Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "Good moisture release" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

EVA material for sneaker sole and preparation method thereof

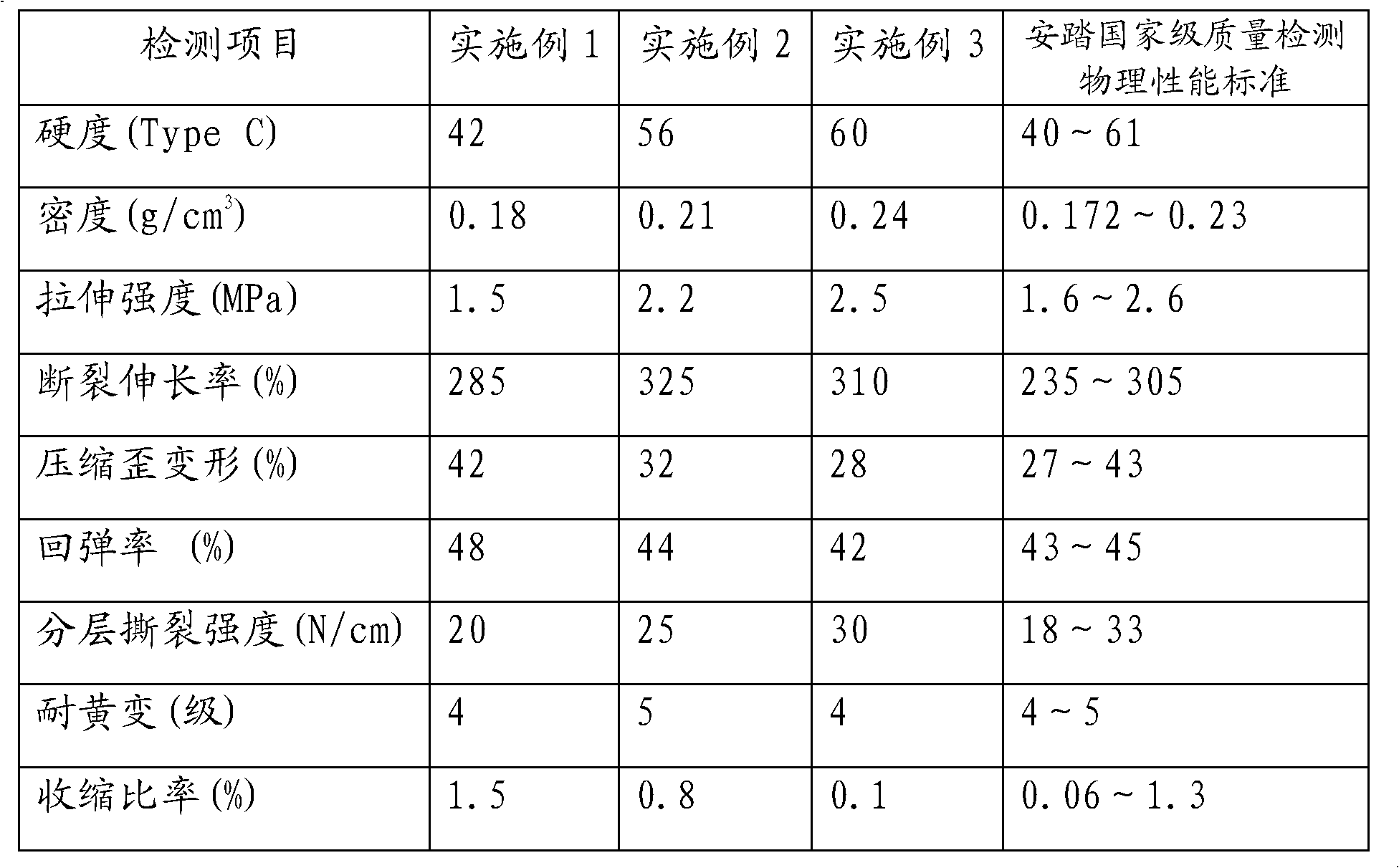

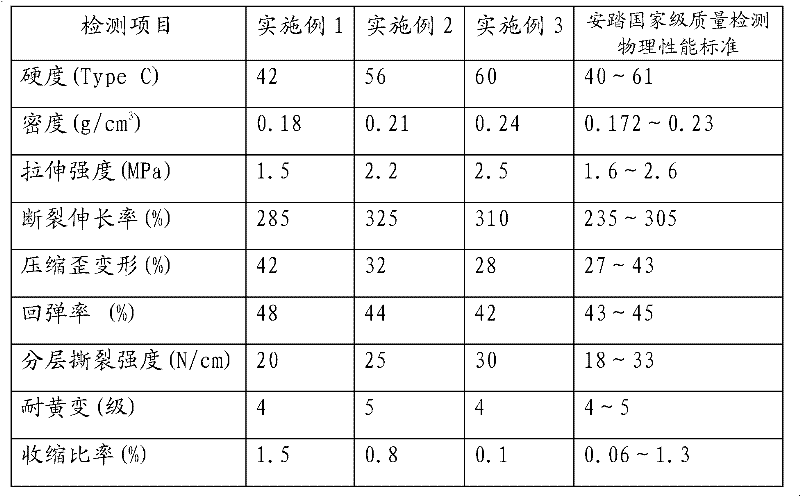

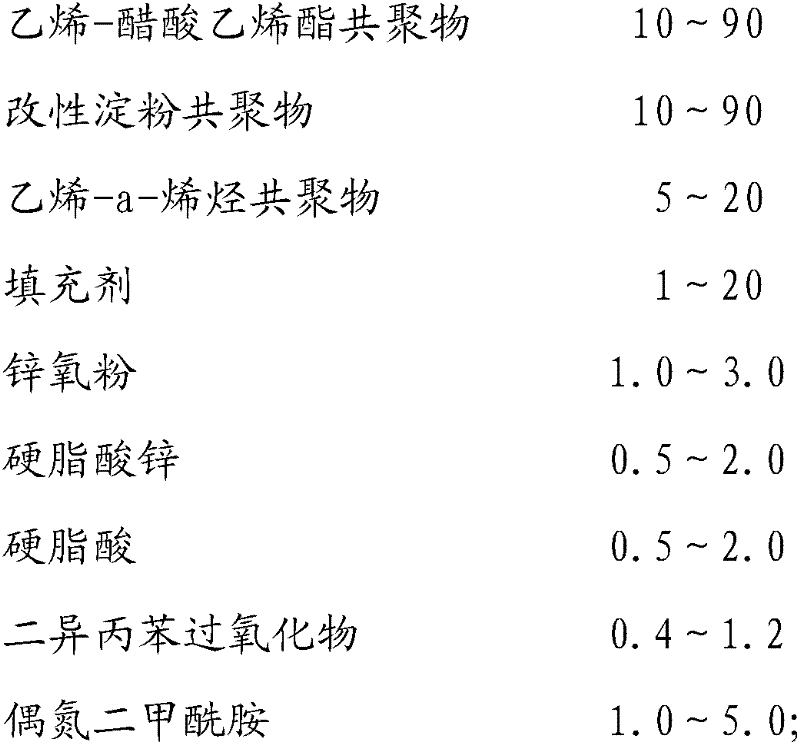

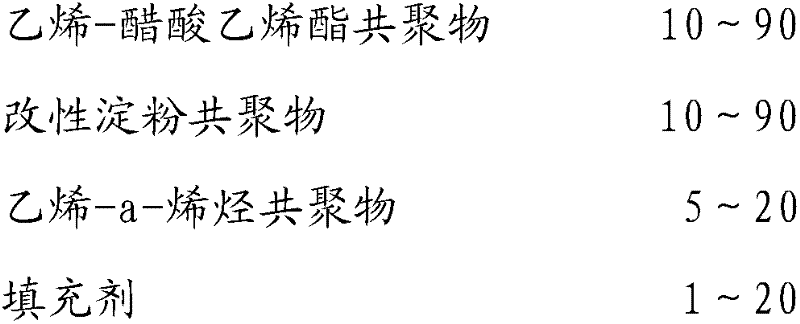

The invention discloses an EVA material for a sneaker sole, which is made by adopting the following components according to part by weight: 10 to 90 portions of ethylene-vinylacetate copolymer, 10 to 90 portions of modified starch copolymer, 5 to 20 portions of ethylene-alpha-olefin copolymer, 0 to 20 portions of filler, 1.0 to 3.0 portions of zinc oxide, 0.5 to 2.0 portions of zinc stearate, 0.5 to 2.0 portions of stearic acid, 0.4 to 1.2 portions of dicumyl peroxide, and 1.0 to 5.0 portions of azobisformamide. The invention adopts EVA expanded material blended and modified by starch / ethylene-vinylacetate copolymer / ethylene-alpha-olefin copolymer, and starch is applied to chemical plastic, thus reducing the usage of chemical raw materials; simultaneously, the starch derivative has the characteristic of natural degradation, and is finally decomposed into carbon dioxide and water, thus causing no pollution to the environment, improving the easy degradation performance of the EVA expanded material, and advocating the industry times of 'low-carbon emission reduction, green environmental protection' of sneakers.

Owner:ANTA CHINA

Semi-worsted emerald pearl fiber blended healthcare yarn and production method and application thereof

InactiveCN103603109ASuitable for processingGood moisture absorption and heat dissipationMonocomponent cellulose artificial filamentYarnYarnMedicine

The invention discloses semi-worsted emerald pearl fiber blended health care yarn and a production method and application thereof. The weight percent of an emerald pearl fiber in the blended yarn is 20-40%, the weight percent of a flax fiber in the blended yarn is 15-30%, the weight percent of a wool fiber in the blended yarn is 30-50%, and the weight percent of a cashmere fiber in the blended yarn is 10-35%. According to performance indexes of the blended yarn, the single yarn breaking strength is 11.4-20.3cN / tex, the single yarn breaking strength variation coefficient Cv value is 10.3-17.9%, and the yarn evenness variation coefficient Cv value is 13.6-20.8%. Not only do the semi-worsted blended health care yarn made of the emerald pearl fiber, the flax fiber, the wool fiber and the cashmere fiber and a manufactured fabric have healthcare functions of antibacterium, deodorization, inflammation diminishing, odor removal, skin care, fitness, beauty and skin moistening and the like, but also the fabric is good in skin friendliness, comfort, moisture absorption, air permeability and dyeing property, soft in touch, attractive and elegant in product appearance, bright in color, full of gloss, good in ultraviolet resistance, unique in appearance and wide in product purpose, and high-quality healthcare fabrics can be produced in the fields of knitting or weaving.

Owner:ZHONGYUAN ENGINEERING COLLEGE

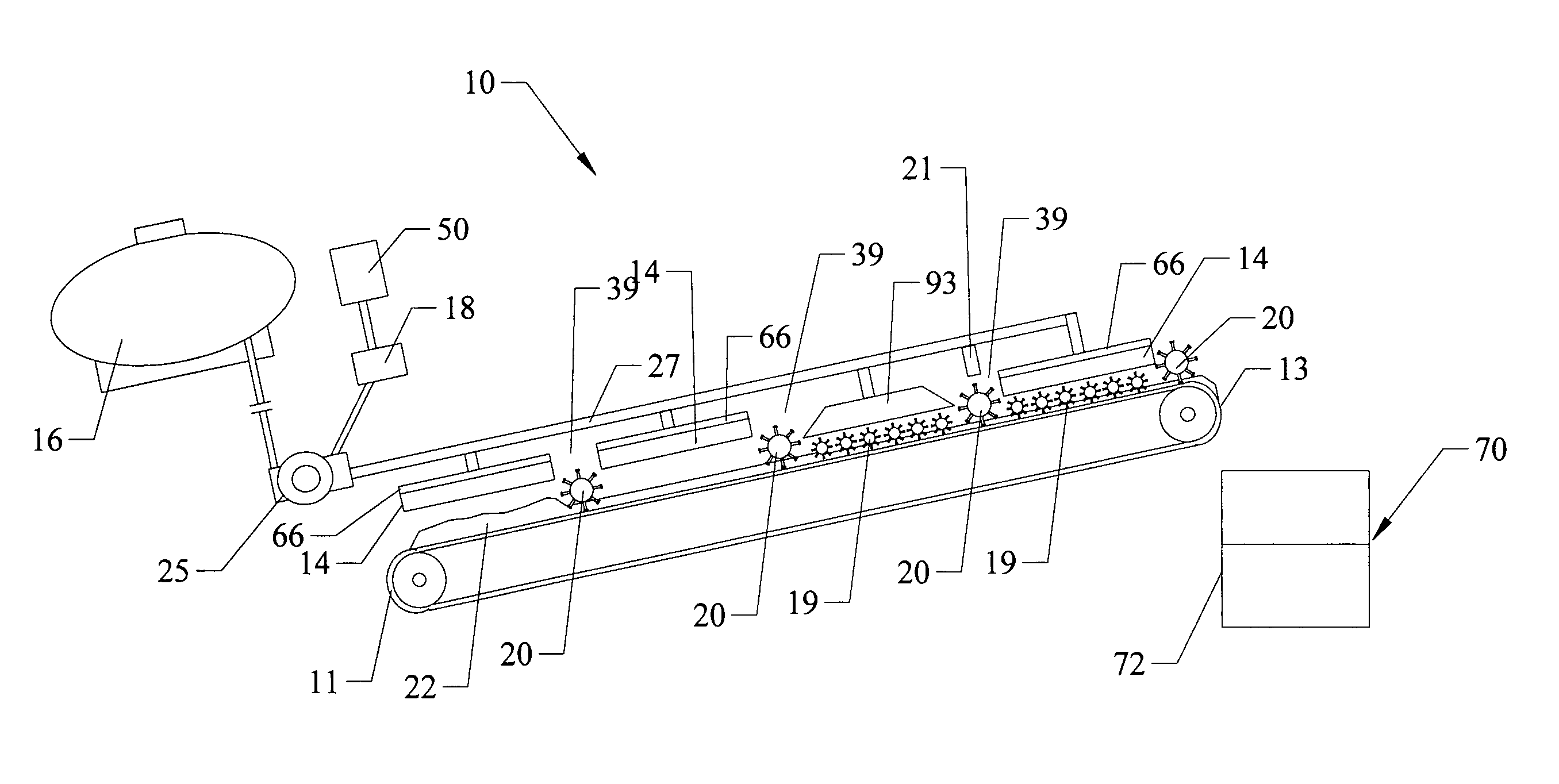

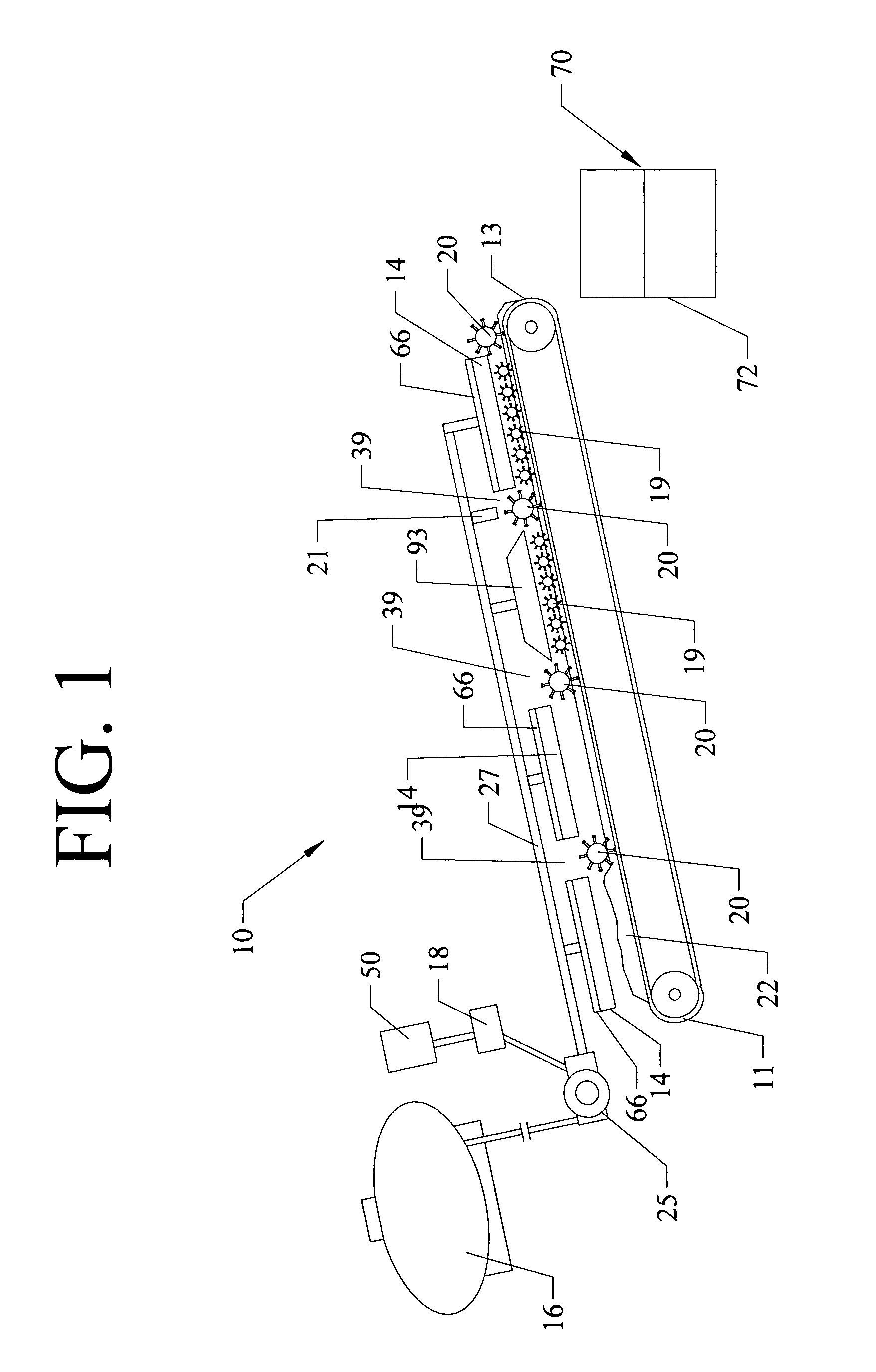

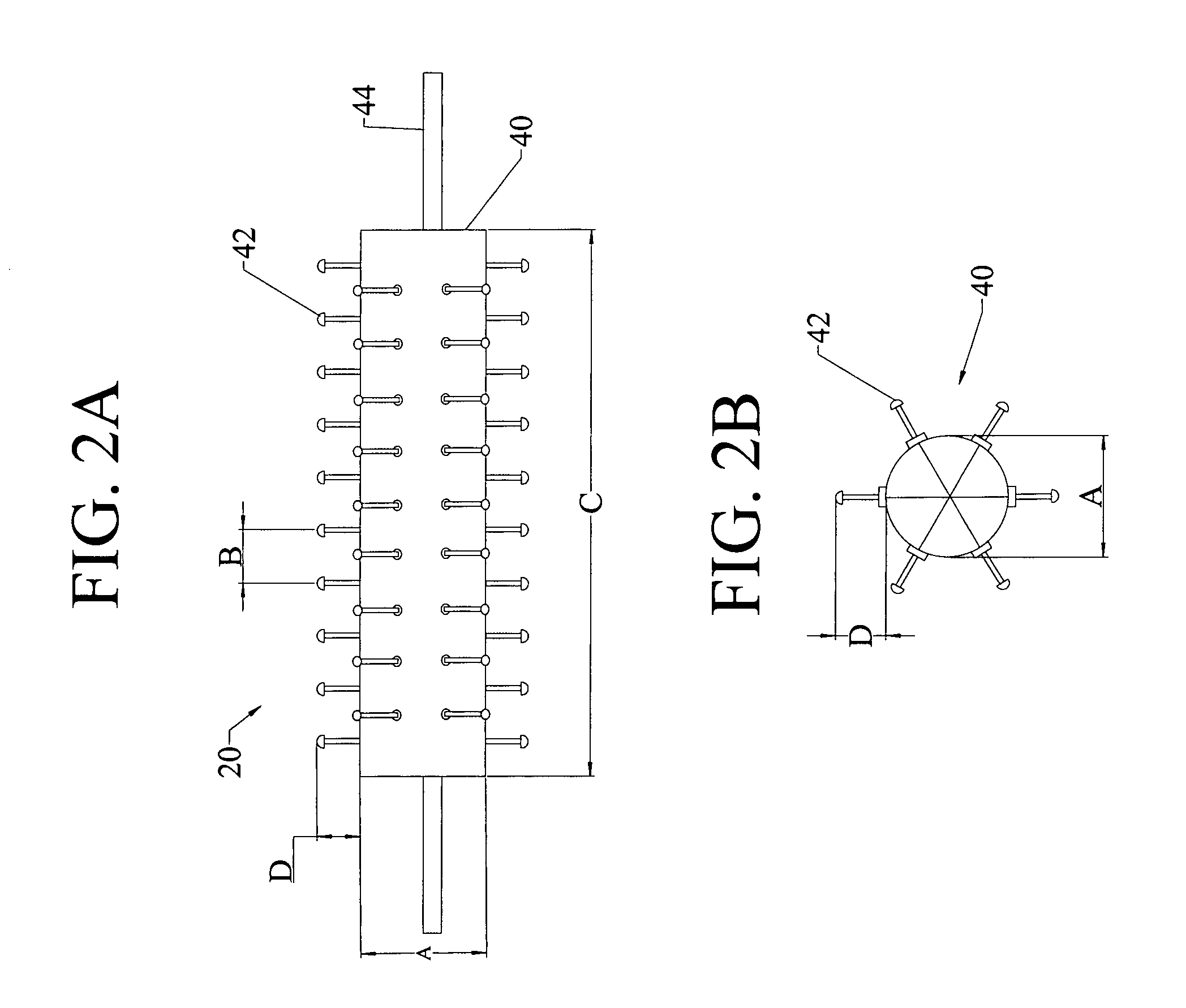

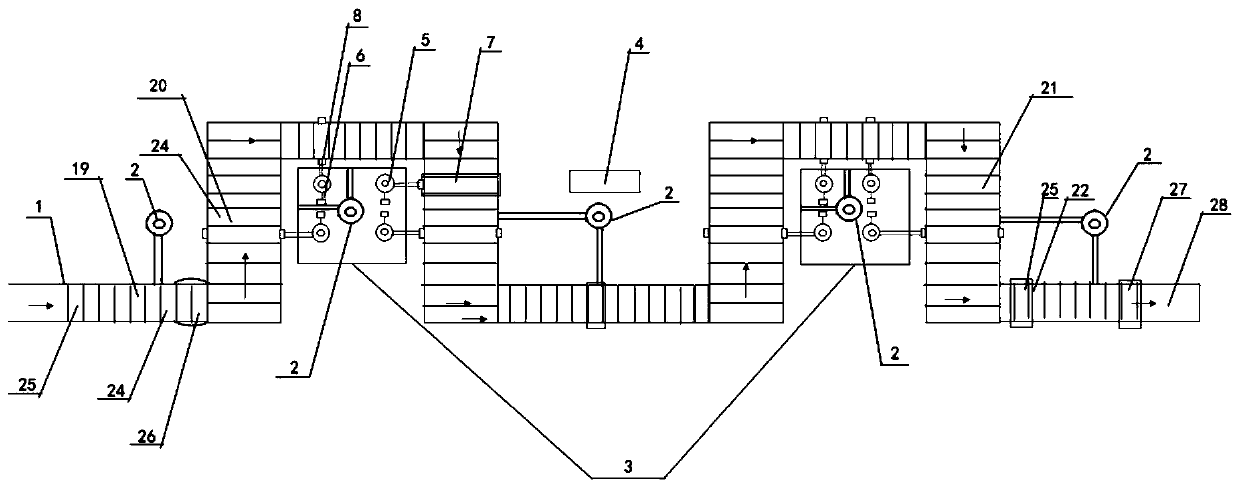

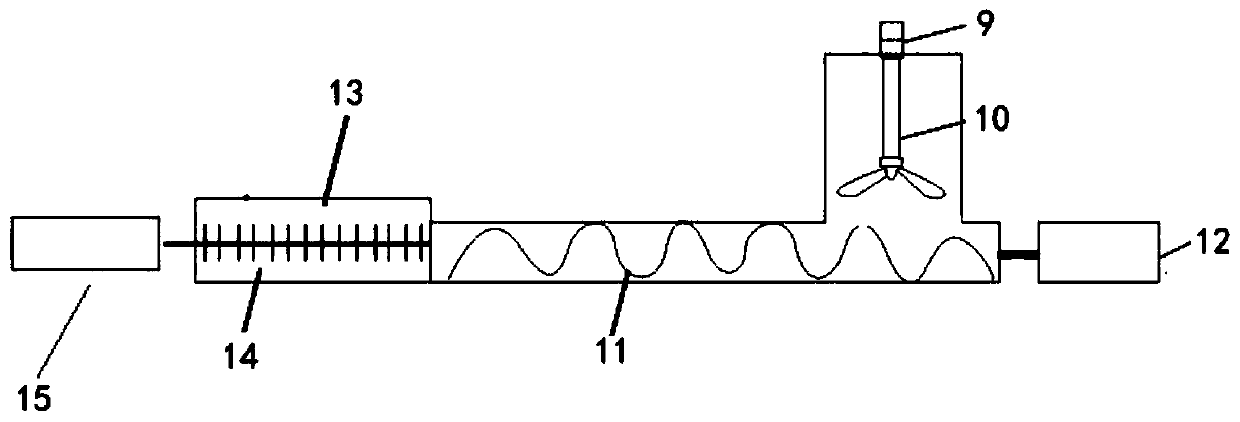

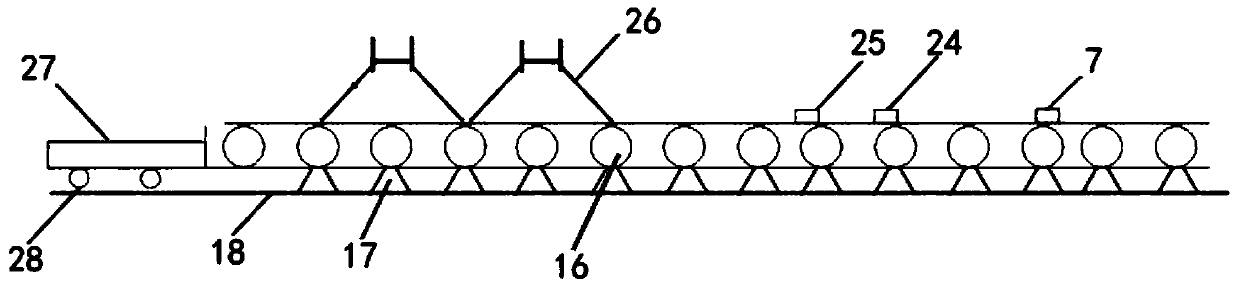

System for producing asphalt from reclaimed asphalt pavement

InactiveUS20110110177A1Easy to useGood moisture releaseDrying solid materials with heatTransportation and packagingRoad surfaceEngineering

A system for producing asphalt from RAP including a conveyor belt, a source of fuel, at least one infrared chamber, at least one rotary mixer, and an asphalt producing module, preferably a drum heater. The system includes measures for carefully controlling the heat of the reclaimed asphalt pavement as it is dried, including controls for adjusting the distance between the infrared chambers and the conveyor belt, controls for turning each individual infrared chamber on and off, and controls for adjusting the rate of the conveyor belt and the rotary mixers.

Owner:VELSOR WESLEY VAN

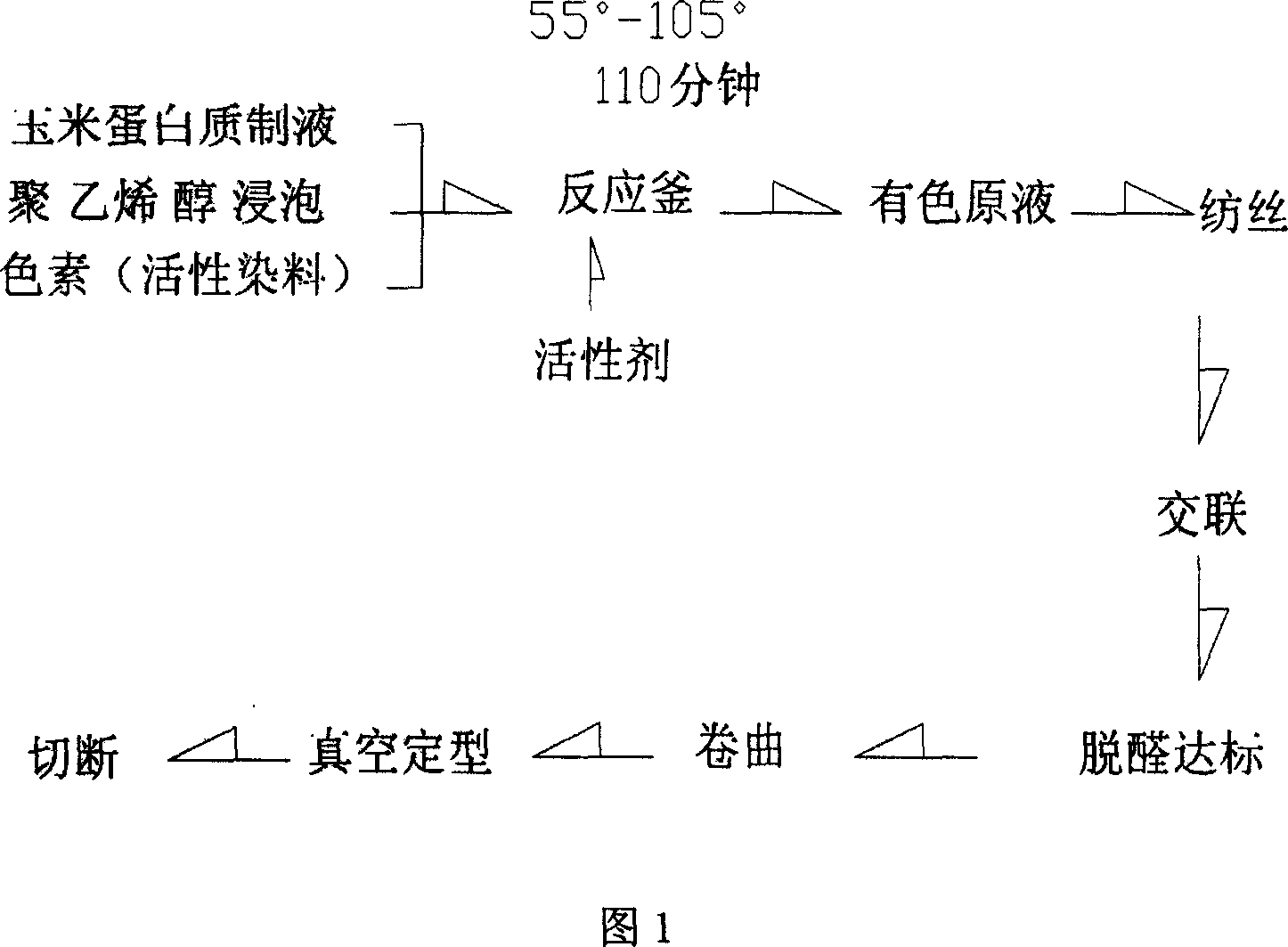

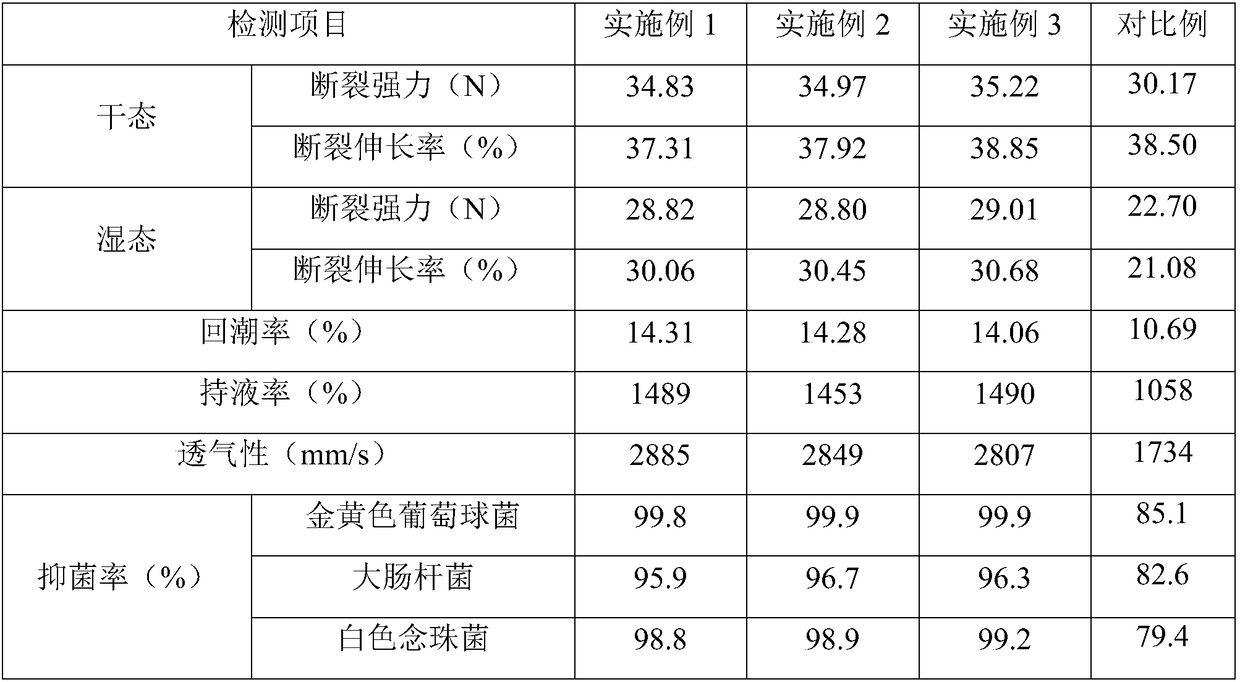

Maize protein colored textile fiber and method for producing same

InactiveCN1952225AHigh color fastnessNo pollution in the processMonocomponent protein artificial filamentDye addition to spinning solutionTextile fiberPhysical chemistry

The invention provides a colored fiber of corn protein and manufacture method. There is activated dye in corn protein. The manufacture method is that activated dye is added in the process for confecting spinning solution and plant protein colored fiber with the density of 0.7-3.0dtex is slubbed by wet spinning technology after ripening and polymerizing in reaction vessel. Because of activated dye added in confecting process, strike and fixation rates are improved. In detection method the cooler fiber has good fastness with five degree and enough light. There are no pollution and public disaster in the activated dye. The fiber is provided with good moisture conduction, light gravity, dry heat resistance and so on. It is knitted and tatted to various ultrathin or thickening apparel fabrics with high grade.

Owner:韩晓根 +1

Bamboo fiber and mulberry silk blended yarn towel and production process thereof

InactiveCN102493100AHigh strengthImprove breathabilityFibre treatmentBleaching apparatusFiberPolymer science

Provided are a bamboo fiber and mulberry silk blended yarn towel and a production process thereof. The bamboo fiber and mulberry silk blended yarn towel comprises a base cloth layer and wool warps, wherein the base cloth layer is formed by body warps and weft yarns, and the wool warps penetrate through interweaving holes formed by the body warps and the weft yarns to form terry layers on one surface or two surfaces of the base cloth layer. The wool warps are blended yarns formed by bamboo fibers and the mulberry silk, and the body warps and the weft yarns of the base cloth layer are pure cotton yarns or pure mulberry silk yarns or blended yarns formed by cotton and the mulberry silk. The production process comprises the steps of yarn warping, warp sizing, machine weaving, dyeing treatment, cutting, sewing and finishing and the like. The towel not only integrates soft and smooth features, good air permeability, moisture absorption and moisture releasability of the bamboo fibers and the mulberry silk and outstanding antibacterial and health-care effects, but also has the advantages of being high in abrasion resistance and strength, long in service life, low in price and the like. The novel product with high quality and price benefits and the appropriate production process of the novel product are provided for towel textile fabrics.

Owner:HUZHOU SICHOUFU TEXTILE

Bamboo charcoal viscose facial mask base cloth and high moisture retention and moisturizing facial mask

ActiveCN108403446AMeet physiological requirementsEliminates allergy riskCosmetic preparationsToilet preparationsCardingSlurry

The invention relates to a bamboo charcoal viscose facial mask base cloth and a high moisture retention and moisturizing facial mask. The bamboo charcoal viscose facial mask base cloth is prepared with the following method: 1) adding nanometer bamboo charcoal powder and sodium alga acid into dispersion solution to be dispersed evenly in bamboo charcoal serous fluid; 2) adding the bamboo charcoal serous fluid into viscose spinning solution to be dispersed evenly, and filtering and deforming to obtain mixed spinning solution; 3) carrying out wet method spinning on the mixed spinning solution toobtain the bamboo charcoal viscose, and carrying out opening, mixing, carding and lapping to obtain a bamboo charcoal viscose felt; 4) dissolving chitosan in acetic acid aqueous solution, adding gelatin to be dissolved to obtain finishing liquor, and dipping the bamboo charcoal viscose felt into the finishing liquor to carry out impregnation modification to obtain a compound fiber felt; 5) carrying out spunlace reinforcement on the compound fiber felt. The bamboo charcoal viscose facial mask base cloth has high constraint ability on serum and good water retention and moisture liberation performance; after the facial mask serum is loaded through a liquid hanging step, the high moisture retention and moisturizing facial mask is obtained, situation that serum loss due to dripping and droppingcan be avoided, and waste is avoided.

Owner:魏科峰

Humidifying, bacteria-inhibiting and fresh-keeping packaging material for fruits, vegetables and other foods, manufacturing method and application thereof

InactiveCN102582963AGood moisture releaseHas a fresh-keeping effectLiving organism packagingBio-packagingPack materialRefrigerated temperature

The invention discloses a humidifying, bacteria-inhibiting and fresh-keeping packaging material for fruits, vegetables and other foods, a manufacturing method and application of the packaging material, and relates to a fresh-keeping packaging material for the fruits, the vegetables and other foods, a manufacturing process and application of the packaging material. The humidifying, bacteria-inhibiting and fresh-keeping packaging material for the fruits, the vegetables and other foods is formed by processing basic humidifying and bacteria-inhibiting raw materials A and B, wherein A is fibrilia, B is viscose fiber, cotton fiber or bamboo carbon fiber, the weight ratio of A and B is 10-90:90-10. The manufacturing method includes the following steps of blending or stranding the fibrilia together with the viscose fiber, the cotton fiber or the bamboo carbon fiber that is processed by a nanometer technology into a yarn or a line, determining the scope of yarn counts to be 5-60Ne (English count) and the fabric tightness to be 40-90%, interweaving the yarns or the lines to be a piece of fresh-keeping cloth, and finally, processing the cloth to be various fresh-keeping packaging materials as required for realizing fresh keeping of the fruits, the vegetables and other foods in a refrigerator fresh-keeping chamber and in the fruits and vegetables storage and transportation processes.

Owner:李清华

Bamboo fiber and corn fiber blending shirt and manufacturing method thereof

The invention relates to a bamboo fiber and corn fiber blending shirt and a manufacturing method thereof, belonging to the technical field of weaving. The bamboo fiber and corn fiber blending shirt is formed by blending 65-80 percent of bamboo fiber and 20-35 percent of corn fiber into yarns and then carrying out printing and dyeing, weaving, posterior-treatment and cutting processes; the color fastness of the bamboo fiber and corn fiber blending shirt can reach 3-4 grade, and the formaldehyde content is less than or equal to 75.0mg / kg. The shirt has the characteristics of low corn fiber content, strong intensity, good draping property, good crease resistance and high color fastness.

Owner:ANJI TANZHUZHUANG BAMBOO FIBER

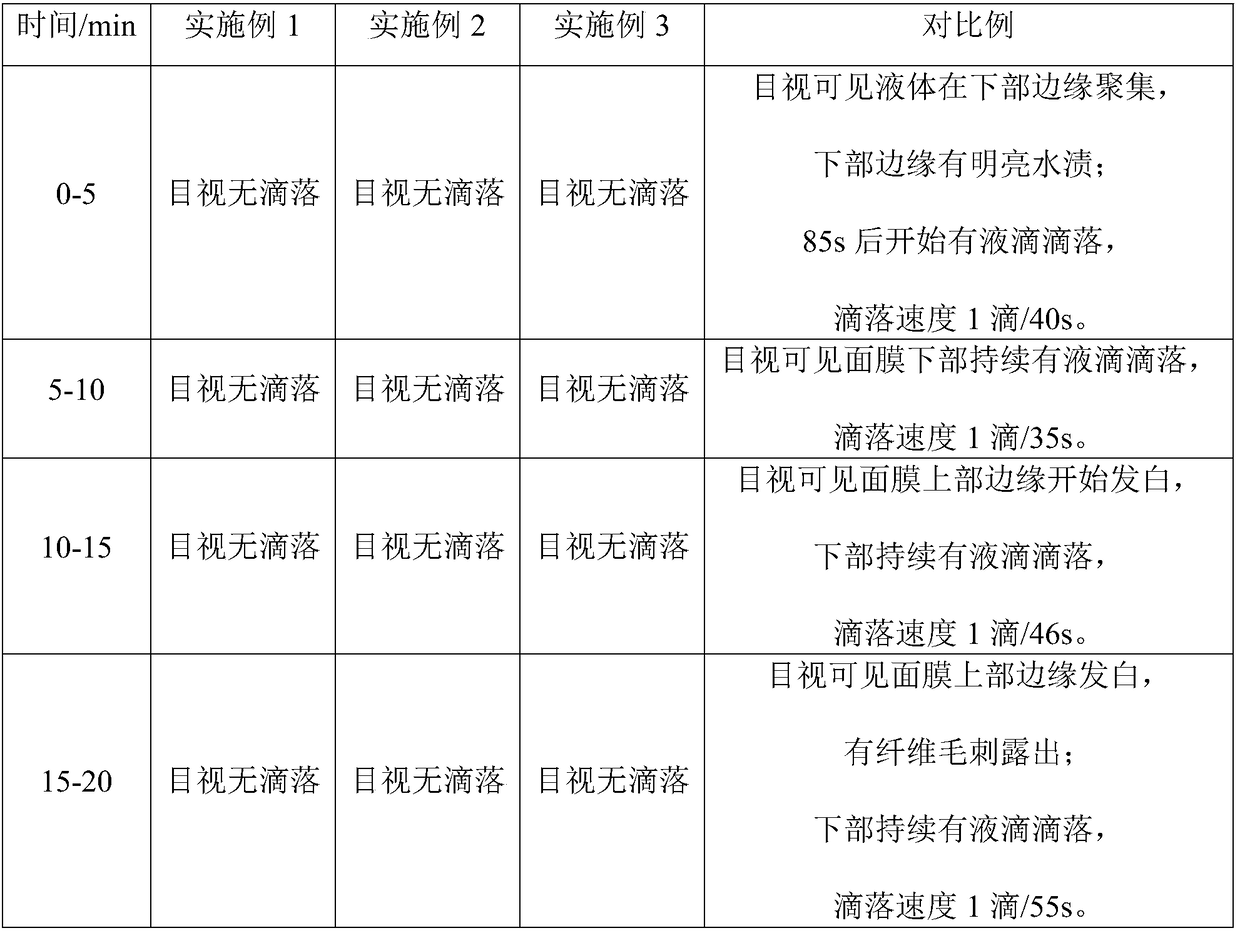

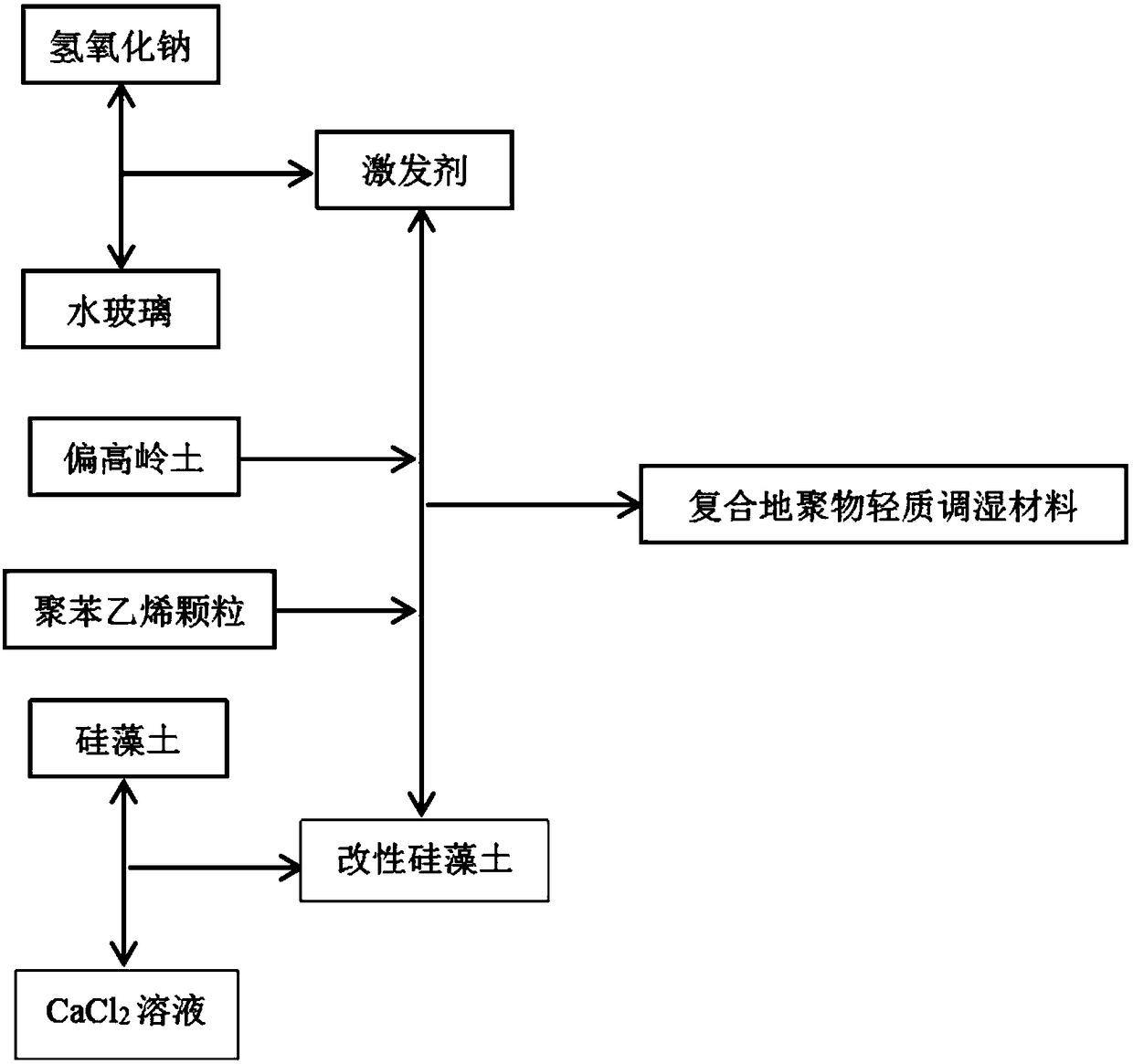

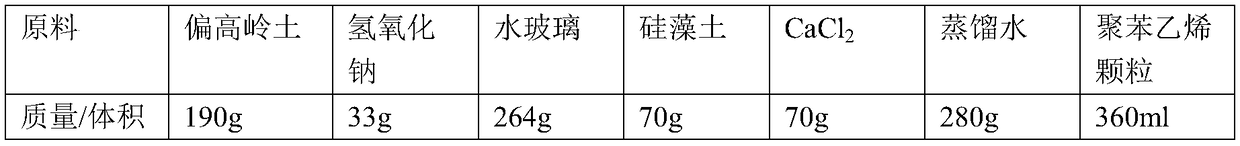

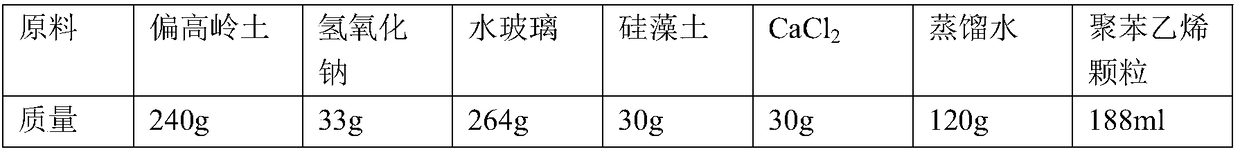

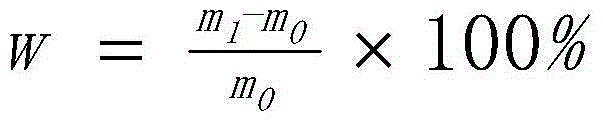

Composite geopolymer lightweight moisture-regulating material and preparation method thereof

ActiveCN109250964AHigh strengthFast moisture absorption and desorption reactionCement productionPolymer scienceDesorption

The invention relates to a composite geopolymer lightweight moisture-regulating material and a preparation method thereof, and belongs to the technical field of composite materials. The moisture-regulating material is prepared from the following components: 100 parts by mass of a cementitious material, 105-115 parts by mass of an activator, and a light aggregate having the amount accounting for 2-5 times the volume of metakaolin, wherein the cementitious material is composed of 70-90 parts by mass of metakaolin and 10-30 parts by mass of modified diatomite, and the light aggregate is polystyrene particles. The preparation method comprises the steps: firstly, stirring solid powder evenly, adding the liquid activator, fully stirring in a concrete stirrer, then adding the polystyrene particles, stirring evenly, pouring into a mould smeared with demoulding oil in advance, placing the mould on a horizontal table top, allowing to stand, curing at room temperature for 1 d, then demoulding totake out a plate-shaped finished product. The prepared moisture-regulating material has the characteristics of high efficiency moisture absorption and desorption, light weight, heat preservation and high strength, no pollution in the preparation process, low energy consumption, no needing of pressure forming and simple process.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Soybean protein colored spinning fiber and its production method

InactiveCN1928169AHigh color fastnessNo pollution in the processMonocomponent globulin artificial filamentDye addition to spinning solutionFiberSoybean protein

The invention provides a soybean protein colored fiber and production method. There is activated dye in soybean protein colored fiber. The production method is described as: during the process of making up filature original fluid, activated dye is put in, then colored fiber of plant protein whose density is 0.7-3.0dtex is ripened, get together and slubbed through technology of wet method filature in reactor. Because activated dye is put in during making up fluid coloring and sessile rates are increased. Coloring firming degree of the colored fiber can reach five grades after measuring.

Owner:韩晓根 +1

Blending high-grade knitting fabric

The invention provides a blending high-grade knitting fabric, and belongs to the technical field of knitting. The blending high-grade knitting fabric is characterized in that according to the percentage by weight in the high-grade knitting fabric, 32% of tencel fibers, 32% of cotton fibers and 10% of copper ammonia fibers are blended and spun, and 10% of rayon is added to be twisted into first yarns and second yarns, each first yarn adopts the S twisting direction, each second yarn adopts the Z twisting direction, and the first yarns and the second yarns are interweaved into the fabric. The blending high-grade knitting fabric has the advantages that the elasticity is good, the strength is high, the hand feel is soft, the luster and brightness are realized, and the trend of environment-friendly clothes is met; the good moisture-absorbing, moisture-discharging, anti-electrostatic, hanging and hydrophily functions are realized.

Owner:ZHEJIANG YANA TEXTILE

Aloe/viscose/modal function sweater and manufacture method thereof

ActiveCN103156302AHigh strengthGood hygroscopicityWeft knittingProtective garmentManufacturing technologyGram

The invention relates to an aloe / viscose / modal function sweater and a manufacture method of the aloe / viscose / modal function sweater. The aloe / viscose / modal function sweater and a manufacture method of the aloe / viscose / modal function sweater are characterized by utilizing fabric weave which is plain weave. Yarn is formed by twisting two strings of 32S fiber siro spun yarn made of 40 percent of aloes, 40 percent of modal and 20 percent of viscose. The doubling twist degree is 320 twist / m, and gram weight is 285g / square meter. Manufacture technology includes that three kinds of fiber siro spun yarn undergo rewinding, panel knitting, looping, flat sewing, hand sewing, washing, drying, pressing, packaging and warehouse entering. In the process of spinning the three kinds of fiber siro spun yarn, main body rough yarn do not pass by a rear roller on a spinning machine, the rough yarn is assisted in feeding with interruption through the rear roller, and diameter runout of the roller is controlled to be small than 0.03mm. The aloe / viscose / modal function sweater is low in cost, less in hairiness, and good in bacteria resistance.

Owner:JIANGYIN XIANGFEI APPAREL

Bacteriostatic radiation protection material

ActiveCN102071510ASolve discomfortSolve the shortcomings of not easy to rinseShieldingWoven fabricsFiberMilk protein

The invention discloses a bacteriostatic radiation protection material, which is formed by warp protein silver fiber and weft protein silver fiber through warp and weft intersection spinning, wherein the protein silver fiber is formed by 40 to 56 percent of milk protein fiber and 44 to 60 percent of sliver fiber in percentage by volume through blended spinning. The bacteriostatic radiation protection material has the texture and the comfort degree similar to or exceeding the those of cashmere products, has the functions that: the human body is protected and nursed, and the bacteriostatic radiation protection material can be repeatedly washed, and the defect that the existing radiation protection clothes are uncomfortable to wear or can not be easily rinsed is overcome.

Owner:北京京港恒星科技发展有限公司

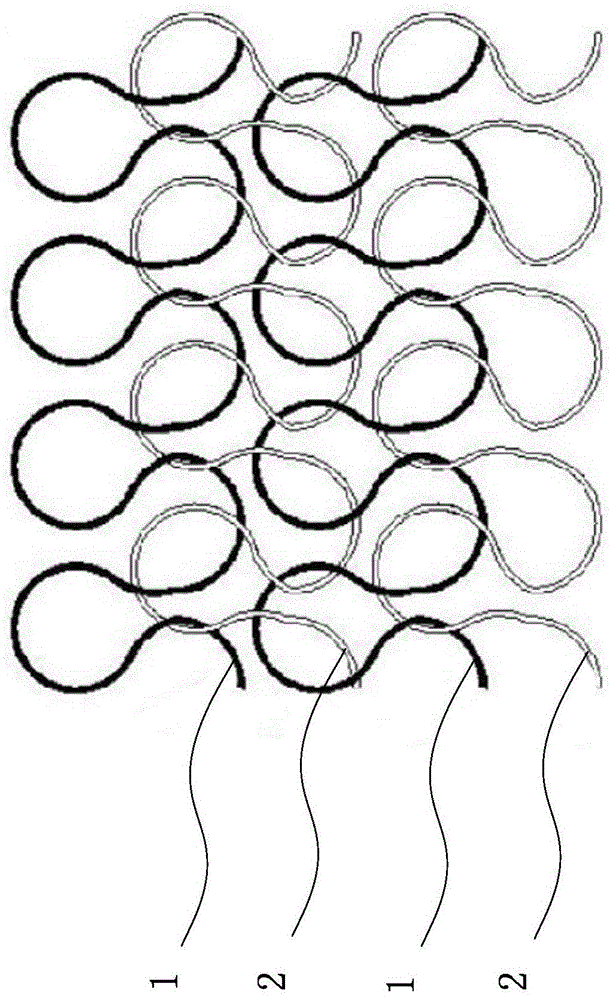

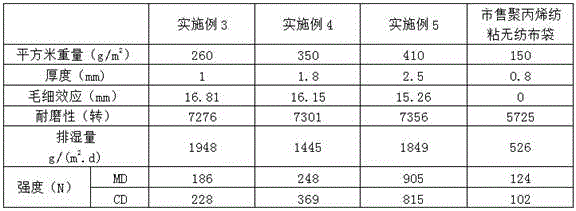

Grain storage bag and preparation method thereof

ActiveCN105755674AImprove preservation qualityNatural bacteriostasisBio-packagingDomestic containersGrain storageNonwoven fabric

The invention discloses a grain storage bag and a preparation method thereof and relates to the field of packaging. The grain storage bag is prepared from polylactic acid fibers and jute fibers. The preparation method of the grain storage bag comprises the following steps: preparing a lower layer polylactic acid filament fiber web by adopting a polylactic acid chip; unwinding jute fiber woven roving cloth and directly laying on the lower layer polylactic acid filament fiber web; preparing an upper layer polylactic acid filament fiber web by adopting the polylactic acid chip, and laying on the jute fiber woven roving cloth to form three layers of fiber webs; pre-reinforcing the three layers of fiber webs to obtain polylactic acid filament non-woven fabric; compounding the polylactic acid filament non-woven fabric through an ultrasonic method, cutting according to a certain specification and then sewing and thermally-sealing to obtain the grain storage bag. According to the grain storage bag disclosed by the invention, point-like compounding is performed by using the degradable polylactic acid fibers, the jute fibers with unique fiber cavity structures and the ultrasonic method, so that the grain storage bag has the advantages that the grain quality deterioration is delayed, the grain storage period is prolonged, and the damage due to collision in the grain transporting process is buffered.

Owner:CHANGSHU GOLD SPRING CHEM FIBERS & KNITTINGS

Polyester ramie fabric

InactiveCN102071524AHigh moisture release performanceGood moisture releaseWeft knittingPolyesterChemistry

The invention discloses a polyester ramie fabric, which comprises ramie yarns, wherein functional fibers compatible with the ramie yarns are polyester filament fibers; the ramie yarns have the specification of 12 counts / 2 to 48 counts / 2 and account for 55 to 85 weight percent; and the polyester filament fibers have the specification of 20 to 40D and account for 15 to 45 weight percent. The polyester ramie fabric is weaved by a flat knitting machine through an interleaving method for double-mouth double-yarn feeding; and the finished product has a double-layer structure, an inner layer is provided with the polyester fibers and an outer layer is provided with the ramie yarns. The polyester ramie fabric has the advantages that: because the polyester has higher moisture liberation, polyester with high strong force and low moisture absorption property is adopted in the inner layer of the fabric; while the outer layer adopts the ramie yarns with high moisture liberation, so that moisture difference is formed between the inner layer and the outer layer of the fabric, the fabric has good moisture absorption property, and the inner layer of the fabric is kept relatively dry. Meanwhile, the polyester yarns make the fabric stiff and smooth, and the wearability is obviously improved compared with that of a pure ramie fabric.

Owner:GUANGDONG QUNFA WEAVING & KNITTING

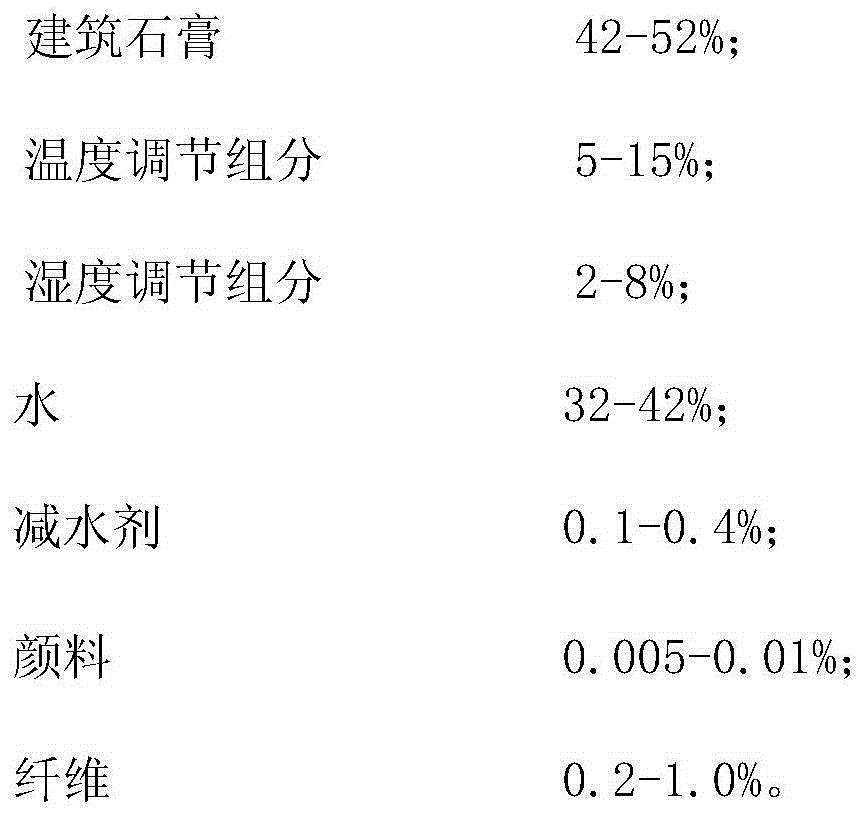

Wall material capable of adjusting indoor environmental temperature and humidity and preparation method of wall material

InactiveCN105218056ASimple preparation processImprove thermophysical propertiesFiberThermal insulation

The invention discloses a wall material capable of adjusting indoor environmental temperature and humidity and a preparation method of the wall material. The wall material is prepared from components in percentage by weight as follows: 42%-52% of building plaster, 5%-15% of temperature adjustment components, 2%-8% of humidity control components, 32%-42% of water, 0.1%-0.4% of water reducing agents, 0.005%-0.01% of pigments and 0.2%-1.0% of fiber. According to the wall material, the preparation process of a functional wall material is optimized, fluctuation of indoor environmental temperature and humidity is reduced, the durability, the anti-permeability, the anti-cracking performance and the fireproof performance of a wall body are improved, and energy consumption is reduced during construction; with the adoption of the temperature adjustment components and the humidity control components, the wall material has the function of indoor environmental temperature and humidity adjustment, the homogeneity of the wall material is guaranteed, and a product has high strength and seldom contracts; the thermal physical performance of the wall material is excellent, the wall body does not require a thermal-insulation layer, and construction procedures are reduced.

Owner:ZHANGZHOU ZHENGBA BUILDING MATERIAL TECH

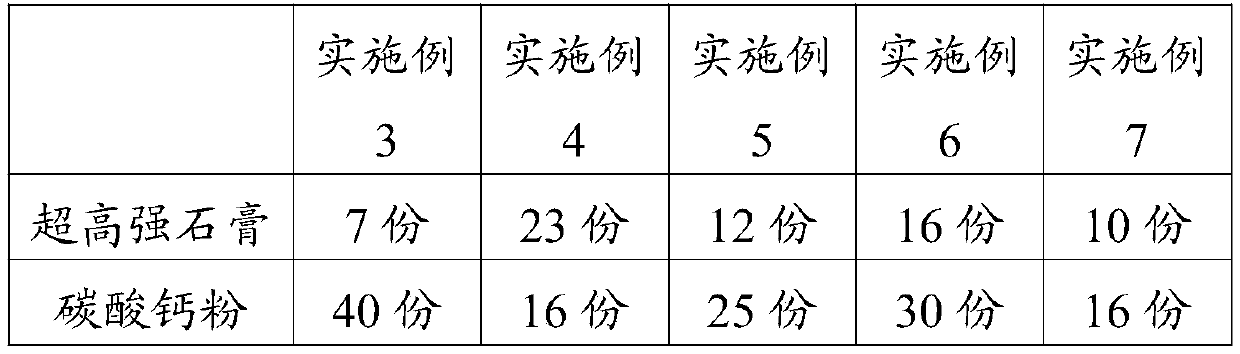

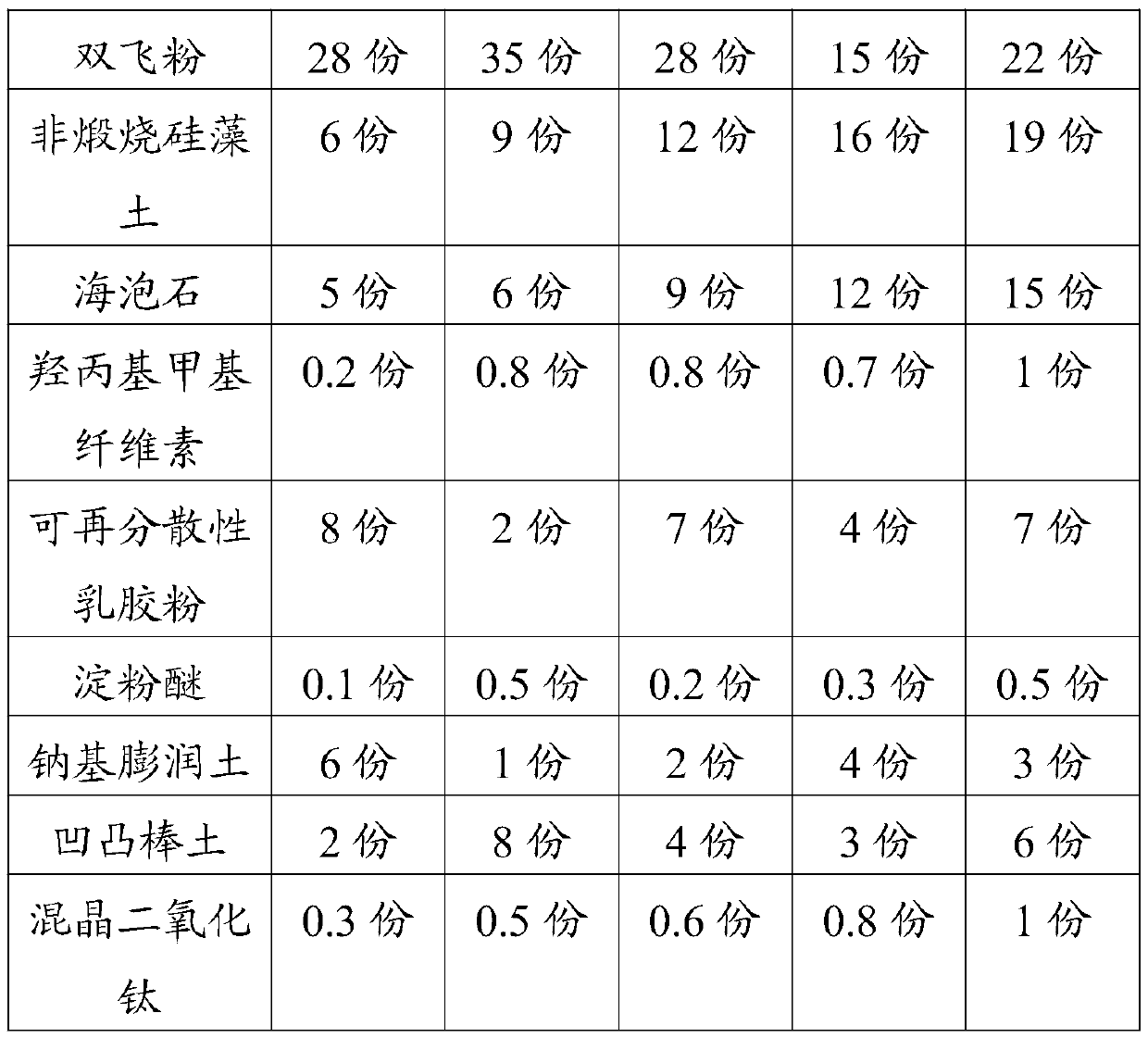

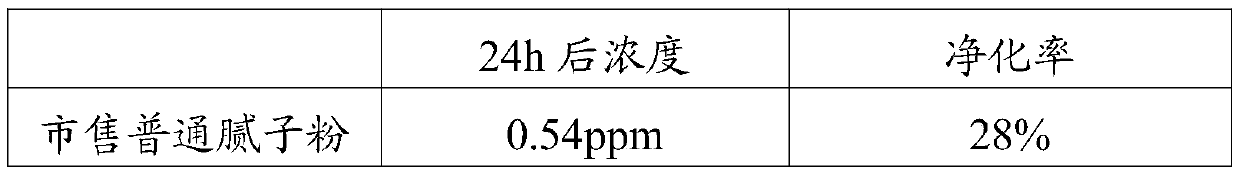

Neutral environment-friendly putty powder and preparation method thereof

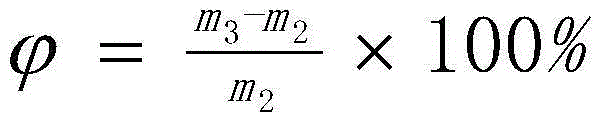

InactiveCN110204944AImprove adsorption capacityLarge aperture rangeFilling pastesSodium BentoniteLiving environment

The invention discloses a neutral environment-friendly putty powder which has the air purification property and is free of coating brushing and smooth in appearance. The putty powder is prepared from,by weight, 7-23 parts of ultra-high-strength gypsum, 16-40 parts of calcium carbonate powder, 15-35 parts of calcium carbonate, 6-19 parts of non-calcined kieselguhr, 0.2-1 part of hydroxypropyl methyl cellulose, 2-8 parts of redispersible latex powder, 0.1-0.5 part of starch ether, 1-6 parts of sodium bentonite, 5-15 parts of sepiolite, 2-8 parts of attapulgite and 0.1-1 part of mixed crystal titanium dioxide. Accordingly, the putty powder has the properties of good safety, environmental protection, water resistance, respiratory hygroscopicity, formaldehyde and harmful gas elimination and the like, and has good capacity of improving the quality of the living environment; meanwhile, the surface of the putty powder is smooth, firm and white, other coating or wallpaper can be omitted, and the effects of protecting the environment and reducing the cost can be achieved.

Owner:长沙标朗住工科技有限公司

Tencel fiber semi-worsted blended yarn

The invention belongs to the technical field of spinning tools, and particularly relates to a tencel fiber semi-worsted blended yarn which comprises, by weight percentage, 30-50% of tencel fibers, 30-40% of bamboo fibers, and 10-30% of cashmere wool. Due to the fact that in the semi-worsted technology, a wool spinning machine and a cotton spinning machine are organically combined, the technology has the advantages that the yield is high, process is short, manpower is saved, and cost is low. Yarns manufactured through the semi-worsted technology have softness of cotton, gloss of silk, and smoothness of linen, and are superior to cashmere wool in abrasion resistance, pilling resistance and strength.

Owner:ZHEJIANG BAIDE TEXTILE

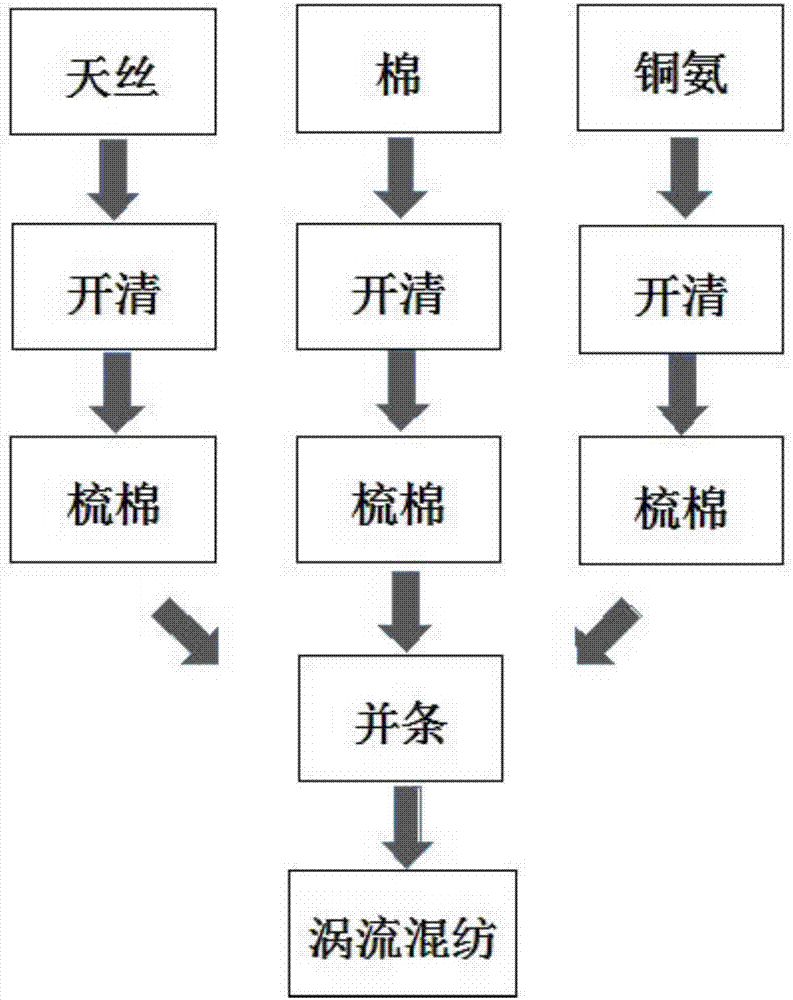

Vortex spinning technology with Tencel, cotton and cupro blended

The invention discloses a vortex spinning technology with Tencel, cotton and cupro blended. The blended yarn includes, by mass, 60% of Tencel, 25% of cotton and 15% of cupro; after opening and cleaning and carding are conducted on Tencel, cotton and cupro respectively, the yarn is spun through drawing and vortex spinning technologies. The composite fibers have the advantages of good elasticity, high wet-and-dry strength, soft hand feeling, elegant gloss, low cost and the like, and have the functions of good moisture absorption and releasability, antistatic property, good drapability and good hydrophilic property.

Owner:ZHEJIANG SHUANGDUN TEXTILE TECH CO LTD

EVA material for sneaker sole and preparation method thereof

The invention discloses an EVA material for a sneaker sole, which is made by adopting the following components according to part by weight: 10 to 90 portions of ethylene-vinylacetate copolymer, 10 to 90 portions of modified starch copolymer, 5 to 20 portions of ethylene-alpha-olefin copolymer, 0 to 20 portions of filler, 1.0 to 3.0 portions of zinc oxide, 0.5 to 2.0 portions of zinc stearate, 0.5to 2.0 portions of stearic acid, 0.4 to 1.2 portions of dicumyl peroxide, and 1.0 to 5.0 portions of azobisformamide. The invention adopts EVA expanded material blended and modified by starch / ethylene-vinylacetate copolymer / ethylene-alpha-olefin copolymer, and starch is applied to chemical plastic, thus reducing the usage of chemical raw materials; simultaneously, the starch derivative has the characteristic of natural degradation, and is finally decomposed into carbon dioxide and water, thus causing no pollution to the environment, improving the easy degradation performance of the EVA expanded material, and advocating the industry times of 'low-carbon emission reduction, green environmental protection' of sneakers.

Owner:ANTA CHINA

Manufacturing process of novel beautifying towel

InactiveCN105951432AGood moisture absorptionGood moisture releaseGrip property fibresVegetal fibresWater bathsAdditive ingredient

The invention relates to the field of textile dyeing and finishing, and provides a manufacturing process of a new type of beauty towel. The finishing process is to immerse the new type of beauty towel in a water bath with a bath ratio of 1:20 at 30°C for 10 minutes. Pre-bake at 90°C for 10 minutes, then bake at 150°C for 100 seconds after pre-bake, then soak in a softener at 45°C with a bath ratio of 1:30 for 10 minutes, and finally wash, dry and dry. Fluffy finish. The advantage of this invention is that the natural mulberry silk sericin with the same 18 amino acid components as the human body is fixed on the surface of the pure cotton towel, so that the terry has the same protein as the human body, and has a "blind date" with human skin Therefore, it can better exert its excellent moisture absorption, moisture release performance and anti-oxidation ability, so that this product has a real beauty effect and becomes a real beauty towel.

Owner:TIANJIN TEXTILE ENG RES INST

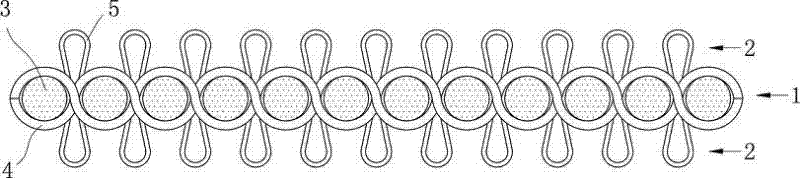

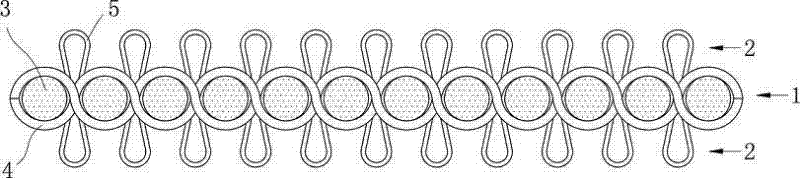

Air vortex spun viscose yarn

The invention discloses air vortex spun viscose yarn. The air vortex spun viscose yarn comprises a yarn body, wherein the yarn body comprises core yarn, winding yarn, a flax fiber layer and a bamboo viscose fiber layer; the core yarn is PTT yarn, and the PTT yarn is made of PTT fibers; the winding yarn is formed by twisting and stranding viscose strong yarns, and the winding yarn is spirally woundaround the outer portion of the core yarn; and the flax fiber layer is formed by spirally coating the winding yarn with flax fibers, and the bamboo viscose fiber layer is formed by spirally coating the flax fiber layer with bamboo viscose fibers. The air vortex spun viscose yarn is soft and comfortable to touch, high in yarn strength, good in elasticity, not prone to break, good in antibacterialperformance, good in moisture absorption and release performance and excellent in comprehensive performance.

Owner:SUZHOU CITY XINGJINGZE FIBER TECH CO LTD

Production technology for plant source colored anti-microbial fiber fabric

InactiveCN104790110AIncrease productivityReduce consumptionWeft knittingBiochemical fibre treatmentYarnFiber

The invention discloses a production technology for plant source colored anti-microbial fiber fabric. Crystal change modification process is conducted through a relaxation cheese, so that the texture is soft, and the evenness is improved; the production efficiency is high by adopting an air-jet loom to weave the plant source colored anti-microbial fiber gray fabric, so that the material consumption is reduced; the production technology for the plant source colored anti-microbial fiber fabric is a technological innovation in the field of textiles. By means of the production technology for the plant source colored anti-microbial fiber fabric, hot dyeing or cold dyeing is conducted on the woven plant source colored anti-microbial fiber gray fabric, scouring, bleaching and mercerizing in a traditional weaving method are omitted, the energy is saved, and the cost is reduced; and the pollution to the environment caused by pollution discharge is avoided; washing or aerowash in the traditional weaving method is replaced by rinsing, the technology is simplified, and the efficiency is improved. Due to the fact that the plant source colored anti-microbial fiber gray fabric is poor in tensile strength and hard, multiple technology processes must be conducted on the plant source colored anti-microbial fiber gray fabric, and therefore the yarn can become soft, and looping can be achieved; accordingly, the fabric is further promoted on the basis of the previous advantages, and the anti-static and anti-microbial functions are achieved.

Owner:NANTONG YOUKAI TEXTILE TECH

Multifunctional healthy shoes

A multifunctional health-care shoe with high elasticity, hydroscopicity and insulating performance, and sure antibacterial and health-care functions features that the fabric for its liner is made of the blended yarn of fibres and kendir fibres and the magnetic sheets are arranged at the positions in its sole, which are correspondent to the relative acupoints on the bottom of foot.

Owner:肖同岩

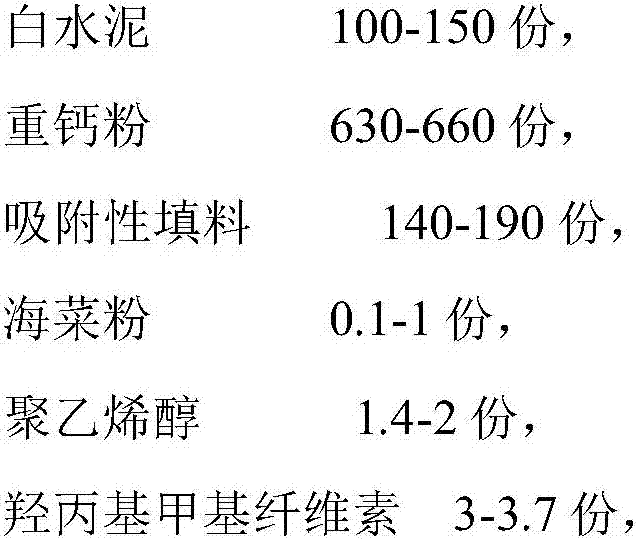

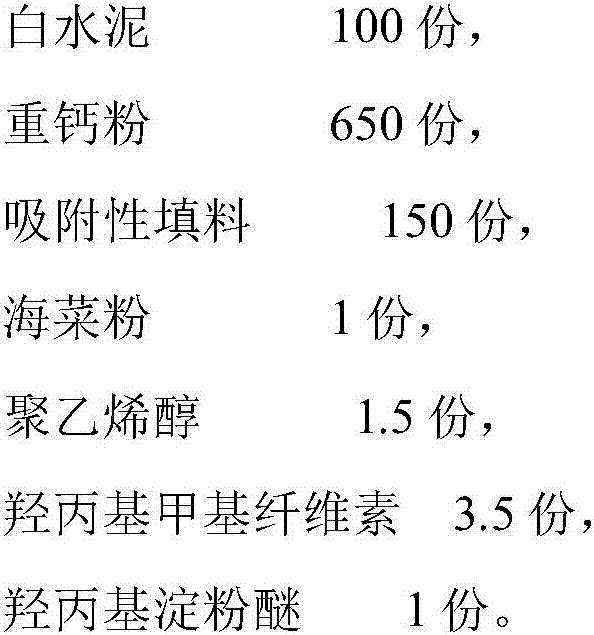

Neutral environment-friendly putty

InactiveCN107057438ADoes not produce strong alkaline substancesModerate pHFilling pastesPolyvinyl alcoholEther

The invention discloses a neutral environment-friendly putty which comprises the following components in parts by weight: 100-150 parts of white cement, 630-660 parts of heavy calcium carbonate powder, 140-190 parts of adsorptive filler, 0.1-1 part of edible seaweed powder, 1.4-2 parts of polyvinyl alcohol, 3-3.7 parts of hydroxypropyl methylcellulose and 0.9-1.2 parts of hydroxypropyl starch ether. The neutral environment-friendly putty has the advantages of high safety and favorable environment friendliness, and has favorable capacity for improving the environment quality.

Owner:BEIJING XIUJIE XINXING BUILDING MATERIAL CO LTD

Intelligent production compound formula and preparation method of novel multifunctional ecological health-maintenance diatom plate

The invention belongs to the field of building interior wall ornament and decoration materials, and particularly relates to an intelligent production compound formula and preparation method of a novelmultifunctional ecological health-maintenance diatom plate. The method comprises the steps that A, the diatom plate is formed by compounding a main material, an aggregate and an auxiliary material; B, the optimized compound formula of the main material, the aggregate and the auxiliary material is adopted; C, an intelligent automatic device is adopted for production, processing and profile preparation. According to the intelligent production compound formula and preparation method of the novel multifunctional ecological health-maintenance diatom plate, comprehensive innovation and transformation are conducted on the basis of multiple pilot scale tests, the defects of complication, high power consumption and high energy consumption are overcome, the principle of natural ecological health maintenance is utilized, the novel multifunctional high-efficiency ecological health-maintenance diatom plate is prepared physically, a new way is opened, production and manufacturing of the novel multifunctional ecological health-maintenance diatom plate are completed on a novel intelligent automatic production line starting from the modification of a raw material of diatomaceous earth and throughthe scientific mixing ratio formula, and the whole process of steps A, B and C is completed continuously.

Owner:辽宁美诚装饰建材有限公司

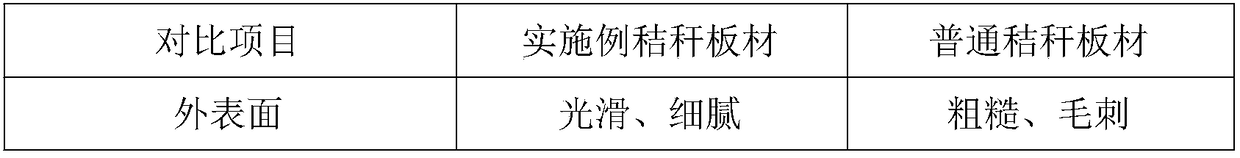

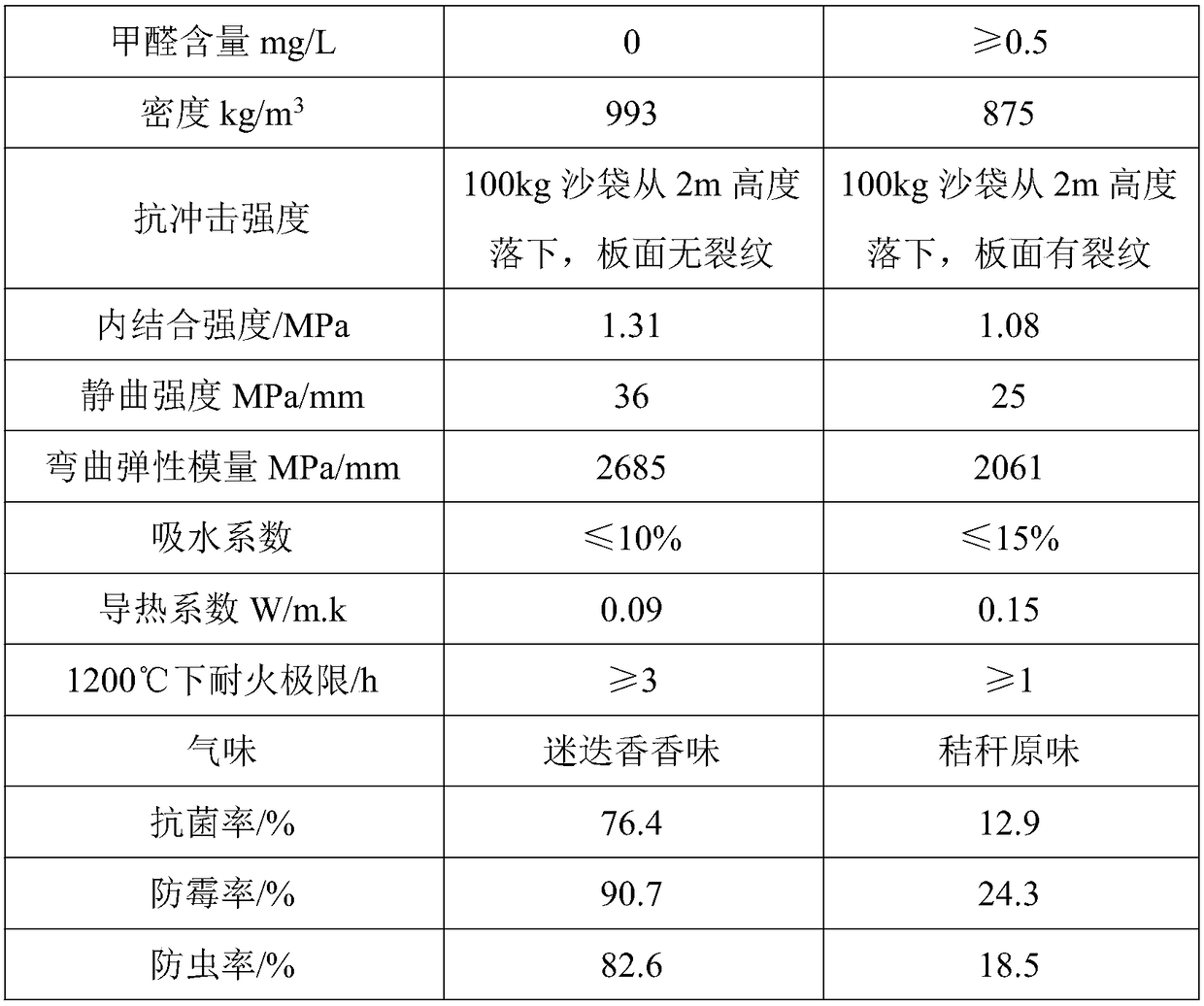

Mildewproof, mothproof and bacteriostatic straw plate and preparation method thereof

InactiveCN109291204AHigh densityHigh bonding strengthWood working apparatusDomestic articlesSurface layerUltimate tensile strength

The invention discloses a preparation method of a mildewproof, mothproof and bacteriostatic straw plate. The preparation method comprises the following steps: smashing crop straws into particles, soaking the particles in sodium hydroxide solution and sulfuric acid solution to obtain straw fibers, mixing the straw fibers with rosemary powder, bamboo charcoal fiber, expanded vermiculite and kieselguhr separately to obtain a surface layer mixture, mixing the straw fibers with coconut carbon fiber and green bean starch to obtain a core layer mixture, paving the surface layer mixture into a die according to the odd number layer principle, paving the core layer mixture into the die according to the even number principle, and carrying out drying, thermo-compression formation, cooling, demoulding,maintaining, edge cutting and packaging to obtain a finished product. The mildewproof, mothproof and bacteriostatic straw plate is non-toxic, tasteless, formaldehyde-free, and environmental-friendly,has higher strength, is high in fireproof performance and humidity resistance, is light in weight, facilitates transportation and construction installation and can enhance memory and refresh throughrosemary. Various performance of the mildewproof, mothproof and bacteriostatic straw plate meets corresponding requirements. Furniture made of the mildewproof, mothproof and bacteriostatic straw platecan effectively prevent mildew, acarid, resist bacteria and can automatically adjust the indoor humidity.

Owner:安徽科纳家居饰材有限公司

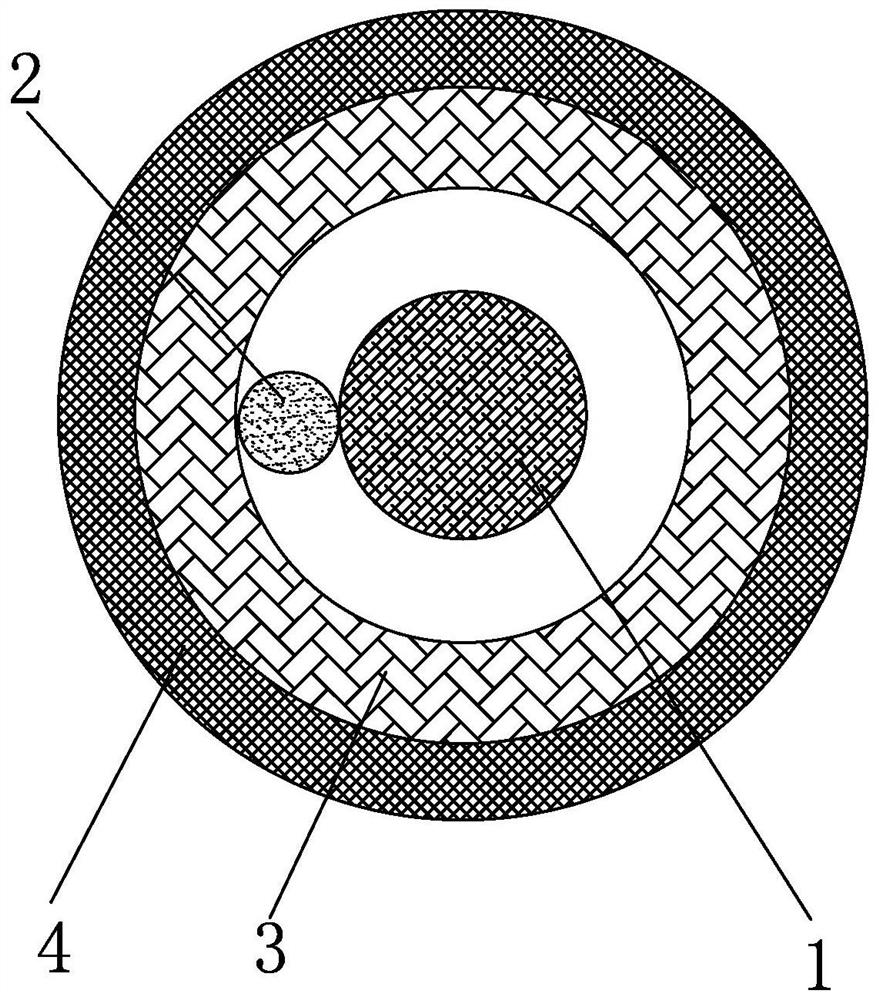

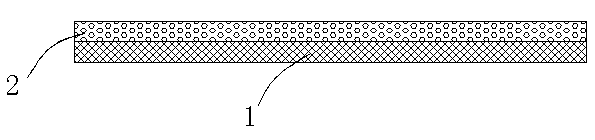

Multifunctional aloe fiber fabric

InactiveCN103526537AFlame retardant hasGood hygroscopicityWoven fabricsVegetal fibresMoisture absorptionHalogen free

The invention discloses a multifunctional aloe fiber fabric which comprises an aloe fiber layer (1), wherein the aloe fiber layer (1) is woven by aloe fiber serving as warp and weft according to a certain warp density and a certain weft density; the thickness of the aloe fiber layer is 0.18 mm; one surface of the aloe fiber layer (1) is coated with a flame retardant layer (2) which is 0.16 mm thick; and the ingredient of the flame retardant layer (2) is halogen-free flame retardant. With the adoption of the scheme, the flame retardant layer is formed by spraying the flame retardant onto a traditional aloe fabric, so that the multifunctional aloe fiber fabric has the advantage of flame retardancy while keeping good moisture absorption and moisture releasability of the aloe fabric.

Owner:WUJIANG LINGTONG TEXTILE FINISHING

Blended yarn of apocynum

A blended kender yarn contains the fibre (80%) chosen from cotton, wool, silk and chemical fibre and the kender fibres (20%). Its advantages are high elasticity and hydroscopicity, and good insulating and antibacterial effect.

Owner:薛冬梅

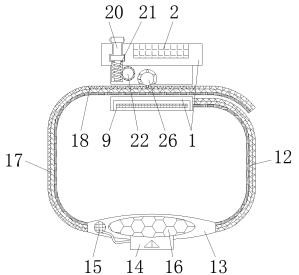

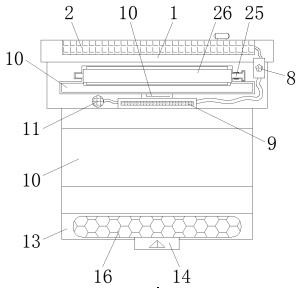

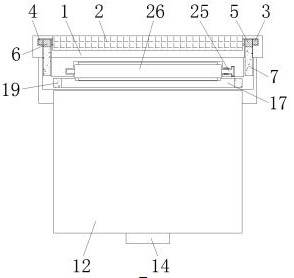

Wearable wrist electronic sphygmomanometer with alarm function for high-intensity training

ActiveCN112120682AWith alarm functionTo achieve the alarm effectEvaluation of blood vesselsSensorsHigh intensityPhysical therapy

The invention discloses a wearable wrist type electronic sphygmomanometer with an alarm function for high-intensity training. The wearable wrist type electronic sphygmomanometer comprises a fixing block, a display screen, a wrist strap I, a micro sucking pump and a wireless signal driver; the display screen is fixedly arranged on the top surface of the fixing block, and a first positive electrodeblock and a first negative electrode block are fixedly arranged on the two sides of the outer surface of the display screen correspondingly; the first positive electrode block and the first negative electrode block are both fixedly arranged in the fixing block; and a second positive electrode block and a second negative electrode block penetrate through the lower surface of the first positive electrode block and the lower surface of the first negative electrode block respectively. According to the wearable wrist type electronic sphygmomanometer with the alarm function for high-intensity training, the wrist strap I and a wrist strap II can be worn and rolled on the arm or the wrist, when a user performs high-intensity training, the blood pressure rises, when a pressure sensor senses that ameasured numerical value is too high, a signal is transmitted to a buzzer, and at the moment, the buzzer makes a sound to give an alarm, and the alarm effect is achieved.

Owner:GUANGDONG ZHANJIANG PROVINCIAL LAB OF SOUTHERN MARINE SCI & ENG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com