Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Expensive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Detection of silicon chip state in box and its center relocation method

InactiveCN1794440ALow costExpensiveSemiconductor/solid-state device manufacturingUsing optical meansSilicon chipPhysics

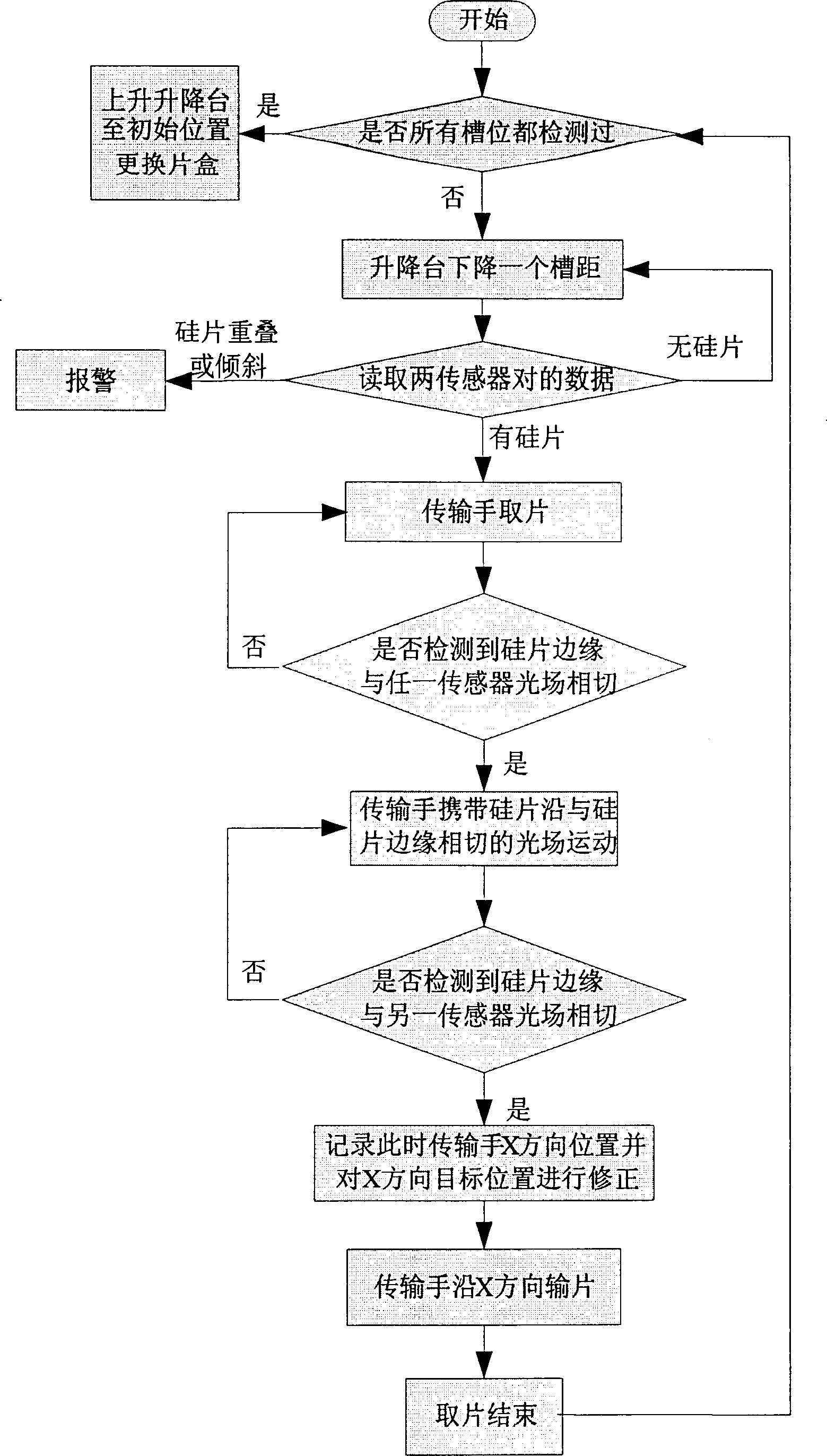

This invention relates to a method for testing a silicon chip state in a box and re-location of its center, in which, the test method includes: designing a light intensity threshold value 10,11, testing the light intensity of any pair of sensors timely of 1S1, if 1S1=!0, then there is no silicon chip, when 10 > 1S1 >11, then there is one, when 1S1 is smaller or equals to 11, there are laminated silicon chips, if the two sensors have different light shading time, then the chips are at the tilted state, the method for re-locating the center includes: when the edges of the chips are tangential to the light-fields of the two sensors at the same time, then the position of a transport mechanical hand on the X direction is P0, when the edges of the chips are tangential to the light-fields of the two sensors, then its position is P1, if P1= P0, then the chips are at the ideal position, if not, the difference between them is the distance should be compensated on the X direction.

Owner:TSINGHUA UNIV

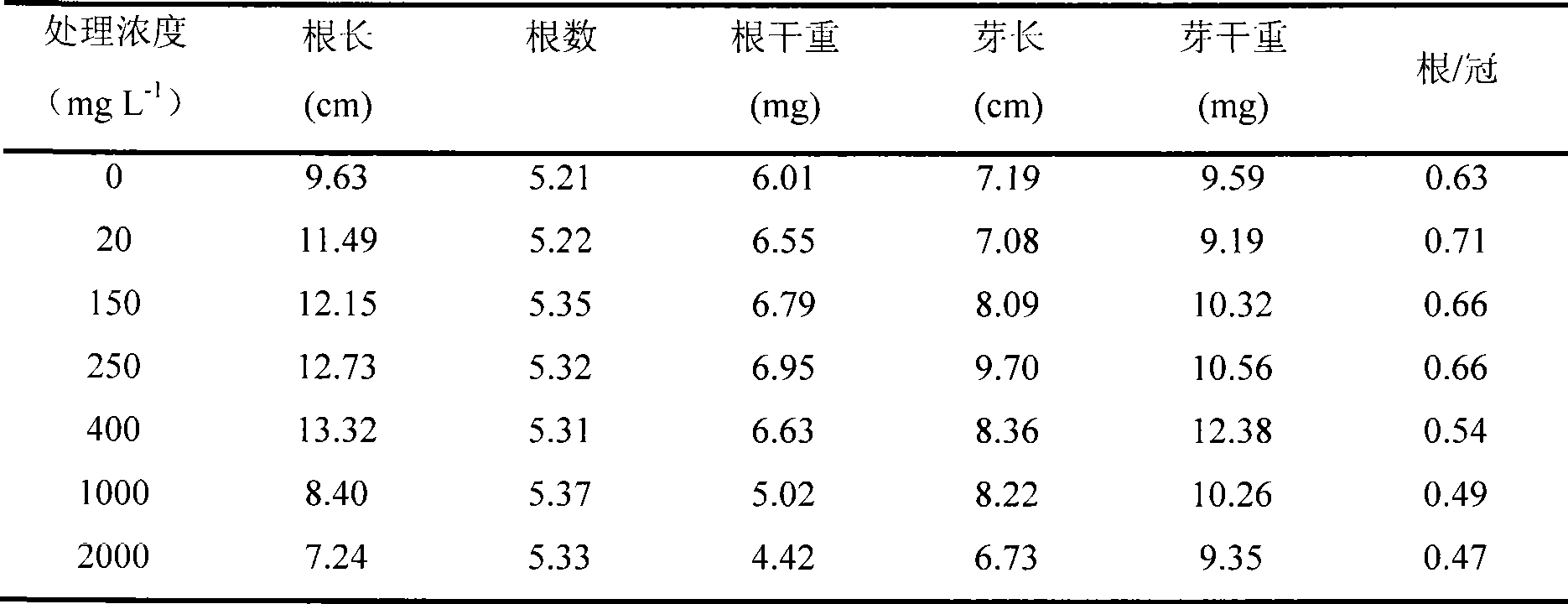

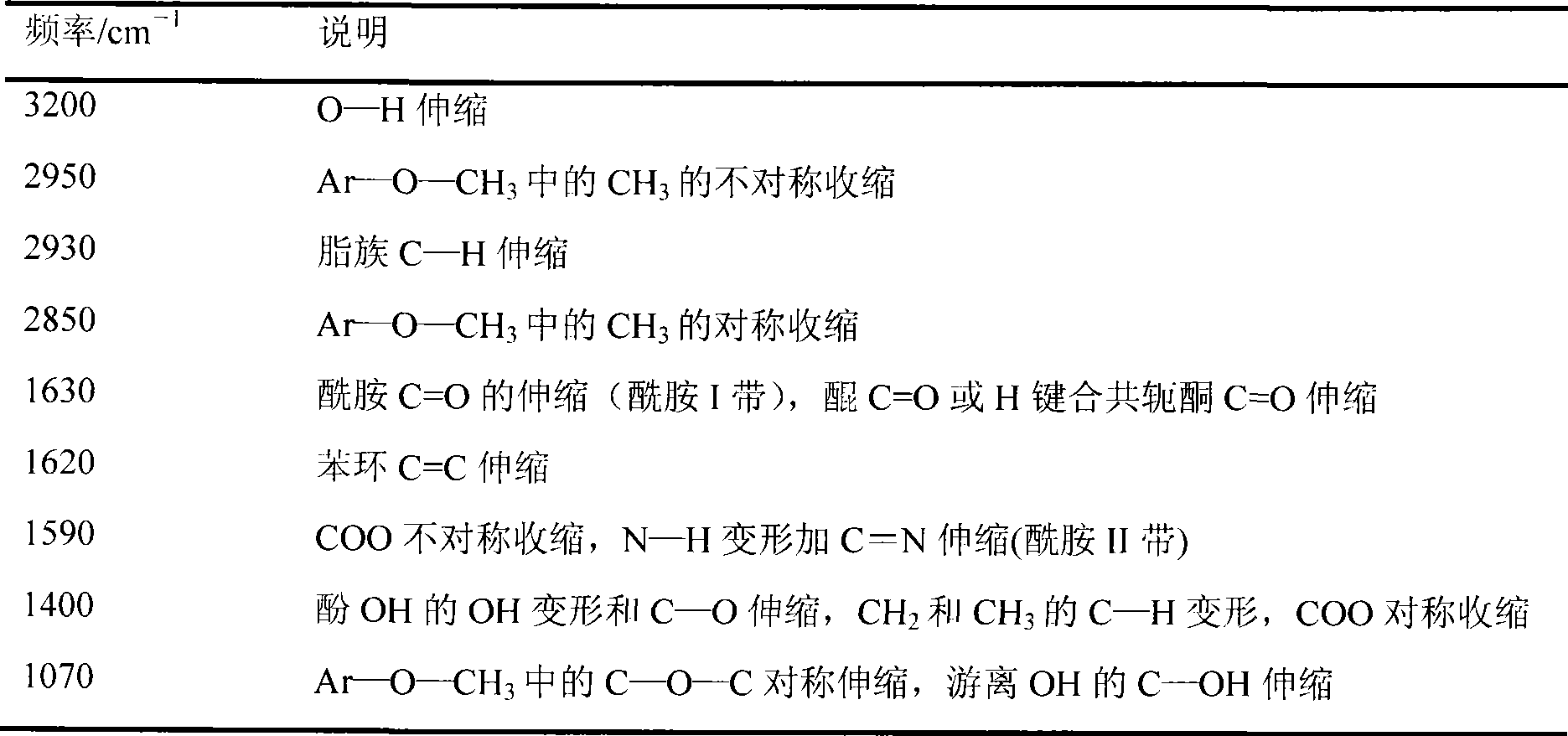

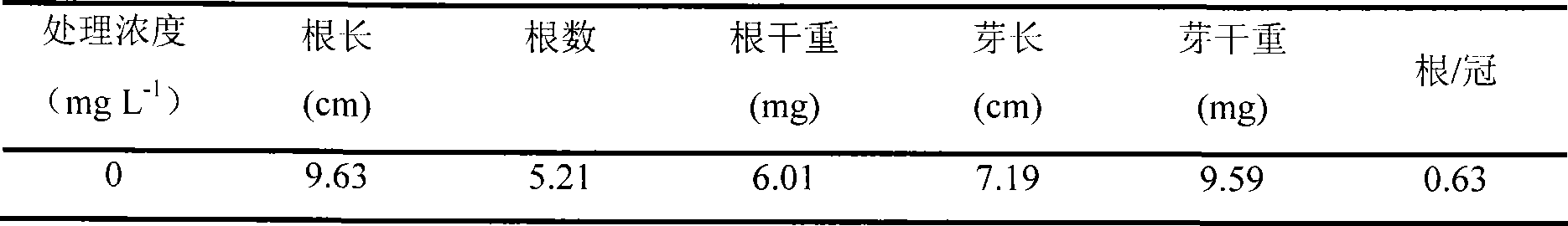

Method for extracting astaxanthin from haematococcus pluvialis

The invention belongs to the technical field of medicines, and relates to a method for extracting astaxanthin from haematococcus pluvialis. The method comprises the steps of culturing a seed stock solution in a glass apparatus with a drainage system, and carrying out later amplification culture of the haematococcus pluvialis and accumulation culture of the astaxanthin after 10-15 d; centrifuging a culture in an exponential growth period of seed culture; and inoculating cell clusters in a BBM basal medium to obtain a primary culture. The later accumulation culture of the astaxanthin is amplification culture by using a breathable plastic bag type simple device provided by the invention. In the accumulation stage, a stress culturing method is adopted to obtain a lab-scale test haematococcus pluvialis culture; and haematococcus pluvialis powder is obtained by spray drying. According to a preparation technology that extracts astaxanthin from the haematococcus pluvialis by adopting an ultrasonic cell disruption assisted mixed solvent extraction method, the haematococcus pluvialis powder is added in an organic solvent to carry out ultrasonic cell disruption, and then the astaxanthin is obtained by the steps of reflux extraction in a water bath, suction filtration, filtrate merging and concentration. Compared with a conventional direct extraction method, the method provided by the invention saves extraction time, and increases astaxanthin yield.

Owner:SHENYANG PHARMA UNIVERSITY

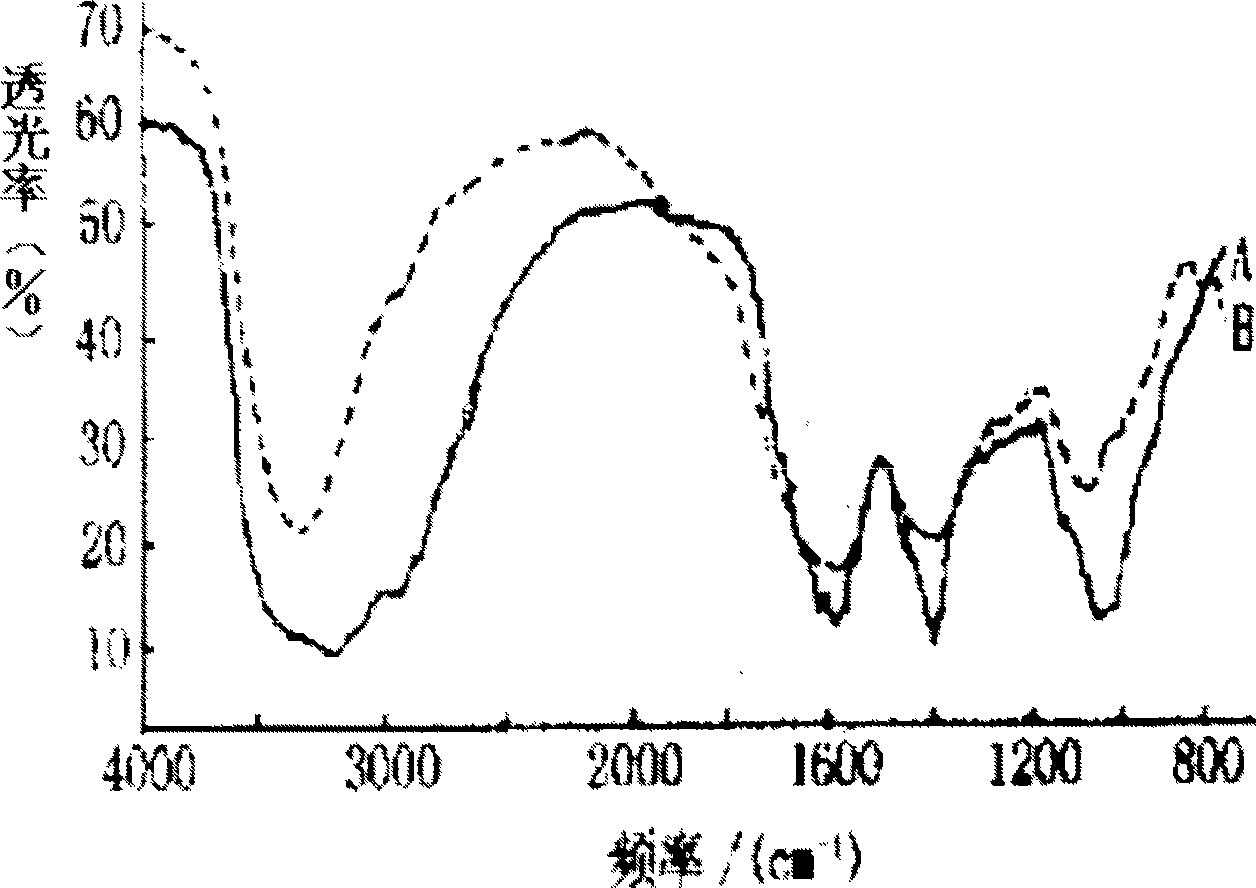

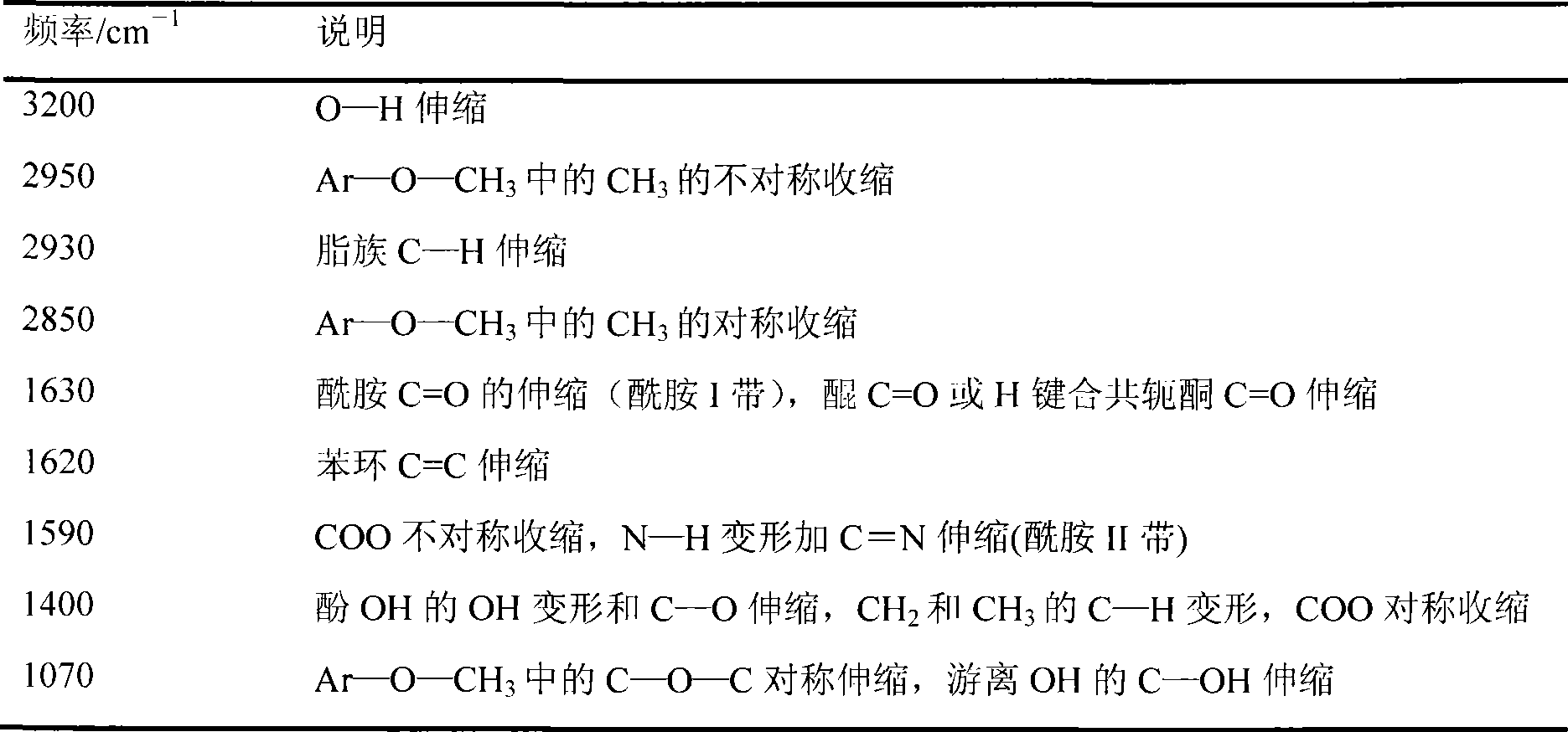

Method for extracting fulvic acid from straw pulp black liquor

The invention provides a method for extracting fulvic acid from straw pulp black liquor, comprising: acid with the conditioning of below pH5 is added into straw pulp black liquor mixed by an alkali process and an ammonium sulfite method so as to separate lignin, later flocculant is added for removing the lignin by filtration, finally the filtrate is the fulvic acid solution; and the fulvic acid solution can also be dried for preparing crude fulvic acid or further purified for obtaining fulvic acid of high purity. The invention can also treat two types of black liquid simultaneously, be used as soil conditioner or water-reducing agent, and can get good economic benefit; the extracted fulvic acid has high price; and the lignin, which is a by-product of the invention, also has wide usage.

Owner:SHANDONG TRALIN PAPER

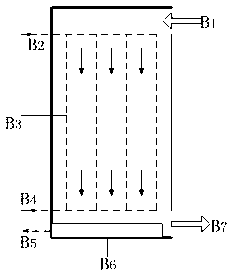

Rice planting method for obtaining rice planted in field with frog

InactiveCN101663979ARich baitHigh in proteinRice cultivationAnimal husbandryRice plantsEcological environment

A rice planting method for obtaining rice planted in a field with frogs belongs to the technical field of the stereo ecological effective production combining scientific planting and culturing. The rice planting method is as follows: frogs are cultivated while rice is planted in the rice field; specific measures are as follows: a waterhole is arranged at a water inlet of the rice field; a ditch isarranged along the periphery of ridge of the rice field; a plastic thin film with 1.2m height surrounds a defensive wall which preventing the frogs from escaping on the periphery of ridge of the ricefield; mound for the wintering of the frogs is arranged in the rice field; after rice is planted in the rice field, the water depth needs to be kept over 3cm; about five thousands of frogs are cultivated per acre. Growing environment of the rice is used for cultivating the frogs which prey on pests and other insects growing in the rice field; excrement of the frogs is used as fertilizer of rice growing. Water body resources and ecology environment of the rice field are fully utilized by cultivating the frogs in the rice field, thus being capable of achieving effects of rice and frog intergrowth and mutual benefit, efficiency improvement and energy consumption. The rice planted in the field with the frogs is pure green superior rice with high grade; and the frogs have very high economicalvalue.

Owner:林贵夫

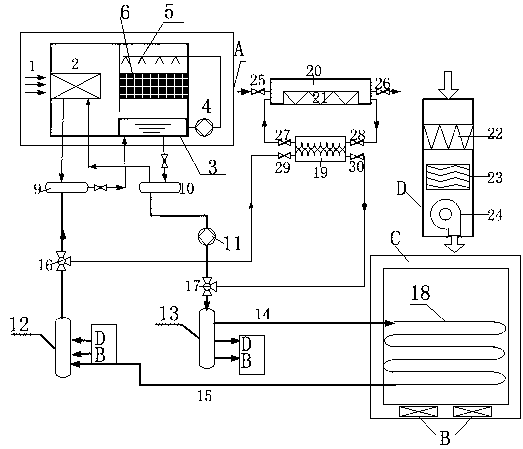

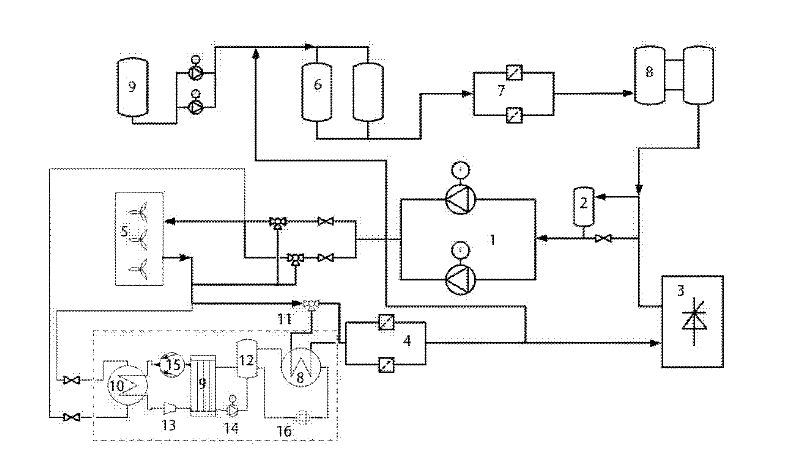

Refrigeration, supply heat and hot water system capable of performing solar evaporative cooling and capillary radiation

InactiveCN103267329ALow costEnergy efficiency is higher than COP valueClimate change adaptationHeating and refrigeration combinationsWater requirementEngineering

The invention relates to a refrigeration, supply heat and hot water system capable of performing solar evaporative cooling and capillary radiation. The refrigeration, supply heat and hot water system is characterized in that a circulation water box in an evaporative cooling system is connected with a water pouring device through a circulation water pump, and the water inlet and water outlet of the circulation water box are respectively connected with the water outlet of a first water collector and the water inlet of a first water knockout drum; the water inlet of the first water collector is respectively connected with the water outlet of an air cooler positioned in an evaporative cooling system and the water outlet of a second water collector, the water outlet of the first water knockout drum is respectively connected with the water inlet of the air cooler and the water inlet of a second water knockout drum, and the water outlet of the second water knockout drum and the water inlet of the second water collector are respectively connected with the water inlet end and water outlet end of a capillary radiation tail end in a room; and a fresh air dehumidifier is communicated with the room, a capillary gravity circulation cabinet is arranged in the room, and the fresh air dehumidifier and the capillary gravity circulation cabinet are respectively connected with the water collector. The refrigeration, supply heat and hot water system provided by the invention has the advantages that the structure is simple, the use is convenient, an energy source is saved, and the fresh air requirements of an air conditioner in winter and summer, the domestic hot water requirements of the whole year and the fresh air requirements of transition seasons are met.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

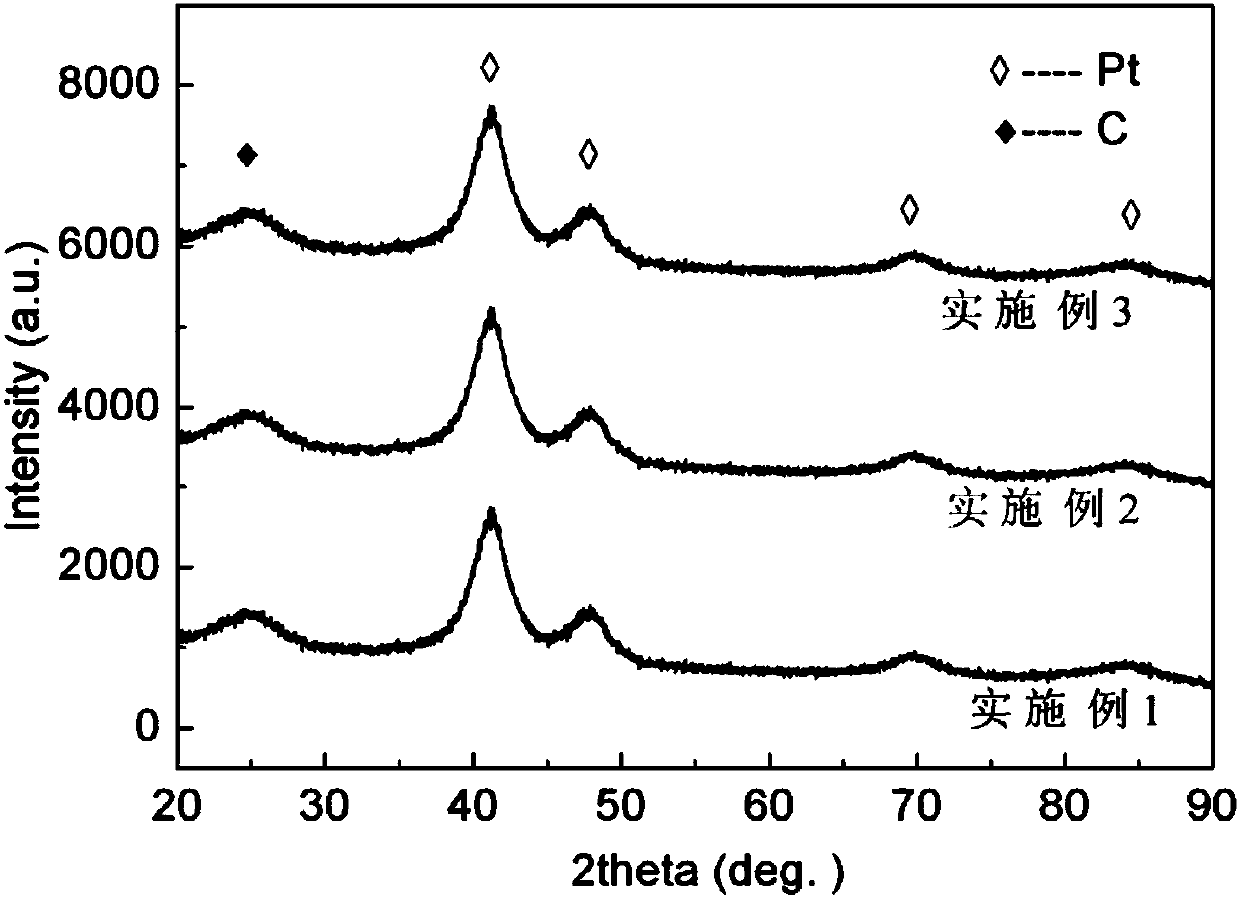

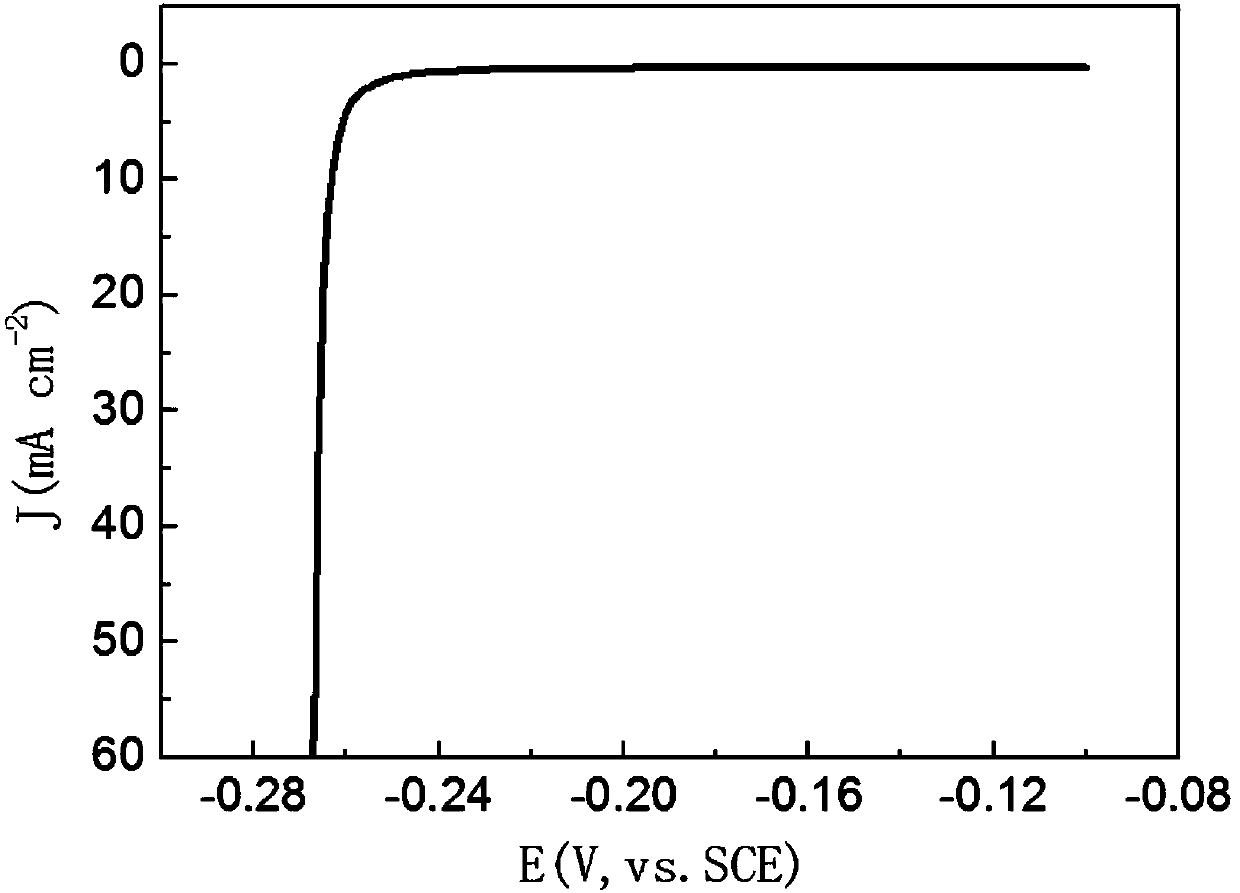

Preparation method for efficiently plaining noble metal and improving electro-catalytic performance thereof

ActiveCN107552044AGood dispersionGood adhesionMetal/metal-oxides/metal-hydroxide catalystsElectrodesElectricityPorous carbon

The invention belongs to the technical field of nano materials and electro-chemical catalysis, and particularly relates to a preparation method for efficiently plaining a noble metal and improving electro-catalytic performance thereof. The preparation method comprises the following steps: uniformly mixing raw materials in a certain element molar ratio, placing into a closed reaction kettle to perform in-situ reduction and loading growth reaction on platinum-based alloy to obtain platinum-based alloy nanoparticles which are uniformly loaded on porous carbon; plaining platinum alloy nano-crystalto obtain a platinum nano-crystalline catalyst which only contains platinum element and is rich in hole and lattice imperfection. The plained platinum nano-particles have the catalytic effect remarkably superior to that of a carbon-loaded platinum catalyst in current commercial application. The nano-crystalline noble metal platinum has the advantages of simple process steps, short flow, adjustable platinum nano-crystalline appearance structure and the like, is easy for large-scale production, and has an important value in the fields of industrial catalyst or other subjects.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

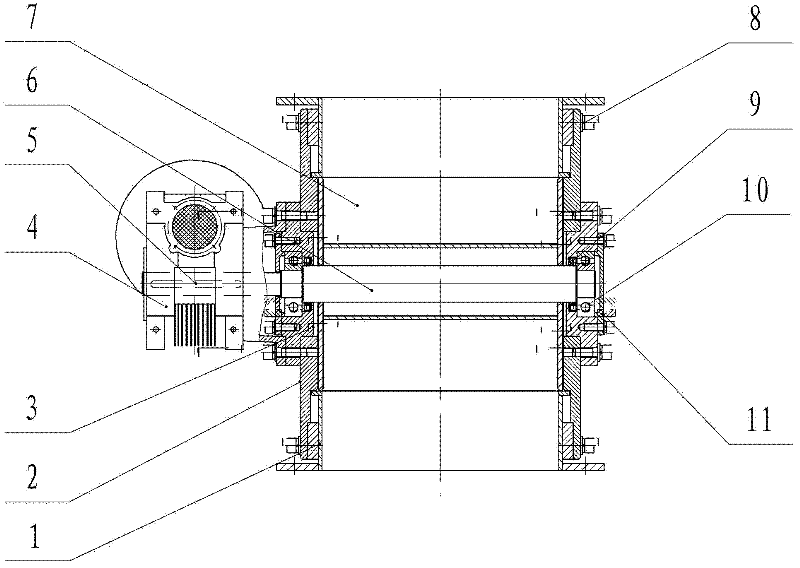

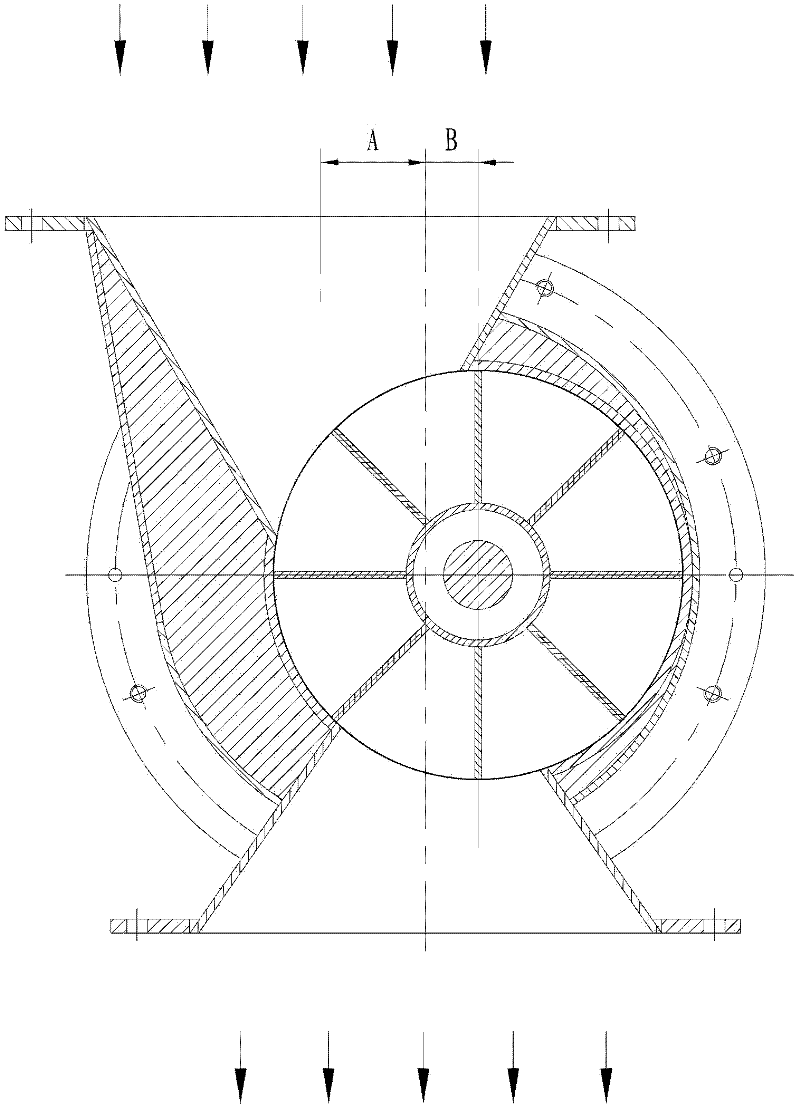

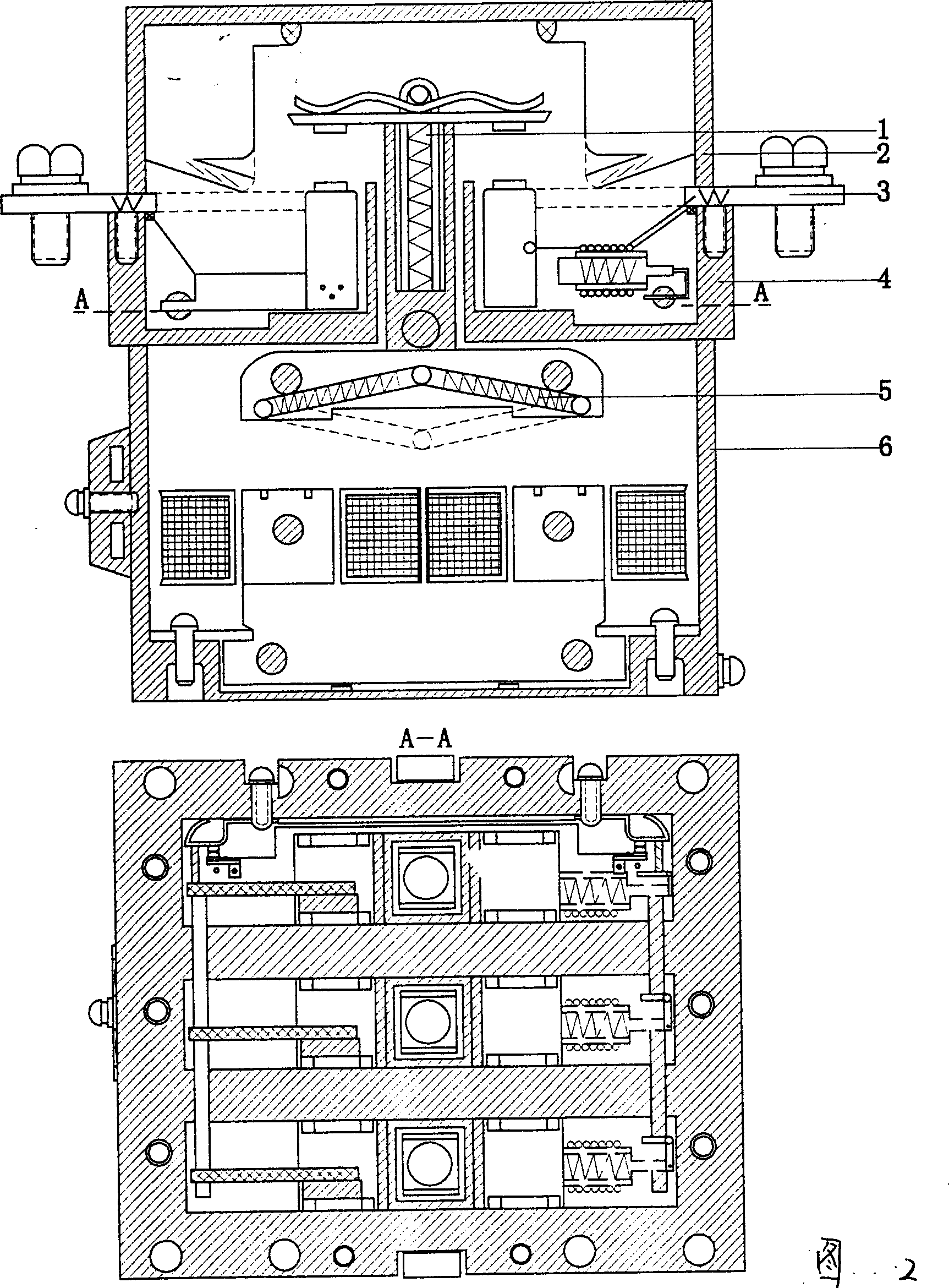

Eccentric star-like cinder valve

InactiveCN102390671AInnovative designCompact structureLoading/unloadingRotary conveyorsMotor speedImpeller

The invention discloses an eccentric star-like cinder valve. The eccentric star-like cinder valve is used for discharging ash and unloading below an ash bucket and a storage bin in the industry such as environmental protection, metallurgy, building materials and the like. The eccentric star-like cinder valve mainly solves the technical problems that materials in a conventional cinder valve cannot be fed uniformly and the like. The technical scheme comprises the main points that: an impeller is arranged in a cavity of an eccentric shell which is similar to a volute shape; bearings are arranged at the two ends of the shell; end covers and the like form approximately closed space with the shell; a material inlet hopper and a material outlet hopper are arranged on the upper surface and the lower surface of the shell; and a material inlet is formed on one side of the radial direction of the impeller and is deviated from the rotation geometric centre of the impeller. The gravity of materials entering the impeller from the material inlet generates tangential force to one side of the impeller, so that the impeller is rotated automatically. A shaft end connected with the impeller is extended out of the shell, and an electromagnetic brake is arranged on the shaft end, so that the impeller is controlled to be rotated according to expected requirements. Or a motor speed reducer is arranged on the shaft end, the motor speed reducer plays a role in boosting when the gravity of the materials is not enough and the impeller is rotated automatically. The cinder valve in the eccentric structure has no air leakage and gas leakage phenomena, can rotate automatically without additional power in general situations, and can fulfill the aim of discharging ash; the power of a matching motor is only 1 / 3 to 1 / 5 of a conventional valve; an energy-saving effect is very obvious; the structure is simple; the manufacturing cost is low; and the eccentric star-like cinder valve is convenient to maintain.

Owner:PINGAN ELECTRICAL

Method for extracting fulvic acid from straw pulp black liquor by ammonium sulfite method

The invention provides a method for extracting fulvic acid from straw pulp black liquor by an ammonium sulfite method, comprising: acid with the conditioning of below pH5 is added into the ammonium sulfite straw pulp black liquor so as to separate lignin, later flocculant is added for removing the lignin by filtration, finally the filtrate is the fulvic acid solution; and the fulvic acid solution can also be dried for preparing crude fulvic acid or further purified for obtaining fulvic acid of high purity. The extracted fulvic acid has expensive price; the lignin, which is a by-product of the invention, also has wide usage; and the invention can also be used as soil conditioner or water-reducing agent, and can get good economic benefit.

Owner:吉林泉德秸秆综合利用有限公司

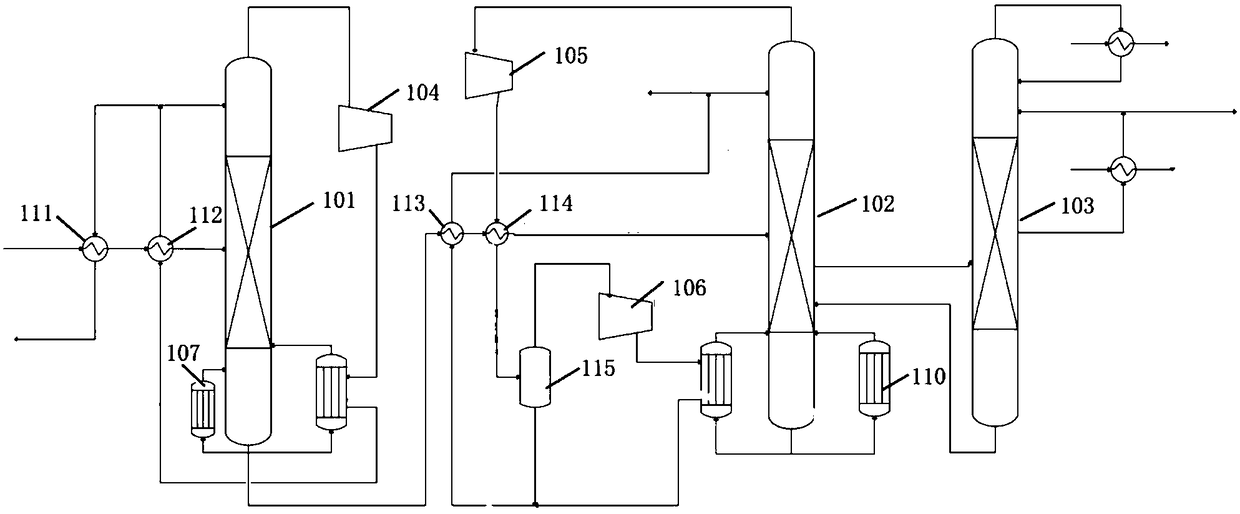

Self-regenerative rectification system and recovery method for dimethylformamide

PendingCN109369444AExpensiveToxicCarboxylic acid amide separation/purificationRecovery methodReboiler

The invention discloses a self-regenerative rectification system for dimethylformamide. The rectification system comprises a dehydrating tower, a refining tower and a deacidification tower and is characterized in that a first compressor is arranged between a steam outlet at the top of the dehydrating tower and a heat source inlet of a reboiler of a tower kettle of the dehydrating tower, a second compressor is arranged between a steam outlet at the top of the refining tower and a heat source inlet of a reboiler of a tower kettle of the refining tower, and a third compressor is further arrangedbetween an outlet of the second compressor and a heat source steam inlet of the reboiler of the tower kettle of the refining tower. Compared with a quadruple-effect rectification system with the sameheat load, the rectification system has the advantages that the number of rectifying towers is decreased to be 3 (the number of rectifying towers of the quadruple-effect rectification system is 5), and the process is shortened; and the self-regenerative rectification system is adopted, by using electric energy, the compressors are driven to compress and heat steam at the tower top to serve as a heat source of the tower kettles, so that a large amount of steam and circulating water are saved, and the operating cost can be saved by more than 14 million yuan every year.

Owner:天津乐科节能科技有限公司

Spray molding production line of oil tank

InactiveCN101698188AImprove protectionPromote cleaner productionPretreated surfacesCoatingsProduction lineAdhesion force

The invention discloses a spray molding production line of an oil tank, which comprises a suspension rack conveying line of an oil tank, wherein the front end of the suspension rack conveying line of the oil tank is provided with an upper component area, and the end of the suspension rack conveying line of the oil tank is provided with a lower component area. The spray molding production line of the oil tank is characterized in that the suspension rack conveying line penetrates through a spray molding chamber, both sides of the bottom of the spray molding chamber are provided with slope faces, the centers of the slope faces are provided with bar-shaped grooves, a plurality of spray molding powder guns are installed at the front side and the back side of the spray molding chamber according to an upper orientation, a middle orientation and a lower orientation and are aligned to different positions of the oil tank hung on the suspension rack conveying line, and the suspension rack conveying line reaches the lower component area after penetrating through a drying chamber at the back side of the spray molding chamber. Molding powder for spray molding can be recovered and recycled, a work site is clean and tidy, and the invention has a protective action to the environment, is also beneficial to the clean production of a workshop, and enhancing the product quality, utilizes high-temperature solidification during spray molding, has stronger adhesion force in comparison with paint and strong hardness, is not easy to cause scratches and also lowers the cost greatly.

Owner:安徽万瑞汽车零部件有限公司 +1

Sesame-flavor blend oil

The invention discloses sesame-flavor blend oil. The sesame-flavor blend oil is prepared from the following raw materials in percentage by weight: 20%-25% of rapeseed oil, 10%-15% of cottonseed oil, 40%-45% of rice bran oil and 20-25% of sesame oil, wherein the sesame oil contains unsaturated fatty acid and amino acid required by a human body, is a first choice among the vegetable oils, and further contains trace elements of iron, zinc, copper and the like required by the human body. The sesame oil is strong in fragrance and relatively high in price, and by being mixed with other common vegetable oil, the blend oil is light in sesame flavor and relatively low in price, and the strong fragrance of the sesame oil does not cover the flavor of the food during cooking.

Owner:广西明华晟粮油科技有限公司

Manufacturing method for coarse-grain austenitic heat-resistance steel material

ActiveCN103846303AExtend the production cycleShorten the production cycleHeat resistanceWater cooling

The invention relates to a manufacturing method for a coarse-grain austenitic heat-resistance steel material, and belongs to the technical field of heat-resistance steel. The manufacturing method comprises the following steps: austenitic heat-resistance steel tubular products and bars are used, wherein the grain sizes of the austenitic heat-resistance steel tubular products are greater than ASTM (American Society for Testing Material) standard 4-level grain size; when the heat-resistance steel tubular product with a ratio of the wall thickness to the inner diameter being 0.2-1.3, the forming through extrusion is directly carried out, and a processing technology of casting, cogging, boring, heating, extruding, heat preservation or hyperthermic treatment and water cooling are adopted; metal bars with coarse-grain austenitic tissues are produced, and a processing technology of casting, cogging, heating, forging, heat preservation or hyperthermic treatment and water cooling is adopted. Technical parameters for controlling are as follows: after the hot extrusion or hot forging deformation is 30%-95%, the final extrusion or final forging temperature is between 1050 DEG C and 1250 DEG C, and the heat preservation is carried out for 2min to 20min and then the water cooling is carried out in a thermal treatment furnace at the temperature of 1150-1250 DEG C. The coarse austenitic tissues with the grain size of greater than the ASTM standard 4-level grain size are obtained.

Owner:CENT IRON & STEEL RES INST

Barrier and explosion-proof skid-mounted device for petrol station

InactiveCN107352499AAvoid heavy pollutionPrevent volatilizationLiquid transferring devicesElectrical conductorPower station

The invention relates to a petrol station device, in particular to a barrier and explosion-proof skid-mounted device for a petrol station. The barrier and explosion-proof skid-mounted device comprises a barrier and explosion-proof petrol storage tank (2), split-type petrol filling machines (10) and control chambers (9) beside the petrol storage tank (2); the petrol storage tank (2) is a double-wall tank, and the petrol storage tank (2) is internally provided with a support (17) which is welded to a skid body (16); a cavity of the double-wall tank is internally provided with petrol-leakage-prevention units (14) and gas detecting alerters (18), and the petrol storage tank (2) is internally provided with a barrier and explosion-proof material (15) which is a column or a sphere of a honeycomb net structure and is made of a metal material; and the barrier and explosion-proof material (15) and the petrol storage tank (2) form a conductor. According to the barrier and explosion-proof skid-mounted device, the petrol storage tank is internally provided with a plurality of cabins, and petrol products of various types can be provided to meet different demands; and the device is of a skid-mounted structure and can be relocated and moved at any moment, the occupied area is small, the station building time is short, the cost is low, use and maintenance are easy and convenient, and the applicable places are wide.

Owner:辽宁易通智能装备制造有限公司

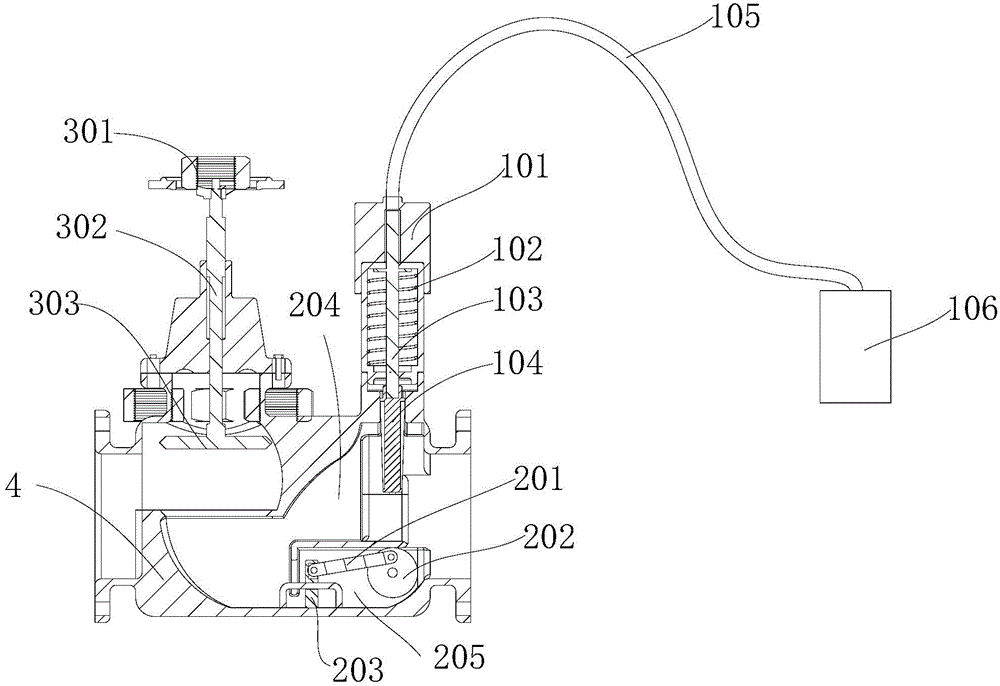

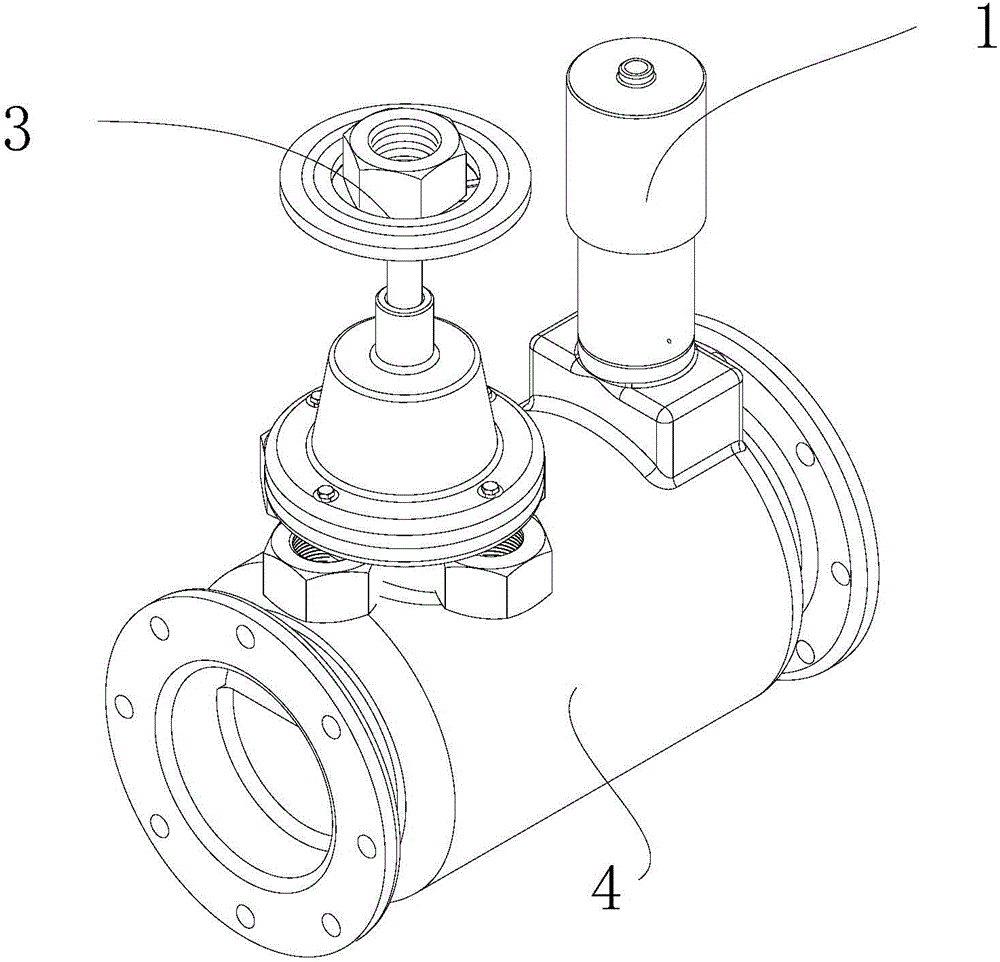

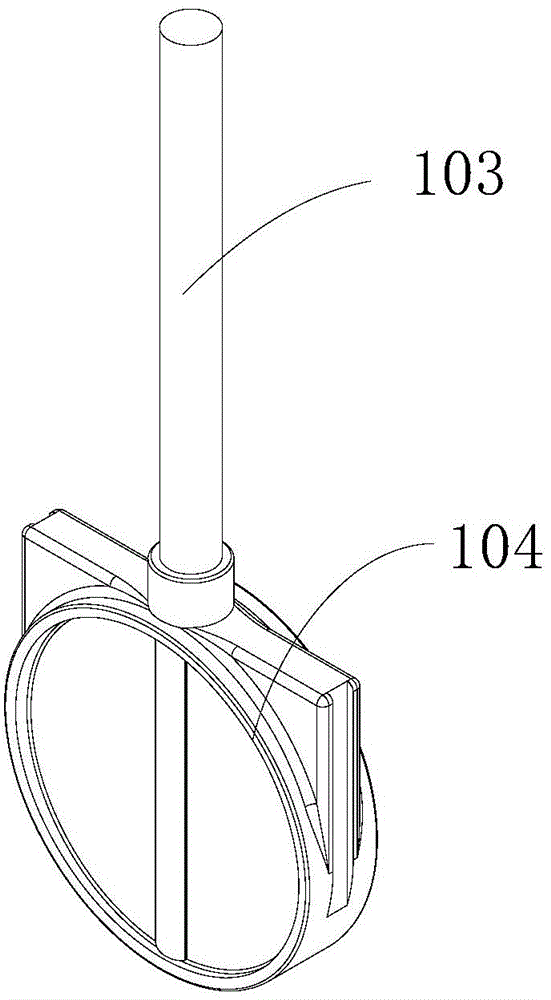

Intelligent adjusting device for circulating water

InactiveCN105485417AExpensivePoor adaptabilityOperating means/releasing devices for valvesPulse flowEngineering

The invention discloses an intelligent adjusting device for circulating water. The intelligent adjusting device comprises a valve body, a self-operated type temperature control part, an automatic pulse flow scouring part and a closing part. According to the intelligent adjusting device for the circulating water, under the premise of achieving the function of a circulating water system, the production cost is reduced, and the functions of descaling and closing are achieved; the water saving effect can be achieved through the intelligent adjusting device for the circulating water; the pulsating flow scouring part can be used for producing pulsating flows, and the growing rate of pipeline dirt can be decreased effectively; the flow closing function can be achieved through the closing part for being replaced on the scene conveniently.

Owner:WUHAN YUDIAN TECH CO LTD

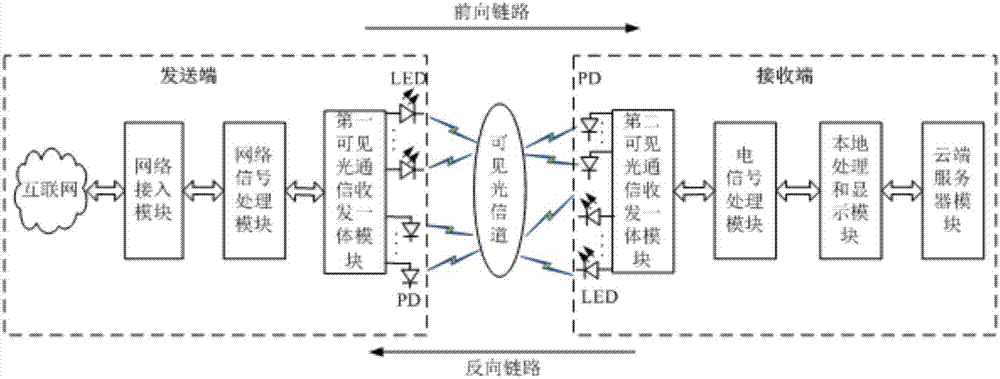

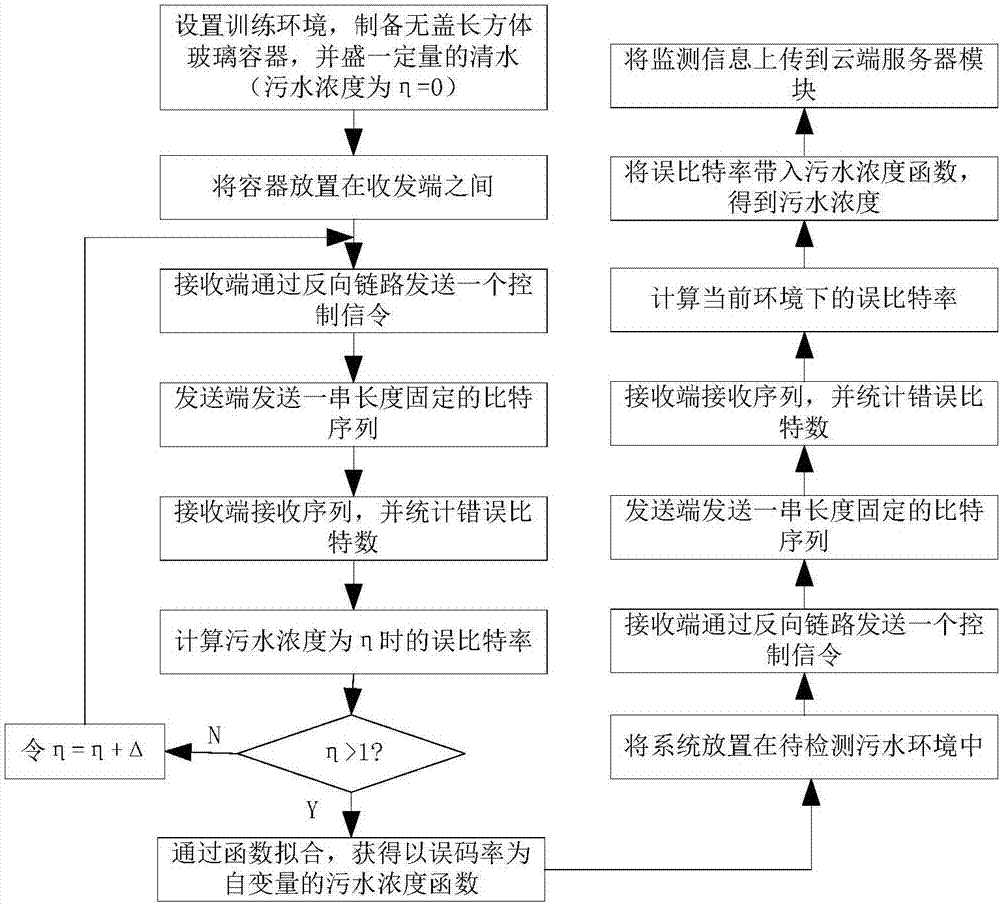

Environment monitoring intelligent visible light communication system and method

ActiveCN107276670ARealize monitoringIncreased bit error rateClose-range type systemsElectromagnetic transmittersComputer hardwareTransceiver

The invention discloses an environment monitoring intelligent visible light communication system and method, having dual functions of data transmission and environmental monitoring and including a network access module, a network signal processing module, first and second visible light communication transceiver modules, an electric signal processing module, a local data processing module and a cloud server module. A network signal enters the network signal processing module via the network access module and is converted into a digital signal and then enters the first visible light communication transceiver module. The signal subjected to electro-optical conversion reaches the second visible light communication transceiver module via a light-emitting diode through a visible light channel. The signal processed by the photodiode is sent to the electrical signal processing module, and a network signal is obtained and sent to a local processing and display module. Environment monitoring is realized by fitting the function of the error bit rate and the pollutant concentration and a result is uploaded to the cloud server module. The system and the method can realize reliable data transmission and monitoring of various environments and realize intelligent transmission of visible light communication.

Owner:南京华睿智光信息科技研究院有限公司

Detection apparatus of leakage point of synthetic gas in cold box for producing hydrogen and carbon monoxide

The invention relates to a detection apparatus of a leakage point of a synthetic gas in a cold box for producing hydrogen and carbon monoxide. The apparatus comprises built-in filters, an external filter, a diaphragm pump and a gas infrared analyzer, the built-in filters are uniformly distributed inside the cold box and are connected with the external filter through pipelines, the pipelines are provided with valves, and the external filter is successively connected with the diaphragm pump and the gas infrared analyzer. Compared to the prior art, the detection apparatus provided by the invention has the advantages of low cost, rapid determination of the leakage point, high reliability and the like.

Owner:SHANGHAI HUALIN IND GASES

Closed type composite cooling system

InactiveCN103476228AMake full use of design capacityReduce dosageCooling/ventilation/heating modificationsCold sideEngineering

The invention discloses a closed type composite cooling system which comprises a cooled device, an air cooler and a cooling water pump. The cooled device, the air cooler and the cooling water pump are connected to form a circulating loop through pipelines, and the system further comprises a first plate heat exchanger, a second plate heat exchanger, a water chilling unit, a cold storage tank, a buffering tank, a first cold pump and a second cold pump. The heat side of the first plate heat exchanger and the heat side of the second plate heat exchanger are connected in the circulating loop in series. The first cold pump, the water chilling unit, the cold storage tank and the buffering tank form a cold storage loop. The first cold pump, the water chilling unit, the cold side of the first plate heat exchanger and the buffering tank form a first cold releasing loop. The second cold pump, the cold storage tank and the cold side of the second plate heat exchanger form a second cold releasing loop. The design temperature of the closed type composite cooling system can be obviously lower than the ultimate temperature of the place, the structure is compact, the using number of air heat exchangers is reduced, the design capacity of the air cooler is fully utilized, cost is lowered, and the application region of the closed type circulating pure water cooling system is widened.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +1

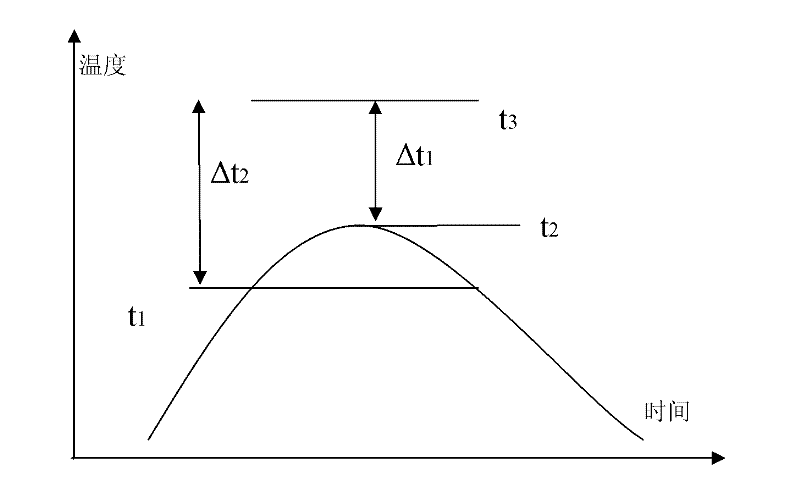

Peak-clipping closed circulating pure water cooling system

InactiveCN102421276AMake full use of design capacityLower design temperatureCooling/ventilation/heating modificationsSystems designEngineering

The invention discloses a peak-clipping closed circulating pure water cooling system. The system comprises an auxiliary circulation loop and a refrigerating circuit; the auxiliary circulation loop is connected with the closed circulating pure water cooling system through a three-way valve; the auxiliary circulation loop can carry out heat exchange with the closed circulating pure water cooling system; the refrigerating circuit is connected with the auxiliary circulation loop and carried out heat exchange with the auxiliary circulation loop; and the refrigerating circuit is connected with an air cooler and carries out heat exchange with the air cooler. According to the peak-clipping closed circulating pure water cooling system provided in the invention, the design temperature can be obviously lower than a local limiting temperature; the structure is compact; a using amount of an air heat exchanger can be reduced; a design capacity of the air cooler can be fully utilized; and costs are reduced; therefore, an application range of the closed circulating pure water cooling system can be expanded.

Owner:GUANGZHOU GOALAND ENERGY CONSERVATION TECH

Safe, environmentally-friendly, efficient, herbicidal, insecticidal, and bactericidal particle and preparation method thereof

InactiveCN108308202AIncrease costOvercome the disadvantages of prone to drug resistanceBiocidePlant growth regulatorsDrug resistancePlant disease

The invention discloses a safe, environmentally-friendly, efficient, herbicidal, insecticidal, and bactericidal particle and a preparation method thereof. The particle comprises following raw materials in parts by weight: 10 to 14 parts of plant originated herbicidal additive, 40 to 50 parts of sustained-release filling earth, 5 to 7 parts of plant oil, 1 to 2 parts of sodium humate, 7 to 11 partsof insecticidal aid, 0.1 to 0.4 part of herbicidal enhancer, 1 to 3 parts of white carbon black, 4 to 6 parts of modified bamboo charcoal, and 3 to 5 parts of adhesion promoter. The provided particlecan kill bacteria, insects, and weeds, is capable of conditioning the soil, has a long effect, can effectively prevent and treat common plant diseases, and is environmentally-friendly, safe, and efficient; drug resistance is difficult to generate; and at the same time, the provided preparation method has the advantages of low production cost, simple technology, high practical value, and good application prospect.

Owner:合肥卓畅农业科技有限公司

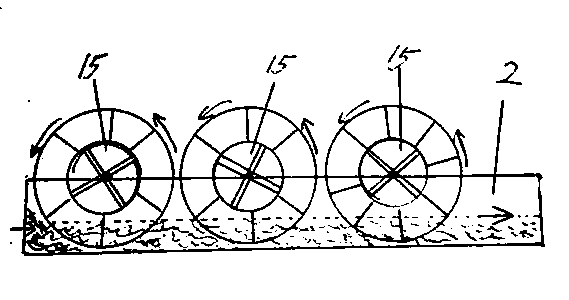

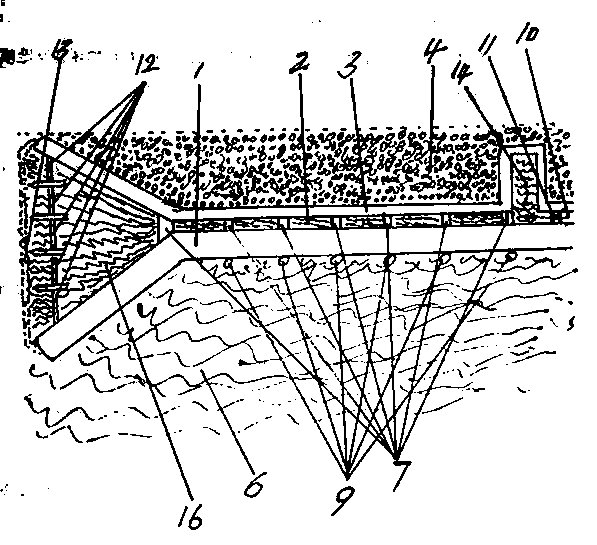

River levee for flood control and power generation

The invention discloses a river levee for flood control and power generation. The river levee comprises a water-retaining wall (1), a drainage channel (2) and a soil-retaining wall (3), wherein the water-retaining wall and the soil-retaining wall are connected with a fixed beam (7), a pressurized water channel (8), a tail water collecting pit (14), a flaring water intake (16) and a subsequent project reserved port (10); the river levees for flood control and power generation are constructed on both sides of a river from the upstream to the downstream by the depth of more than 4 meters of a first riverbed (5) at the position of a riverway (6) on the basis of the existing river levees (4); a waterwheel type hydroturbine (15) erected on the drainage channel (2) is pushed to rotate by virtue of the head formed between the ground and the underground, and then a generator is driven to rotate by use of a speeder, and therefore, the purpose of power generation is achieved. The river levee for flood control and power generation has the advantages of no demand on diversion channel construction, avoidance of river closure, no inundated area, no requirement on immigration, no influence on normal shipping, great reduction of construction period and construction cost, and the like.

Owner:杨德林

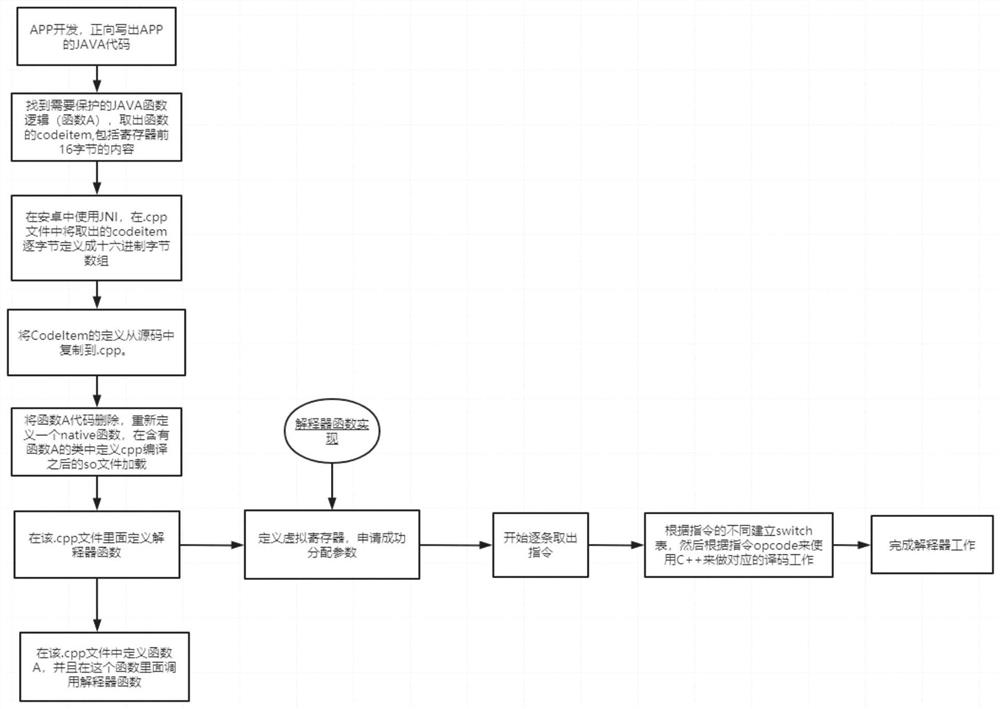

Method and system for realizing VMP protection at Android end

ActiveCN113127004ALittle impact on performanceReduce risk of leakageSoftware maintainance/managementCode compilationStart timeJava

The invention provides a method for realizing VMP protection at Android end, which comprises the following steps of S1, developing an application function by using a JAVA function, compiling the JAVA function or a JNI function to generate a. Cpp format file of a so file, and naming the. Cpp format file as pro.cpp; s2, defining a function A, and copying CodeItem of the function A; s3, deleting all codes of the function A, and defining a JNI function with the same name as the function A under the category of the function A; s4, copying the definition of CodeItem in the source code of the Android system to the cpp file; s5, defining a function A and an interpreter function in the cpp file, and calling the interpreter function in the function A; step S6, converting the byte array of the CodeItem into the CodeItem defined in the cpp file in an interpreter function, and then defining a virtual register; step S7, taking out the instructions in the CodeItem one by one; step S8, compiling the APK through a compiler. According to the invention, the VMP protection of the APP can be completed at the start time of the APP.

Owner:福建省天奕网络科技有限公司

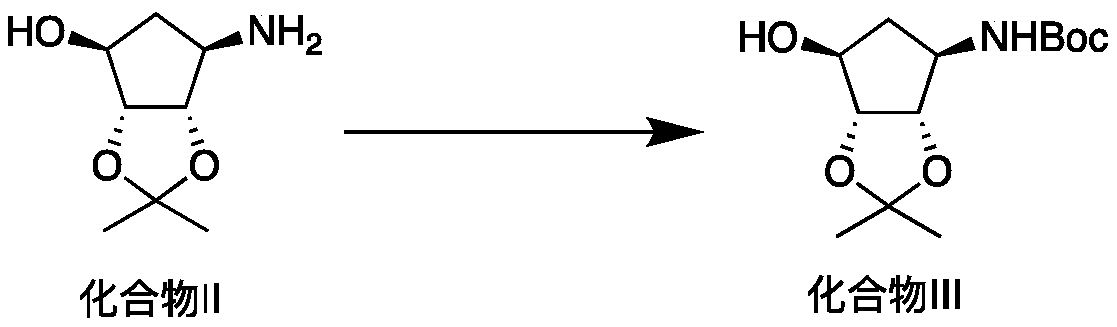

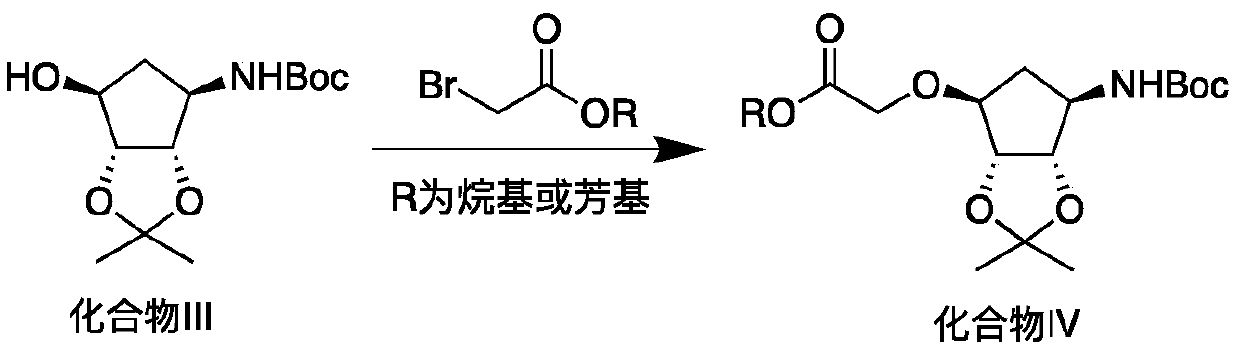

Production method of key intermediate of ticagrelor

ActiveCN110627765AExpensiveThe preparation process is economical and environmentally friendlyOrganic chemistryDi-tert-butyl dicarbonateCombinatorial chemistry

The invention discloses a production method of a key intermediate compound I of ticagrelor. The production method comprises the following steps: (1) subjecting a compound II and di-tert-butyl dicarbonate to a reaction to obtain a compound III; (2) subjecting the compound III and 2-bromoacetate to a reaction, and conducting recrystallization to obtain a compound IV; (3) subjecting the compound IV to the action of a reducer to obtain a compound V; and (4) subjecting the compound V and a Boc removal reagent to obtain the compound I. Compared with the prior art, the production method of the key intermediate compound I of the ticagrelor has the advantages that the technology is simple, the purity of a finished product is high, the production cost is low, industrial production is easy, and the like.

Owner:ZHEJIANG LEPU PHARMA CO LTD

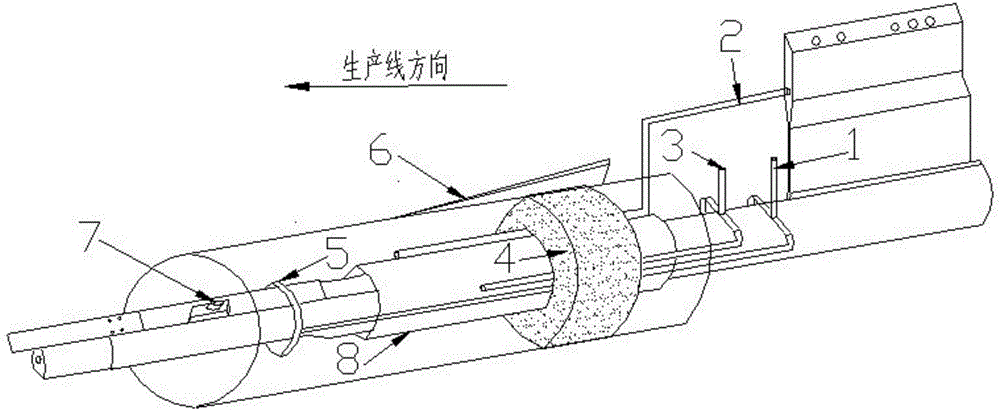

Water curtain argon integrated welding protection device in high frequency longitudinally welded pipe

ActiveCN105014267AWide range of pipe diametersImprove the utilization rate of argonWelding/cutting auxillary devicesAuxillary welding devicesEngineering

The present invention provides a water curtain argon integrated welding protection device in a high frequency longitudinally welded pipe. Inner burr mandrels, a first water curtain protection water inlet, an arbor impedance upper part slag cleaning water pipe and an argon inlet are fixed to the arbor of the device through screws. A first water curtain protection is connected to the inner burr mandrels respectively, a second high temperature cotton protection is fastened at the periphery of the inner burr mandrels through a sealant, and the first water curtain protection and the first water curtain protection water inlet are fixedly connected through a bolt. The device has the advantages that the device is suitable for the high frequency longitudinally welding production of a large span pipe diameter stainless steel with the diameter of 108mm to 660mm, a high silicon pipe line steel and other material, the argon directly acts the inside of a pipe body, and the utilization rate is high. According to the device, the consumption of a protection gas is 1 / 4 of an original consumption, the replacement frequency of the protection gas is reduced, since the protection gas is expensive, the production cost is greatly reduced, and when a production pipe diameter is larger, the cost reduction is more obvious.

Owner:TIANJIN PIPE GROUP CORP

Manufacturing method of semi-steel engineering tire

The invention relates to a manufacturing method of a semi-steel engineering tire. The manufacturing method includes the steps of primary forming, secondary forming and vulcanizing. Primary forming specifically includes the following steps of (1) nylon rubber strip preparing and tire body forming, (2) toe opening steel wire ring forming, (3) toe opening steel wire ring bucking and rubber coating, and (4) shoulder wedge fitting. Secondary forming specifically comprises the following steps of (5) gas-tight layer fitting, (6) belted layer fitting, (7) tread fitting, and (8) sidewall fitting. The manufacturing method overcomes the defects of poor heat dissipation, poor puncture resistance and poor abrasion resistance caused by the fact that all skeleton materials of a bias tire are nylon threads and the defects of thin sidewall prone to being scratched, high cost and expensive price caused by the fact that all skeleton materials of an all steel radial tire are steel wires; the effects thatsidewalls of the tire are thick, a tire body is high in strength, scratching preventing is achieved, heat dissipation of the tread is good, and puncture resistance and abrasion resistance are achievedare achieved; and in addition, a toe opening steel wire ring is made of graphene steel wires, a belted layer is a graphene steel wire belted layer, so that high strength, fast heat conduction and lowweight are achieved.

Owner:黄果树科技有限公司

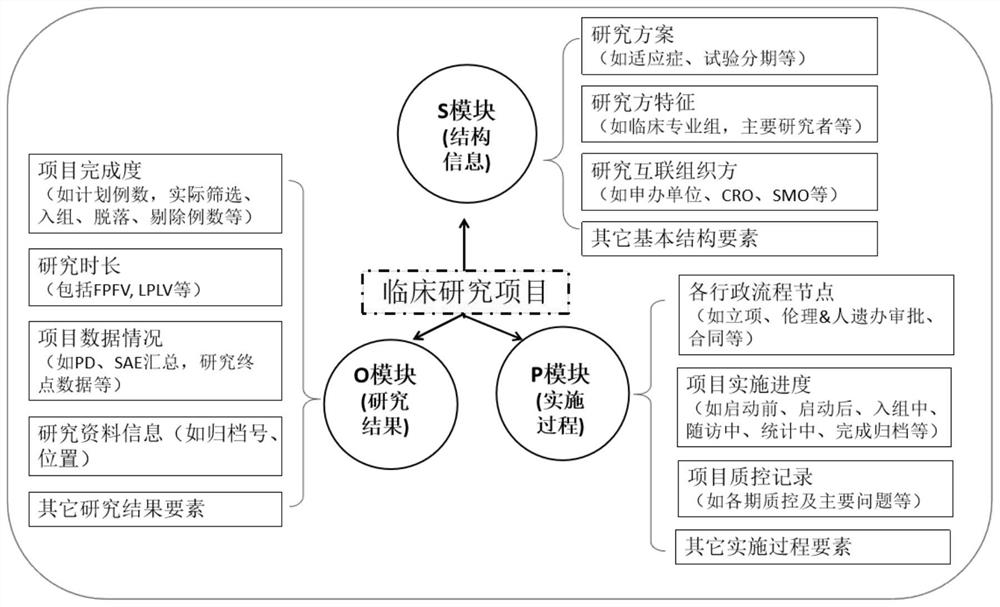

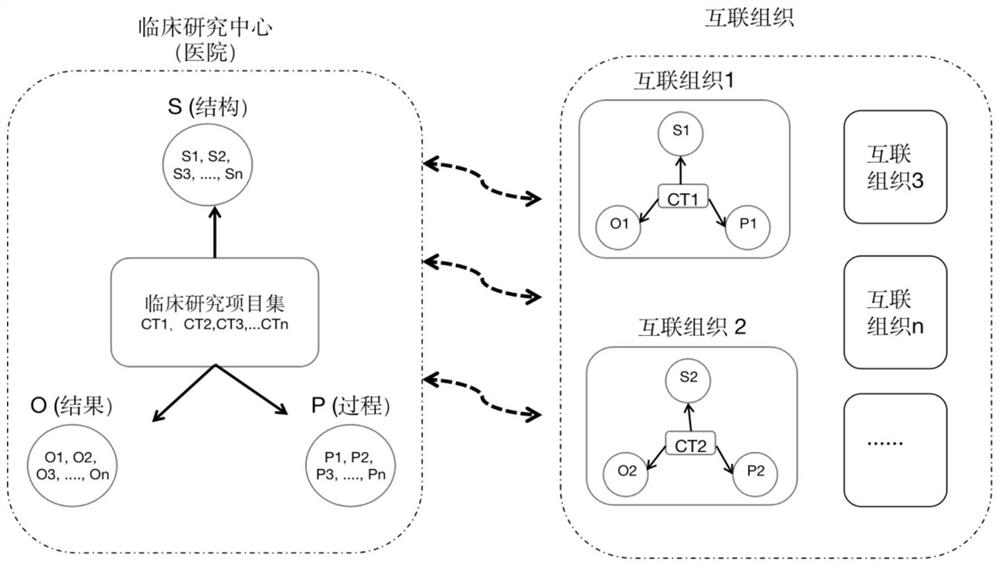

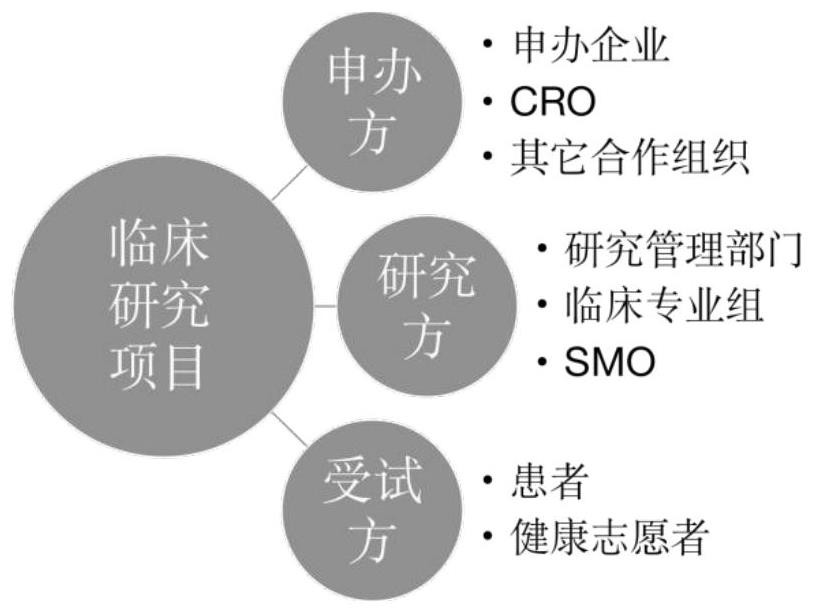

Clinical research SPO quality management method and system based on aPaaS

PendingCN114242189AExpensiveMedical data miningDatabase management systemsSoftware designClinical research

The invention relates to a clinical research SPO quality management method and system based on aPaaS, and belongs to the field of computers. The method comprises the following steps: S1, establishing SPO quality dimension elements of clinical research, namely quality element modules on three dimensions of a structure S, a process P and a result O of a project; s2, constructing an SPO basic database relationship on the aPaaS platform; s3, deploying a localization system of the research center; and S4, integrating the SPO shared data chain set of each project, implementing interactive management, and improving the project quality. The invention relates to a lightweight, simple, convenient, shared and interactive quality management method and system, which can be used for solving the problems that a current clinical research quality management information system is designed by IT personnel of a professional software company, a designer is unfamiliar with a clinical test, software design is complex, operation is tedious, training time is long, updating is troublesome, and efficiency is high. And software price is high, data information is difficult to share, and project management is lagged.

Owner:THE FIRST AFFILIATED HOSPITAL OF SOOCHOW UNIV

Tin-based fade-resistant anti-brittle-fracture with pure gold color imitation 24K gold

The invention discloses a tin-based fade-resistant anti-brittle-fracture with pure gold color imitation 24K gold. The alloy comprises the following components of, by weight, 0.2-0. 4 wt.% of P, 1.5-1.8 wt.% of Ti, 0.6-0. 8 wt.% of Mo, 4.0-6.0 wt.% of Cu, 0.4-0.6 wt.% of Y, 2.0-4.0 wt.% of Sb, 0.1-0.3 wt.% of C, and the balance tin. The invention provides a cheap and fade-resistant tin-based alloywith the color of 24K gold for the decoration industry in China, and the situation that most of the conventional imitation gold alloys are copper-based alloys is broken through. The production cost isreduced, and the problem in the field is effectively solved. It is expected that the implementation and industrialization of the material can obtain good economic and social benefits.

Owner:GUANGZHOU YUZHI TECH CO LTD

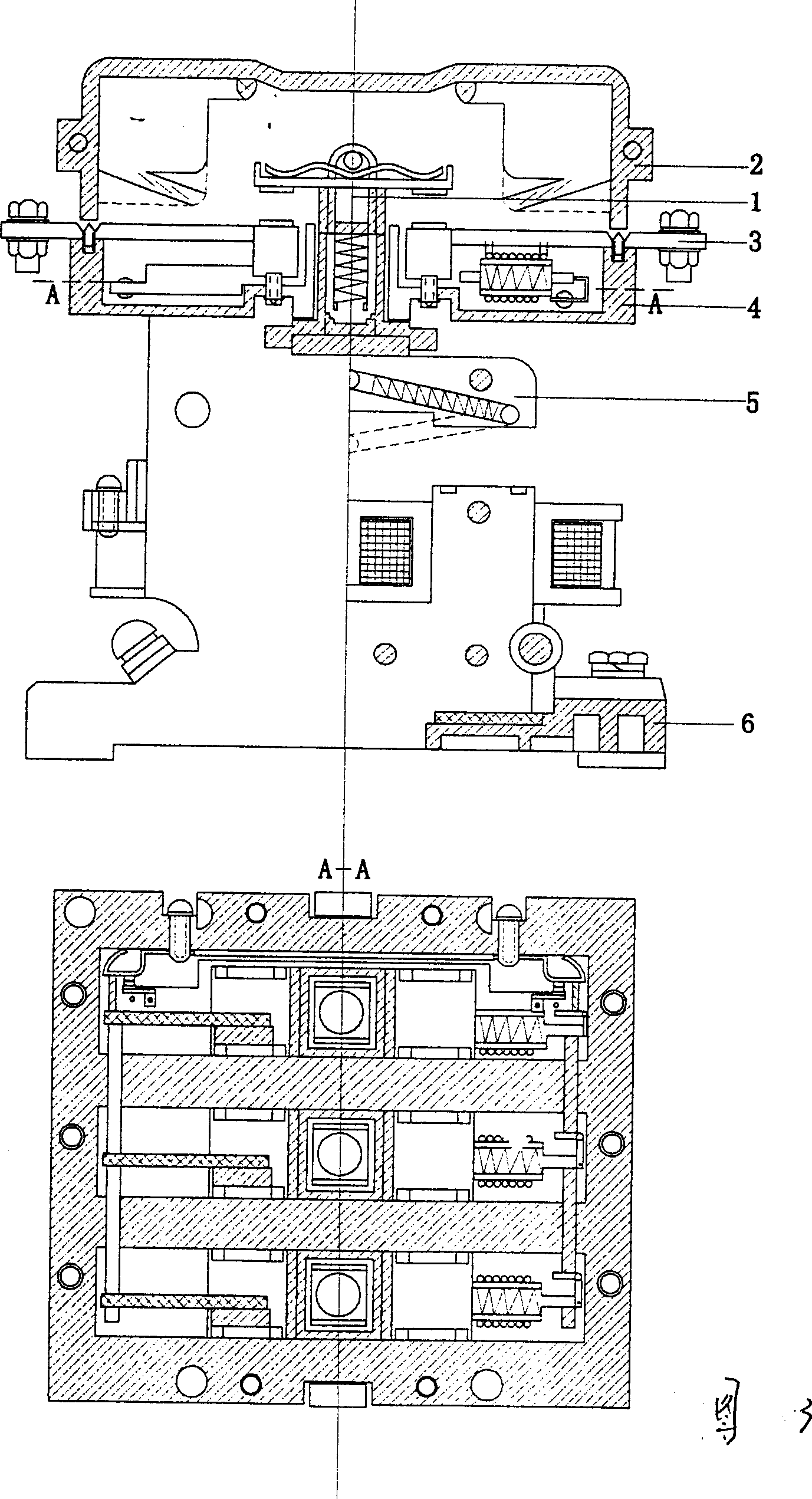

Contact protector

InactiveCN1495821AOvercome the disadvantage of not having self-protectionEasy to operateCircuit-breaking switches for excess currentsElectromagnetic relaysLow voltageEngineering

The present invention belongs to the field of low voltage apparatus. Its technical key lies in characteristic combination of on-off and protection, forced point of elastic force and counterforce combination and arc-extinguishing and vibration absorption. It is a direct-acting double-break contact three-layer stereo-arrangement, its structure is compact, the contact and protection element are connected together, and have the double functions of switch and protection. It can be used in the power circuit whose frequency is AC 50(60)Hz, voltage is to 670V (1200V) and current is 6A-4500A, and has the protection action for overload, low-voltage, short-circuit and open-phase in the circuit, and can be used for protecting electric equipments of motor, etc.

Owner:黄信琰

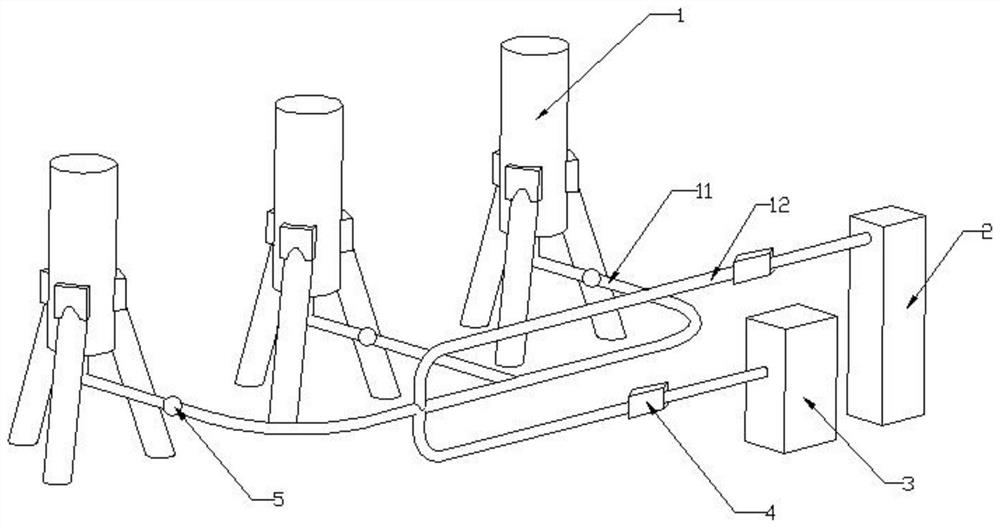

Centralized water supply device for sand washer

PendingCN113560248AExpensiveMaterial requirements are highCleaning using liquidsWater useElectromagnetic valve

The invention discloses a centralized water supply device for a sand washer. The centralized water supply device comprises a plurality of sand washing towers, a first water pump and a second water pump. The first water pump and the second water pump are connected to the interior of a main pipe through respective water supply pipes, and one-way valves are arranged in the water supply pipes. The main pipe is connected with the sand washing towers through a plurality of water conveying branch pipes, and electromagnetic valves are arranged on the water conveying branch pipes. In the system, the two water pumps are connected in parallel, and therefore the multiple sand washing towers can be connected; and through the manner of increasing and decreasing the water conveying branch pipes, the multiple sand washing towers can be theoretically connected in parallel, each sand washing tower is connected with the two water pumps, and accordingly the water using requirement of the sand washing towers is met.

Owner:扬中磊金建材有限公司

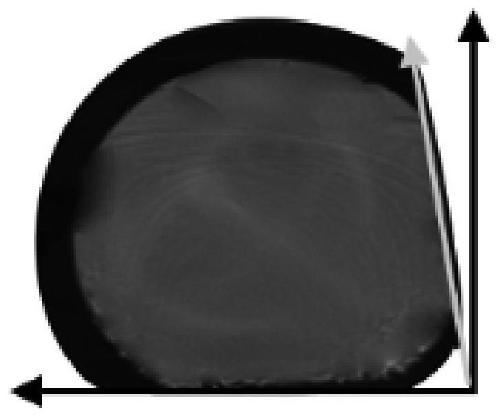

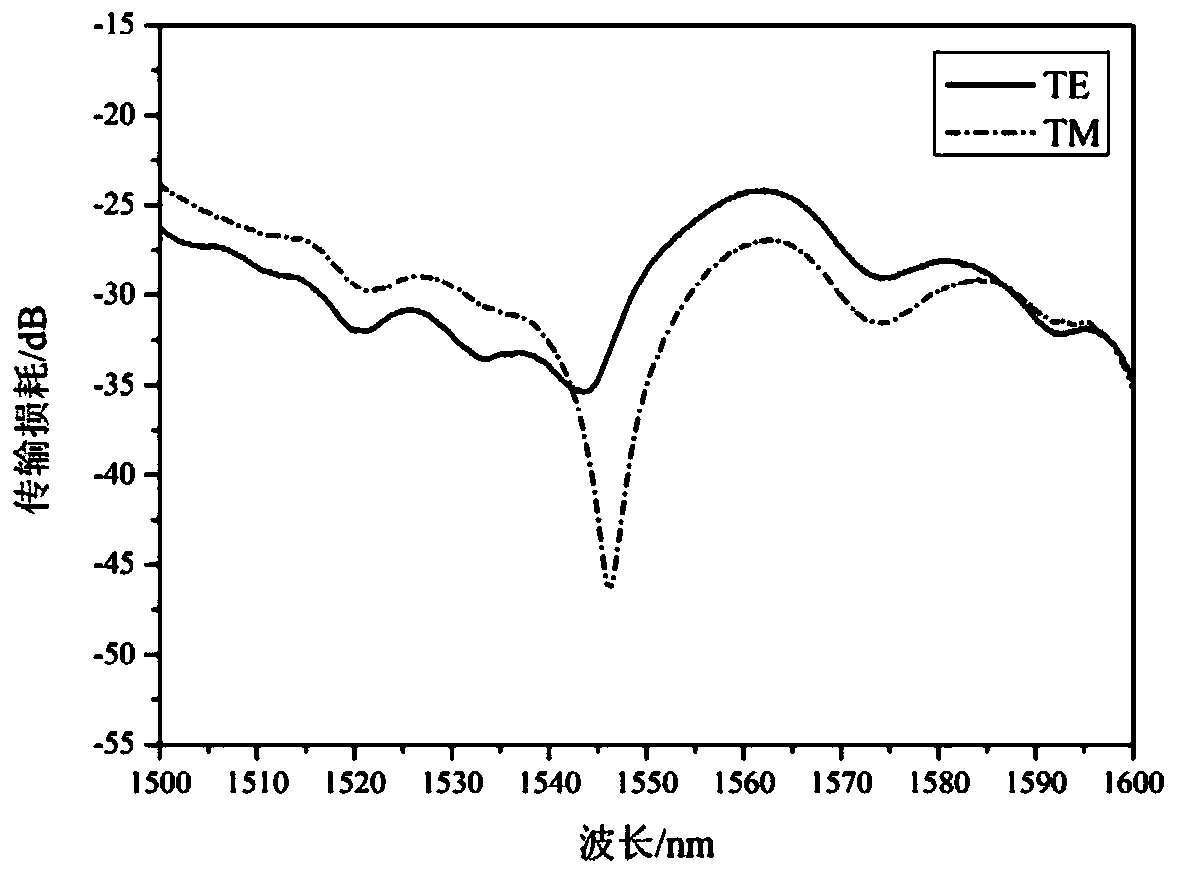

Processing method to obtain asymmetric waveguide structure through processing on optical fiber

InactiveCN111251096AExpensiveEasy to processGrinding feed controlPlane surface grinding machinesEngineeringWaveguide

The invention discloses a processing method to obtain an asymmetric waveguide structure through processing on an optical fiber. The processing method comprises the following steps of 1, briefly processing the optical fiber to be processed; 2, installing abrasive paper on a roller of polishing and grinding equipment; 3, setting a polishing-grinding depth and a polishing-grinding length of the polishing and grinding equipment, and setting a proper rotating speed of the roller; fixing the optical fiber on an optical fiber clamp; 4, monitoring the polishing-grinding depth in real time through a CCD, and carrying out two-face polishing and grinding; and 5, flatly fixing a sample on a glass slide. According to the processing method, the fiber core diameter of the multimode optical fiber used is105 mu m, and the cladding diameter is 125 mu m; an asymmetric structure construction method is adopted, used materials are low in manufacturing cost, machining procedures are easy to master, repeatability is good, and accordingly quantitative production can be realized; and besides, an original circular symmetrical structure of the optical fiber is destroyed in the method, so that the asymmetricwaveguide structure has certain polarization dependence so as to own potential values for being used as a polarization control device.

Owner:苏州凯文堡尼光电科技有限公司

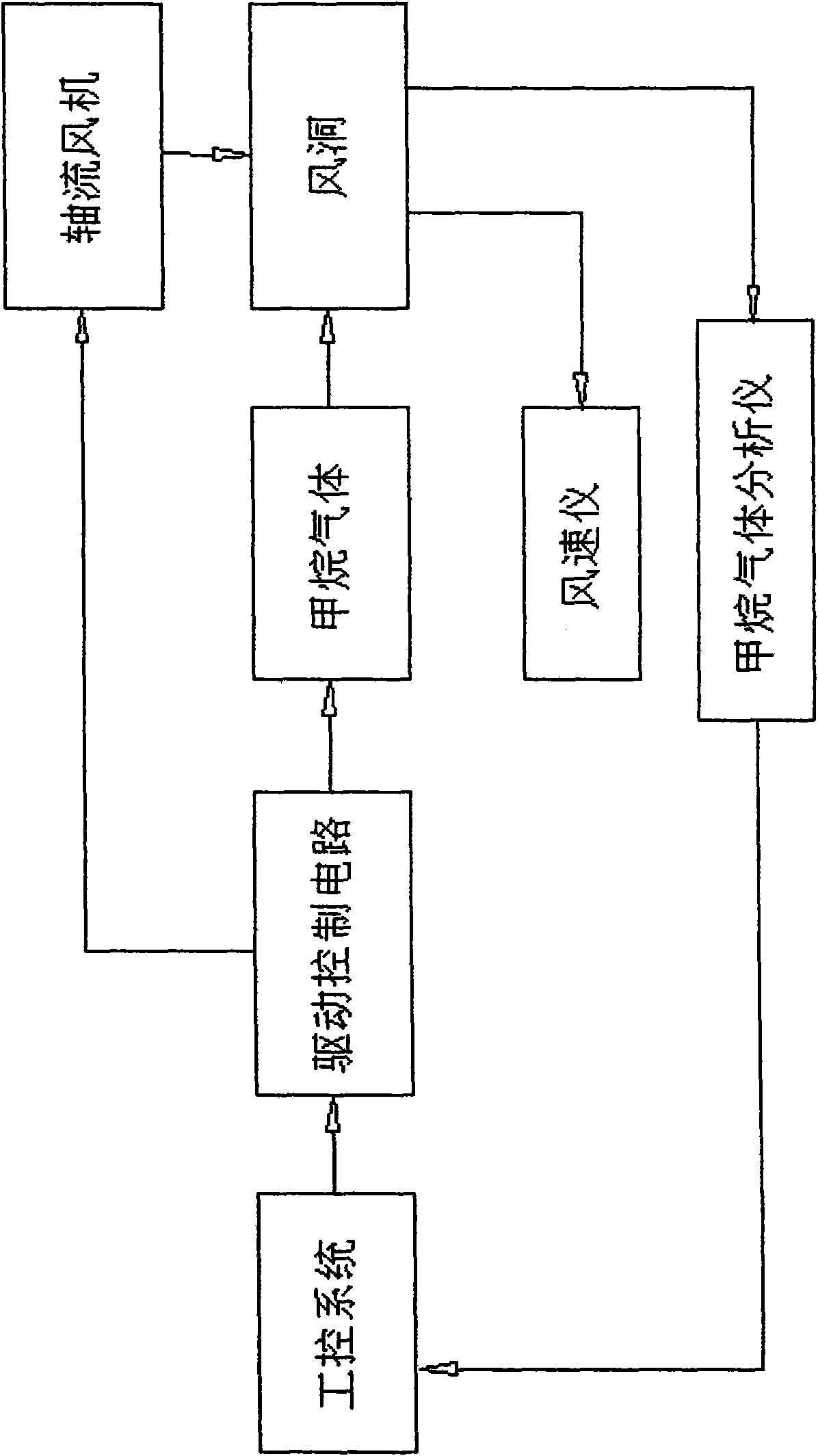

Wind-speed influence test device of methane alarming mine lamp

InactiveCN102033083AImprove accuracyReduce mistakesAerodynamic testingMaterial analysis by electric/magnetic meansTest efficiencyTest sample

The invention relates to a wind-speed influence test device of a methane alarming mine lamp, which is mainly used for enhancing test efficiency, the accuracy of test results and the like. In the technical scheme of the invention, a gas analyzer is arranged on the test device and respectively connected with a wind tunnel and a controller, and the controller is connected with a sample gas component; through the starting-up setting of the controller, the test device can automatically adjust the concentration of methane in the wind tunnel step by step from low to high and detect concentration, provide an alarming signal and display an alarming point when an test sample alarms, and record the information of date, time and like; and the test device is suitable for wind-speed influence test of various methane alarming mine lamps.

Owner:CHINA COAL TECH & ENG GRP SHANGHAI RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com