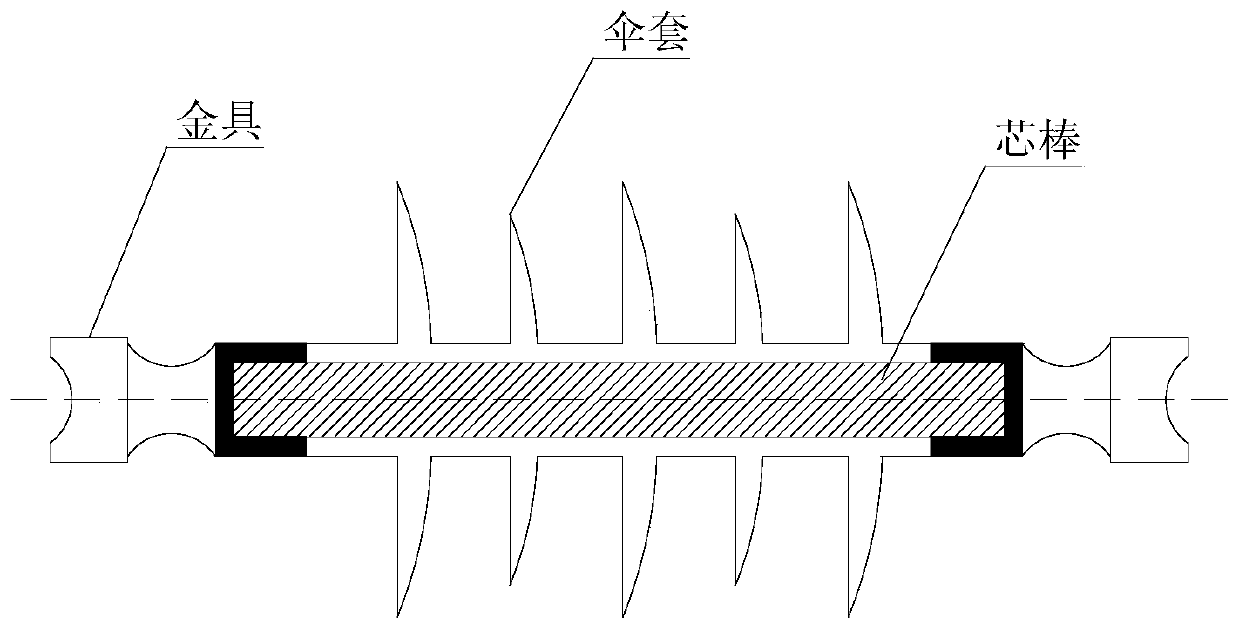

Basalt fiber insulator core rod

A basalt fiber and insulator technology, applied in insulators, electrical components, circuits, etc., can solve the problems of network mutual inductance, mandrel breakage, pollution flashover, etc., and achieve the effect of large safety operation margin, high mechanical strength and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A basalt fiber insulator core rod, the fiber is made of 2000tex basalt fiber roving, the tensile strength is 2600MPa, and the elastic modulus is 85GPa; the resin is made of high temperature resistant modified epoxy resin, the tensile strength is 82MPa, the bending strength is 88MPa, the elasticity Modulus 950MPa. Basalt fiber volume resistivity 1.45×10 13 Ω m, volume resistivity of high temperature resistant resin 1.3×10 13 Ω·m, glass transition temperature 160°C. After the basalt fiber is heat-treated, the tensile breaking strength of the yarn is 0.55 / (N / tex), and the strength retention rate is 66%.

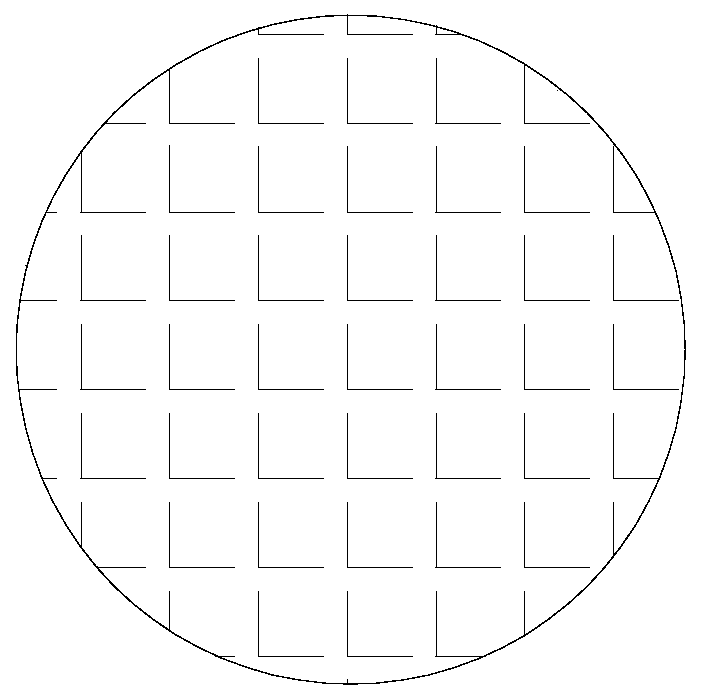

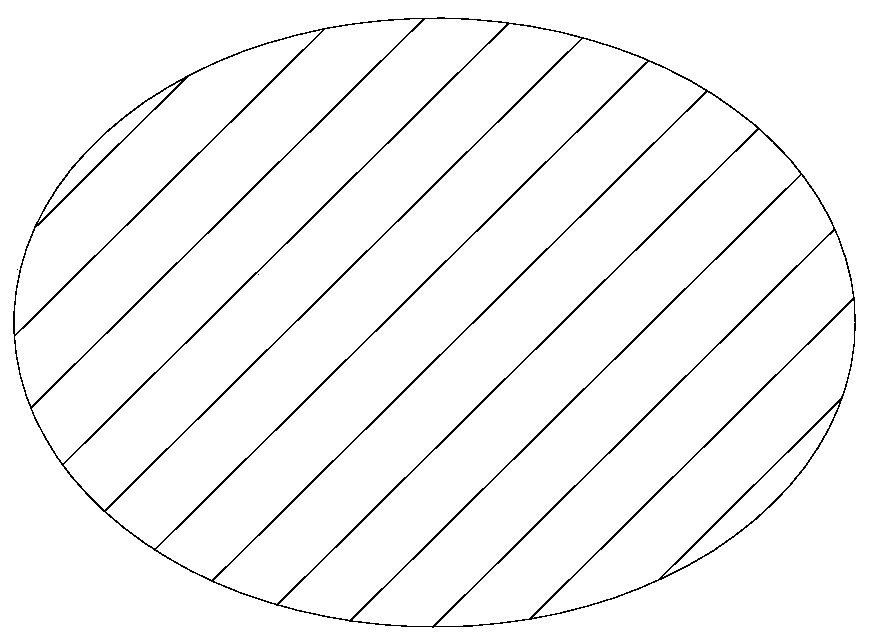

[0037] The basalt fiber insulator mandrel adopts the pultrusion molding process. Firstly, the continuous basalt fiber roving is soaked in the resin. Under the action of the traction force, the traction speed is 1m / min. By heating the mold, it is rapidly solidified and formed at a solidification temperature of 200°C to form basalt. The fiber insulator mandrel has a circ...

Embodiment 2

[0039] A basalt fiber insulator core rod, the fiber is made of 2400tex basalt fiber roving, the tensile strength is 3400MPa, and the elastic modulus is 88GPa; the resin is made of high temperature resistant modified epoxy resin, the tensile strength is 85MPa, the bending strength is 90MPa, Modulus 1000MPa. Basalt fiber volume resistivity 1.48×10 13 Ω m, volume resistivity of high temperature resistant resin 1.35×10 13 Ω·m, glass transition temperature 160°C. After the basalt fiber is heat-treated, the tensile breaking strength of the yarn is 0.56 / (N / tex), and the strength retention rate is 66%.

[0040] The basalt fiber insulator mandrel adopts the pultrusion molding process. First, the continuous basalt fiber roving is soaked in the resin. Under the action of the traction force, the traction speed is 1m / min. By heating the mold, it is rapidly solidified and formed at a solidification temperature of 220°C to form basalt. The fiber insulator mandrel has a circular section an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com