Power battery frame air tightness detection pressing mechanism

A technology of air tightness detection and pressing mechanism, which is applied in the direction of liquid/vacuum measurement for liquid tightness, etc., which can solve problems such as inability to seal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

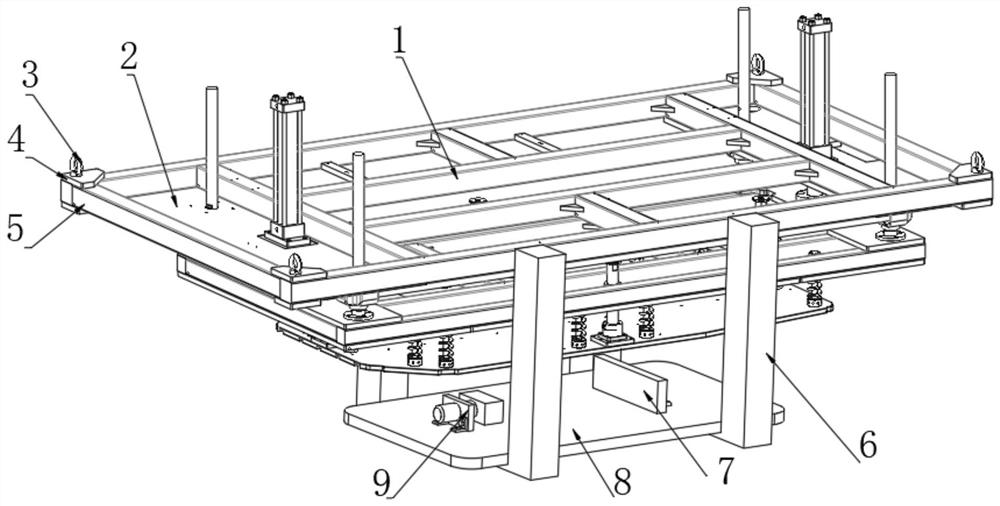

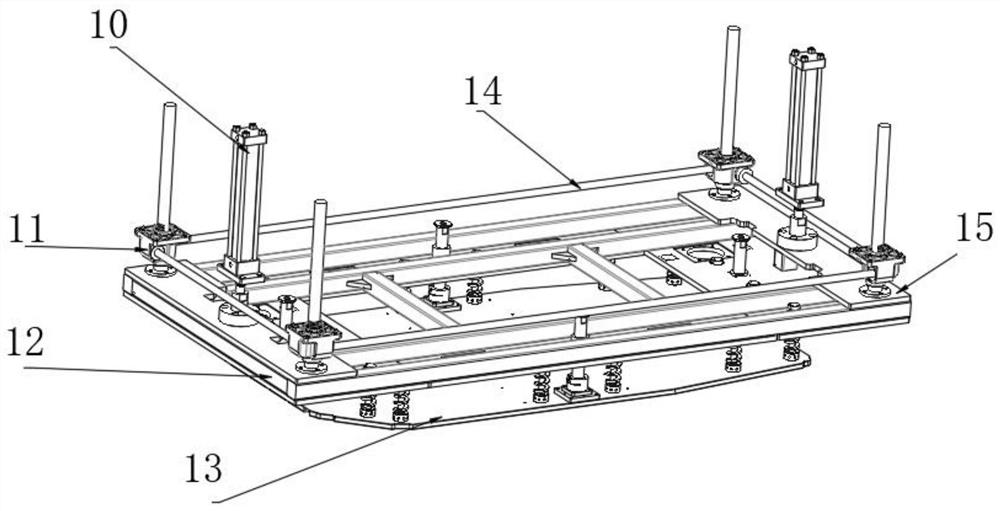

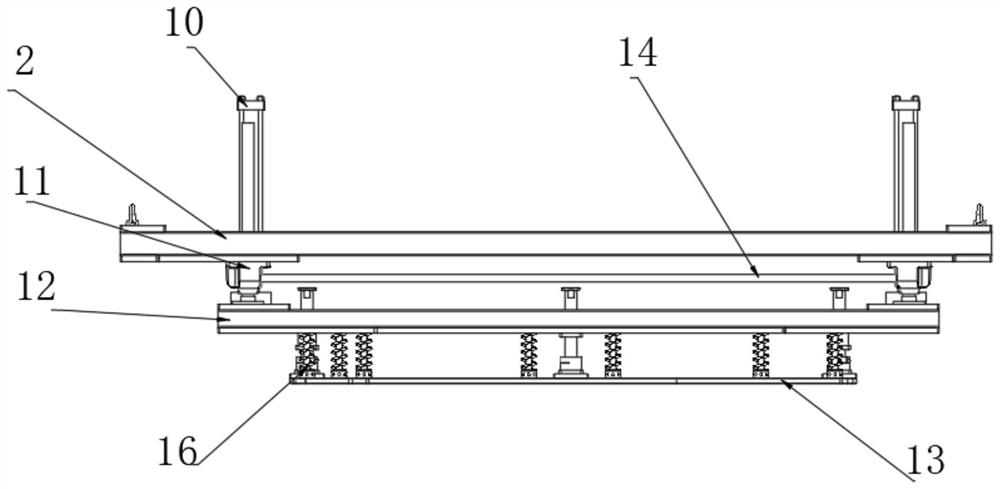

[0031] like figure 1 , 2 , 3, 4, 5, 6, 7, and 8, the embodiment of the present invention provides a power battery frame air-tightness detection and compression mechanism, including a fixed installation frame 5, which is welded and fixed between the two sides of the fixed installation frame 5 Fix the top frame cross bar 1, the two ends of the lower surface of the fixed installation frame 5 are respectively welded and fixed with two cylinder fixing seats 2, and the two cylinder fixing seats 2 are respectively fixed and installed with two output ends vertically downward. Cylinder 10, the upper and lower ends of the four corners of the fixed installation frame 5 are welded and fixed with suspension ring connecting plates 4, wherein the four suspension ring connection plates 4 at the upper end are respectively fixedly welded with fixed suspension rings 3, the output ends of the two cylinders 10 Each of the high-precision rack synchronous lifting assembly fixing plates 15 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com