A kind of anti-water tree type polyolefin cable material and preparation method thereof

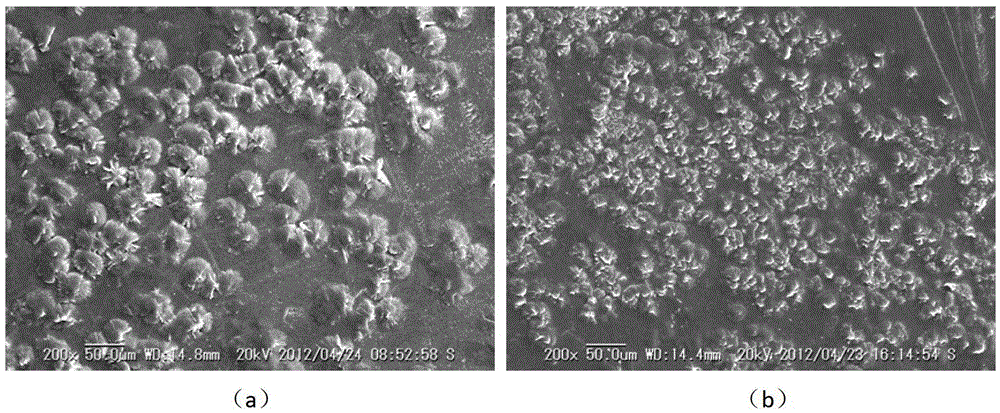

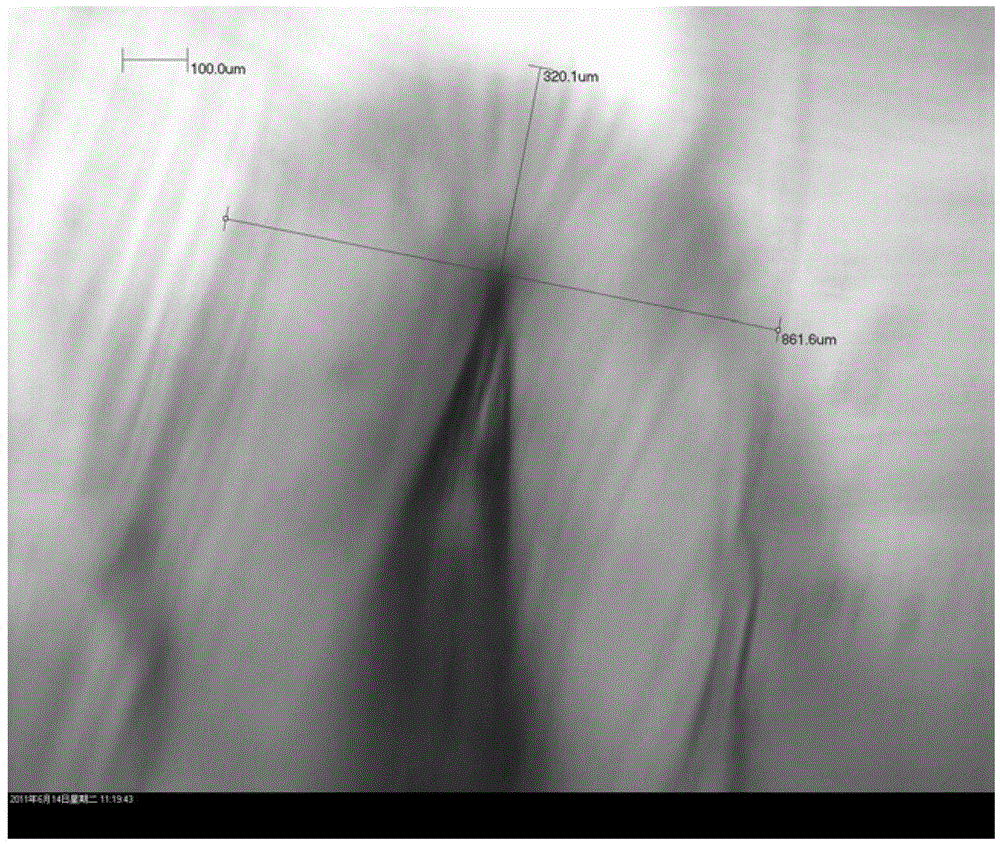

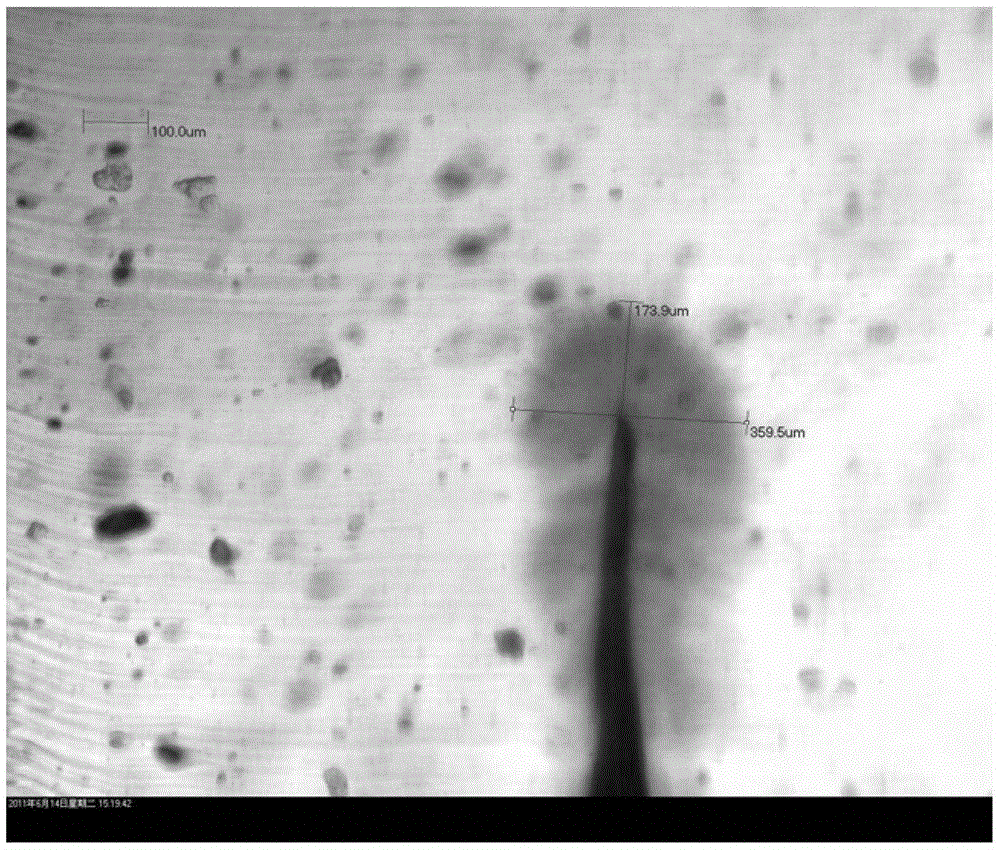

A polyolefin cable material, water tree resistance technology, applied in plastic/resin/wax insulators, organic insulators, etc., can solve the problem of no application, achieve uniform distribution of water, superior water tree resistance, excellent strength and toughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A water-tree-resistant polyolefin cable material, comprising 70 parts by mass of low-density polyethylene with a melt index of 1.8g / 10min, 30 parts of water-tree-resistant masterbatch, 1 part of dicumyl peroxide ( DCP), 0.3 parts of triallyl isocyanurate, 1 part of tetrakis [β-(3.5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester and 0.2 parts of 1026 rheological modification sex agent.

[0029] Among them, the anti-water tree masterbatch includes by mass components: 69.4 parts of low-density polyethylene with a melt index of 1.8g / 10min, 25.5 parts of inorganic porous particles with modified surface and 5 parts of ethylene-ethyl acrylate; , the surface-modified inorganic porous particles are obtained by treating the inorganic porous particles with a surface treatment agent, and the inorganic porous particles have a particle size less than or equal to 5 μm and a specific surface area greater than or equal to 50 m 2 / g of zeolite, the surface treatment ag...

Embodiment 2

[0035] A water-tree-resistant polyolefin cable material, comprising 80 parts by mass of low-density polyethylene with a melt index of 2.2g / 10min, 20 parts of water-tree-resistant masterbatch, and 1.5 parts of di-tert-butyl peroxide (DTBP), 0.2 parts of benzoyl peroxide, 0.2 parts of diethylaminopropylamine, 2 parts of tris[2.4-di-tert-butylphenyl] phosphite and 0.1 parts of FX-5924 rheology modifier .

[0036]Among them, the anti-water tree masterbatch includes by mass components: 69.6 parts of low-density polyethylene with a melt index of 2.2g / 10min, 20.4 parts of inorganic porous particles with modified surface and 10 parts of ethylene-vinyl acetate copolymer ; Wherein, the surface-modified inorganic porous particles are obtained by treating the inorganic porous particles with a surface treatment agent, and the inorganic porous particles have a particle size of less than or equal to 5 μm and a specific surface area of greater than or equal to 50 m 2 / g of porous zinc carb...

Embodiment 3

[0042] A water-tree-resistant polyolefin cable material, comprising 85 parts by mass of low-density polyethylene with a melt index of 2.0g / 10min, 15 parts of water-tree-resistant masterbatch, and 1 part of dicumyl peroxide ( DCP), 1 part of 2,5-dimethyl-2,5-di-tert-butylperoxyhexane, 0.5 parts of diethylaminopropylamine, 2 parts of 4,4'-thiobis(6-tetra butyl m-cresol) and 0.25 phr of SD‐86 rheology modifier.

[0043] Among them, the anti-water tree masterbatch includes by mass components: 79.8 parts of low-density polyethylene with a melt index of 2.0g / 10min, 10.2 parts of inorganic porous particles whose surface has been modified, 5 parts of maleic anhydride grafted Metallic polyethylene and 5 parts of maleic anhydride grafted polyethylene, wherein the surface-modified inorganic porous particles are obtained by treating the inorganic porous particles with a surface treatment agent, and the inorganic porous particles have a particle size of less than or equal to 5 μm , the sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com