Multi-station clamping equipment for capacitor machining

A capacitor processing and clamping equipment technology, which is applied in the field of capacitors, can solve the problems of round aluminum shell dents, round aluminum shell falling off, aluminum foil electrodes are easy to be squeezed out, etc., and achieve the effect of preventing dents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

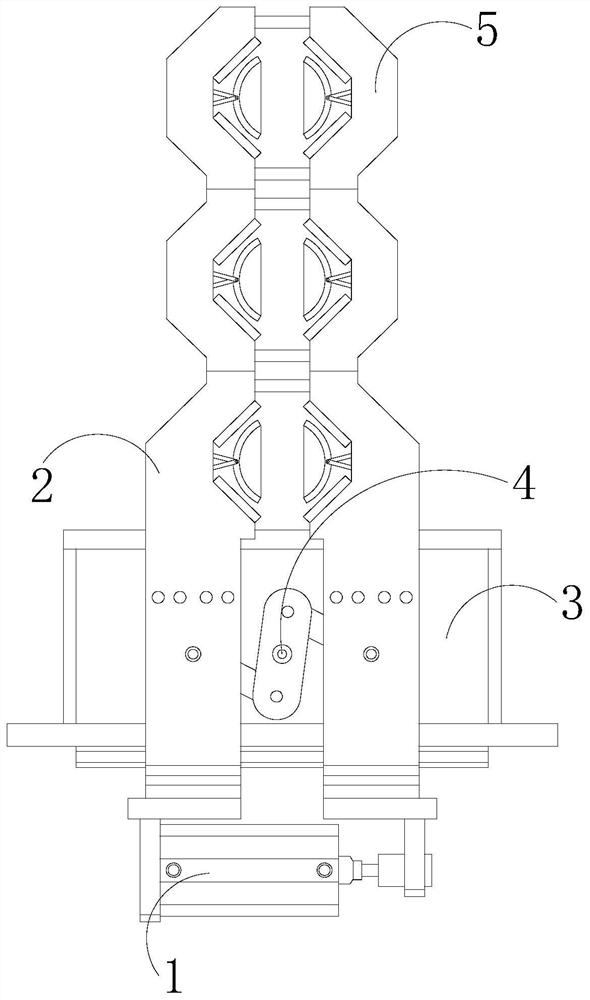

[0022] as attached figure 1 to attach Figure 4 Shown:

[0023] The present invention is a multi-station clamping equipment for capacitor processing. Its structure includes a cylinder 1, a linkage frame 2, a mounting frame 3, a linkage rod 4, and a clamping device 5. Fixed, the linkage frame 2 is installed on the outer surface of the installation frame 3, and the inside of the linkage frame 2 is connected to the linkage rod 4, and the middle part of the linkage rod 4 is connected to the inner axis of the installation frame 3. The linkage frame 2. A clamping device 5 is fixedly installed on the upper end. The clamping device 5 includes an outer splint 51, a spring 52, an extruding rod 53, an outer supporting device 54, and a collision device 55. The lower end of the outer splint 51 is connected to the upper end of the linkage frame 2. and the inner side of the outer splint 51 is embedded with a spring 52, and the extruding rod 53 is installed on the inner side of the outer sp...

Embodiment 2

[0029] as attached Figure 5 to attach Figure 7 Shown:

[0030]Wherein, the interference device 55 includes a telescopic hose 551 and a fitting mechanism 552, one end of the telescopic hose 551 is fixedly installed inside the outer splint 51, and the other end of the telescopic hose 551 is fixed to the outer end surface of the fitting mechanism 552, The laminating mechanism 552 is located on the inner surface of the outer splint 51. There are four laminating mechanisms 552 in total. The area where the outer surface of the dielectric capacitor is bonded and clamped, disperses the clamping force, and prevents dents from occurring during the clamping process of the aluminum shell of the circular aluminum shell paper dielectric capacitor.

[0031] Wherein, the fitting mechanism 552 includes a fitting plate 52a, a rubber strip 52b, and an air bag mechanism 52c. The outer end surface of the fitting plate 52a is fixed to the flexible hose 551, and the inner end surface of the fitt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com