Transfer mechanism, blade root transferring trolley, blade tip transferring trolley and blade transfer system

A car body and load-bearing structure technology, which is applied in the direction of wind engine transportation, wind power generation, etc., can solve the problems of difficult blade transfer, blade loss, trolley skidding, etc., and achieve the effect of ensuring the stability of transportation, reducing loss, and ensuring levelness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

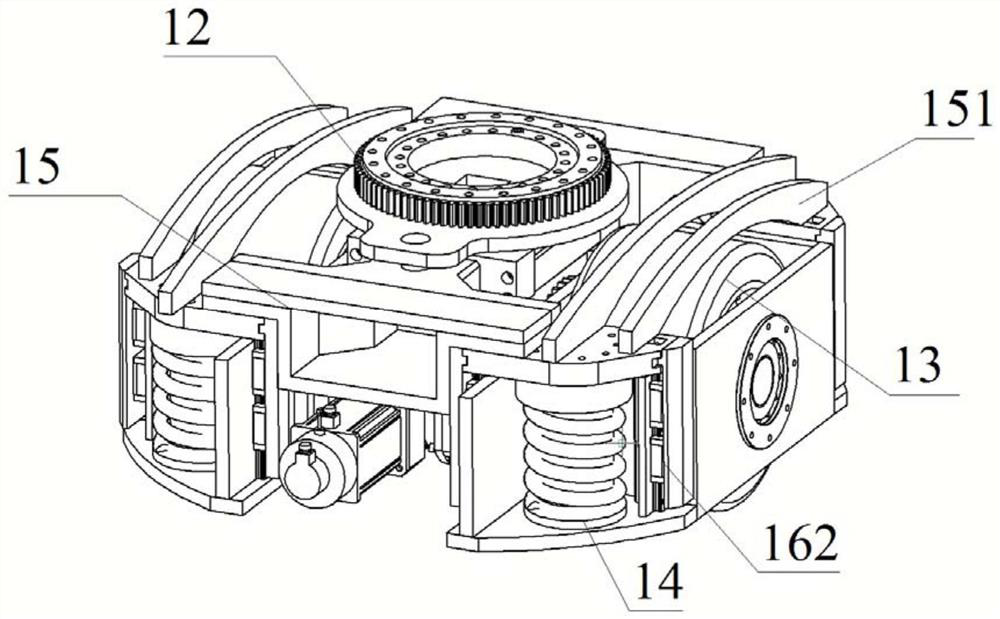

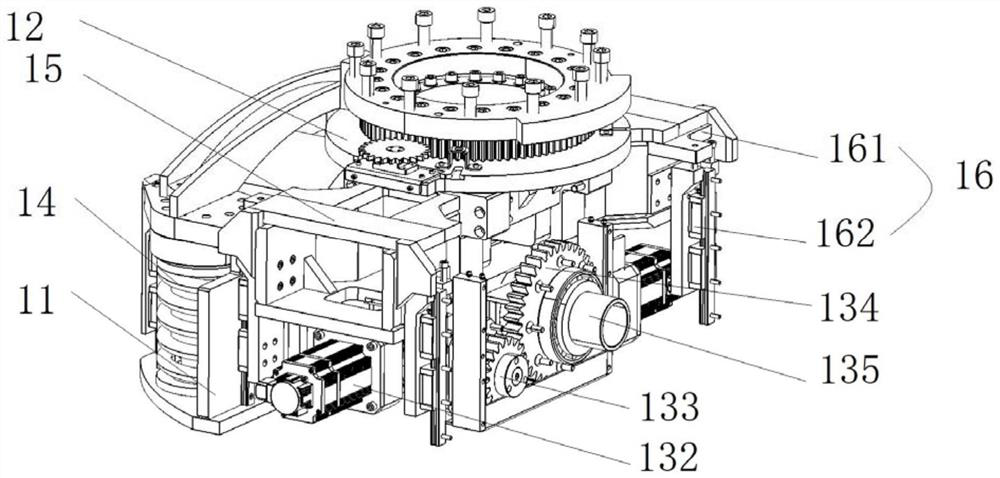

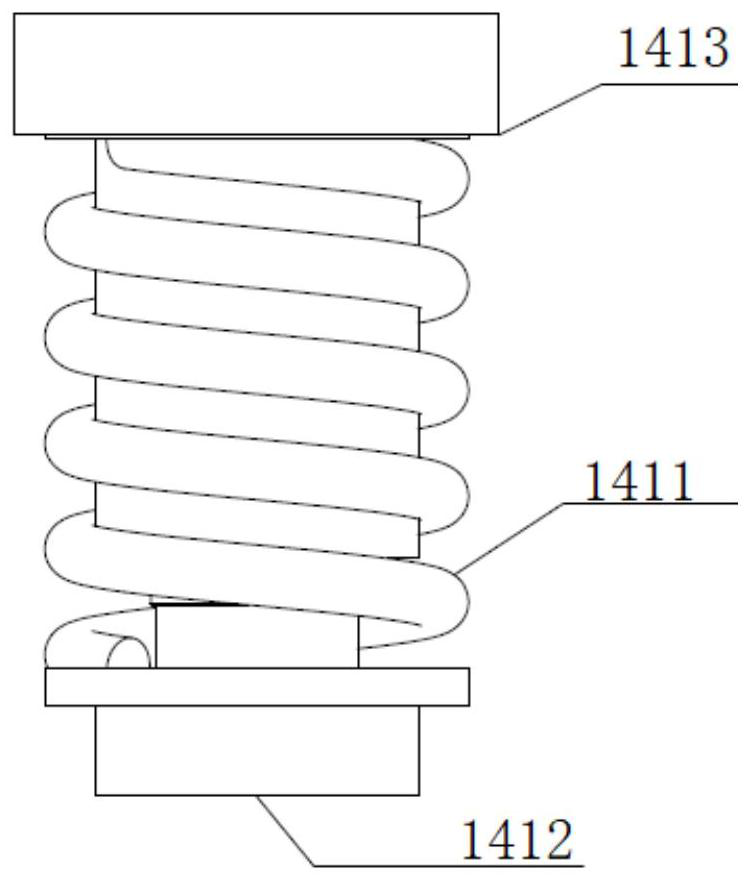

[0108] This embodiment provides a transfer mechanism, such as Figure 1 to Figure 10 As shown, it includes: a transfer base frame 11 ; a load bearing structure 12 , a roller assembly 13 , a buffer assembly 14 and a swing bridge assembly 15 . Wherein, the carrying structure 12 has a mounting portion 122 disposed toward one side of the rotating base frame; the roller assembly 13 includes: a roller member 131 and a roller driver 132, and the roller driver 132 is installed on the transfer base frame 11 Above, the roller member 131 is driven by the roller driver 132 to rotate relative to the transfer base frame 11; the buffer assembly 14 has at least one biasing member, and one end of the biasing member is installed on the transfer base frame 11; the swing bridge assembly 15 and the installation part 122 are pivotally rotated; the swing arm 1512 assembly has a swing structure 151, and the swing structure 151 and the biasing member are opposite to the other side of the transfer base...

Embodiment 2

[0125] This embodiment provides a blade root transfer trolley 2, such as Figure 11 to Figure 13As shown, it includes the transfer mechanism in Embodiment 1, the first car body bracket 21 and the first carrier plate 22 . Wherein, the bearing part 121 of the transfer mechanism is fixedly connected with the first vehicle body bracket 21; the first bearing plate 22 is driven by the rotation driver 24 and is rotatably installed on the first vehicle body bracket 21, so The bearing plate is used for bearing and fixing the blade root. Specifically, there are four transfer agencies.

[0126] Such as Figure 11 As shown, the blade root transfer trolley 2 also includes a first reset mechanism 23, and the first reset mechanism 23 is connected between the first car body bracket 21 and the first carrier plate 22, and is used to drive the first A carrier plate 22 is reset to the initial position; by setting the first carrier plate 22 on the blade root transfer trolley 2, and realizing me...

Embodiment 3

[0134] This embodiment provides a tip transfer trolley 3, such as Figure 14 to Figure 16 As shown, it includes: the transfer mechanism in Embodiment 1, the second vehicle body bracket 31 and the second carrier plate 32 . Wherein, the bearing part 121 of the transfer mechanism is fixedly connected with the second vehicle body bracket 31; the second bearing plate 32 is driven by a mobile driver and is slidably installed on the second vehicle body bracket 31, the The second bearing plate 32 is used for bearing and fixing the blade tip. By setting the second carrier plate 32, and by setting the mobile drive and the second reset mechanism to realize mechanical drive and mechanical limit, the offset of the vehicle due to longitudinal asynchrony during double linkage is realized.

[0135] Such as Figure 15 and Figure 16 As shown, the blade tip transfer trolley 3 provided in this embodiment also includes a second reset mechanism, and the second reset mechanism is connected betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com