Bilateral shear frame jacking method

A technology of bilateral shearing and jacking, applied in the field of steel rolling, can solve the problems of increasing the difficulty and workload of maintenance workers, affecting the safety and reliability of personnel and equipment, and affecting the production line, so as to avoid a large number of disassembly and assembly of equipment and calibration. The work of nuclear equipment, improving maintenance efficiency, and ensuring the effect of smooth production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be understood that the preferred embodiments are only for illustrating the present invention, rather than limiting the protection scope of the present invention.

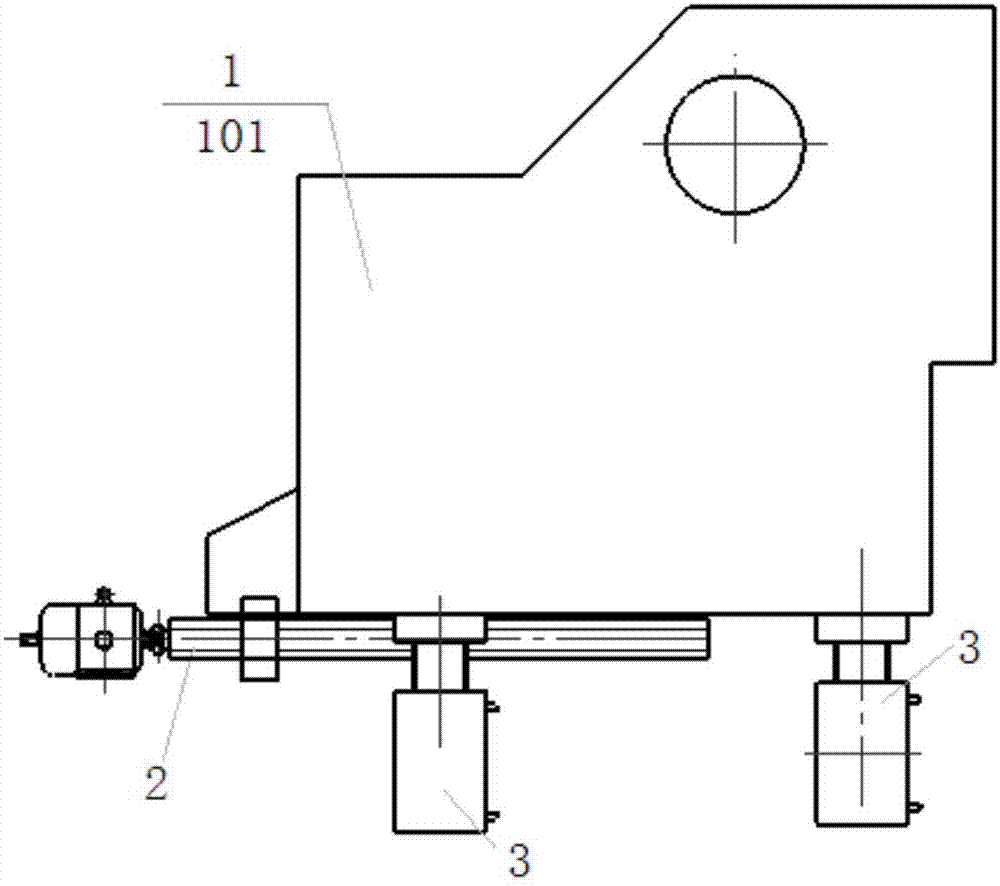

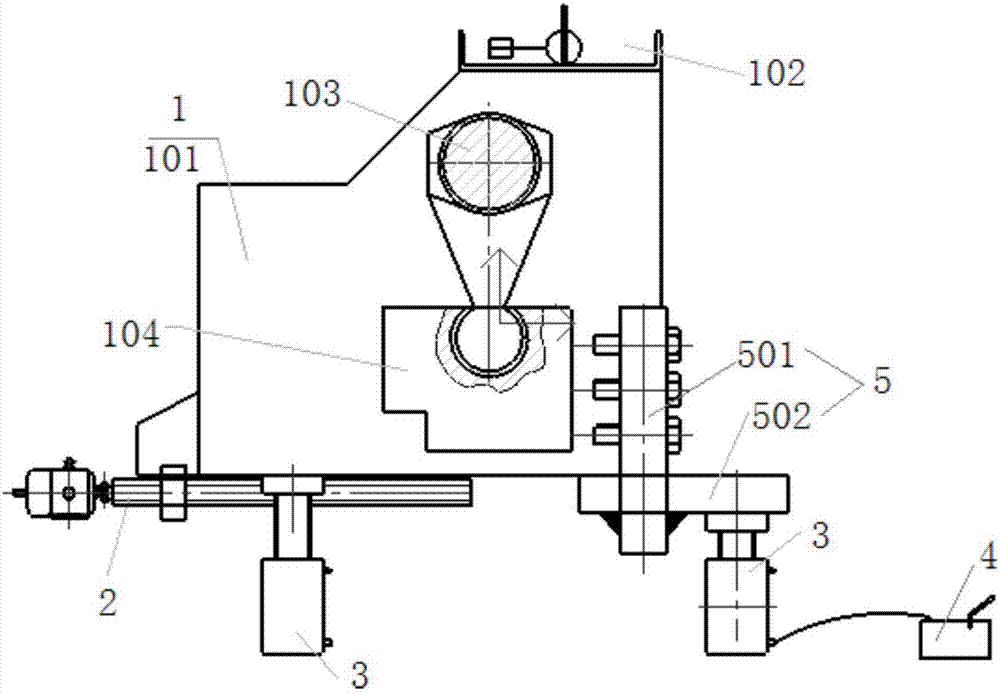

[0034] Such as figure 2 As shown, a kind of double shear frame jacking method provided by the present invention specifically comprises the following steps:

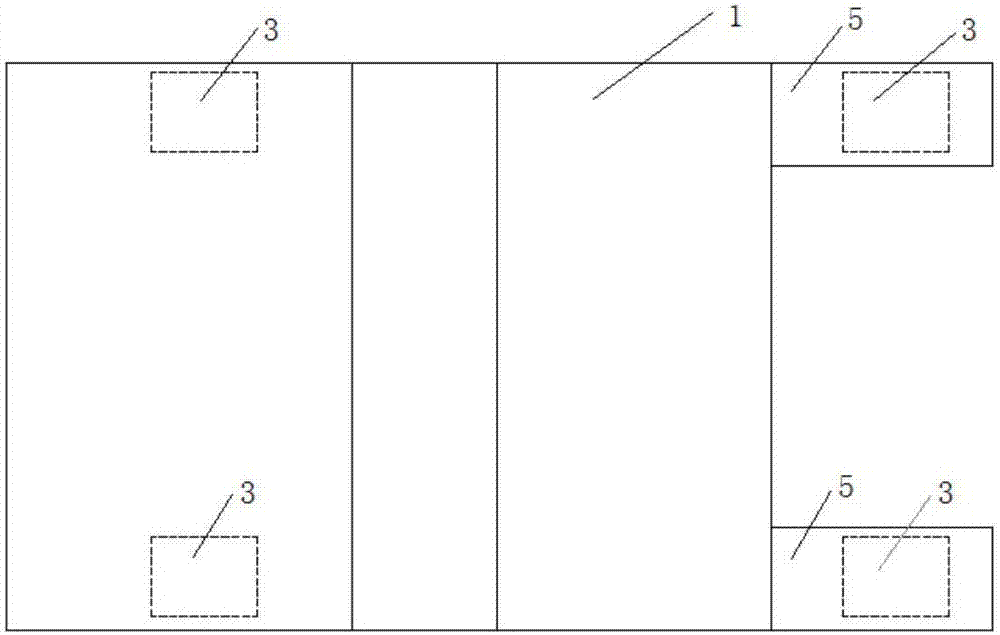

[0035] First, combined with the drawings, statistically calculate the full load weight of frame 1 without removing the components in frame 1, and calculate and measure the position of the center of gravity when frame 1 is fully loaded; then, according to the full load of frame 1 weight, find the matching jacking device 3; then, make the jacking tool 5 and the auxiliary contour block 6, the jacking tool 5 is detachably installed on the frame 1, and is used for jacking The device 3 cooperates to reset the lifting c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com