Neutral environment-friendly putty powder and preparation method thereof

A kind of putty powder and environmental protection technology, which is applied in the field of building decoration materials, can solve the problems of the decorative surface returning to alkali and blooming, endangering personal safety, and stimulating construction workers, and achieves the effects of improving air quality, simplifying construction steps, and simplifying construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

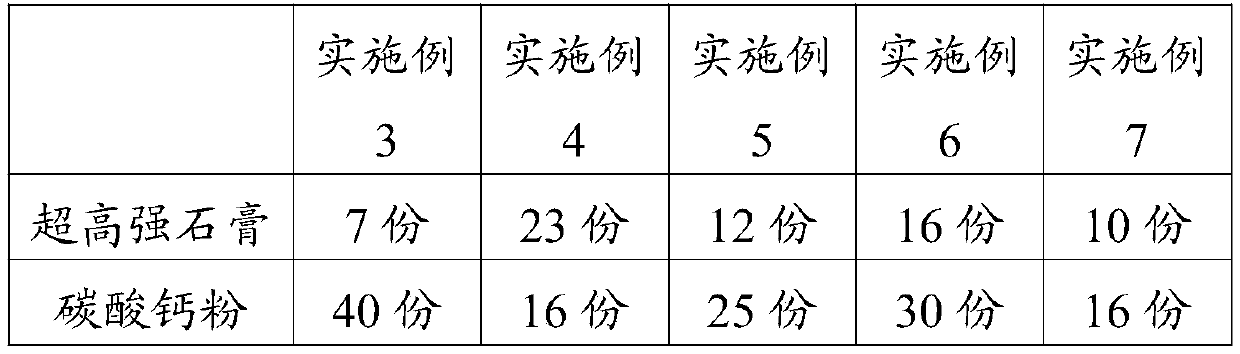

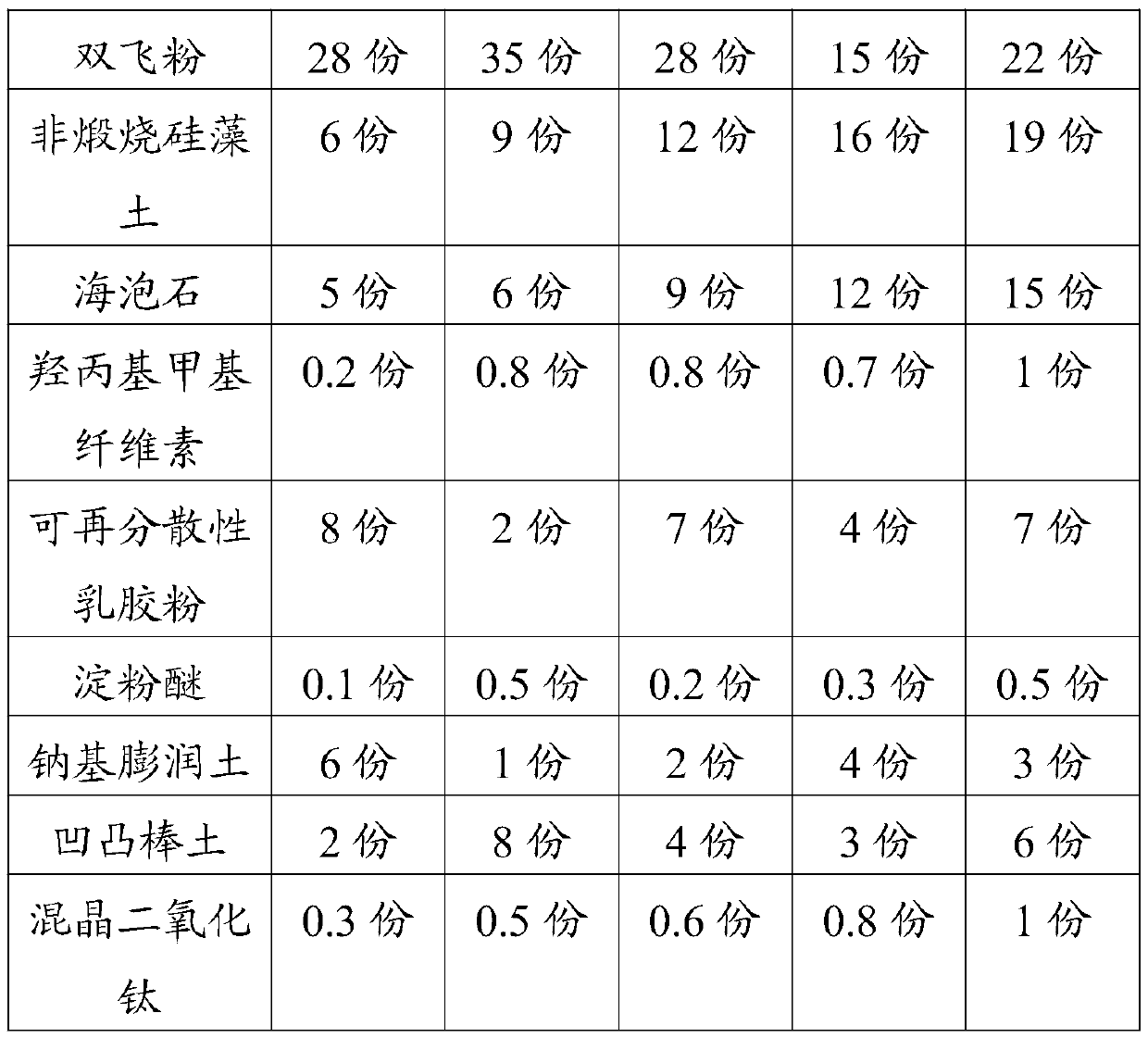

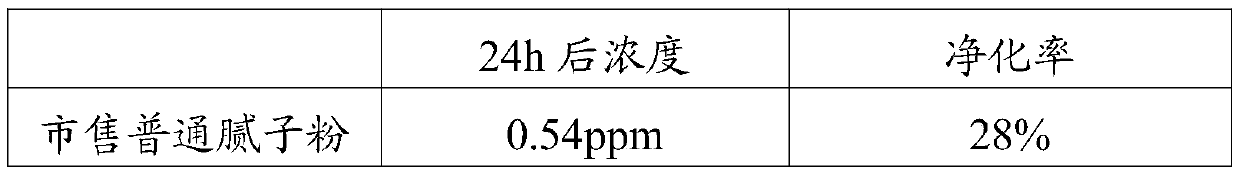

[0025] The invention provides a neutral environment-friendly putty powder, which is composed of the following raw materials in parts by weight: 7-23 parts of super high-strength gypsum, 16-40 parts of calcium carbonate powder, 15-35 parts of Shuangfei powder, and 6-19 parts of diatomite , 5-15 parts of sepiolite, 0.2-1 part of hydroxypropyl methylcellulose ether, 2-8 parts of redispersible latex powder, 0.1-0.5 parts of starch ether, 1-6 parts of bentonite, 2 parts of attapulgite ~8 parts, mixed crystal titanium dioxide 0.1~1 part.

[0026] Among them, ultra-high-strength gypsum is gypsum calcined and ground at above 600°C; calcium carbonate whiteness ≥ 95%, mesh number 700-800 mesh; Shuangfei powder whiteness ≥ 90%, mesh number 200-300 mesh; silicon Celite is non-calcined diatomite with a whiteness of ≥90% and a mesh size of 380-480 mesh; sepiolite with a whiteness of ≥87% and a mesh size of 200-300 mesh; hydroxypropyl methylcellulose is the viscosity Slow-dissolving hydroxy...

Embodiment 2

[0029] Preparation of mixed crystal titanium dioxide:

[0030]Stir a titanium salt among tetraethyl titanate, butyl titanate, propyl titanate, isopropyl titanate, and titanium oxysulfate with absolute ethanol in a solvent for 2h to 10h, wherein the titanium salt, anhydrous The weight ratio of ethanol to solvent is 1:(1.5~4):(0.1~0.3), the solvent is acetylacetone or glacial acetic acid, after fully stirring, add ethanol solution with a mass fraction of 20%, wherein titanium salt and ethanol solution The weight ratio is 1: (0.5 ~ 1.2), standing for 5h ~ 24h, forming nano-mixed crystal TiO 2 Then put the sol in a drying oven, dry it at 100-150°C, put it in a muffle furnace, bake it at 500-550°C for 30-60min, take it out after natural cooling, and grind it to get the mixed crystal TiO 2 powder.

[0031] The preparation process of Example 1 and the mixed crystal titanium dioxide prepared in Example 2 will be adopted below, and the specific raw material ratio will be used to pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com