Environment-friendly wire processing system

A kind of wire processing and environmental protection technology, applied in the direction of circuit, electrical components, cable/conductor manufacturing, etc., can solve the problems affecting the electrical performance and mechanical performance of the wire, deformation, the wire is not tight, etc., to achieve the effect of maintenance and repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

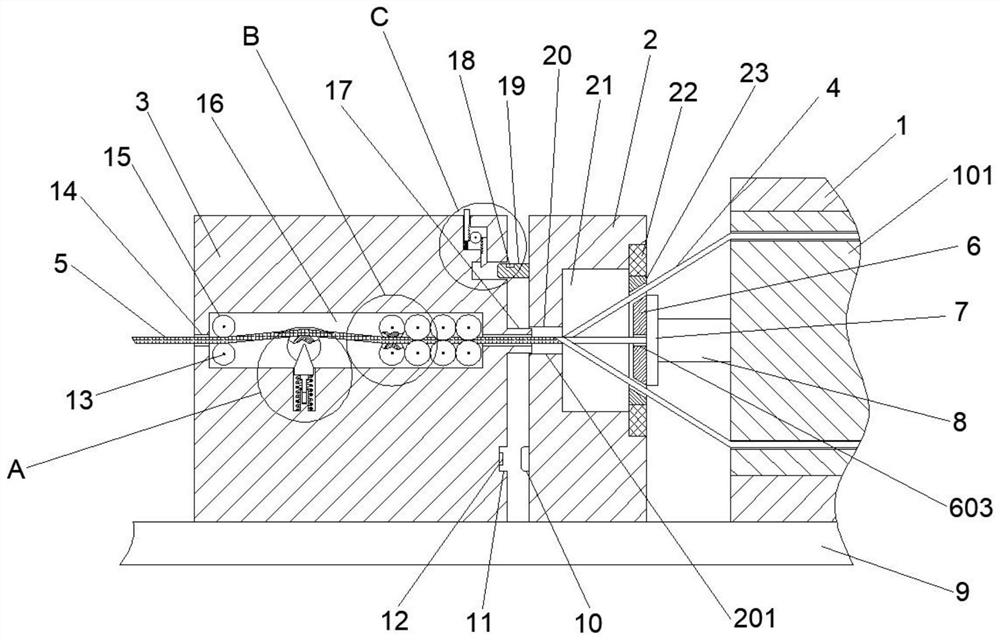

[0044] As an embodiment of the present invention, refer to figure 2 , the wire stopper includes a reeling warehouse 21 arranged in the reeling table 2, the right end of the reeling warehouse 21 is communicated with the outside of the reeling table 2, a bearing 22 is fixedly installed at the entrance of the reeling warehouse 21, and the inner ring of the bearing 22 is provided with The limiting ring 23 is symmetrically and fixedly connected with a plurality of limiting grooves 601 on the limiting ring 23 .

[0045] When the monofilament wire 4 enters the twisting table 2, the monofilament wire 4 is naturally stretched under the action of the tension force, and falls into the limiting groove 601. When the stranding table 2 performs the twisting operation, the monofilament The deformation of the wire 4 under the action of centrifugal force is limited by the limit ring 23, and at the same time, the limit ring 23 is pushed by the monofilament wire 4 and rotates under the support o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com