Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Guarantee smooth production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

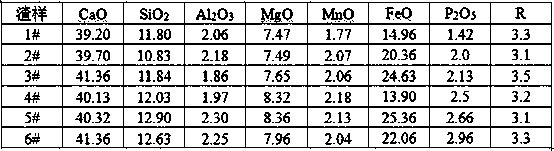

Converter smelting process with low lime consumption

InactiveCN110373511AAvoid meltingGuaranteed to meltManufacturing convertersProcess efficiency improvementAlkalinitySmelting process

The invention discloses a converter smelting process with low lime consumption. The process comprises the steps that part of final slag is reserved according to the content of P2O5 in converter slag before converter tapping; after tapping, a deoxidizer is added according to the FeO content in the slag to reduce the oxidizability of the slag; all light-burned dolomite required in the dephosphorization period is added, slag splashing furnace protection operation is carried out, scrap steel is added firstly, and all lime required in the dephosphorization period is added; molten iron is added after the lime is added, a deoxidizing gun is ignited, and return ore or ore is added to adjust slag components after ignition; after the dephosphorization time, the carbon content and the temperature reach the requirements, inverse dephosphorization slag operation is carried out; after slag pouring is finished, the deoxidizing gun is ignited for the second time, and the feeding amount is controlled according to the alkalinity requirement; and oxygen supply is stopped when the carbon and the temperature meet the requirements, and part of the final slag is reserved according to the mass percentagecontent of P2O5 in the final slag for next smelting in the furnace. Lime consumption is reduced, the converter slag amount and the steel material consumption are reduced, and the problems of phosphorus enrichment, phosphorus return and dry dedusting explosion release in the slag are avoided.

Owner:HANDAN IRON & STEEL GROUP +1

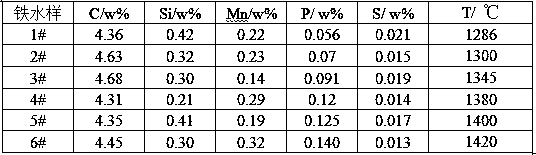

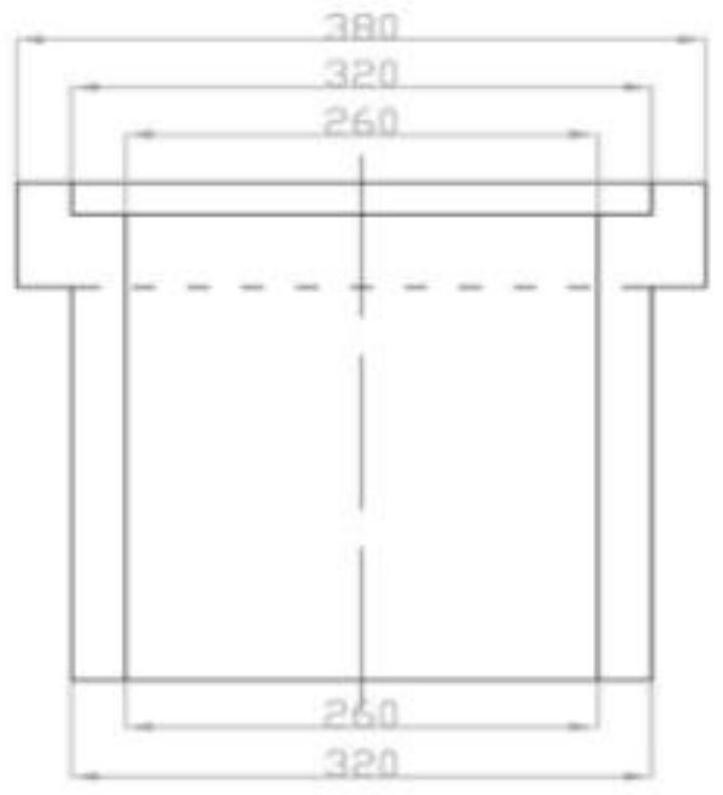

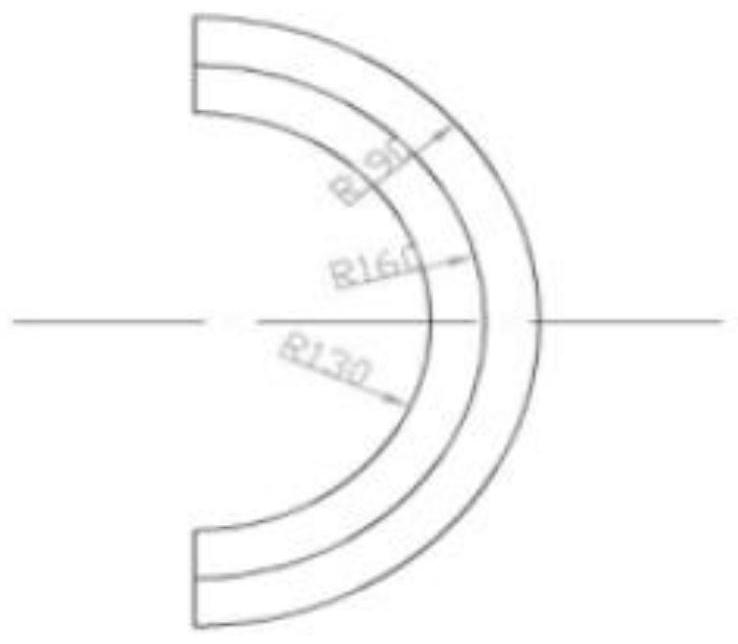

Method for improving RH vacuum furnace bottom groove life

The invention provides a method for prolonging the service life of a bottom tank of an RH vacuum furnace. The method is characterized in that: the opposite side of an argon blowing system of a vacuum chamber is added with an argon blowing system, the position of a riser and the position of a downcomer are exchanged when a new varnished tube is mounted, and an argon tube of the riser is connected to the newly added argon blowing system. The method helps realize the alternate use of a circulation tube at the ascending side and a circulation tube at the descending side of the bottom tank by exchanging the position of the riser and the position of the downcomer, thus avoiding that the circulation tube at one side always bears the intense scouring of the raising steel flow, effectively prolonging the service life of the circulation tubes, and further prolonging the service life of the bottom tank. The method has obvious effect and can help improve the average service life of the bottom tank by more than one fold.

Owner:ANGANG STEEL CO LTD

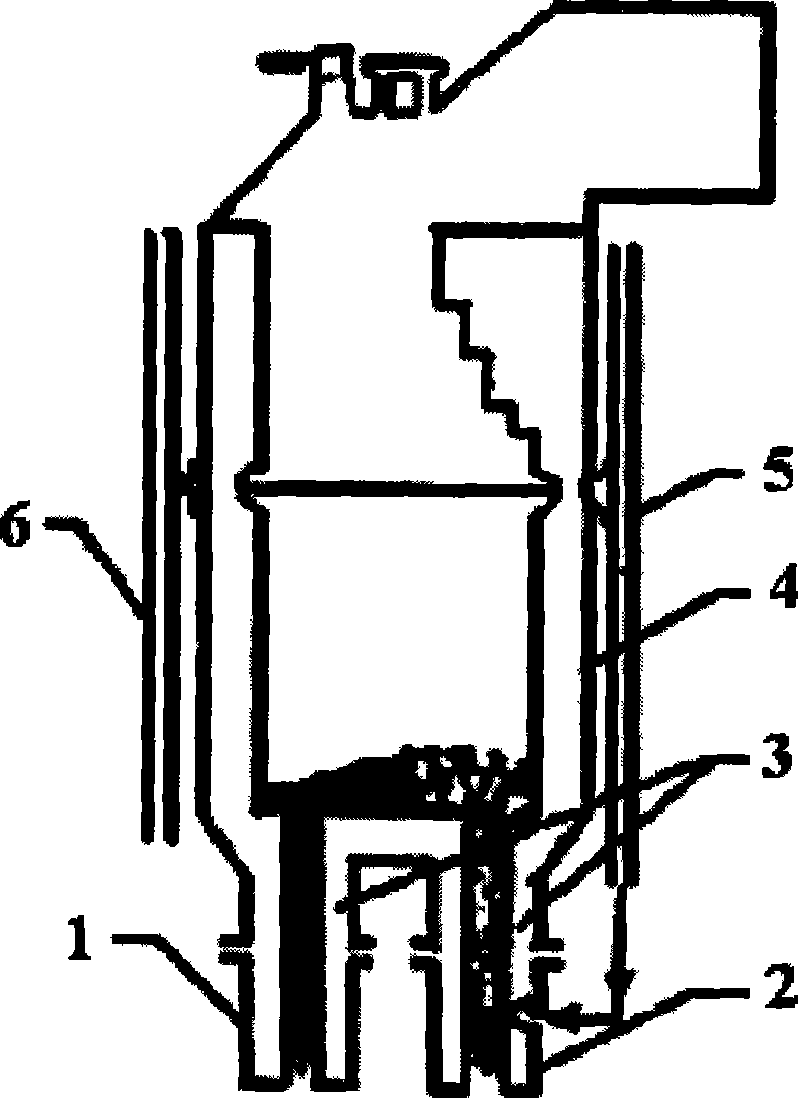

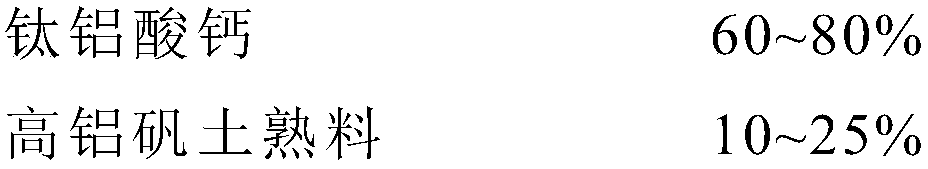

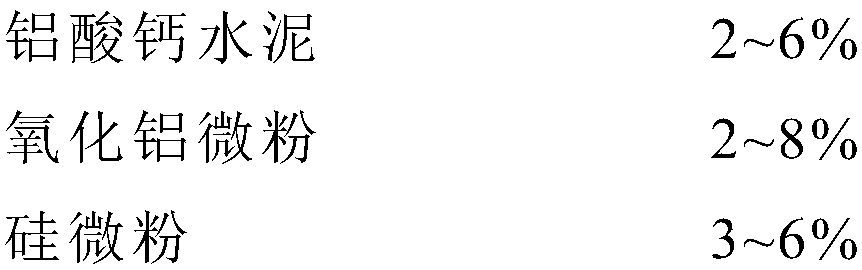

Titanium calcium aluminate castable for ladle or foundry ladle and preparation method thereof

The invention discloses a titanium calcium aluminate castable for ladle or foundry ladle. The titanium calcium aluminate castable for ladle or foundry ladle comprises (by weight): 60-80% of titanium calcium aluminate, 10-25% of high alumina bauxite clinker, 2-6% of calcium aluminate cement, 2-8% of alumina micro-powder and 3-6% of silica micropowder. In the preparation, polypropylene fiber and a water reducer are added, wherein the polypropylene fiber accounts for 0.01-0.04% of total weight of the raw materials; and the water reducer accounts for 0.1-0.5% of weight of the raw materials. by adding the alumina micro-powder and silica micropowder, volume stability of the ladle or foundry ladle can be maintained at the use temperature, and damage degree and potential safety hazard of the product are effectively reduced. By using calcium aluminate cement and silica micropowder as a compound binder, the product has good workability and medium and high temperature strength, service life is long, repair frequency is reduced, and smooth production of ladle is guaranteed. By using titanium calcium aluminate in quantity, volume stability of the titanium calcium aluminate castable at medium and high temperature is good, and the strength is high.

Owner:WUGANG REFRACTORY CO LTD

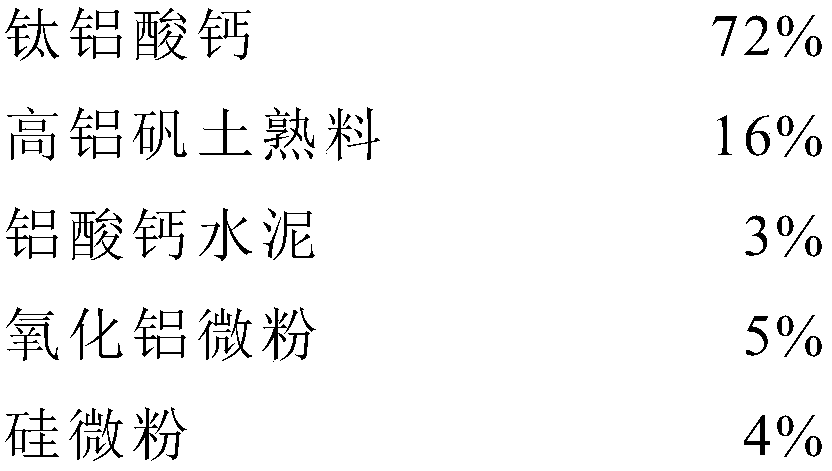

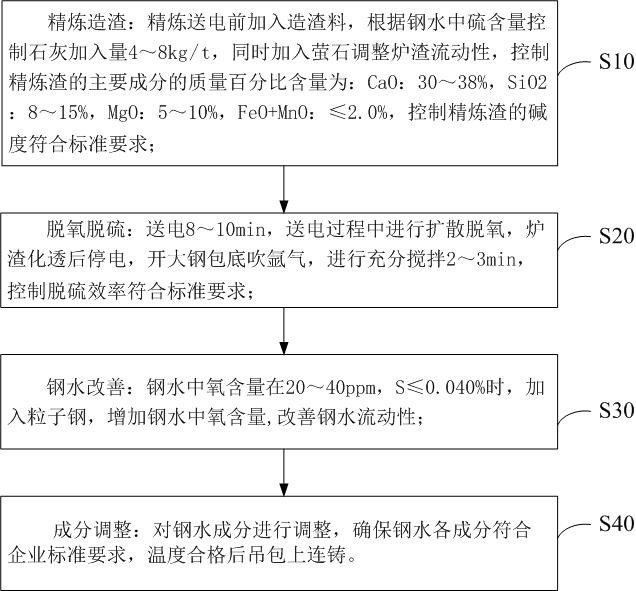

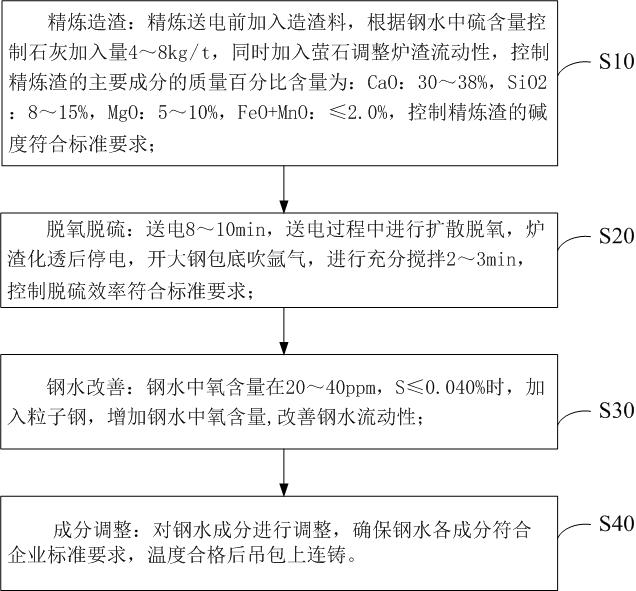

Smelting method capable of improving fluidity of molten steel after refining and desulfurizing of deformed steel bar

ActiveCN113234990AImprove the fluidity of molten steelGuaranteed normal pouringManufacturing convertersSlagSulfur content

The invention discloses a smelting method capable of improving fluidity of molten steel after refining and desulfurizing of a deformed steel bar. A deformed steel bar refining and desulfurizing process comprises the steps of converter smelting, post-furnace and argon station treatment, LF refining and continuous casting; and an LF refining process comprises the steps of: adding slag making material lime before refining and power transmission, and adding fluorite at the same time to adjust slag fluidity; controlling the alkalinity of refining slag to meet the standard requirement; carrying out diffusion deoxidation in the power transmission process, cutting off power after the slag is completely molten, expanding a steel ladle for bottom blowing argon, and controlling the desulfurization efficiency to meet the standard requirement; adding particle steel to increase the oxygen content in the molten steel and improve the fluidity of the molten steel; and adjusting the components of the molten steel to ensure that the components of the molten steel meet the standard requirement, and continuously casting on a crane ladle after the temperature is qualified. According to the technical scheme provided by the invention, after the sulfur content in the molten steel in the refining process reaches the standard requirement, a proper amount of oxidizing material high-quality particle steel is added, so that the fluidity of the molten steel is improved, a pouring nozzle is prevented from being blocked, and pouring in the continuous casting process is smooth.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

Method for repairing converter lining through pig iron and slag

InactiveCN105925752APlay the role of refractory materialQuick fixManufacturing convertersSlagEconomic benefits

The invention relates to a method for repairing a converter lining, in particular to a method for repairing a converter lining through pig iron and slag. According to the technical scheme, the method for repairing the converter lining through the pig iron and the slag comprises the following steps that after the pig iron is added into a converter, the slag is quickly condensed on a converter lining part needing to be shimmed, and the slag is made to be repeatedly condensed on the converter lining part needing to be shimmed in the process of shaking the converter through the adhesion performance of the pig iron and the slag. By means of the method for repairing the converter lining through the pig iron and the slag, the consumption of the materials for repairing the converter is remarkably reduced, the refractory cost is reduced, and good economic benefits are achieved; and moreover, the time for repairing the converter can be saved, controlling of production rhythm is facilitated, and the productivity is further improved.

Owner:BENGANG STEEL PLATES

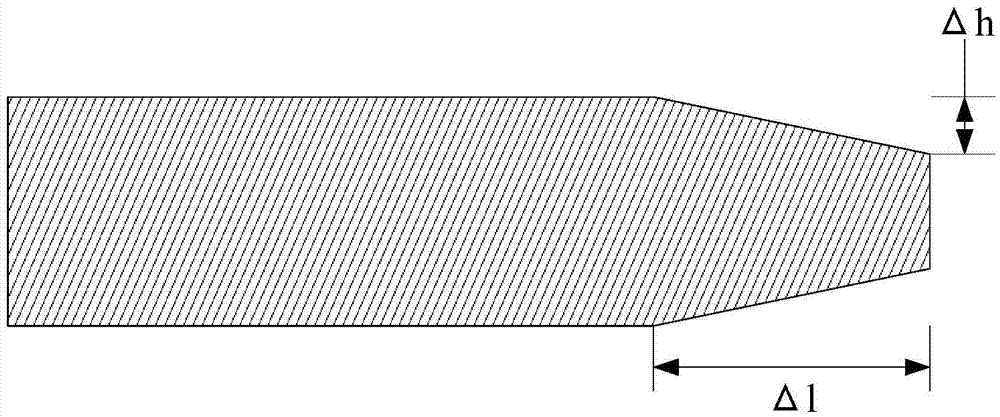

Method for reducing finish mill steel biting impact

InactiveCN106890852AReduce shockProtection worksRolling equipment maintainenceMetal rolling arrangementsMaterials scienceBiting

The invention relates to a method for reducing the steel bite impact of a finishing mill. In the rough rolling process set before the finishing rolling process: in the penultimate pass, when the slab is rolled to the set position, the The reduction increases by the set value; in the penultimate pass, the reduction of the rolling rolls is set to zero. The method for reducing the steel bite impact of the finishing mill in the present invention effectively reduces the impact of the finishing mill's steel bite without changing the control logic of the finishing mill, protects the work rolls and main shafts of the finishing mill, and ensures the smoothness of the rolling line. The production runs smoothly, which can meet the production process and ensure the safety of the finishing rolling equipment.

Owner:BAOSHAN IRON & STEEL CO LTD

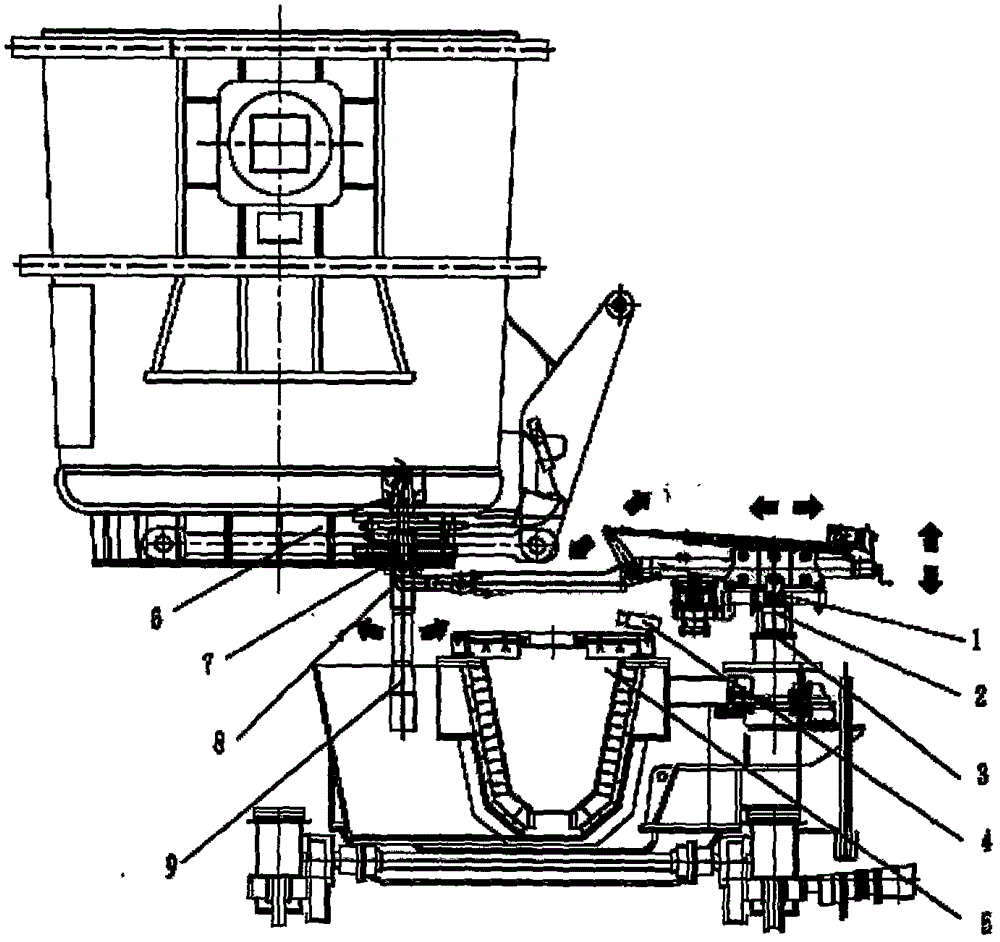

Special automatic manipulator for continuous casting steel

InactiveCN106424696ARealize labor savingRealize unmanned operationMelt-holding vesselsEngineeringManipulator

The invention discloses a special automatic manipulator for continuous casting steel. The automatic manipulator is characterized in that the automatic manipulator is provided with a sleeve connected with a base; the sleeve can ascend and descend and can rotate leftwards and rightwards; the sleeve is connected with a long arm which can extend and contract; a circular ring is arranged at the tail end of the long arm, and can sleeve a long nozzle; the circular ring is connected with the long arm; through a certain mechanical form, front-back overturn and left-right overturn can be realized, and the movement of the long nozzle can be realized. The amount of movement in various freedom degrees is recorded by a sensor, the automatic manipulator can move to a designated position according to an instruction. A camera is arranged nearby the automatic manipulator, place analysis is carried out according to shot images, the automatic manipulator is instructed to move, and full-automatic operation is realized.

Owner:吕晏含

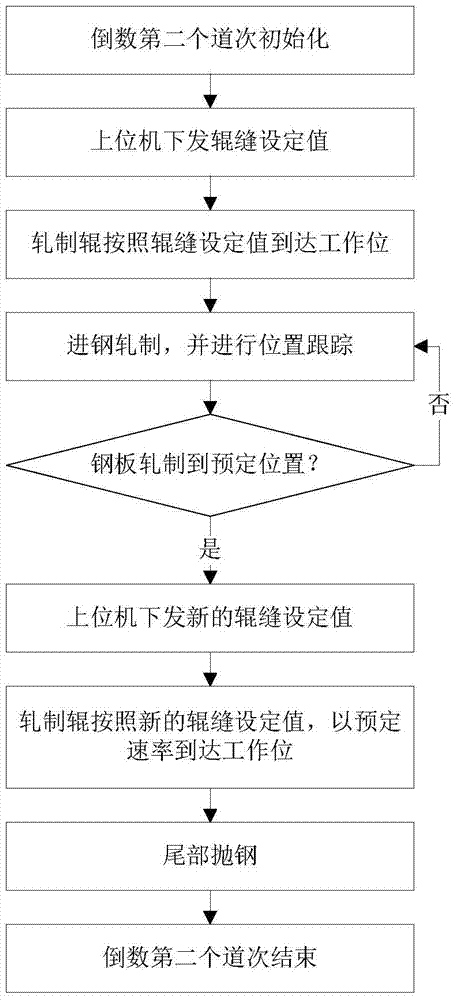

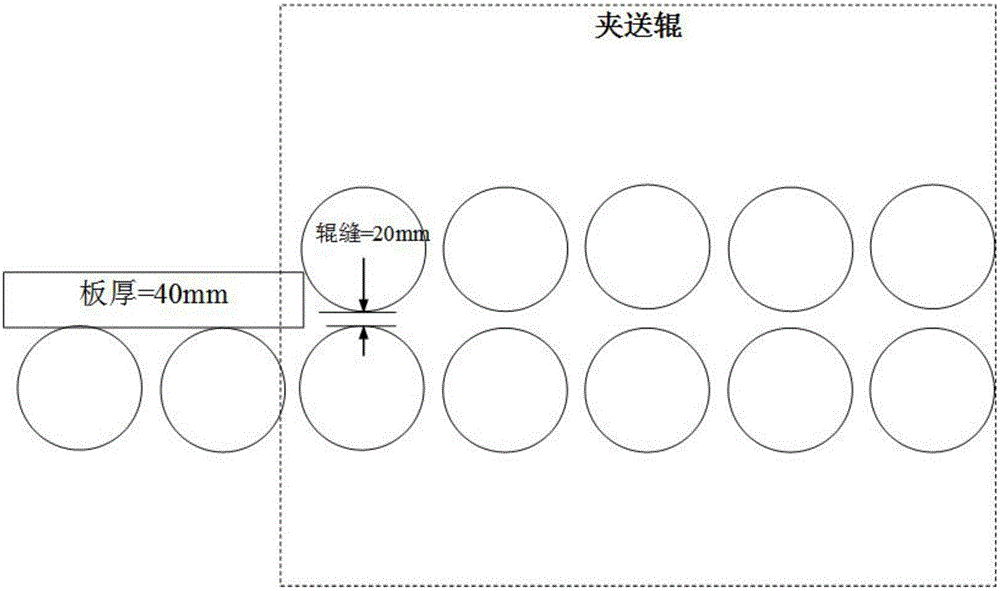

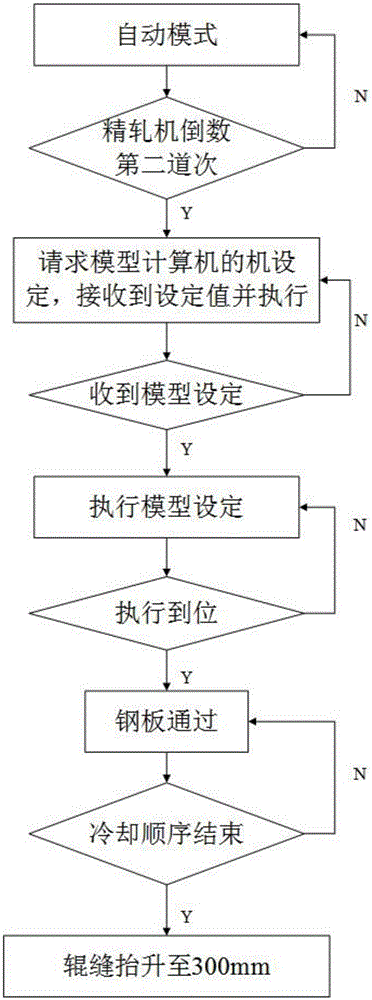

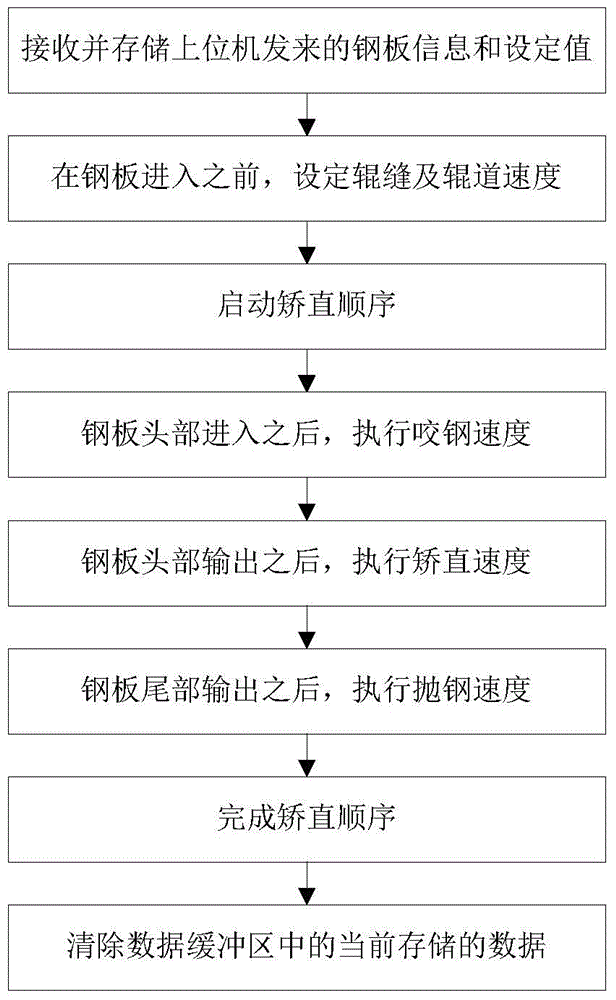

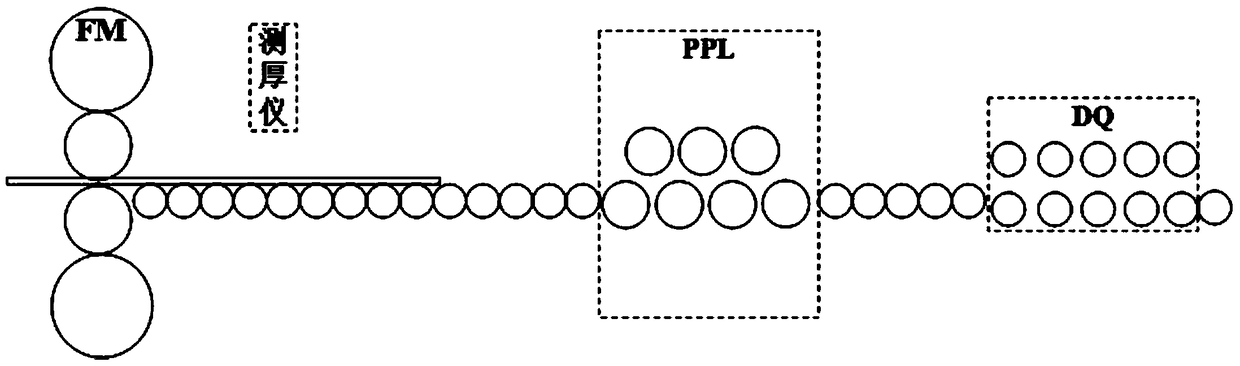

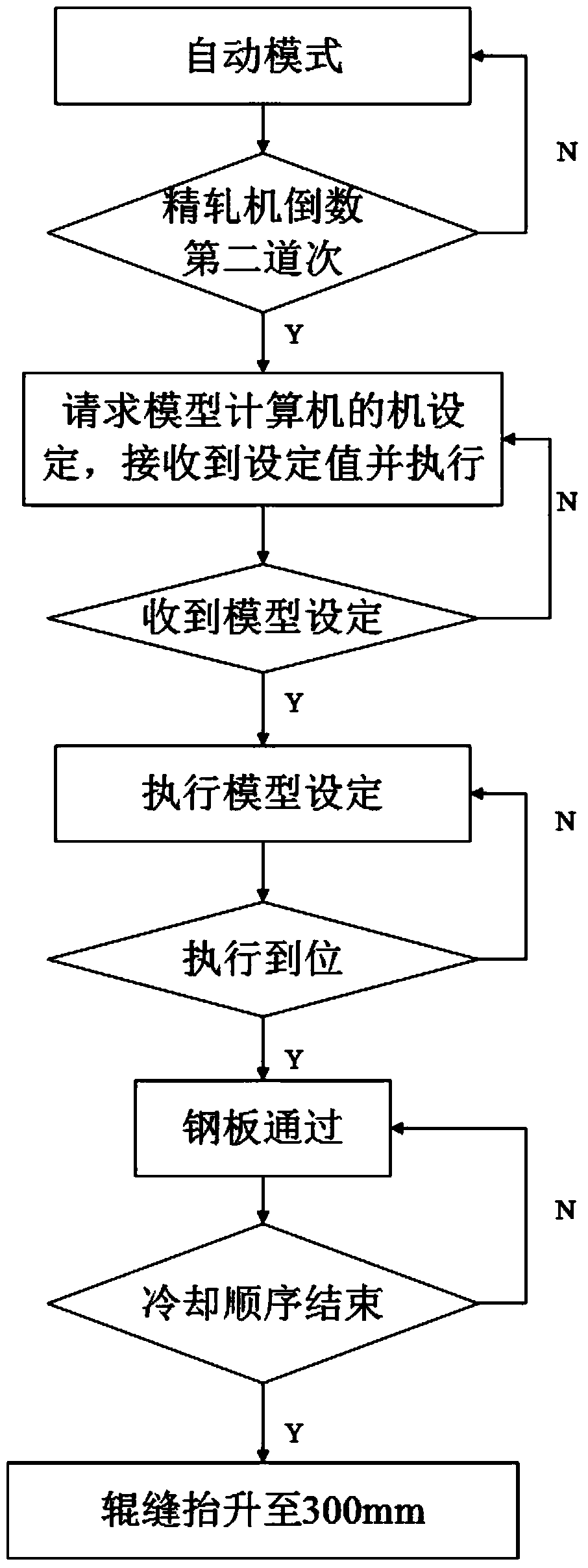

Pinch roll interlock protection control method

ActiveCN106694564AEliminate the risk of being hitGuarantee smooth productionRoll mill control devicesRolling safety devicesEngineeringMechanical engineering

The invention discloses a pinch roll interlock protection control method which comprises the following steps: Step 1, running pinch roll action under the automatic or manual mode; Step 2, judging whether finishing mill throws steel, if yes, moving to Step 3; otherwise, moving to Step 4; Step 3, carrying out the quick-opening process of cleaning between rolls; and Step 4, carrying out the lifting process of cleaning between rolls. According to the pinch roll interlock protection control method, under the conditions that the production technology is met and equipment safety is ensured, other detecting equipment of a rolling line area is introduced, and novel interlock protection logic is designed at the same time, so that the risk that a pinch roll is collided is effectively eliminated, and smooth production of a rolling line is ensured.

Owner:BAOSHAN IRON & STEEL CO LTD

Preparation method of hot rolled steel coil used for oil and gas pipeline

InactiveCN103361556AReduce the chance of secondary oxidationImprove cleanlinessTemperature control deviceMetal rolling arrangementsNitrogenHigh pressure water

The invention relates to a preparation method of a hot rolled steel coil used for an oil and gas pipeline. The preparation method comprises the following steps of: (1) after designing components, desulphurizing molten iron, then smelting in a converter, switching from nitrogen to argon, then carrying out deep desulfurization and calcium treatment in a ladle furnace, and tapping to obtain molten steel; (2) continuously casting the molten steel to obtain a slab, afterwards heating the obtained slab, then carrying out rough rolling and finish rolling on the slab after dephosphorization by using high-pressure water, and finally winding to obtain the hot rolled steel coil. The preparation method provided by the invention can be used for reducing surface cracks of the slab, improving the one-time qualified rate of the slab, realizing the direct and hot charging rolling of the slab, raising the hot delivery rate of direct charging, saving energy and reducing emission; through reasonable optimization and control of hot rolling process parameters, the water is used for replacing metals, so that the production cost is reduced.

Owner:NINGBO IRON & STEEL

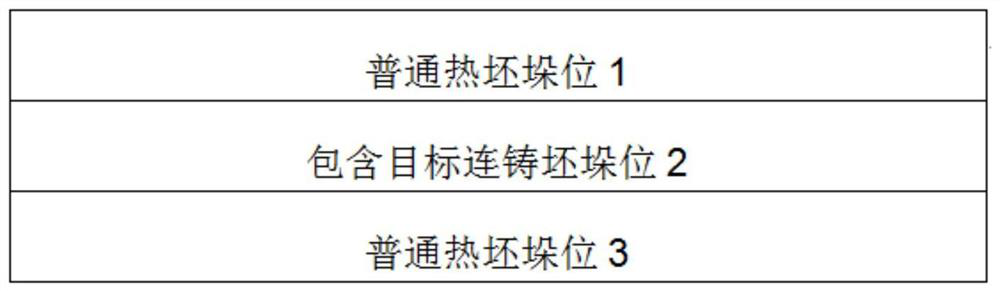

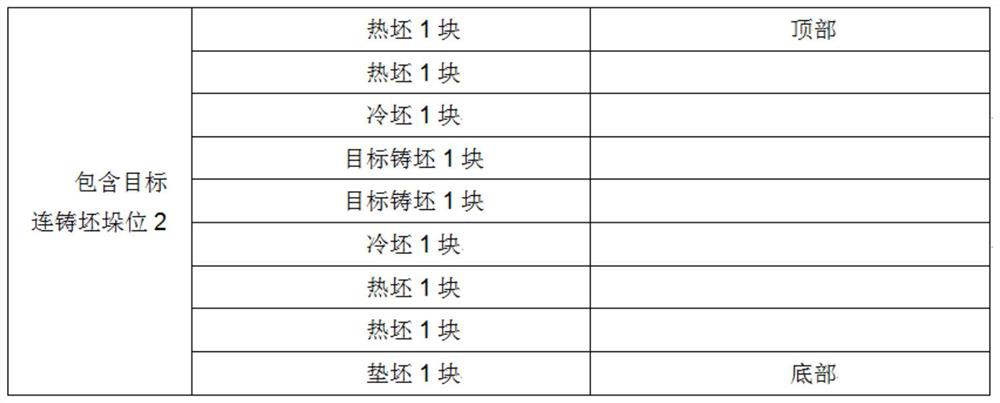

Charging pretreatment method and cold charging heating method of high-carbon high-alloy continuous casting billet

The invention provides a charging pretreatment method of a high-carbon high-alloy continuous casting billet. The charging pretreatment method comprises the following steps that A) stacking and slow cooling are carried out on the high-carbon high-alloy continuous casting billet; and B) the stacked and slowly cooled high-carbon high-alloy continuous casting billet is preheated. The invention furtherprovides a cold charging heating method of the high-carbon high-alloy continuous casting billet, namely, the high-carbon high-alloy continuous casting billet subjected to charging pretreatment is subjected to cold charging heating. By optimizing the casting billet offline slow cooling and cold charging heating process system, the corner structure form of the casting billet is changed, the formation of corner brittle structures and oxidation decarburization layers is inhibited, and the problem of cold charging fracture of a high-carbon high-alloy steel casting billet is effectively solved, sothat the smooth production of high-carbon high-alloy steel is ensured, and the rejection rate is reduced.

Owner:PANGANG GRP XICHANG STEEL & VANADIUM CO LTD

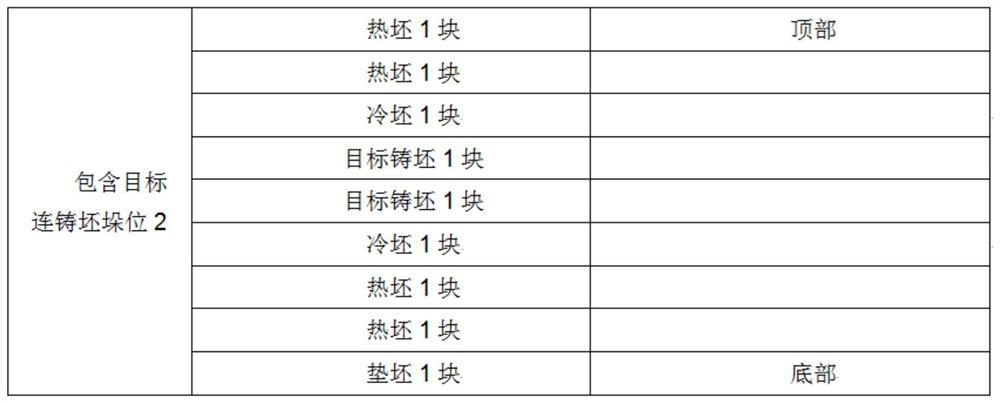

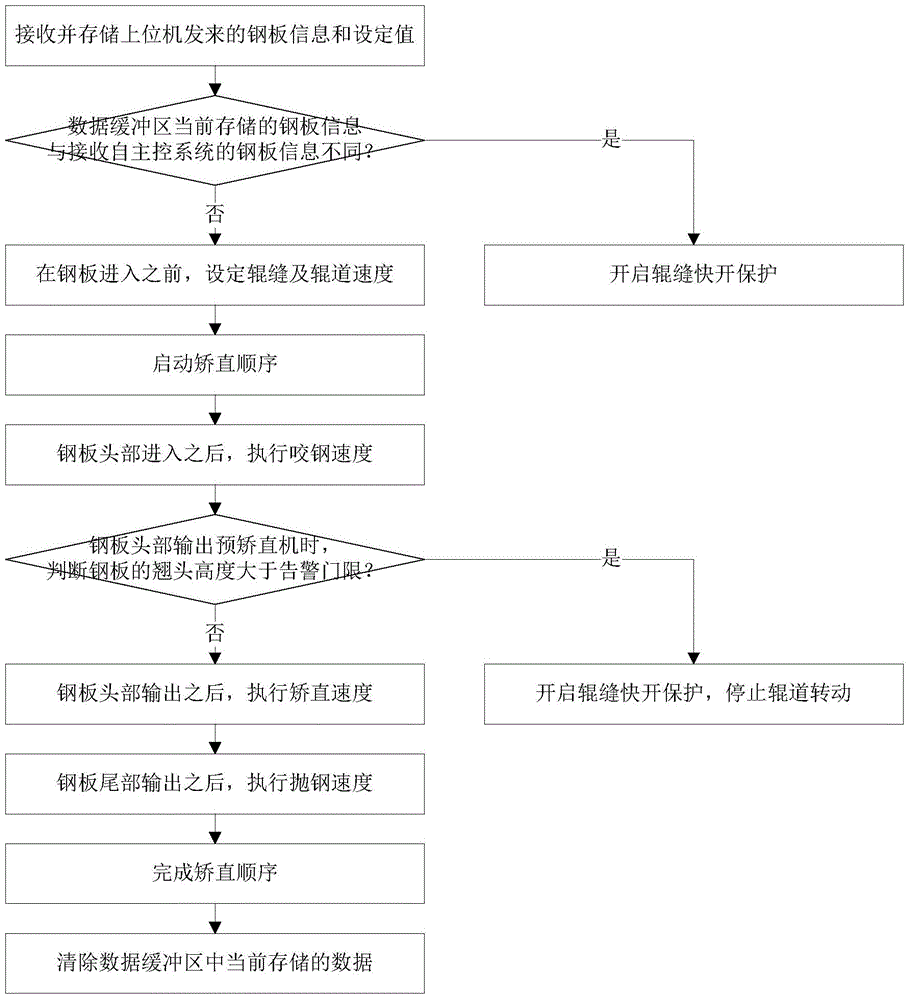

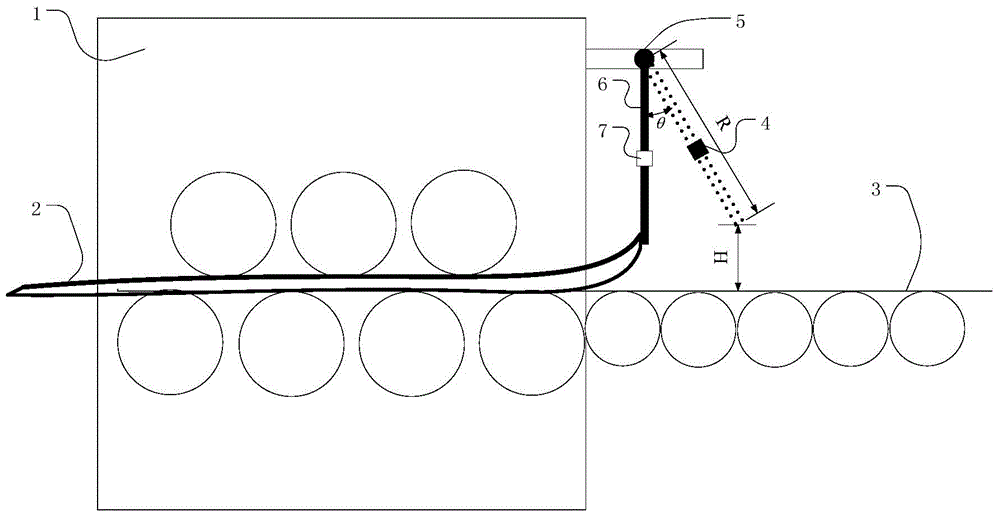

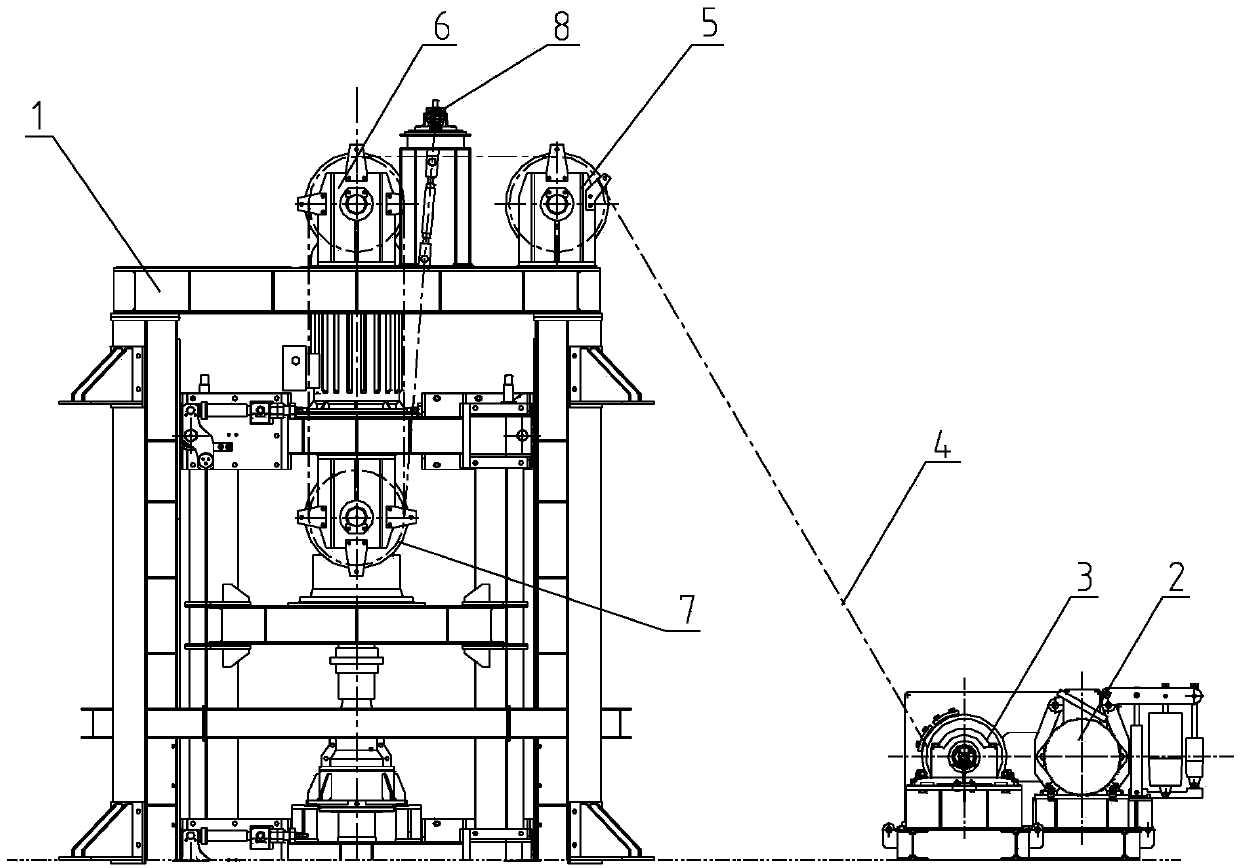

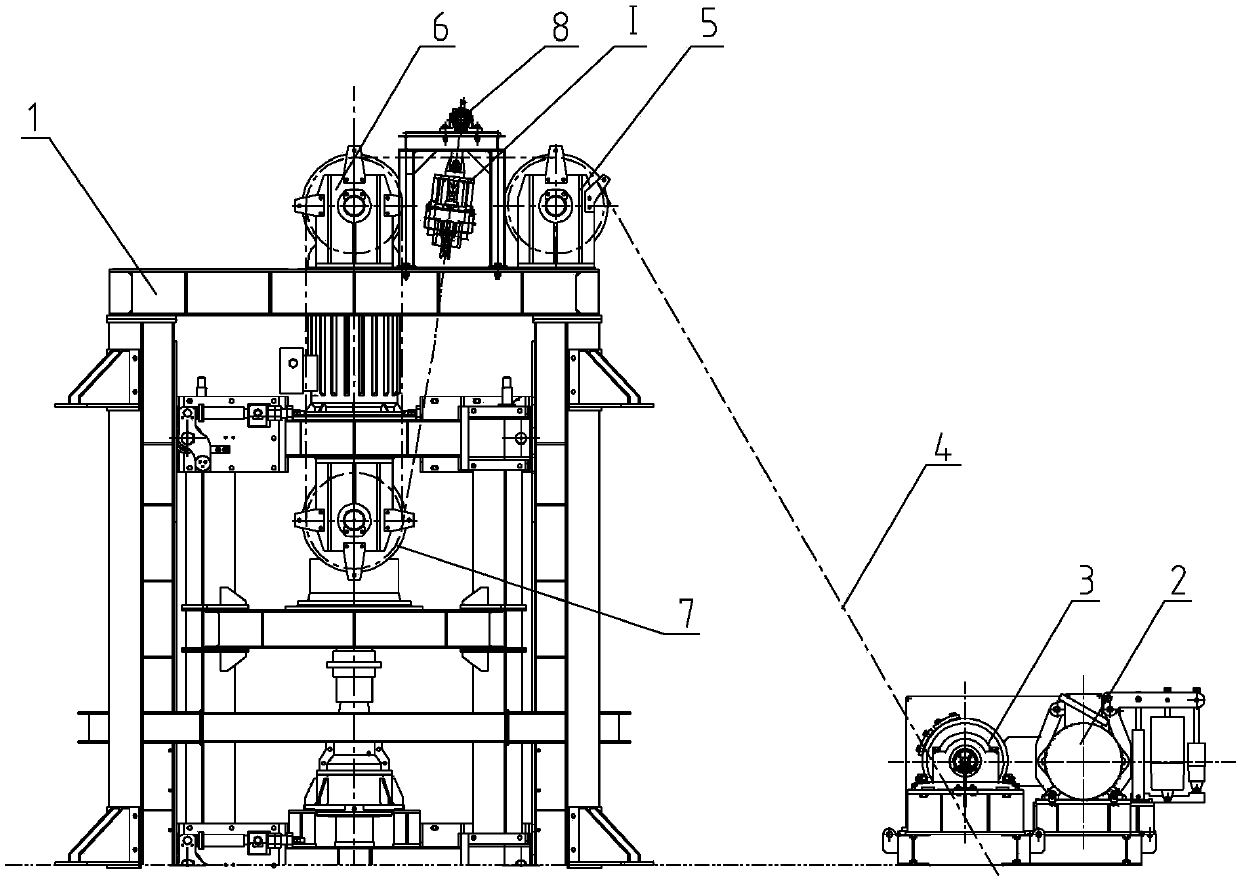

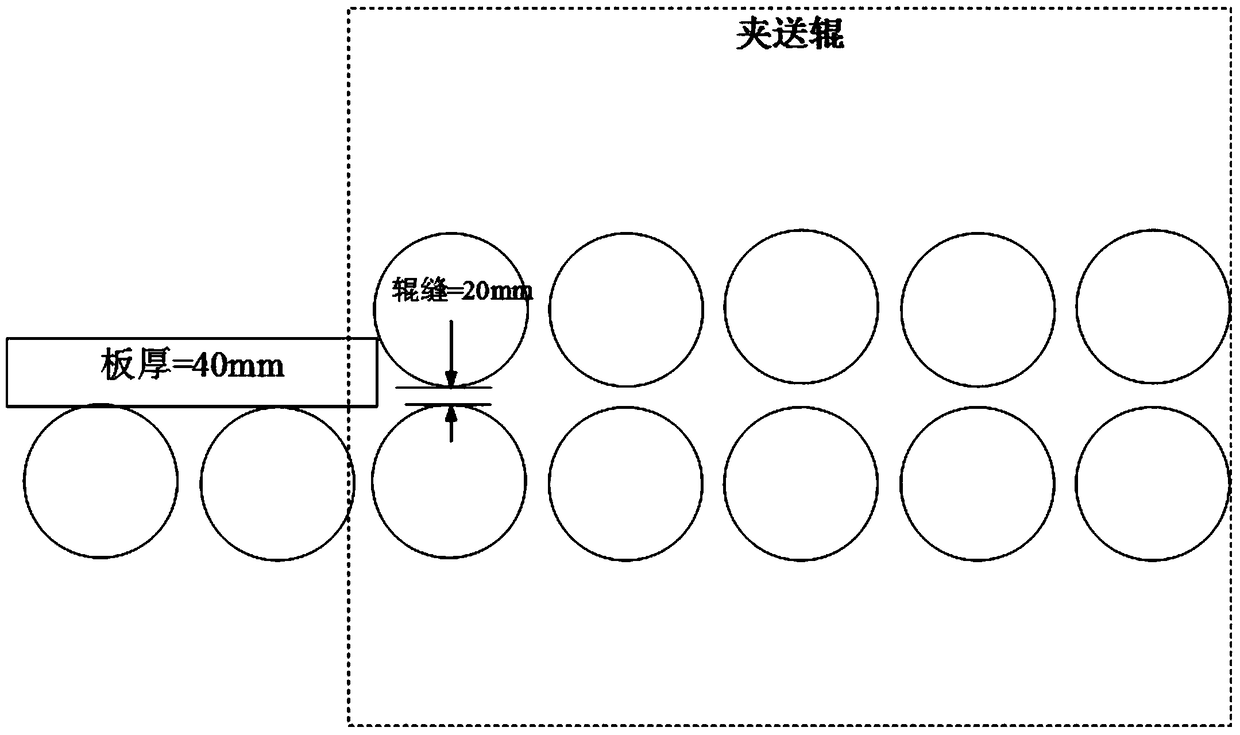

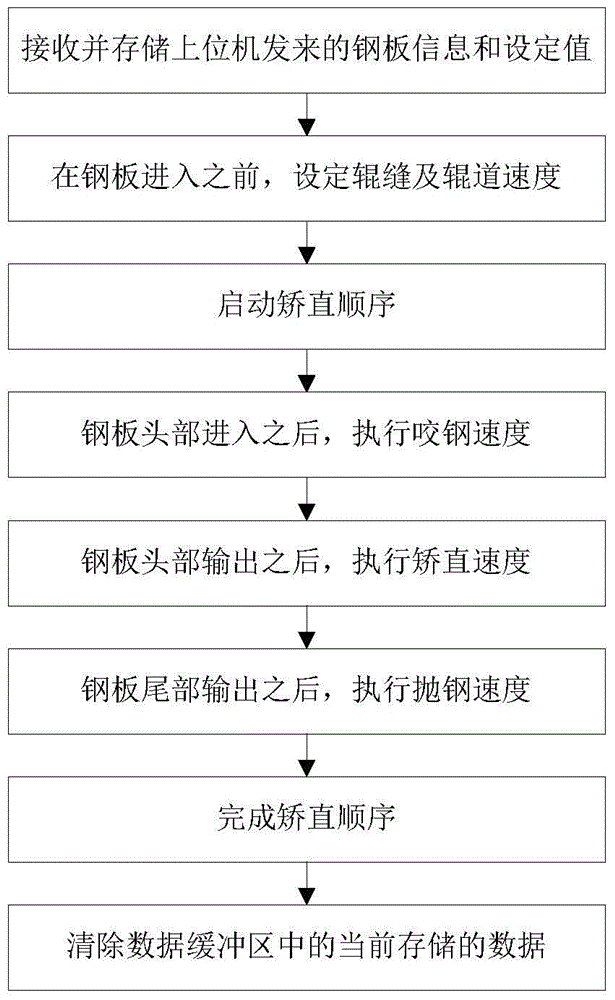

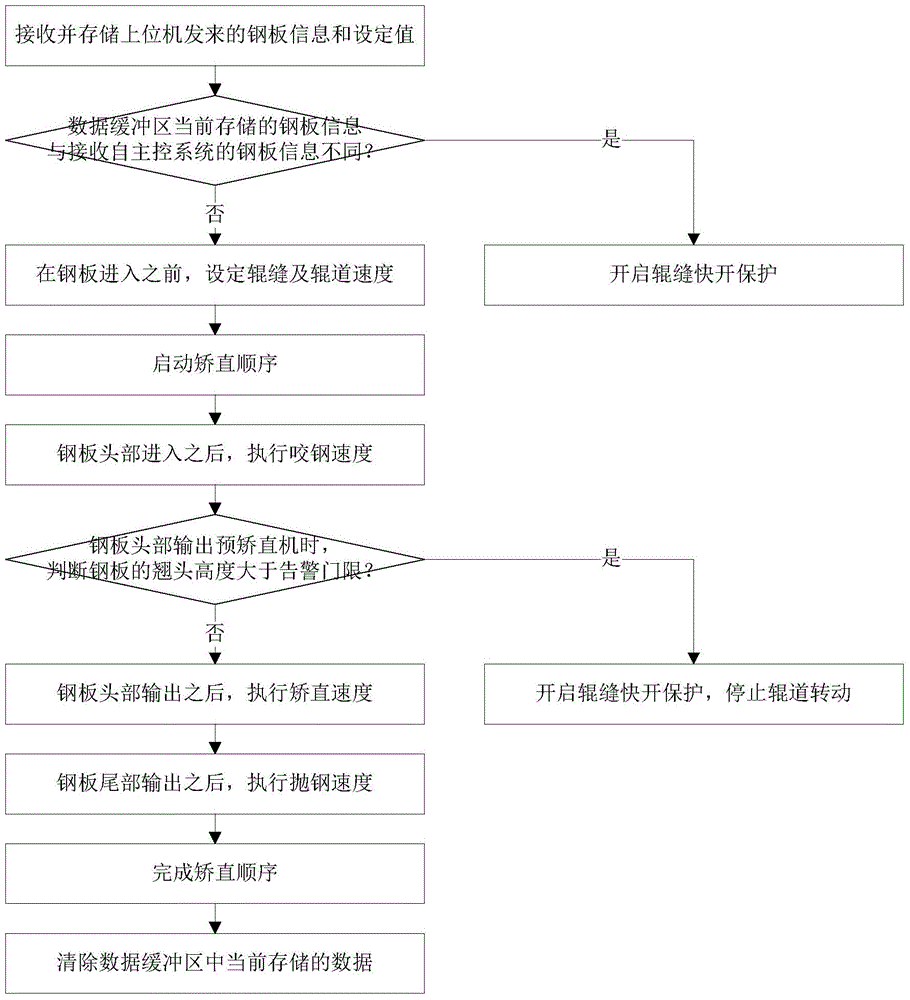

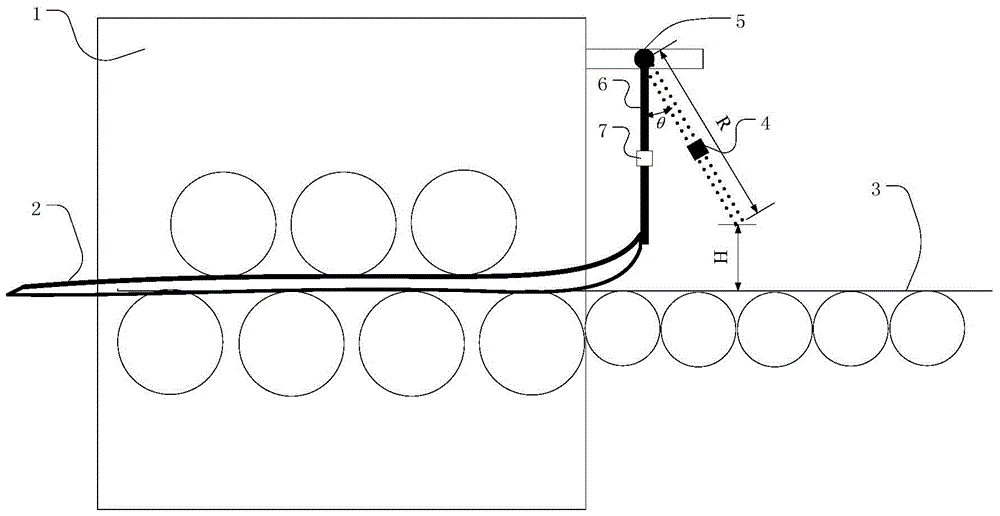

Method for preventing collision of pre-straightening steel plate and subsequent equipment, and steel plate head warping detection apparatus

ActiveCN104801569AGuarantee smooth productionEnsure safetyRoll mill control devicesMeasuring devicesSheet steelProtection mechanism

The present invention discloses a method for preventing collision of a pre-straightening steel plate and subsequent equipment, and a steel plate head warping detection apparatus. The method comprises: detecting the head warping height of the steel plate when outputting a pre-straightening machine on the head portion of the steel plate, and if the head warping height is larger than the alarm threshold, starting the roller seam rapid-opening protection of the pre-straightening machine. According to the present invention, the method uses the multiple protection mechanisms to carry out abnormal protection on the pre-straightening process; and with the apparatus, the steel plate head warping condition output by the equipment and meeting the alarming condition can be alarmed, such that the collision of the pre-straightening steel plate and the subsequent equipment can be effectively prevented so as to ensure safe production.

Owner:BAOSHAN IRON & STEEL CO LTD

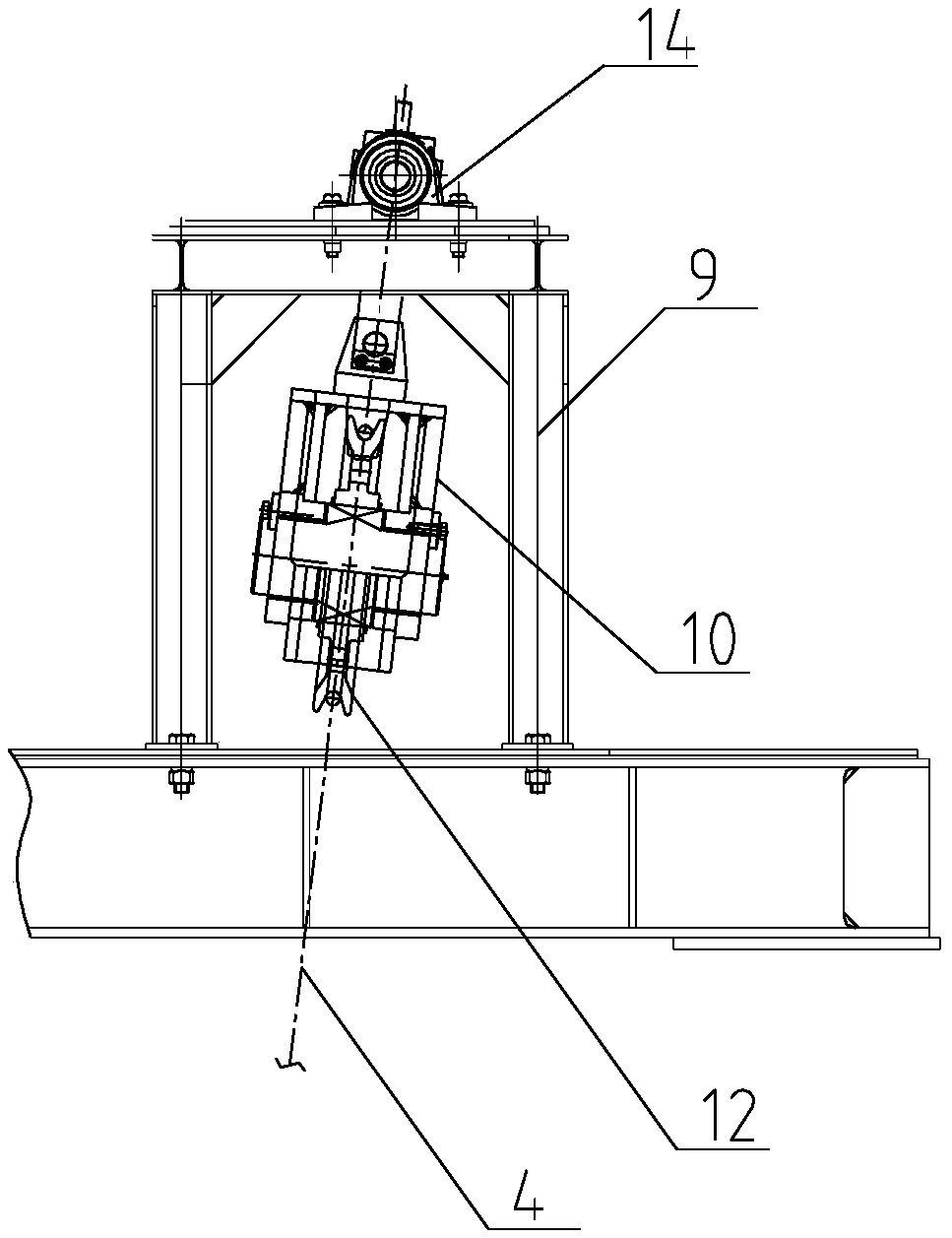

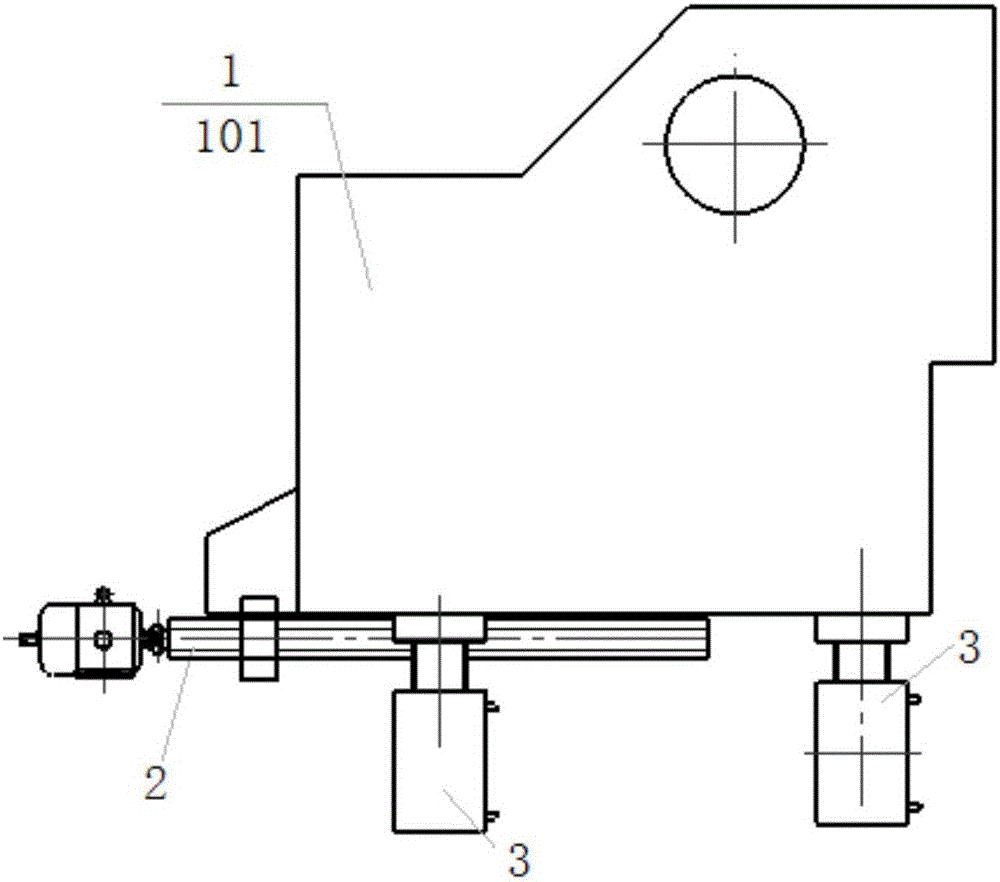

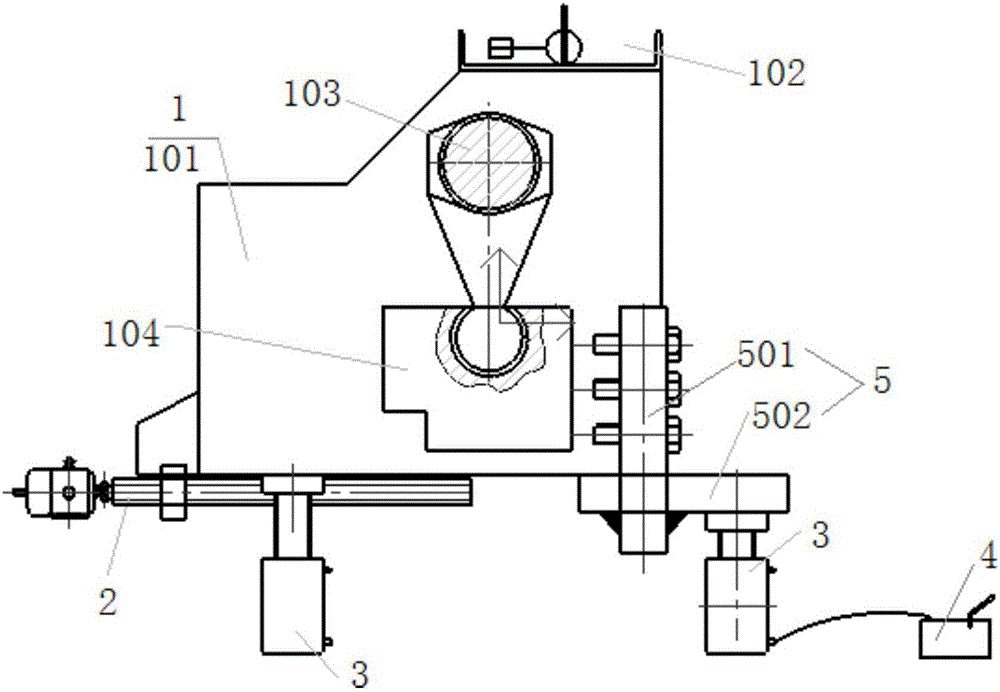

Anti-blocking device for KR process stirring desulfurization lifting trolley

The invention relates to an anti-blocking device for a KR process stirring desulfurization lifting trolley. The anti-blocking device comprises a fixed bracket, a movable bracket, transmission wheels,bearings with vertical seats, supporting seats and adjusting bolts. The transmission wheels are suspended in the fixed bracket through the movable bracket, the two ends of each supporting seat are supported by the bearings with vertical seats, the upper ends of the adjusting bolts pass through the supporting seats and are connected with weighing sensors, and the lower ends of the adjusting bolts are hinged to ear seats on the movable bracket. A steel wire rope drawn out from a steel wire rope reel successively bypasses a first crown block, a second crown block and a movable pulley in a first lifting trolley transmission mechanism, passes through the two transmission wheels, then bypasses a movable pulley, a second crown block and a first crown block in a second lifting trolley transmissionmechanism and then returns to the steel wire rope reel. According to the anti-blocking device, the original two groups of independent transmission systems of the lifting trolley are integrated into an integral transmission system through the transmission wheels, so that the portions, on the two sides of the lifting trolley, of the steel wire rope are ensured to be stressed uniformly, and the blocking of the lifting trolley in a stirring frame is avoided.

Owner:鞍钢集团工程技术有限公司

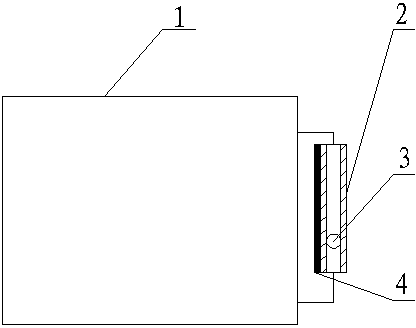

Electrical device for hydraulic leakage detection

InactiveCN104196826AEasy to detectGuarantee smooth productionFluid-pressure actuator testingFuel tankEngineering

The invention discloses an electrical device for hydraulic leakage detection. The electrical device comprises an oil tank, a liquid level meter, a floating ball, a detector and a computer processor. The detector is installed outside the liquid level meter and can detect magnetic force generated by the floating ball. The detector is connected with the computer processor. The electrical device has the following advantages that when leakage of a hydraulic system occurs, a liquid level numerical value of return oil of the hydraulic system in the oil tank changes greatly, if the change of the liquid level numerical value exceeds the change of the liquid level numerical value generated under the circumstance that the hydraulic system oil tank is normal and does not leak, the computer processor detects a liquid outlet level numerical value according to the position, detected by the detector, of the floating ball, automatically judges the accidents of leakage of the hydraulic system, gives a hint and an alarm, and warns staff to pay attention to and check the hydraulic system, and leakage faults can be stopped at the beginning of the accidents, so that the detection ability of the hydraulic system is improved, and smooth production is ensured.

Owner:蔡宏磊

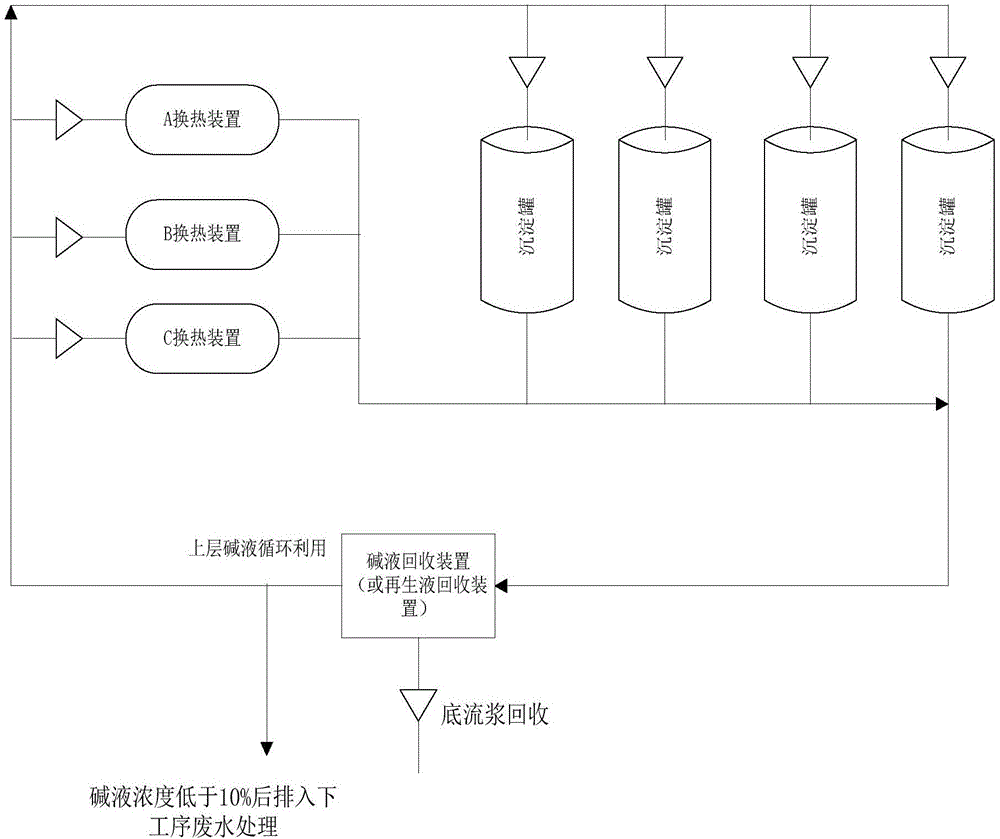

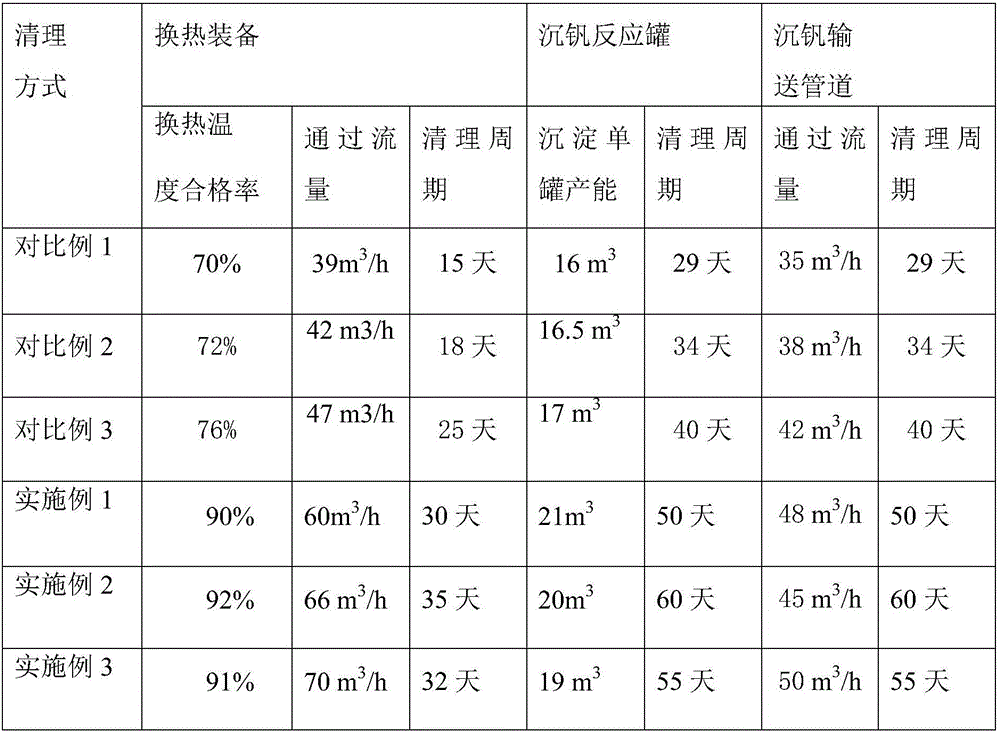

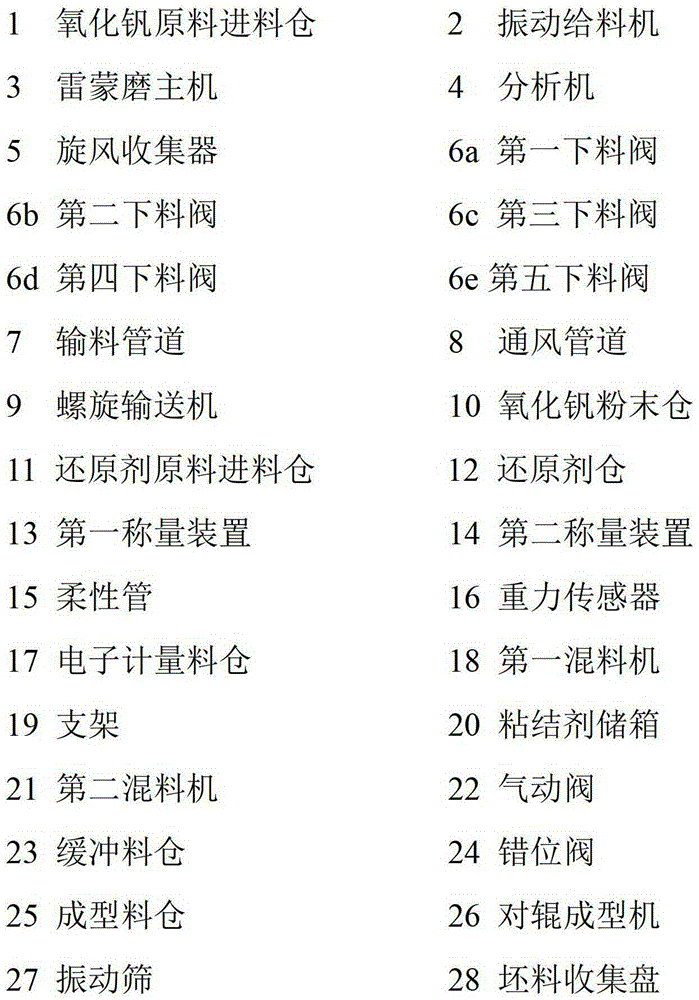

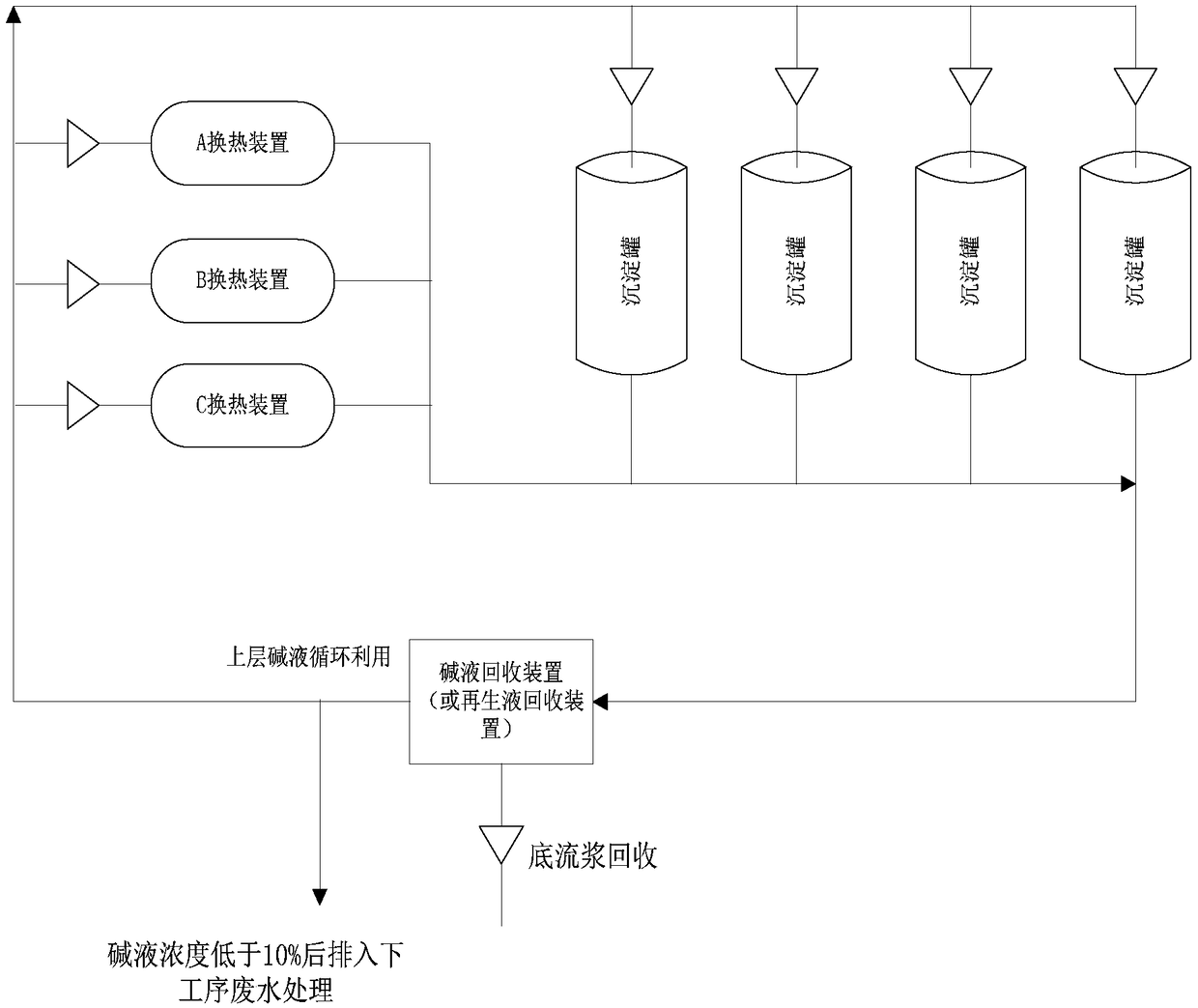

Treatment method for scale on surface of vanadium production equipment

The invention relates to a treatment method for scale, in particular to a treatment method for scale on the surface of vanadium production equipment and belongs to the field of metallurgy. The treatment method for the scale on the surface of the vanadium production equipment comprises the following steps that firstly, measuring is conducted; secondly, calculating is conducted, wherein the dosage of an anti-scaling agent is calculated according to the formula that the thickness of a scale layer times the inner surface area of the equipment is equal to 200 kg / m<3> to 250 kg / m<3>; thirdly, the scale is removed; fourthly, cleaning is conducted; and fifthly, waste liquid is recycled. According to the treatment method for the scale on the surface of the vanadium production equipment, the scale problem of the equipment under the calcified roasting-acid pickling vanadium liquid technology is effectively solved, it is ensured that production is smoothly conducted, and the production efficiency is improved.

Owner:攀钢集团西昌钒制品科技有限公司

Bilateral shear frame jacking method

ActiveCN106002193BReduce work intensityImprove maintenance efficiencyMetal working apparatusShearing machine accessoriesGravity centerGravitation

The invention discloses a jacking method of a rack of double-sided shears. The jacking method comprises the following steps of (1) determining the full load weight and the unbalanced centre-of-gravity position of the rack under the condition that components on the rack are not dismantled; (2) determining jacking devices for jacking the rack; (3) manufacturing a jacking tool and assisting contour blocks; (4) placing a sufficient number of jacking devices at the reasonable jacking positions in a jacking area of the double-sided shears; and (5) progressively increasing the height of the rack with the aid of the assisting high-equivalent blocks so as to jack the rack to the required height during the repeated station switching jacking of all the jacking devices, on the contrary, progressively reducing the height of the rack with the aid of the assisting high-equivalent blocks to complete falling and resetting of the rack during the repeated station switching jacking of all the jacking devices. According to the jacking method, rack jacking is completed reasonably and safely under the condition that components on the rack are not required to be dismantled, so that not only is the working intensity of maintainers reduced, but also the maintaining efficiency is improved, and smooth production is ensured.

Owner:CHONGQING IRON & STEEL CO LTD

Crystallizer casting powder and application thereof

PendingCN114309507AImprove the lubrication effectFunction increaseMetallurgyCrystallization temperature

Based on the total weight of the crystallizer casting powder, the crystallizer casting powder is prepared from the following components in percentage by weight: 36.5 to 44.5 percent of CaO, 20.5 to 26.5 percent of SiO2, 3 to 9 percent of BaO, 0.5 to 1.5 percent of Li2O, 5 to 8 percent of Na2O, 10 to 12 percent of F, 3 to 5 percent of Al2O3, 2 to 4 percent of MgO, 0 to 1.5 percent of Fe2O3, 8 to 10 percent of C and the balance of inevitable impurities. The content of different components is controlled to play a synergistic role, so that the crystallizer casting powder has the properties of high alkalinity, low melting point, moderate viscosity, low transition temperature, high crystallization temperature and high crystallization proportion, and the crystallizer casting powder is ensured to have good lubrication and heat transfer functions in the high-pulling-speed continuous casting process; the continuous casting process is smooth; and the surface quality of a casting blank is improved.

Owner:湖南华菱涟源钢铁有限公司 +1

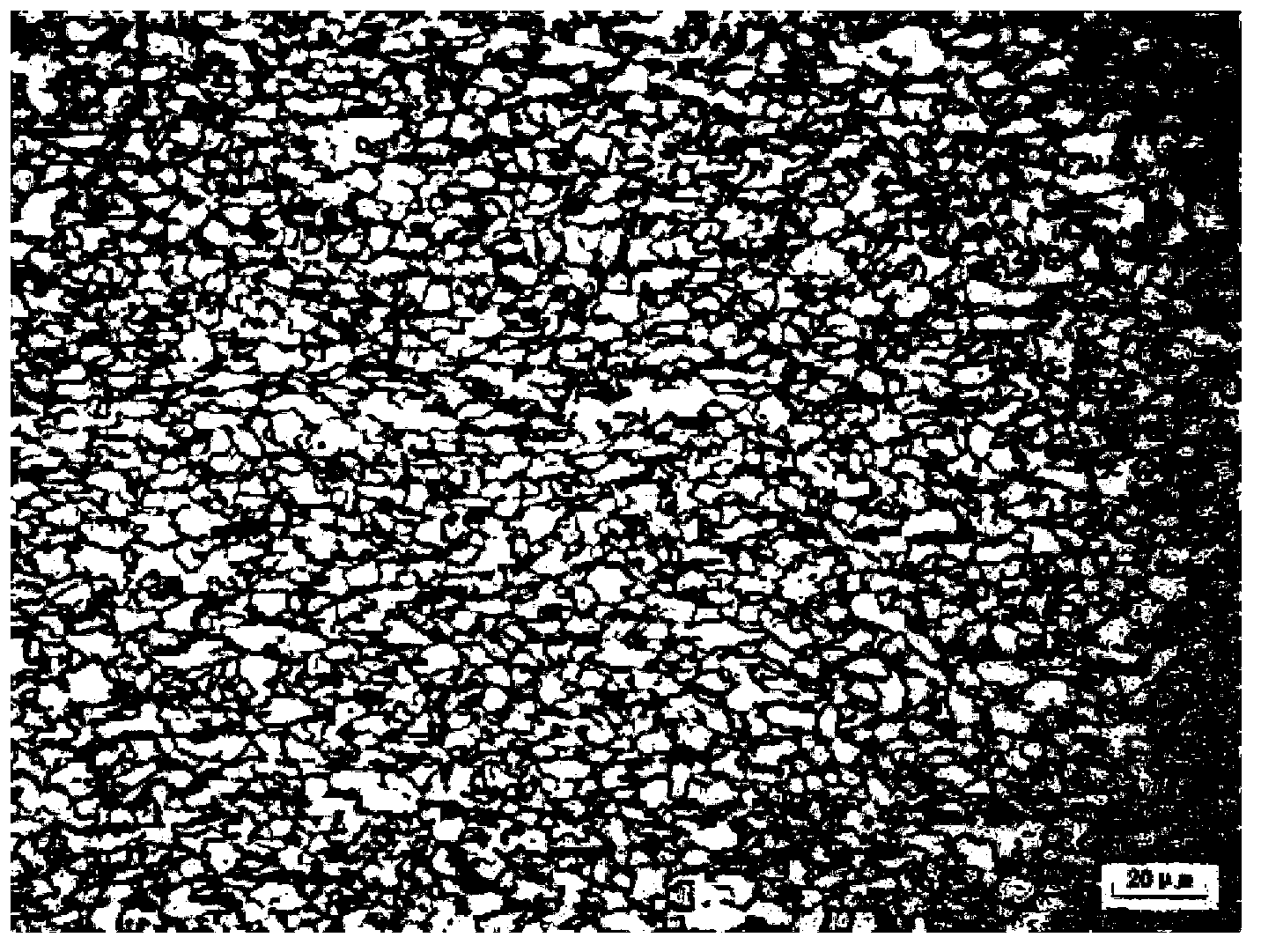

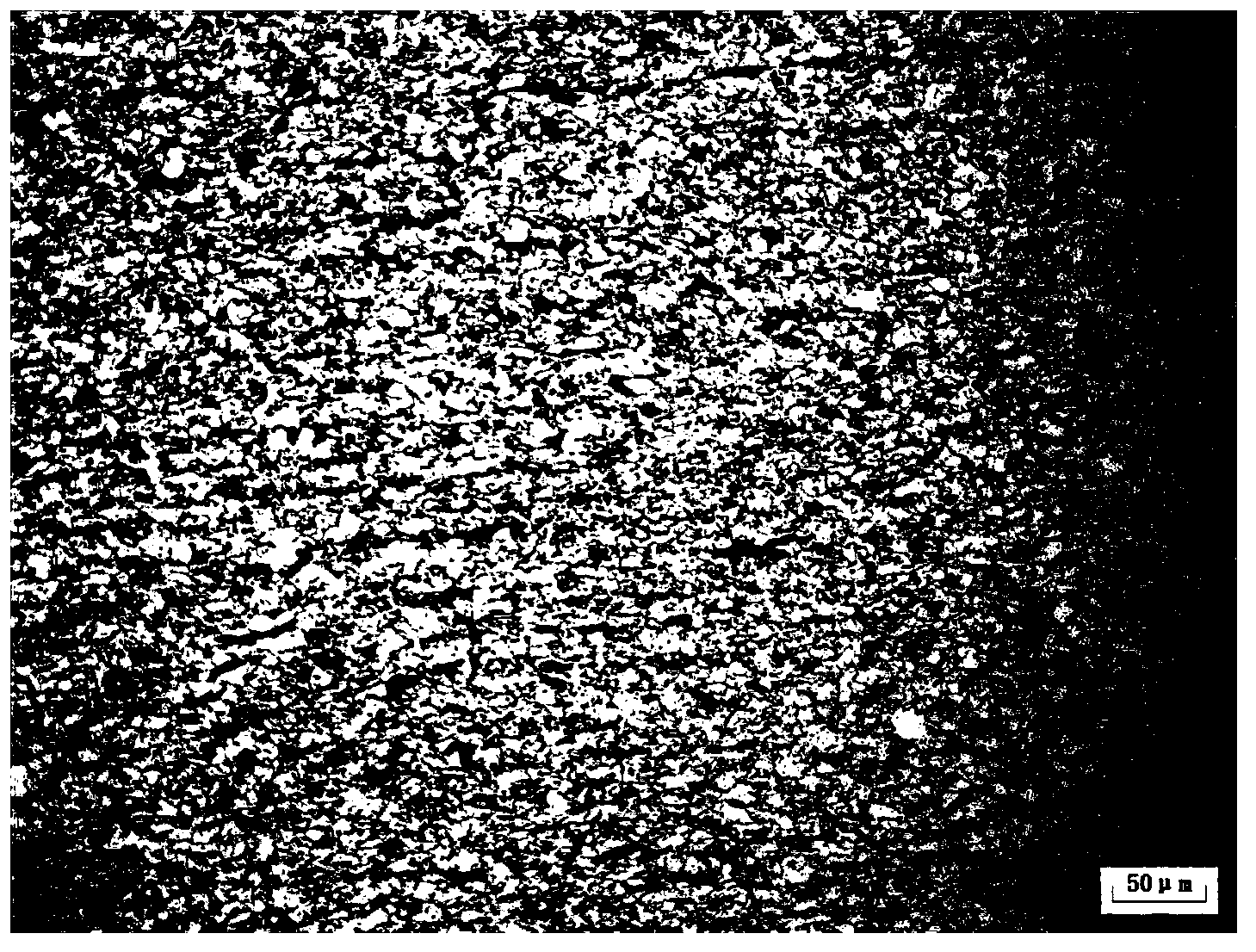

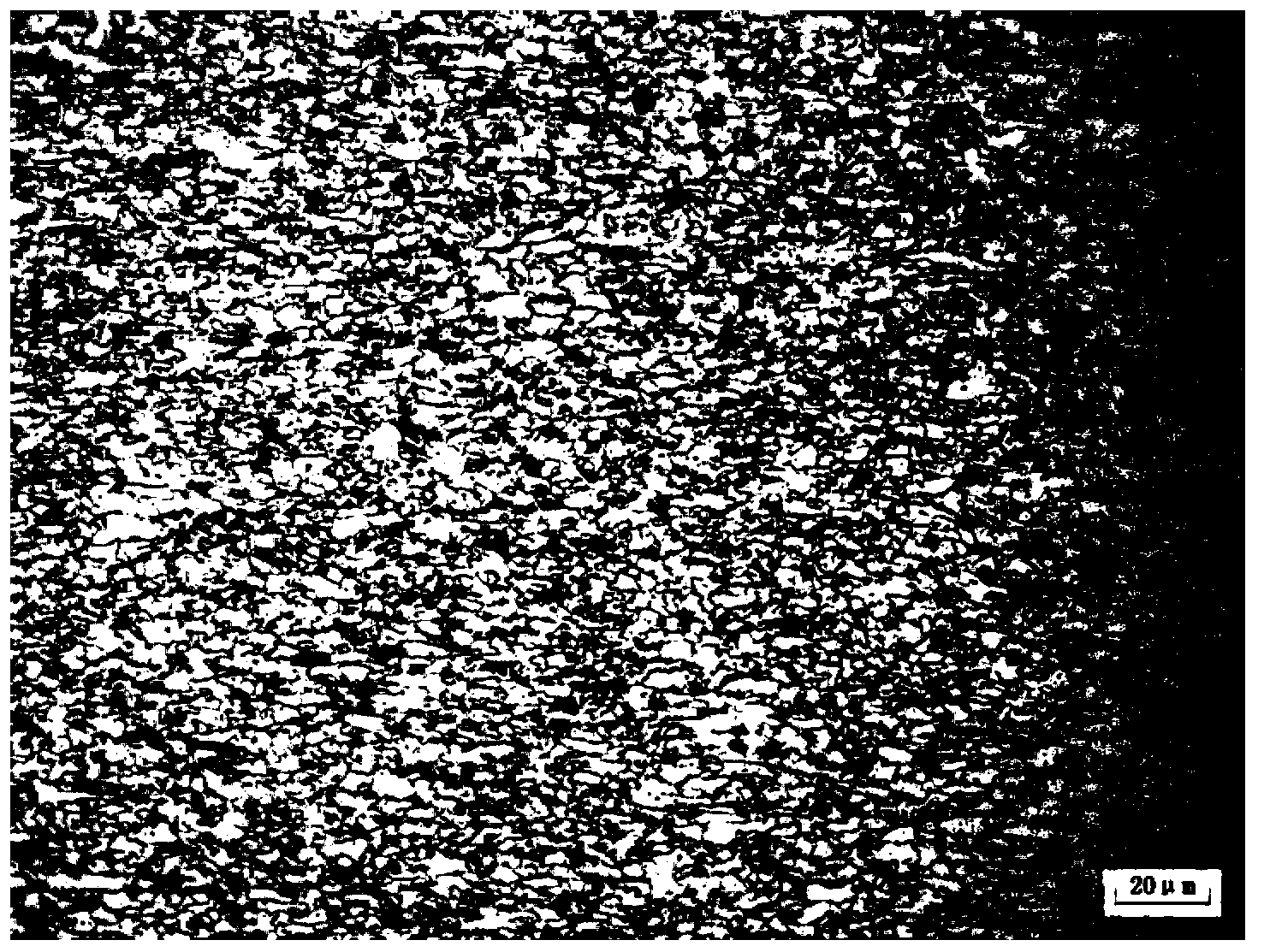

A Method for Eliminating Transverse Cracks at the Corner of Slab under High Scrap Steel Ratio Production Mode

ActiveCN108677080BCrack controlRealize strict content controlManufacturing convertersProcess efficiency improvementSmelting processTitanium

A method for eliminating casting blank corner transverse cracks under a high-scrap-ratio production mode comprises the following steps that a, scrap steel classified preparation is conducted; b, control over scrap steel adding in the converter smelting process is conducted, specifically, the relation of Cueq<=0.15% serves as a scrap steel adding principle; c, heat-carrying materials are added in the converter smelting process, specifically, according to the temperature and component of molten iron and the adding quantity of scrap steel, the adding quantity of the heat-carrying materials is determined; and d, control of the N content in the converter smelting process is conduced, specifically, good-quality white ash is adopted for slagging materials, and the content of N in the steel is conducted to be smaller than or equal to 50 ppm. According to the method for eliminating the casting blank corner transverse cracks under the high-scrap-ratio production mode, quantum chemistry calculation of the influence of the content of elements such as Cu, Ni, As and N in the scrap steel on the casting blank corner quality is obtained according to long-term exploration and repeated tests, the adding quantity and types of the scrap steel are controlled in a refined mode, and the adverse factor of the high microelement content on the casting blank quality is eliminated; through titanium nitrogen fixation, steel hardening caused by the high N content is prevented; and the casting blank corner cracks can be effectively controlled under the condition of the converter large-scrap-ratio production mode.

Owner:天铁热轧板有限公司

A smelting method for improving the fluidity of molten steel after refining and desulfurization of rebar

ActiveCN113234990BGuarantee smooth productionImprove liquidityManufacturing convertersSlagMolten steel

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

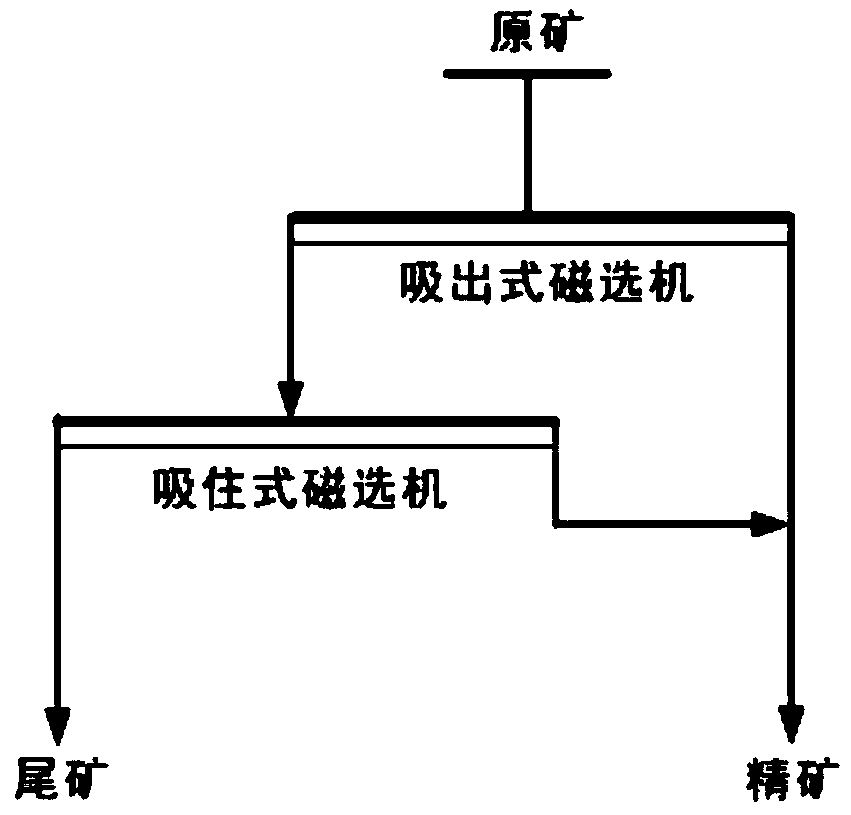

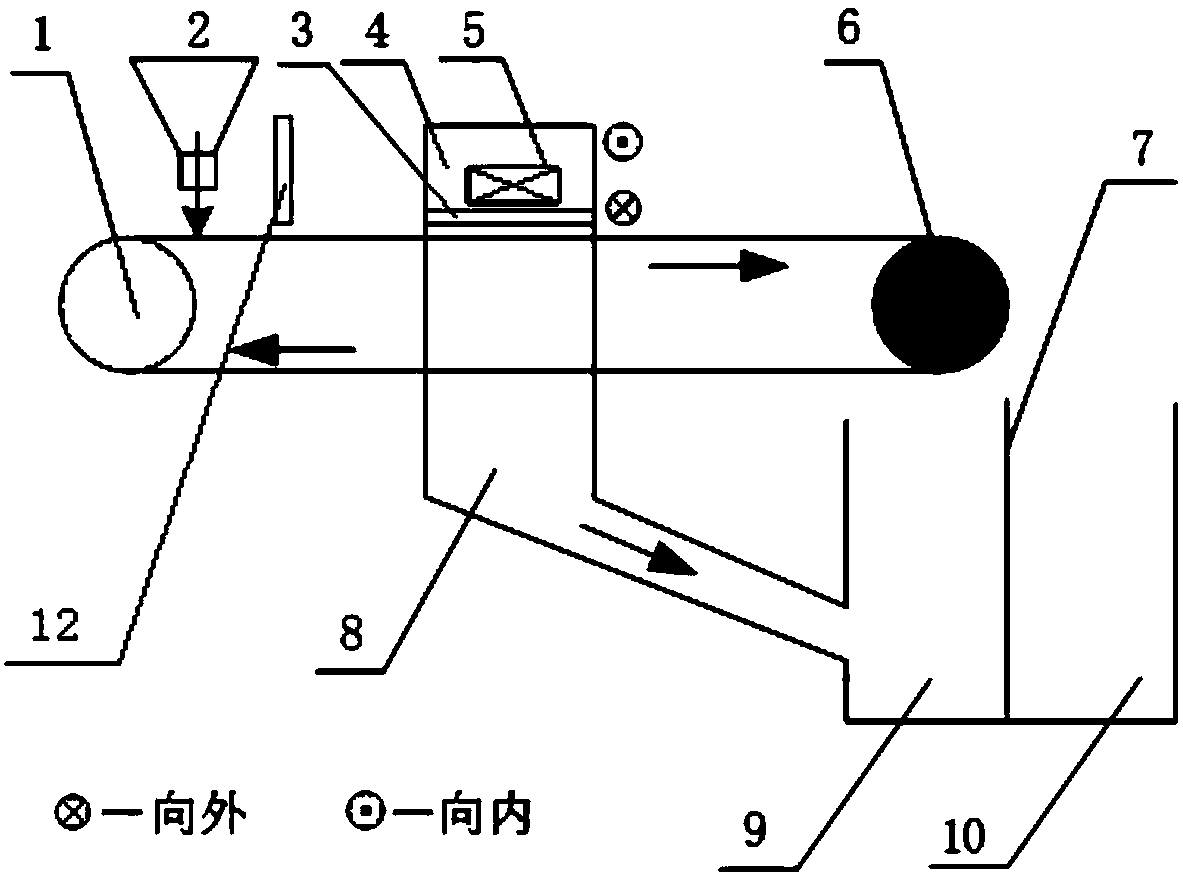

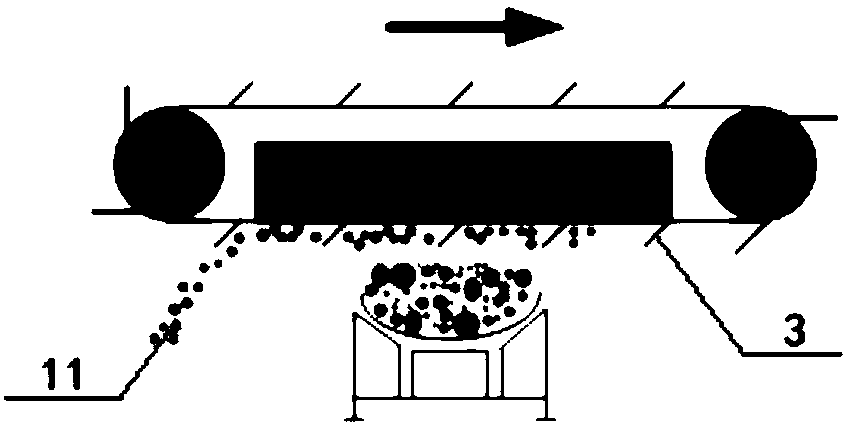

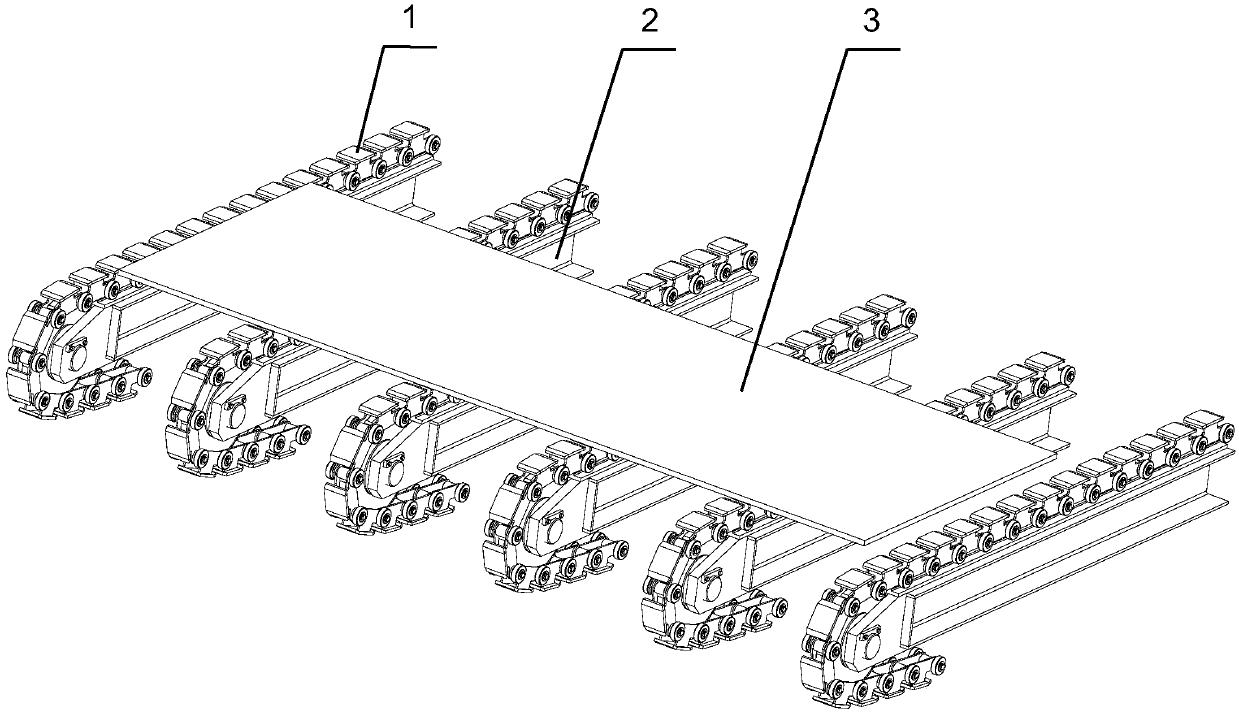

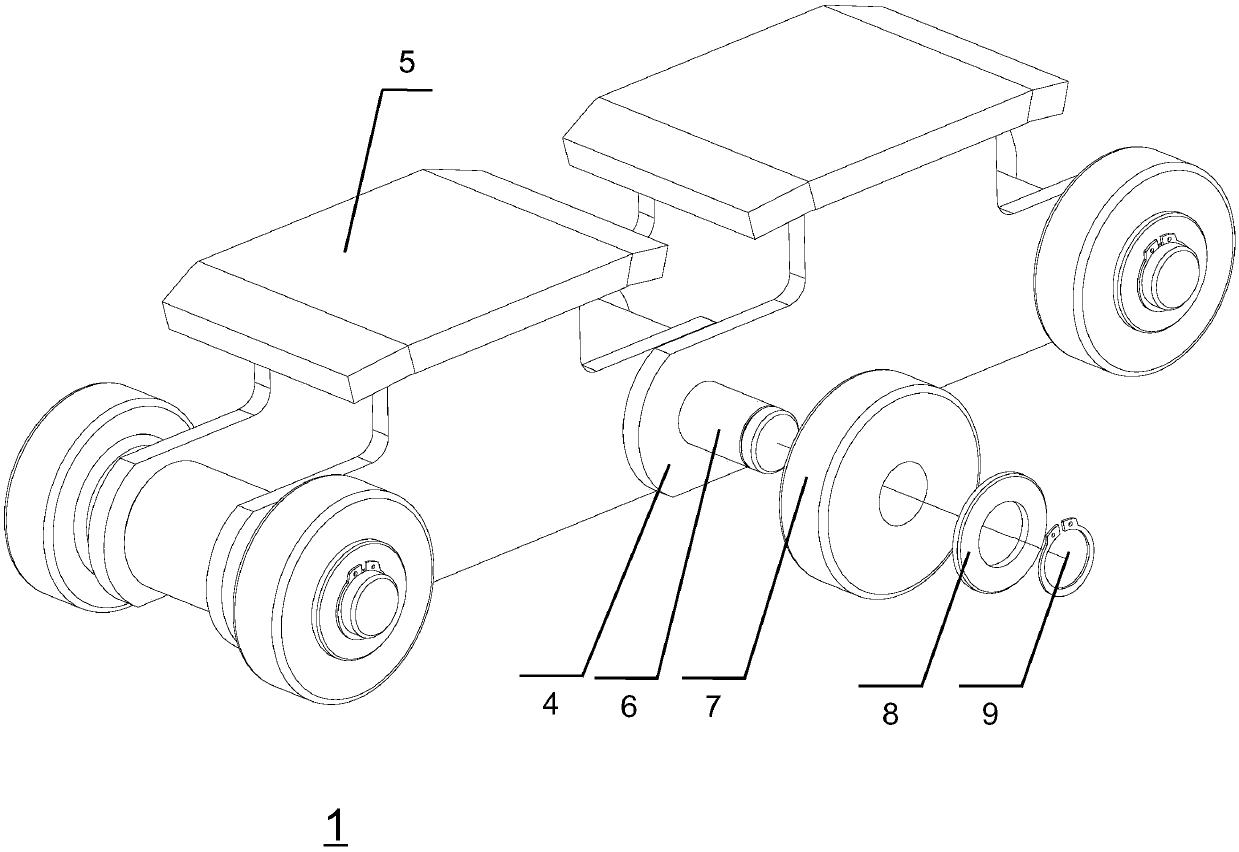

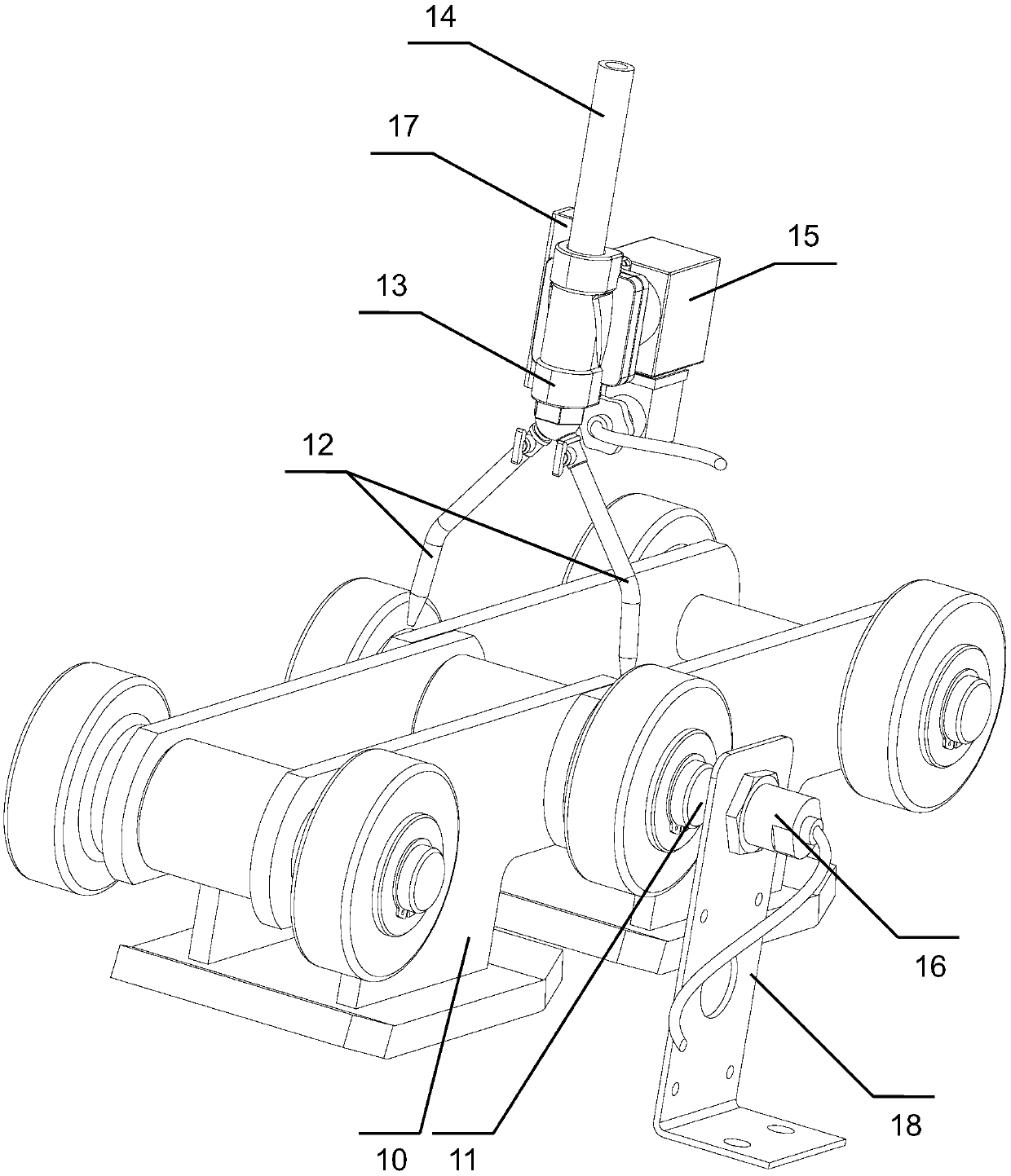

Crawler belt discharged ore suction-out and suction dry type magnetic separator and sorting method thereof

The invention discloses a crawler belt discharged ore suction-out and suction dry type magnetic separator and a sorting method thereof. The crawler belt discharged ore suction-out and suction dry typemagnetic separator comprises a suction-out type magnetic separator, a suction type magnetic separator, a suction-out type magnetic separator concentrate chute and a material receiving groove. The suction-out type magnetic separator is arranged above the suction type magnetic separator, the suction-out type magnetic separator and the suction type magnetic separator are mutually crossed and vertically arranged, and the suction-out type magnetic separator concentrate chute is formed in the bottom of the suction type magnetic separator and arranged in the suction-out type magnetic separator advancing direction and in the side, stretching out of the suction type magnetic separator, of a crawler belt. The suction-out type magnetic separator concentrate chute is connected with a magnetic productgroove of the material receiving groove. The material receiving groove is formed in the bottom of a suction type magnetic separator magnetic sliding wheel. In the production process, an updraught magnetic separator is forced to discharge ore, the problem about material blockage can be solved, the pulverized product dry type primary selection effect is improved, a large amount of qualified waste stone is thrown out, the grinding and separation feeding amount is reduced, and energy saving, consumption reducing and efficient utilization of magnet ore can be achieved.

Owner:UNIV OF SCI & TECH LIAONING

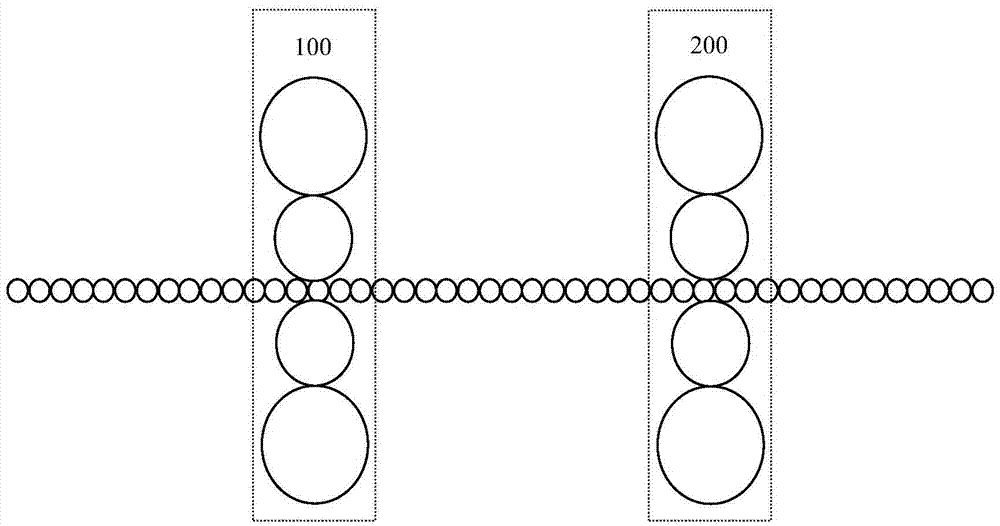

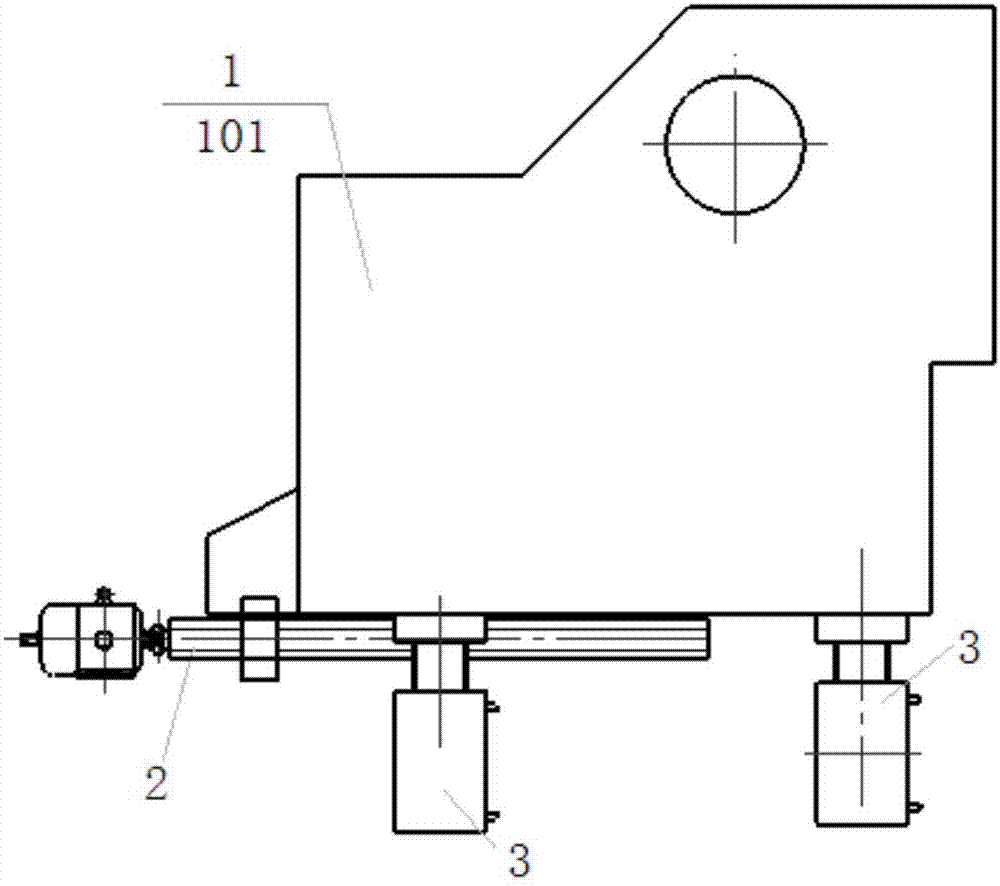

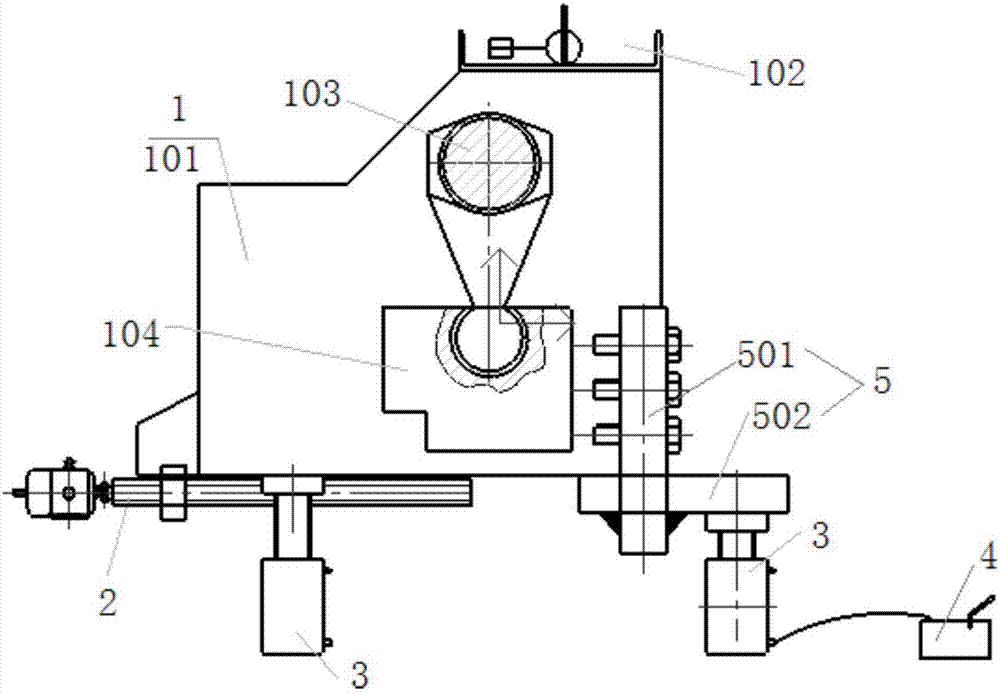

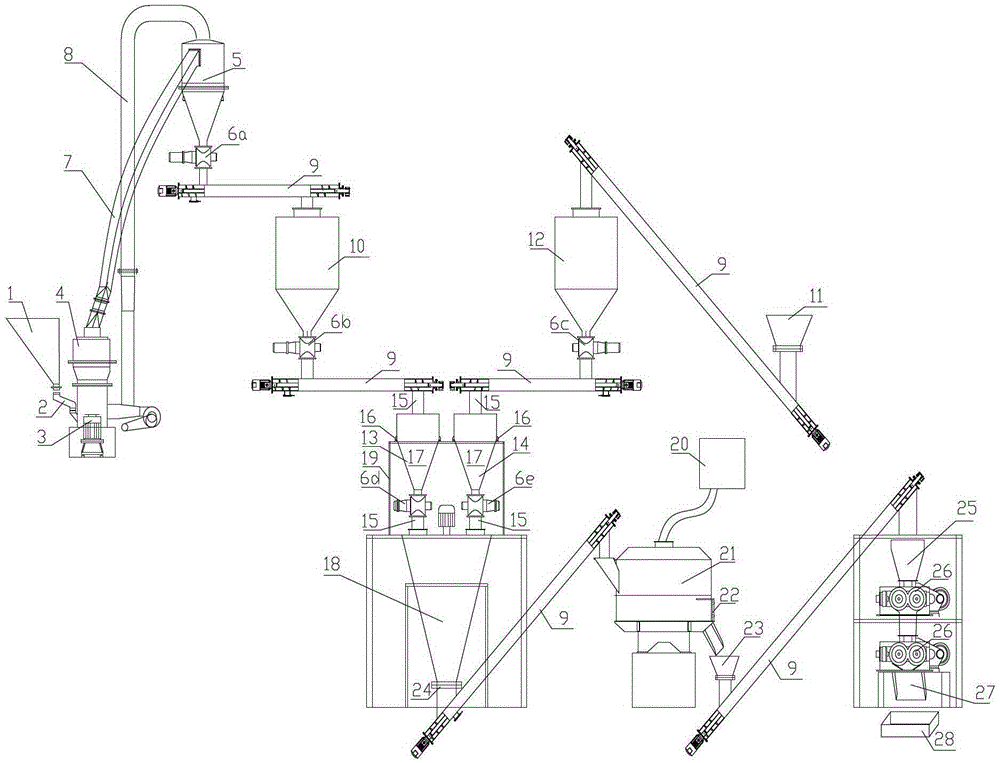

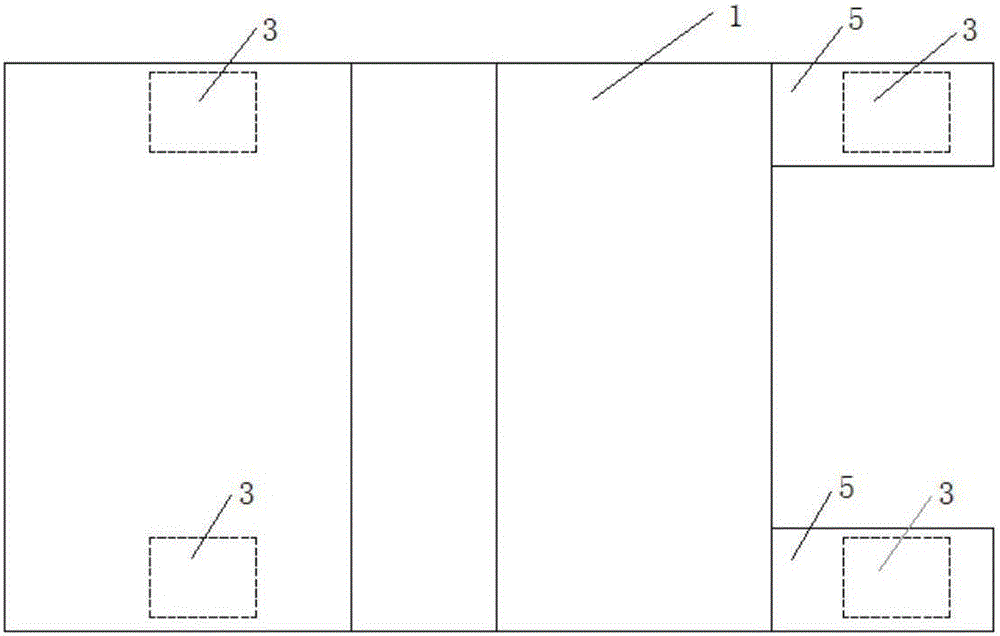

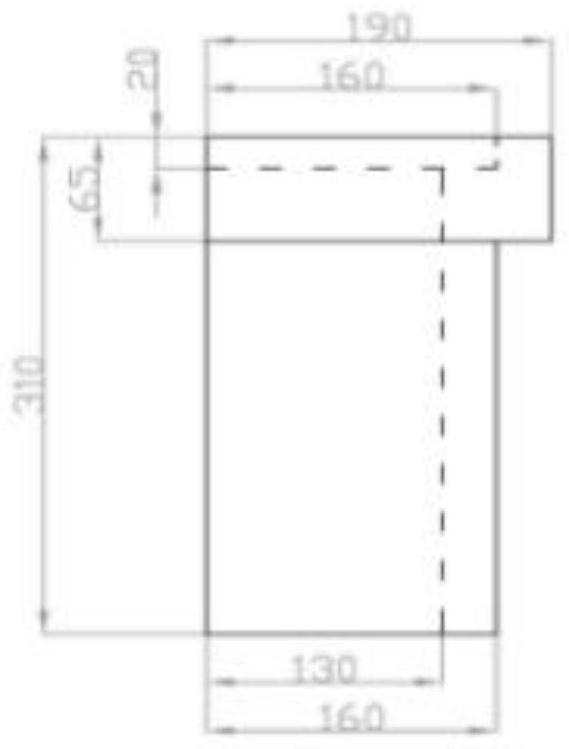

Production line for the production of blanks for vanadium-nitrogen alloys

The invention discloses a production line for producing vanadium-nitrogen alloy billets. The production line comprises a raw material supply system, a metering and burdening system, a material mixing system and a billet forming system which are sequentially connected, wherein the raw material supply system comprises a vanadium oxide powder supply unit and a reducing agent supply unit, the vanadium oxide powder supply unit and the reducing agent supply unit are respectively connected with the metering and burdening system to convey vanadium oxide powder and a reducing agent, which are in line with requirements, into the metering and burdening system, the metering and burdening system is used for weighing the vanadium oxide powder and the reducing agent and conveying the well weighed vanadium oxide powder and the well weighed reducing agent into the material mixing system, the material mixing system is used for mixing the vanadium oxide powder and the reducing agent, preparing billet powder and further conveying the billet powder into the billet forming system, and the billet forming system is used for manufacturing the billets from the billet powder.

Owner:胡力

Treatment method for surface fouling of vanadium production equipment

Owner:攀钢集团西昌钒制品科技有限公司

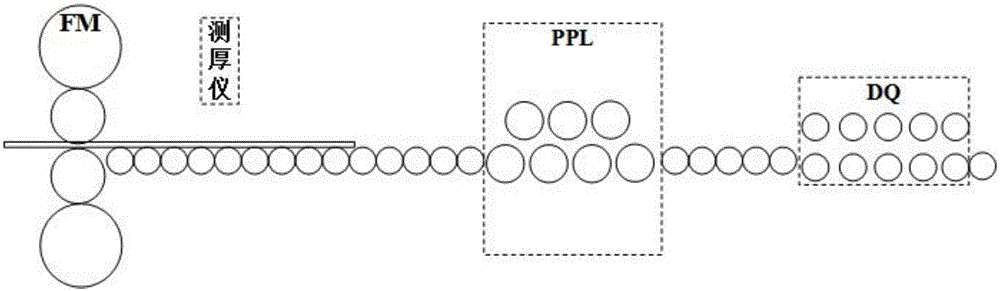

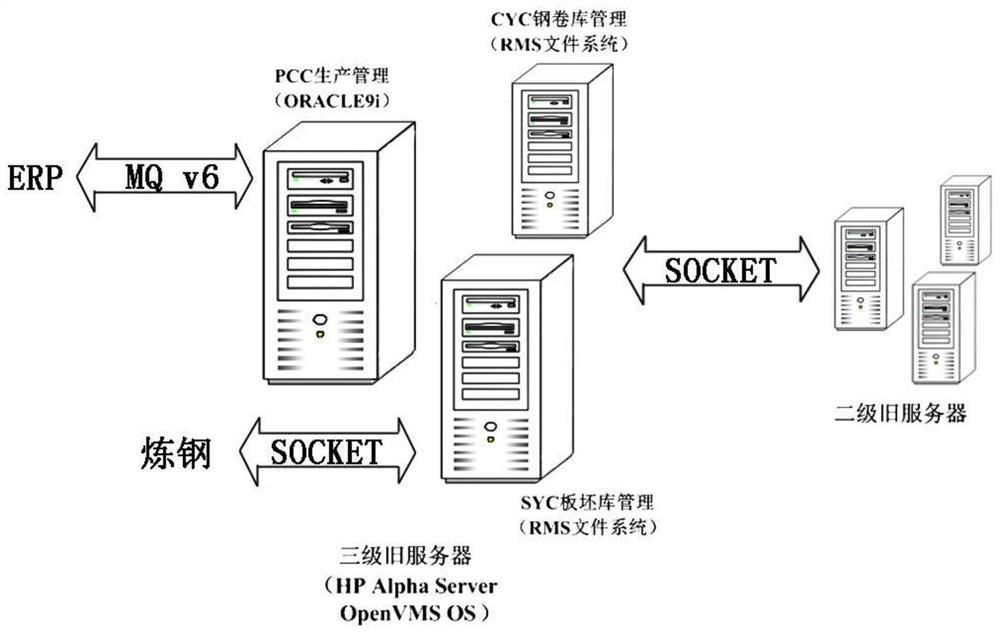

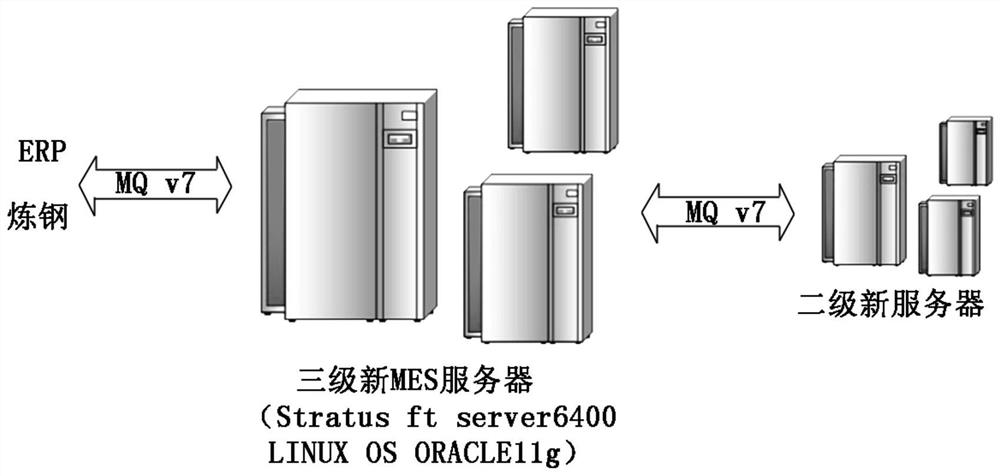

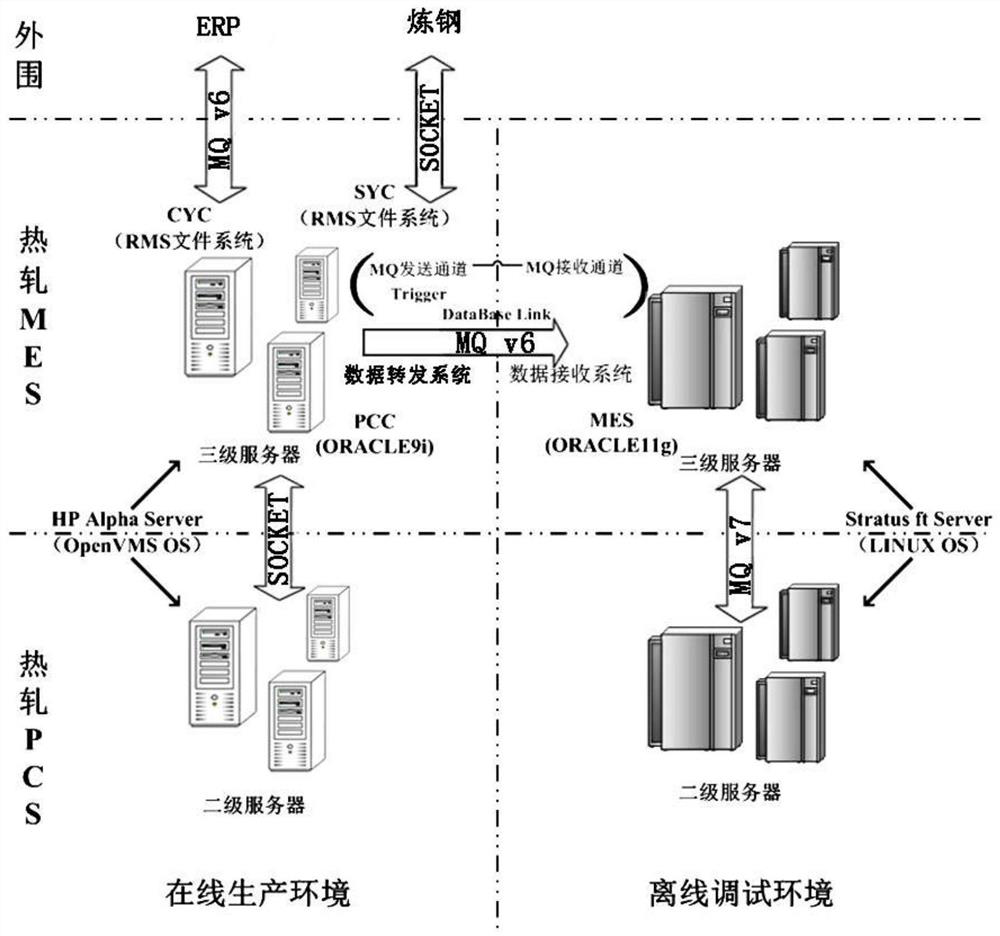

A data acquisition method for parallel debugging of hot-rolled strip mes system

ActiveCN107798444BGuarantee smooth productionImprove work efficiencyResourcesManufacturing computing systemsProduction lineData simulation

The present invention relates to a parallel debugging data acquisition method of hot-rolled strip steel MES system, which builds servers and application systems of hot-rolled new and old MES systems, collects production data required for debugging in real time, and realizes new and old MES in the process of system upgrading and transformation. The system runs in parallel, which not only ensures the normal on-site production, but also transmits the online data in the production process to the offline new third-level MES system in real time, and sends it to the offline new second-level PCS system, which is used as debugging data to simulate production and offline debugging The system is synchronized with production. The advantage is: through the implementation of the debugging data collection method, on the one hand, the online production and development and debugging of the hot rolling 1780 production line are realized in parallel, and the important production data of PDI required for debugging are provided for the second and third new systems in real time and accurately, which greatly improves Improve the work efficiency of system debugging and ensure that the project duration and quality meet the expected standards.

Owner:ANGANG STEEL CO LTD

Jacking method of rack of double-sided shears

ActiveCN106002193AReduce work intensityImprove maintenance efficiencyMetal working apparatusShearing machine accessoriesEngineeringGravity center

The invention discloses a jacking method of a rack of double-sided shears. The jacking method comprises the following steps of (1) determining the full load weight and the unbalanced centre-of-gravity position of the rack under the condition that components on the rack are not dismantled; (2) determining jacking devices for jacking the rack; (3) manufacturing a jacking tool and assisting contour blocks; (4) placing a sufficient number of jacking devices at the reasonable jacking positions in a jacking area of the double-sided shears; and (5) progressively increasing the height of the rack with the aid of the assisting high-equivalent blocks so as to jack the rack to the required height during the repeated station switching jacking of all the jacking devices, on the contrary, progressively reducing the height of the rack with the aid of the assisting high-equivalent blocks to complete falling and resetting of the rack during the repeated station switching jacking of all the jacking devices. According to the jacking method, rack jacking is completed reasonably and safely under the condition that components on the rack are not required to be dismantled, so that not only is the working intensity of maintainers reduced, but also the maintaining efficiency is improved, and smooth production is ensured.

Owner:CHONGQING IRON & STEEL CO LTD

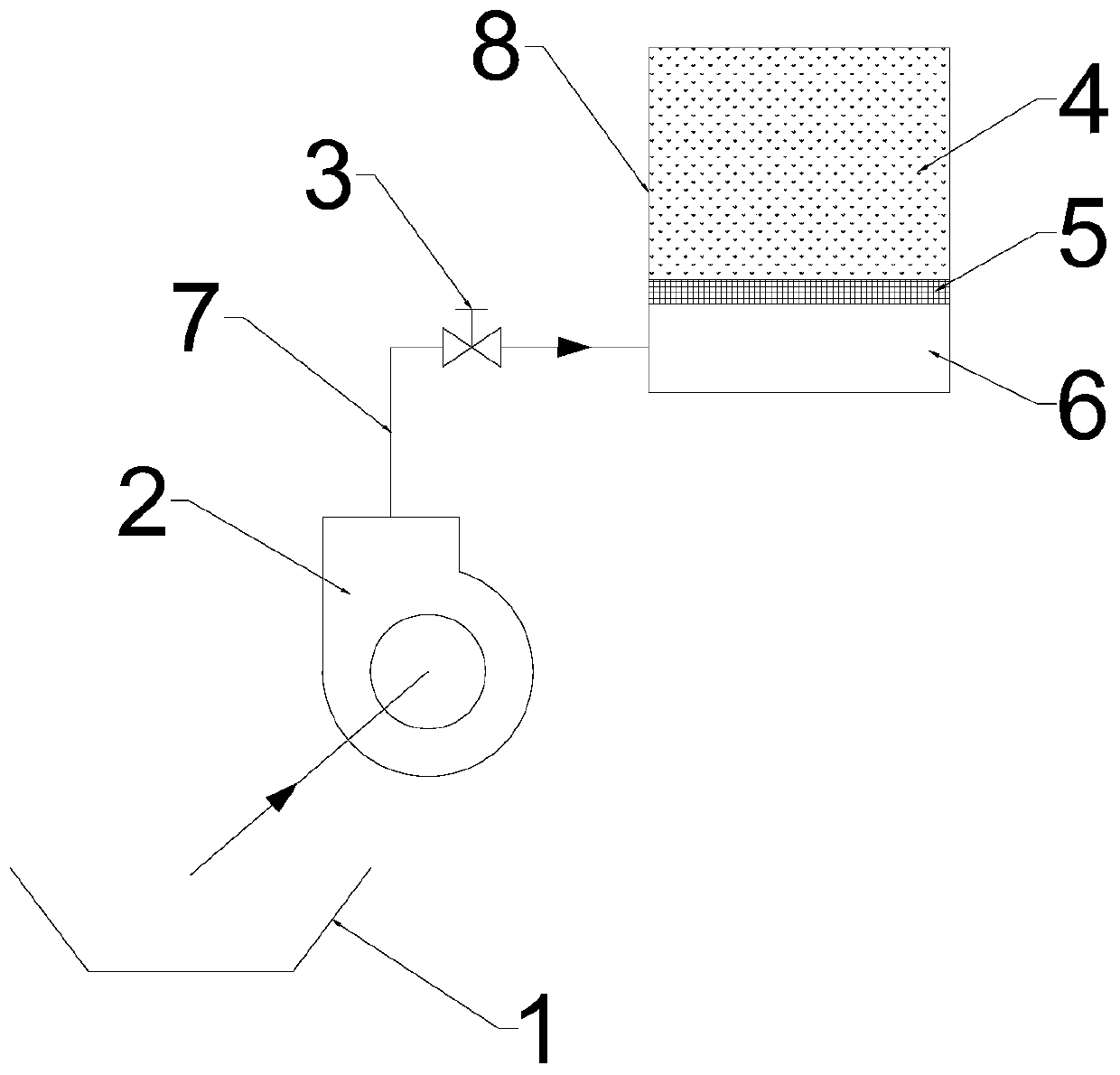

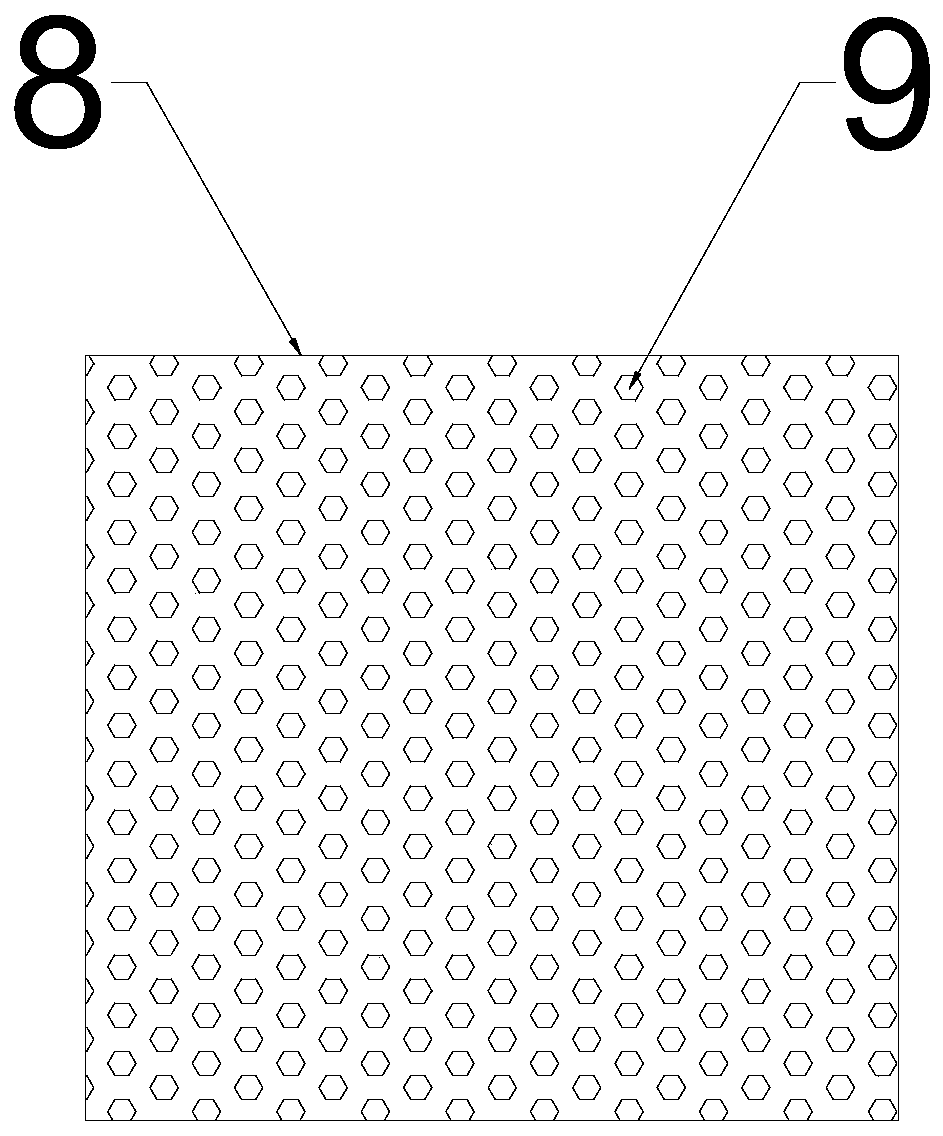

Casting powder baking device for continuous casting

PendingCN111397309AEliminate the risk of overheatingImprove uniformityDrying solid materials with heatDrying gas arrangementsHeat transfer efficiencyComposite material

The invention discloses a casting powder baking device for continuous casting. The casting powder baking device for continuous casting comprises a high-pressure vortex fan arranged above a tundish, wherein an air outlet of the high-pressure vortex fan is connected with an air pipe, and an adjusting valve is arranged on the air pipe. The casting powder baking device for continuous casting further comprises a fluidization box, fluidization particles; filter cloth and an air chamber are sequentially arranged in the fluidization box from top to bottom; the top of the fluidization box is open; andthe end, away from the air outlet, of the air pipe communicates with the air chamber. According to the casting powder baking device for continuous casting, the local overburning hidden danger is eliminated, the baking uniformity is improved, the heat transfer efficiency is improved, the bonding steel leakage accidents are reduced, smooth production is guaranteed, and the casting blank quality is further improved.

Owner:WUHU XINXING DUCTILE IRON PIPES

Automatic oiling device for conveying chains of transverse moving rack

InactiveCN110759217ASuppress noiseImprove friction conditionsGearing detailsEscalatorsEngineeringSprocket

The invention discloses an automatic oiling device for conveying chains of a transverse moving rack. The device is arranged on a tension chain wheel fixing support of each conveying chain, and each conveying chain comprises a side chain plate and roller shafts arranged on the two sides of the side chain plate; the oiling device comprises a plurality of oiling mechanisms and an electrical mechanismconnected with the plurality of oiling mechanisms; the electrical mechanism is used for controlling the plurality of oiling mechanisms to carry out oiling operation on the conveying chains; each oiling mechanism comprises two oil dripping hard pipes, a three-way joint, an oil inlet pipeline, a normally-closed electromagnetic valve and a normally-opened proximity switch; and the electrical mechanism comprises a manual button switch, an automatic contact switch and a power-on delay relay. The oiling device is used for improving the friction conditions between rollers and the roller shafts, inhibiting generation of broken chains and reducing on-site noise.

Owner:BAOSHAN IRON & STEEL CO LTD

Formula and manufacturing method of slag ladle trunnion anti-sticking steel sheath

The invention discloses a formula and a manufacturing method of a slag ladle trunnion anti-sticking steel sheath, which relate to the technical field of casting residue treatment. According to the formula of the slag ladle trunnion anti-sticking steel sheath, the formula comprises 60-90% of slag, 5-30% of lime, 5-10% of a binder and the balance of a refractory material, and the refractory material is a mixture formed by mixing CaO and Al2O3 according to the proportion of 3: 1-6: 1. According to the formula and the manufacturing method of the slag ladle trunnion anti-sticking steel sheath, the matched trunnion sheath is manufactured, the sheath is placed at the position of the trunnion when the slag ladle receives slag steel, and the sheath is taken down when the slag ladle is hoisted. The formula effectively prevents slag steel from being adhered to the trunnion when the steel ladle is turned over casting residues, so that the lifting of the slag ladle is prevented from being influenced, the casting residue slag steel in the steel ladle is effectively prevented from being adhered to form a weight at the trunnion in the pouring process, so that the phenomenon that a slag ladle lifting appliance cannot be completely clamped into the trunnion for lifting the slag ladle is prevented, smooth production is ensured, and the hidden danger of pouring the slag ladle caused by the weight of the slag steel adhered to the trunnion of the ladle is reduced.

Owner:MAANSHAN IRON & STEEL CO LTD

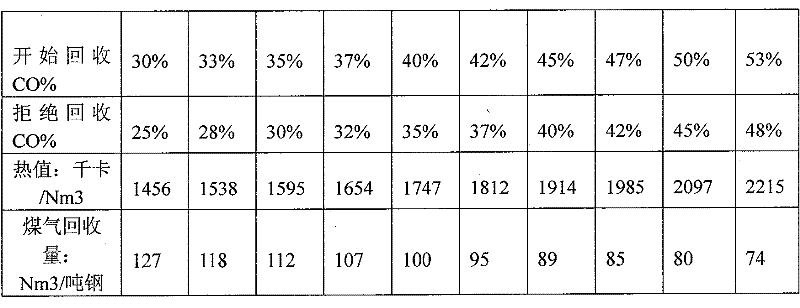

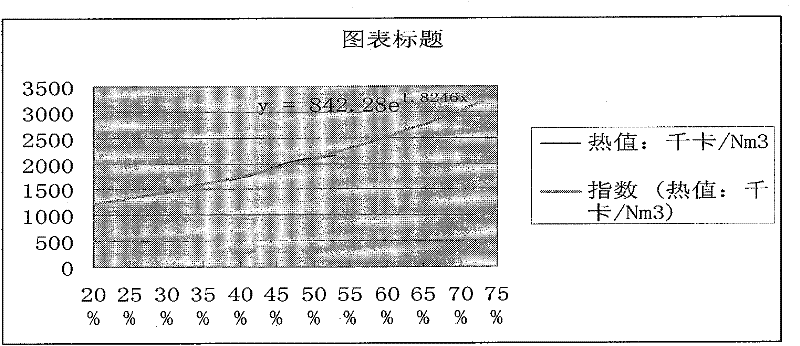

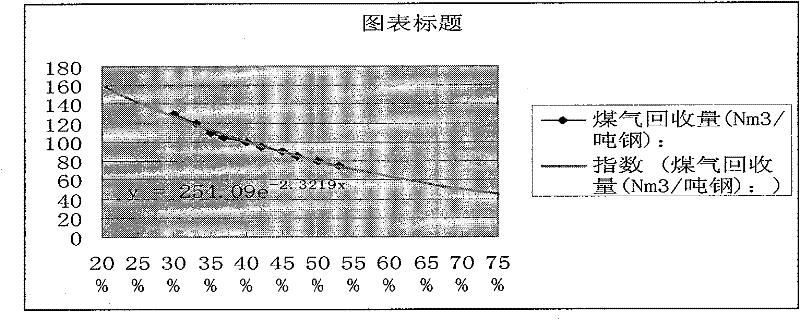

Method for reclaiming coal gas of converter through guidance of mathematical model

InactiveCN101713010BGuarantee smooth productionMeet production needsManufacturing convertersProcess efficiency improvementSteelmakingThermodynamics

The invention relates to a method for reclaiming coal gas of a converter through guidance of a mathematical model, which belongs to the technical field of metallurgical steelmaking and is used for solving the problem that caloric value of the coal gas of the converter can only be detected by a testing method. The method adopts the following technical scheme that: a mathematical model of the CO content which is reclaimed at the beginning and is refused to be reclaimed by the converter coal gas and the caloric value and the reclaiming amount of the converter coal gas is established; and a computational formula of the caloric value and the reclaiming amount of the converter coal gas is given out; and the computational formula of the coal gas caloric value Y1 is as follows: Y1=842.28e<1.8246>X, and X is more than or equal to 25 percent and less than or equal to 75 percent. According to field detection data, the mathematical model of the CO content which is reclaimed and is refused to be reclaimed by the converter coal gas and the caloric value and the reclaiming amount of the converter coal gas is established, and the computational formula is formed. By adopting the computational formula, according to the field practical situation the value of the CO content which is reclaimed and refused to be reclaimed by the converter coal gas can be adjusted and the caloric value and the reclaiming amount of the converter coal gas can be rapidly calculated, so that the reclaiming amount of the coal gas is improved and the method is favorable for a converter coal gas user to perform smooth production.

Owner:HANGANG GRP HANBAO IRON & STEEL +1

Control Method of Interlocking Protection of Pinch Roller

ActiveCN106694564BEliminate the risk of being hitGuarantee smooth productionRoll mill control devicesRolling safety devicesEngineeringMechanical engineering

The invention discloses a pinch roll interlock protection control method which comprises the following steps: Step 1, running pinch roll action under the automatic or manual mode; Step 2, judging whether finishing mill throws steel, if yes, moving to Step 3; otherwise, moving to Step 4; Step 3, carrying out the quick-opening process of cleaning between rolls; and Step 4, carrying out the lifting process of cleaning between rolls. According to the pinch roll interlock protection control method, under the conditions that the production technology is met and equipment safety is ensured, other detecting equipment of a rolling line area is introduced, and novel interlock protection logic is designed at the same time, so that the risk that a pinch roll is collided is effectively eliminated, and smooth production of a rolling line is ensured.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for preventing pre-straightening steel plate from colliding with subsequent equipment and steel plate warping detection device

ActiveCN104801569BGuarantee smooth productionEnsure safetyRoll mill control devicesMeasuring devicesSheet steelProtection mechanism

The present invention discloses a method for preventing collision of a pre-straightening steel plate and subsequent equipment, and a steel plate head warping detection apparatus. The method comprises: detecting the head warping height of the steel plate when outputting a pre-straightening machine on the head portion of the steel plate, and if the head warping height is larger than the alarm threshold, starting the roller seam rapid-opening protection of the pre-straightening machine. According to the present invention, the method uses the multiple protection mechanisms to carry out abnormal protection on the pre-straightening process; and with the apparatus, the steel plate head warping condition output by the equipment and meeting the alarming condition can be alarmed, such that the collision of the pre-straightening steel plate and the subsequent equipment can be effectively prevented so as to ensure safe production.

Owner:BAOSHAN IRON & STEEL CO LTD

Converter pretreatment and cold charging and heating method for high-carbon and high-alloy continuous casting slab

Owner:PANGANG GRP XICHANG STEEL & VANADIUM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com