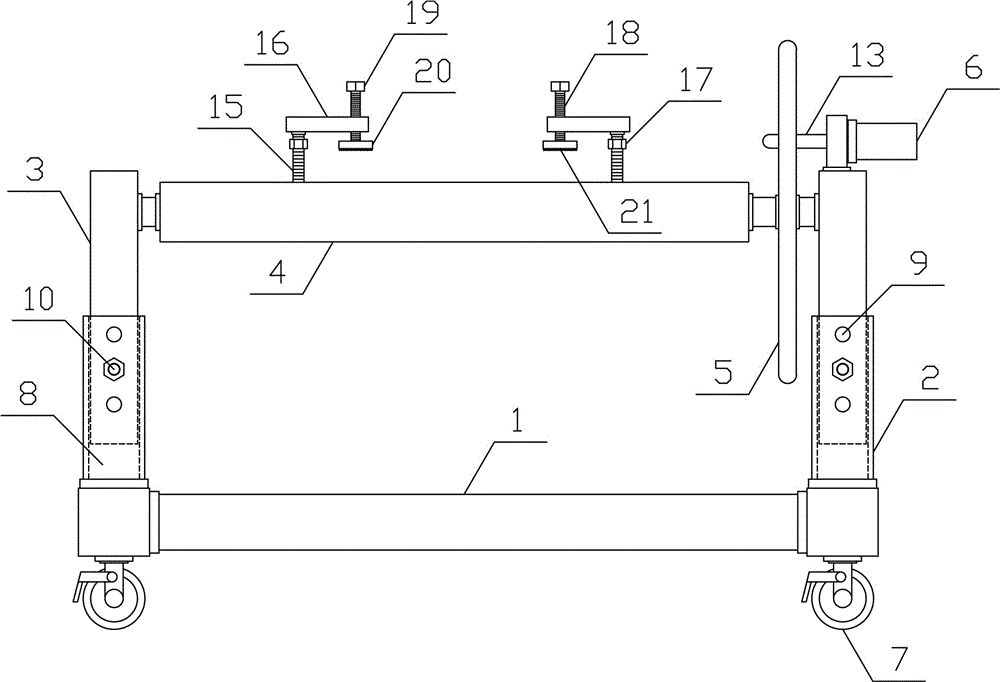

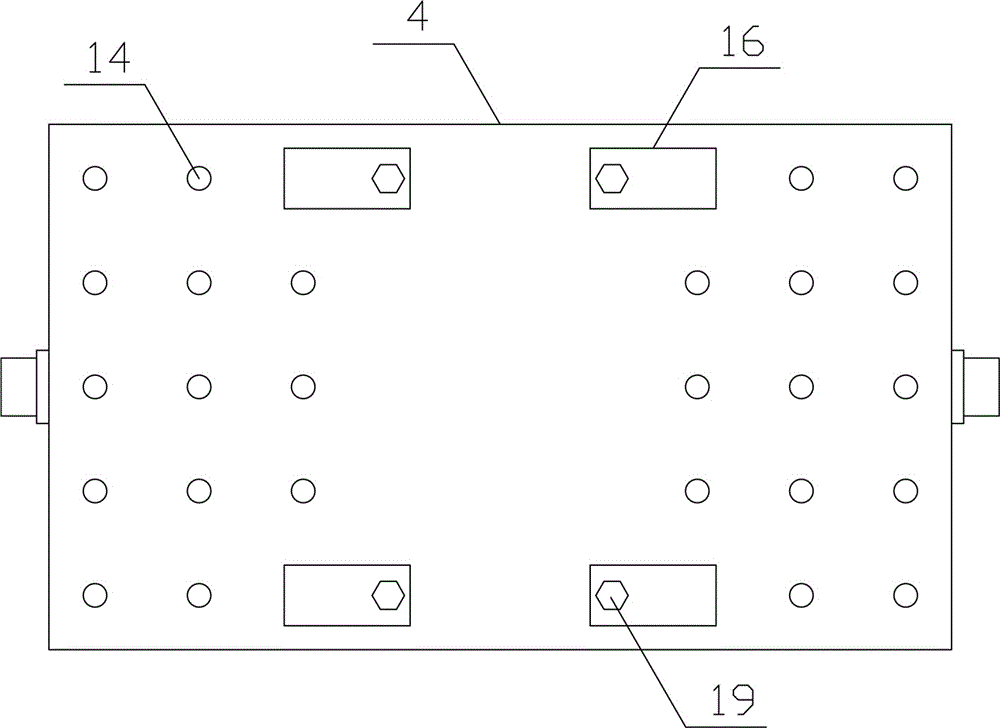

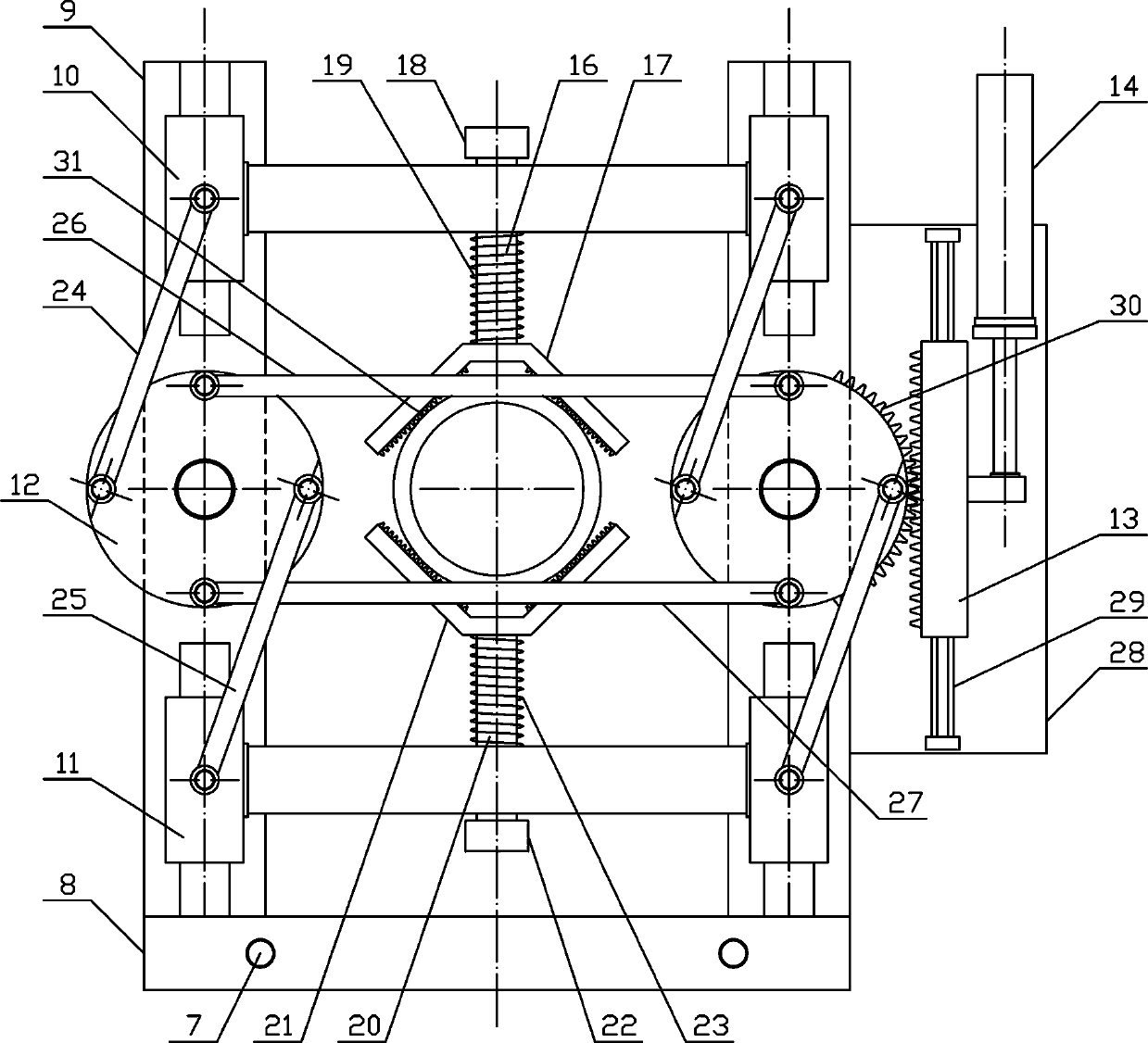

Plate machining turnover mechanism

InactiveCN106217328AAvoid offsetImprove processing efficiencyWork holdersWork benchesEngineeringMachining

The invention discloses a plate machining turnover mechanism, and belongs to the field of machining equipment. The plate machining turnover mechanism comprises a translation base, a lifting sleeve, lifting plates, a plate fixed plate, a rotating wheel disc and a fixed cylinder; multiple brake universal wheels are uniformly arranged on the lower side of the translation base; the lifting plate is vertically arranged in the lifting sleeve; the middle parts of two sides of the plate fixed plate are rotationally connected to the lifting plates on two sides above the translation base; the rotating wheel disc is vertically arranged between one side of the plate fixed plate and the lifting plates; multiple plate locking holes are uniformly formed in the upper side of the plate fixed plate; the lower end of a fixed lead screw is in threaded connection with the plate locking holes; one end of a support plate is in threaded connection with a lifting lead screw; and a plate clamping plate is arranged at the lower end of the lifting lead screw. The plate machining turnover mechanism is reasonable in structure design, can firmly press and fix plates with multiple size specifications, can overturn the plates according to the plate machining demands, and satisfies the plate machining demands.

Owner:屠明州

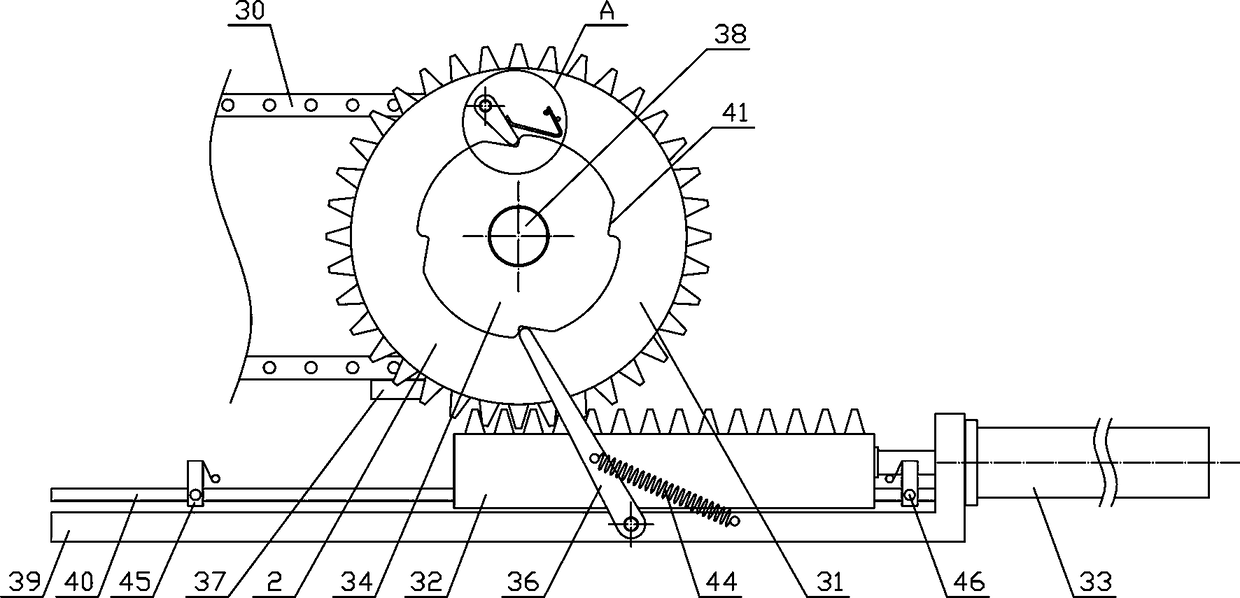

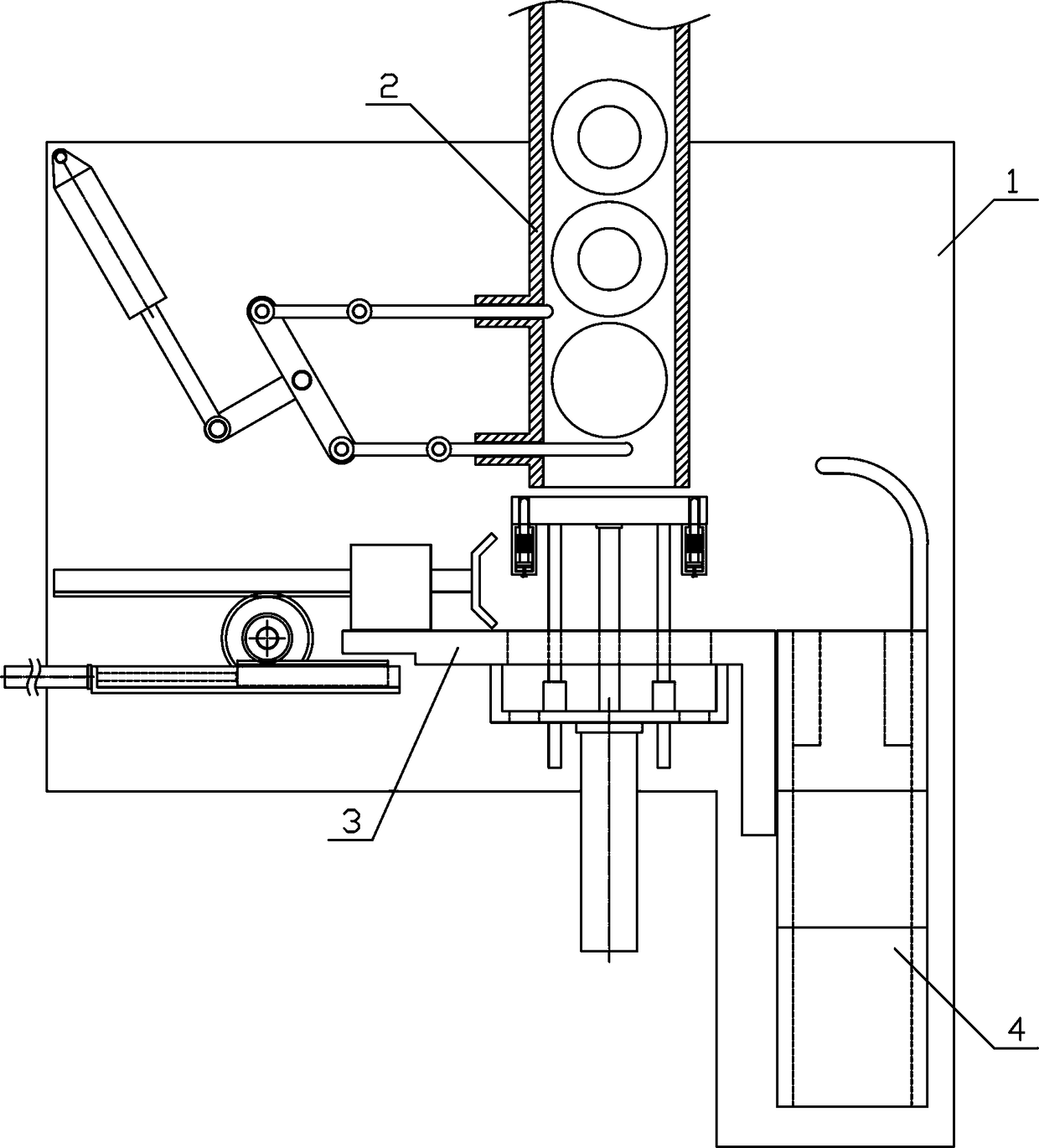

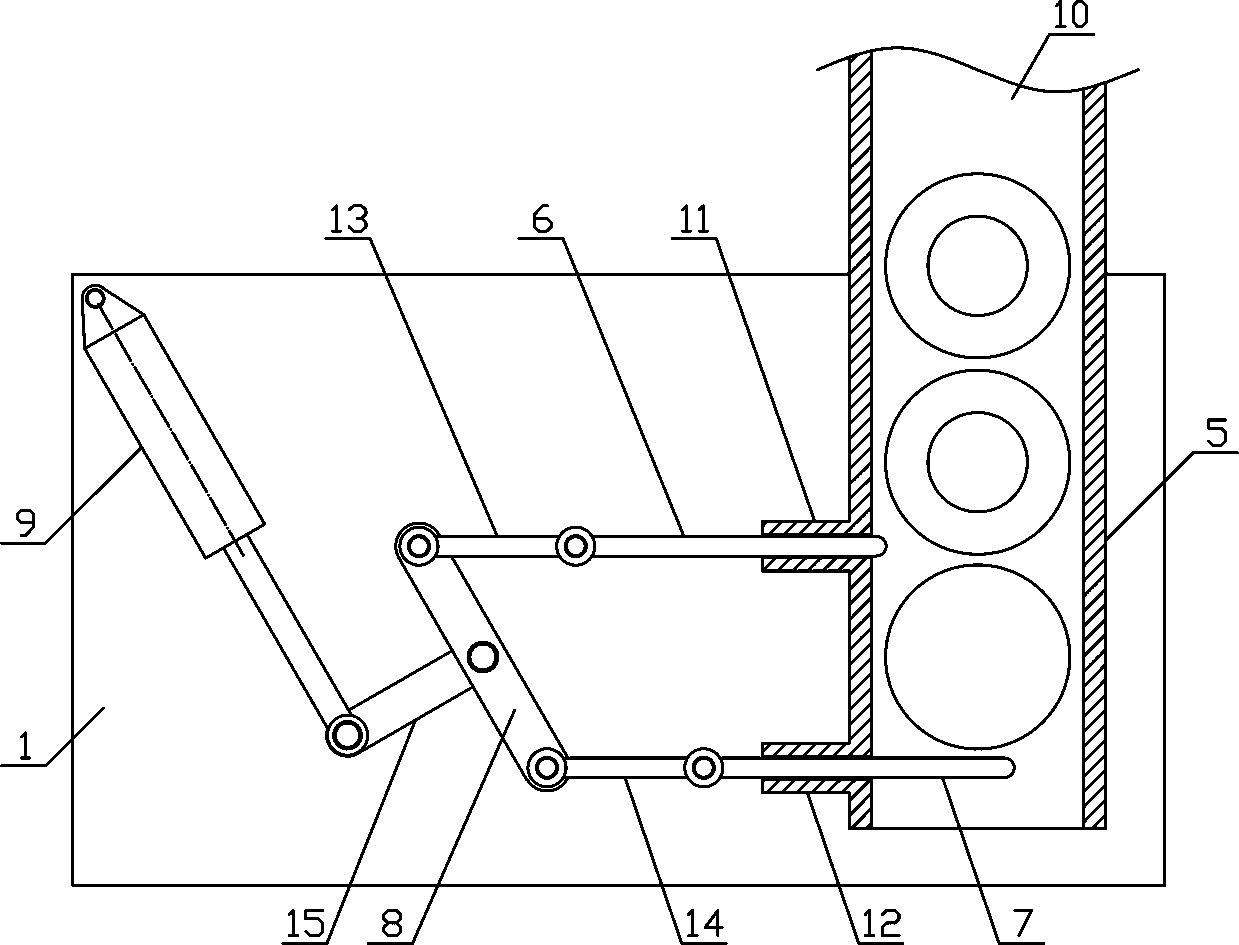

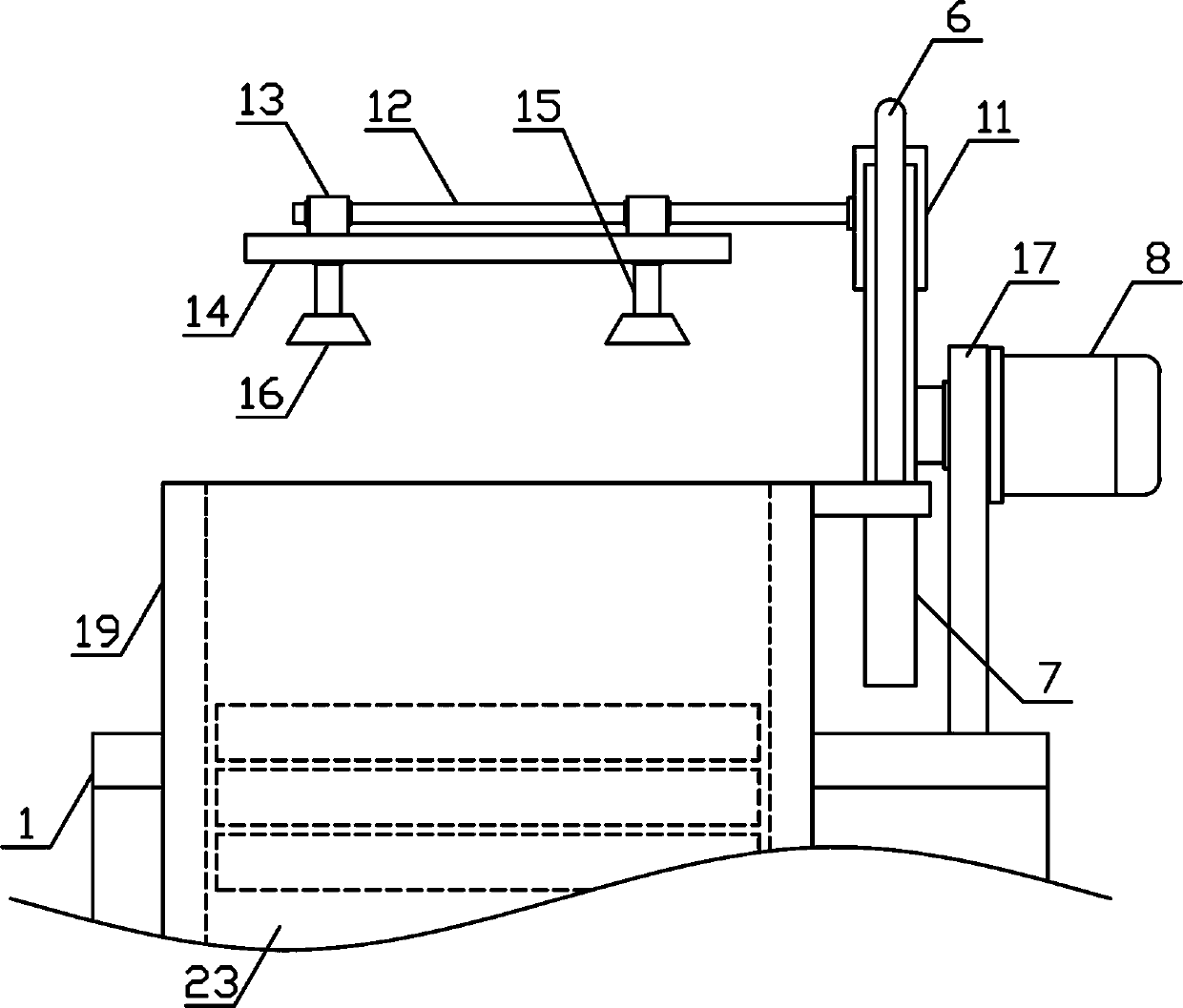

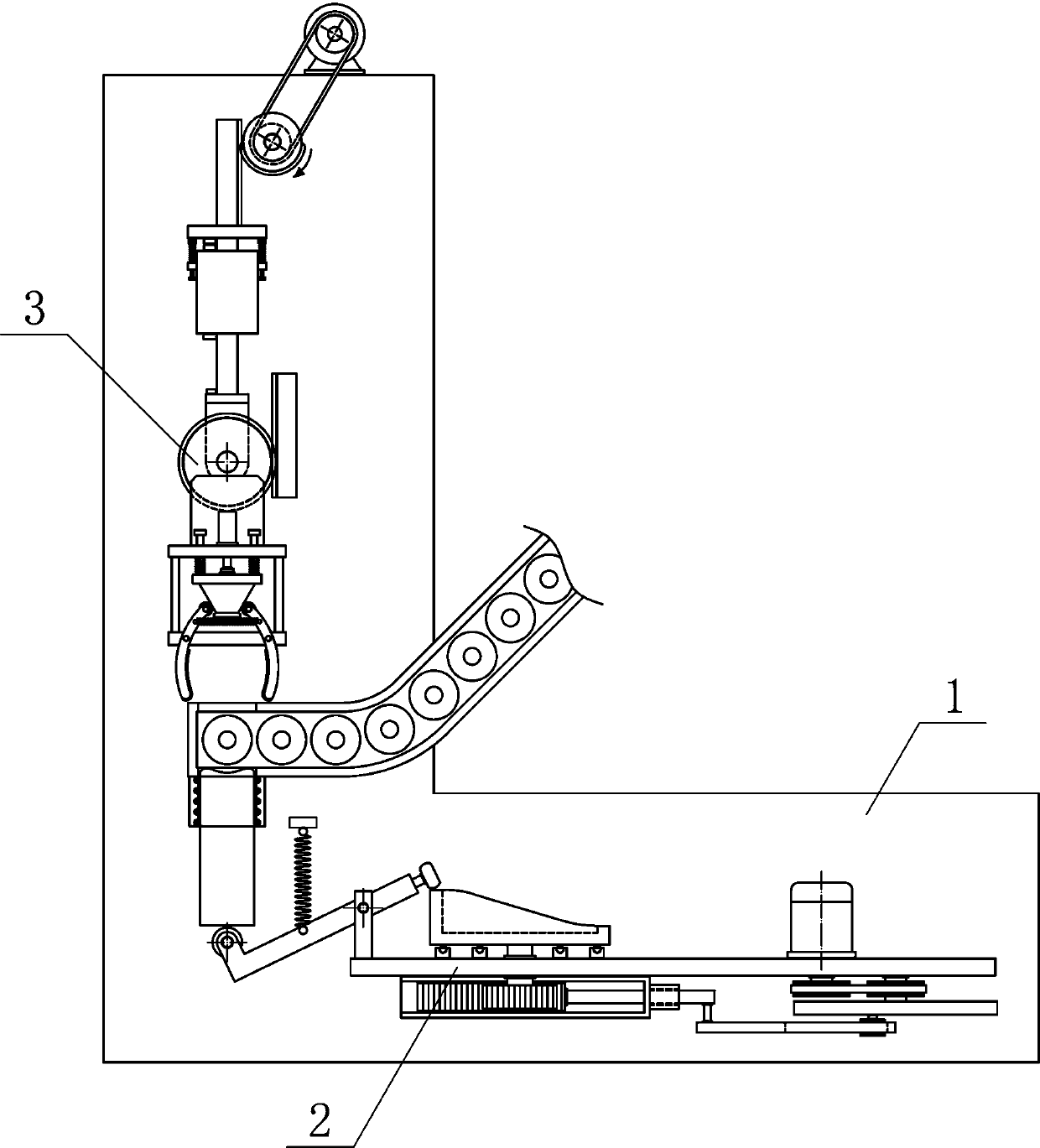

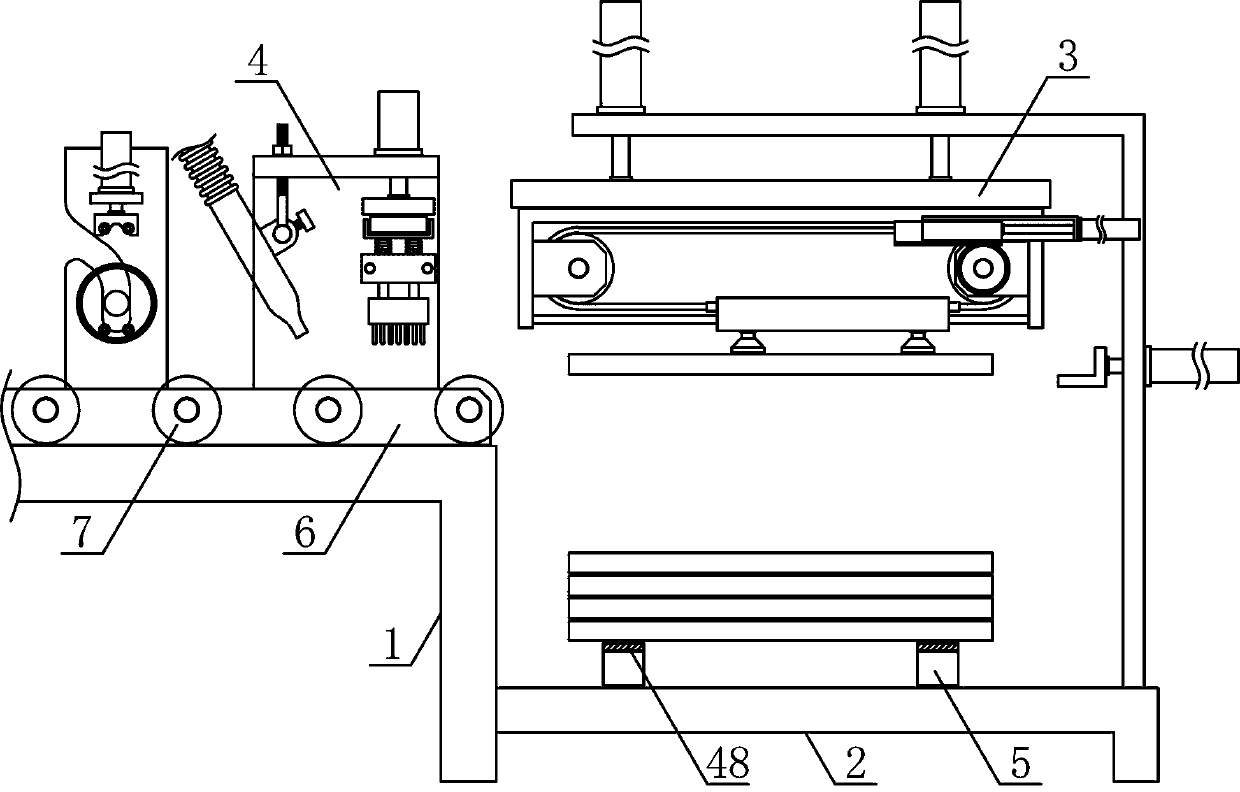

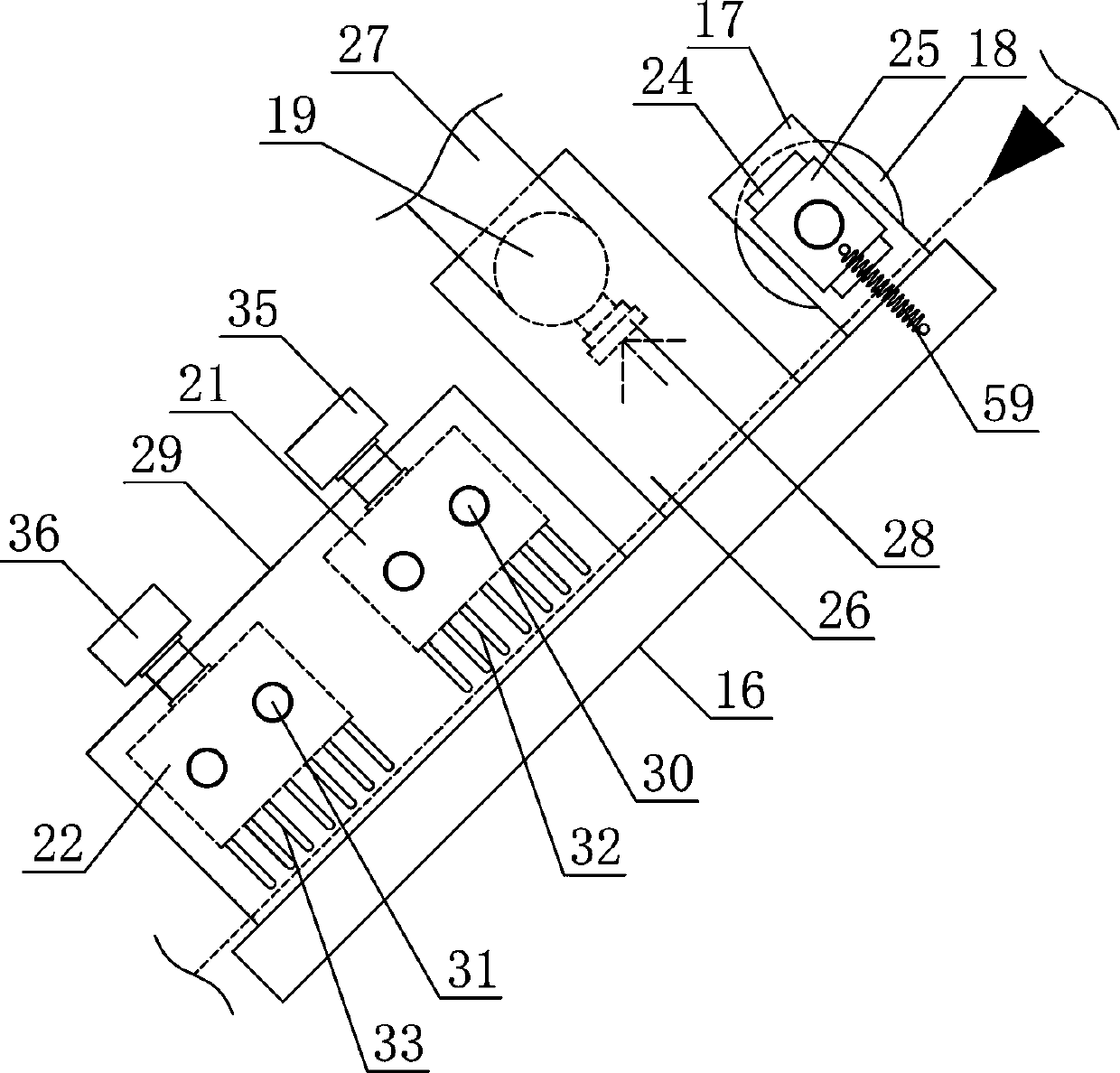

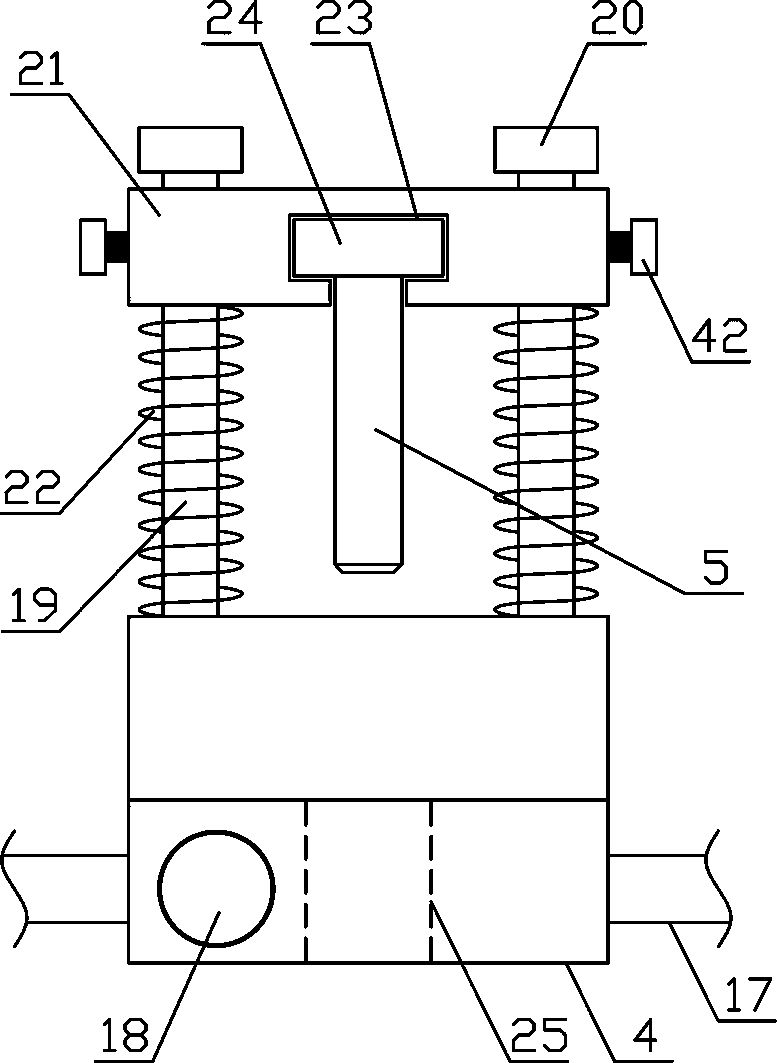

Sectional material feeding and punching mechanism

InactiveCN108526508AReasonable structural designPlay the role of speed reduction and shock absorptionMetal working apparatusBoring/drilling componentsBuilding materialMultiple dimension

The invention discloses a sectional material feeding and punching mechanism, and belongs to the field of building material processing mechanical equipment. According to the sectional material feedingand punching mechanism, a driving mechanism is horizontally arranged on one side of the lower portion of a feeding support, and a rear material bearing mechanism and a punching mechanism are fixedly arranged on one side of the upper portion of the feeding support in sequence in the horizontal direction. A feeding guide plate is arranged on a horizontal movement guide rod in a sliding mode in the horizontal direction, an adjusting guide plate is arranged on an adjusting guide rod in a sliding mode in the horizontal direction, and a material clamping support is horizontally and fixedly arrangedon the upper side of the adjusting guide plate. Two attraction armatures are uniformly and fixedly arranged on the outer side of a feeding chain, a feeding gear is vertically connected with the portion, located on one side of a feeding ratchet, of a feeding rotating shaft in a rotating mode, and a horizontal movement rack is arranged on a driving guide rod in a sliding mode in the horizontal direction. The sectional material feeding and punching mechanism is reasonable in structural design, can conduct stable accurate and intermittent feeding of sectional materials, can conduct efficient punching machining of the sectional materials as required, is suitable for feeding and machining of the sectional materials with multiple dimensions, and meets the requirements for machining and utilization.

Owner:沈洁

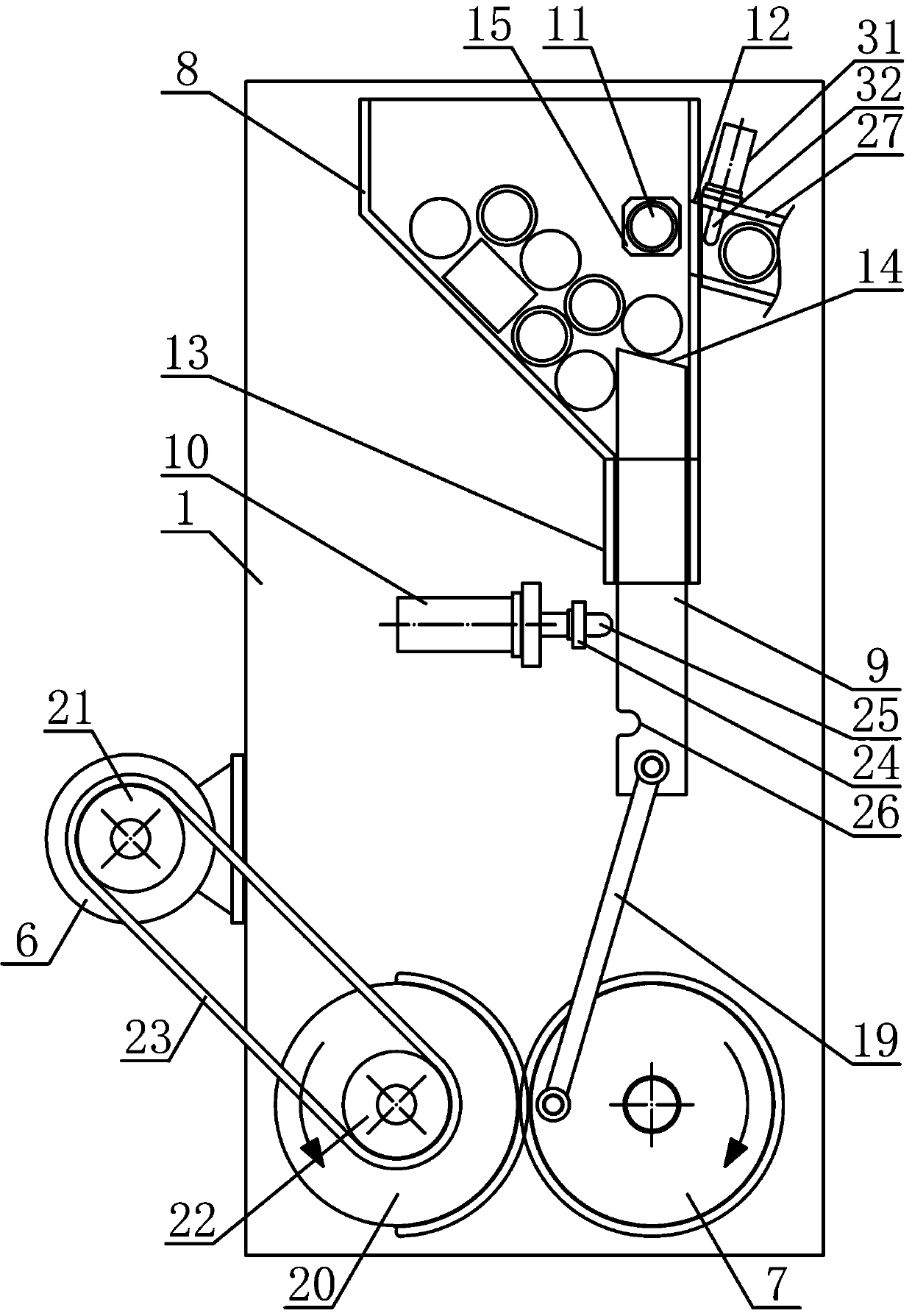

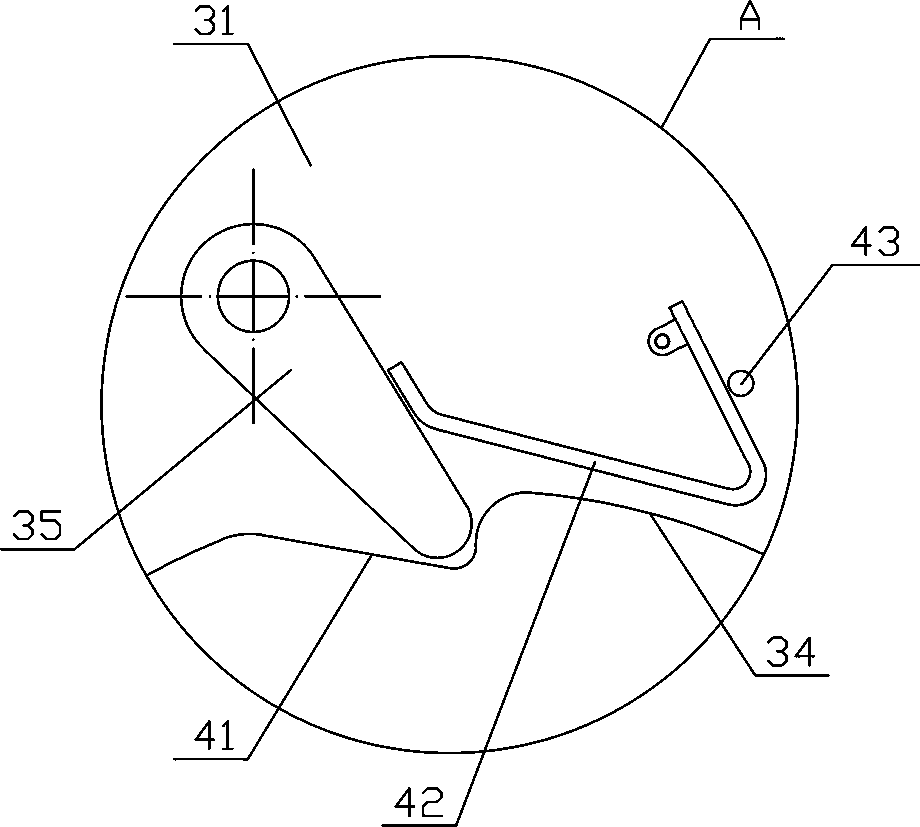

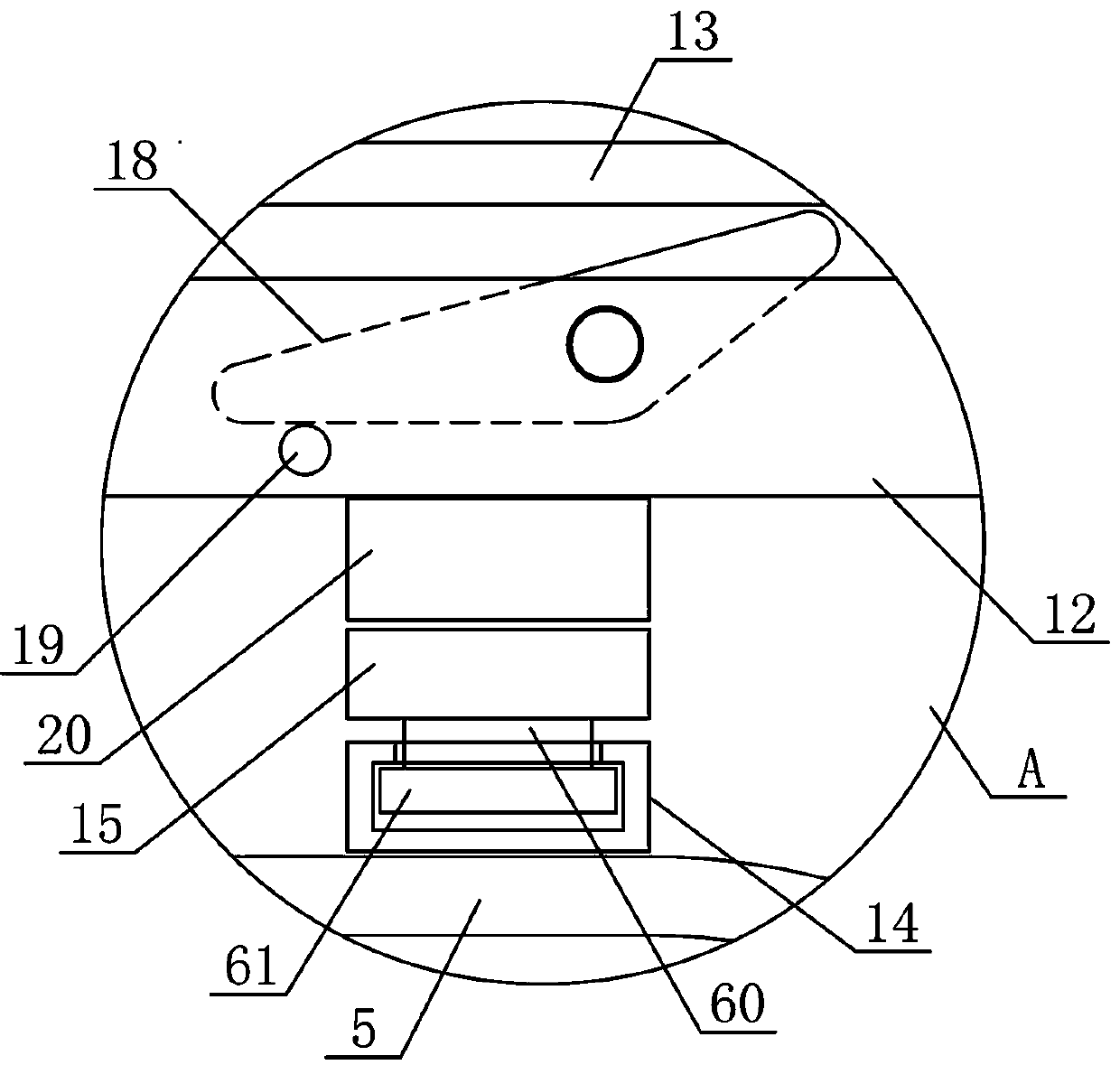

Material guide turning mechanism for end closed pipe fittings

InactiveCN109704025AReasonable structural designHigh degree of automationConveyor partsRound barEngineering

The invention discloses a material guide turning mechanism for end closed pipe fittings, and belongs to the field of workpiece processing mechanical equipment. The outer end of a pipe guide rotating plate on the lower side of a pipe storage hopper of the material guide turning mechanism is provided with a transfer pipe groove, a pipe moving guide plate is slidably arranged on a guide plate sleeve,the end of the pipe moving guide plate is provided with a pipe containing clamping slot, a reciprocating swing rod is arranged on a pipe guide support on the lower side of the pipe moving guide plate, the lower end of the reciprocating swing rod is hinged to the pipe guide support, the middle portion of one side of a turning connecting plate is fixedly arranged at the end of the side, along the pipe moving guide plate, of a fixed rotating shaft, a pipe bearing round bar is fixedly arranged on one side of a pipe bearing baffle at the output end of a pipe bearing air cylinder, and a pipe transferring belt is horizontally arranged on the upper side of a pipe transfer support. The material guide turning mechanism is reasonable in structural design, the pipe fittings can be conveniently and efficiently fed in an oriented manner one by one, the pipe fittings can be vertically turned one by one stably and accurately, the pipe fittings can be sequentially conveyed at a vertical working position, the automation degree of pipe fitting feeding and processing is carried out, and the processing and using needs are met.

Owner:TONGXIANG TANGCHAO ADVERTISEMENT CO LTD

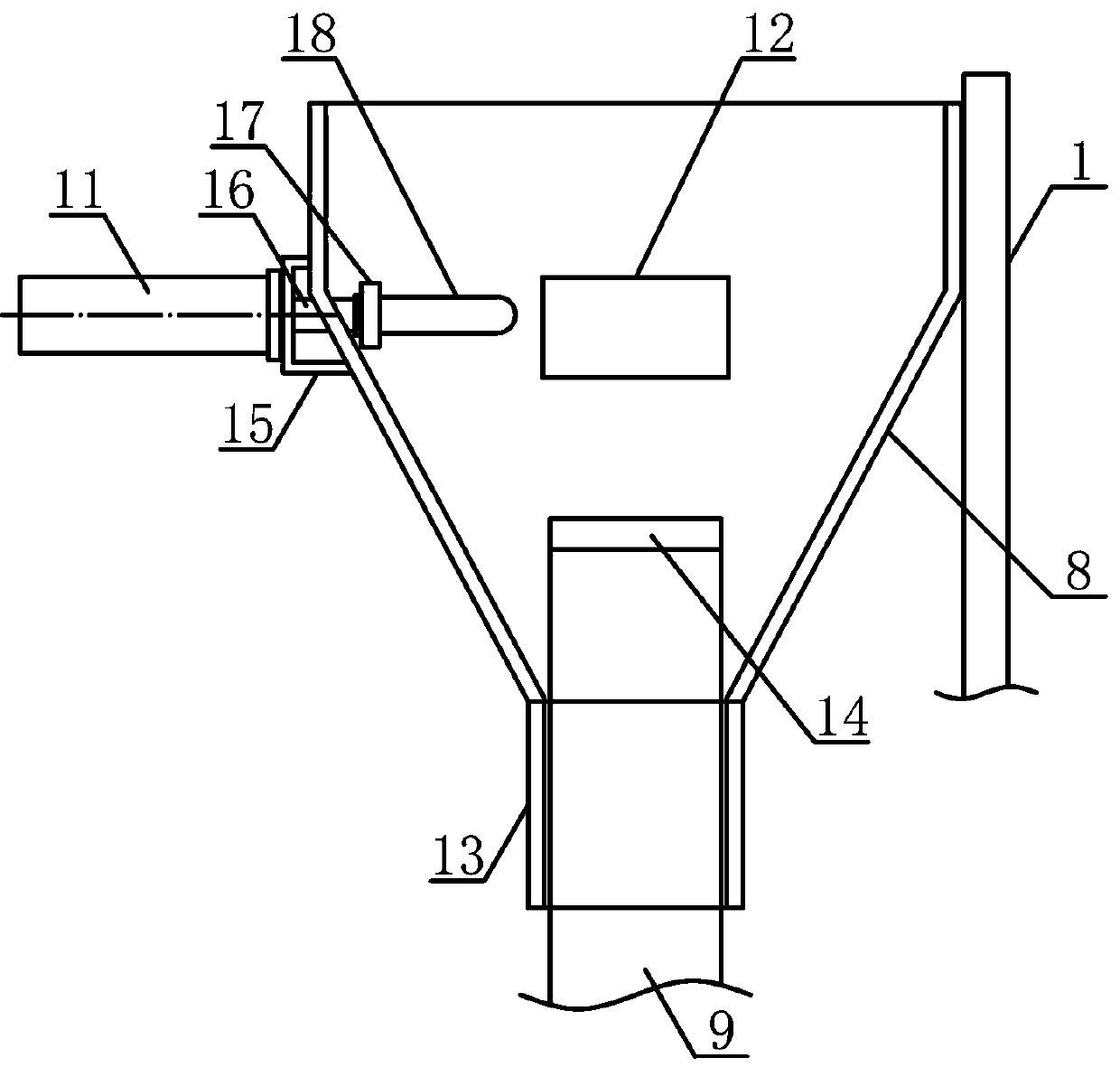

Stepped shaft type workpiece settling and feeding mechanism

InactiveCN109128974ARealize loading automationConvenient and accurate alignmentMetal working apparatusMechanical equipmentMachining

The invention discloses a stepped shaft type workpiece settling and feeding mechanism, and belongs to the field of workpiece processing mechanical equipment. A falling mechanism and a pushing mechanism are sequentially arranged on one side of a fixed support from top to bottom; an upper partition plate and a lower partition plate are sequentially and horizontally arranged on one side of a fallingpipeline from top to bottom; the output end of a bearing cylinder is fixedly connected with the middle of the lower side of a lifting bearing board; limiting mechanisms are fixedly arranged on two sides of the lower portion of the lifting bearing board vertically and upwards; a horizontal moving push rod is arranged on a horizontal moving bracket in a sliding mode in the horizontal direction and is horizontally and fixedly provided with a horizontal moving push board along the lifting bearing board; and a workpiece settling mechanism comprises a guide support, a workpiece settling hopper and adischarging pipe. The structural design is reasonable, stepped shaft type workpieces can be horizontally moved and pushed one by one stably and efficiently, the workpieces can be arrayed and fed in the fixed direction conveniently and accurately in the vertical direction, the automation degree of workpiece feeding is improved, and needs of machining and use are met.

Owner:嘉兴汉羿文化传播有限公司

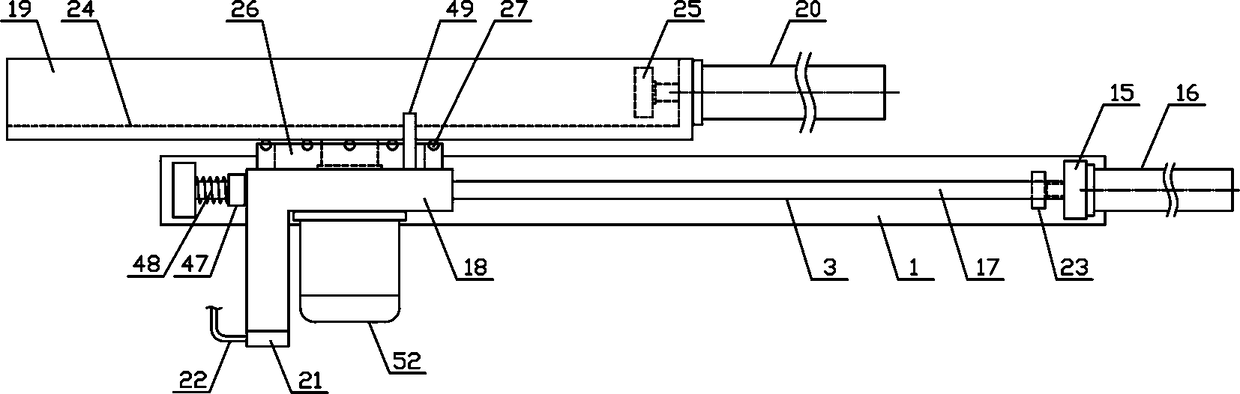

Pipe fitting reversing and feeding mechanism

InactiveCN108820802ASmooth slidingRealize automatic adjustmentConveyor partsPipe fittingMechanical equipment

The invention discloses a pipe fitting reversing and feeding mechanism, and belongs to the field of workpiece machining and conveying mechanical equipment. A reversing mechanism is vertically disposedon one side of the upper portion of a fixed bracket, and a pipe-guiding mechanism is obliquely and downwardly disposed on the fixed bracket on the lower side of the reversing mechanism; a turnover mechanism is vertically disposed on the fixed bracket on the lower side of the pipe-guiding mechanism, and a pipe-discharging charge-pipe is horizontally arranged at the lower end of a pipe-guiding charge-pipe in a communicating mode; a pipe-limiting mechanism is fixedly arranged on the lower side of a pipe-placing clamping groove in inclined and upward modes, wherein the pipe-placing clamping groove is formed in the lower end of a pipe-blocking connecting plate; a pipe-blocking fixing block is fixedly and horizontally arranged in the middle of the pipe-guiding charge-pipe, and a pipe-feeding push plate of a circular arc structure is vertically arranged at the upper end of a pipe-pushing turnover plate; and the upper end of a slide downward charge-pipe communicates with the lower end of thepipe-guiding charge-pipe, and one end of a pipe-collecting turnover plate is connected to the upper side of the slide downward charge-pipe in a hinged mode. The pipe fitting reversing and feeding mechanism is reasonable in structural design, and pipe fittings can be transferred smoothly and conveniently one by one in a reversing mode, turnover is carried out accurately during the pipe fitting feeding process, thereby the automatic adjustment of pipe fitting working stations is realized, and the needs of machining and use are met.

Owner:嘉兴汉羿文化传播有限公司

Round can shunting feeding transfer mechanism

InactiveCN108657787APrevent slidingAccurate reciprocating slidingConveyorsConveyor partsEngineeringTransfer mechanism

The invention discloses a round can shunting feeding transfer mechanism, and belongs to the field of container equipment processing machinery equipment. Two can transfer mechanisms are horizontally arranged on a fixed bracket which is located on one side of the shunting mechanism from top to bottom. The middle portion of the upper part of an upper can guiding pipe communicates with the lower end of a can bearing hopper, and the upper can guiding pipe and a lower can material pipe are integrally shaped. A shunting rotary plate is vertically arranged in a rotating clamping groove of a rotating bracket, a round can clamping groove is formed in the outer side of the shunting rotary plate in the radial direction of the shunting rotary plate, and a can pushing cylinder is horizontally fixedly arranged on a can pushing bracket on one side of the round can clamping groove. A turning rotating shaft is horizontally rotatably connected to the upper side of a turning bracket. An arc-shaped grooveplate is horizontally fixedly arranged on the outer side of a turning connecting plate, and a turning can groove is formed in the arc-shaped groove plate. According to the round can shunting feeding transfer mechanism, the design is reasonable, round cans can be transported smoothly and sequentially one by one, so that the round cans be transported in a shunting mode, and the automatic turning ofthe round cans can be realized in the process of the shunting transfer of the round cans so as to meet the needs of processing and use.

Owner:海宁市波菲特进出口有限公司

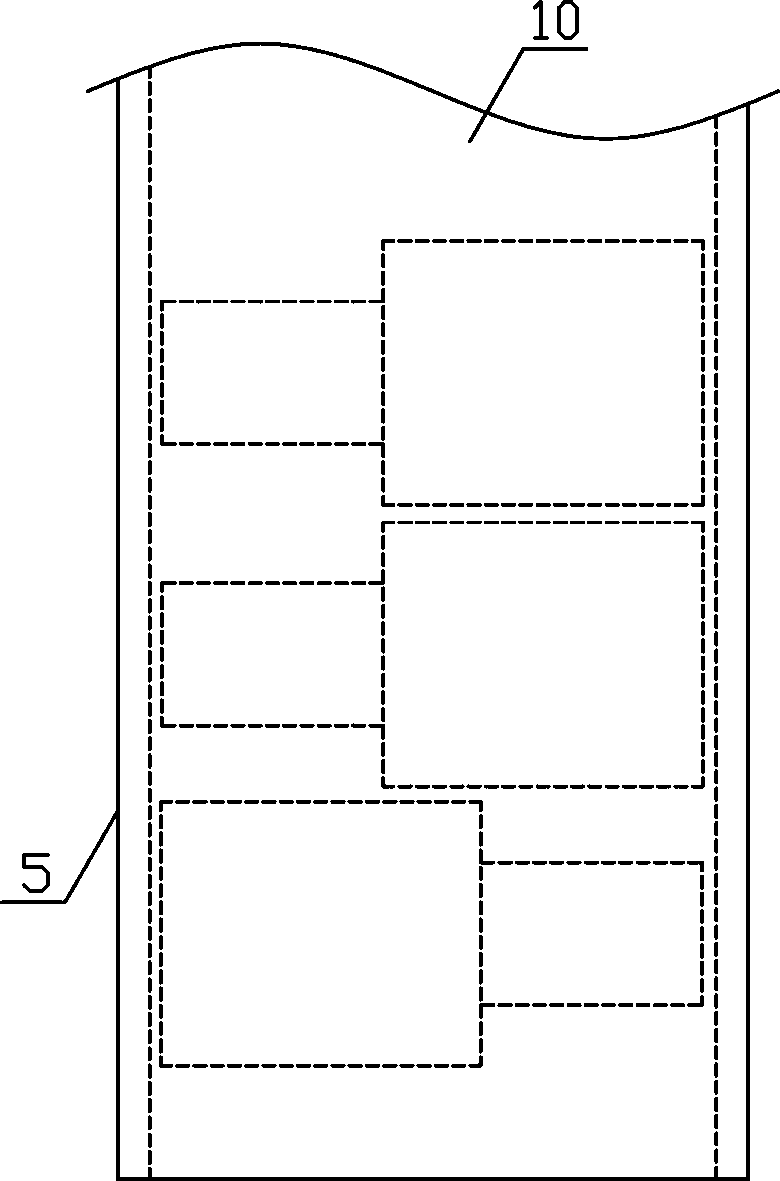

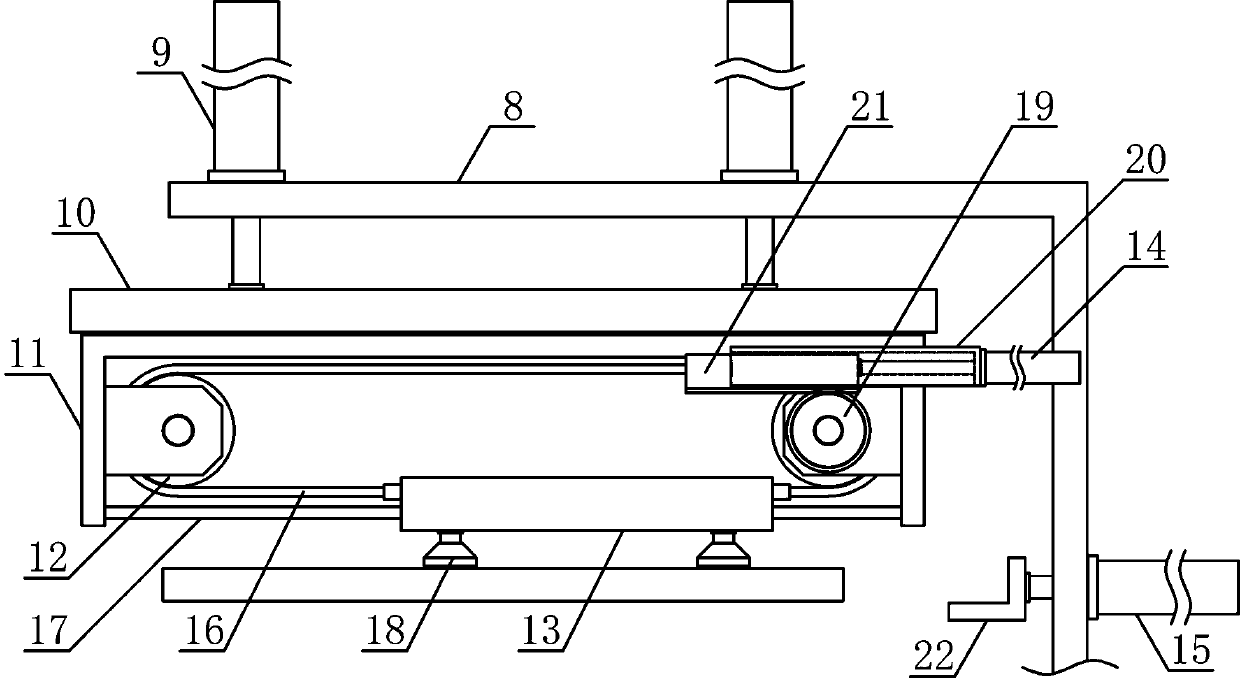

Sheet workpiece continuous feeding mechanism

InactiveCN109648378AReasonable structural designRealize continuous feedingMetal working apparatusEngineeringMechanical equipment

The invention discloses a sheet workpiece continuous feeding mechanism and belongs to the field of workpiece machining and conveying mechanical equipment. A feeding mechanism body and a material conveying mechanism of the feeding mechanism are sequentially arranged on the part, on one side of a material guiding mechanism, of a fixing bracket in the horizontal direction; a translation bracket is horizontally arranged on the part, on the lower side of a storage hopper, of the fixing bracket; a translation connecting plate is slidably arranged on a translation guide bar in the horizontal direction; the middle of the lower side of a rotating disc is fixedly connected with the upper end of a feeding rotating shaft; a material suction guiding plate is vertically arranged on one side of a material suction bracket; the output end of a material suction air cylinder is fixedly connected with the middle of one side of the material suction guiding plate; a plurality of material suction mechanismsare sequentially and uniformly arranged on the material suction guiding plate in the horizontal direction; and a material conveying belt is arranged on the upper side of a material conveying bracket.The feeding mechanism is reasonable in structure design, a plurality of sheet workpieces can be sequentially sucked and fixed, and the multiple sucked and fixed sheet workpieces can be synchronously transferred and conveyed, so that the sheet workpiece feeding automation degree is increased, and the machining demands are met.

Owner:嘉兴汉羿文化传播有限公司

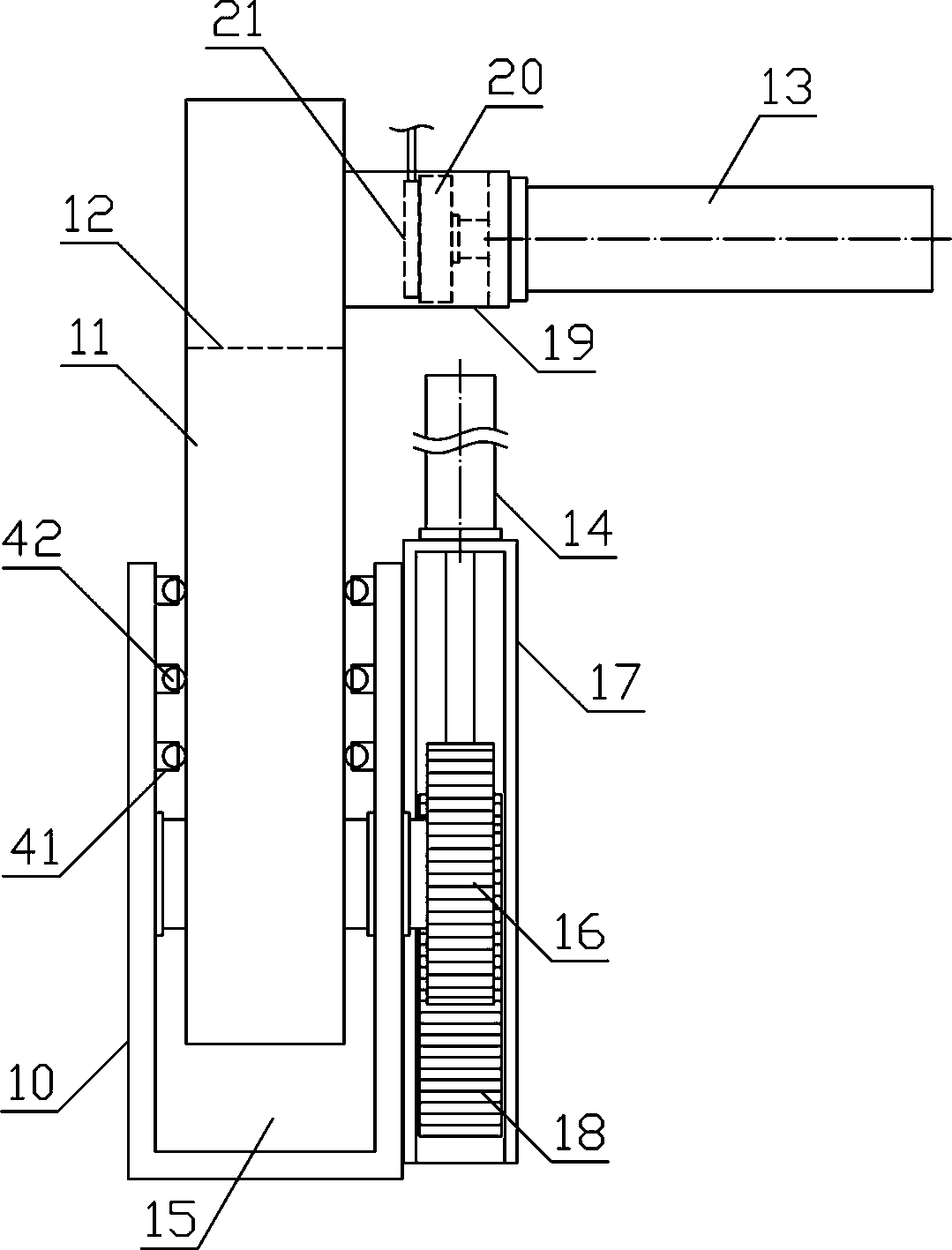

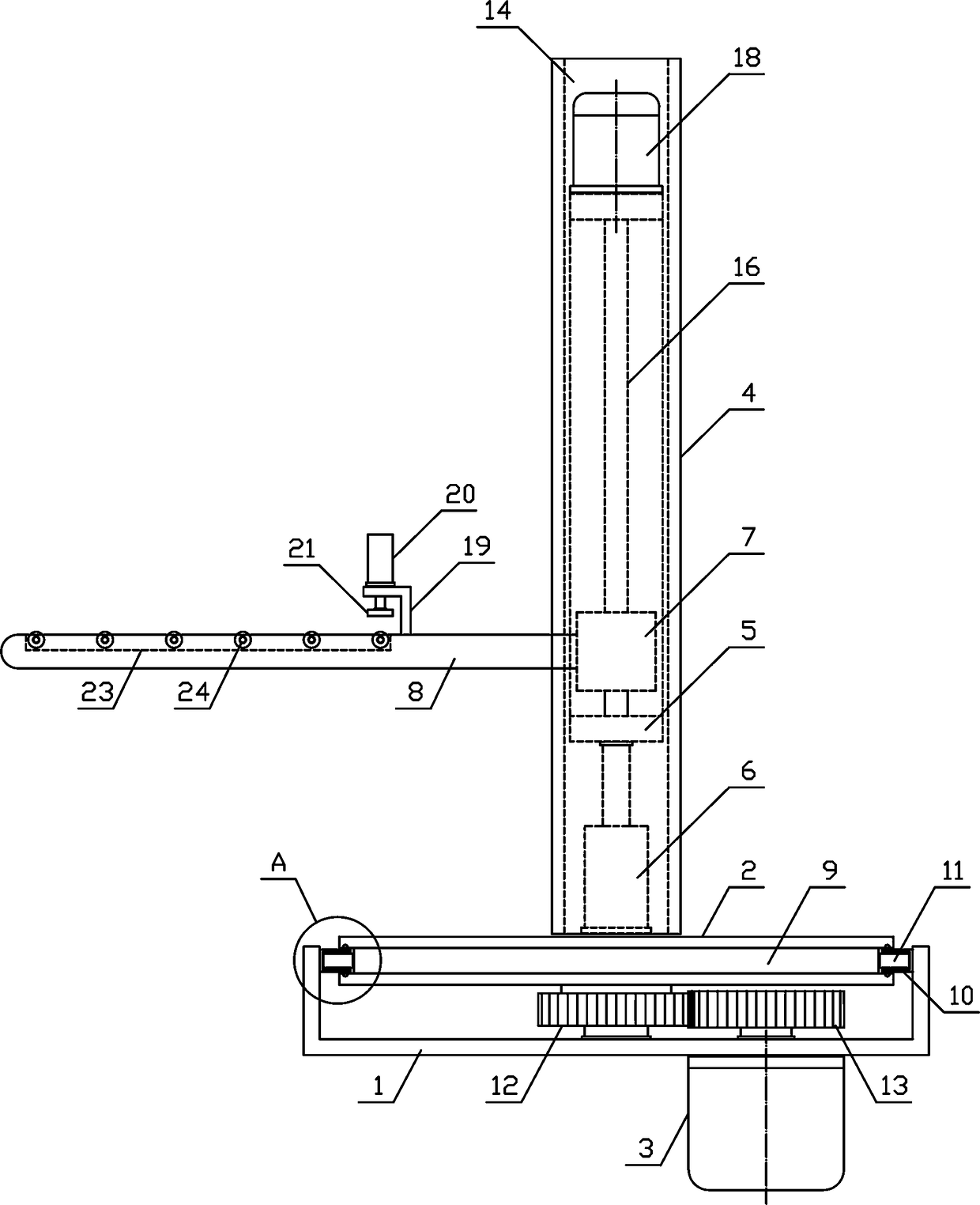

Shaft sleeve continuous vertical lifting mechanism

InactiveCN108861542AAdjust reciprocating rangeAvoid inertia shockLifting framesConveyor partsMechanical equipmentSprocket

The invention discloses a shaft sleeve continuous vertical lifting mechanism, and belongs to the field of workpiece machining mechanical equipment. The shaft sleeve continuous vertical lifting mechanism comprises a fixing bracket, a shaft sleeve transferring mechanism and a lifting mechanism. Buffers are fixedly arranged on the fixing bracket on both ends of one side of a swinging cylinder separately, and the buffers are arranged vertically upwards. A shaft sleeve receiving connection plate is horizontally and fixedly arranged on one side of a translation bracket, rotating sprockets are connected to the upper and lower sides of a lifting bracket, and the upper and lower sides of a lifting chain separately mesh with the rotating sprockets in a winding mode. A lifting guide plate is slidablyarranged on a lifting guide rod in the vertical direction, limiting switches are separately arranged on the lifting bracket on the upper and lower sides of a limiting connecting plate, and a shaft sleeve clamping mechanism is horizontally arranged on one side of the lifting guide plate. The shaft sleeve continuous vertical lifting mechanism is reasonable in structural design, can clamp and fix shaft sleeves of various sizes and specifications conveniently and firmly, and can vertically lift the shaft sleeves more stably and efficiently so that the shaft sleeves can be transferred to requiredworking positions, the automation degree of shaft sleeve transferring is improved, and the needs of processing and use are met.

Owner:晋正正

Sheet workpiece pushing feeding mechanism

InactiveCN110921285AReasonable structural designHigh degree of automationConveyorsStacking articlesEngineeringMechanical equipment

The invention discloses a sheet workpiece pushing feeding mechanism, and belongs to the field of conveying mechanical equipment for workpiece machining. A material pushing mechanism of the sheet workpiece pushing feeding mechanism is vertically arranged on the portion, at the lower side of a material moving mechanism, of a fixed support, and a turnover mechanism is vertically arranged on the portion, at one side of a material pushing mechanism, of the fixed support; a material feeding pipe is vertically arranged on one side of a material conveying belt, a translation pushing plate is slidablyarranged on a material pushing base in the horizontal direction, and a discharging slot matched with the size and dimension of a discharging channel is horizontally formed in one side of the upper portion of the translation pushing plate; and the output end of a feeding cylinder is fixedly connected with the middle of one side of a feeding guide plate, a turnover rotating shaft is horizontally androtationally connected in a rotating shaft sleeve at the output end of each turnover cylinder, and a conveying guide belt is horizontally arranged on one side of the lower portion of a conveying support. The sheet workpiece pushing feeding mechanism is reasonable in structural design, continuous translation feeding of sheet workpieces can be achieved, the sheet workpieces can be subjected to translation and turnover conveying piece by piece, the automation degree of sheet workpiece feeding is improved, and the machining and using requirement are met.

Owner:沈洁

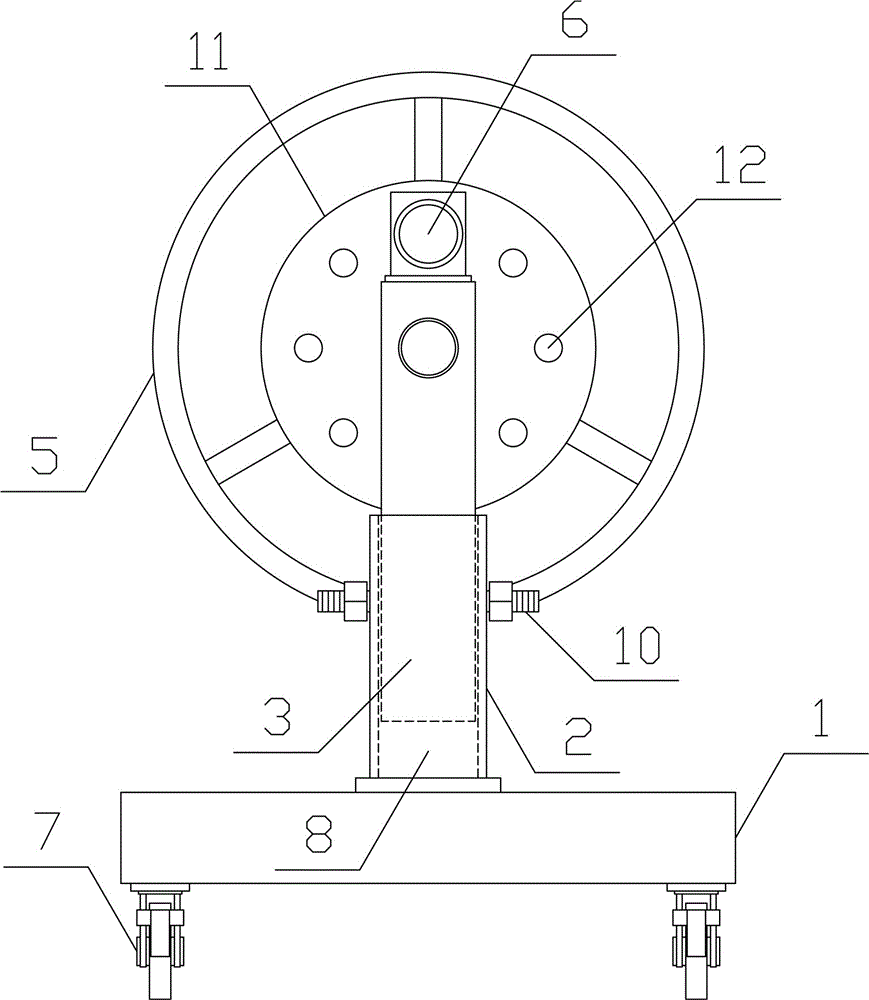

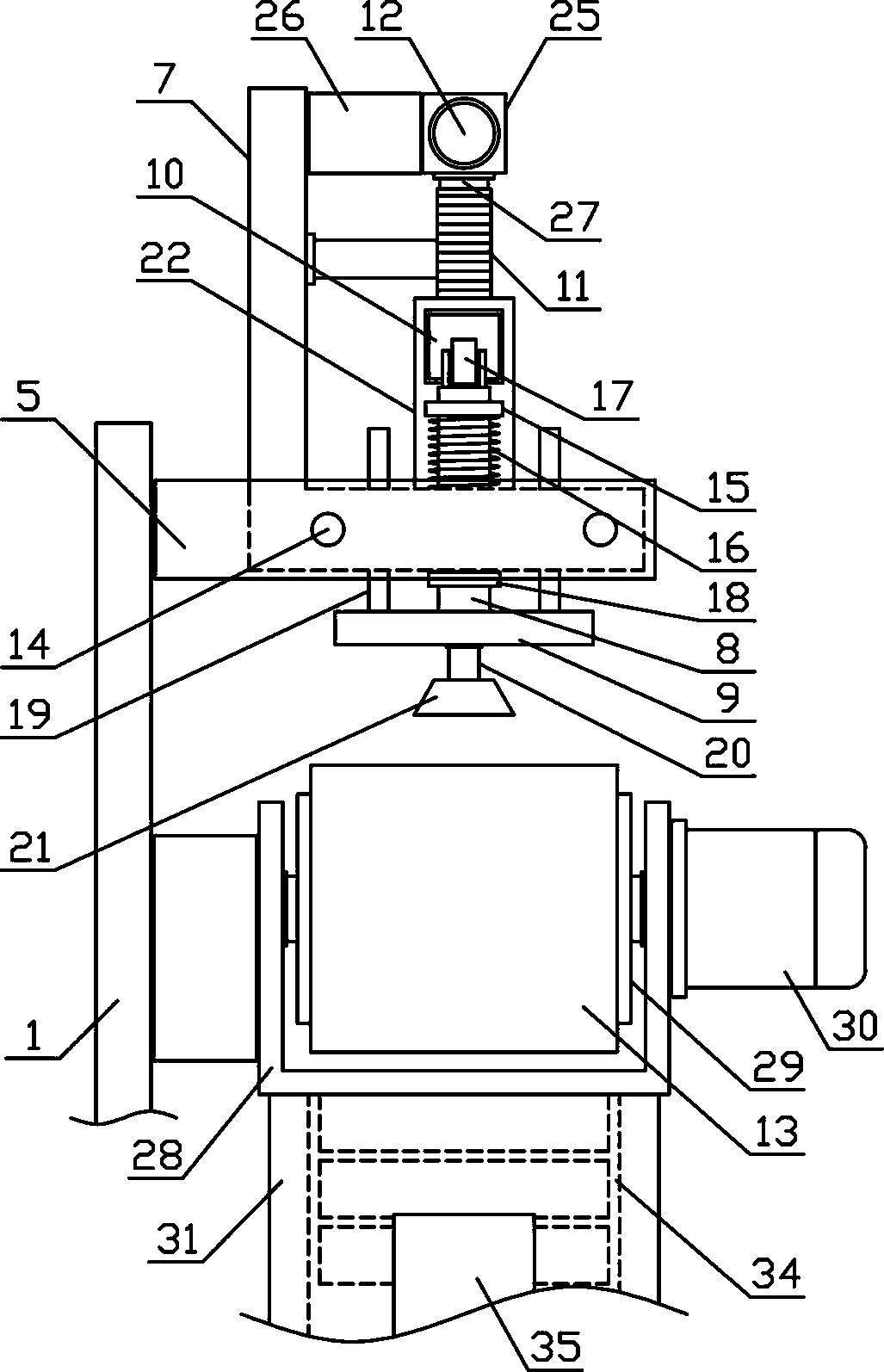

Steel pipe circular weld mechanism

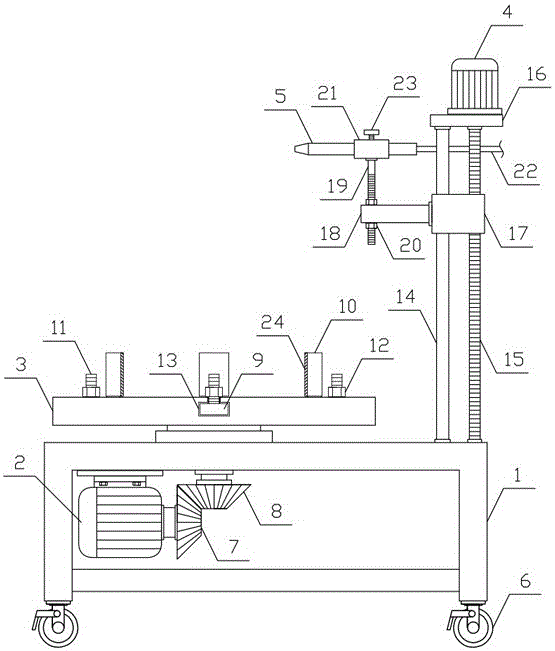

ActiveCN105904148ASimple structureImprove efficiency and qualityWelding/cutting auxillary devicesAuxillary welding devicesSteel tubeWeld seam

The invention discloses a steel pipe circular weld mechanism and belongs to the field of steel pipe machining mechanical equipment. The steel pipe circular weld mechanism comprises a horizontal moving support, a rotation motor, a steel pipe holding plate, a lifting motor and a steel pipe welding gun, wherein a plurality of universal wheels with brakes are evenly arranged on the lower side of the horizontal moving support; the round steel pipe holding plate is horizontally and rotatably connected on the upper side of the horizontal moving support; a plurality of steel pipe clamping mechanisms are symmetrically arranged on the steel pipe holding plate in the radial direction; a lifting guide rod and a lifting screw rod are vertically arranged on one side of the upper portion of the horizontal moving support correspondingly; a lifting support can go up and down along the lifting guide rod; hold-down nuts are connected on an adjustment screw rod on the upper side and the lower side of a fixation plate in a threaded mode; a horizontal moving sleeve is horizontally arranged at the upper end of the adjustment screw rod; and the steel pipe welding gun can move horizontally along the horizontal moving sleeve. The steel pipe circular weld mechanism is reasonable in structural design and capable of vertically and firmly fixing steel pipes and conducting circular welding on the steel pipes conveniently and efficiently, and meets the requirements for machining and using.

Owner:GUANGDONG WALSALL STEEL PIPE IND

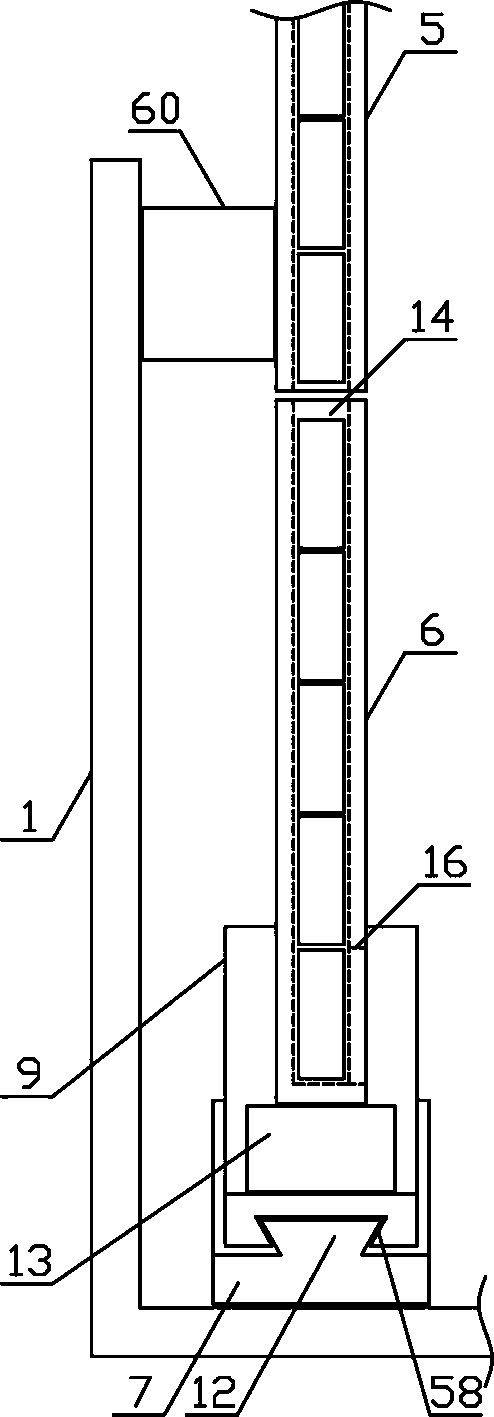

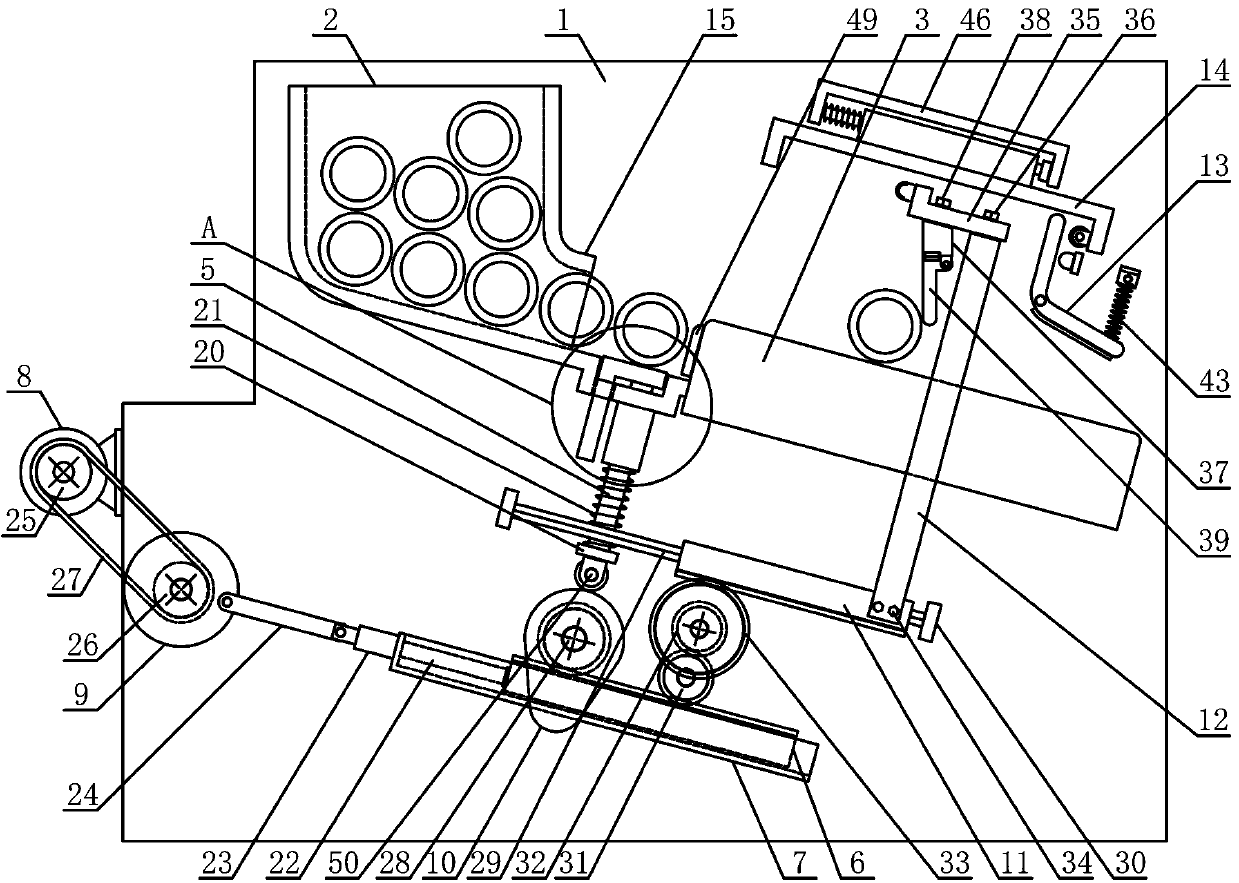

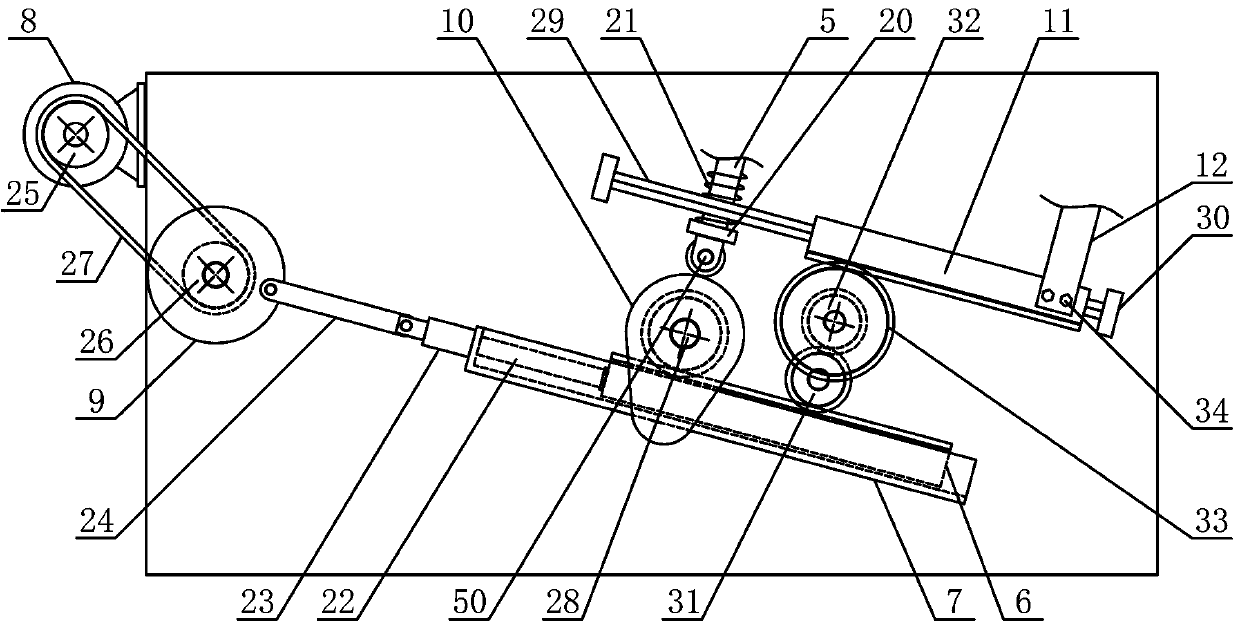

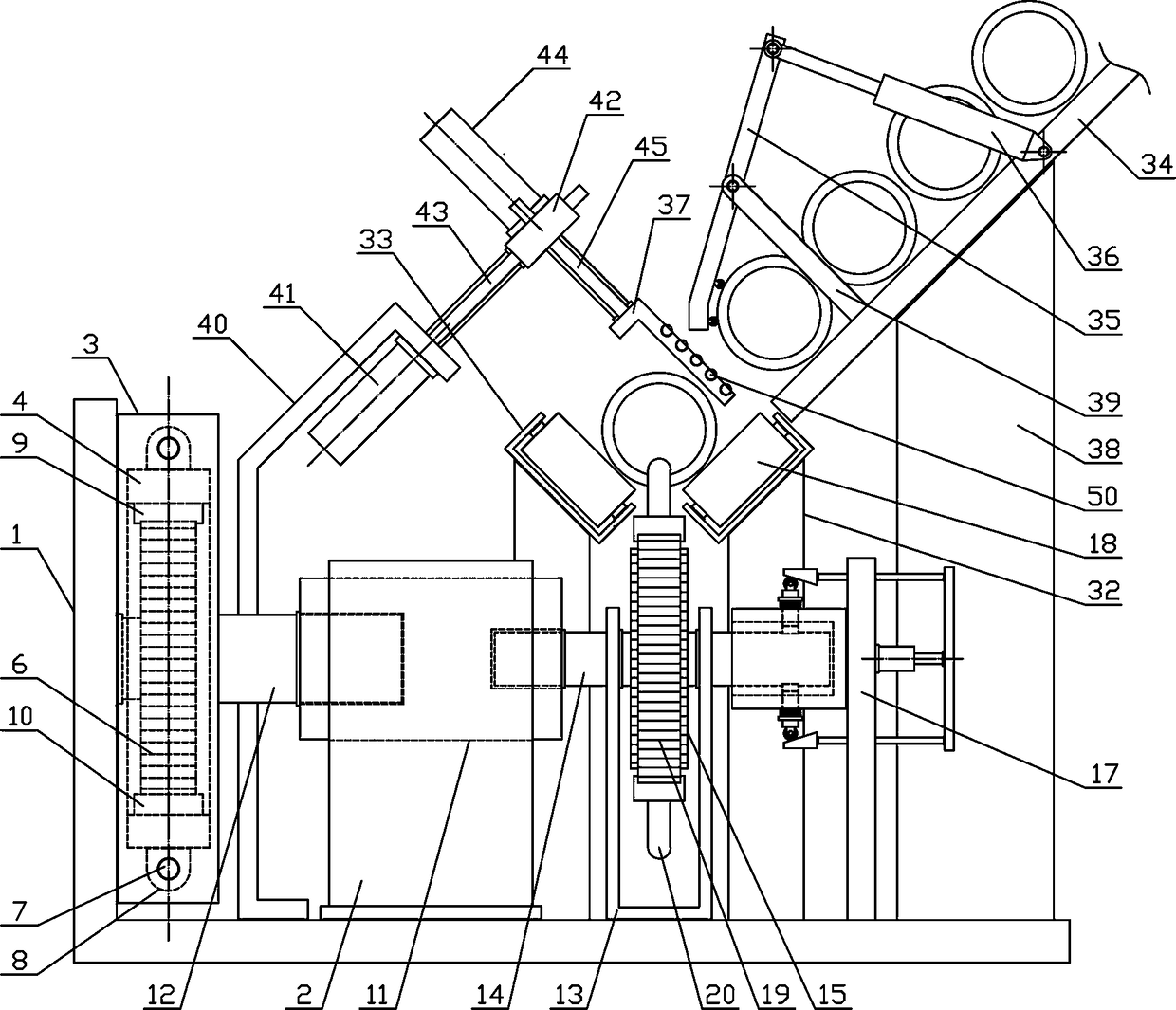

Chemical fiber bobbin continuous transferring and feeding device for chemical fiber processing

ActiveCN111039094AHigh degree of automationSmooth and accurate reciprocating translational movementFilament handlingFiberGear wheel

The invention discloses a chemical fiber bobbin continuous transferring and feeding device for chemical fiber processing and belongs to the field of textile processing mechanical equipment. Accordingto the chemical fiber bobbin continuous transferring and feeding device for chemical fiber processing of the invention, a bobbin feeding mechanism is horizontally and fixedly arranged at the lower side of a bobbin guiding support; a bobbin transferring mechanism above one side of the bobbin feeding mechanism is vertically arranged on the bobbin guiding support; a push rod rotating slope is arranged on the upper side of a reciprocating rotating cam; the middle of a reciprocating rotating rod is hinged to the upper side of a rotating rod supporting seat; a bobbin guiding and feeding pipe locatedabove the reciprocating rotating rod is fixedly arranged on the bobbin guiding support; a lifting transferring guide plate is slidably arranged on a lifting fixing sleeve in a vertical direction; a gear rotating support at the lower end of the lifting transferring guide plate is vertically and rotationally connected with a lifting rotating gear; and a bobbin clamping mechanism is fixedly arrangedon one side of the lifting rotating gear in the radial direction of the lifting rotating gear. The chemical fiber bobbin continuous transferring and feeding device is reasonable in structural design,can efficiently, stably and sequentially feed and machine chemical fiber bobbins one by one, is high in automation degree, and meets processing and using requirements.

Owner:桐乡市富昌化纤股份有限公司

Working method of sheet workpiece conveying mechanism for machining

InactiveCN110902360AReasonable structural designHigh degree of automationConveyorsStacking articlesMechanical equipmentMachining

The invention discloses a working method of a sheet workpiece conveying mechanism for machining, and belongs to the field of workpiece machining and conveying mechanical equipment. A material moving guide plate is slidably arranged on a translation guide rod in the horizontal direction, material suction guide rods are vertically slidably arranged on the two sides of the material moving guide platecorrespondingly, lifting connecting plates are horizontally and fixedly arranged at the lower ends of the material suction guide rods, and vacuum suction cups are horizontally and fixedly arranged atthe lower ends of suction cup connecting rods on the two sides below the lifting connecting plates. The discharging pipe is vertically arranged between conveying guide belts on the two sides below the material moving guide plate, a horizontal moving push plate is arranged on the material pushing base in a sliding mode in the horizontal direction, a discharging groove hole matched with a discharging channel in size and specification is horizontally formed in one side above the horizontal moving push plate, and a conveying guide belt is horizontally arranged on one side below a conveying support. The structural design is reasonable, sheet workpieces can be alternately combined to be fed, the sheet workpieces can be horizontally moved, turned and conveyed one by one, the automation degree ofsheet workpiece feeding is improved, and the machining and using requirements are met.

Owner:沈洁

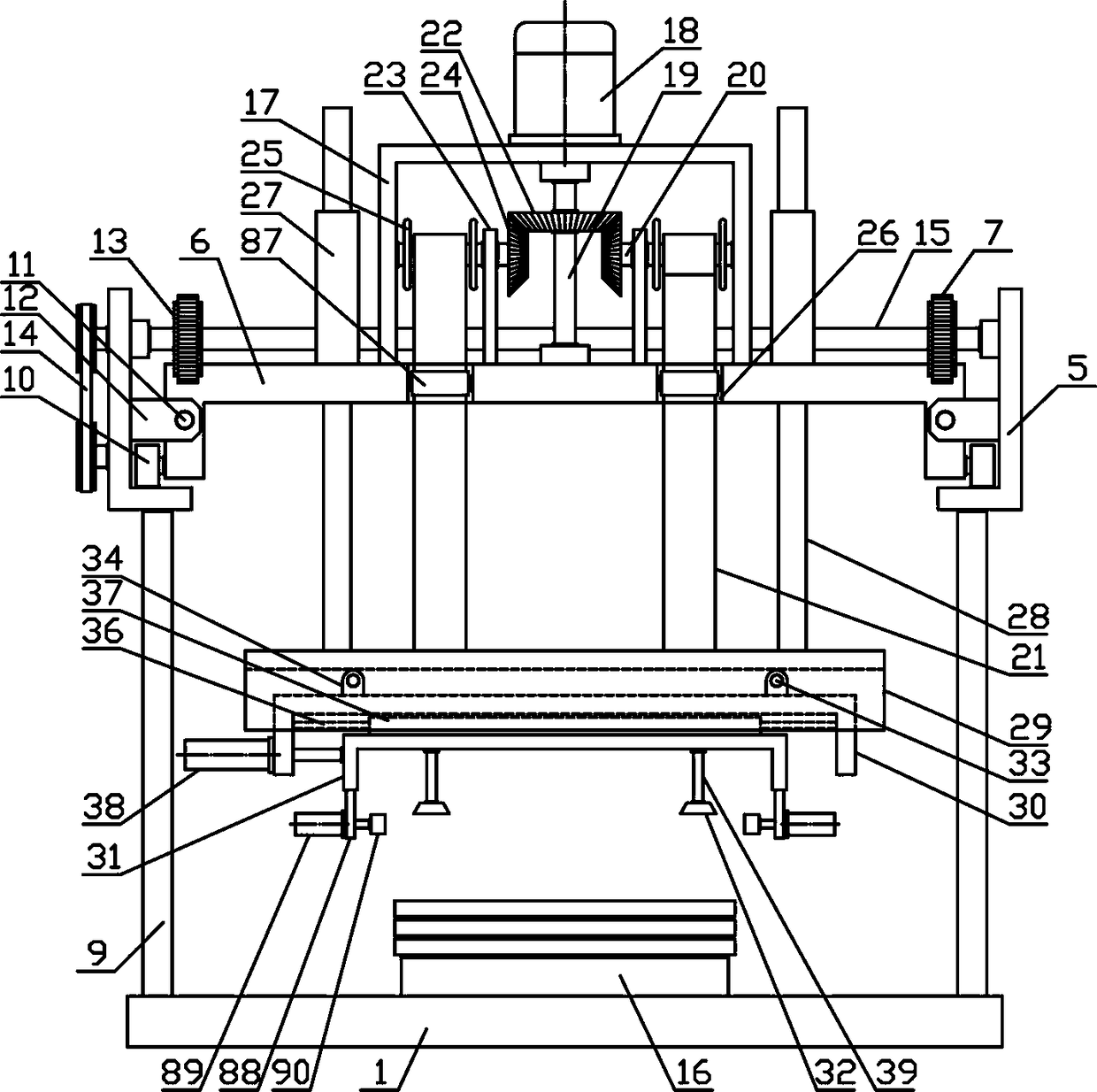

Prop plate dust removal device

InactiveCN110404832AImprove handling efficiencyImprove efficiencyCleaning using toolsCleaning using gasesMechanical equipmentEngineering

The invention discloses a prop plate dust removal device, and belongs to the field of display prop machining mechanical equipment. A plate moving mechanism of the device is fixedly arranged on the upper side of a plate placing support, a dust removal mechanism is fixedly arranged on the upper side of the guide plate support, a plurality of guide plate rotating rollers are arranged on the upper side of the guide plate support, a lifting support is horizontally and fixedly arranged on the lower side of a lifting connecting plate, a translation guide plate is arranged on a moving plate guide rodin a sliding mode in the horizontal direction, a plurality of moving plate suckers are uniformly and fixedly arranged on the lower side of the translation guide plate, a dust removal support is horizontally and fixedly arranged on the upper side of a rotary roller support, a dust brushing mechanism and a dust collection material pipe are sequentially arranged on the dust removal support in the horizontal direction, and a dust pastingmechanism is horizontally arranged on the upper side of the rotary roller support on one side of the dust collection material pipe. The device has the advantages that the structural design is reasonable, and prop plates can be rapidly and stably lifted and transferred one by one, so that the prop plates are subjected to efficient and smooth continuous dust removal processing, the automation degree of dust removal and machining of the prop plates is high, and the requirements of machining and use are met.

Owner:浙江高人道具有限公司

Flat pushing and conveying mechanism of pipe fitting

InactiveCN110466945AHigh degree of automationReasonable structural designConveyorsConveyor partsPipe fittingEngineering

The invention discloses a flat pushing and conveying mechanism of a pipe fitting, and belongs to the field of workpiece conveying and processing machinery and equipment. A driving mechanism of the flat pushing and conveying mechanism is horizontally arranged on the side, below a pipe pushing mechanism, of a pipe moving support, a plurality of armature sleeves are fixedly arranged on the outer sideof a pipe pushing belt, translation armatures are arranged on the outer sides of the armature sleeves, a pipe pushing support is fixedly arranged at the position, along the end of the pipe pushing belt, of a translation guide rod, the pipe pushing support is provided with a plurality of pipe pushing rotating plates in the horizontal direction, adsorption electromagnets matched with the translation armatures are fixedly arranged on one side below the pipe pushing support, a guide pipe feed pipe is fixedly arranged on the pipe moving support on the supper side of the end part of an guide pipe bearing rod, the middle part of one side of a reciprocating pendulum plate is vertically and rotatably connected with a transfer rotating shaft, and a transfer ratchet wheel is fixedly and coaxially arranged on the transfer rotating shaft on the outer side of the reciprocating pendulum plate. According to the flat pushing and conveying mechanism of the pipe fitting, the structure design is reasonable, the pipe fitting can be smoothly and accurately pushed and loaded in sequence and intermittently in the horizontal direction, the automation degree of the pipe fitting transfer is improved, and the needs of processing and use are met.

Owner:章凌霞

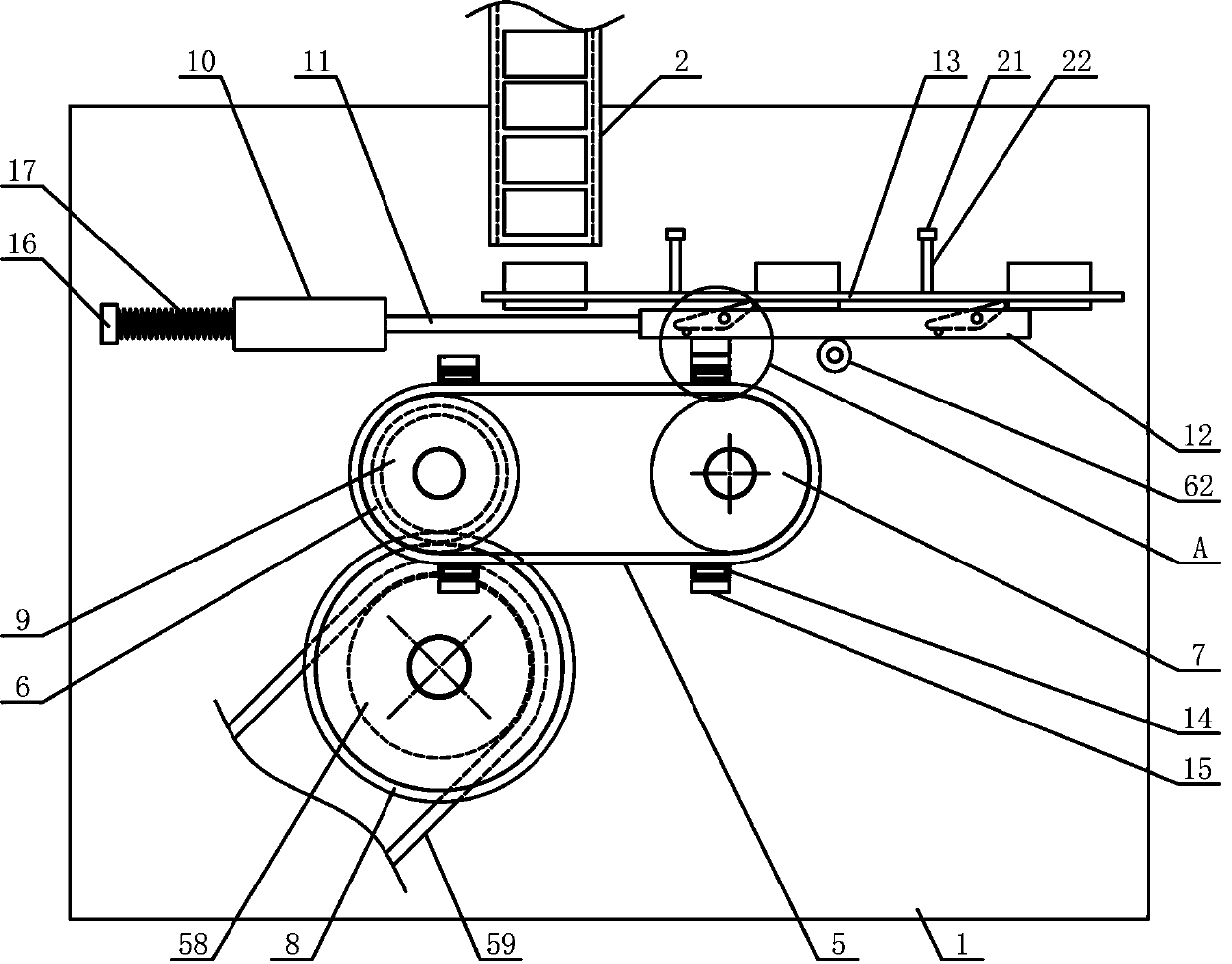

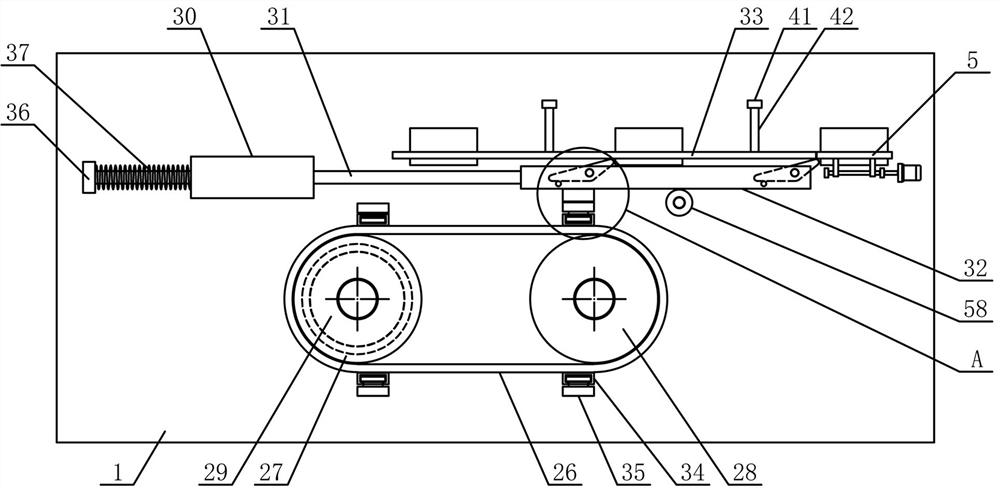

Tubing processing and branching conveying mechanism

InactiveCN108555659AReasonable structural designHigh degree of automationMetal working apparatusPunchingMechanical equipment

The invention discloses a tubing processing and branching conveying mechanism, and belongs to the field of material processing and conveying mechanical equipment. A punching mechanism of the tubing processing and branching delivery mechanism is obliquely and fixedly arranged on a processing base between a blanking mechanism and a guiding mechanism, a tubing storage hopper is arranged on the upperside of a tubing blanking pipe in a communicated mode, a punching rotating rod is rotatably connected with the output end of a punching motor at the middle part of the upper side of a lifting connecting board, a board rotating air cylinder is obliquely arranged between a punching bearing board and the processing base, a tubing bearing mechanism is arranged on one side above a guiding disc in the radial direction of the guiding disc, branching conveyor belts are horizontally and symmetrically arranged on the parts, on the two sides of the guiding disc, of the processing base in the radial direction of the guiding disc, and a driving mechanism is arranged on the part, on one side of the lower end of a guiding rotating shaft, on the processing base. The tubing processing and branching delivery mechanism is reasonable in structural design, tubing can be subjected to steady and intermittent blanking one by one and subjected to punching processing, and the processed tubing can be subjected to branching conveying, so that the tubing processing and conveying automation degree is improved, and the requirements of processing use are met.

Owner:TONGXIANG TANGCHAO ADVERTISEMENT CO LTD

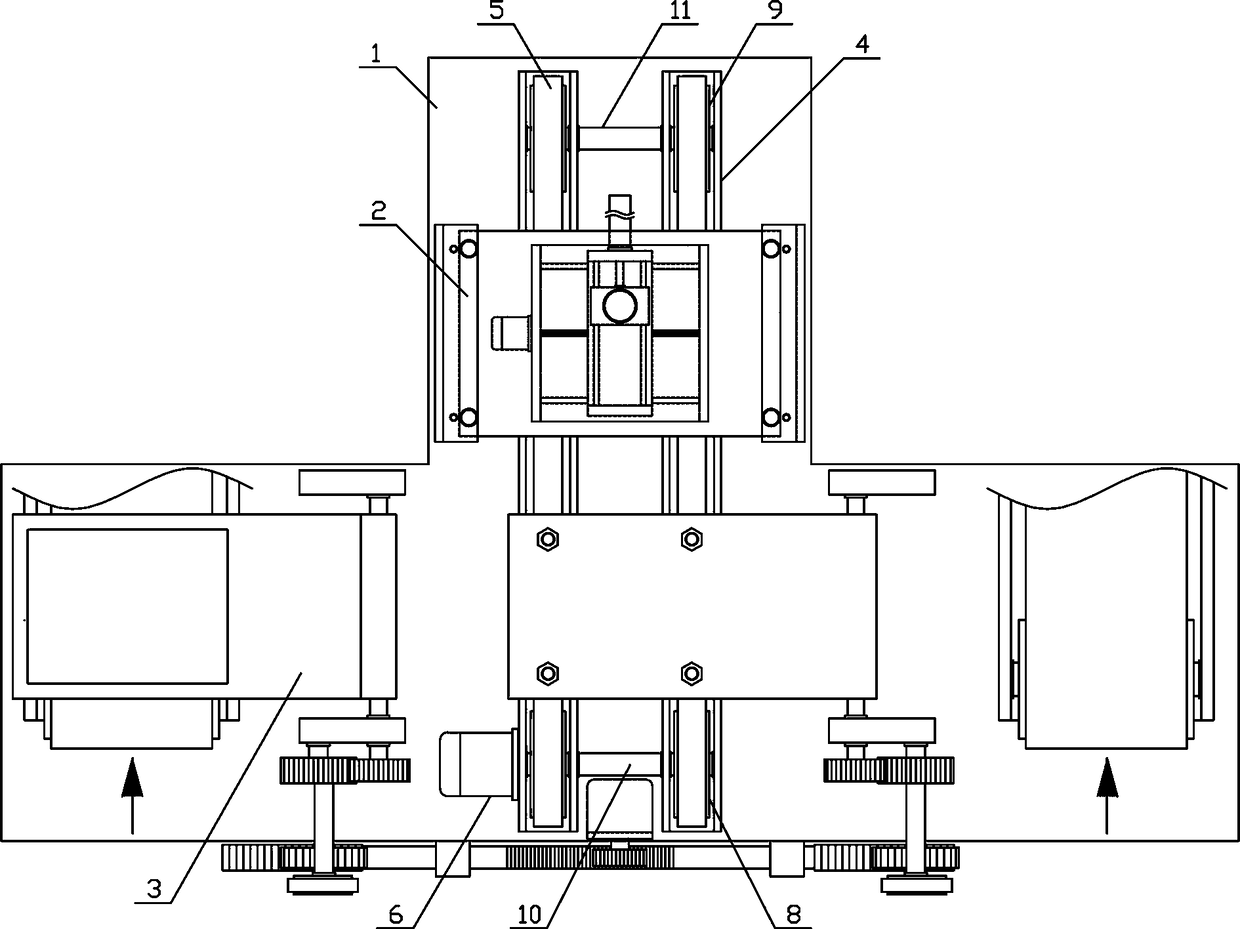

Plate transferring and feeding mechanism

InactiveCN108792566APrevent slippageReasonable structural designConveyorsConveyor partsArchitectural engineeringMechanical equipment

The invention discloses a plate transferring and feeding mechanism and belongs to the field of mechanical equipment for construction material processing. As for the plate transferring and feeding mechanism, a roller guide groove of an arc structure is formed in the outer side of a rotating base; a transferring gear is fixedly arranged in the middle of the lower side of the rotating base in a horizontally coaxial mode; a drive gear at the output end of a rotary electromagnet is in engaged connection with the transferring gear; guide supports are vertically and symmetrically arranged on the twosides of the upper portion of the rotating base in the radial direction of the rotating base; a lifting support is slidably arranged on the guide supports in the vertical direction; lifting cylindersare fixedly arranged at the positions, below the two sides of the lifting support, of the rotating base in a vertically upward mode; a lifting guide plate is slidably arranged on a feeding guide rod in the vertical direction; and feeding bearing rods are horizontally and fixedly arranged at the two ends of one side of the lifting guide plate. The plate transferring and feeding mechanism is reasonable in structural design, plates can be stably supported and fixed and can be horizontally transferred as needed, the degree of automation of plate transferring is increased, and the processing and usage requirements are met.

Owner:晋正正

Fabric compounding apparatus

ActiveCN110802909AUnwinding is smooth and orderlyEfficient and smooth coatingSpraying apparatusLaminationElectric machineryMechanical equipment

The invention discloses a fabric compounding apparatus, and belongs to the field of textile processing machinery and equipment. In the apparatus, the middle of an unwinding turntable is horizontally and fixedly provided with an unwinding bearing rod, the terminal end of a pressure disc rotation rod at the upper side of the unwinding turntable is vertically and rotationally connected with a dampingrotation wheel, a pressure rod slide block is arranged on a rotation guide rod in a sliding manner, a cloth guide bearing plate is tilted downwards and fixedly arranged on a composite support frame at the lower side of the unwinding bearing rod, a feeding roller is horizontally arranged at the upper side of the cloth guide bearing plate, a plurality of gluing nozzles are arranged at the lower side of a glue spraying guide pipe, an upper material guide roller and a lower material guide roller are arranged in a compression fit manner, an upper pressing support frame and a lower pressing supportframe are arranged on the composite support frame in order from top to bottom, and a cloth pulling motor and a cloth pulling roller are connected by a cloth pulling chain in a transmission manner. The structure design of the apparatus is reasonable, the continuous and smooth compounding of the fabric can be performed rapidly and efficiently during the material transfer process, the efficiency andquality of fabric compounding are improved, the automation degree is high, and the needs of processing and use are met.

Owner:TONGXIANG YUESHUN WRAP KNITTING

Continuous shunting feeding mechanism

InactiveCN108689088AReasonable structural designQuick and easy translation resetConveyorsEngineeringMechanical equipment

The invention discloses a continuous shunting feeding mechanism, and belongs to the field of workpiece conveying mechanical equipment. A material pushing mechanism is horizontally and fixedly arrangedon the feeding bracket at one side of the feeding mechanism, an intermittent driving mechanism is horizontally arranged on the feeding bracket at the lower side of the material pushing mechanism, a material suction electromagnet is horizontally and fixedly arranged on the lower side of a connecting guide plate, a rotating base is rotatably connected to middle of the lower side of a material bearing bracket, a material pushing cylinder is horizontally and fixedly arranged on one side of the material bearing bracket, two adsorption armatures are uniformly and fixedly arranged on the outer sideof a feeding chain, a feeding rotating shaft on one side of a feeding ratchet wheel is vertically and rotatably connected with a feeding gear, the feeding gear is connected with the upper side of a translation rack in a meshing mode, and a plurality of the conveying guide belts on the upper side of the feeding bracket are perpendicular to feeding guide rods. The continuous shunting feeding mechanism has reasonable structural design, can carry out translational feeding on a plurality of workpieces as a whole, and can carry out shunting feeding and conveying on the fed workpieces one by one in an orderly manner to meet the requirements of machining and use.

Owner:沈洁

Plate veneering processing device

ActiveCN109015955AReasonable structural designSmooth and accurate adsorption and fixationPlywood pressesVeneer pressesMechanical equipmentHot press

The invention discloses a plate veneering processing device, and belongs to the field of plate processing mechanical equipment. A feeding mechanism, a skin covering mechanism and a surface pressing mechanism are horizontally and fixedly arranged on the upper side of a fixing base in sequence in the horizontal direction. A lifting mechanism is vertically arranged in the middle of the upper side ofa horizontal-moving guide plate, and a plate adsorbing mechanism is horizontally arranged on the lower side of the lifting mechanism. A plurality of plate bearing rotating rollers are horizontally androtationally connected to a plate bearing support sequentially in the horizontal direction. A skin pulling mechanism is horizontally arranged on the positions, on one sides of the multiple plate bearing rotating rollers, on the plate bearing support, and a surface pressing support is vertically arranged on the position, on one side of the skin covering mechanism, on the fixing base. A plate bearing platform is horizontally and fixedly arranged in the middle of the surface pressing support, and a hot pressing support is horizontally located on the upper side of the plate bearing platform. Theplate veneering processing device is reasonable in structural design, plates can be horizontally moved and fed accurately block by block, the plates can be automatically subjected to skin covering processing, efficient and stable veneering processing for the plates is achieved, and thus needs for processing and using are met.

Owner:ZHEJIANG MINGTAO IND

Sheet stock punching and branching mechanism

InactiveCN108543983AHigh degree of automationAffects normal translation teleportationMetal working apparatusBoring/drilling componentsPunchingMechanical equipment

The invention discloses a sheet stock punching and branching mechanism, and belongs to the field of material machining and conveying mechanical equipment. A transfer mechanism is horizontally arrangedin the middle of the upper side of a fixed base, a punching mechanism and a branching mechanism are horizontally arranged on the upper side of the fixed base in sequence in the conveying direction ofthe transfer mechanism, the two sides of a guide belt are wound and connected to a main conveying guide wheel and an auxiliary conveying guide wheel correspondingly, the output end of a bearing air cylinder is fixedly connected with the lower side of a lifting connection plate, a punching rotating rod is vertically and rotationally connected to the output end of a punching motor, adsorption turnover plates are arranged on the upper sides of turnover supports on the two sides of a transfer base and branching conveying belts are fixedly and horizontally arranged on the two sides of the transferbase. The structural design is reasonable, sheet stock can be efficiently and accurately punched and machined in the conveying process, the machined sheet stock can be continuously and stably conveyed in a branching mode, the sheet stock machining and conveying automation degree is improved, and machining and use requirements are met.

Owner:TONGXIANG TANGCHAO ADVERTISEMENT CO LTD

Thin sheet workpiece overturning feeding mechanism

InactiveCN110921284AReasonable structural designHigh degree of automationConveyorsStacking articlesStructural engineeringMechanical equipment

The invention discloses a thin sheet workpiece overturning feeding mechanism, and belongs to the field of workpiece machining and conveying mechanical equipment. A moving guide plate of the thin sheetworkpiece overturning feeding mechanism is slidably arranged on a horizontal-moving guide rod in the horizontal direction, sucking guide rods are vertically and slidably arranged on the two sides ofthe moving guide plate correspondingly, lifting connecting plates are horizontally and fixedly arranged at the lower ends of the sucking guide rods, vacuum suction cups are horizontally and fixedly arranged at the positions, on the two sides of the lower parts of the lifting connecting plates, of the lower ends of suction cup connecting rods, a discharging material pipe is vertically arranged between conveying guide bands on the two sides of the lower part of the moving guide plate, a horizontal-moving pushing plate is slidably arranged on a pushing base in the horizontal direction, a discharging slotted hole matched with a discharging channel in size and specification is horizontally formed in one side of the upper part of the horizontal-moving pushing plate, and a conveying guiding beltis horizontally arranged on one side of the lower part of a conveying bracket. The thin sheet workpiece overturning feeding mechanism is reasonable in structural design, thin sheet workpieces can be fed alternately in a combined mode, and can be overturned and conveyed in a horizontal-moving mode block by block, the automatic degree of thin sheet workpiece feeding is increased, and demands of machining and using are met.

Owner:沈洁

Wood plate compress-conveying mechanism

The invention discloses a wood plate compress-conveying mechanism and belongs to the field of wood processing mechanical equipment. The wood plate compress-conveying mechanism comprises a fixed base, guide rollers, a compressing support, a conveying belt, lifting guide rods and a lifting screw, the plurality of guide rollers are horizontally, evenly and rotatably connected onto the top of the fixed base along a wood plate conveying direction, conveying limit mechanisms are disposed on two sides of the upper portion of the fixed base respectively, the compressing support is horizontally disposed above the guide rollers, two ends of the compressing support are horizontally and rotatably connected with conveying rollers respectively, the conveying belt is horizontally disposed on the conveying rollers, a conveying motor drives the conveying rollers, two ends of one side of the compressing support are vertically provided with guide sleeves respectively, the lifting guide rods are vertically and downwardly passed through the guide sleeves and fixed to the top of the fixed base, the middle of one side of the compressing support is vertically provided with a lifting sleeve that is in threaded connection with the lifting screw. The wood plate compress-conveying mechanism is reasonable in structural design, can compress and convey wood plates efficiently, easily and accurately and meets the requirement for processing wood plates.

Owner:于星杰

Pipe fitting end fixing mechanism

ActiveCN107717317AQuick fixQuick end fixationWelding/cutting auxillary devicesAuxillary welding devicesPipe fittingEngineering

The invention discloses a pipe fitting end fixing mechanism, and belongs to the field of machining auxiliary equipment. The pipe fitting end fixing mechanism comprises a fixing base, an adjusting motor, transverse moving supports and a pipe clamping mechanism; the transverse moving supports are horizontally and symmetrically arranged on the two sides of a transverse moving guide rod correspondingly, two sides of a transverse moving screw are in threaded connection to the transverse moving supports on the two sides of the upper portion of the fixing base, the pipe clamping mechanism is arrangedon an adjusting guide rod in a sliding manner in the horizontal direction, a transverse moving base is arranged on the adjusting guide rod in a sliding manner in the horizontal direction, the middlesof lifting supports on the two sides of the transverse moving base are vertically and rotatably connected with rotating discs, upper connecting rods and lower connecting rods are symmetrically arranged on the two sides of the two rotating discs on the two sides of the upper portion of the transverse moving base, and a pipe clamping rack is arranged on a lifting guide rod in a sliding manner in the vertical direction. The pipe fitting end fixing mechanism is reasonable in structural design,

Owner:江门市安隆五金工艺有限公司

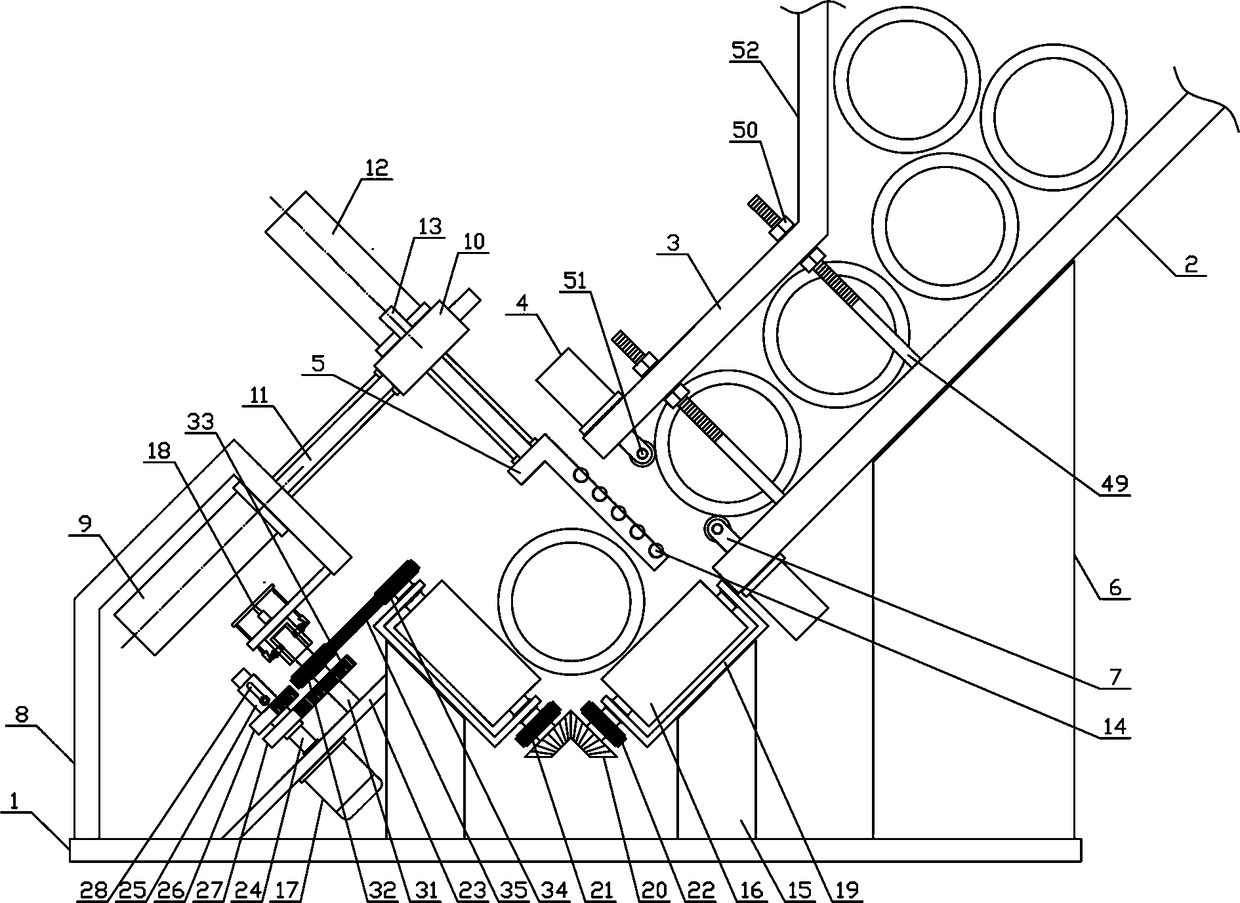

Continuous loading device for metal round pipe processing

InactiveCN111195689AReasonable structural designRealize root-by-root support and guidanceMetal-working feeding devicesStripping-off devicesStructural engineeringMechanical engineering

The invention discloses a continuous loading device for metal round pipe processing and belongs to the field of mechanical workpiece processing and transferring equipment. A pipe storage hopper and apipe guiding bedplate are fixedly arranged on the upper side of a round pipe transferring bracket in an inclination direction from top to bottom, successively. A lifting pipe pushing rod is slidably arranged on a push rod lifting bushing in the inclination direction. A lifting pipe pushing plate is fixedly arranged at the upper end of the lifting pipe pushing rod. A pipe bearing reciprocating toothed plate is slidably arranged on a reciprocating toothed plate guide bar in the inclination direction. A pipe bearing reciprocating connecting plate is obliquely and fixedly arranged on the end partof the lower side of the pipe bearing reciprocating toothed plate. A pipe bearing inclined connecting plate is fixedly arranged at the upper end of the pipe bearing reciprocating connecting plate. A lower rotating baffle plate is arranged on the lower side of an upper fixed connecting plate of the pipe bearing inclined connecting plate. The middle part of a pipe guiding rotating baffle plate is rotatably connected to the round pipe transferring bracket. The continuous loading device for metal round pipe processing is reasonable in structural design, can efficiently and smoothly guide and transfer metal round pipes successively and stably, so that the degree of automation of transferring the metal round pipes is improved and the processing and using demands are met.

Owner:黄薇婷

Aluminum product continuous punching mechanism

InactiveCN108787856AEasy to assemble and disassembleReasonable structural designMetal-working feeding devicesStripping-off devicesPunchingEngineering

The invention discloses an aluminum product continuous punching mechanism and belongs to the field of sectional material machining equipment. Rotating roller brackets on the two sides of a space belowa material conveying bracket are rotationally connected with material guide rotating rollers; a plurality of punching brackets are arranged on a horizontal movement guide rod in a sliding manner in the horizontal direction; punching pressure rods are vertically and fixedly arranged at the middle parts of the lower sides of adjusting guide plates; a punching pressure plate is horizontally and fixedly arranged on the lower side of a lifting pressure plate; rotating pressure rods are correspondingly and vertically arranged at the parts, on the two sides of a space above the lifting pressure plate, on the material conveying bracket; pushing rod cams are arranged at the parts, on one sides of the rotating pressure rods, on the material conveying bracket; and the output end of a rotary electromagnet is in transmission connection with the pushing rod cam on one side of the material conveying bracket by a punching belt. The structural design is reasonable, aluminum products can be subjected to punching machining conveniently, rapidly, stably and efficiently in the conveying process according to the requirement, scratched marks on the surfaces of the aluminum products in the machining process can be avoided, the punching machining efficiency and the punching machining quality of the aluminum products are improved, and the machining and using requirements are met.

Owner:蔡燕

Working method for pipe fitting translation conveying mechanism

InactiveCN112265803AImprove the degree of automation of transmission processingReasonable structural designConveyorsConveyor partsPipe fittingStructural engineering

The invention discloses a working method for a pipe fitting translation conveying mechanism and belongs to the field of workpiece conveying and machining mechanical equipment. According to the workingmethod for the pipe fitting translation conveying mechanism, a guide pipe material pipe is vertically and fixedly arranged on one side above a pipe moving support, translation armatures are arrangedon a plurality of armature sleeves fixedly arranged on the outer side of a pipe pushing belt, a plurality of pipe pushing rotating plates are arranged on a pipe pushing support at the end portion of atranslation guide rod in the horizontal direction, an adsorption electromagnet is arranged on one side below the pipe pushing support, guide pipe bearing rods are horizontally and symmetrically arranged on the two sides of the upper portion of the pipe pushing support respectively, a guide pipe inclined plate inclines downwards and is fixedly arranged on the part, on one side below a pipe movingmechanism, of the pipe moving support, and a conveying material pipe is vertically and fixedly arranged on the part, on the lower side of the guide pipe inclined plate, of the pipe moving support. Thepipe fitting translation conveying mechanism is reasonable in structural design, pipe fittings can be stably, accurately and sequentially pushed and fed in an intermittent translation mode in the horizontal direction and can be conveniently and smoothly rotated to adjust the conveying station, the automation degree of pipe fitting conveying and machining is improved, and the machining and using requirements are met.

Owner:章凌霞

Pipe unloading and translation mechanism

InactiveCN108706285AImprove efficiencyQuality improvementConveyorsConveyor partsElectromagnetic clutchEngineering

The invention discloses a pipe unloading and translation mechanism, and belongs to the field of building material machining mechanical equipment. A reciprocating driving mechanism is vertically fixedon one side of the upper side of a fixed base; a connecting bracket is vertically fixed between the reciprocating driving mechanism and a pushing mechanism; an unloading mechanism is arranged on the upper side of the pushing mechanism; the connecting bracket is horizontally and rotationally connected with an electromagnetic clutch; one end of a one-way clutch on one side of a rotating gear is horizontally arranged in the electromagnetic clutch; a pushing rotating shaft above a pushing bracket is horizontally arranged in the electromagnetic clutch; a damping mechanism is arranged at one end ofthe pushing rotating shaft; pipe pushing support rods are symmetrically arranged on the outer side of a pushing chain; and an unloading mechanism comprises a pipe guide inclined plate, a pipe stop rotating rod, a lower pipe cylinder and a lower pipe baffle plate. The pipe unloading and translation mechanism is reasonable in structural design, can gradually and stably unload pipes, and can flatly shift the pipes as needed efficiently and accurately to meet the machining and use demands.

Owner:桐乡市川泰纺织科技有限公司

Continuous reciprocating clamping-transferring mechanism

InactiveCN109292377AReasonable structural designImprove the automation of feedingConveyorsMechanical equipmentEngineering

The invention discloses a continuous reciprocating clamping-transferring mechanism and belongs to the field of mechanical equipment for textile material transportation. The continuous reciprocating clamping-transferring mechanism is characterized in that a transferring mechanism is vertically arranged on the lower side of a driving mechanism; a main transferring belt and an auxiliary transferringbelt are horizontally arranged on two sides of the lower part of a guiding belt bracket; the rotating transportation speed of a front transferring belt and that of a rear transferring belt are the same; a transferring electromagnet is horizontally arranged on the upper side of an adsorption base and the adsorption base is arranged on the upper side of a translation guiding plate; the output end ofa lifting air cylinder on an air cylinder bracket is fixedly connected with the middle of the upper side of a translation bracket; a transferring guiding plate is slidably arranged on transferring guiding rods in the horizontal direction; a clamping connecting plate is horizontally arranged on one side of the lower part of a transferring connecting plate; and a rotating air cylinder is arranged between the upper side of the clamping connecting plate and the transferring connecting plate. The continuous reciprocating clamping-transferring mechanism disclosed by the invention is reasonable in structural design; the translation guiding plate can be smoothly and accurately driven to perform translation motion in a continuous reciprocating manner; a textile material can be efficiently transferred and fed; the textile material feeding automation degree can be improved; and the processing and using requirements can be met.

Owner:桐乡市红旗塑料包装袋厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com