Sealing device and vacuum tire mould

A sealing device and tire mold technology, applied in tires, household appliances, other household appliances, etc., can solve problems such as rupture of sealing rings, avoid excessive extrusion and impact, increase production efficiency, and ensure the effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

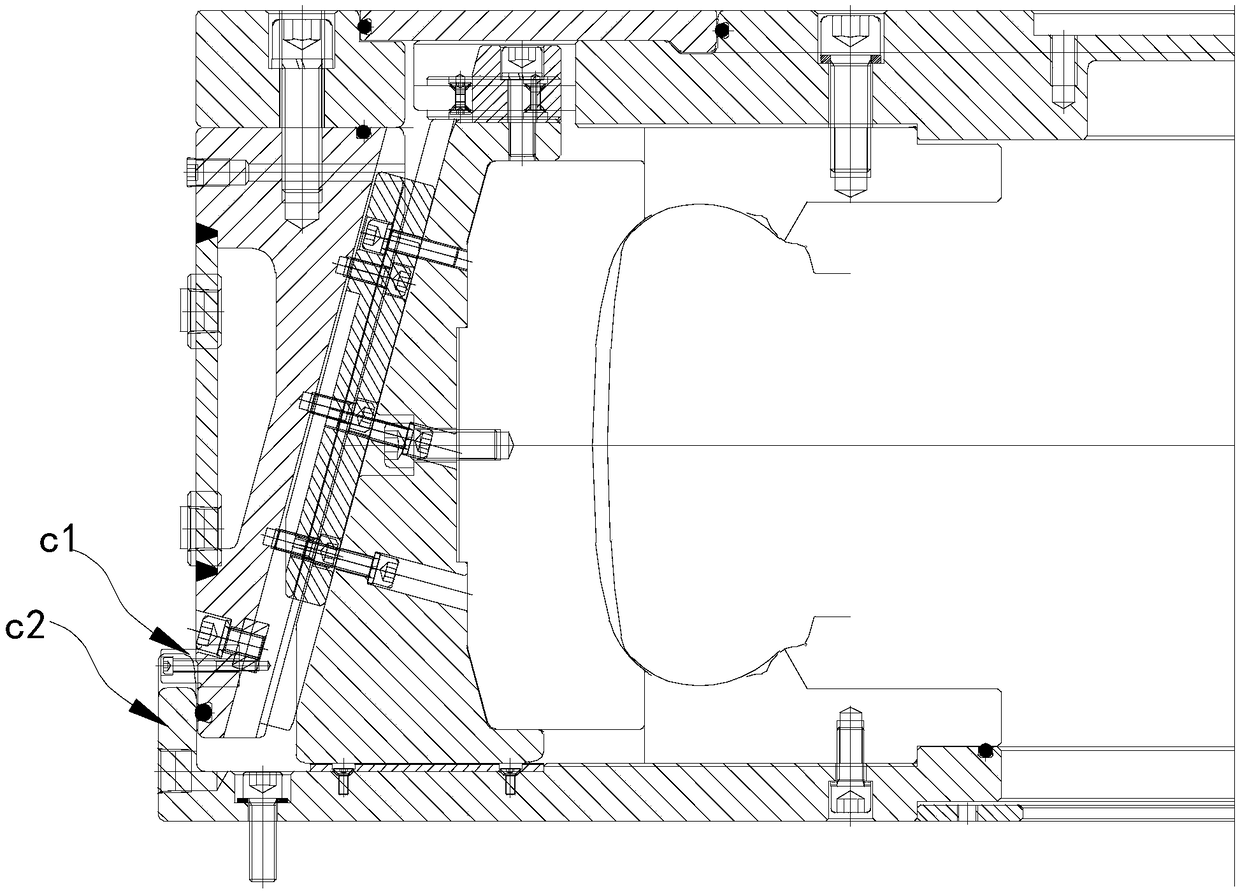

[0057] Please refer to Figure 4 to Figure 7 , a sealing device 10, which cooperates with the guide ring 21 and the base 22 of the vacuumized tire mold 20 to seal the vacuumized tire mold 20, including a first sealing member 100, a floating sealing ring 200 and an elastic device 300.

[0058] The base 22 has a circumferentially arranged first annular groove 22a; the floating seal ring 200 is disposed in the first annular groove 22a through an elastic device 300; the elastic device 300 is configured to provide an elastic force that makes the floating seal ring 200 approach the guide ring 21; The first sealing member 100 is embedded in the end of the floating sealing ring 200 close to the guide ring 21 , and the first sealing member 100 is configured to cooperate with the guide ring 21 and the sealing device 10 to achieve a sealing effect.

[0059] The sealing device 10 cooperates with the guide ring 21 and the base 22 of the vacuum tire mold 20. The sealing method of the guide ...

Embodiment 2

[0089] Figure 6 A schematic diagram of a sealing device 10 is provided for Embodiment 2 of the present invention. Please refer to Figure 6 , it can be seen from the figure that the sealing device 10 in this embodiment is roughly the same, the difference is that the sealing device 10 in this embodiment includes sealing structures in other positions, such as between the upper cover 24 and the guide ring 21 The sealing structure between the slider 25 and the base 22, the sealing structure at other positions and the sealing device between the base 22 and the guide ring 21 are combined to provide a seal for the vacuuming operation and support the vacuuming operation. .

[0090] This embodiment also provides a vacuumized tire mold 20, which includes any one of the sealing devices 10 described above. Vacuum tire mold 20 comprises loam cake 24, guide ring 21, slide block 25, pattern block, vacuum air nozzle 26, and vacuum air nozzle 26 can be arranged on guide ring 21 top, also c...

Embodiment 3

[0092] This embodiment of the present invention also provides a vacuumized tire mold 20, which includes any one of the sealing devices 10 described above. Since the vacuum tire mold 20 is equipped with the above-mentioned sealing device 10, it can also avoid excessive extrusion and impact of the sealing ring, thereby protecting the sealing ring, prolonging the service life of the sealing ring, and ensuring production efficiency.

[0093] At the same time, the vacuumized tire mold 20 provided by the embodiment of the present invention can be obtained through simple modification on the basis of the existing non-vacuumized vacuumized tire mold, and the vacuuming operation can be performed in advance, which saves costs and increases production efficiency.

[0094] In the present embodiment, the specific implementation of the vacuum tire mold 20 is provided, please refer to Figure 4-Figure 6 . Wherein, a kind of usage mode of vacuumizing tire mold 20 is as follows:

[0095] refe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com