Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Feel lubricated" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pearl fiber towel product and production method thereof

InactiveCN101403159AFeel lubricatedLubricate the skinBiochemical fibre treatmentBleaching apparatusPerspirationSizing

The invention relates to a pearl fiber towel product which adopts raw materials of pearl fiber yarn or fiber blended yarn of pearl fiber and cotton, hemp, Tencel, bamboo fiber, and Modal and the like to weave the terry shape and cut pile shape towel products. The manufacturing process flow of the pearl fiber towel product is: warping-sizing-weaving-desizing and degreasing-bleaching-staining-after finishing. The product is characterized in that the formula of the desizing and degreasing technology is: 5-15g / l of amylase, 15-30g / l of salt, and 2-10g / l of penetrant; and the formula of the bleaching technology is: 5-10g / l of rongalite, 2-10g / l of calcined soda, and 2-10g / l of refining agent. The pearl fiber towel product manufactured by adopting the method of the invention has soft hand-feeling, the function of moisture absorption and perspiration, without destroying nutrition ingredient in the pearl fiber, and the functions of skin nourishment and skin care.

Owner:王政军

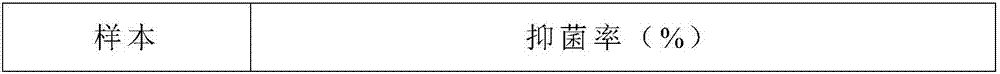

Plant type washing-free antibacterial spray and preparation method thereof

InactiveCN106943454AEffective antibacterialImprove stabilityAntibacterial agentsAerosol deliveryInjection siteUmbilical cord

The invention discloses a plant type washing-free antibacterial spray and a preparation method thereof. The spray is a water solution comprising the following raw materials in parts by weight: 10 to 20 parts of composite traditional Chinese herbal extract, and 0.05 to 0.2 part of benzalkonium chloride; wherein the composite traditional Chinese herbal extract is composed of the following raw materials in parts by weight: 2 to 4 parts of wild chrysanthemum, 2 to 4 parts of honeysuckle flower extract, 1 to 2 parts of dandelion extract, 0.09 to 0.2 part of radix scutellariae extract, and 0.06 to 0.2 part of licorice extract. The spray is prepared from plants and does not contain alcohol, the toxicity is reduced, and the effect is enhanced. The formula is mild and neutral, is suitable for the skin of children, and can prevent dry skin and chapped skin in winter. The spray has the advantages that water washing is not needed, the drying speed is quick, and the spray does not contain any toxin, is nonirritant, and can kill viruses and bacteria efficiently. The spray can be used to disinfect the skin of infants and children and umbilical cords of infants, is also suitable for the people, who is allergic to alcohol, and can be used to disinfect surgery / injection part, hands, surgical incision, wounds, perineum mucosa, and the like.

Owner:黑龙江童医生儿童生物制药有限公司

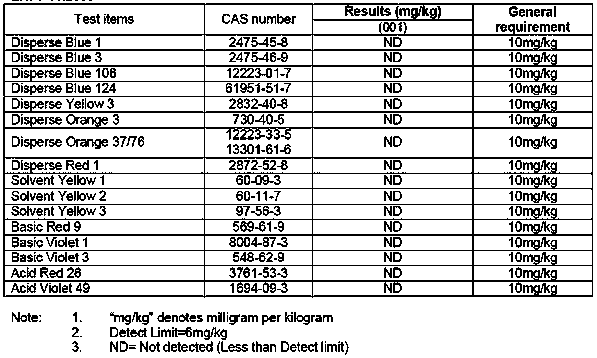

Dye for comprehensive color repairing process of double-faced leather and comprehensive color repairing process of double-faced leather

InactiveCN107916582AGood coloring effectFeel lubricatedDyeing processWastewaterBrightness perception

The invention provides a dye for a comprehensive color repairing process of double-faced leather. The dye comprises, by weight, 60-70 parts of penetrating agents, 5-25 parts of dye water, 1-2 parts ofcolor fixing agents and 10-20 parts of water. The invention further provides a comprehensive color repairing process of the double-faced leather. By the aid of the dye of a specific formula and the corresponding comprehensive color repairing process, according to dyed leather, particularly, the leather with large rough board discoloration, a dyed hair surface and an undyed leather board surface,the leather board surface is dyed, the color of the leather board surface is repaired and improved, coloring effects are greatly improved, a leather board is lubricating in hand feeling and high in oil feeling, color brightness and plumpness of fabric surface can be improved, and the fabric surface has comfortable silk feels. The comprehensive color repairing process is simple, easy to operate andless in sewage discharge, dyes are sufficiently absorbed, chemical materials are saved, and discharge of waste gas, wastewater and solid waste is reduced.

Owner:HENAN PROSPER SKINS & LEATHER ENTERPRISE

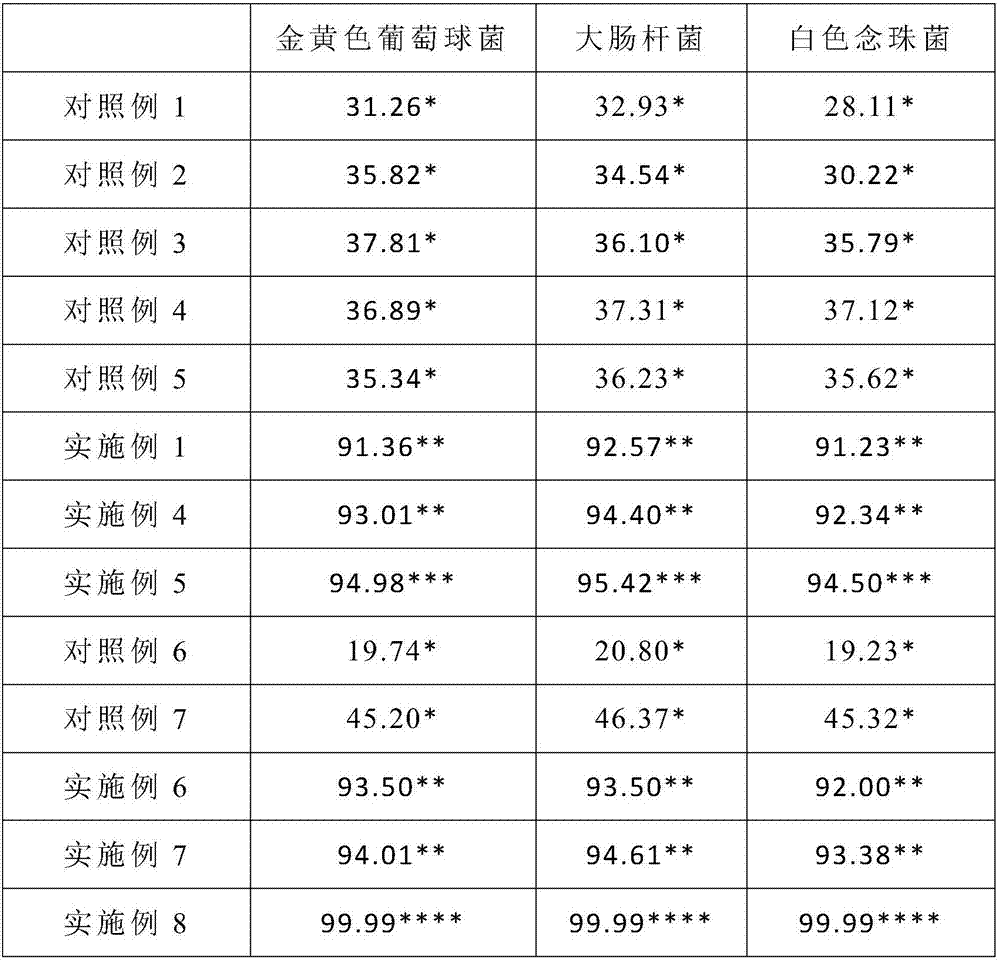

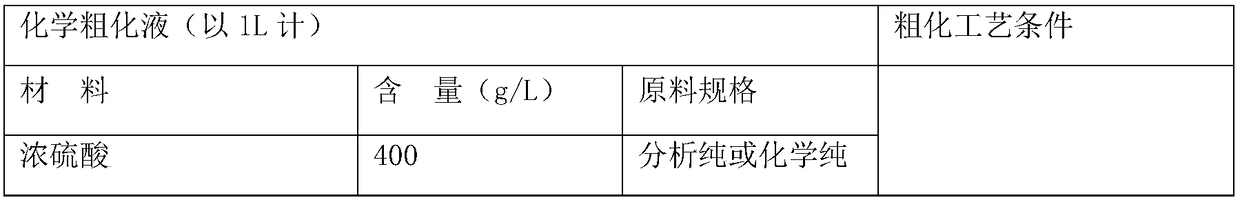

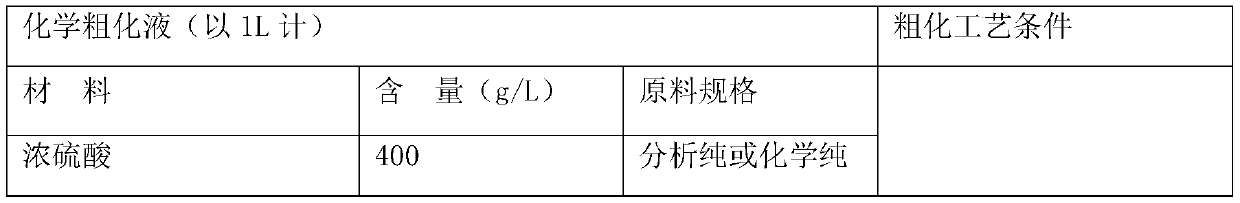

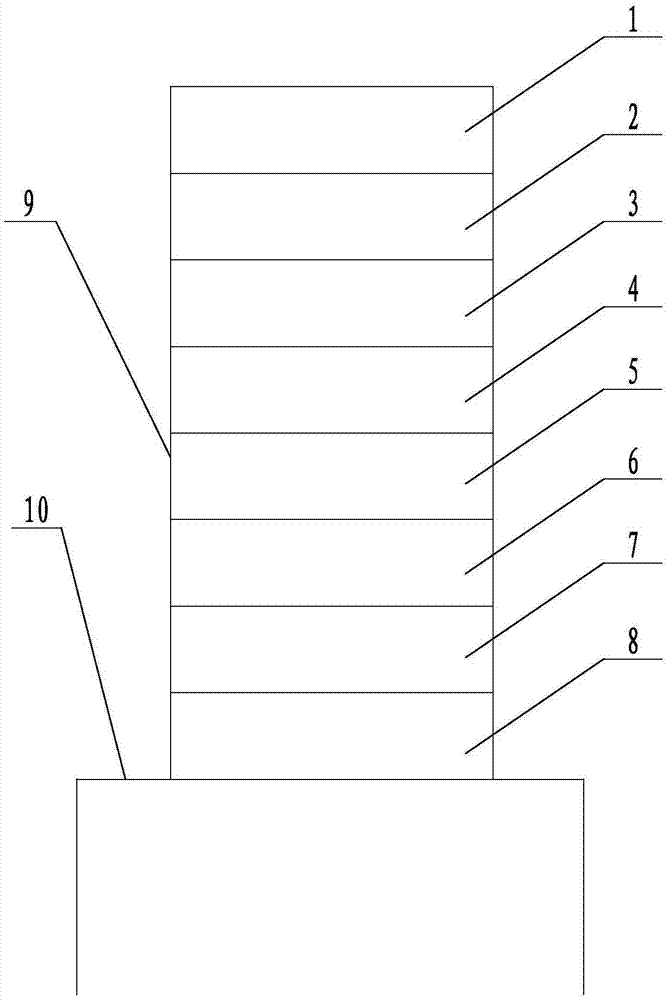

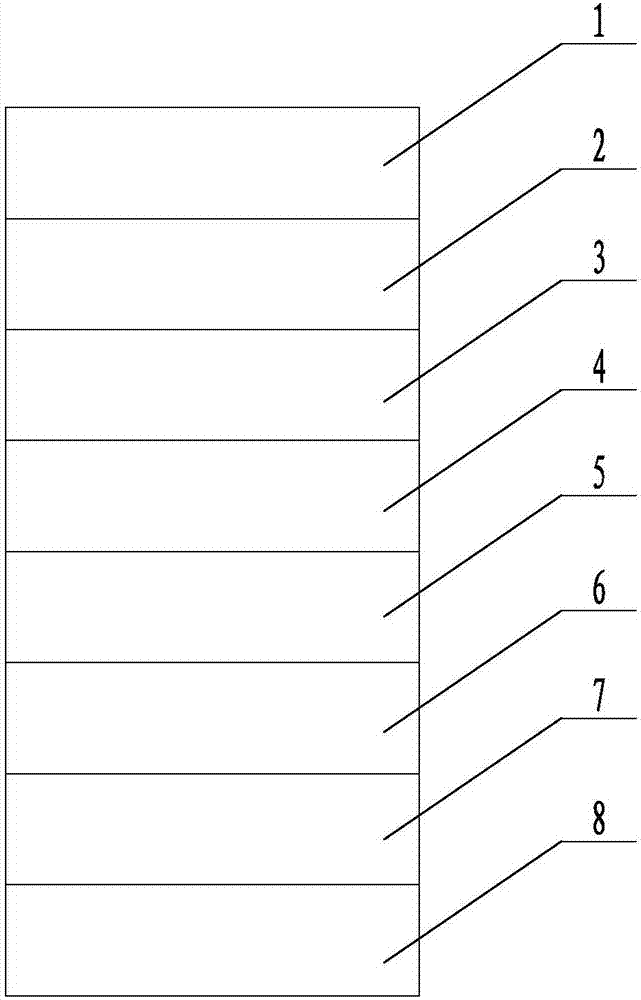

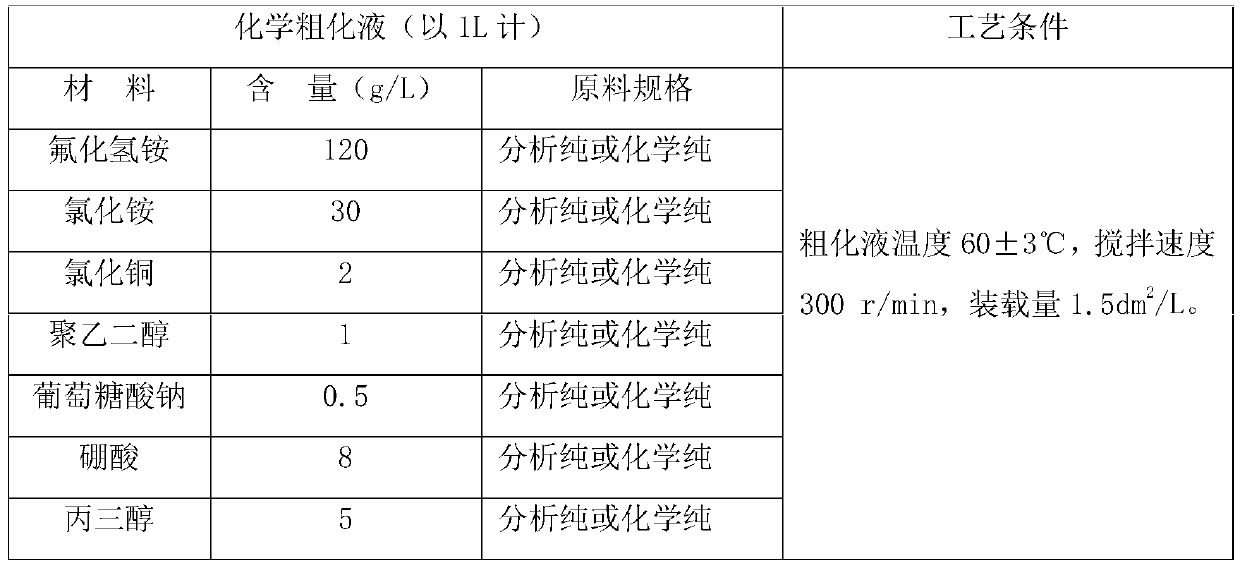

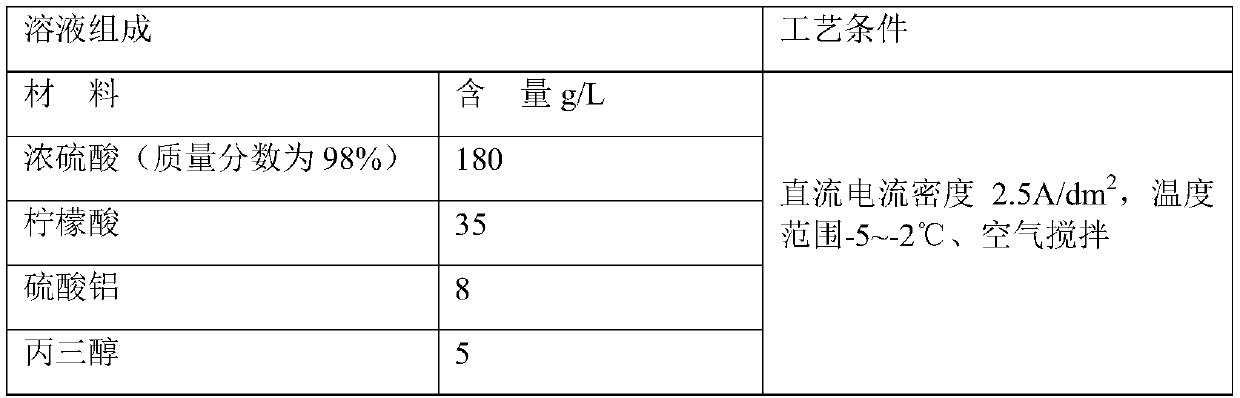

Method for preparing wear-resistant self-lubricating coating of aluminum and aluminum alloy

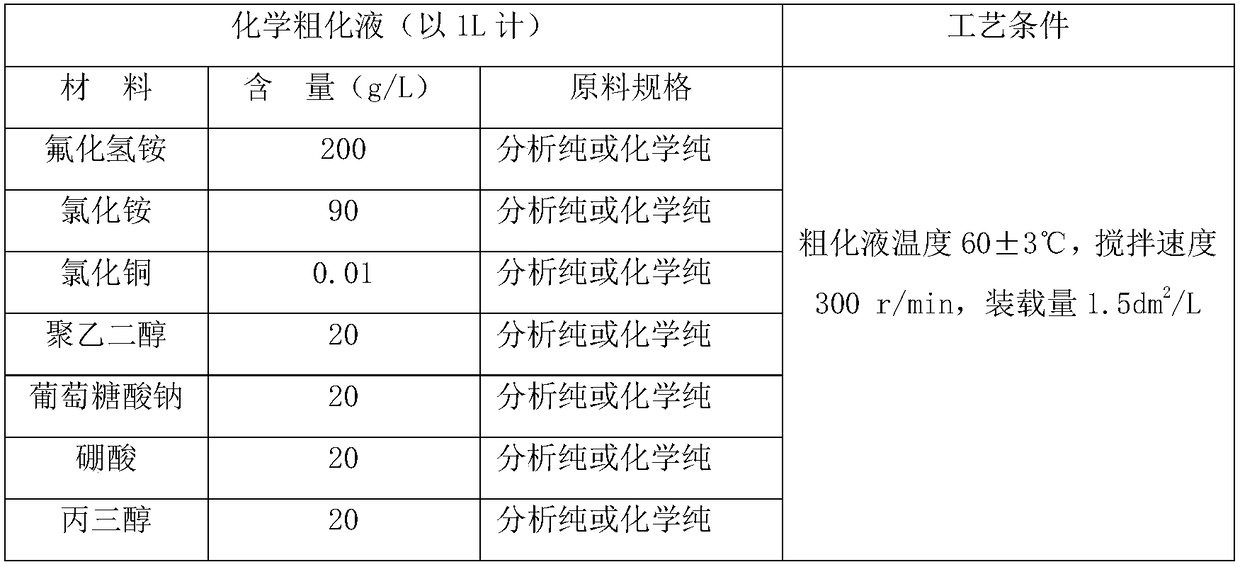

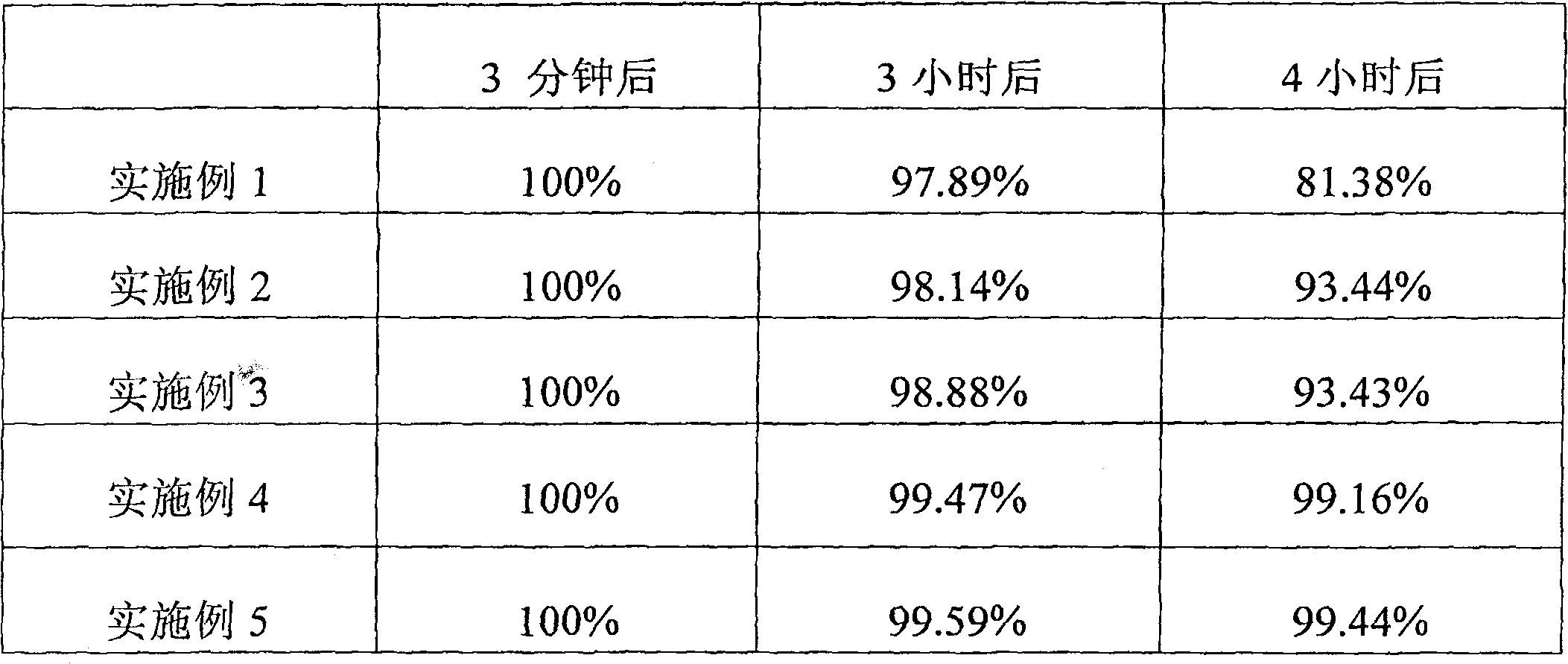

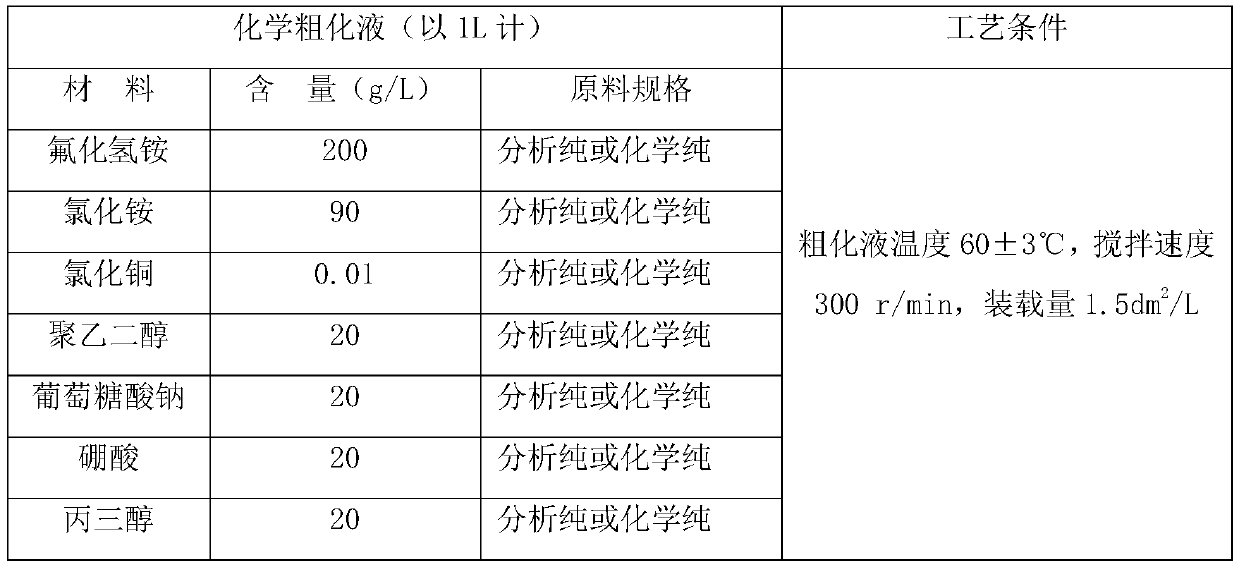

The invention particularly relates to a method for preparing a wear-resistant self-lubricating coating of aluminum and aluminum alloy. The method comprises the steps of firstly, carrying out roughening treatment on a matrix, then, preparing a self-lubricating coating A on the surface of the matrix, carrying out polishing treatment on the self-lubricating coating A, then, carrying out pretreatmenton a test piece, then, preparing a hard particle reinforcing phase by adopting an electrochemical in-situ growth method, and finally, preparing a self-lubricating coating B on the hard particle reinforcing phase, wherein the roughening treatment adopts a chemical roughening or mechanical roughening method, a roughening solution for chemical roughening treatment contains 80-200g / L of ammonium bifluoride, 10-90g / L of ammonium chloride, 0.01-5g / L of copper chloride, 1-20g / L of polyethylene glycol, 0.5-20g / L of sodium gluconate, 1-20g / L of boric acid and 1-20g / L of glycerol, and the mechanical roughening method comprises sandblasting roughening, shot jetting roughening, shot blasting roughening or 3D printing roughening. According to the method, the coefficient of friction of the wear-resistant self-lubricating coating is effectively lowered, and the service life of the wear-resistant self-lubricating coating is prolonged.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

Method for preparation of colorful rotor-spinning viscose stocking yarns

InactiveCN104695077AEvenlyFeel lubricatedContinuous wound-up machinesOpen-end spinning machinesYarnEngineering

The invention relates to the technical field of yarn preparation, in particular to a method for preparation of colorful rotor-spinning viscose stocking yarns. The method includes the steps: 1) selection and matching of raw materials; 2) pretreatment of dyed viscose fibers; 3) bale arrangement; 4) blowing and carding; 5) drawing; 6) rotor spinning; 7) final inspection and baling. Due to adoption of the technical scheme, the prepared colorful rotor-spinning viscose stocking yarns are novel yarns made by blending of various colorful viscose fibers, and later-stage spinnability of the dyed fibers is greatly improved due to oil feeding treatment of the dyed fibers in preparation. Fabrics made of the yarns integrate advantages of all of the raw materials and are skin friendly, soft, elegant and glossy, the yarns made by an international most advanced rotor spinning machine have the advantages of uniformity in unevenness, flawlessness, knot avoidance, smoothness in handfeel, high abrasion resistance and the like and are most ideal raw materials for high-grade knitted underwear, and successful development of the colorful rotor-spinning viscose stocking yarns opens a new field of rotor-spinning yarns.

Owner:ZHEJIANG HUZHOU WEIDA TEXTILE GRP

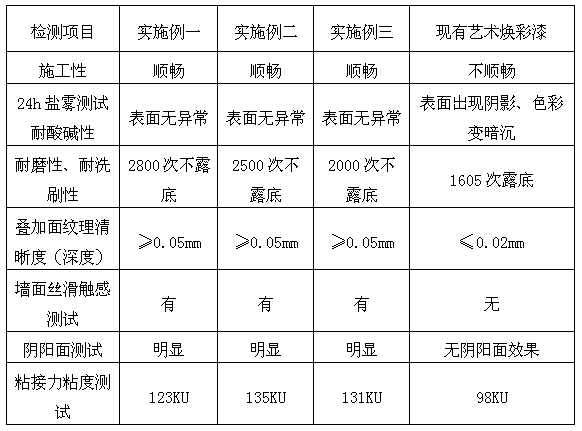

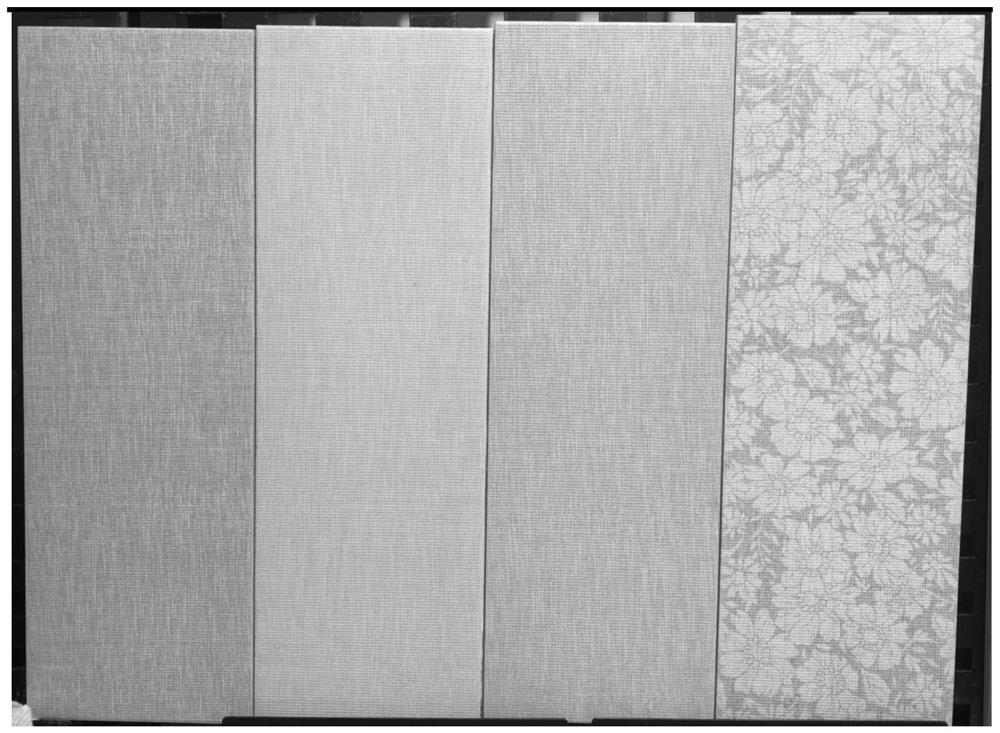

Art renewal lacquer and preparation method thereof

InactiveCN109337427AEasy to makeLong penetration timeAntifouling/underwater paintsPaints with biocidesLacquerWear resistance

The invention discloses art renewal lacquer and a preparation method thereof. The art renewal lacquer has superior adhesion, lubricating property, film-forming property, water resistance, mildew resistance, wear resistance, stain resistance, resistance to acid and base and wash resistance, so that a construction process can be more smooth, and the problem of construction difficulty is solved. A wall space applied with the art renewal lacquer has the effects that obvious male and female faces are formed, the surface has silky touch, the stacking surface has clear lines and the overall color issoft. The problems in the conventional art renewal lacquer that poor construction often occurs during construction, the covering power is low, the effect of male and female faces is avoided, the stacking surface has no clear lines, the wall space smoothness is low, the wall space is free of silky touch and poor in wash resistance, wear resistance, stain resistance and resistance to acid and base and the like are solved.

Owner:罗浮塔涂料科技有限公司

Alpaca, tencel and refined flax blended yarn and production process thereof

InactiveCN102191600AOvercome the lack of qualityWith UV protectionFibre treatmentYarnWorstedUltraviolet

The invention provides a semi-worsted alpaca, tencel and refined flax blended yarn and a production process thereof. The blended yarn and the production process have the following beneficial effects: as the preferred raw natural fibers are taken as the bases and the special production procedures are simultaneously adopted for blending, the problems of great blending difficulty and poor spinnability of the three kinds of natural fibers in the prior art are solved and the blended yarn has the advantages of the alpaca, tencel and refined flax and overcomes the defect of single raw fiber quality; the fabrics woven by the blended yarn have bright colors and smooth handfeel, are flat and smooth, have good moisture absorption and heat retention and resist bacteria and protect health; the clothes made of the fabrics are comfortable to wear and elegant, have smooth handfeel and have the functions of caring the skins, absorbing moisture and releasing sweat, resisting bacteria and protecting health and preventing ultraviolet; and at the same time, the blended yarn products can have the excellent natural colors of the raw fibers without being dyed and are not easy to fade, thus reducing the manufacturing cost and the environmental pollution.

Owner:徐州沃尔格羊绒制品有限公司

Preparation method of medical antibiosis washing-protection liquid

InactiveCN102600048AGood antibacterial effectSuitable for long-term useCosmetic preparationsToilet preparationsLindera erythrocarpaFiltration

The invention discloses a preparation method of a medical antibiosis washing-protection liquid. The preparation method is characterized in that the preparation method comprises the following steps of: (1) preparing a compound essential oil by using Lindera erythrocarpa Makinl, folium eucalypti, Rhododendron dauricum and elecampane through a supercutical fluid CO2 extraction method; (2) adding water which is four-six times of medicinal materials in papaya, Stephania tetrandra S, rhizoma kaempferiae, and viola hamiltoniana to boil and decoct two times, one-two hours for one time, filtering, combining filter liquor decocted in two times, and concentrating the filter liquor; (3) slowly stirring the filter liquor and adding propylene glycol, refrigerating and standing so as to obtain the filter liquor through the filtration; and (4) using a centrifugal machine to centrifuge filter liquor obtained through the step 3, taking a supernatant liquor, adding the obtained compound essential oil inthe step 1, uniformly mixing, carrying out sterilization on circulated steam for 30 minutes at 100 DEG C, and packaging. The clinical experiment proves that the products prepared by the preparation method provided by the invention can carry out rapid disinfection on the hand, and can keep a longer bacteriostasis state.

Owner:张玲

Medical antibacterial washing and nursing liquid

InactiveCN103721145AGood antibacterial effectGood skin careAntisepticsPlant ingredientsBiomedical engineeringKaempferia

The invention discloses a medical antibacterial washing and nursing liquid which is characterized by being prepared from papaya, kerr treebine keaf, lindera erythrocarpa makinl, folium eucalypti, kaempferia galangal, viola hamiltoniana and folium rhododendri daurici. Clinical experiment shows that hands can be rapidly sterilized by using the liquid, and the antibacterial state can be maintained for a long time.

Owner:张彦录

Preparation method of novel anti-static fiber

The invention relates to a preparation method of an anti-static fiber, and particularly the preparation method has the advantages that the cost is cost, and the fiber is good in electric conductivity, strong in electric conduction durability, lubricating in hand feeling and excellent in dyeing property. The preparation method specifically comprises the following steps: gradually adding ultra-fine copper powder into liquid-state polyamide hot melt adhesive under high-speed stirring condition according to the proportion that the weight ratio is 0.1% by weight-10% by weight, simultaneously adding 0.01% by weight-0.1% by weight of lubricating agent and 0.01% by weight-0.1% by weight of antioxidant, fully mixing, then coating on the surface of the fiber during the heat setting process of the fiber, cooling and then curing so as to obtain the fiber with the good anti-static property.

Owner:SHANGHAI LANGYI FUNCTIONAL MATERIALS

Glaze composition, glaze, preparation method of glaze, ceramic tile and preparation method of ceramic tile

The invention provides a glaze composition, a glaze, a preparation method of the glaze, a ceramic tile and a preparation method of the ceramic tile. The glaze composition is prepared from the following raw materials in percentage by mass: 25-27 percent of zirconium white frit, 3-5 percent of quartz stone, 5-7 percent of wollastonite, 21-23 percent of matte frit, 8-10 percent of washed kaolin, 5-7percent of calcined kaolin and 23-25 percent of zirconium silicate. The glaze comprises a glaze composition and a solvent. The preparation method of the glaze comprises the step of mixing the glaze composition with the solvent to obtain the glaze. The ceramic tile comprises a green brick and a glaze layer arranged on at least one surface of the green brick, and the glaze layer is prepared from theglaze. The preparation method of the ceramic tile comprises the following steps: firing the green brick for the first time, cooling, glazing, and firing for the second time to obtain the ceramic tile. By using the glaze provided by the invention, the ceramic tile with good texture, obvious details and grains and low cost can be prepared by one-time glazing and one-time firing after glazing.

Owner:景德镇欧神诺陶瓷有限公司

Water-borne polyurethane coating agent containing superfine down fiber-porous polystyrene microspheres

InactiveCN105803795AImprove surface activityImprove thermal stabilityGrip property fibresFiberMicrosphere

The invention discloses a water-borne polyurethane coating agent containing superfine down fiber-porous polystyrene microspheres. The superfine down fiber-porous polystyrene microspheres are prepared by the following steps of treating down fibers into superfine fibers with high surface activity and high thermal stability, and doping the superfine fibers in polystyrene; prepared composite porous polystyrene microspheres have good air and moisture permeability of down fibers and also have an excellent heat insulating effect; by using the composite porous polystyrene microspheres, the clammy feeling of a traditional polyurethane coating can be effectively relieved, a coating with smooth hand feeling, high luster, high permeability and warm-protection, safety and skin friendliness is obtained, and use experience of fabric is remarkably improved.

Owner:ANHUI WANLING DOWN & FEATHER PROD

Medical antibacterial cleansing liquid

InactiveCN102579930AGood antibacterial effectSuitable for long-term useAntisepticsDermatological disorderElecampaneViola arcuata

The invention discloses medical antibacterial cleansing liquid. The medical antibacterial cleansing liquid is characterized by being prepared from papaya, kerr treebine roots and stem, lindera thunbergii makino, folium eucalypti, kaempferia galanga, viola arcuata, dahurian rhododendron leaves and elecampane. Clinical experiments prove that the medical antibacterial cleansing liquid can be used for rapidly disinfecting hands and an antibacterial state can be kept for a long time.

Owner:孙着叶

Medical antibacterial washing and caring liquid

InactiveCN103768473AGood antibacterial effectSuitable for long-term useCosmetic preparationsToilet preparationsLindera erythrocarpaBiomedical engineering

The invention discloses a medical antibacterial washing and caring liquid which is characterized by being prepared by processing carica papaya, root of kerr treebine, lindera erythrocarpa makinl, folium eucalypti, rhizoma kaempferiae, viola arcuata and folium rhododendri daurici. Clinical experiments prove that the medical antibacterial washing and caring liquid can rapidly disinfect hands, and can keep longer bacteriostatic state.

Owner:张彦录

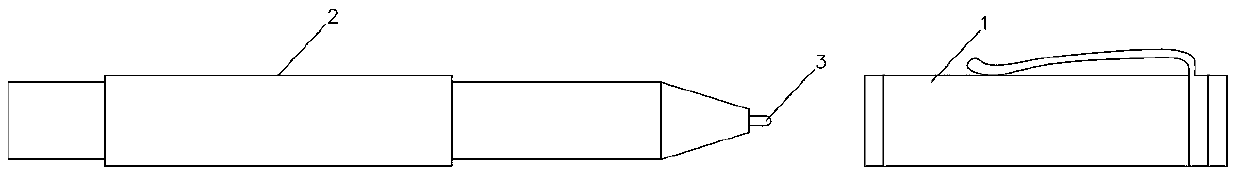

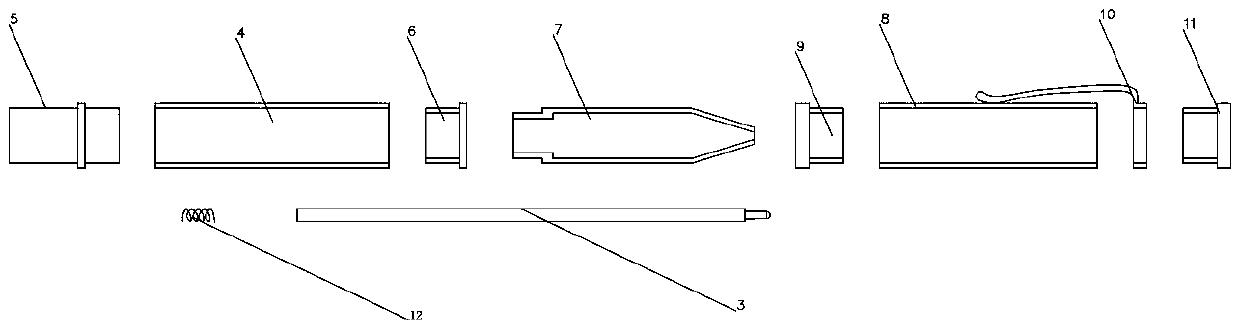

Carbon fiber decorative ballpoint pen and manufacturing method thereof

The invention discloses a carbon fiber decorative ballpoint pen and a manufacturing method thereof. The pen comprises a pen sleeve, a refill and a pen body, and is characterized in that cylindrical sleeves, molded by carbon fiber reinforced epoxy resin winding pipes, sleeve the pen body and / or the pen sleeve. The sleeves are manufactured by special materials and processes. The ballpoint pen has the following effects: (1) the weight is low; and the strength is high; (2) the decorative effect is good; the product grade is high; as carbon fibers have the characteristics of low weight, good thermal conductivity, good epoxy resin transparency and good skin feel, the cylinders are contacted with human skin to achieve the advantages of lubrication and good holding force; and (3) the practicability is better; carbon fiber reinforced composite materials have the advantages of heat resistance and aging resistance, so that the cylinders achieve better practicability and adaptability; the specifications of the cylinders are freely changed; and even if the sizes of the cylinders are increased, the practicability cannot be influenced.

Owner:江门市瑞祥复合材料研究院有限公司

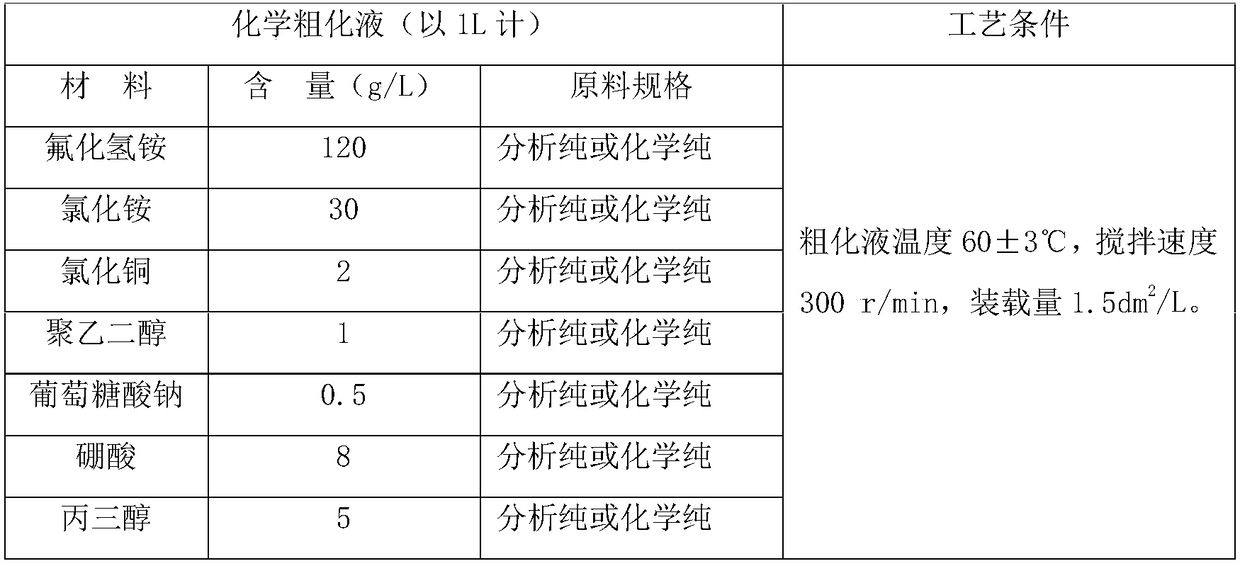

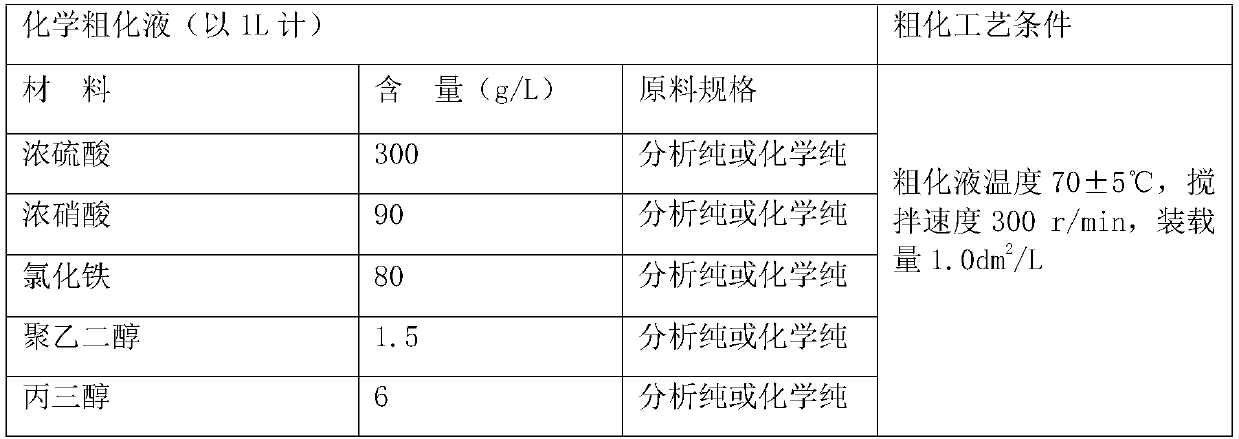

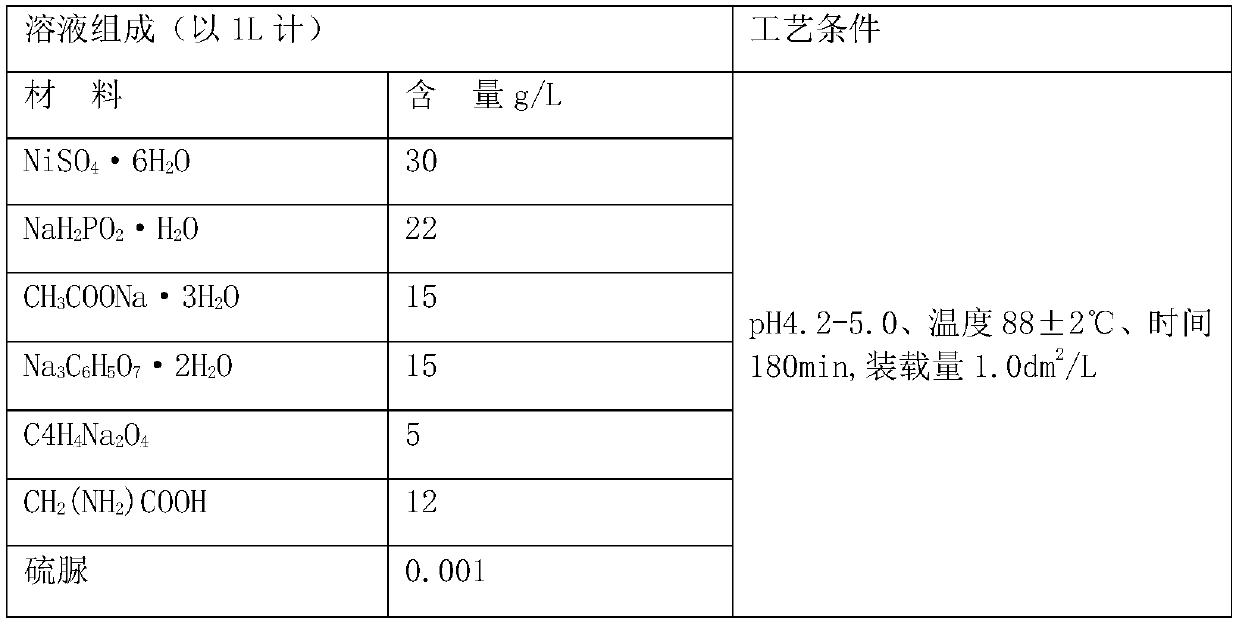

Preparation method of wear-resistant self-lubricating coating for steel material

ActiveCN109267042AGood self-lubricating performanceImprove job stabilityLiquid surface applicatorsLiquid/solution decomposition chemical coatingAbrasive blastingWear resistant

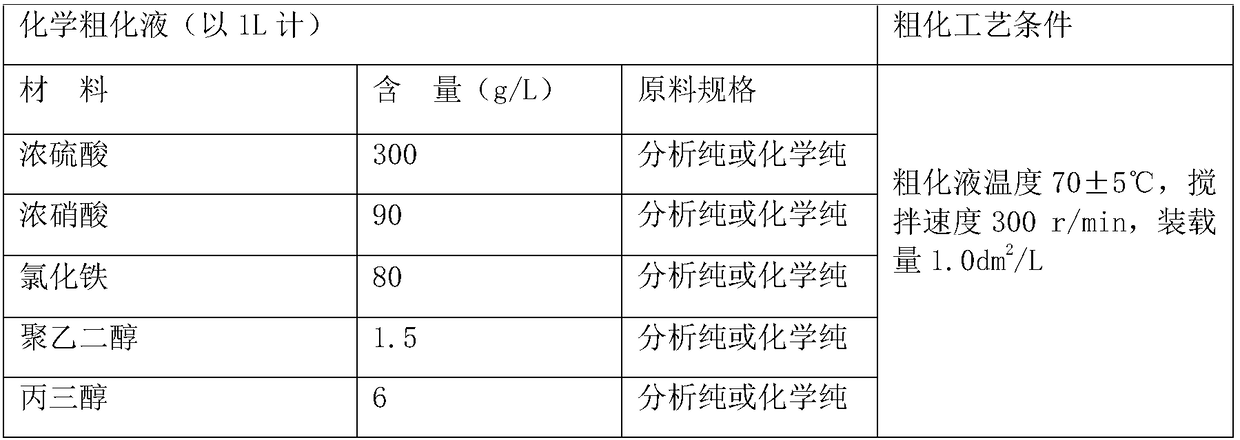

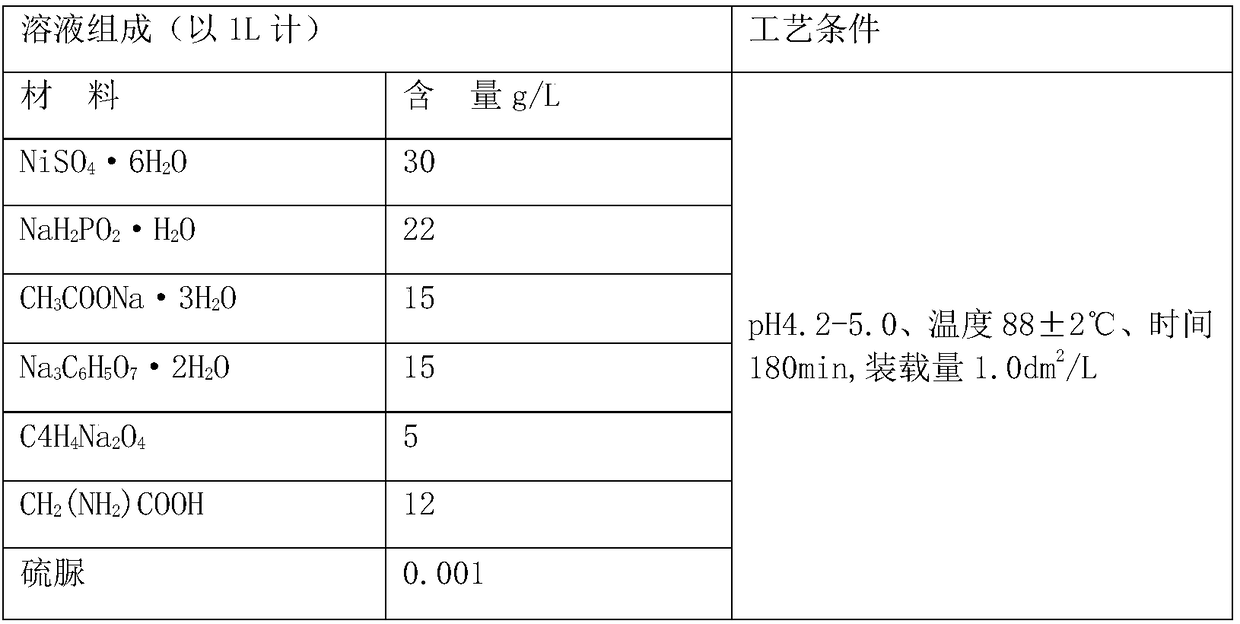

The invention concretely relates to a preparation method of a wear-resistant self-lubricating coating for a steel material. The method comprises the following steps of carrying out roughening treatment on a matrix firstly, then preparing a self-lubricating coating A on the surface of the matrix, carrying out polishing treatment on the self-lubricating coating A, then carrying out pretreatment on asample part, afterwards, preparing a hard particle-reinforced phase, and finally, preparing a self-lubricating coating B on the hard reinforced phase. A chemical roughening or mechanical roughening method is adopted for the roughening treatment, a roughening solution used for the chemical roughening treatment is prepared from 270-400 g / L concentrated sulfuric acid, 50-140 g / L concentrated nitricacid, 40-90 g / L ferric chloride, 1-20 g / L polyethylene glycol and 1-20 g / L glycerine, and the mechanical roughening method comprises sand blast roughening, ball blast roughening or ball throwing roughening. According to the method, the dry film friction coefficient of the coating can be lowered, the friction resistant wear life of the coating is prolonged, and the prepared coating has excellent corrosion resistance.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

Preparation method of novel anti-static fiber

The invention relates to a preparation method of an anti-static fiber, and particularly the preparation method has the advantages that the cost is cost, and the fiber is good in electric conductivity, strong in electric conduction durability, lubricating in hand feeling and excellent in dyeing property. The preparation method specifically comprises the following steps: gradually adding ultra-fine copper powder into liquid-state polyamide hot melt adhesive under high-speed stirring condition according to the proportion that the weight ratio is 0.1% by weight-10% by weight, simultaneously adding 0.01% by weight-0.1% by weight of lubricating agent and 0.01% by weight-0.1% by weight of antioxidant, fully mixing, then coating on the surface of the fiber during the heat setting process of the fiber, cooling and then curing so as to obtain the fiber with the good anti-static property.

Owner:SHANGHAI LANGYI FUNCTIONAL MATERIALS

Hyaluronic acid multi-effect moisture-retaining and moistening mask and preparation method thereof

PendingCN114099406AIncrease supplyPromote excretionCosmetic preparationsToilet preparationsBiotechnologyCucumber juice

The invention relates to the technical field of facial beautification, and discloses a hyaluronic acid multi-effect moisture-retaining and moisture-permeable mask and a preparation method thereof.The hyaluronic acid multi-effect moisture-retaining and moisture-permeable mask comprises deionized water, a humectant, a thickening agent and a solubilizer and further comprises the following components: green cucumber juice filtrate, pearl powder, hyaluronic acid, glycosyl trehalose, panthenol, sweet almond protein and degradable film cloth; according to the hyaluronic acid multi-effect moisture-retaining permeable mask, moisture is absorbed to the surface layer of skin through hyaluronic acid, nutrition supply of the skin and excretion of waste are promoted, and cells are full of moisture; under the action of hyaluronic acid, active substances in the pearl powder and the green cucumber powder are promoted to act on skin cells, so as to repair damaged cells, supplement nutrition, strongly resist oxidation, scavenge free radicals, restore young state and fade fine wrinkles; the panthenol and the sweet almond protein can moisturize and relieve the skin sensitivity at the same time. The hand feeling is smooth after use, and the moisturizing, anti-wrinkle, whitening and skincare effects on the skin are remarkable.

Owner:广东画景医药生物科技有限公司

Preparation method of wear-resistant self-lubricating coating for iron and steel materials

ActiveCN109267042BReduce dry film coefficient of frictionImprove friction and wear lifeLiquid surface applicatorsLiquid/solution decomposition chemical coatingSand blastingPolyethylene glycol

The invention concretely relates to a preparation method of a wear-resistant self-lubricating coating for a steel material. The method comprises the following steps of carrying out roughening treatment on a matrix firstly, then preparing a self-lubricating coating A on the surface of the matrix, carrying out polishing treatment on the self-lubricating coating A, then carrying out pretreatment on asample part, afterwards, preparing a hard particle-reinforced phase, and finally, preparing a self-lubricating coating B on the hard reinforced phase. A chemical roughening or mechanical roughening method is adopted for the roughening treatment, a roughening solution used for the chemical roughening treatment is prepared from 270-400 g / L concentrated sulfuric acid, 50-140 g / L concentrated nitricacid, 40-90 g / L ferric chloride, 1-20 g / L polyethylene glycol and 1-20 g / L glycerine, and the mechanical roughening method comprises sand blast roughening, ball blast roughening or ball throwing roughening. According to the method, the dry film friction coefficient of the coating can be lowered, the friction resistant wear life of the coating is prolonged, and the prepared coating has excellent corrosion resistance.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

In-mold labeling anti-counterfeiting bottle cap and preparation method thereof

InactiveCN107369376AHigh anti-counterfeiting strengthGood lookingStampsClosure with auxillary devicesInformation layerEngineering

The invention belongs to the technical field of anti-counterfeiting, and in particular relates to an anti-counterfeiting bottle cap pasted in a film and a preparation method thereof. Anti-counterfeit bottle caps pasted inside the film include anti-counterfeit labels and cap body pasted inside the film. The anti-counterfeit label pasted inside the film is set on the top of the cap body. Protective layer, first information layer, first substrate layer, second information layer, composite adhesive layer, second substrate layer and molten adhesive layer, static elimination layer, protective layer, first information layer, first substrate layer, the second information layer, the composite glue layer, the second base material layer and the melted glue layer are connected sequentially from top to bottom, the melted glue layer is connected with the top of the bottle cap body, and the second base material layer is transparent. The invention improves the anti-counterfeiting strength, has good appearance and high cost performance, and solves the problem that the coding on the reverse side cannot be combined with the carrier.

Owner:孙涵

In-mold anti-counterfeiting label and preparation method thereof

InactiveCN107331287AIncrease productivityReduce positive and negative alignment deviationStampsSynthetic resin layered productsInformation layerAdhesive

The invention belongs to the technical field of anti-counterfeiting, and in particular relates to an anti-counterfeiting label pasted in a film and a preparation method thereof. The anti-counterfeiting label in the film includes the first base material layer, the static elimination layer, the protective layer, the first information layer, the first base material layer, the second information layer, the compound adhesive layer, the second base material layer and the melt adhesive layer from above connected successively to the bottom, and the second substrate layer is transparent. The invention improves the anti-counterfeiting strength, has good appearance effect, and solves the problem that the coding on the reverse side cannot be combined with the carrier.

Owner:孙涵

Preparation method of aluminum and aluminum alloy wear-resistant self-lubricating coating

ActiveCN109402708BFeel lubricatedReduce coefficient of frictionElectrolytic coatingsCopper chlorideSand blasting

The invention particularly relates to a method for preparing a wear-resistant self-lubricating coating of aluminum and aluminum alloy. The method comprises the steps of firstly, carrying out roughening treatment on a matrix, then, preparing a self-lubricating coating A on the surface of the matrix, carrying out polishing treatment on the self-lubricating coating A, then, carrying out pretreatmenton a test piece, then, preparing a hard particle reinforcing phase by adopting an electrochemical in-situ growth method, and finally, preparing a self-lubricating coating B on the hard particle reinforcing phase, wherein the roughening treatment adopts a chemical roughening or mechanical roughening method, a roughening solution for chemical roughening treatment contains 80-200g / L of ammonium bifluoride, 10-90g / L of ammonium chloride, 0.01-5g / L of copper chloride, 1-20g / L of polyethylene glycol, 0.5-20g / L of sodium gluconate, 1-20g / L of boric acid and 1-20g / L of glycerol, and the mechanical roughening method comprises sandblasting roughening, shot jetting roughening, shot blasting roughening or 3D printing roughening. According to the method, the coefficient of friction of the wear-resistant self-lubricating coating is effectively lowered, and the service life of the wear-resistant self-lubricating coating is prolonged.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

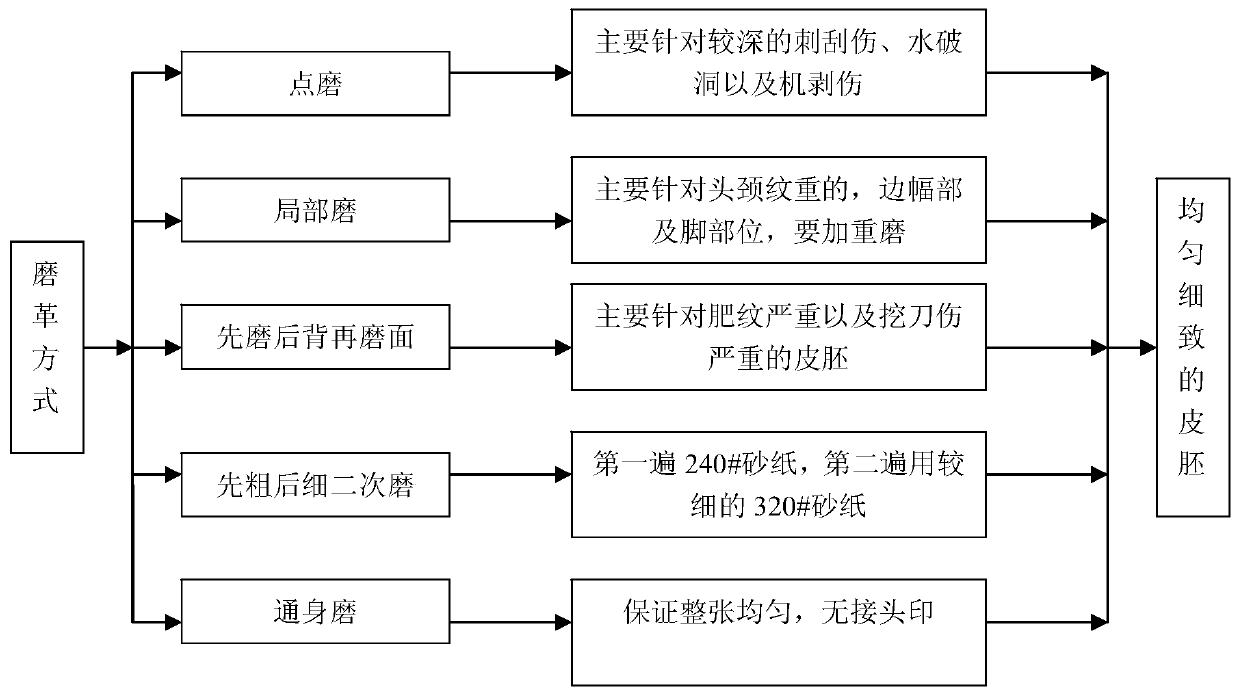

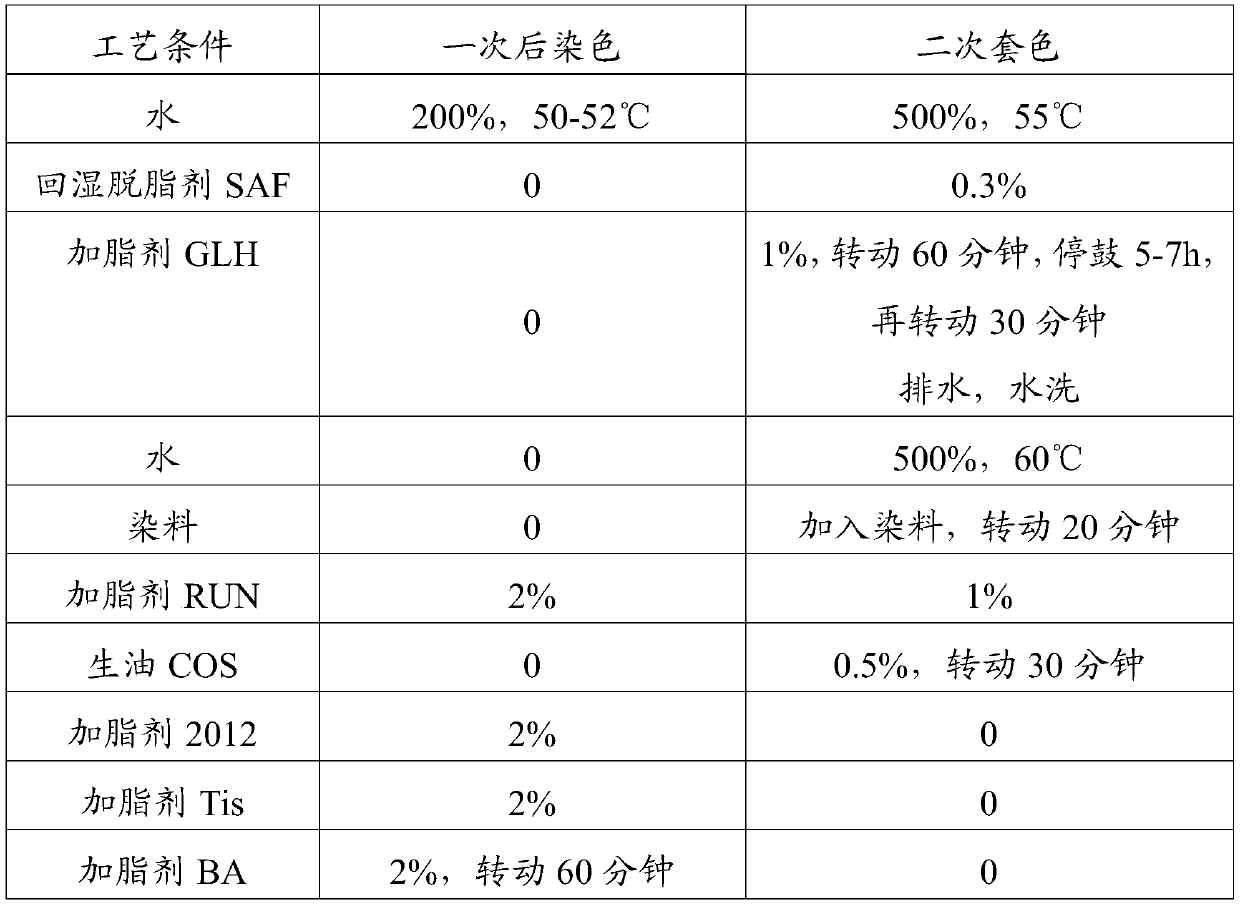

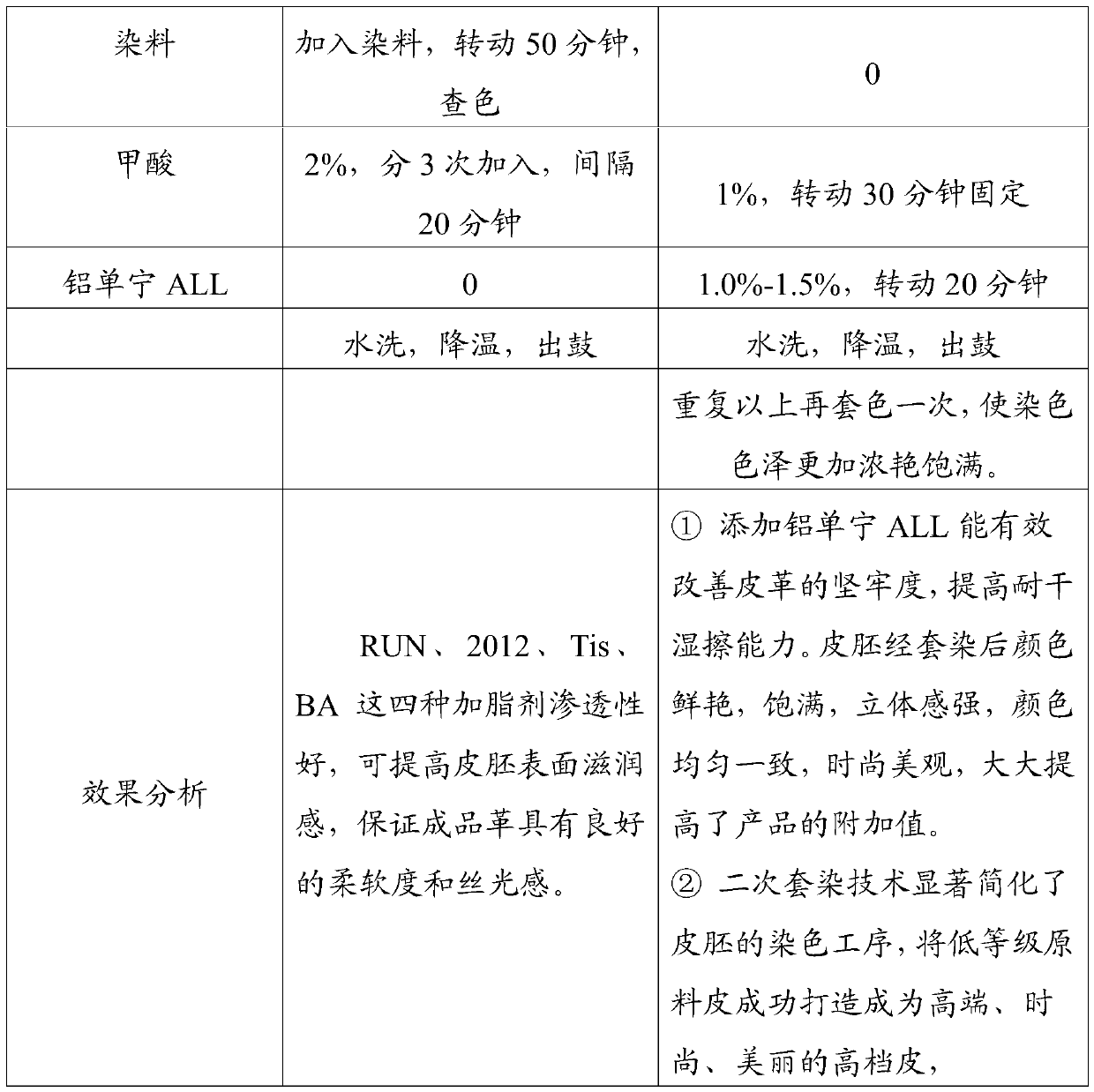

Manufacturing method of high-assignment secondary over-dyed frosted leather

ActiveCN110982959AImprove flatnessImprove embossing effectTanning treatmentDyeing processMaterials preparationProcess engineering

The invention discloses a manufacturing method of high-assignment secondary over-dyed frosted leather. The manufacturing method comprises a material preparation procedure, a retanning procedure, a neutralizing procedure, a filling dyeing procedure, a fat liquoring and re-dyeing procedure, a primary drying procedure, a leather buffing procedure and a secondary over-dying procedure which are sequentially carried out. Compared with the prior art, the method adopting the secondary over-dyeing technology, adopting an environmentally-friendly aldehyde tanning agent and an environmentally-friendly synthetic tanning agent to replace conventional chromium powder for tanning and adopting a natural vegetable tanning agent as an environmentally-friendly filling agent to supplement the tanning agent has the advantages of filling cover, improvement of the flatness and the embossing property of the leather surface in a multilayer, high-dimensional and all-around mode, solving of the problem of balance between low-grade raw material leather making and ecological development, successful upgrading of the low-grade raw material leather into the environmentally-friendly leather product with the high additional values, efficient utilization of resources, and remarkable improvement of the additional values of the low-grade raw material leather and the utilization rate of the finished leather.

Owner:FENGAN LEATHER

Glaze composition, glaze and preparation method thereof, ceramic tile and preparation method thereof

The invention provides a glaze composition, a glaze and a preparation method thereof, a ceramic tile and a preparation method thereof. The glaze composition, whose raw materials are calculated by mass percentage, includes: 25-27% of zirconium white frit, 3-5% of quartz stone, 5-7% of wollastonite, 21-23% of matte frit, and 8% of washed kaolin ‑10%, calcined kaolin 5‑7 and zirconium silicate 23‑25%. Glazes, including glaze compositions and solvents. The preparation method of the glaze comprises: mixing the glaze composition and a solvent to obtain the glaze. Ceramic tiles, including adobe and a glaze layer arranged on at least one surface of the adobe, and the glaze layer is made by using the glaze. The preparation method of ceramic tiles comprises: firing the brick adobe for the first time, glazing after cooling, and then firing for the second time to obtain the ceramic tiles. Using the glaze provided by the application, ceramic tiles with good texture, obvious details and lines, and low cost can be produced after one-time glazing and one-time firing after glazing.

Owner:景德镇欧神诺陶瓷有限公司

Washing powder and preparation method thereof

InactiveCN109294768AFeel lubricatedSkin careInorganic non-surface-active detergent compositionsMedicineCleaning product

The invention discloses washing powder, which is prepared from the following raw materials by mass: 10-20 parts of a Camellia pancake extract, 20-40 parts of a Retinervus Luffae Fructus extract, 3-5 parts of a cortex dictamni extract, 1-3 parts of a seaweed extract, 1-4 parts of white clay, and 0.5-1 part of a lavender extract. The preparation method comprises: (1) taking the raw materials, wherein the raw materials are weighed according to the ratio; (2) mixing, wherein the raw materials are uniformly mixed; and (3) sterilizing, wherein 100-120 DEG C hot air sterilization is performed, and sealing packaging is performed to obtain the washing powder. According to the present invention, the washing powder has characteristics of strong decontamination cleaning ability, effective sterilizing,effective odor removing and skin moisturizing, and is the ideal safe cleaning product for kitchen appliances, fruits and vegetables and the like.

Owner:湖南银鑫油业有限公司

Medical antibacterial cleansing liquid

InactiveCN102579930BGood antibacterial effectSuitable for long-term useAntisepticsDermatological disorderPapaya familyMedicine

The invention discloses medical antibacterial cleansing liquid. The medical antibacterial cleansing liquid is characterized by being prepared from papaya, kerr treebine roots and stem, lindera thunbergii makino, folium eucalypti, kaempferia galanga, viola arcuata, dahurian rhododendron leaves and elecampane. Clinical experiments prove that the medical antibacterial cleansing liquid can be used for rapidly disinfecting hands and an antibacterial state can be kept for a long time.

Owner:孙着叶

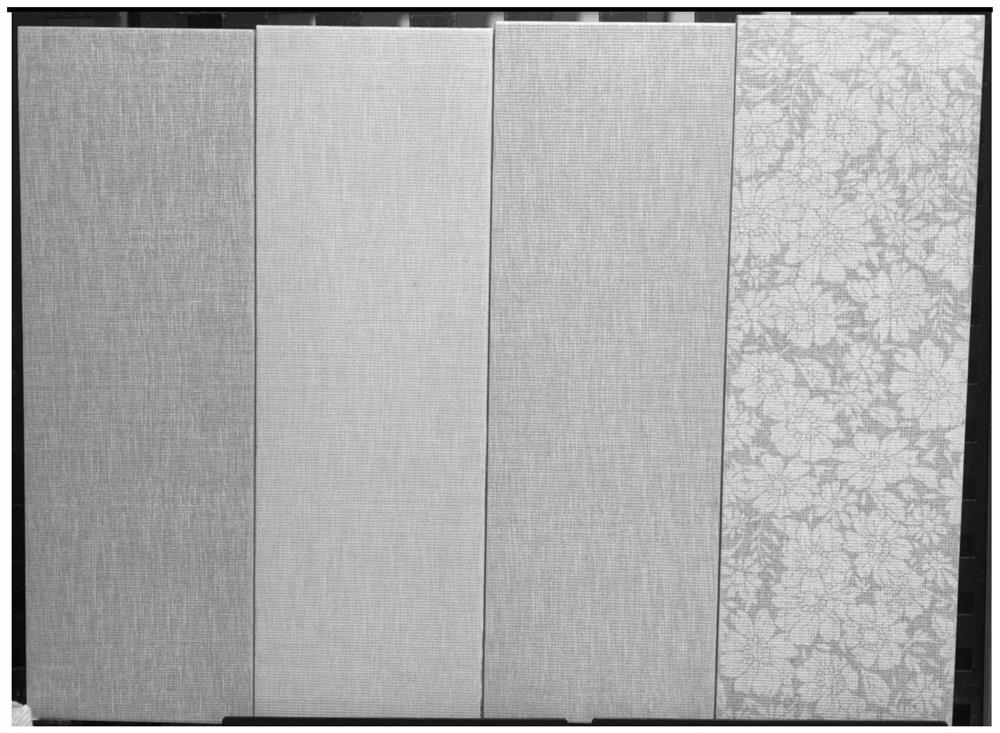

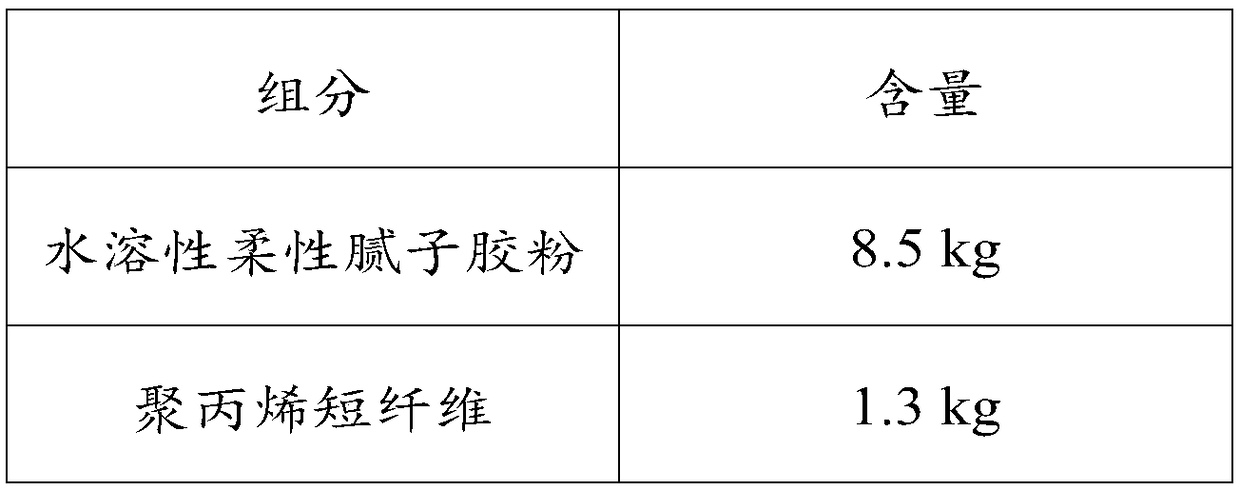

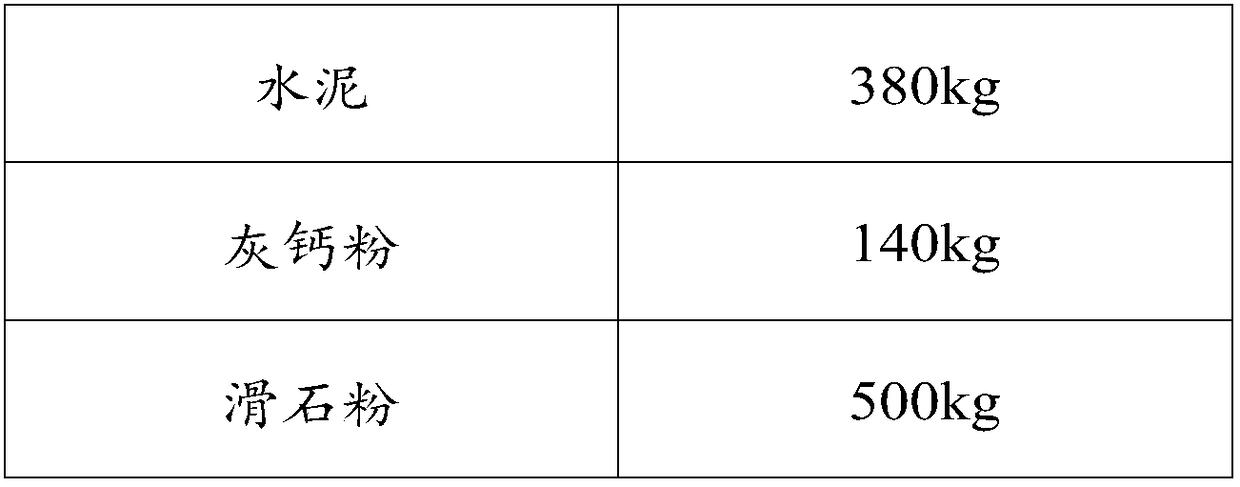

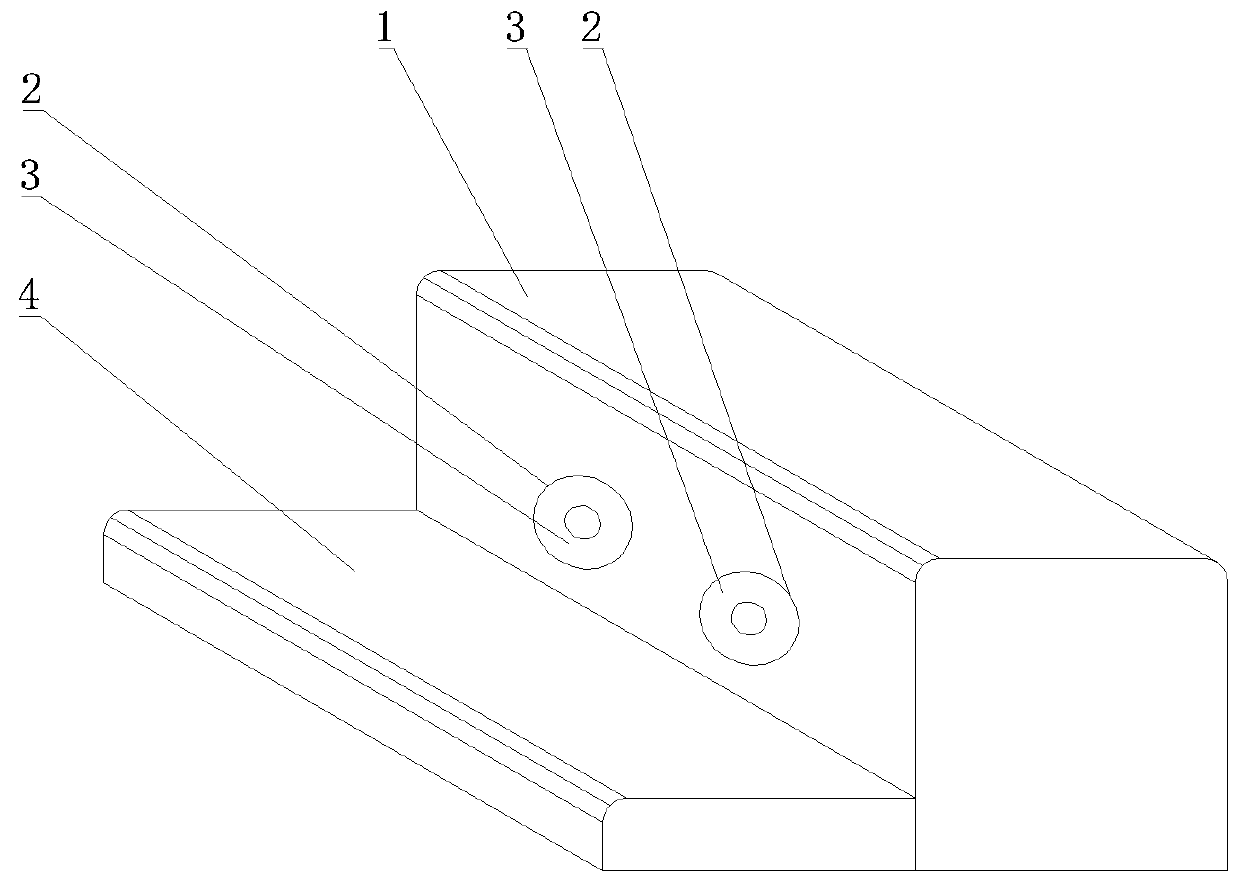

Putty powder and high elastic fiber putty for wall crack resistance

InactiveCN108912799AImprove flexibilityStrong waterproof and crack resistanceFilling pastesFiberCrack resistance

The invention provides putty powder and high elastic fiber putty for wall crack resistance, and relates to the field of building materials. The putty powder comprises 8 to 10 parts by weight of water-soluble flexible putty rubber powder; 1 to 2 parts by weight of polypropylene short fiber; 350 to 450 parts by weight of cement; and 540 to 700 parts by weight of calcium powder. The high elastic fiber putty comprises liquid slurry and the putty powder; the liquid slurry comprises 70 to 130 parts of an acrylic emulsion; 70 to 130 parts of aqueous polyurethane resin; and 4 to 6 parts of an auxiliary agent. The putty powder and the high elastic fiber putty have high flexibility, high adhesion, strong elongation and high film forming property, and can effectively solve the risk of wall cracking.

Owner:CHINA RAILWAY CONSTR ENG GROUP +1

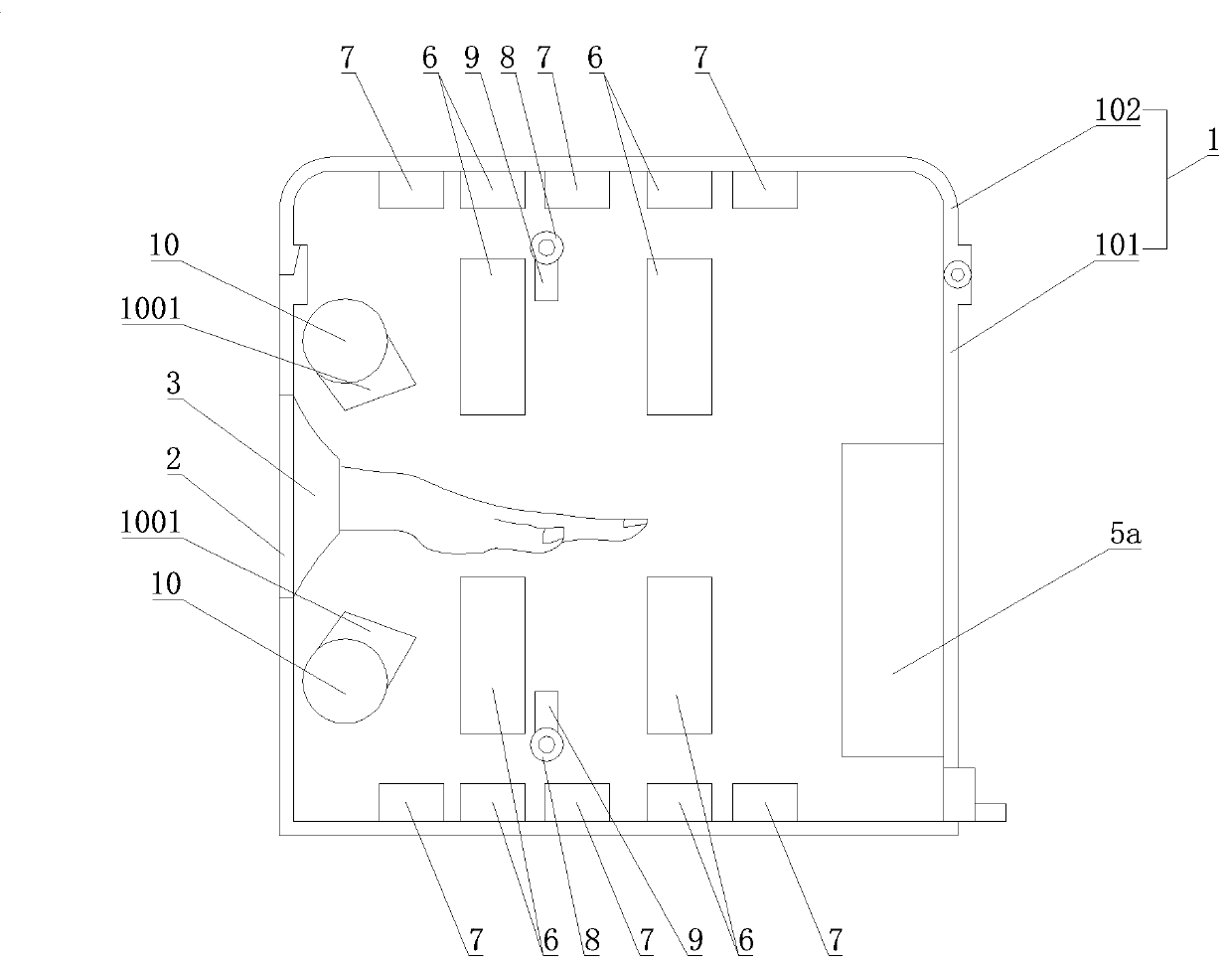

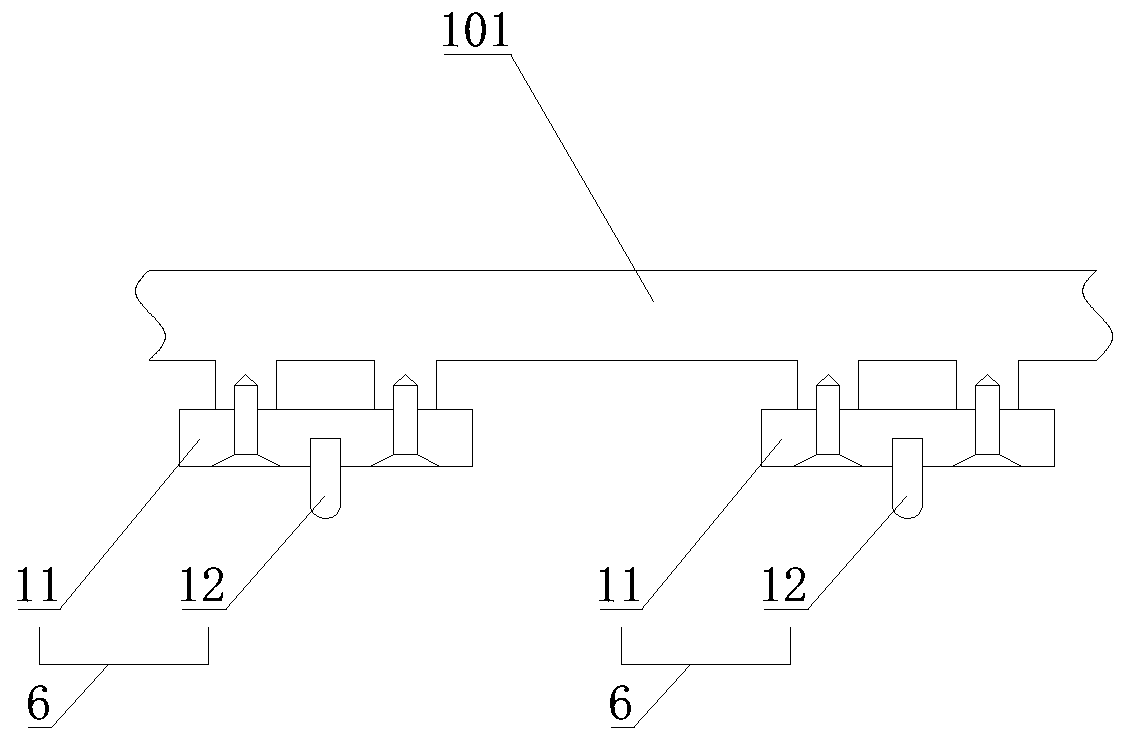

Hand skin maintaining equipment

InactiveCN110090142APromote absorptionImprove nutritional statusMedical devicesBathing devicesNutritional statusCutin

The invention discloses hand skin maintaining equipment. The hand skin maintaining equipment is characterized by comprising a hand maintaining box, wherein a hand stretching hole which accommodates hands to extend in is formed in the side wall of the hand maintaining box; a maintenance fluid coating device and a warm steaming device are arranged in the hand maintaining box; a maintenance fluid jaris connected to the maintenance fluid coating device; maintenance fluid is accommodated in the maintenance fluid jar; the maintenance fluid coating device is used for coating the maintenance fluid tohands which extend into the hand stretching hole; and the warm steaming device is used for enabling the temperature in the hand maintaining box to be under a preset temperature. According to the handskin maintaining equipment disclosed by the invention, the hands are automatically cleaned in a closed space, and are subjected to maintenance fluid coating and warm maintenance to promote the absorption of skin histocytes, soften cutin, improve the nutritional status of hand skin, and increase the water content of hand skin, so that the hand skin is full in cell and smooth in hand feeling, and high-quality living requirements of hand skin maintenance of people are met.

Owner:陈传喜

Environment-friendly type oil-based ink for ballpoint pen

InactiveCN107216714AComply with limited prohibition requirementsStable and long-term storageInksHandwritingEngineering

The invention provides environment-friendly type oil-based ink for a ballpoint pen. The environment-friendly type oil-based ink is prepared from a thickener, a coloring agent, a dispersant, resin and an organic solvent. The environment-friendly type oil-based ink can be stored for a long period, has good high-temperature and high-humidity oil leakage resistance, is easy for handwriting and has a lubricating hand feeling; the environment-friendly type oil-based ink composition meets the requirements on organic matter limitation and forbidding of European Union EN71part9-2005.

Owner:胡永辉

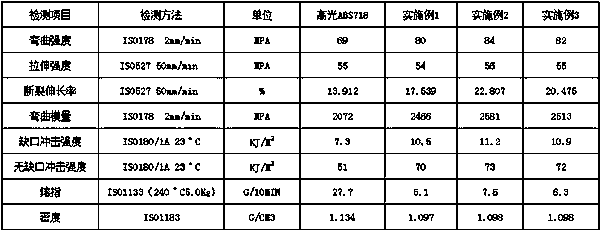

Preparation method of high polymer material special for cosmetic brush packaging

The invention discloses a preparation method for a high polymer material special for cosmetic brush packaging. The preparation method comprises the following steps that 1, raw materials are prepared;2, acrylonitrile-butadiene-styrene plastic and polycarbonate are dried for 3-4 hours at the temperature of 90-100 DEG C and then used for a standby; 3, the raw materials are added in sequence, evenlymixed for 10-15 minutes in a high-speed stirring machine and fed into a twin-screw extruder for sufficient plastification and mixing, and extrusion, cooling, granulation and drying are conducted to obtain the high polymer material. The high polymer material prepared by using the preparation method has the advantages that the static friction of the product is stable, the dynamic friction is uniform, and the product is not prone to abrasion or deformation. According to diversified requirements for the product, more requirements for the structures of the brushes need to be supported by more excellent mechanical properties, and better surface activity is needed for surface painting, gold stamping, printing and the like; due to a better coloring ability, the material facilitates dye dispersion,and a very good color effect is achieved.

Owner:安徽威普达材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com