In-mold anti-counterfeiting label and preparation method thereof

A technology of anti-counterfeiting labels and substrate layers, which is applied in the field of anti-counterfeiting labels in film and its preparation, can solve the problem that the coding on the reverse side cannot be combined with the carrier, etc., and achieves the effect of reducing the deviation of the positive and negative positions and improving the production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

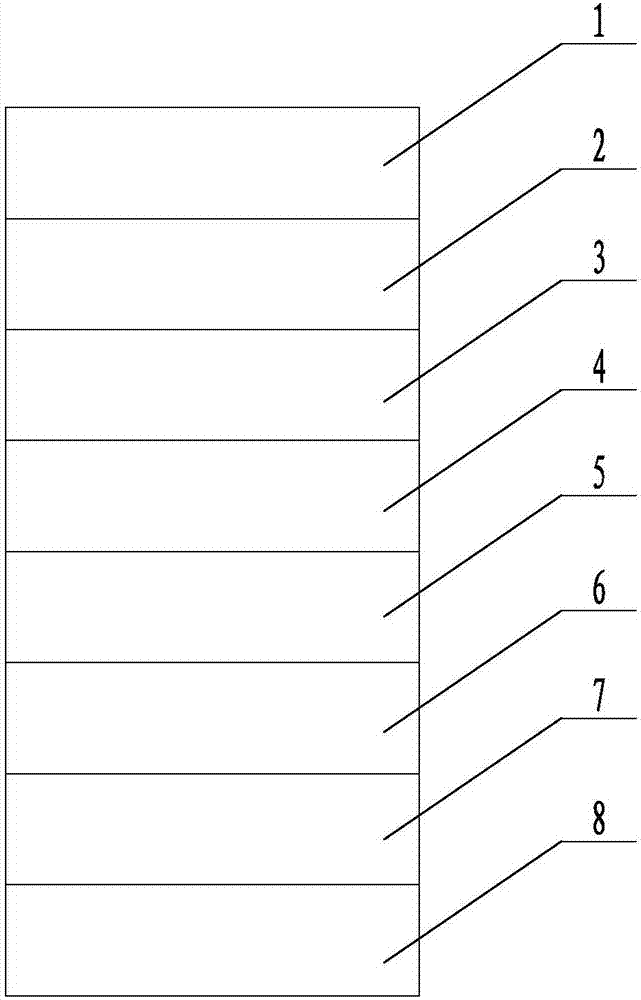

Image

Examples

Embodiment 1

[0032] Customer orders (1 million)

[0033] (1) Selecting a first substrate layer with a thickness of 8 μm;

[0034] (2) The first information layer and the second information layer are given on the first substrate layer by means of front and back printing;

[0035] (3) Use two-component glue to combine the first substrate layer and the second substrate layer together, and cure for 24 hours;

[0036] (4) protective layer protection is carried out on the surface of the first substrate layer;

[0037] (5) Use a coating machine to coat static elimination liquid on the protective layer;

[0038] (6) Coating meltable glue on the second substrate layer;

[0039] (7) Die-cutting: Use an automatic die-cutting machine to cut into individual films and paste anti-counterfeiting labels inside.

Embodiment 2

[0041] Customer orders (2 million)

[0042] (1) Selecting a first substrate layer with a thickness of 50 μm;

[0043] (2) The first information layer and the second information layer are given on the first substrate layer by means of front and back printing;

[0044] (3) The first substrate layer and the second substrate layer are composited together using a two-component adhesive, and cured for 36 hours;

[0045] (4) protective layer protection is carried out on the surface of the first substrate layer;

[0046] (5) Use a coating machine to coat static elimination liquid on the protective layer;

[0047] (6) Coating meltable glue on the second substrate layer;

[0048] (7) Die-cutting: Use an automatic die-cutting machine to cut into individual films and paste anti-counterfeiting labels inside.

Embodiment 3

[0050] Customer orders (3 million)

[0051] (1) Selecting a first substrate layer with a thickness of 120 μm;

[0052] (2) The first information layer and the second information layer are given on the first substrate layer by means of front and back printing;

[0053] (3) The first substrate layer and the second substrate layer are composited together using a two-component adhesive, and cured for 48 hours;

[0054] (4) protective layer protection is carried out on the surface of the first substrate layer;

[0055] (5) Use a coating machine to coat static elimination liquid on the protective layer;

[0056] (6) Coating meltable glue on the second substrate layer;

[0057] (7) Die-cutting: Use an automatic die-cutting machine to cut into individual films and paste anti-counterfeiting labels inside.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com