A new machine room-less elevator load-bearing structure

A technology for a machine room-less elevator and a load-bearing structure, which is applied in the elevator field, can solve the problems of difficulty in adjusting levelness, low space utilization rate, insufficient top floor height, etc., and achieves the effects of levelness adjustment, high space utilization rate, and construction cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

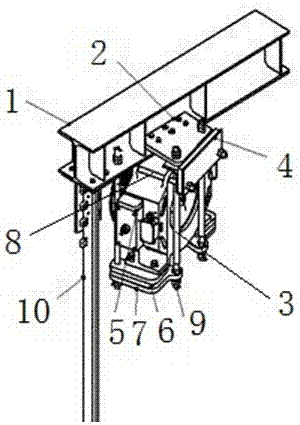

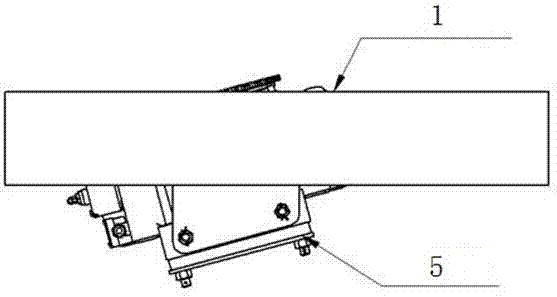

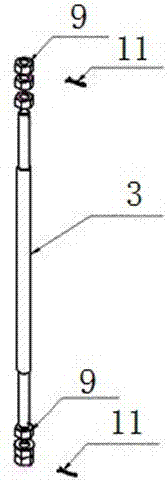

[0021] Example. The load-bearing structure of a new machine room-less elevator consists of figure 1 , figure 2 and image 3 As shown, including the load-bearing beam 1, the bottom of the load-bearing beam 1 is provided with a connecting plate 2 and a round hole, the round hole is located next to the connecting plate 2, and the connecting plate 2 is also provided with a round hole, the round hole at the bottom of the load-bearing beam 1 and the connection Threaded rods 3 are pierced in the round holes on the plate 2, and the lower part of the threaded rods 3 is pierced with a fixing plate 7, and the upper and lower ends of the threaded rods 3 are provided with nuts, and the fixing plate 7 is provided with a traction machine 5. The traction machine 5 is located below the connecting plate 2 .

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com