Bamboo fiber and mulberry silk blended yarn towel and production process thereof

A technology of bamboo fiber and blended yarn, which is applied in textiles, textiles, papermaking, fabrics, etc., can solve the problems of stickiness, stiffness, short service life, and hardening, and achieve moisture-releasing antibacterial, long service life, and good air permeability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

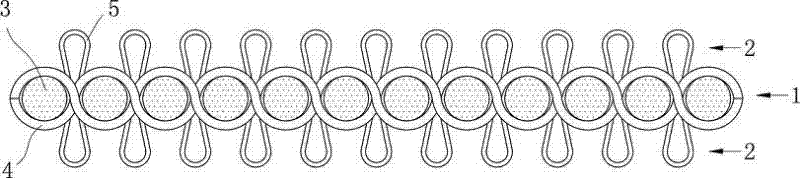

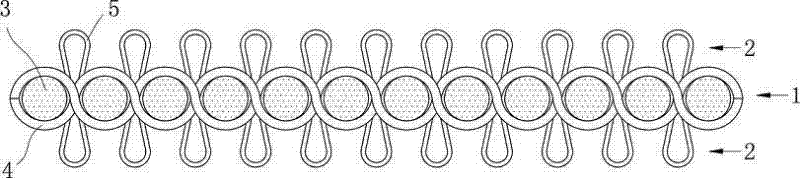

[0017] Embodiment 1, double-faced towel, the hair warp yarn 5 of its double-sided terry layer 2 adopts bamboo fiber and silkworm silk blended yarn, and its component counts by weight percentage: bamboo fiber 65, silkworm silk 35; And base cloth The ground warp yarn 3 and the weft yarn 4 of layer 1 then adopt the blended yarn of high strength cotton and silkworm silk.

[0018] Its production process includes the following steps: yarn warping, sizing, weaving on the machine, dyeing treatment and cutting, sewing and finishing.

[0019] Yarn warping: Warp the above-mentioned ground warp yarn 3 and the wool warp yarn 5 of the pile layer 2. The warping machine adopts the Barber-Coleman GP type warping machine, and the speed of the machine is controlled within 250m / min. Configure smaller tension, the tension ring quality is 12g, 11g, 10g respectively; the weft yarn is pre-shrunk by LMA442-180 pre-shrinking finishing machine.

Embodiment 2

[0025] Embodiment 2, is particularly suitable as the one-sided towel of pillow cover, and the wool warp yarn 5 of the terry layer 2 on one side adopts the blended yarn of bamboo fiber and silkworm silk, and its component is calculated by weight percentage: bamboo fiber 60, silkworm silk silk 40; and the ground warp yarn 3 and the weft yarn 4 of the base fabric layer 1 are pure cotton yarns. The above-mentioned ground warp yarn 3, weft yarn 4 and wool warp yarn 5 are machine-woven into a single-side towel with a single-side pile layer, and the production process is the same as that of Example 1. After testing, the single-sided towel feels soft and skin-friendly, the breaking strength is ≥180N, the water absorption is 0.48s, the color fastness to washing is 4-5, and the color fastness to rubbing is 4-5.

Embodiment 3

[0026] Embodiment 3 is particularly suitable for double-sided towels as towel quilts. The wool warp yarn 5 of the double-sided terry layer 2 adopts bamboo fiber and silkworm silk blended yarn, and its components are calculated by weight percentage: bamboo fiber 70, silkworm silk silk 30; and the ground warp yarn 3 and weft yarn 4 of the base fabric layer 1 adopt pure silkworm silk yarn. The above-mentioned ground warp yarn 3, weft yarn 4 and wool warp yarn 5 are machine-woven or a double-sided towel with a double-sided pile layer, and the production process is the same as that of Example 1. After testing, the double-sided towel feels soft and skin-friendly, the breaking strength is ≥180N, the water absorption is 0.57s, the color fastness to washing is 4-5, and the color fastness to rubbing is 4-5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com