Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

110results about How to "Guaranteed safety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

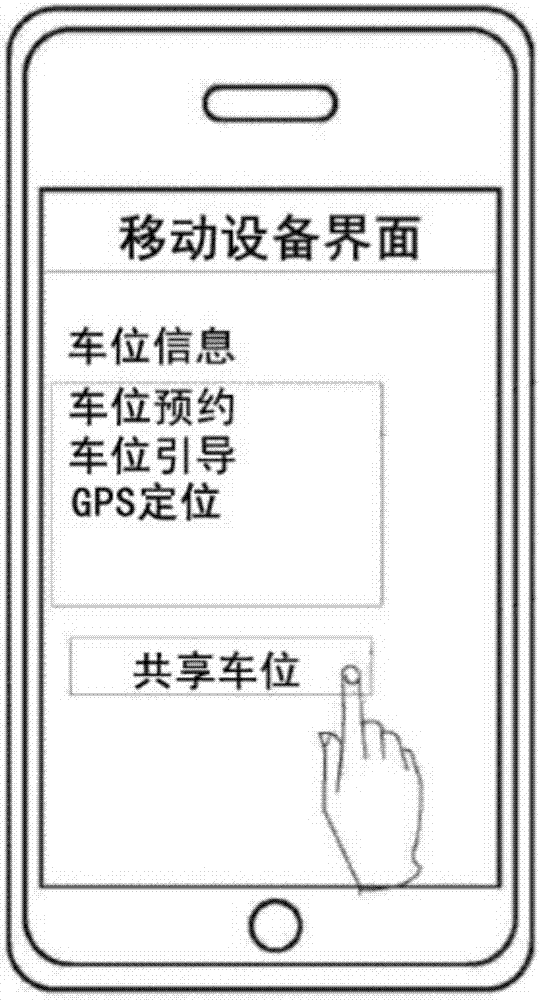

Community parking stall sharing system and community parking stall sharing method

PendingCN106960595ASimple structureSimple and fast operationTicket-issuing apparatusIndication of parksing free spacesDisplay devicePattern perception

The invention discloses a community parking stall sharing system and a community parking stall sharing method. The community parking stall sharing system is constituted by a cloud server; a plurality of mobile terminals, a plurality of parking stall terminals, and a plurality of community parking stall sharing display devices, which are respectively in a signal connection with the cloud server. The geomagnetic modules of the parking stall terminals are used for autonomous perception, and accurate identification of vehicles is realized by parking stall state information and the vehicle positioning information of the mobile terminals, and timely repelling of illegal vehicles is carried out, and the unattended supervision of the parking stalls is realized. The cloud server is used for the storage, the analysis, and the publishing of the parking stall information, and the community parking stall sharing display devices are used to display the information of all of the sharing parking stalls of the community dynamically, and the mobile terminals are used for parking stall sharing and parking stall guiding. The parking stall terminals are used to detect the driving-in and the leaving of the target vehicles, and the cloud server is used for charging.

Owner:JIANGSU UNIV OF SCI & TECH

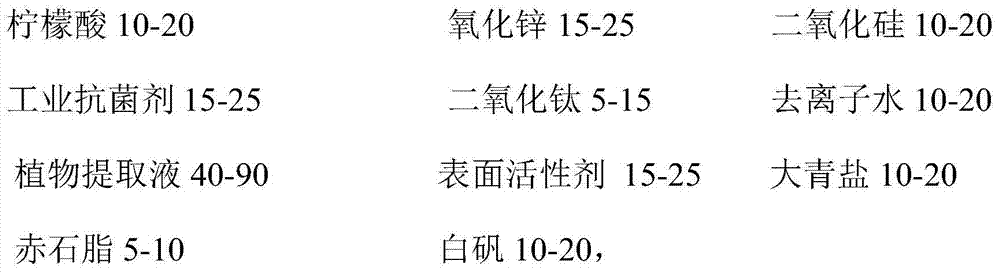

Benzaldehyde scavenger

The invention discloses a benzaldehyde scavenger, which is composed of citric acid, zinc oxide, silicon dioxide, an industrial antibacterial agent, titanium dioxide, deionized water, a plant extracting solution, a surfactant, halite, red halloysite and alum. According to the benzaldehyde scavenger disclosed by the invention, the raw materials are high in degree of safety and non-toxic, are not added with toxic ingredients, and do not contain industrial product ingredients, so that high safety can be ensured, harmful gas such as formaldehyde and benzene can be directly removed without lighting, and the benzaldehyde scavenger is safe, reliable, non-toxic, harmless, free of secondary pollution and really environment-friendly.

Owner:BEIJING ZHONGTIAN GUOHONG ENVIRONMENTAL PROTECTION SCI & TECH

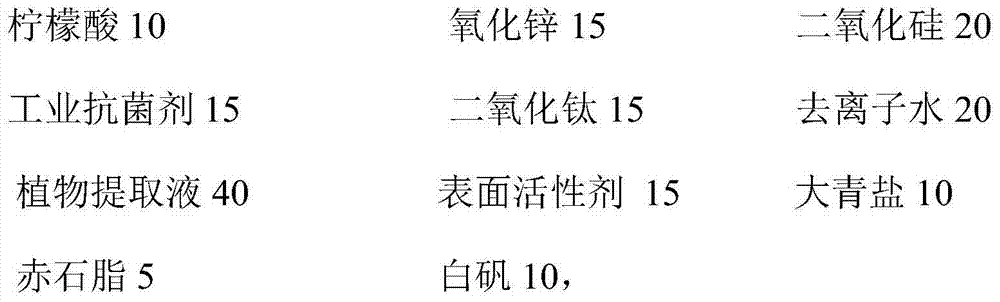

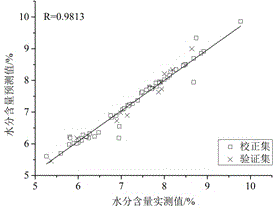

Multi-index rapid detection method for radix astragali

ActiveCN104792652AImprove data processing efficiency and model training accuracyGood stabilityWeighing by removing componentComponent separationWave bandQuality control

The invention provides a multi-index rapid detection method for radix astragali. The multi-index rapid detection method for radix astragali comprises the following steps: determining quality control indexes by acquiring the radix astragali, determining a modelling wave band of the indexes, and building a quantitative calibration model and quantitative release standards for near infrared spectrum characteristic information and contents of moisture, extract, astragaloside and calycosin-7-glucoside in the radix astragali by adopting a BP artificial neural network calculation method based on principal component analysis. The multi-index rapid detection method for the radix astragali can be used for accurately determining contents of moisture, extract, astragaloside and calycosin-7-glucoside in the radix astragali at the same time; compared with the traditional method, the built detection analysis method and quantitative release standards can be used for more quickly judging whether the radix astragali is qualified or not and for determining whether the radix astragali can enter into a follow-up production process link; the built detection analysis method and quantitative release standards can meet rapid and efficient field requirements and have an application prospect in screening of production medicinal materials and comprehensive quality evaluation.

Owner:ZHEJIANG UNIV

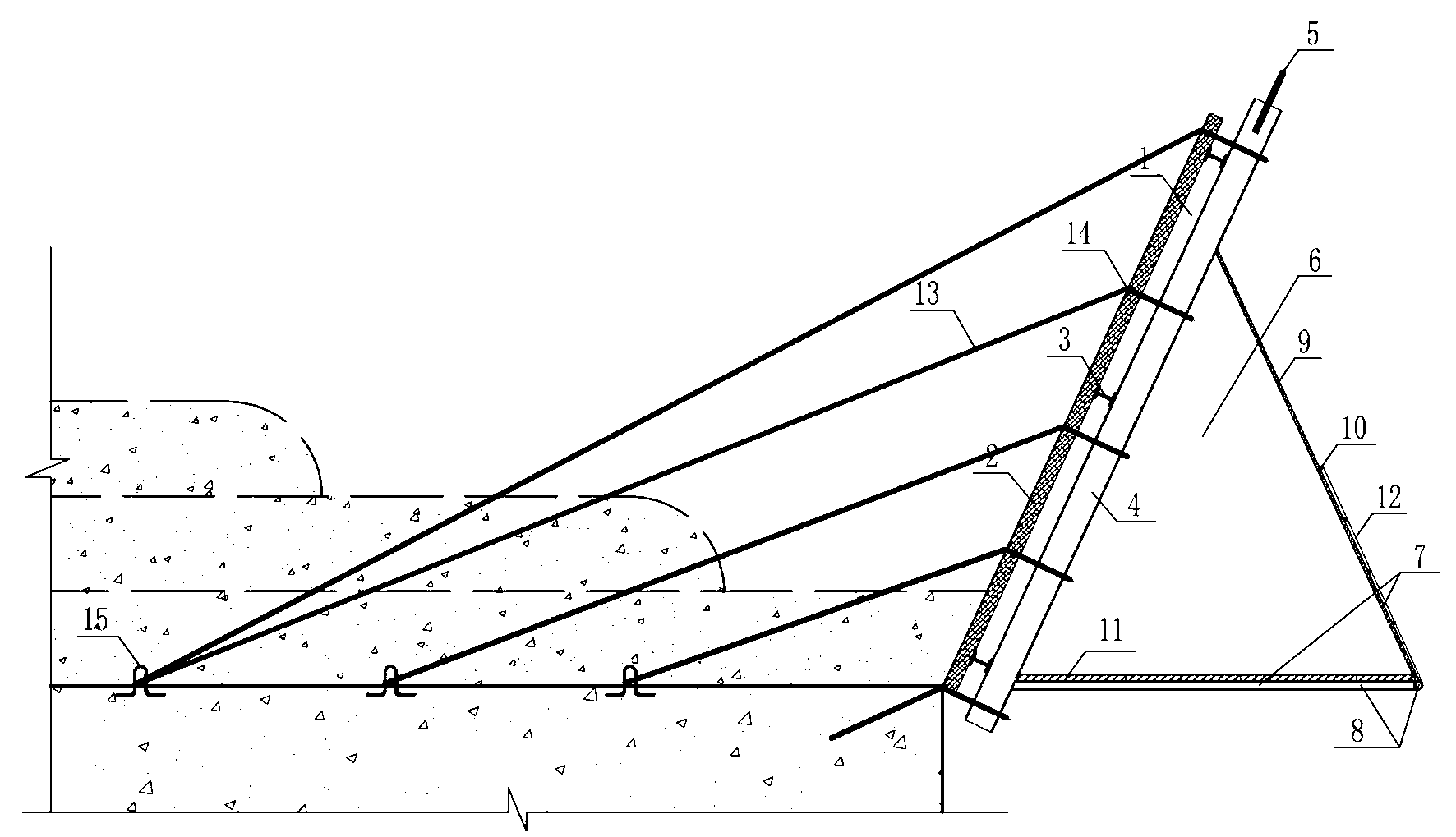

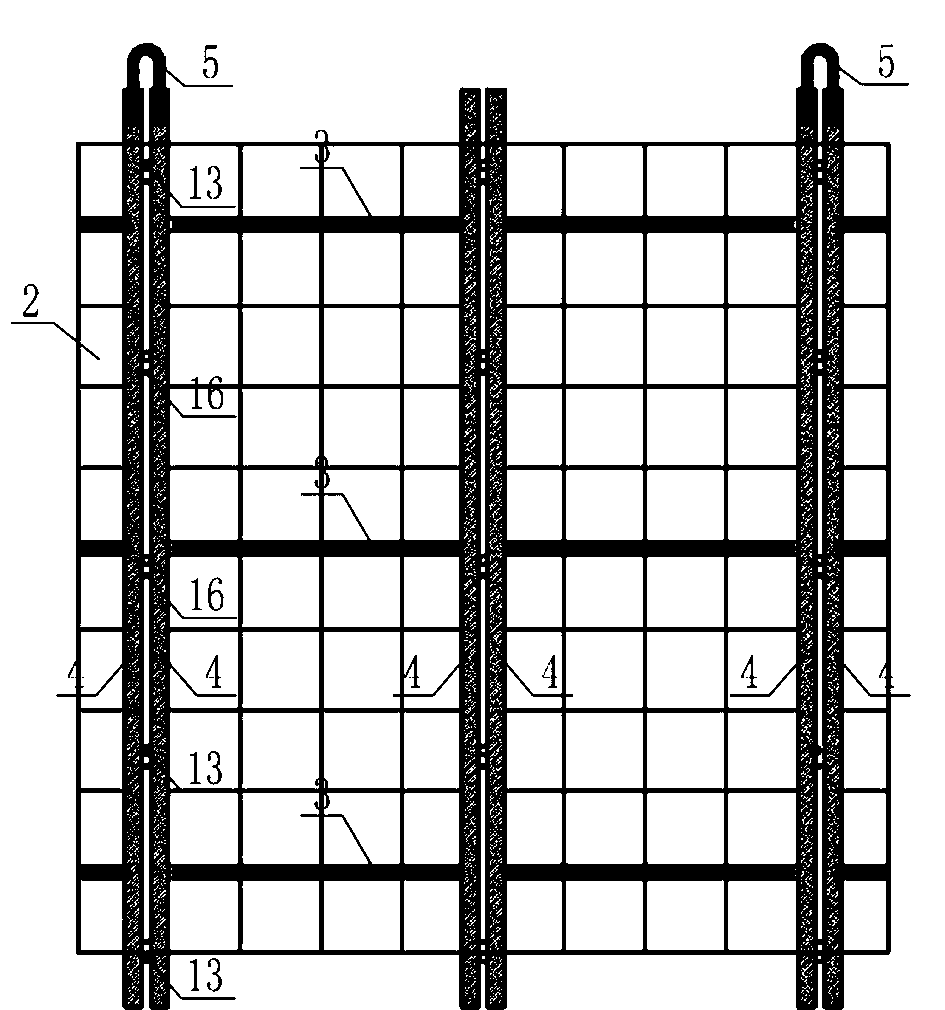

Construction method for deep foundation pit supporting and protecting system

The invention relates to a construction method for a deep foundation pit supporting and protecting system. According to the construction method, multi-row multi-direction jet-grouting mixing reinforced piles are combined with foundation pit composite supporting and protecting piles in a diagonal steel pipe supporting system, and the multi-row multi-direction jet-grouting mixing reinforced piles can be used for reinforcing adjacent soil, thereby forming relatively-high-strength anchor piles; hot-rolled seamless steel pipes are adopted for diagonal steel pipe supporting; and generally, steel pipes with the pipe diameter of 400 mm, 600 mm or 800 mm are adopted. The construction method has the advantages that compared with a traditional row pile supporting scheme, the scheme that the multi-row multi-direction jet-grouting mixing reinforced piles are combined with the foundation pit composite supporting and protecting piles in the diagonal steel pipe supporting system can save the cost by 20-50% and shorten the construction period by 40% when being used for excavation of a foundation pit with the excavation depth of 10-15 m and the area of 10,000 square meters or above; the steel supporting construction technique is simple and feasible, and can be reused; and accordingly, compared with a general supporting and protecting structure, the deep foundation pit supporting and protecting system is lower in cost and more remarkable in comprehensive benefit.

Owner:JIANGSU JIANGZHONG GROUP

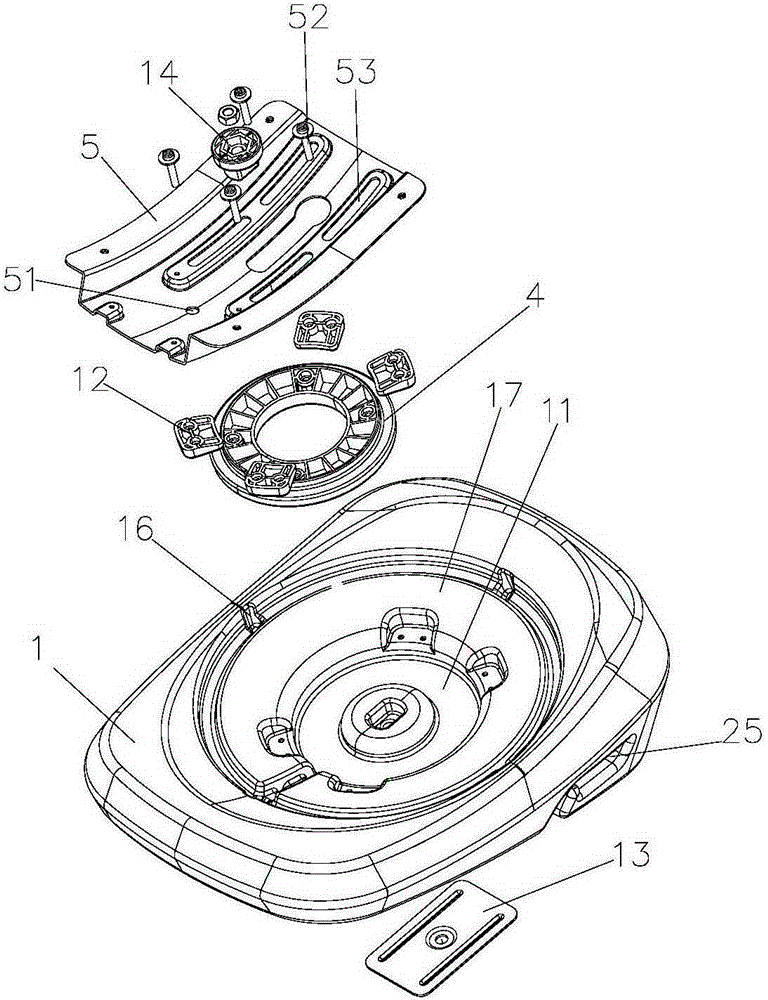

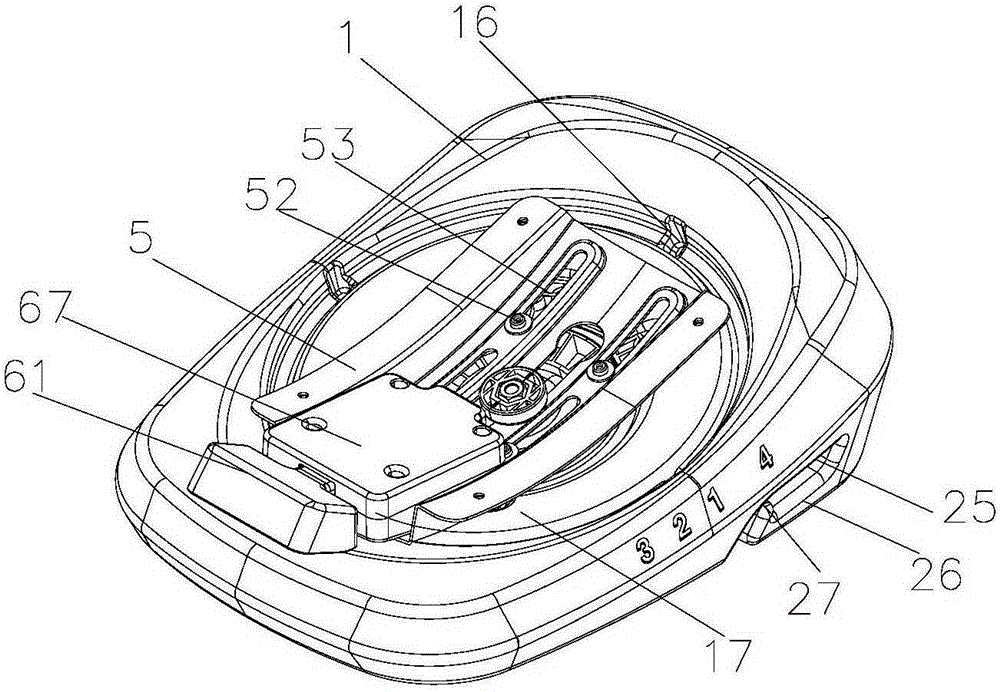

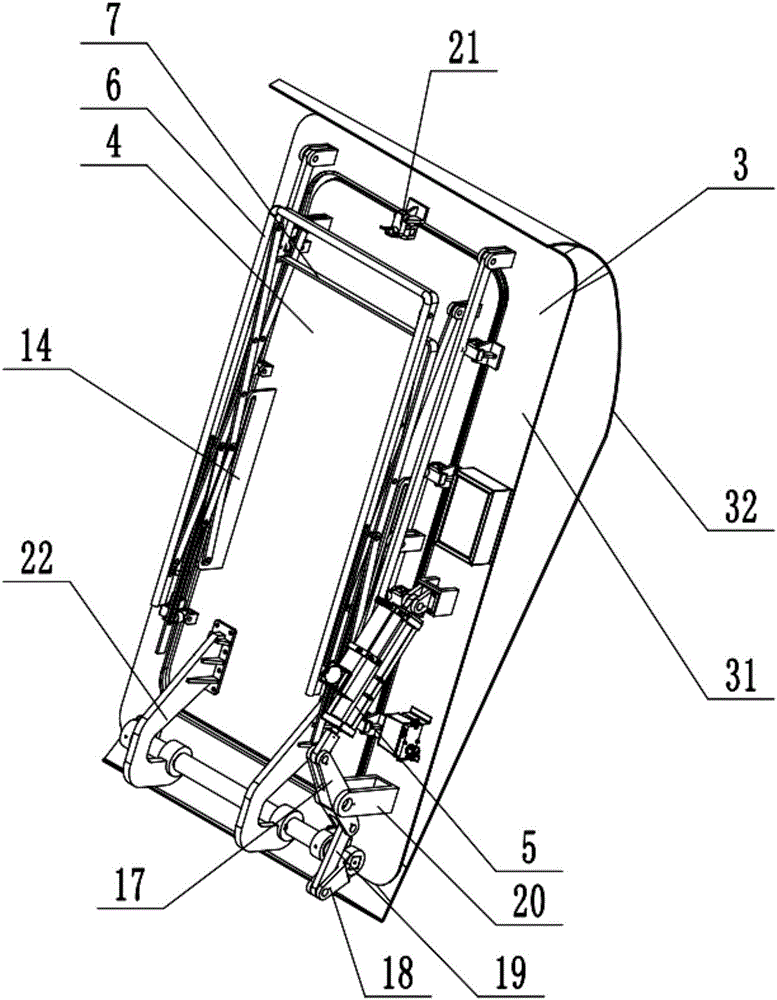

Child safe seat

Owner:常州安宝宝儿童座椅有限公司

Payment authentication method and device

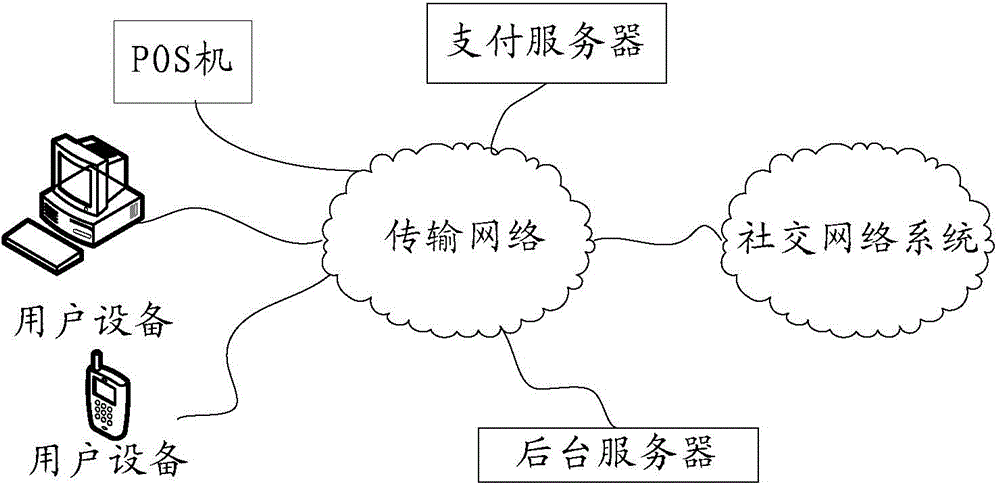

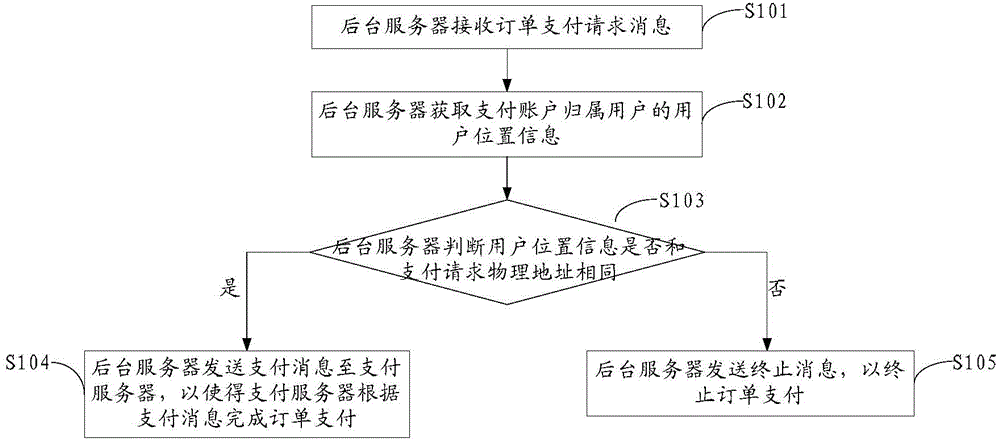

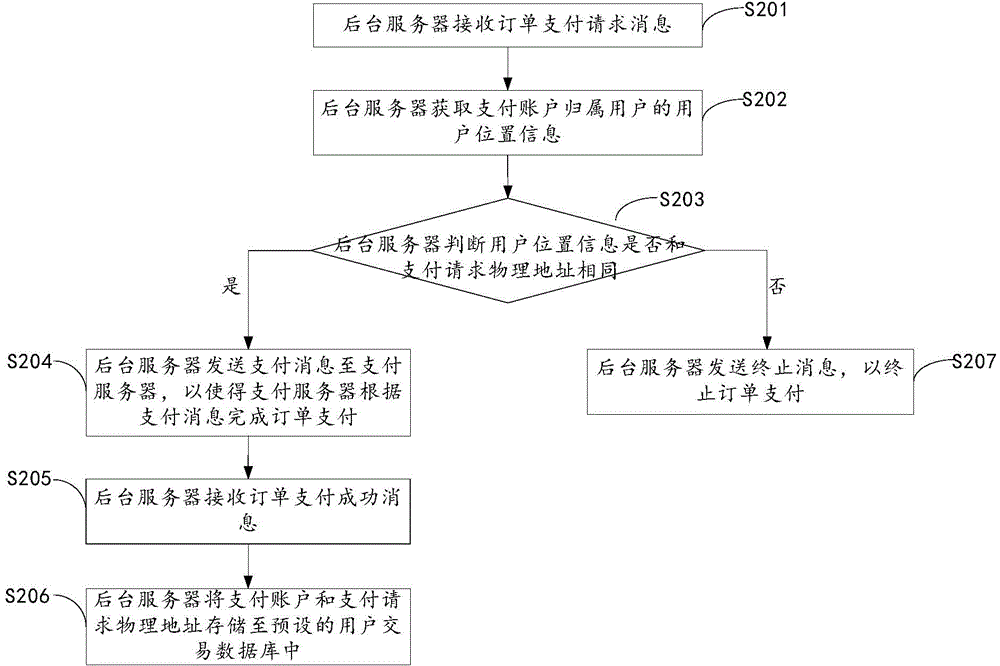

The embodiment of the invention provides a payment authentication method and a payment authentication device and relates to the technical field of payment safety. The method and the device could improve accuracy for judging a transaction state and strengthen safety of transaction. The method comprises the steps as follows: receiving order payment request information, wherein the order payment request information at least comprises a payment account number and a payment request physical address; obtaining user position information of a user who the payment account number belongs to and judging whether the user position information is the same as the payment request physical address; transmitting a payment message to a payment server if the user position information is the same as the payment request physical address so that the payment server could finish the order according to the payment message, and transmitting a stop message to the payment server if the user position information is not the same as the payment request physical address so as to terminate the order payment.

Owner:CHINA UNITED NETWORK COMM GRP CO LTD

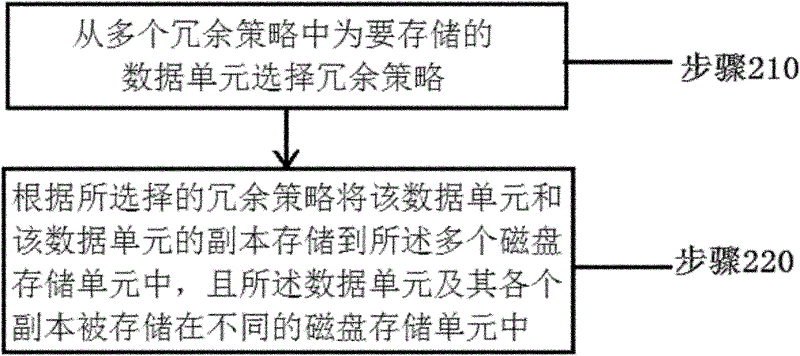

Data storage system and method

InactiveCN102622184AGuaranteed safetySave disk spaceInput/output to record carriersControl cellEngineering

The invention provides a data storage system and a method for storing data by using the system. The system comprises a plurality of disk storage units, a redundant strategy database and a storage control unit. The data storage method and the system select redundant strategies respectively according to different data units, save disk spaces on the basis of system safety guarantee, further improve system performance, and reduce operation cost successfully.

Owner:北京东方广视科技股份有限公司

Nonlinear multielement compound pile foundation

The present invention relates to a new-type pile foundation. It can be extensively used for treating various soft ground bases of multistoried, high-rise and super high-rise industrial and civil buildings and road and bridge, etc. Its main technique is characterized by that (1), the plane arrangement form of piles adopts non-symmetrical units or symmetrical units to make combination; (2), it adopts a small quantity of long piles, these long piles mainly are placed in the positions bearing larger load under the column (or under the wall) or central position of symmetrical unit, its single pile is friction pile; (3), it has a lots of short piles, said short pile can be pipe-sinking pile, CFG pile, cement mixed pile or shaped pile; (4), it utilizes said short pile and soil to form the invented composite ground base, on its surface a layer of bedding sandstone is laid; and (5), its total safety degree is greater than 2, its total settlement is less than 50 mm and its difference settlement is less than 10 mm.

Owner:CHINA THREE GORGES UNIV

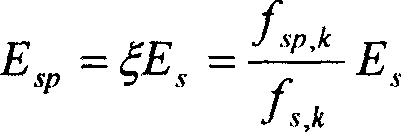

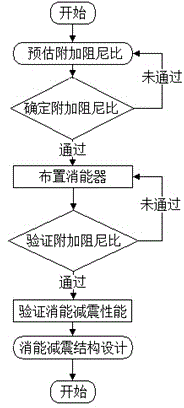

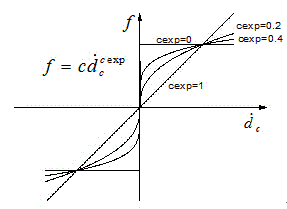

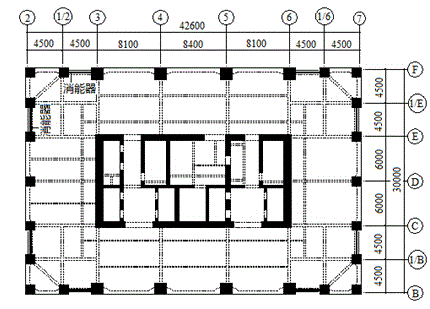

Method for designing structure with stiction energy dissipater

ActiveCN104405054AGuaranteed safetyAvoid multiple iteration problemsShock proofingDesign softwareClassical mechanics

The invention provides a method for designing a structure with stiction energy dissipaters. The method comprises the following steps: predicting a required additional damping ratio; determining the additional damping ratio according to main calculation parameters; determining the distribution positions of energy dissipaters according to a certain principle and determining the quantity of the energy dissipaters; according to the calculated average energy consumed by the energy dissipaters under an earthquake effect, selecting the type of the energy dissipaters; if the difference between the main calculation result of a non-linearity time interval analysis method of an energy-dissipation shock-absorption unit and the main calculation result of an elastic time interval analysis method with the additional damping ratio is not greater than 10%, determining that the additional damping ratio value is reasonable; analyzing the performances of an energy-dissipation shock-absorption structure under a macroquake by use of a non-linearity power time interval analysis method; after damping ratio and performance verification, performing energy-dissipation shock-absorption structure design with conventional design software by use of a simplified linearity method. According to the design method, iterative calculation is not needed, the problem of repeated iterations in additional damping ratio calculation is avoided, and the safety degree of the simplified linearity analysis method is also ensured.

Owner:甘肃省建筑设计研究院有限公司

Double-oil-tank heating and oil supply switching control system

ActiveCN104895712AEnsure safetyGuaranteed safetyInternal combustion piston enginesEngine controllersElectricityControl system

The invention relates to a double-oil-tank heating and oil supply switching control system. The double-oil-tank heating and oil supply switching control system comprises a primary oil tank, a secondary oil tank, an ignition lock, a fuel tank, a selector switch, a switching valve assembly, a primary oil tank diesel filter, a secondary oil tank diesel filter, a primary oil tank heating system, a secondary oil tank heating system, a leading wire and a connecting pipeline. According to the double-oil-tank heating and oil supply switching control system, a primary oil tank heating relay, a secondary oil tank heating relay and the fuel oil selector switch are connected, so that heating is only performed on a working oil supply loop, electricity loss caused by unnecessary heating is reduced, and safety of a power supply loop is improved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Medical waste crushing treatment device and treatment process adopting same

PendingCN107030091AGuaranteed stabilityGuaranteed safetyGas current separationSolid waste disposalMedical wasteEnvironmental engineering

The invention provides a medical waste crushing treatment device which comprises a feeding conveyer belt, a feed opening, a crushing chamber, a sorting room, a compression chamber and a moving chamber, wherein the feeding conveyer belt is mounted at the right end of the feed opening; a feeding hopper is arranged on the feeding conveyer belt; the invention further provides a treatment process adopting the medical waste crushing treatment device. Compared with the prior art, the medical waste crushing treatment device and the treatment process adopting the same have the benefits as follows: wastes can be compressed and stored in a classified manner and wait to be transferred to different garbage disposal plants, expenses spent on garbage disposal are reduced for the society, environmental requirements of medical wastes on stabilization, securitization, reduction and harmlessness are ensured, and meanwhile the conformity to the development tendency of modern medical waste treatment is achieved.

Owner:SHANDONG JINGHUA ENVIRONMENTAL SCI & TECH

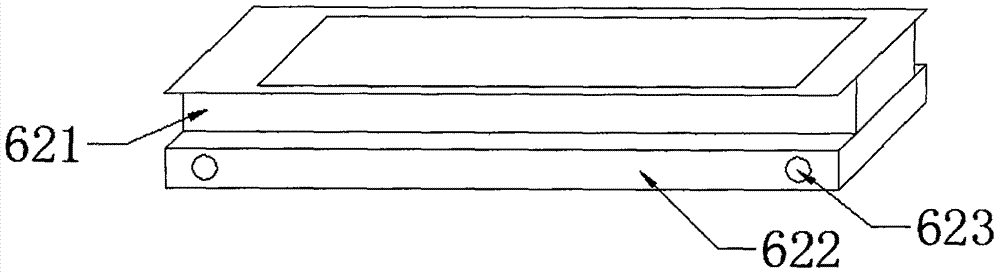

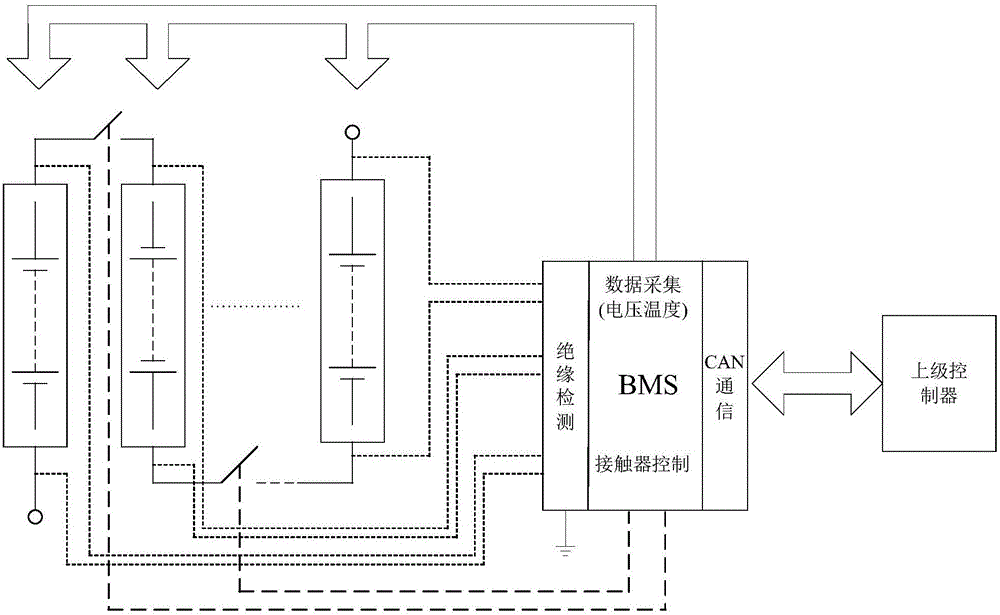

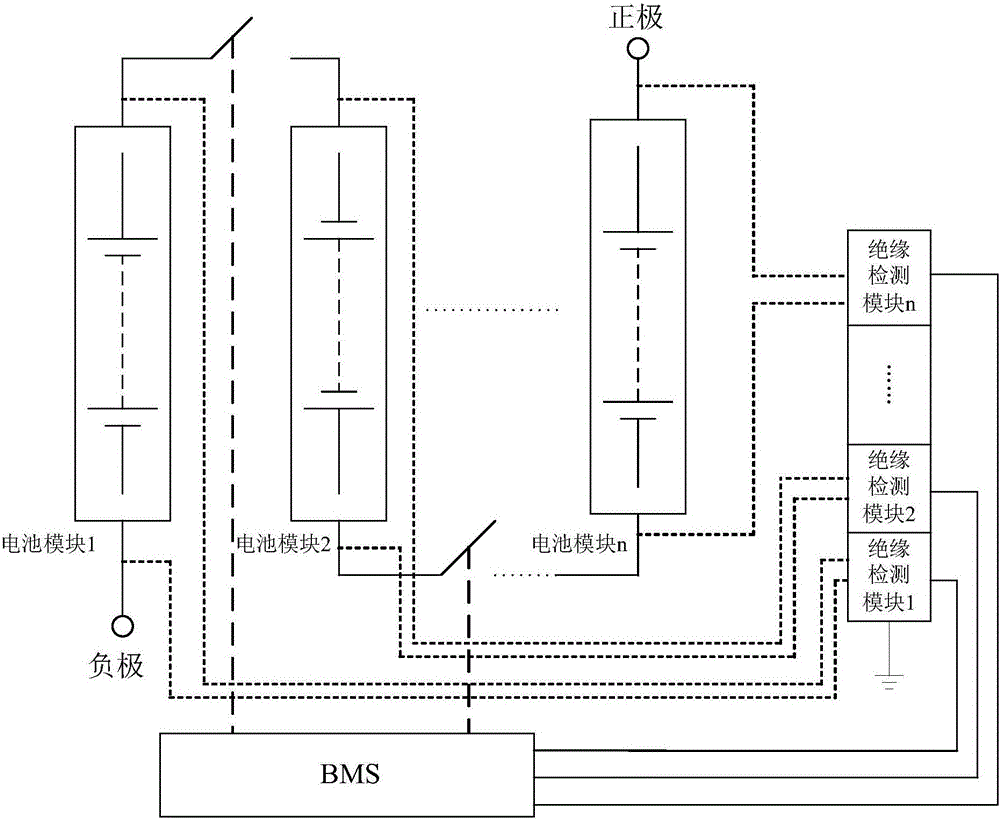

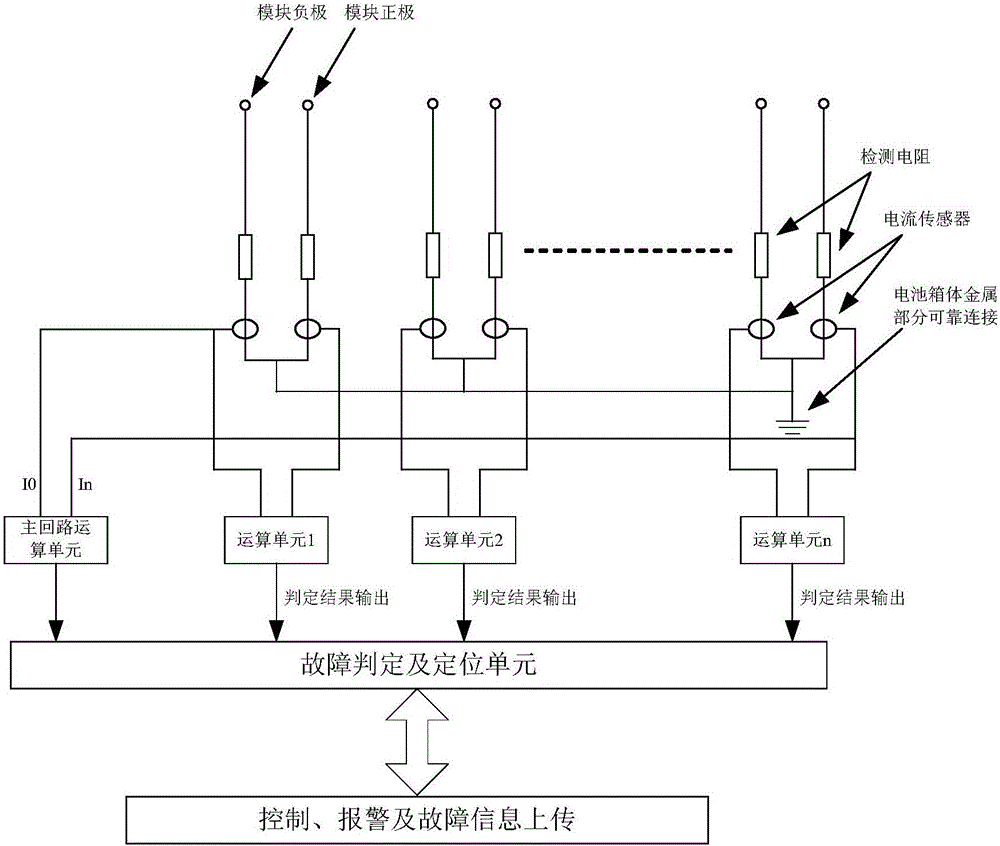

Battery pack insulation detection apparatus and insulation detection method thereof

ActiveCN105676091AGuaranteed safetyEnsure reliabilityTesting dielectric strengthElectrical resistance and conductanceElectrical battery

The invention relates to a battery pack insulation detection apparatus and an insulation detection method thereof. The insulation detection apparatus includes a controller and insulation detection modules one-to-one corresponding to battery modules. Signal input terminals of each insulation detection module are connected to a positive electrode and a negative electrode of the corresponding battery module. The output of the insulation detection modules is connected to a signal input terminal of the controller. During the insulation detection, for any one battery module, firstly current values on a positive electrode detection resistor and on a negative electrode detection resistor corresponding to the battery module are collected. Then the collected two current values are compared. When an error between the two current values is larger than a preset first comparison threshold, the battery module is judged as defective insulation. The detection apparatus can accurately obtain that which battery module in the battery pack has an insulation fault, accurately judges the insulation fault position in the battery pack, lays foundation for subsequent fault maintenance and fault elimination, and ensures the safety, the reliability and the economy of the battery pack usage.

Owner:CALB CO LTD

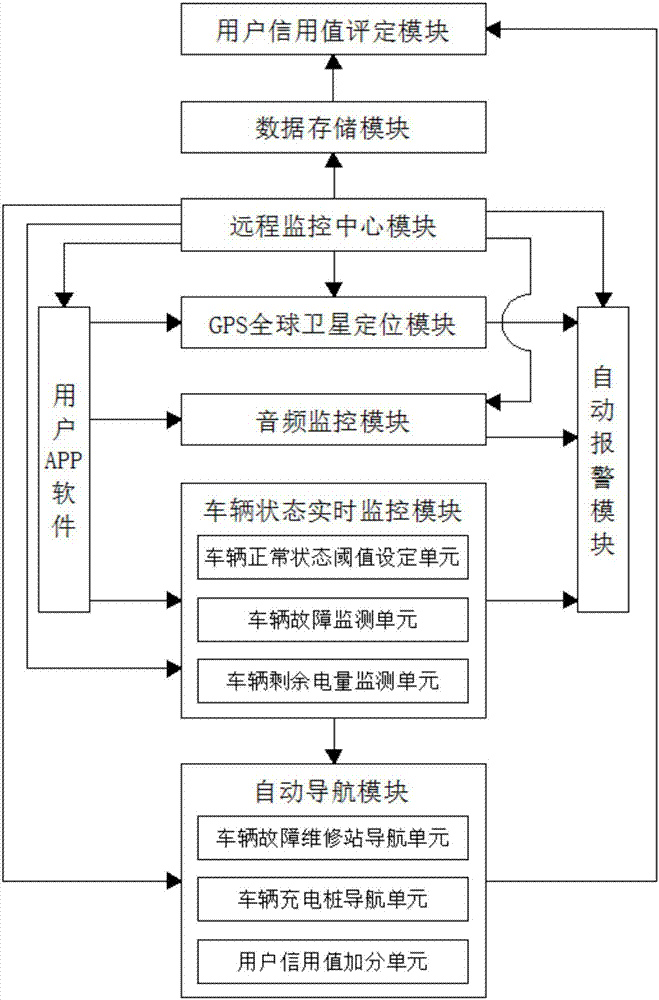

Vehicle remote automatic monitoring method

InactiveCN107491023AImprove normativeImprove securityProgramme controlComputer controlAutomatic vehicle monitoringElectricity

The invention belongs to the technical field of vehicle monitoring, and in particular relates to a vehicle remote automatic monitoring method. The problem that a single remote vehicle monitoring function cannot extract and screen safety, status and other comprehensive information of a shared vehicle for a manager and a user, has low degree of intelligence and automation, and is inconvenient to use in the prior art is solved. The method comprises the steps that a remote automatic vehicle monitoring system is established; the user who is certified registers user APP software to select the vehicle; and a GPS global satellite positioning module, an audio monitoring module and a vehicle status real-time monitoring module automatically monitor the vehicle status and the driving behavior of the user in real time during the entire process of the vehicle activation. According to the invention, the real-time position, the safety status, the electricity quota of the vehicle and the user quality of the vehicle are comprehensively monitored; the damage rate and the accident rate of the used shared vehicle are effectively reduced; the maximum economy and safety of the shared vehicle are ensured; and the method is worthy of promotion.

Owner:GUANGDONG INST OF SCI & TECH

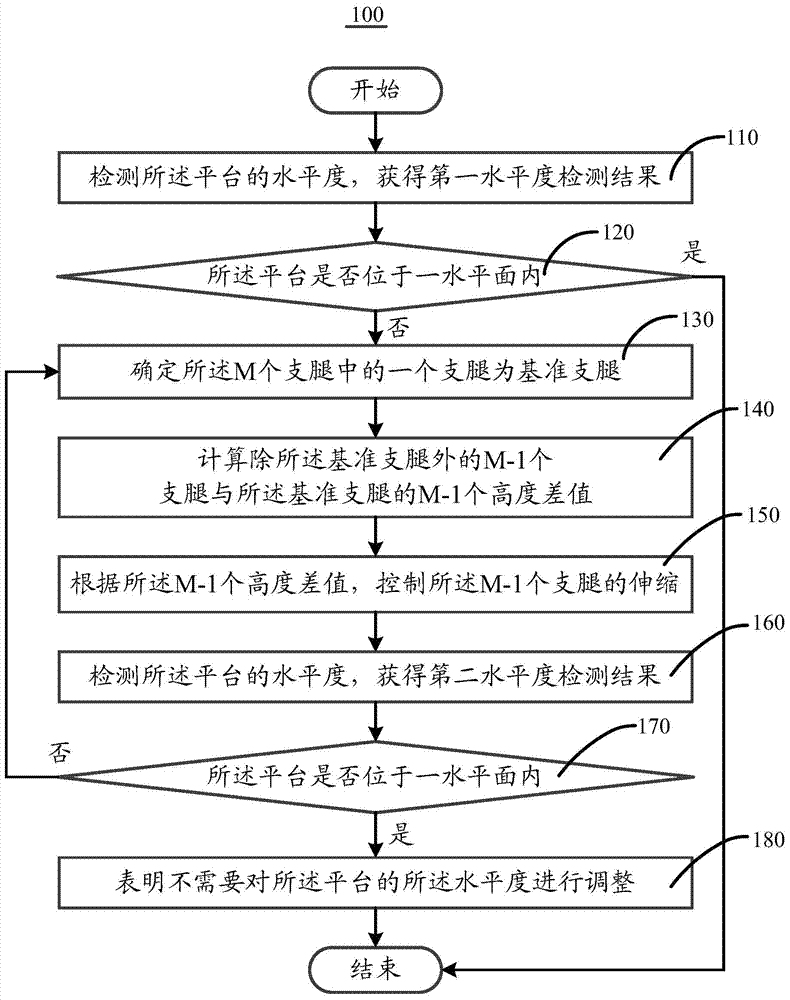

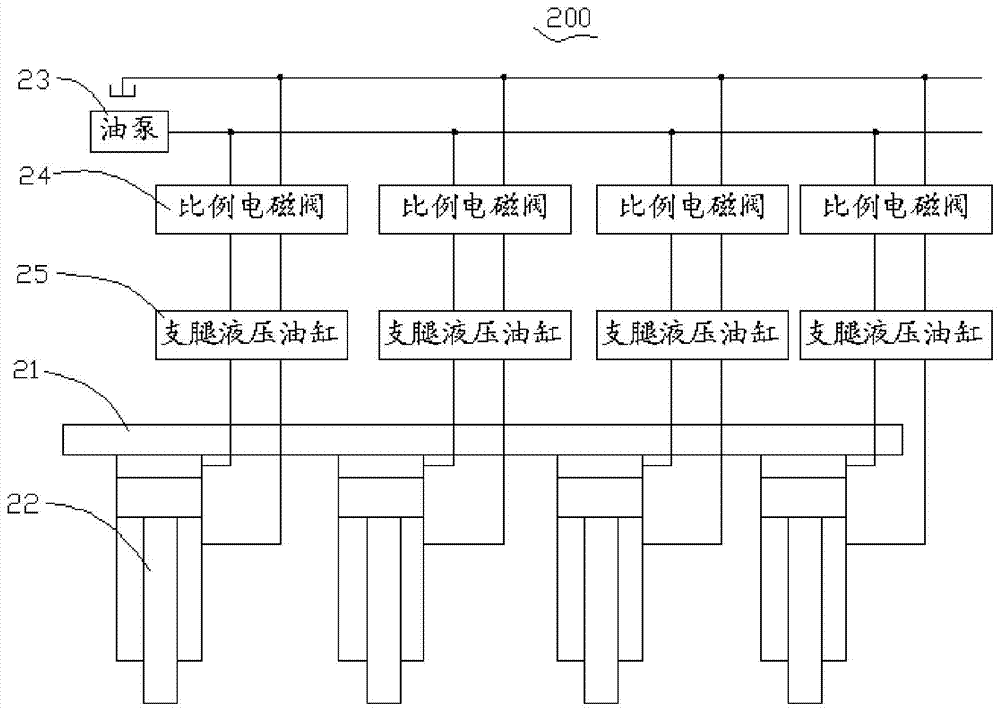

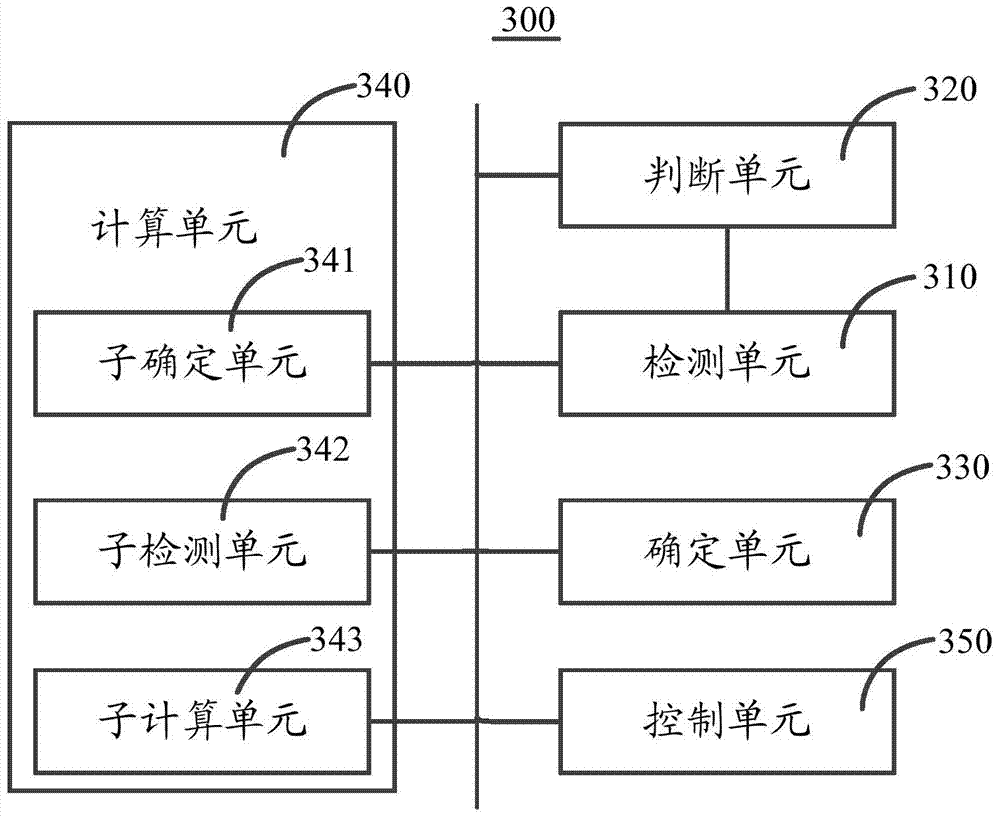

Method and system for adjusting levelness of platform of engineering machinery equipment

ActiveCN103693572AQuick level adjustmentSave operating timeVehicle fittings for liftingCranesHeight differencePetroleum engineering

The invention discloses a method and a system for adjusting the levelness of a platform of engineering machinery equipment. The engineering machinery equipment comprises M supporting legs which are used for supporting the platform, wherein M is an integer which is greater than or equal to 2. The method for adjusting the levelness of the platform of the engineering machinery equipment comprises the following steps: detecting the levelness of the platform to obtain a first levelness detection result; judging whether the platform is positioned in a horizontal plane according to the first levelness detection result to obtain a first judgment result; when the first judgment result indicates that the platform is not positioned in the horizontal plane, determining that one of the M supporting legs is a reference supporting leg; calculating M-1 height difference values between the reference supporting leg and the other M-1 supporting legs; further controlling the telescoping of the M-1 supporting legs according to the M-1 height difference values, so as to enable the platform to be positioned in the horizontal plane.

Owner:ZOOMLION HEAVY IND CO LTD

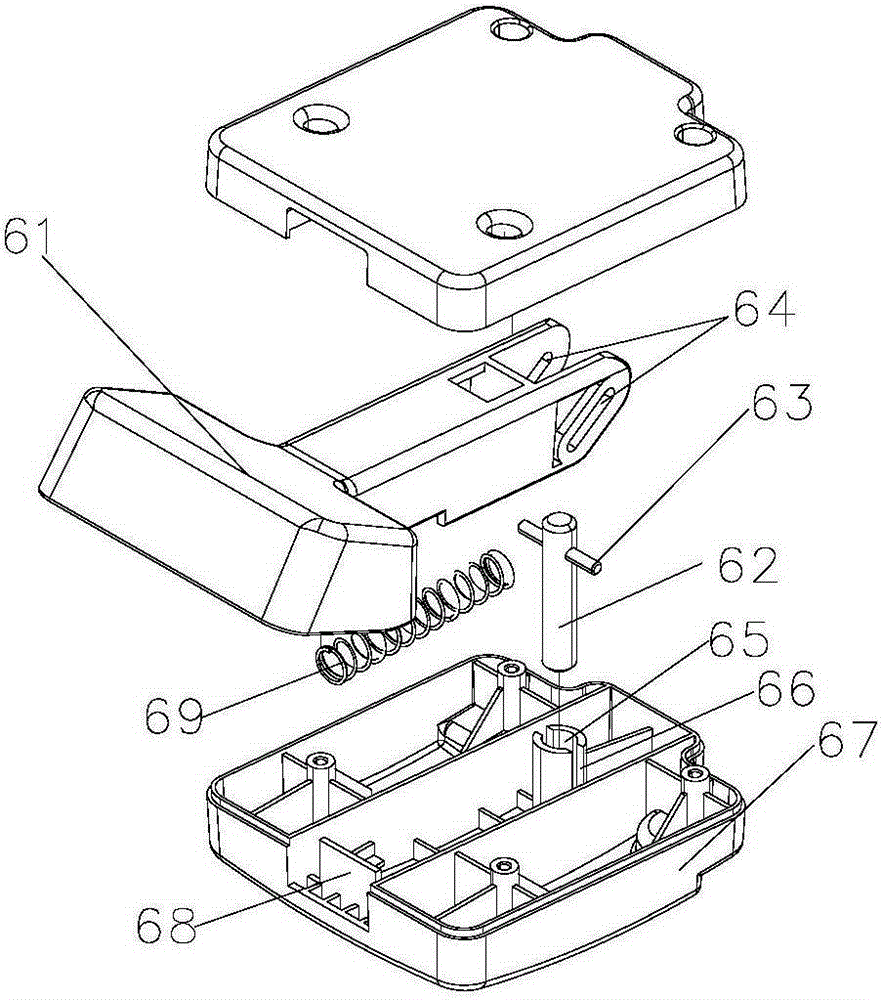

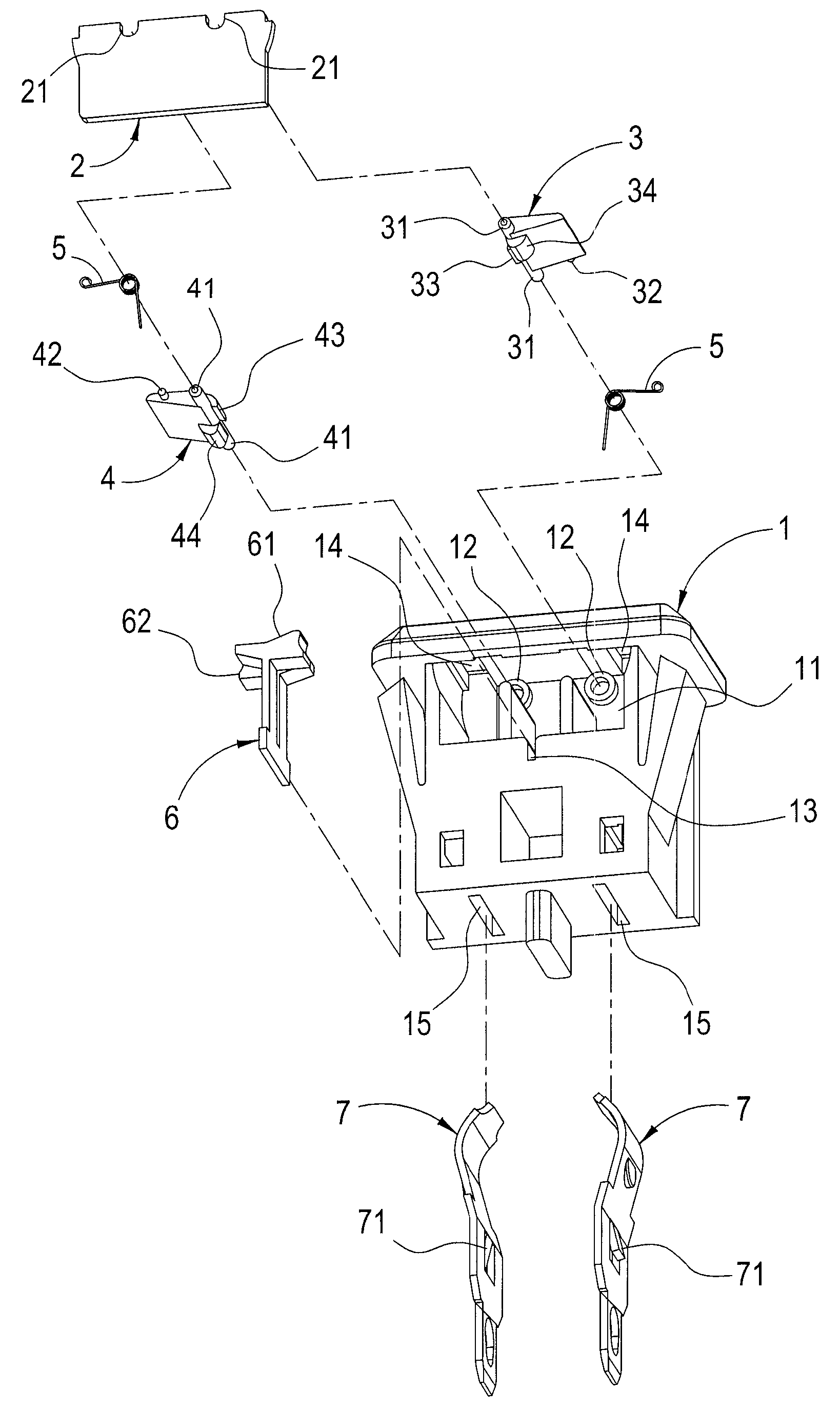

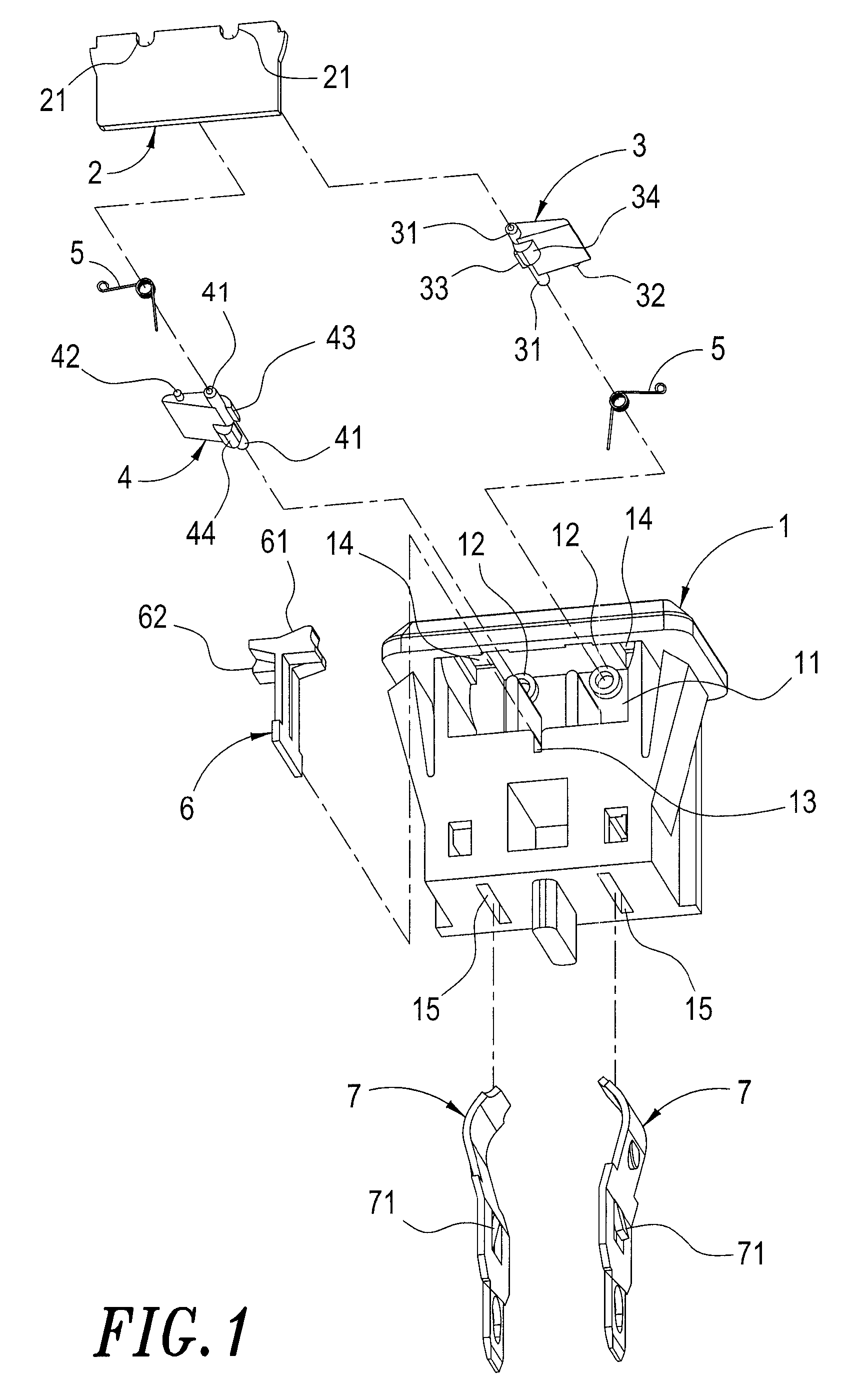

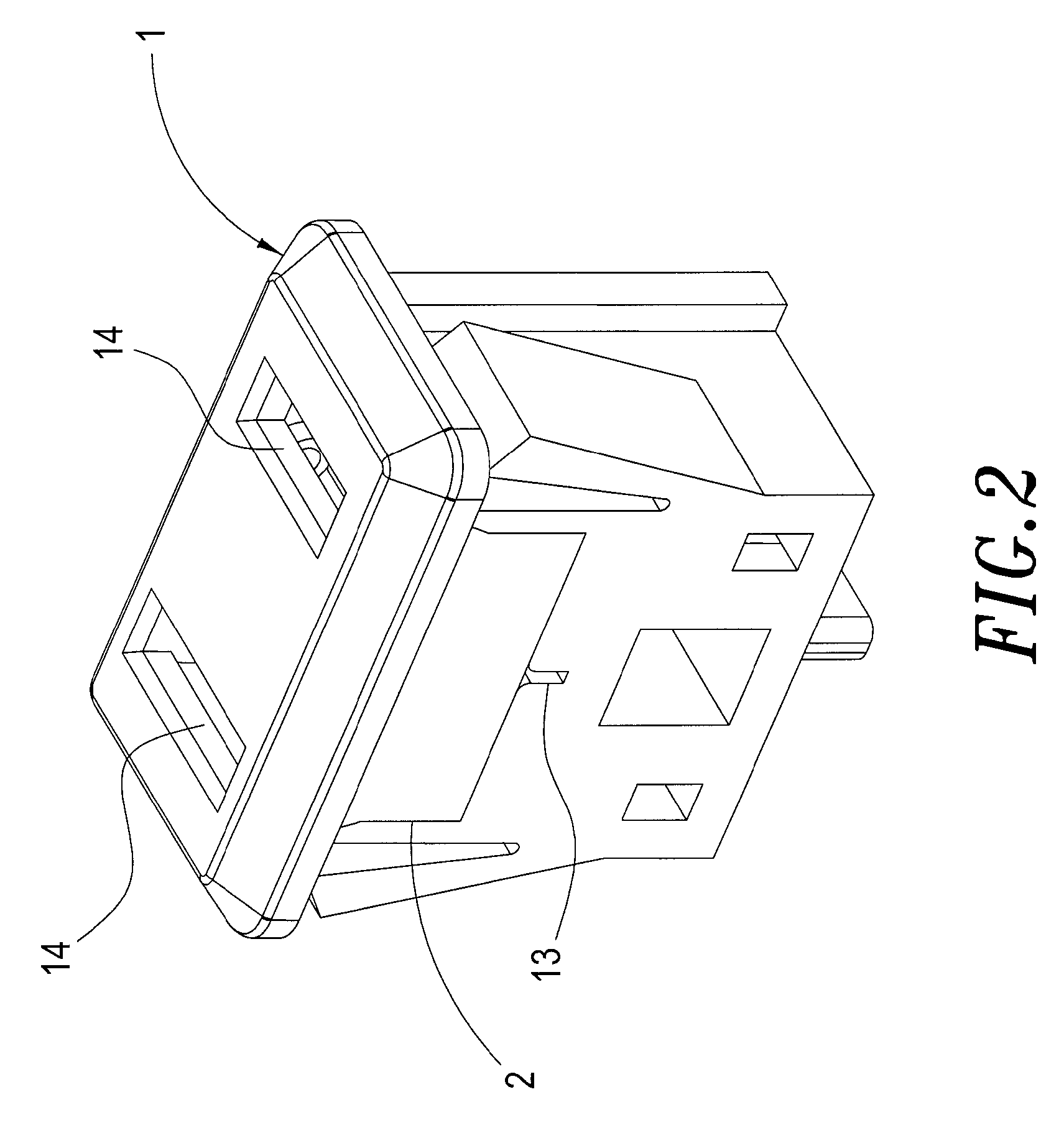

Jack structure

InactiveUS7211729B1Simple structureGuaranteed safetyElectric discharge tubesCasings/cabinets/drawers detailsEngineeringElectric shock

Disclosed is an improved jack structure, includes a main body, a cover, two protective covers, a lock piece and a conductive piece. When an object is inserted into a single one of insertion holes each corresponding to one of the protective covers on the main body, a corresponding one of the protective covers is pushed to move. A protrusion of the pushed protective cover then pushes an urging portion of the lock piece and the urging portion is stopped by the other one of the protective covers. Therefore, the improved jack structure can be prevented from being inserted with an acute object and thus from occurrence of electric shock.

Owner:JAZZ HIPSTER

Powdery emulsion explosive for on-site mixed loading and preparation method of powdery emulsion explosive

ActiveCN106008122AReduce production and transportation costsImprove intrinsic safetyExplosive working-up apparatusNon-explosive/non-thermic compositionsCelluloseExplosive Agents

The invention discloses a powdery emulsion explosive for on-site mixed loading. The powdery emulsion explosive comprises powdery latex substrate and a sensitizer. The mass ratio of the powdery latex substrate to the sensitizer is 30: (1-1.5). The powdery latex substrate comprises sodium nitrate, crystal modifiers, flame inhibitors, water, compound additives, oil-phase materials, compound emulsifiers and emulsification assistants. The sensitizer comprises expanded perlite, carboxymethyl cellulose, polyvinyl alcohol, ammonium bicarbonate, phosphoric acid, water, urea and ammonium nitrate. The invention further discloses a preparation method of the powdery emulsion explosive for on-site mixed loading. The emulsion explosive has high detonation velocity, brisance and coupling degree and few fumes; cost is low, the state of the explosive is hard, and work capacity is high; less poisonous gas is generated during preparation, safety of operators can be improved, and environment protection can be realized; the preparation process is simple and easy to operate.

Owner:宜兴市阳生化工有限公司

Hydraulic bow door device

The invention relates to a hydraulic bow door device, comprising a bow door moveably installed on a deck through a hinged shaft; the bow door comprises a door frame and a hinge which are installed together in a sealing manner; the front face side of the door frame is equipped with a hydraulic driving cylinder, and a cylinder body of the hydraulic driving cylinder is hinged with the door frame; the end part of a piston rod thereof is hinged with the hinged shaft through a first link rod component; after pushing out the piston rod of the hydraulic driving cylinder, the bow door is overturned to be a horizontal placing state; the front face side of the bow door is equipped with a foldable guardrail component. According to the invention, the guardrail component is combined with the bow door; when the bow door is opened, the guardrail can be unfolded, so as to guarantee the protecting safety of a channel formed after connecting the bow door with a wharf; the hydraulic bow door device is reasonable in structural design; the opening operations of the guardrail and the bow door are simple; when the hydraulic driving cylinder drives the bow door, the route is short, and the supporting stability is good.

Owner:WUXI XINFAN MARINE EQUIP CO LTD

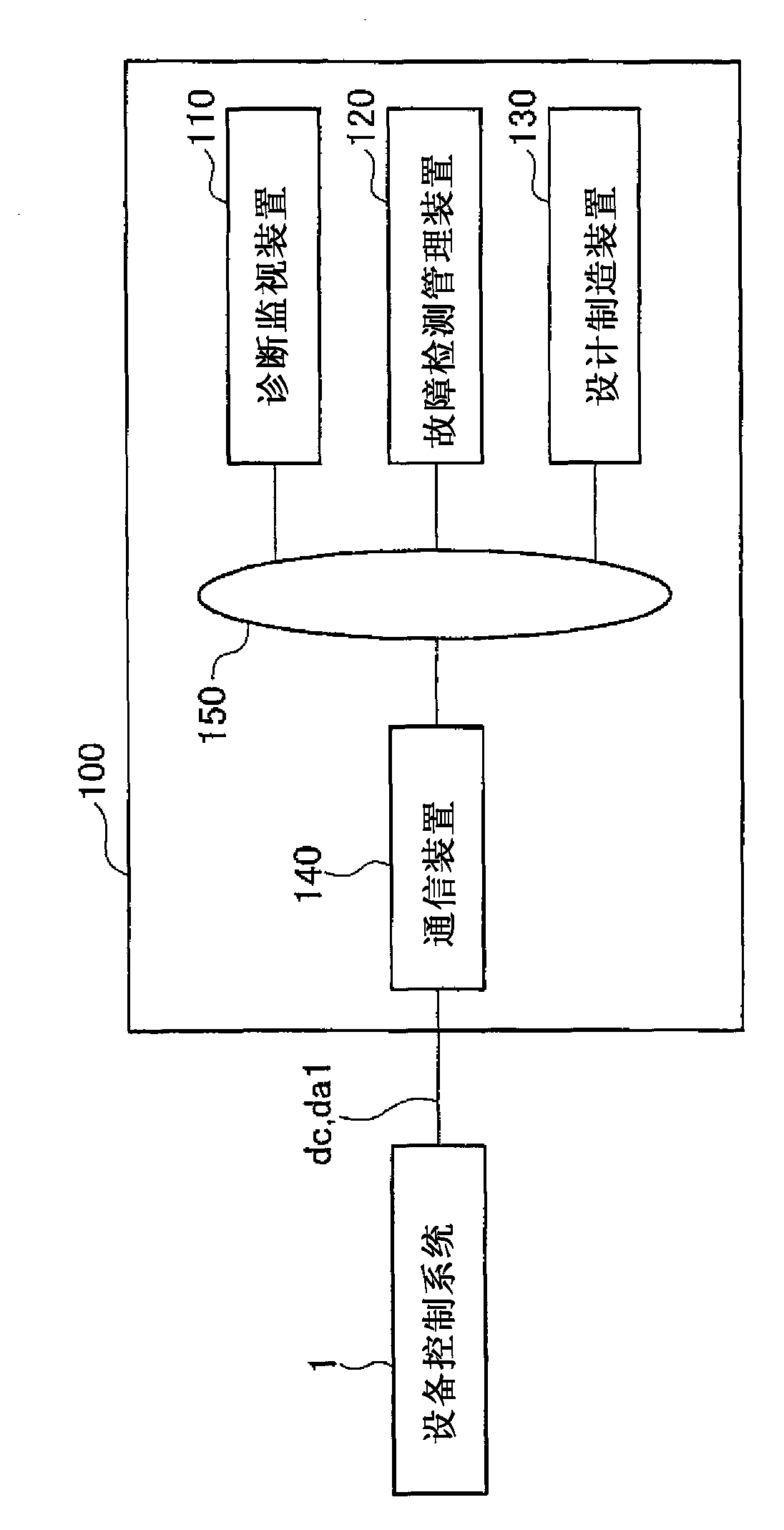

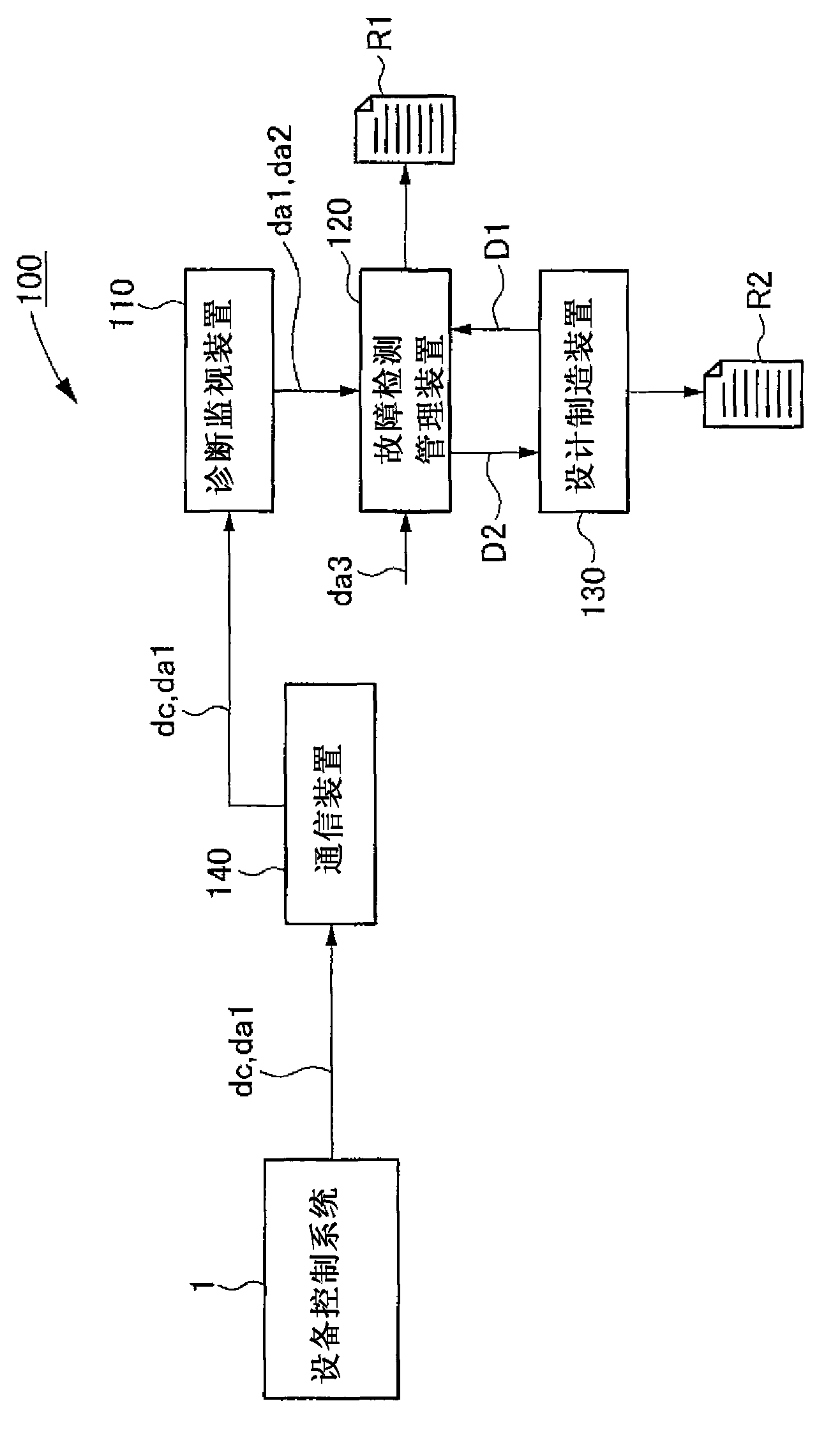

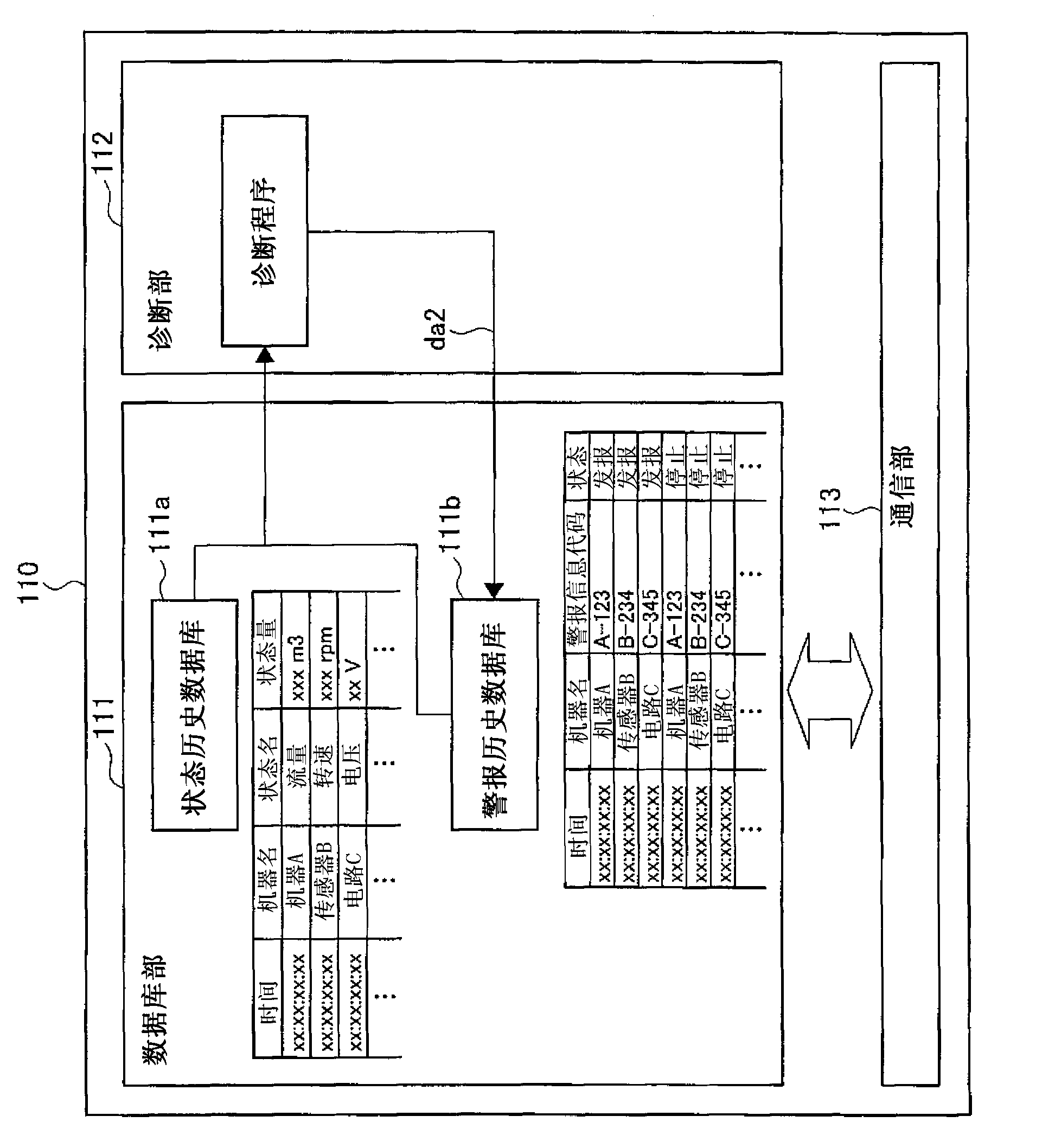

Plant safety design assistance device and plant monitoring and maintenance assistance device

ActiveCN103229118AEasy information exchangeGuaranteed safetyProgramme controlElectric testing/monitoringPlant safetyControl system

A plant safety design assistance device (100) is configured by a communication device (140), a diagnosing and monitoring device (110), a fault inspection management device (120), and a design and manufacturing device (130) being interconnected via a network (150). The diagnosing and monitoring device (110) receives plant status information (dc) from a plant control system (1) and carries out monitoring and diagnosing on the plant. The fault inspection management device (120) maintains fault inspection information (D2) of an apparatus which is used in the plant. The design and manufacturing device (130) maintains design and manufacturing information of the apparatus which is used in the plant. The design and manufacturing device (130) receives the fault inspection information (D2) from the fault inspection management device (120), and carries out a plant safety design which takes the fault inspection information into account. The plant safety design is thus assisted, with the plant monitoring and maintenance activities being linked therewith.

Owner:MITSUBISHI HEAVY IND LTD

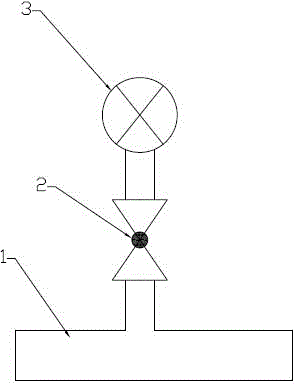

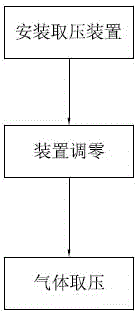

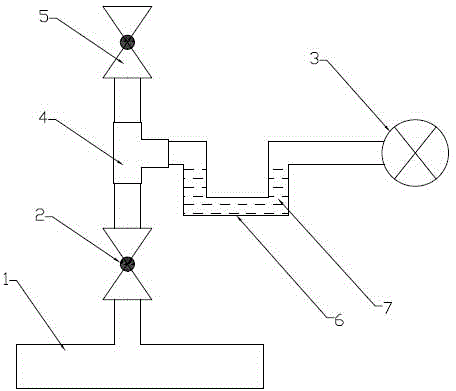

Online gas pressure-tapping method and online gas pressure-tapping device

InactiveCN104019934AImprove work efficiencyImprove efficiencyFluid pressure measurementTransmitterPetroleum engineering

The invention provides an online gas pressure-tapping method and an online gas pressure-tapping device. The method comprises the steps of (1) mounting the pressure-tapping device, (2) resetting the device, and (3) carrying out gas pressure-tapping. The device comprises a main ball valve, a pressure transmitter, a tee joint, an auxiliary ball valve and a U-shaped pipeline; one end of the main ball valve is communicated with a gas pipeline by use of a pressure-tapping pipeline, while the other end of the main ball valve is connected with a lower opening of a three-way joint by use of a pipeline; the auxiliary ball valve is connected with an upper opening of the three-way joint by use of a pipeline; one end of the U-shaped pipeline is connected with a right opening of the three-way joint, while the other end of the U-shaped pipeline is connected with the pressure transmitter. The online gas pressure-tapping method and the online gas pressure-tapping device have the advantages that the traditional mounting manner is broken through, the working efficiency is improved, necessary isolation measure is carried out, the pressure-tapping pipeline is convenient to dredge, and the safety and accuracy are greatly improved.

Owner:JIGANG GRP

Yacht

InactiveCN104176202AEnsure safetySmooth liftWaterborne vesselsSpecial purpose vesselsRecreationMarine engineering

The invention relates to a yacht. The yacht is characterized in that a movable diving platform for aquatic recreation of passengers on the yacht is arranged, a hydraulic device and mechanical arms are arranged at the lower part, and the hydraulic device is controlled to enable the mechanical arms to move, so that the diving platform can be lifted and lowered stably. The diving platform is kept to be horizontal during lifting and lowering and can carry the passengers during lifting and lowering, and the platform can be lowered under the water, so that the passengers on the yacht can enter the water, get on the yacht and have fun in water conveniently. A hydraulic protection lock is arranged on the yacht, and when the diving platform is located in the highest position, the platform can be locked, so that the safety of the yacht is guaranteed. A horizontal adjusting device is arranged on the yacht, so that the platform can be ensured to be horizontal regardless of the perpendicularity of the mounting position on the yacht.

Owner:YAGUANG TECH GRP CO LTD

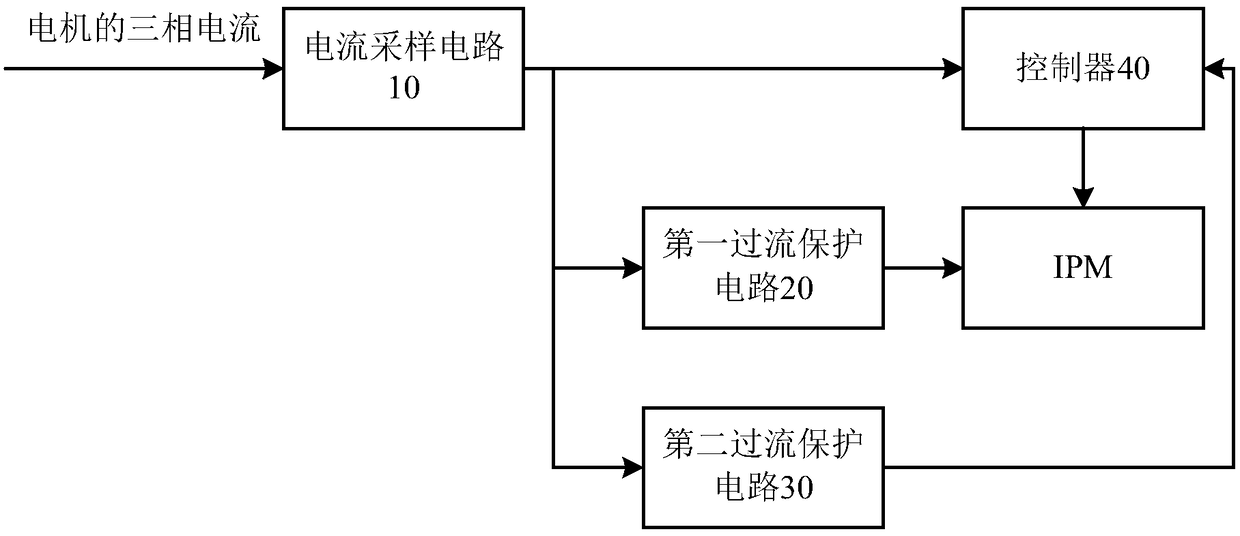

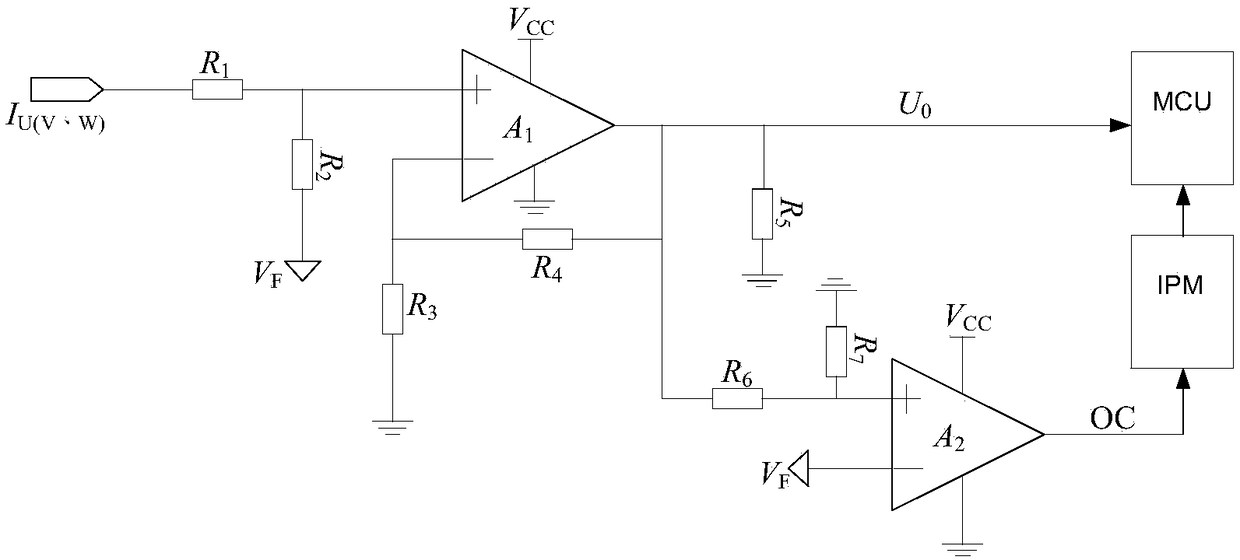

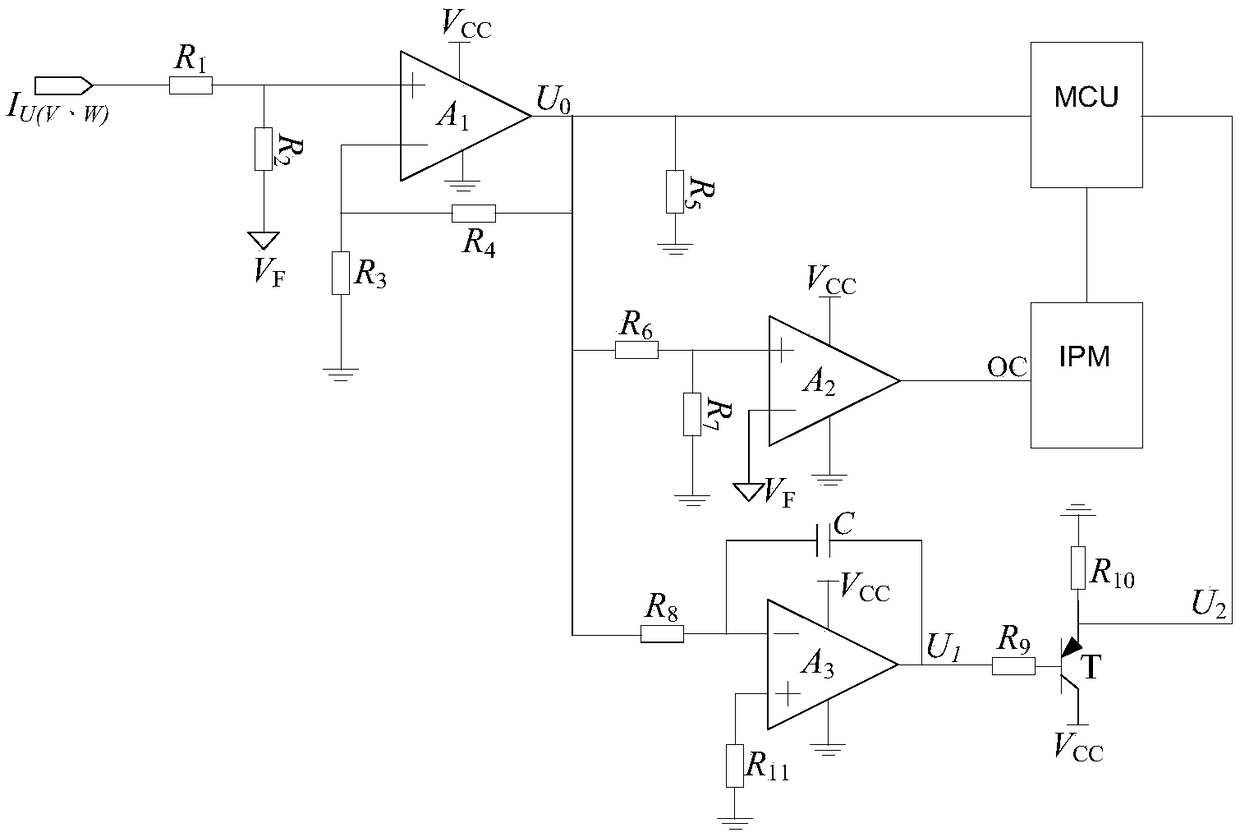

IPM protection device, motor and IPM protection method thereof

PendingCN109193569AExtended service lifeSolve burntEmergency protective circuit arrangementsMotor driveThree-phase

The invention discloses an IPM protection device, an electric motor and an IPM protection method thereof. The device comprises a current sampling circuit, a first overcurrent protection circuit, a second overcurrent protection circuit and a controller, wherein, the current sampling circuit is used for collecting the three-phase current of the motor driven by the IPM to be protected, and outputtinga first output signal under the normal condition of the current sampling circuit, or outputting a second output signal under the abnormal condition of the current sampling circuit. The first overcurrent protection circuit is used for realizing overcurrent protection of IPM to be protected according to the first output signal under the control of the controller. The second overcurrent protection circuit is configured to realize overcurrent protection of the IPM to be protected according to the second output signal under the control of the controller. The scheme of the invention can solve the problem that the IPM internal power device is burned out after the operational amplifier chip fails in the current sampling circuit, and the protection reliability is poor, so that the effect of improving the protection reliability is achieved.

Owner:GREE ELECTRIC APPLIANCES INC

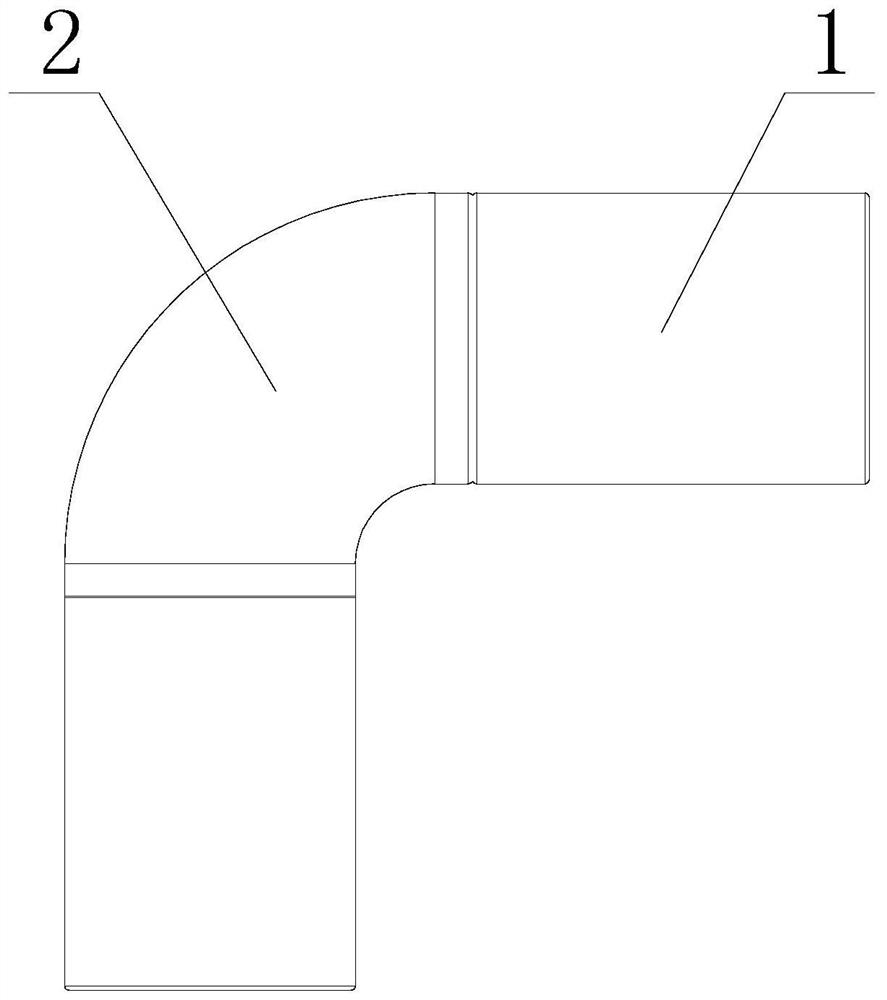

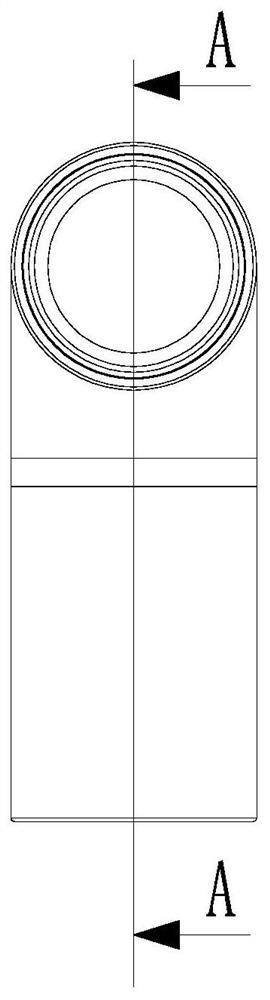

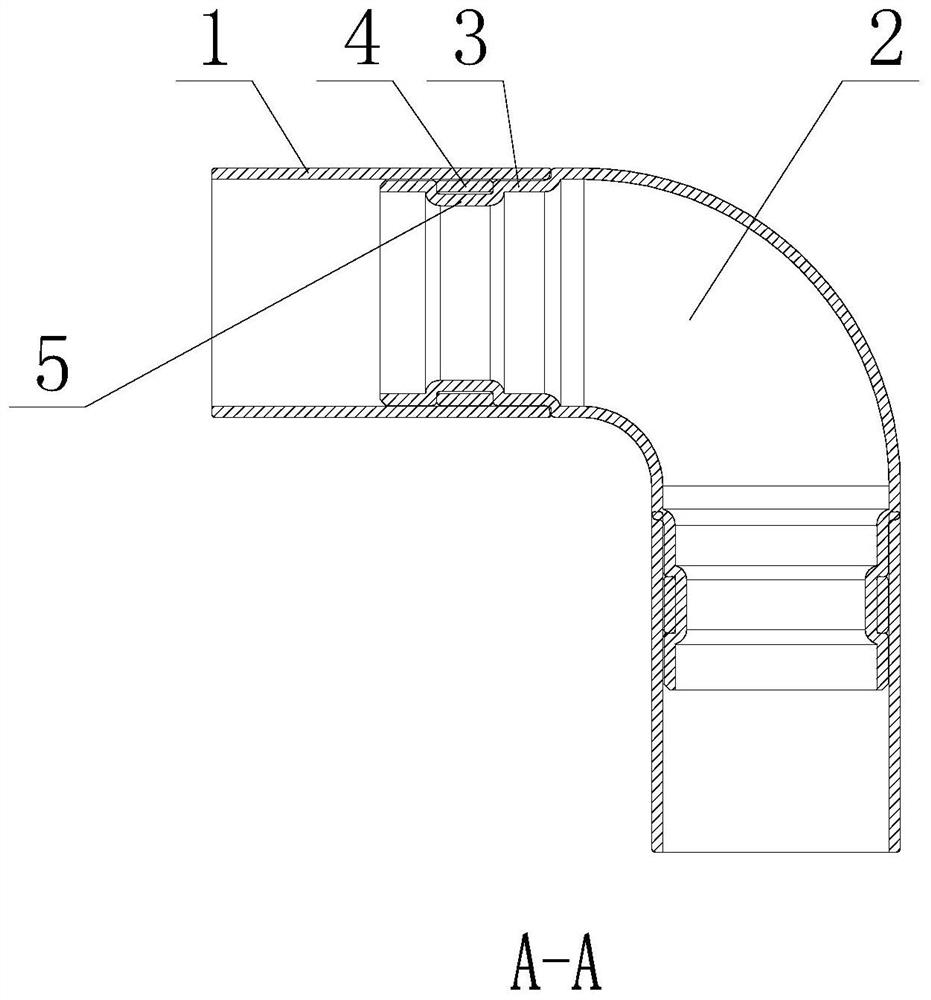

Pipe internally inlaid with welding flux and welding technology

PendingCN111761251AImprove flow uniformityGuaranteed safetySoldering apparatusWorkpiece edge portionsPipe fittingEngineering

The invention relates to a pipe internally inlaid with welding flux. The pipe internally inlaid with the welding flux comprises to-be-connected pieces comprising a first pipe piece and a second pipe piece and a connecting portion comprising an internal extension portion which is overlapped during insertion connection of the first pipe piece and the second piece. The internal extension portion is provided with an annular groove used for installing the welding flux. If the annular groove is arranged on the second pipe piece, the annular groove is of an inwards recessed structure. If the annulargroove is arranged on the first pipe fitting, the annular groove is of an outwards protruding structure. The welding flux is in contact connection with the first pipe piece and the second pipe piece.The welding flux is arranged on the overlapped portion of the first pipe piece and the second pipe piece in a sleeving manner. A welding technology comprises the following steps that S1, the welding flux is fed into the annular groove in advance; S2, a heating machine is adopted for heating, and after the welding flux is molten, a pipe piece contact gap is filled; wherein, in the step S1, feedingthe welding flux comprises grooving and filling, the welding flux is silver welding flux and phosphorus-copper welding flux, and the heating machine is a high-frequency heating machine. The pipe internally inlaid with the welding flux and the welding technology have the advantages that penetration depth and firmness of welding are ensured, construction safety is ensured, and the welding difficultyis lowered.

Owner:XINXIANG FENGXIN METAL PROD CO LTD

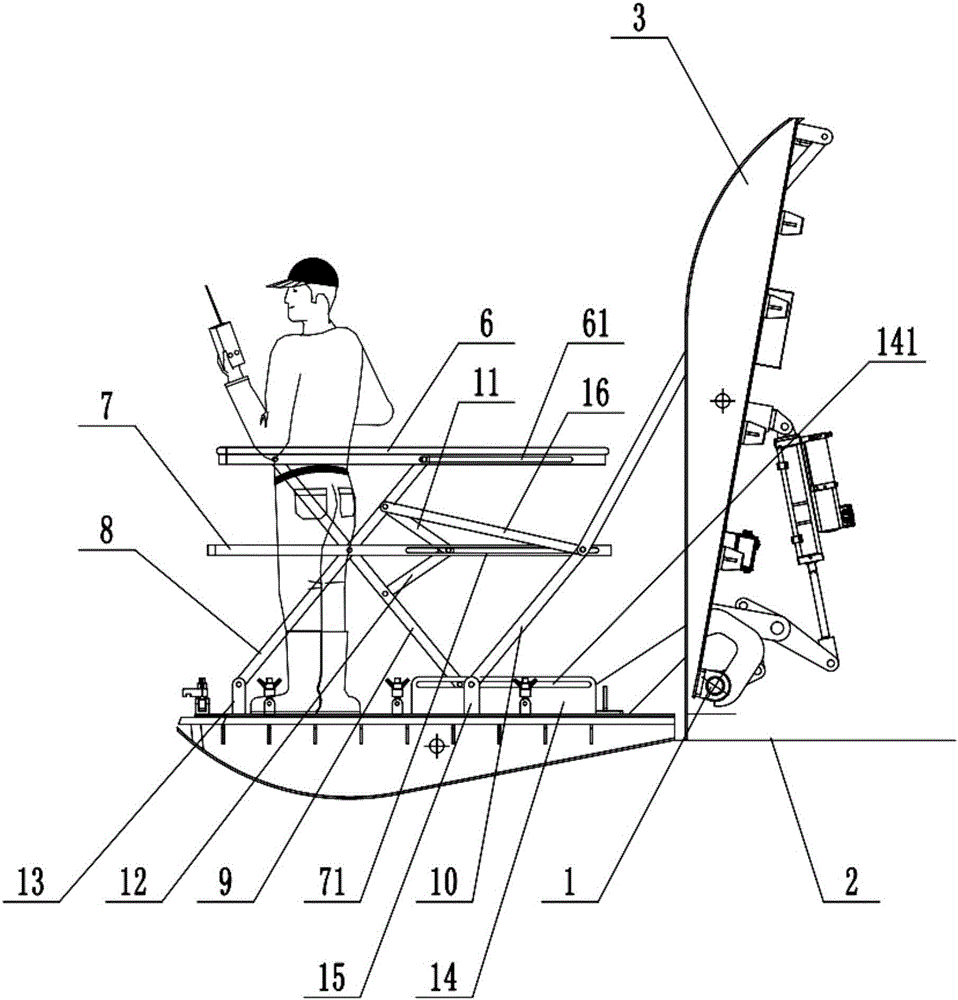

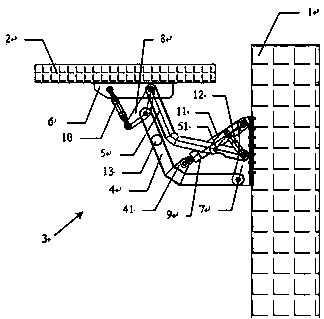

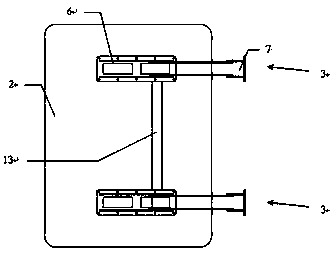

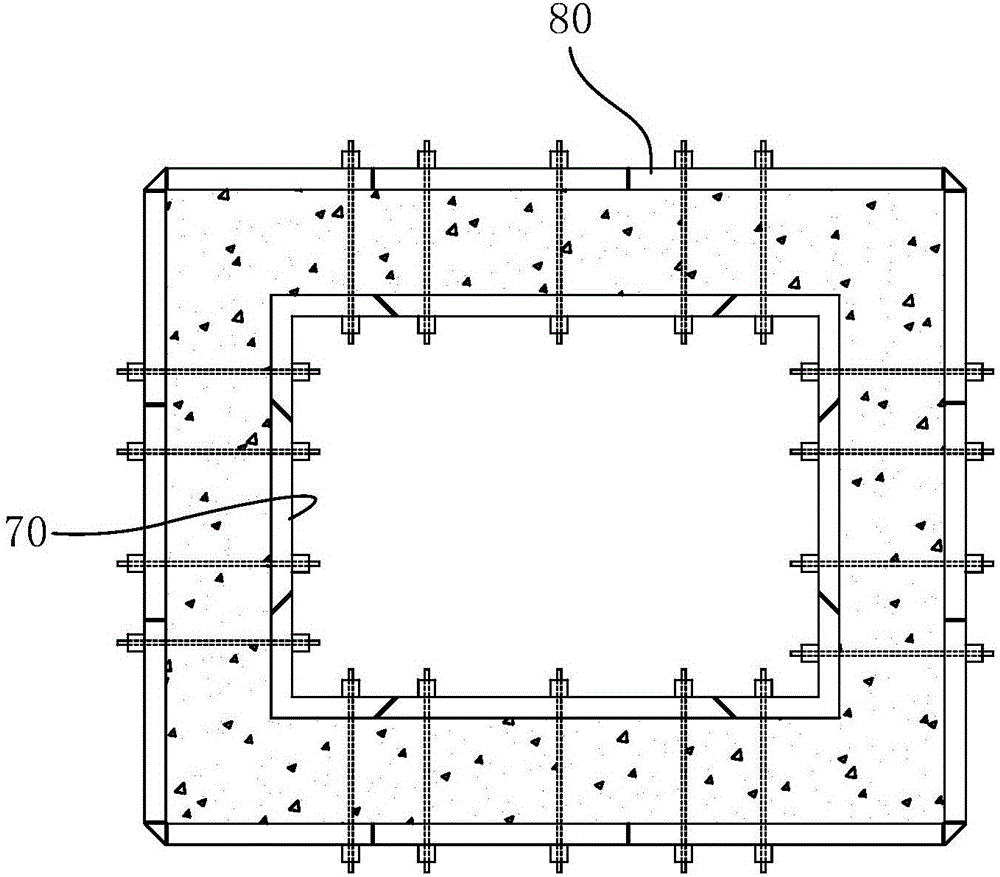

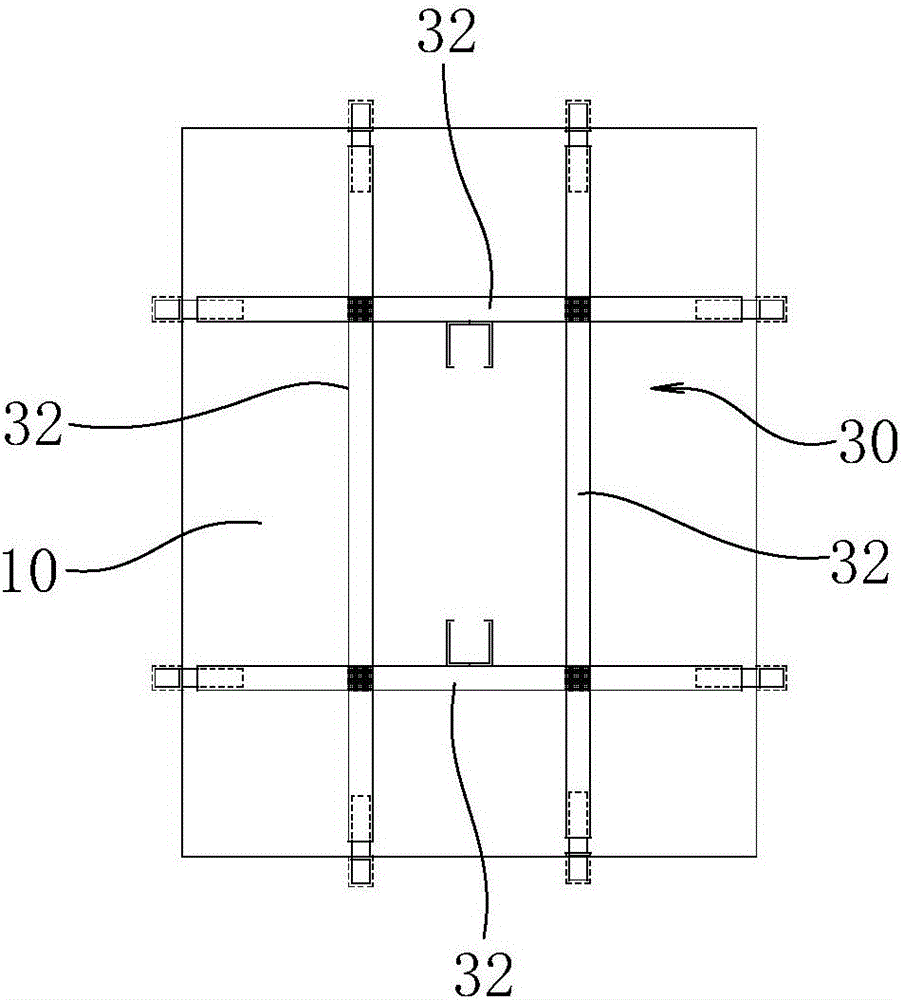

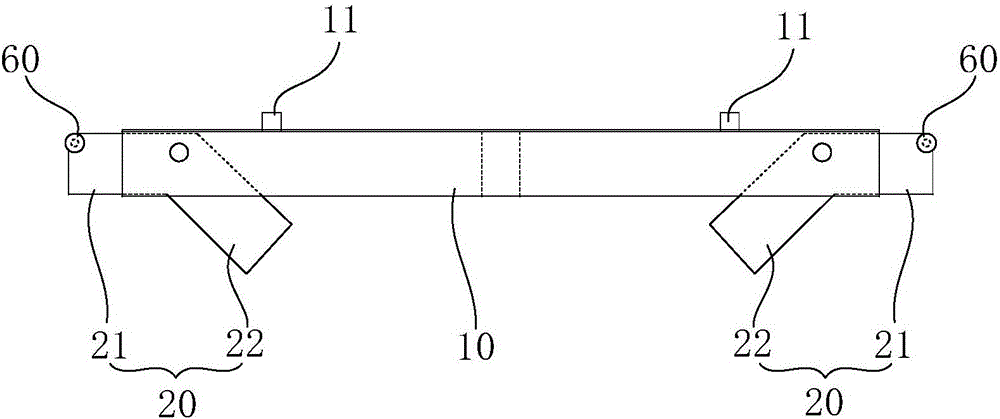

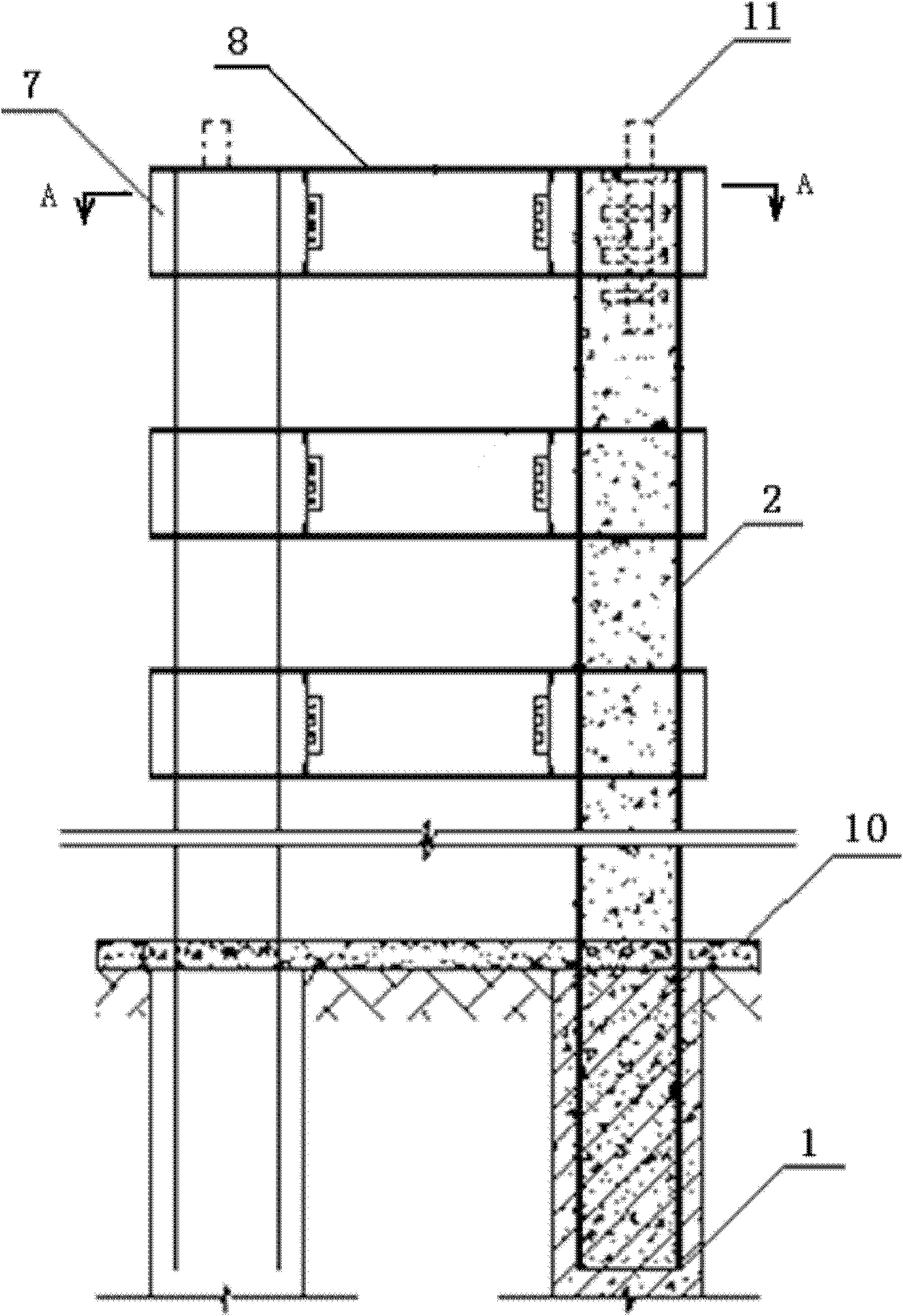

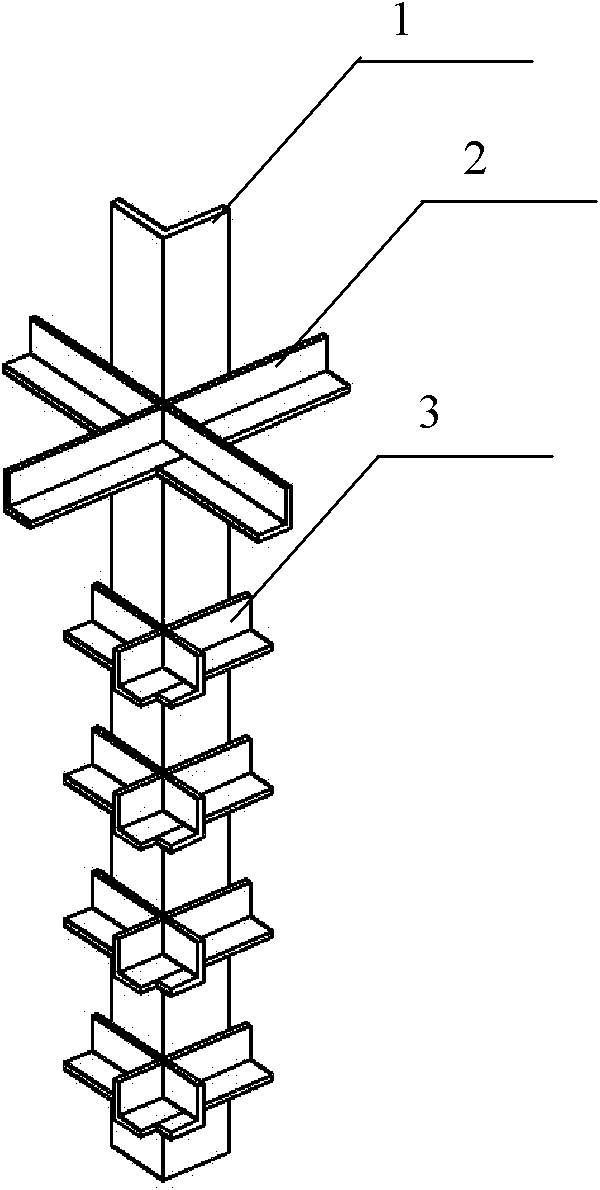

Electric hydraulic construction platform device of elevator shaft and construction method of shear wall of elevator shaft

PendingCN107178204AEnsure safetyImprove efficiencyForms/shuttering/falseworksBuilding support scaffoldsElectro hydraulicShear wall

The invention relates to an electric hydraulic construction platform device of an elevator shaft and a construction method of a shear wall of the elevator shaft. Supporting operation frame bodies are arranged around a supporting platform and abut against or are separated from the upper end of the shear wall of the elevator shaft; a hanging frame body is arranged on the supporting platform; detachable formworks are arranged on the periphery of the hanging frame body; the formworks are spliced with one another to form a construction inner formwork of the shear wall of the elevator shaft; a lifting structure is further arranged on the supporting platform to drive the supporting platform to move upward; the four supporting operation frame bodies are erected at the upper end of the shear wall of the elevator shaft to support the supporting platform; the hanging frame body is mounted on the supporting platform; the formworks are fixed to the hanging frame body to form the construction inner formwork of the shear wall of the elevator shaft in an enclosing mode; an outer formwork is arranged outside the hanging frame body; and after concrete is solidified, the lifting structure is started to lift the supporting platform to a high storey, therefore personnel security and the security degree of the whole construction can be guaranteed through the electric platform device, and efficiency is high.

Owner:GESHAN CONSTR GROUP

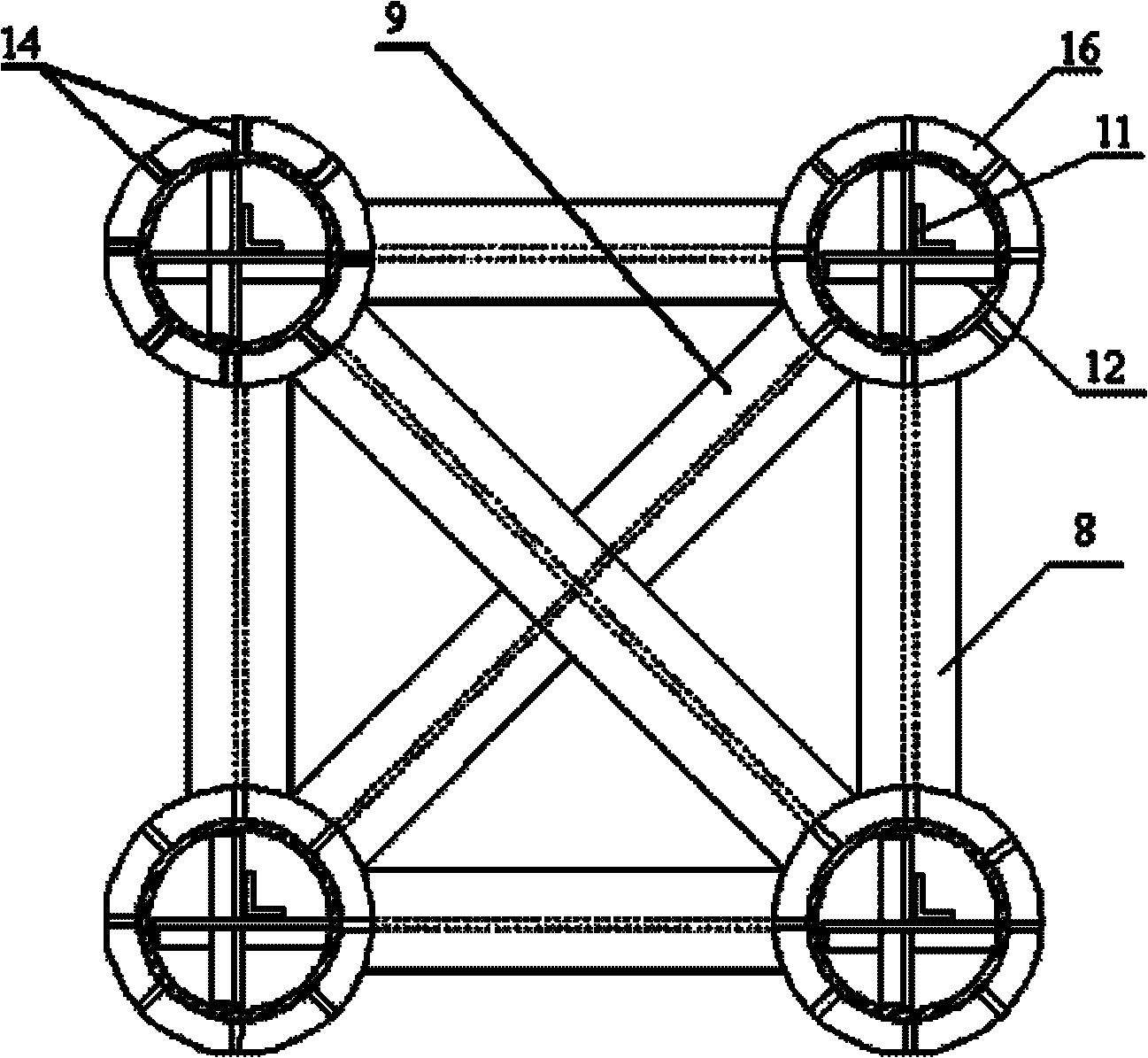

Tower crane foundation

ActiveCN102134856ASimple construction processSave construction materialsFoundation engineeringReinforced concreteEngineering

The invention discloses a tower crane foundation, wherein four reinforced concrete piles driven underground are arranged in a square and at four corners and fixedly connected with the lower parts of coaxial steel tube concrete columns through a reinforcement cage inside; the upper parts of the four steel tube concrete columns are provided with tower crane anchors that can be fixedly connected with a tower body; the outer surfaces of the upper and middle parts of the four steel tube concrete columns are fixedly provided with steel reinforcing rings; the steel reinforcing rings are fixedly connected with steel supports mutually crossing horizontally and horizontal steel supports; and the top of each reinforced concrete pile is provided with a reinforced concrete beam. Being simple in construction process and firm and reliable in overall structure, the tower crane foundation saves construction materials, reduces construction cost and is especially suitable for construction on soft soil layers.

Owner:TIANJIN CONSTR ENG MAIN CONTRACTING

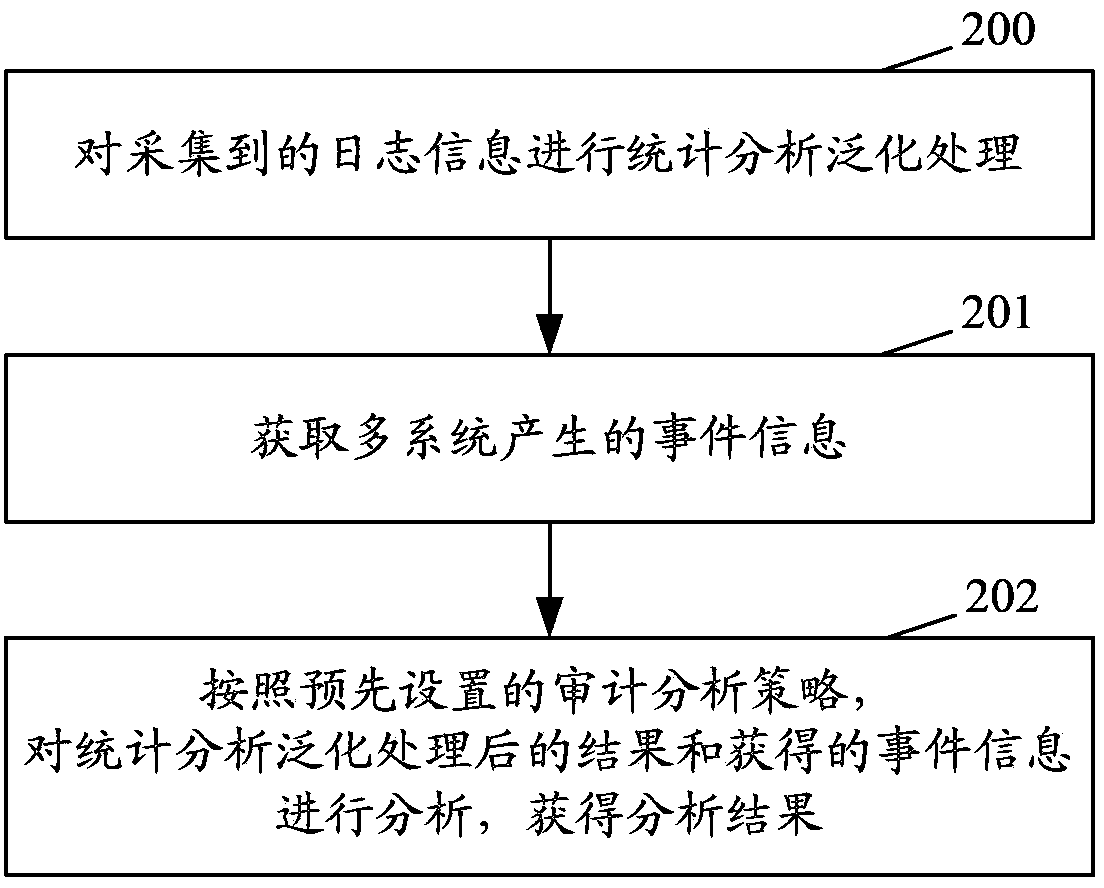

Safety audit method and device

InactiveCN103812682AReduce security risksGuaranteed normalizationData switching networksComputer scienceSecurity management

Provided is a safety audit method and device. The safety audit method comprises the steps of performing statistic analysis generalization on acquired log information and obtaining event information produced by multiple systems; analyzing a processing result and obtained event information after the statistic analysis generalization according to a preset audit analysis strategy to obtain an analysis result. By adopting the safety audit method and device, safety audit is performed on behaviors of operation and maintenance persons in an operation and maintenance region in safety management platforms, and the operation and maintenance behaviors of the operation and maintenance region in the safety management platforms are standardized and securitized. In addition, managers can perform the safety audit on the operation behaviors of the operation and maintenance persons in various safety systems according to the analysis result, detects illegal events and performs follow-up processing, and accordingly the safety risk of the operation and maintenance behaviors is reduced.

Owner:ZICT TECH CO LTD

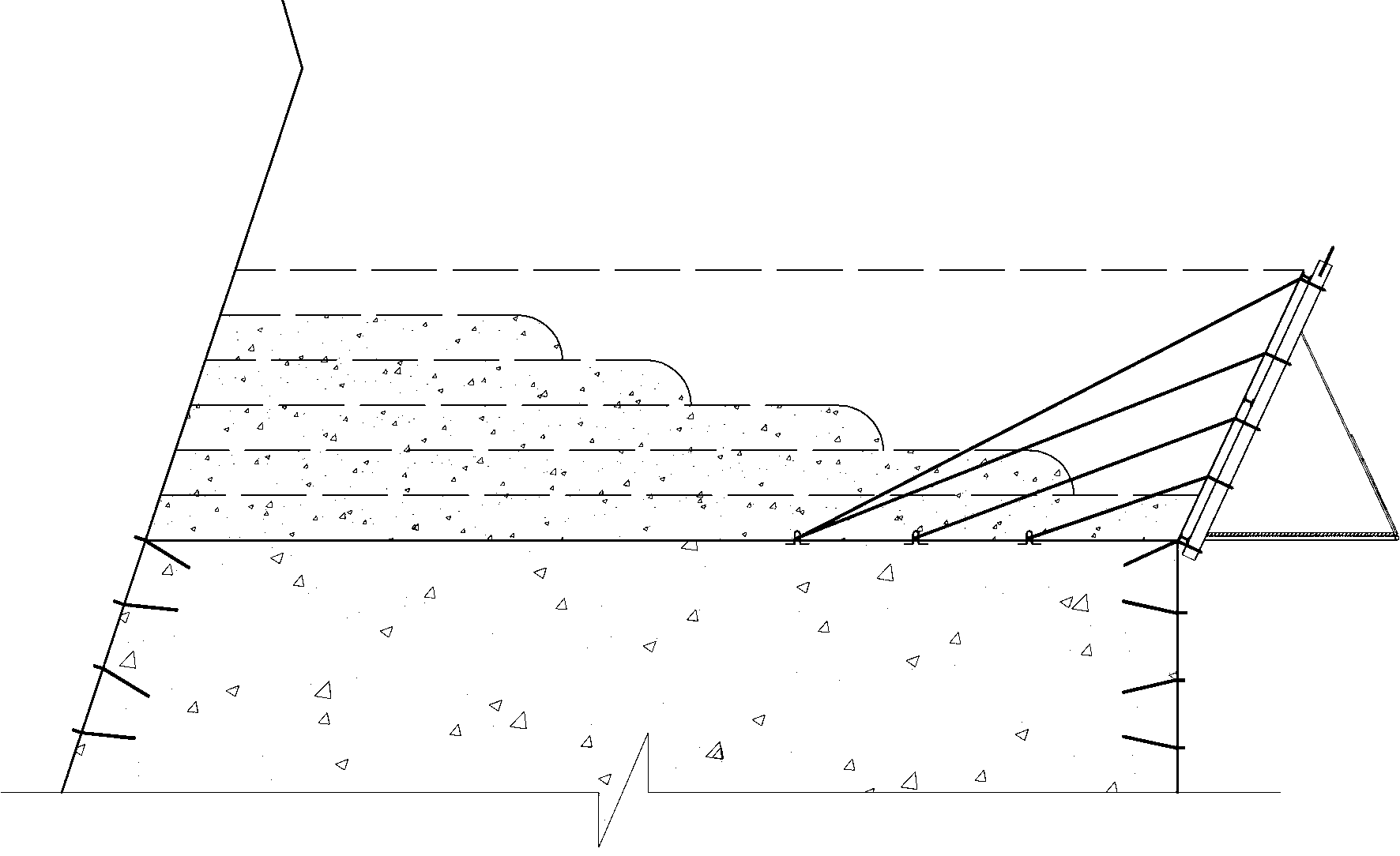

Dam stilling pool prefabricated gallery crowned arch steel template

A combined-type cantilever template for pouring a dam inclined part comprises a combined steel template and a safety working platform. The combined steel template comprises a steel template, transverse ribs and longitudinal ribs, wherein brace holes for connecting template braces are formed in the steel template; the braces are connected with the steel template through bolts in the brace holes; the transverse ribs are fixed on the rear back of the steel template; the longitudinal ribs are fixed on the transverse ribs; the safety working platform comprises a bracket and a safety net; the bracket comprises a transverse brace and a longitudinal brace connected with each other; a containment rail is arranged on the longitudinal brace; and a springboard is arranged on the transverse brace. According to the combined-type cantilever template, the template and the safety working platform are integrated; separately erecting formwork and setting up the safety working platform are not needed; manufacturing is simple; mounting and dismantling are convenient; in addition, the manufacture can be carried out on site according to the actual situation. The steel template is particularly applicable to construction of pouring the dam inclined part and other building fields with equal conditions. The combined-type cantilever template is convenient to manufacture, low in cost, aesthetically pleasing and favorable for requirements of on-site civilized construction.

Owner:CHINA GEZHOUBA GROUP NO 5 ENG

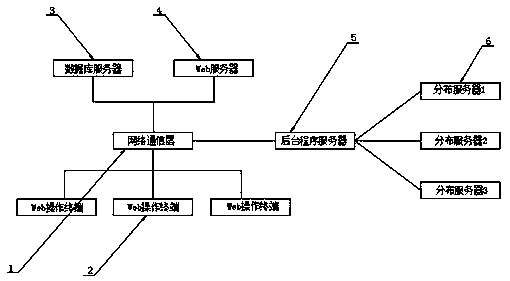

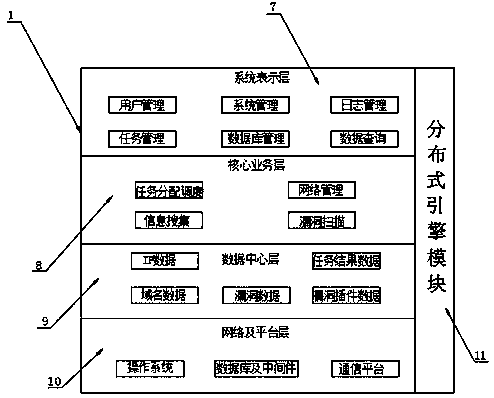

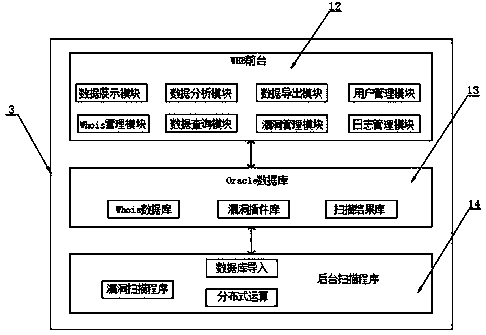

Network space vulnerability merging platform system

ActiveCN108833368AImprove scanning efficiencyImprove accuracyTransmissionDatabase serverNetwork communication

The invention discloses a network space vulnerability merging platform system. The network space vulnerability merging platform system comprises a network communication layer, wherein a connecting endof the network communication layer is provided with a plurality of Web operation terminals; an output end of the network communication layer is provided with a database server and a Web server respectively; the connecting end of the network communication layer is provided with a background program server; and a connecting end of the background program server is provided with a plurality of distributed servers. The network communication layer, a distributed control technology and scanning are adopted, so that the working efficiency of a system platform is increased by means of the advantages and efficiency of a distributed form; large regional network targets can be scanned; and the functions of studying how to allocate tasks and automatically distinguish idle nodes and returning result data are optimized specially. A search engine is adopted to perform information collection and target scanning operations in the Internet, so that the scanning efficiency and accuracy of a wide range ofnetwork conditions are increased.

Owner:深圳极限智能信息技术有限公司

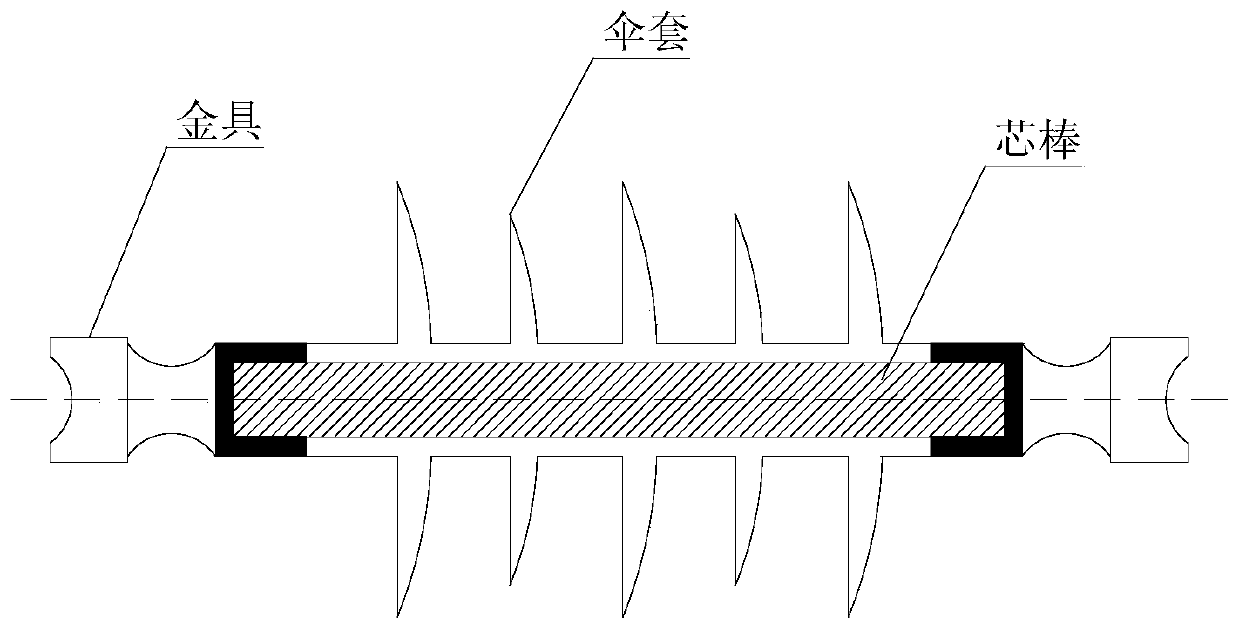

Basalt fiber insulator core rod

The invention provides a basalt fiber insulator core rod. The core rod comprises basalt fibers, high-temperature-resistant resin and a curing agent, wherein the core rod is formed by adopting a pultrusion process, the section of the core rod is round or similar to a circle, the volume fraction of the basalt fiber is 65-75%, the volume fraction of the high-temperature-resistant resin is 20-40%, andthe volume fraction of the curing agent is 5-10%. According to the basalt fiber insulator core rod, the tensile strength is 1200-1500 MPa, the bending strength is 1200-1400 MPa, the mechanical strength is high, the requirement of the electric power industry for a large-diameter high-strength core rod is met, meanwhile, the structure is reliable, the performance is stable, the safe operation margin is large, flashover, breakdown and pollution flashover accidents are avoided, and safe operation of a line is guaranteed. Besides, the basalt fiber insulator core rod is high in temperature resistance and insulating property, the requirements of high-voltage and extra-high-voltage circuits for large-diameter high-strength core rods are met, and the increasingly-developed requirements of the power industry are met.

Owner:衡水瑞纤新材料科技有限公司

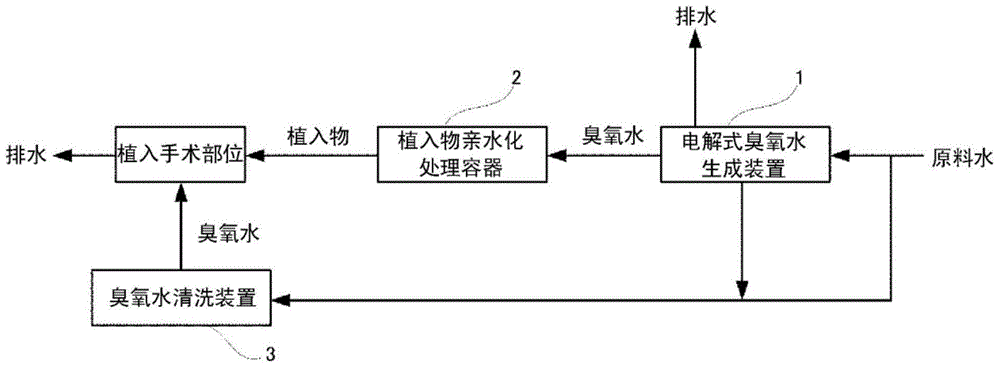

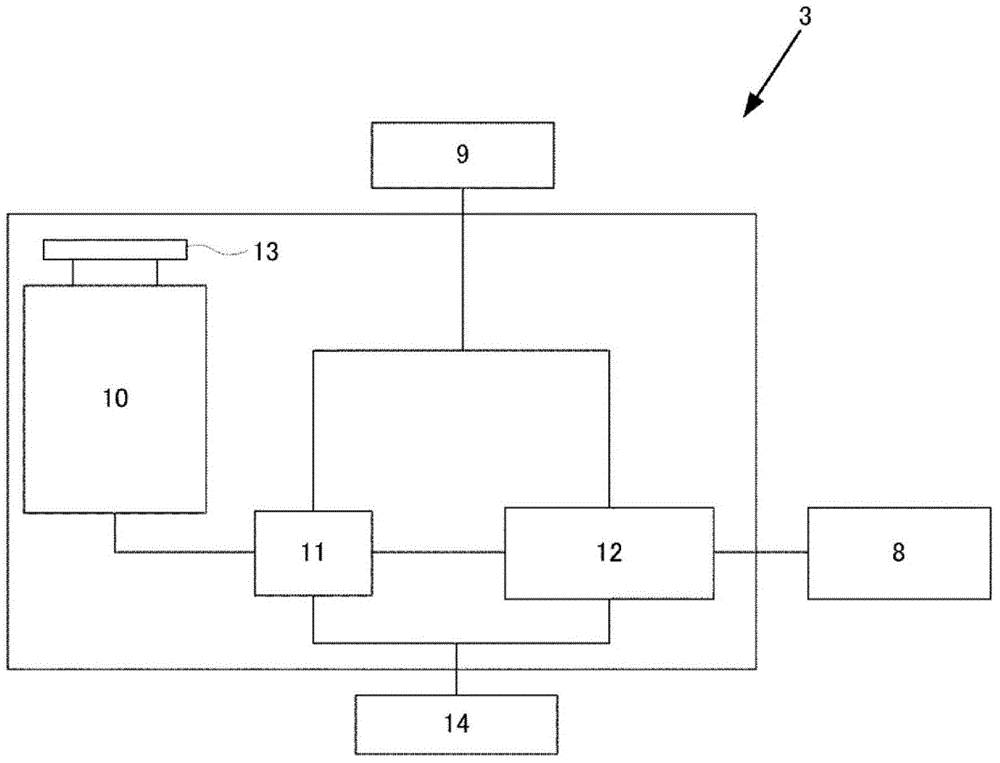

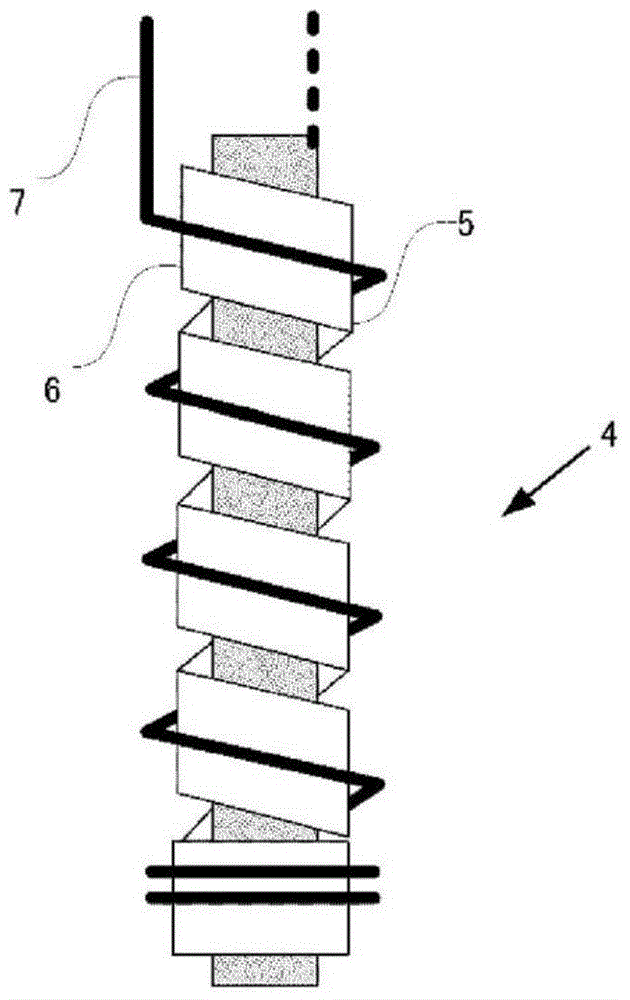

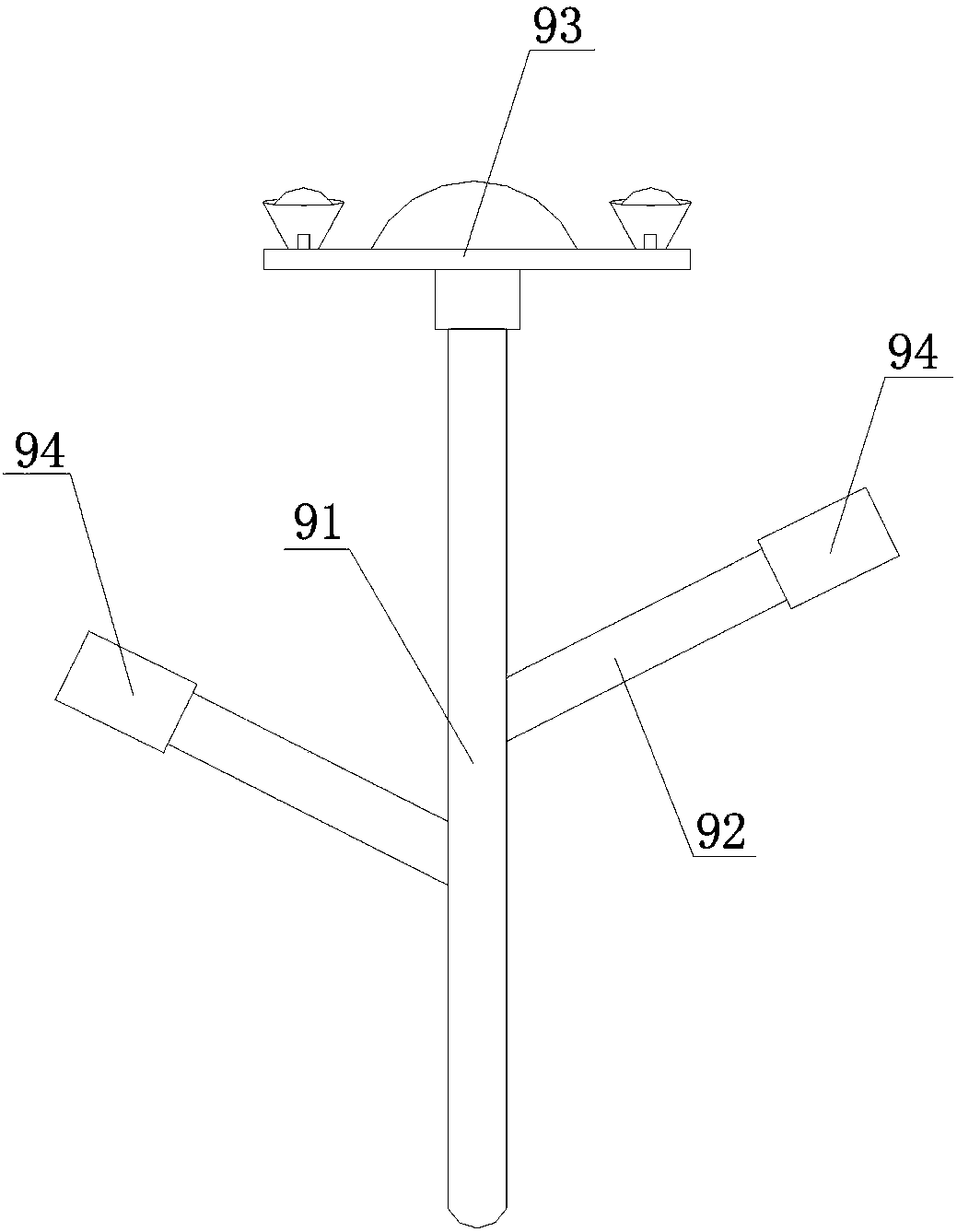

Processing method and processing device for implant material having excellent biocompatibility

InactiveCN104582746AGuaranteed securityAvoid pollutionDental implantsPharmaceutical delivery mechanismImplant materialBiocompatibility Testing

A processing method for an implant material having excellent biocompatibility, in particular, a processing method and processing device for a dental implant material. A processing method and processing device for implant material having excellent biocompatibility, characterized in that an implant material composed of titanium or titanium alloy and having a roughened surface is immersed in electrolytic ozone water, the electrolytic ozone water is held at normal temperature, whereby pollution caused by adsorption of carbides onto the surface of the implant material is prevented, and hydrophilicity is imparted.

Owner:学校法人爱知学院 +1

Energy-saving and environment-friendly office table capable of improving air quality

The invention discloses an energy-saving and environment-friendly office table capable of improving the air quality, for solving the problems that in the prior art, the function is single, the energyconsumption is high, and the office environment can not be improved. The office table comprises an office table main body mainly composed of an office table top and support plates, drawers provided with fingerprint locks, an image capturing lens, a liquid crystal touch display screen and a table lamp, wherein the table lamp comprises a table lamp post, table lamp support posts, illuminating lampsand a disinfecting lamp; the disinfecting lamp comprises a threaded mounting part, a lamp holder, an energy-saving lamp and ultraviolet lamps, and each ultraviolet lamp comprises a loudspeaker-shapedlampshade, an ultraviolet lamp tube and a light-outgoing lens; the office table top is provided with a PM2.5 detector, an anion generator, a small fan, a grille air inlet and a grille air outlet. Theenergy-saving and environment-friendly office table capable of improving the air quality is simple in structure, scientific and reasonable in design, and convenient to use, and has the sterilizing function, important materials can be safely stored, energies can be effectively saved, the office environment can be effectively improved, and meanwhile, the degree of automation is high.

Owner:成都申川节能环保工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com