Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Excellent welding characteristics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High strength thin steel sheet excelling in weldability and process for producing the same

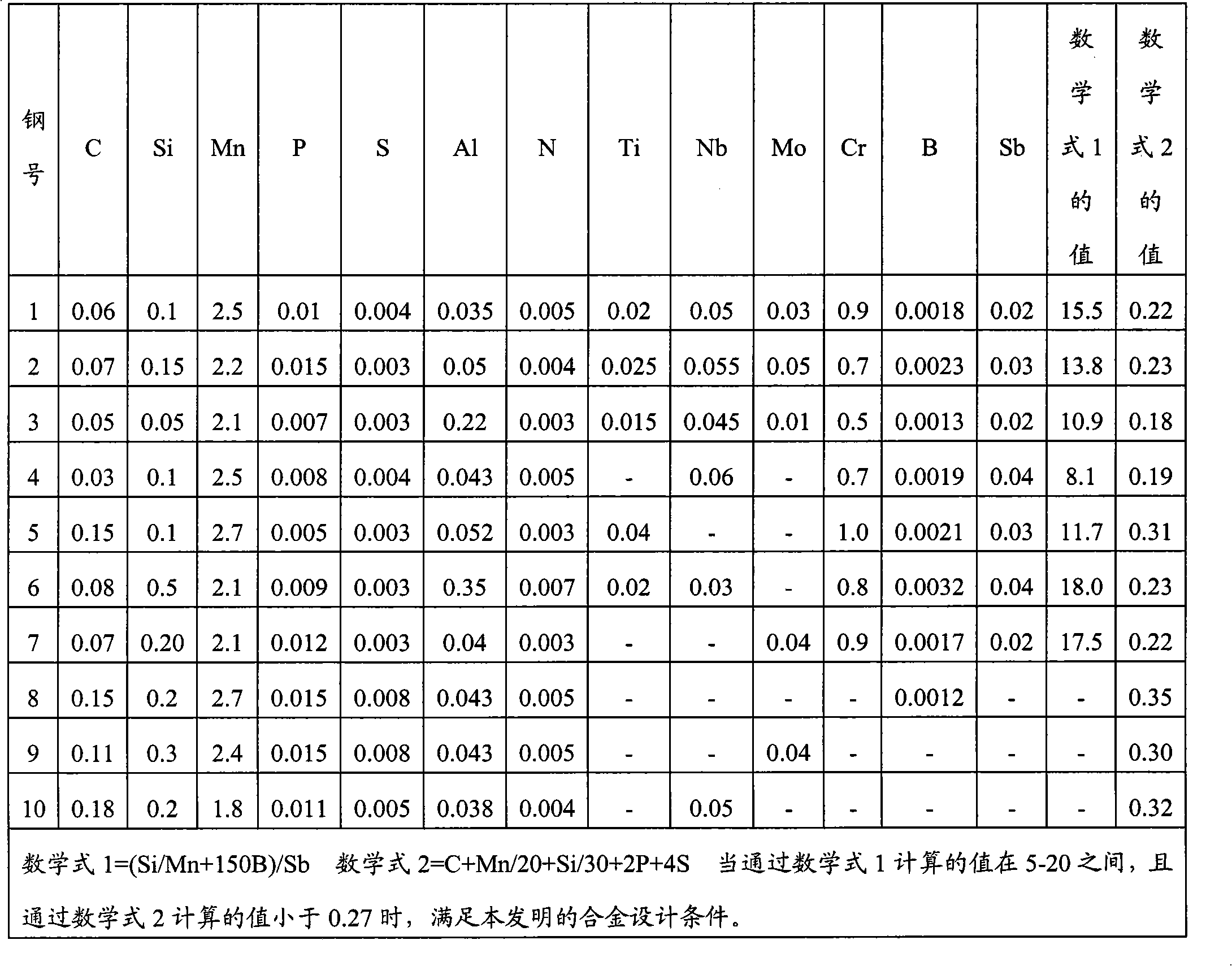

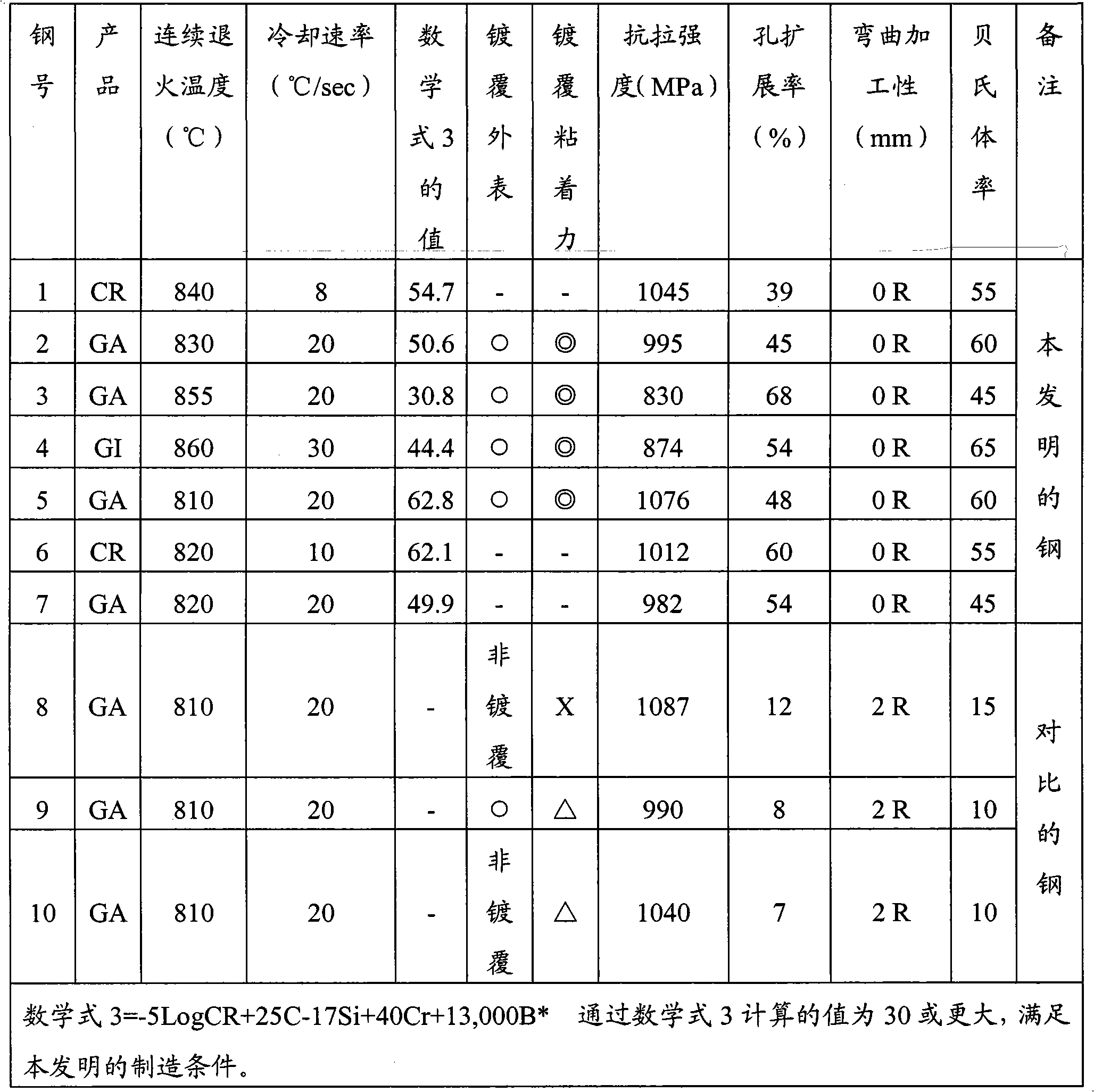

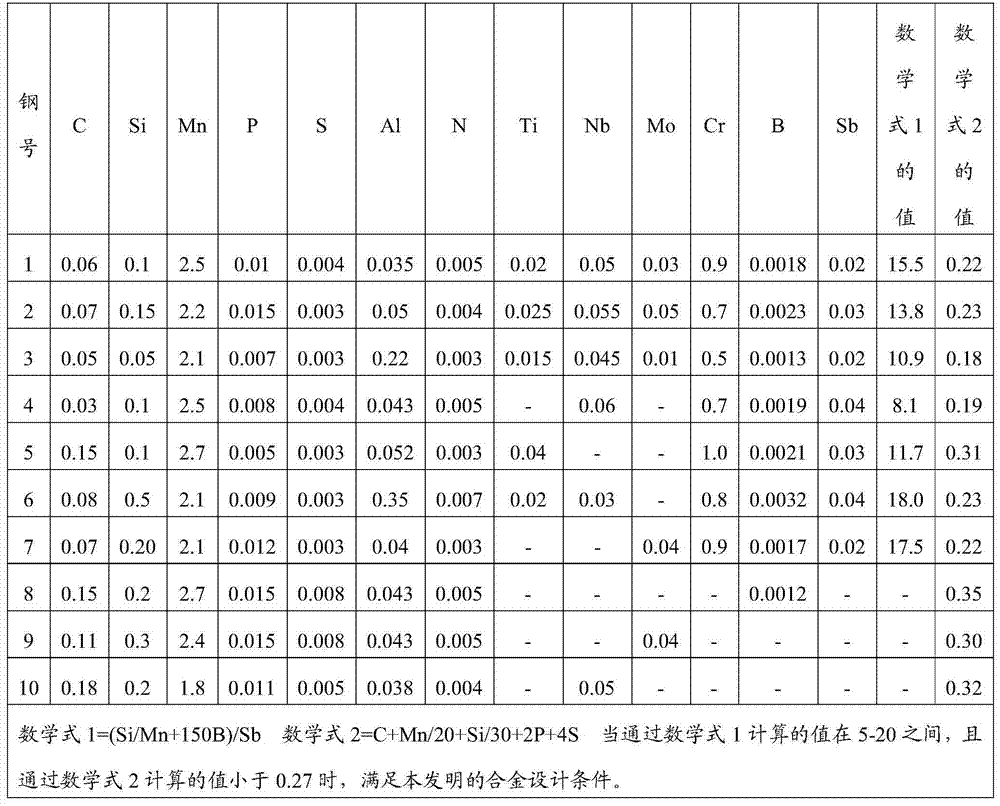

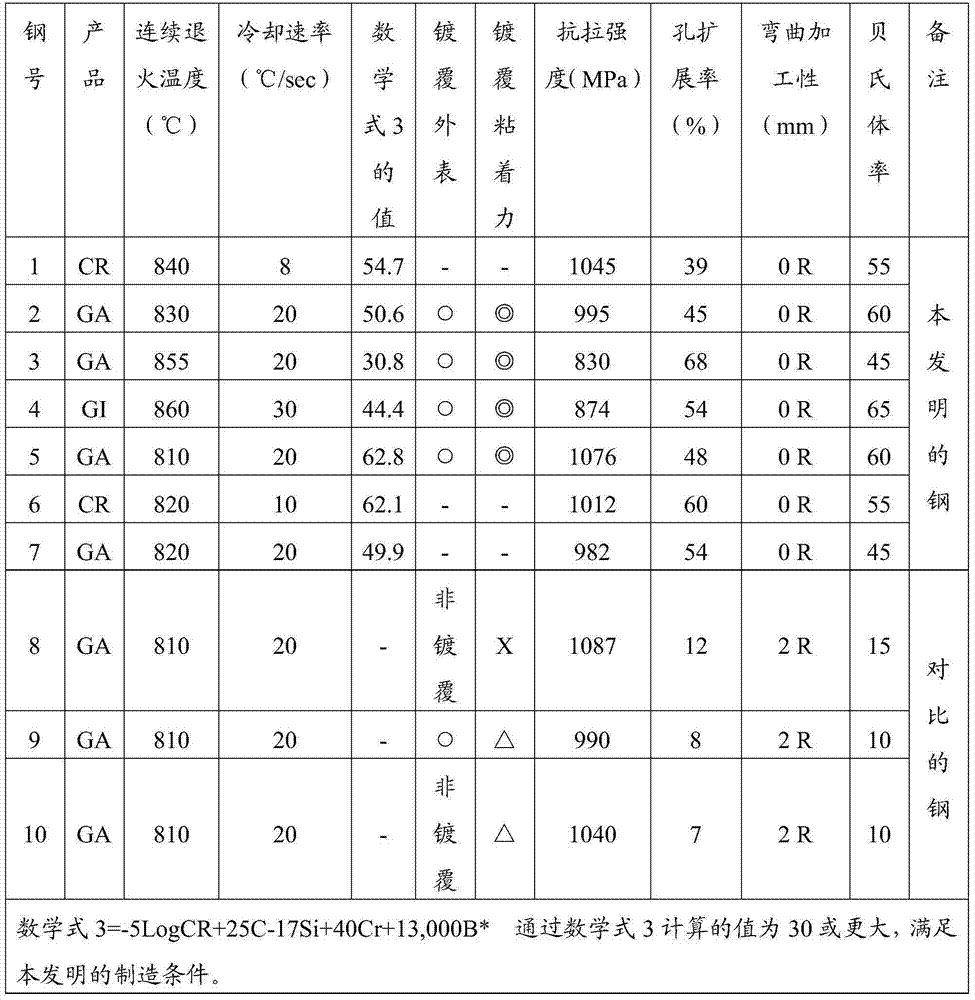

Provided are a high strength thin steel sheet having tensile strength of about 800 MPa or more, and a manufacturing method thereof. The thin steel sheet is mainly used for construction materials, home appliances, and automobiles. The thin steel sheet has excellent plating char not acteristic, welding characteristic, bending workability, and hole expansion ratio. The thin steel sheet includes, in weight %, C: 0.02-0.20%, Si: 1.5% or less, Mn: 1.5-3.0%, P: 0.001-0.10%, S: 0.010% or less, SoLAl: 0.01-0.40%, N: 0.020% or less, Cr: 0.3-1.5%, B: 0.0010-0.0060%, Sb: 0.001-0.10%, and including at least one material selected from the group consisting of Ti: 0.003-0.08%, Nb: 0.003-0.08%, and Mo: 0.003-0.08%, and includes Fe and other inevitable impurities as a remainder. Here, Si, Mn, B, Sb, P, and S meet conditions of 5 < (Si / Mn + 150B) / Sb < 20 and C + Mn / 20 + Si / 30 + 2P + 4S < 0.27. Also, the manufacturing method can secure workability of the thin steel sheet.

Owner:POHANG IRON & STEEL CO LTD

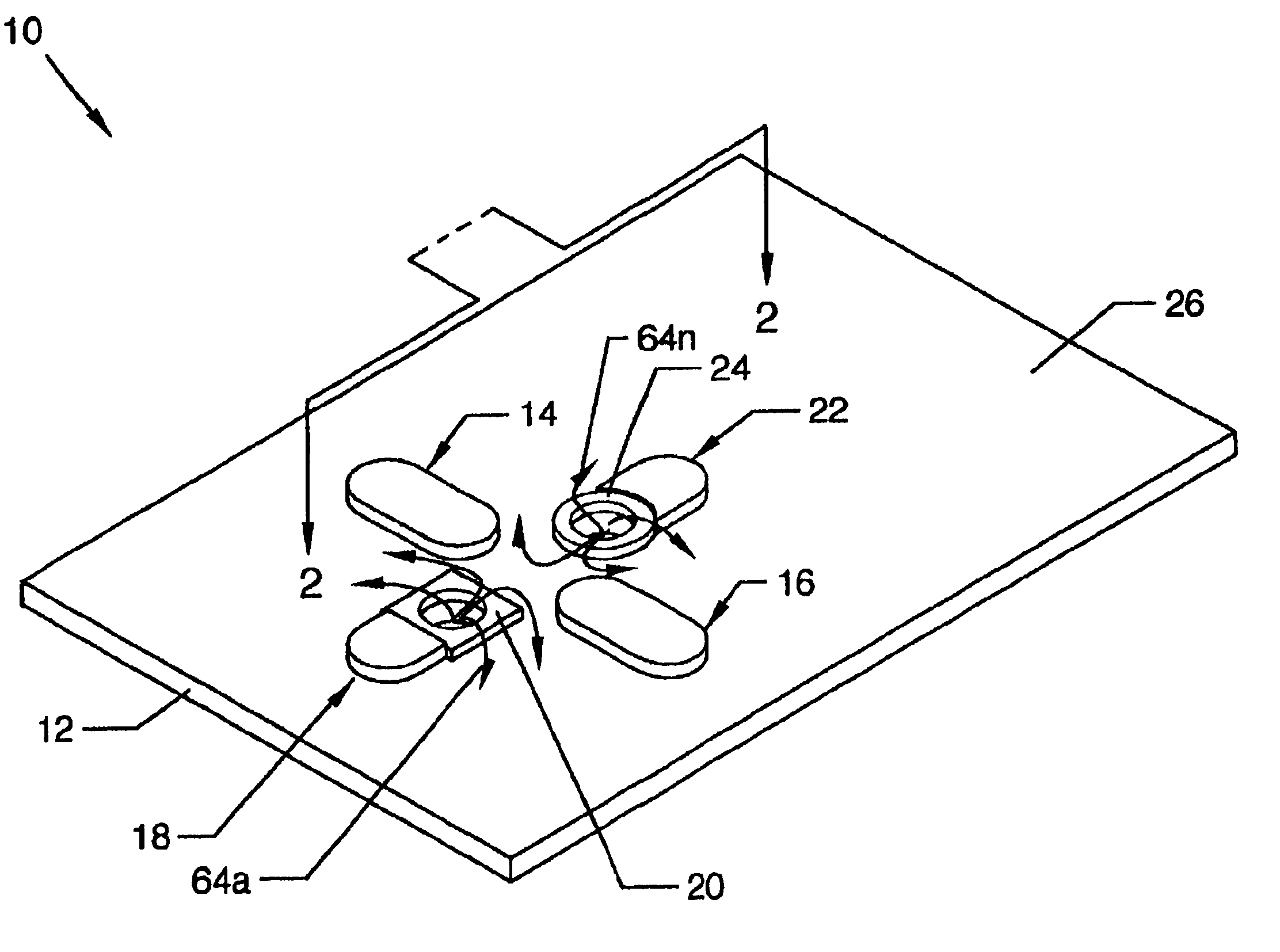

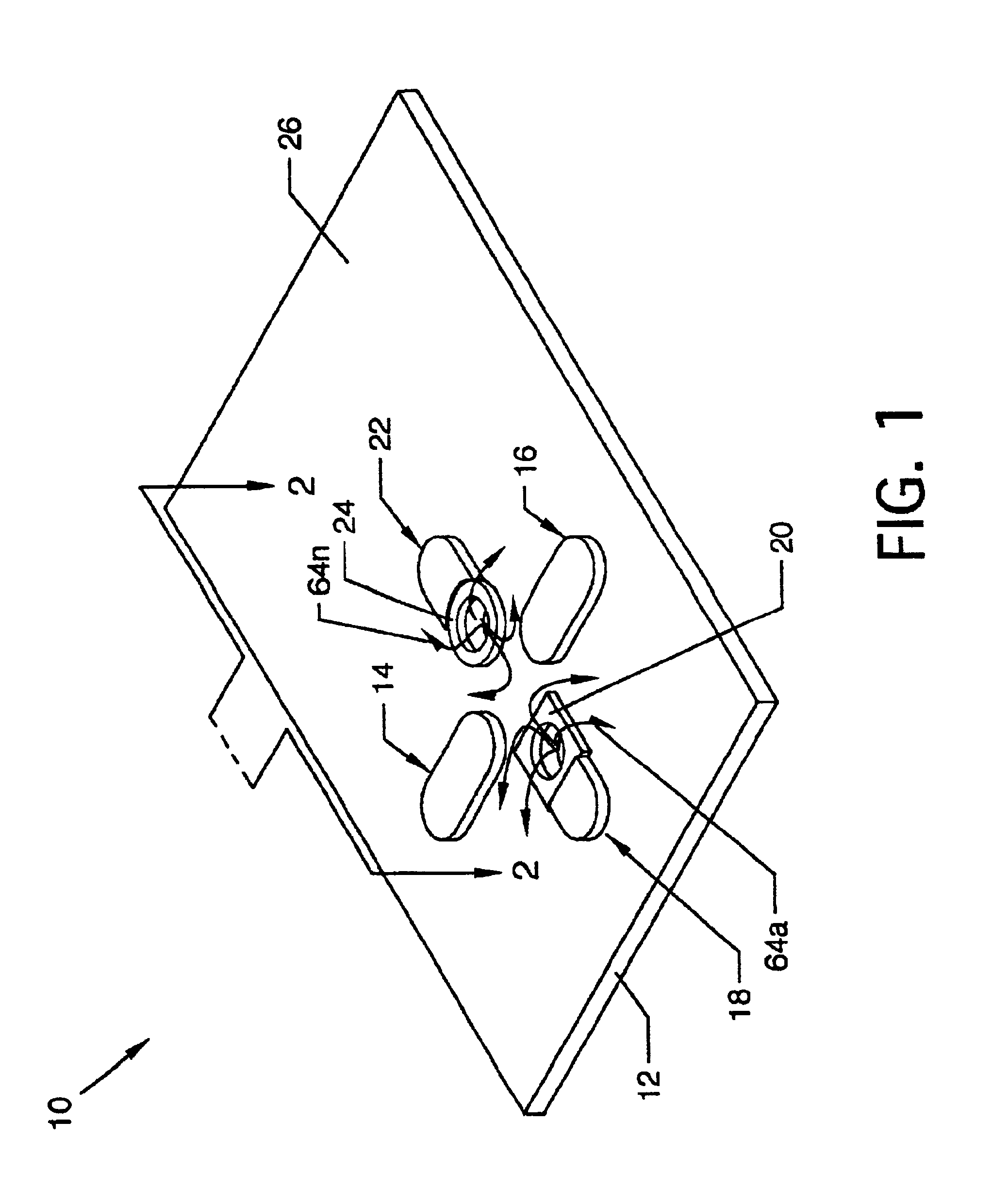

Circuit board having improved soldering characteristics

InactiveUS6707683B1Improve featuresIncrease spacingPrinted circuit assemblingPrinted circuit aspectsAtmospheric airElectronic component

A circuit board having improved soldering characteristics having raised structure consisting of spacer pads arranged to provide for vertical distancing of electrical or electronic components from the component side planar surface of the circuit board. Such spacing is complementary to top vented soldering stations where the spacing allows solder process gases to flow unimpeded from the soldering stations through the spacing to atmosphere.

Owner:DAKTRONICS

Solder paste for signal processing substrate and preparation method thereof

ActiveCN105397343AModerate viscosityExtended shelf lifeWelding/cutting media/materialsSoldering mediaIndiumPolyethylene glycol

The invention discloses a solder paste for a signal processing substrate and a preparation method thereof. The method comprises the following steps: 1) mixing Sn-Zn alloy, copper, indium, chloroauric acid hydrated, polyvinylpyrrolidone, a reducing agent and water to enable contact reaction so as to obtain an activating metal composition; 2) heating and dissolve rosin, rosin amine, organic acid, imidazole and tris(2-carboxyethyl) isocyanurate to obtain mixed liquor I; 3) mixing the mixed liquor I, a thixotropic agent and a preservative, and then cooling to obtain mixed liquor II; 4) mixing the mixed liquor II and polyethylene glycol to obtain a soldering flux; 5) refrigerating the soldering flux, and then performing dispersion mixing for the soldering flux and the activating metal composition under a vacuum condition and in the presence of X-rays, so as to obtain the solder paste for the signal processing substrate. The solder paste prepared by the preparation method is outstanding in chemical stability, low in welding temperature, and outstanding in expansion rate.

Owner:芜湖雅葆轩电子科技股份有限公司

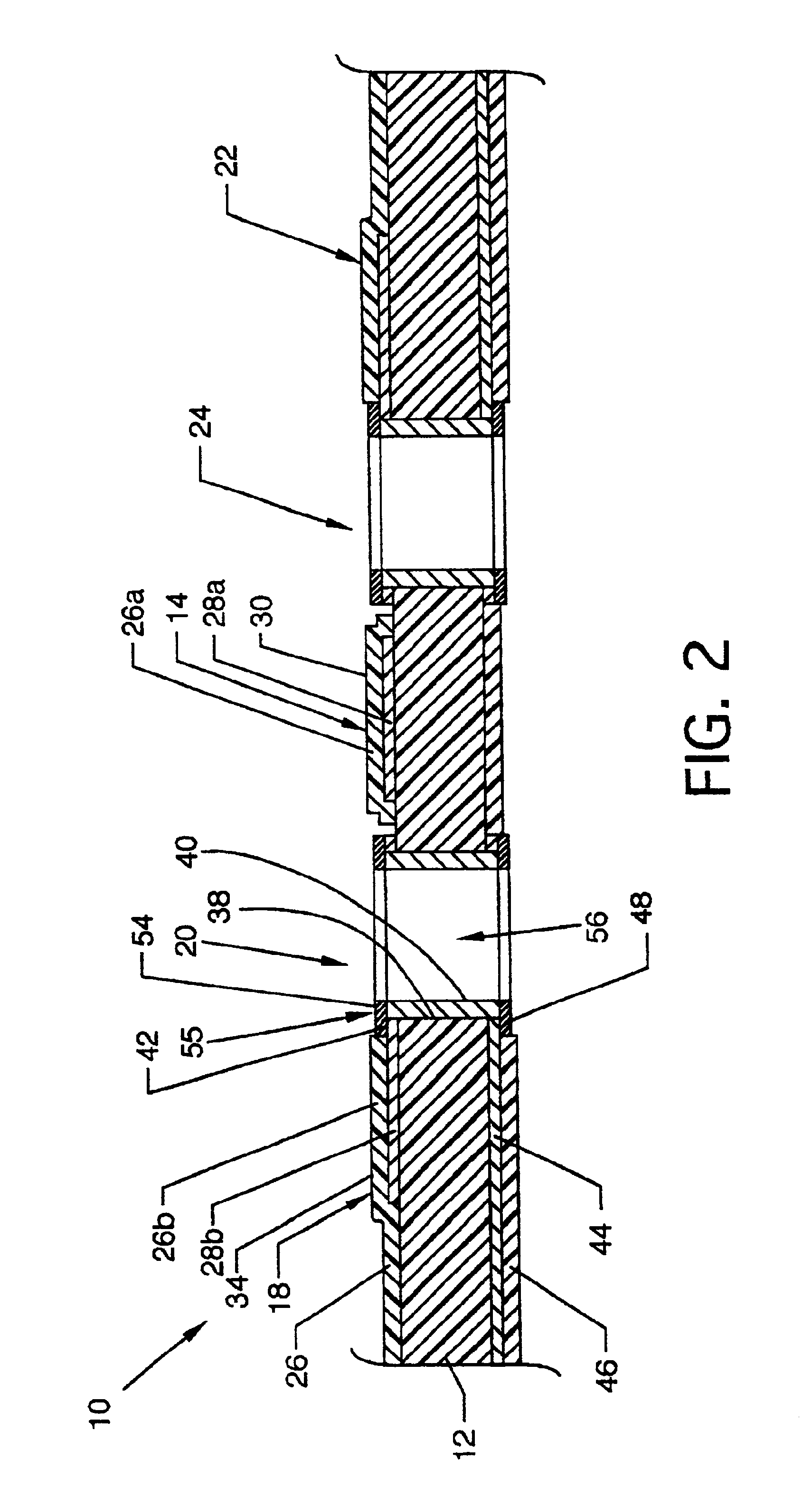

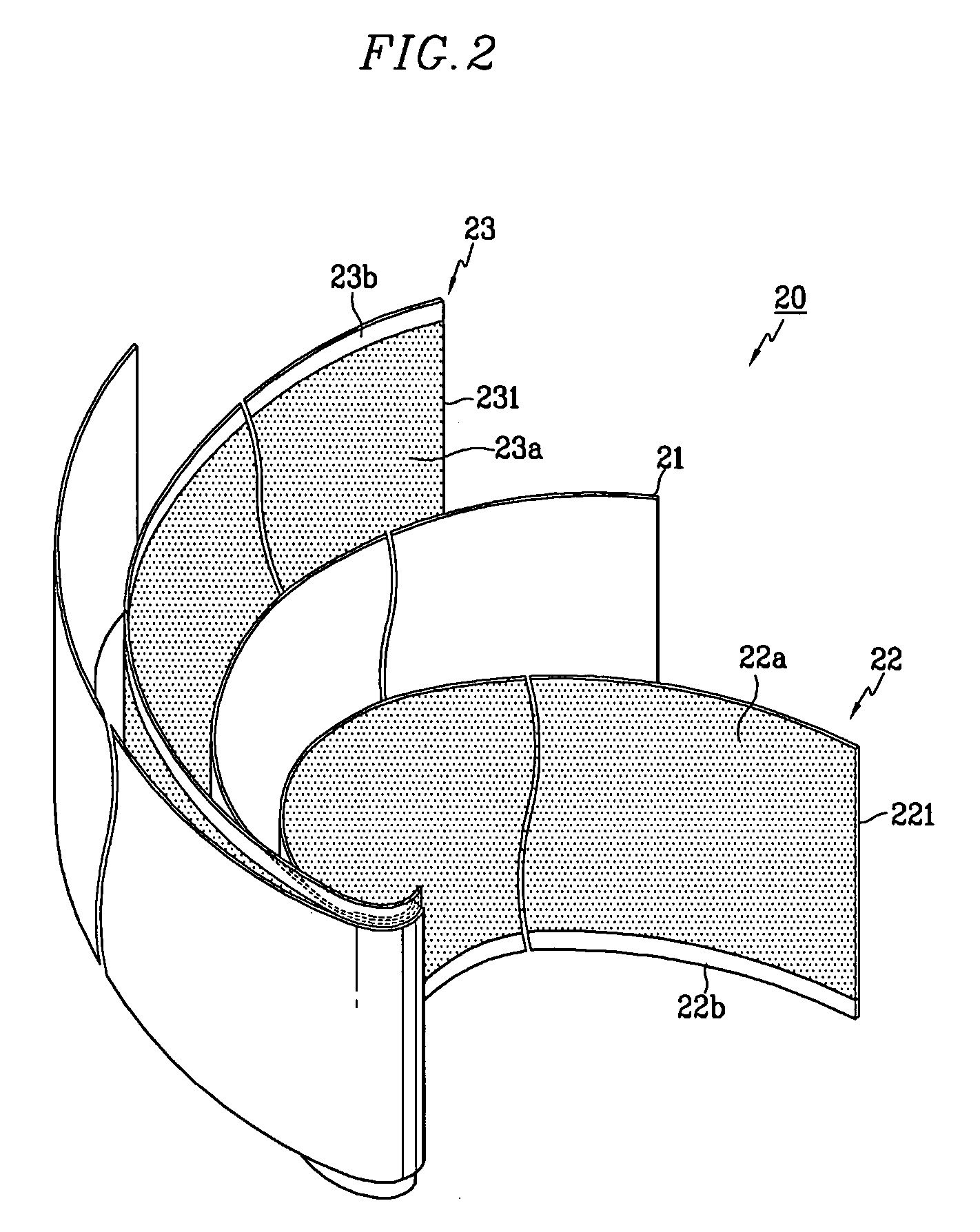

Electric resistance welded stainless clad steel pipe and method of manufacturing the same

InactiveUS20180243809A1Decrease productivityIncrease production costShaping toolsRectilinear seam weldingElectrical resistance and conductanceElectric resistance welding

Provided are an electric resistance welded stainless clad steel manufactured by forming a hot-rolled steel strip of clad steel including low-carbon low-alloy steel and stainless steel into a cylindrical shape, and electric resistance welding the edges of the hot-rolled steel strip, characterized in that the flattening characteristic of an electric resistance weld, as-welded, satisfies the formula h / D<0.3, wherein h is the flattened height at fracture (mm) and D is the outer diameter of the pipe (mm), and a method of manufacturing the same.

Owner:JFE STEEL CORP

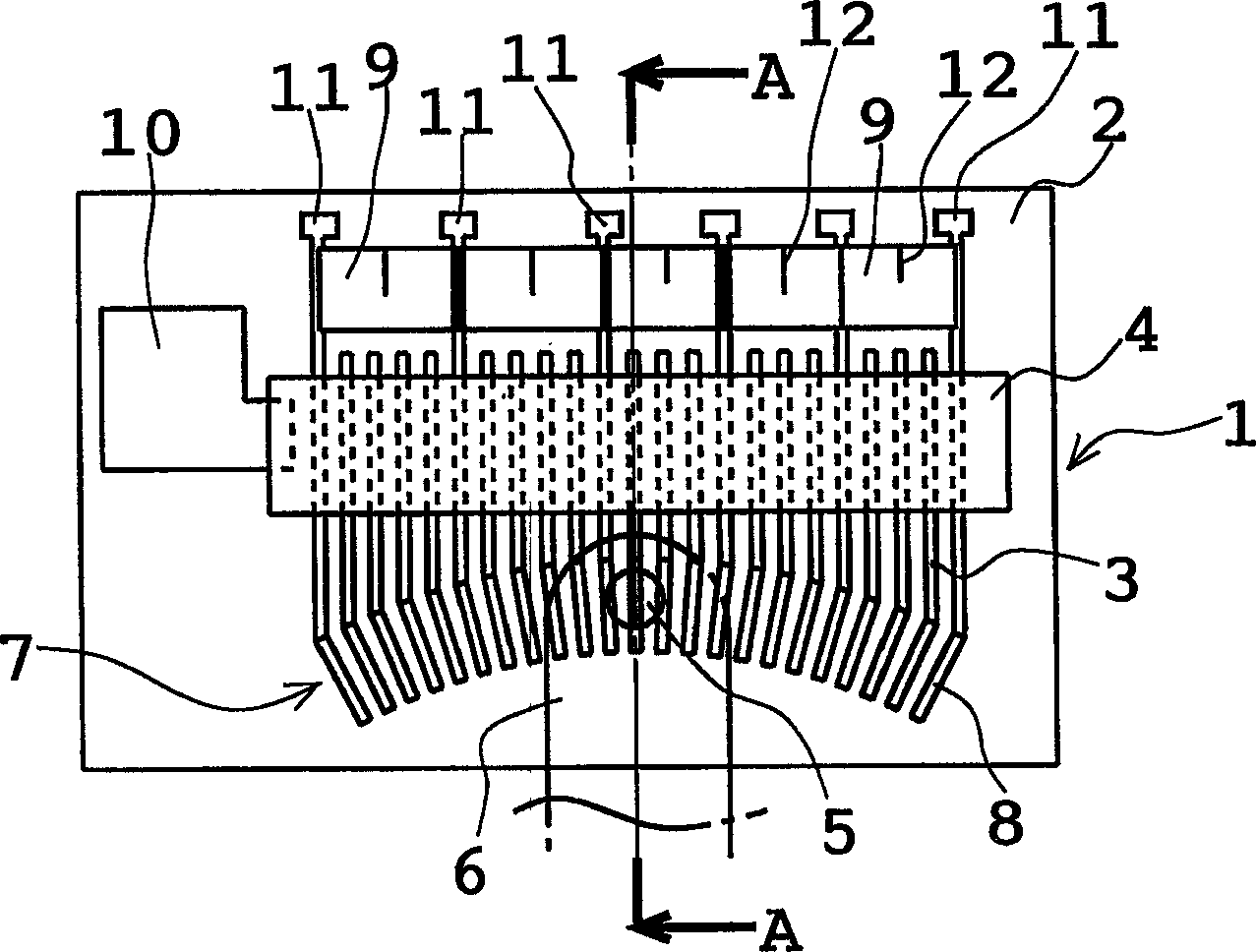

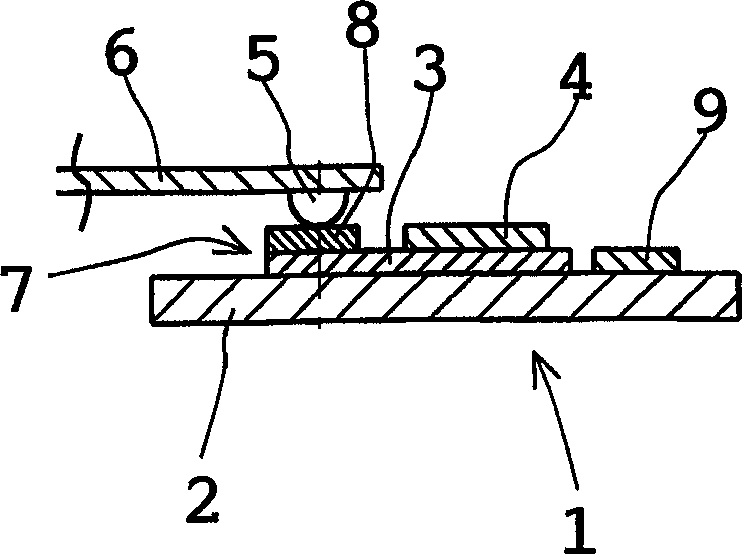

Liquid level sensor

InactiveCN1564931AExcellent welding characteristicsResistant degenerationResisitors with sliding contactLevel indicators by floatsEngineeringPalladium

A liquid level detecting apparatus resistant to the deterioration and corrosion thereof is provided while holding down an increase in the manufacturing cost thereof. This apparatus 1 has fixed electrodes 3 on which a sliding contact point 5 is slidingly moved in accordance with a fluctuation of a float, and a first resistor 4 connected to the fixed electrodes 3, the fixed electrodes 3 being made of at least silver (Ag), palladium (Pd) and a glass component, a weight ratio of the silver (Ag) to palladium (Pd) being not lower than 75 wt. % to not higher than 25 wt. %, a sliding portion 7 of the fixed electrodes 3 on which the sliding contact point 5 is slidingly moved being covered with second resistors 8 a resistance value of which is lower than that of the first resistor 4.

Owner:NIPPON SEIKI CO LTD

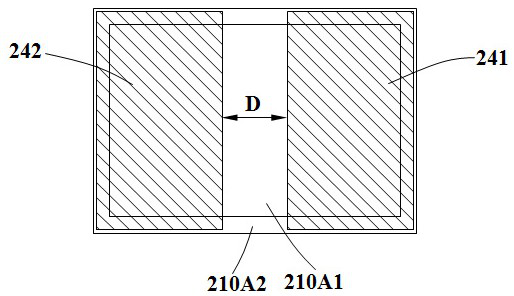

Light emitting diode and manufacturing method thereof

PendingCN112768484AHigh surfaceExcellent welding characteristicsSolid-state devicesSemiconductor/solid-state device manufacturingElectrical connectionActive layer

The invention discloses a light emitting diode and a manufacturing method thereof. In some embodiments, the light emitting diode comprises a transparent substrate having a first surface and a second surface opposite to each other, and a sidewall connecting the first surface and the second surface; a light-emitting table top which is formed on the first surface of the transparent substrate and comprises a light-emitting epitaxial laminated layer, wherein the light-emitting epitaxial laminated layer comprises a first conductive type semiconductor layer, an active layer and a second conductive type semiconductor layer which are stacked from the first surface of the transparent substrate; a supporting layer which is formed on the outer periphery of the light-emitting epitaxial laminated layer, wherein a plane is formed by the supporting layer and the light-emitting table top, and the cross sectional area of the plane is not smaller than that of the first surface of the transparent substrate; a first electrode disposed on the plane and electrically connected to the first conductive type semiconductor layer; and a second electrode disposed on the plane and electrically connected to the second conductive type semiconductor layer.

Owner:XIAMEN SANAN OPTOELECTRONICS CO LTD

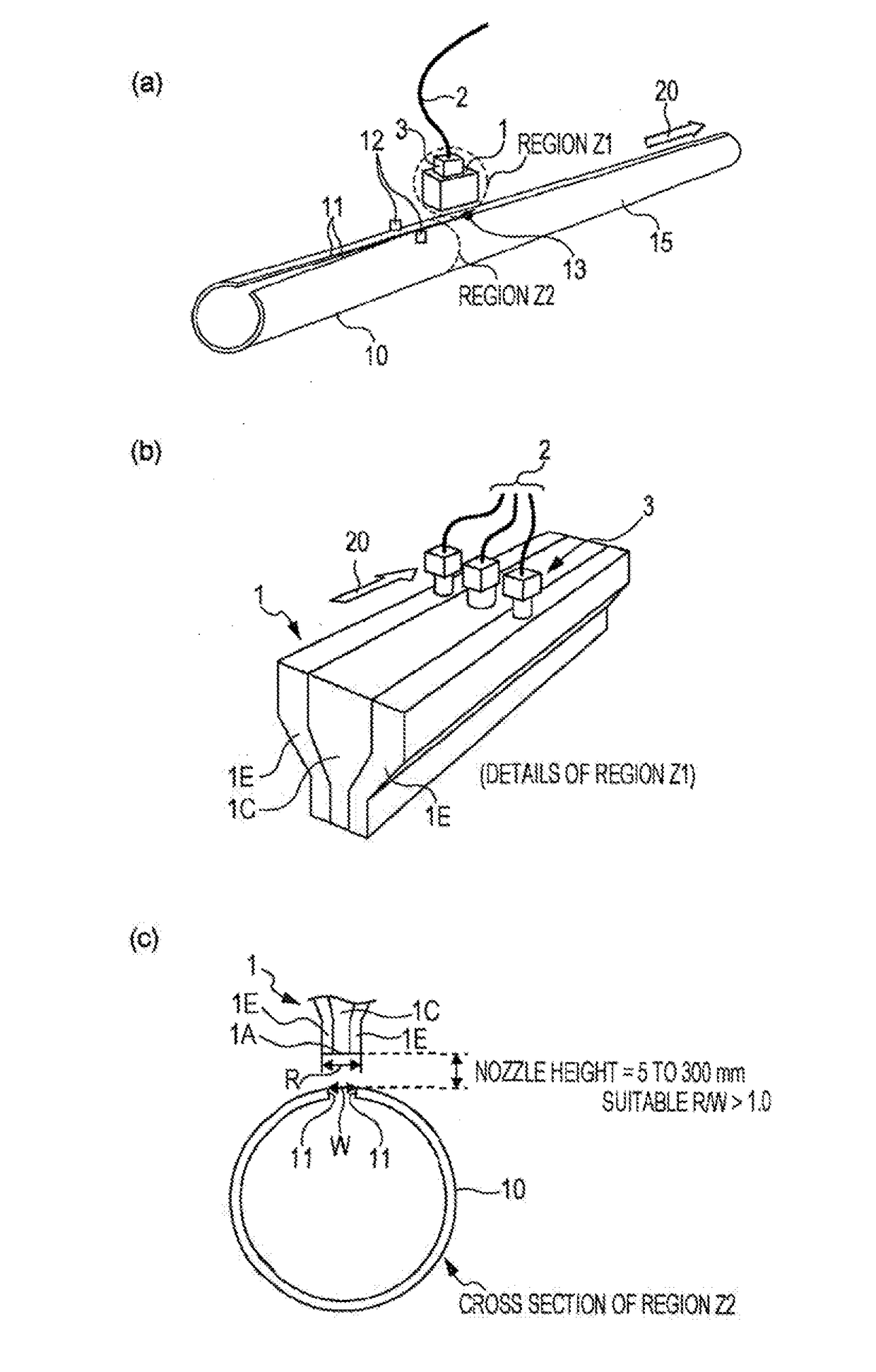

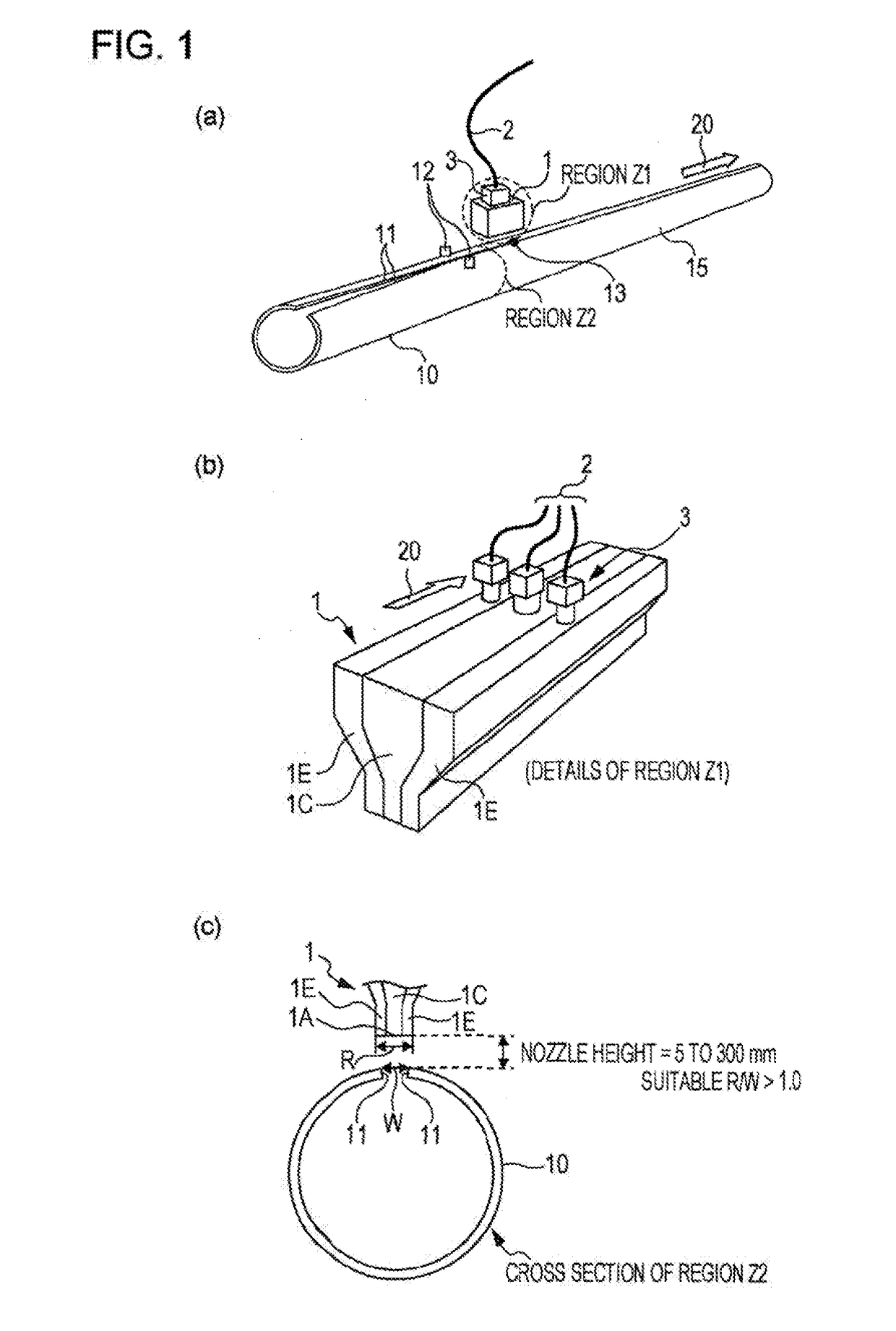

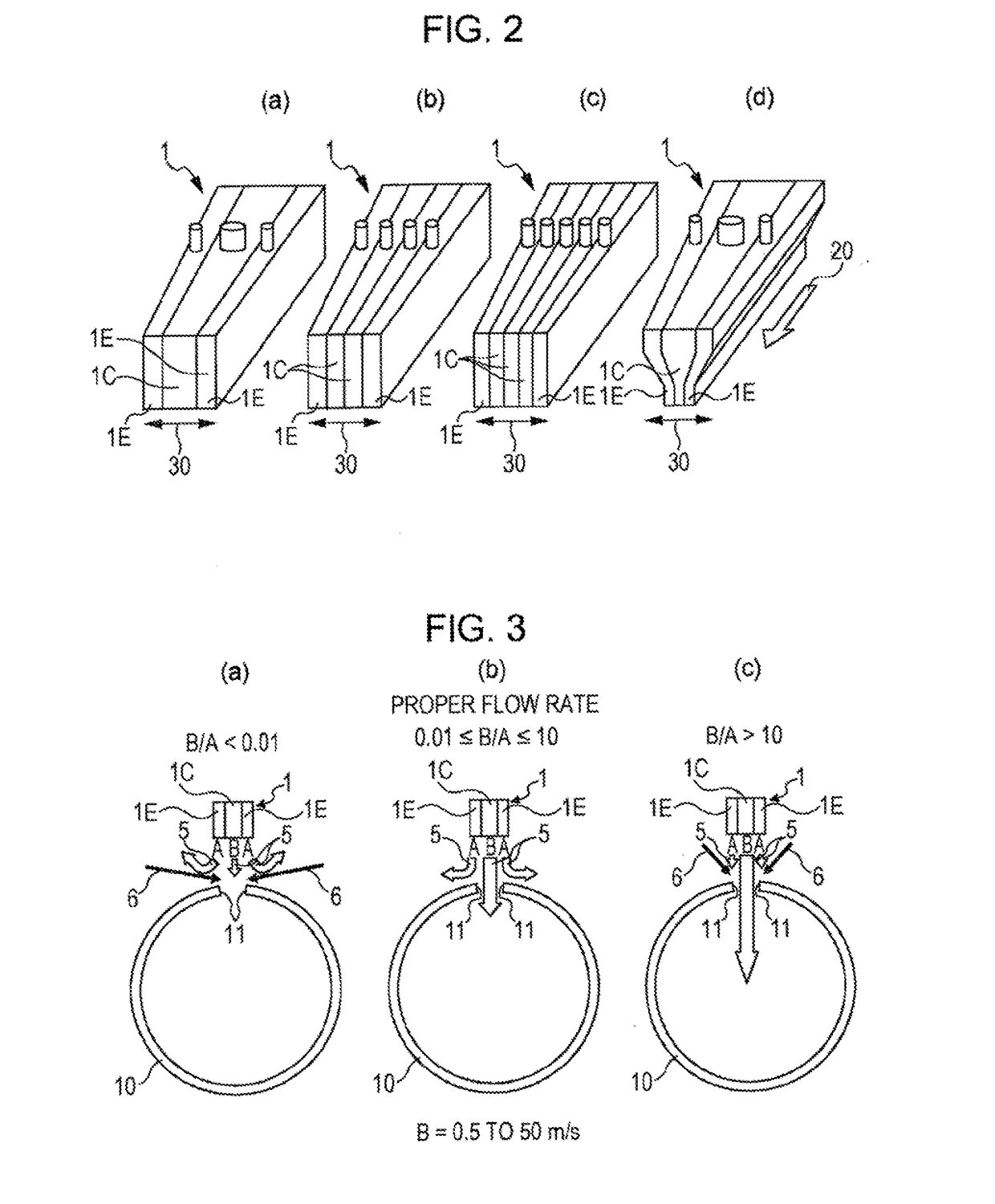

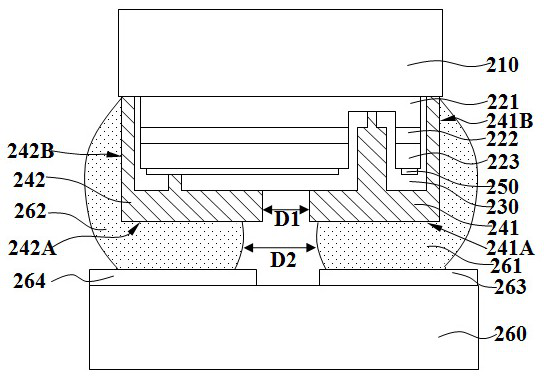

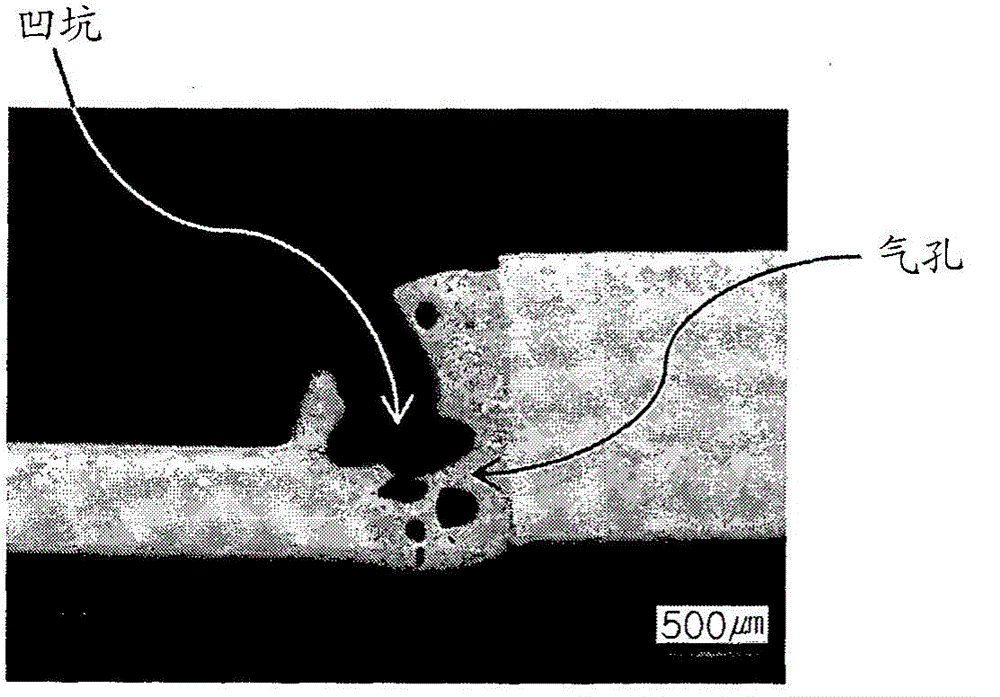

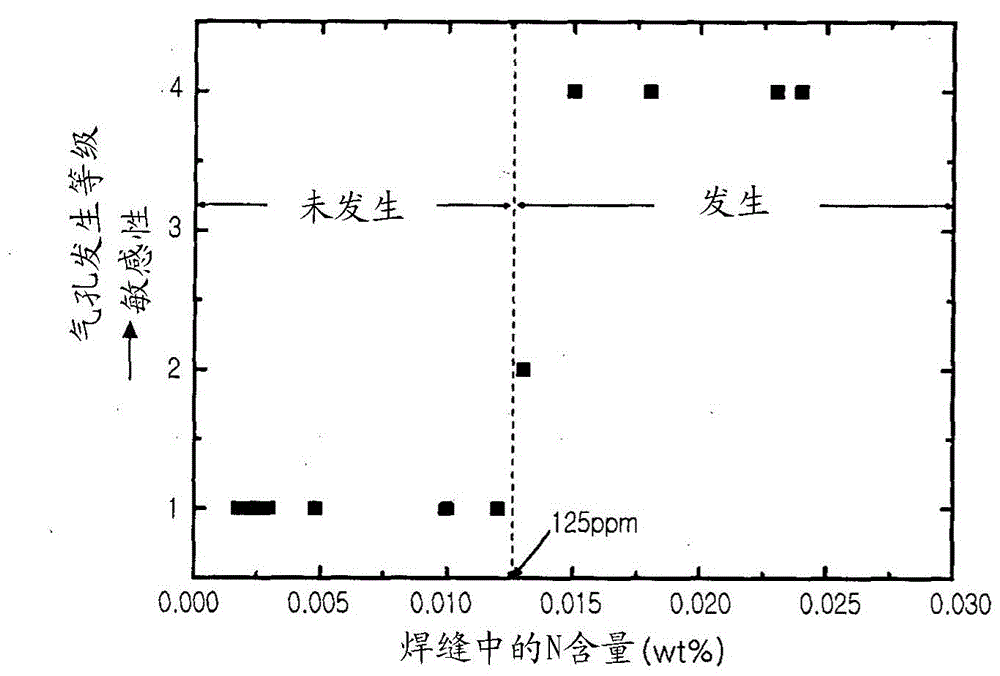

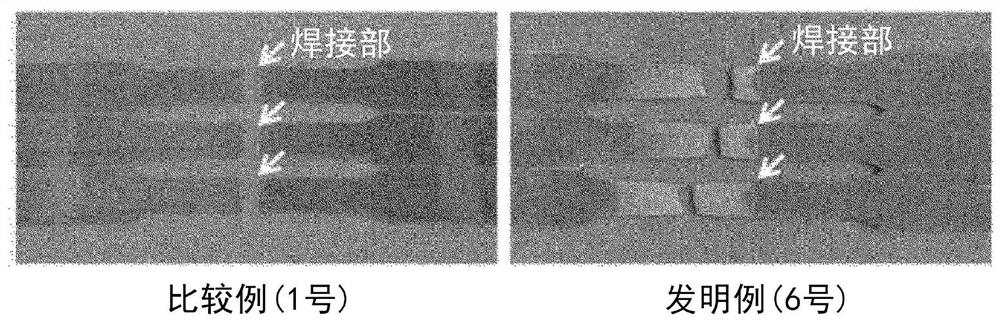

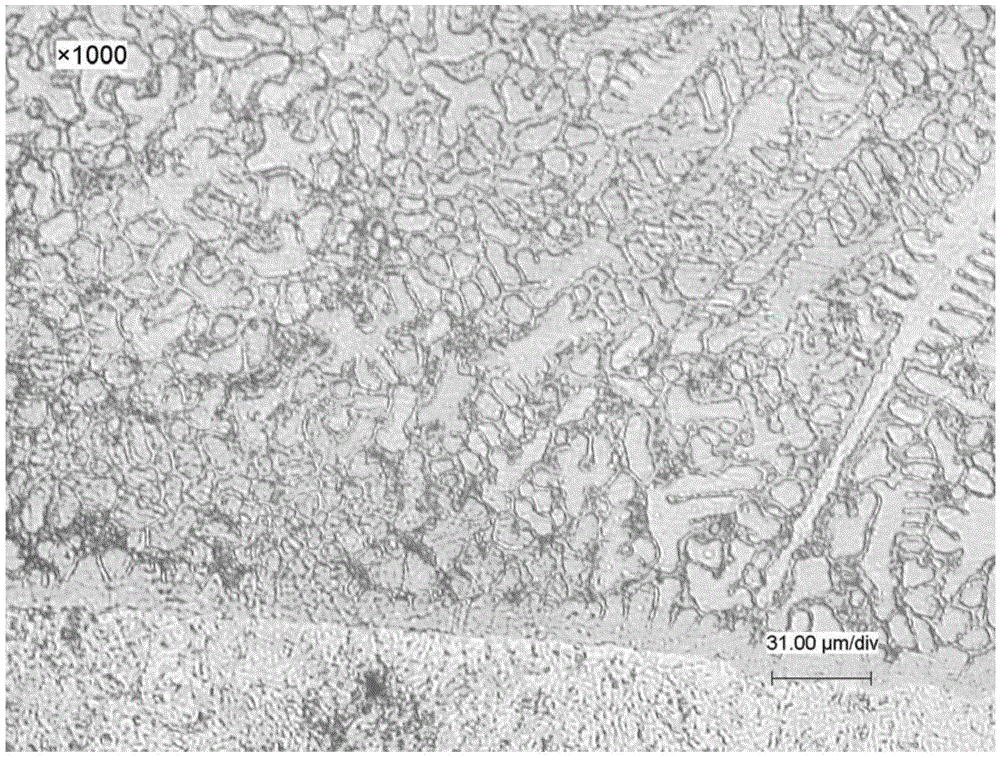

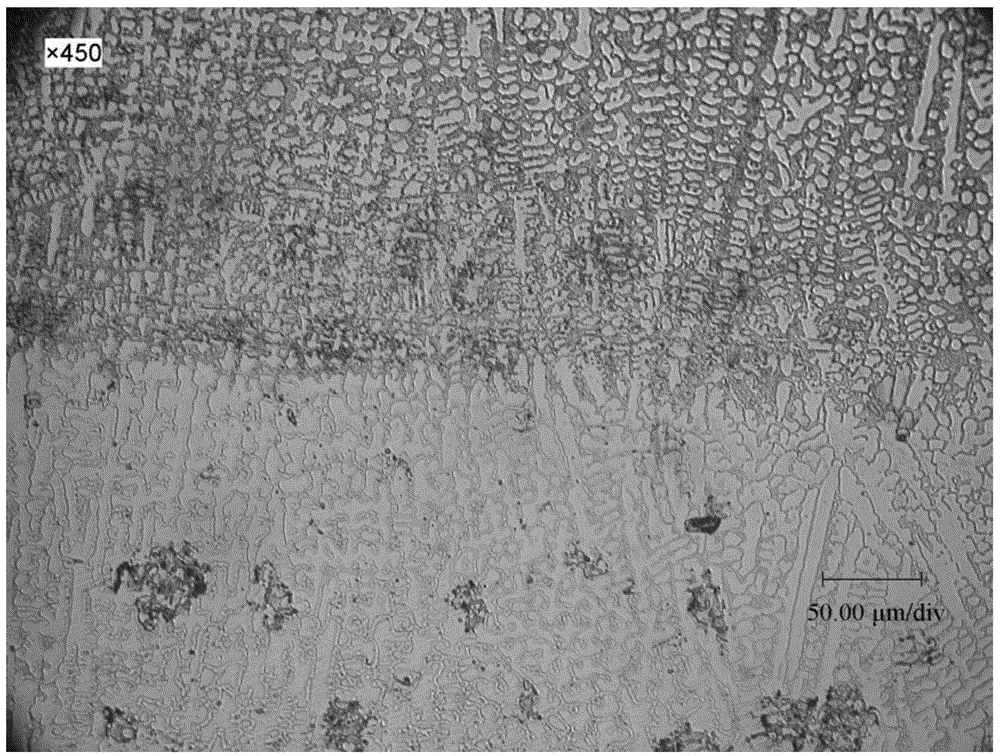

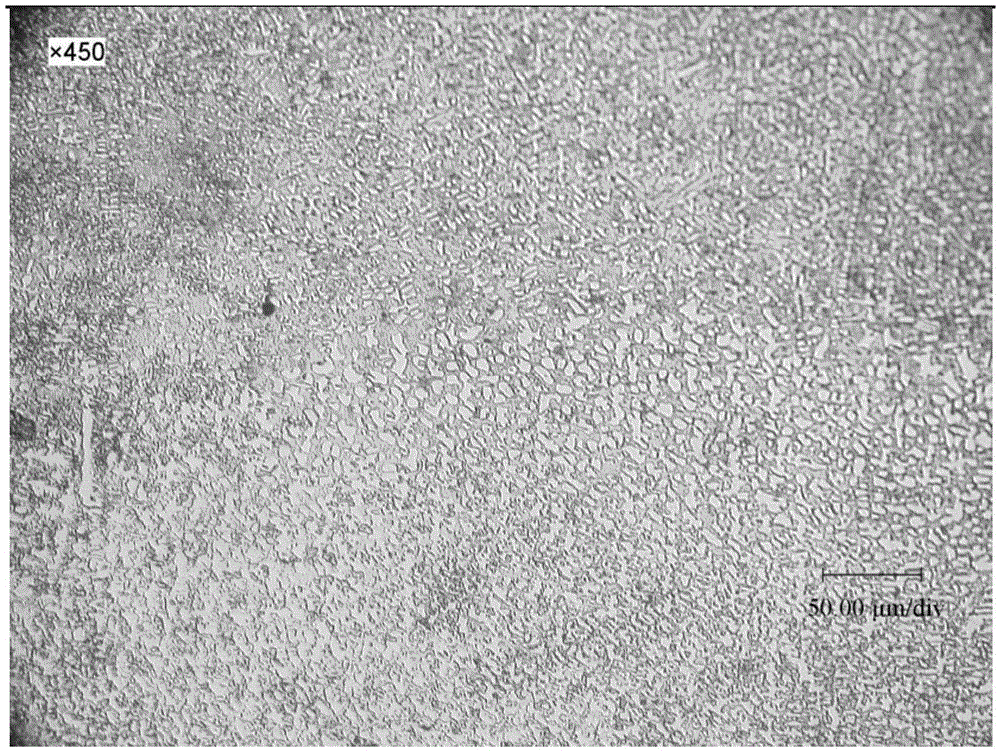

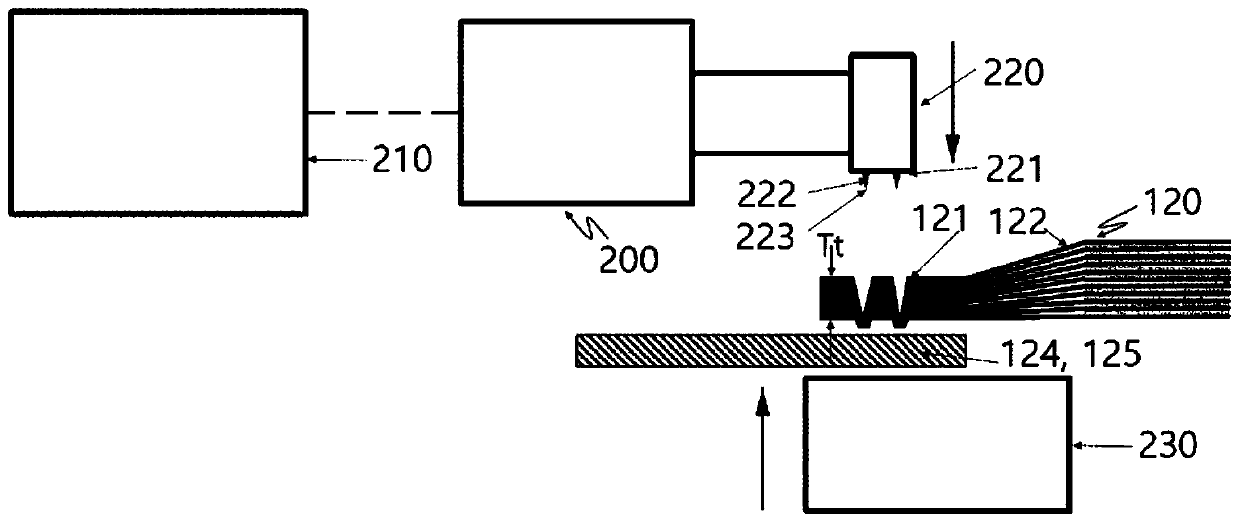

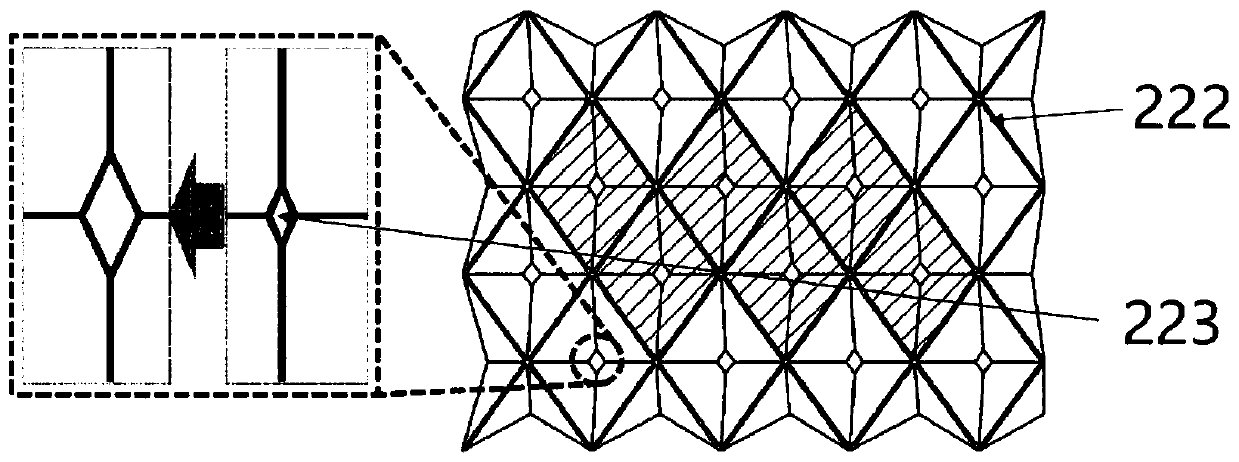

Method for laser welding and welded metal using the same

InactiveCN104602860AExcellent welding characteristicsGood formabilityVehicle componentsWelding/soldering/cutting articlesShielding gasOptoelectronics

The present invention relates to a laser welding method that is capable of preventing defects such as pores or pits from being formed in a weld and improving formability of the weld during laser welding, and a welded member using the same. In the laser welding method of performing welding by irradiating laser onto a portion to be welded, there are provided a laser welding method of including supplying a shielding gas to a laser irradiation part and a rear side of the laser irradiation part, and a welded member having welds formed therethrough.

Owner:POHANG IRON & STEEL CO LTD

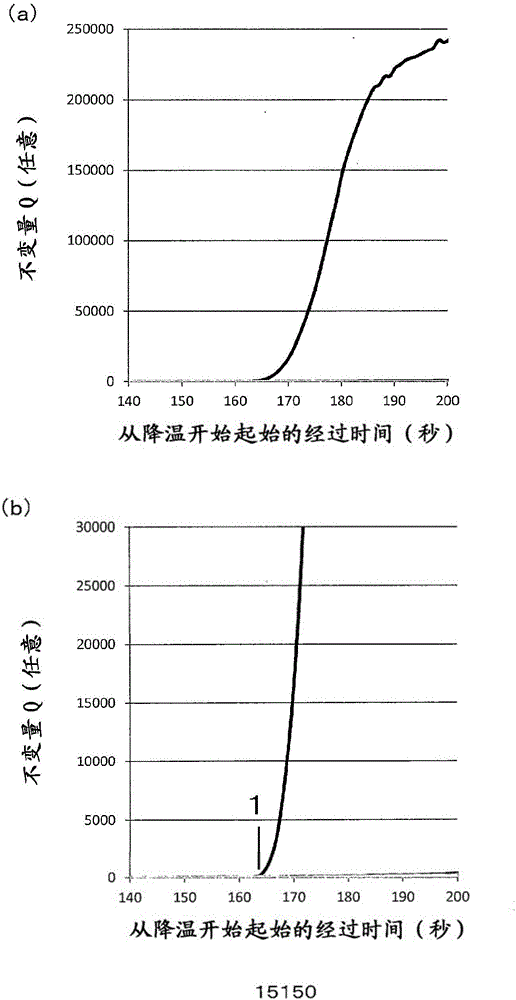

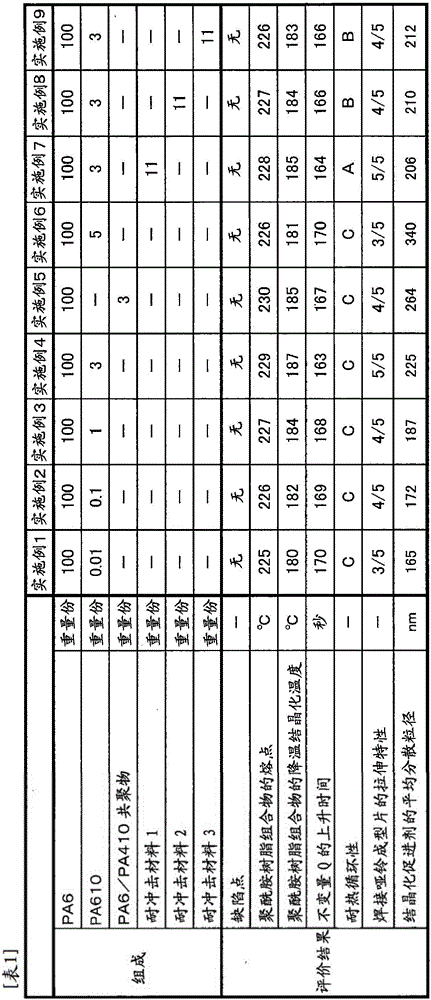

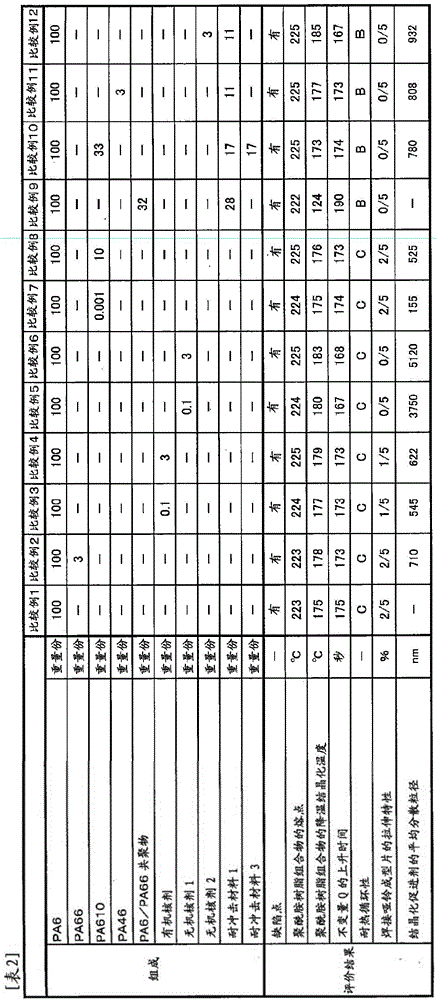

Polyamide resin composition for molded article to be in contact with high-pressure hydrogen, and molded article obtained therefrom

ActiveCN106255726AExcellent welding characteristicsFast crystallizationVessel mounting detailsVessel wallsHigh pressure hydrogenPolyamide

A polyamide resin composition for molded articles to be in contact with high-pressure hydrogen, the polyamide resin composition comprising a blend of a polyamide-6 resin (A) and a polyamide resin (B) which has a melting point, as determined by DSC, that is not higher than the temperature which is higher by 20oC than the melting point of the polyamide-6 resin (A) and which has a crystallization temperature during cooling, as determined by DSC, that is higher than the crystallization temperature during cooling of the polyamide-6 resin (A), the amount of the polyamide resin (B) being 0.01-5 parts by weight per 100 parts by weight of the polyamide-6 resin (A). The polyamide resin composition can give a molded article which, even when high-pressure hydrogen charging and pressure release are repeated, is inhibited from developing flaws and which has excellent weld properties.

Owner:TORAY IND INC

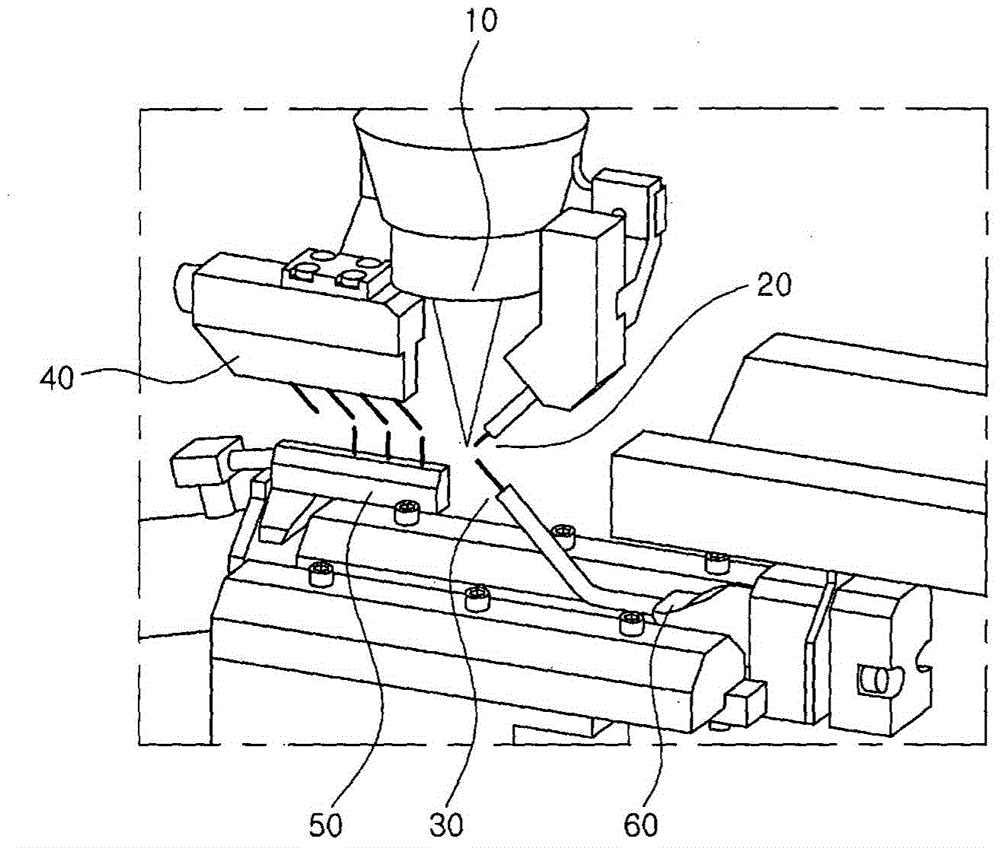

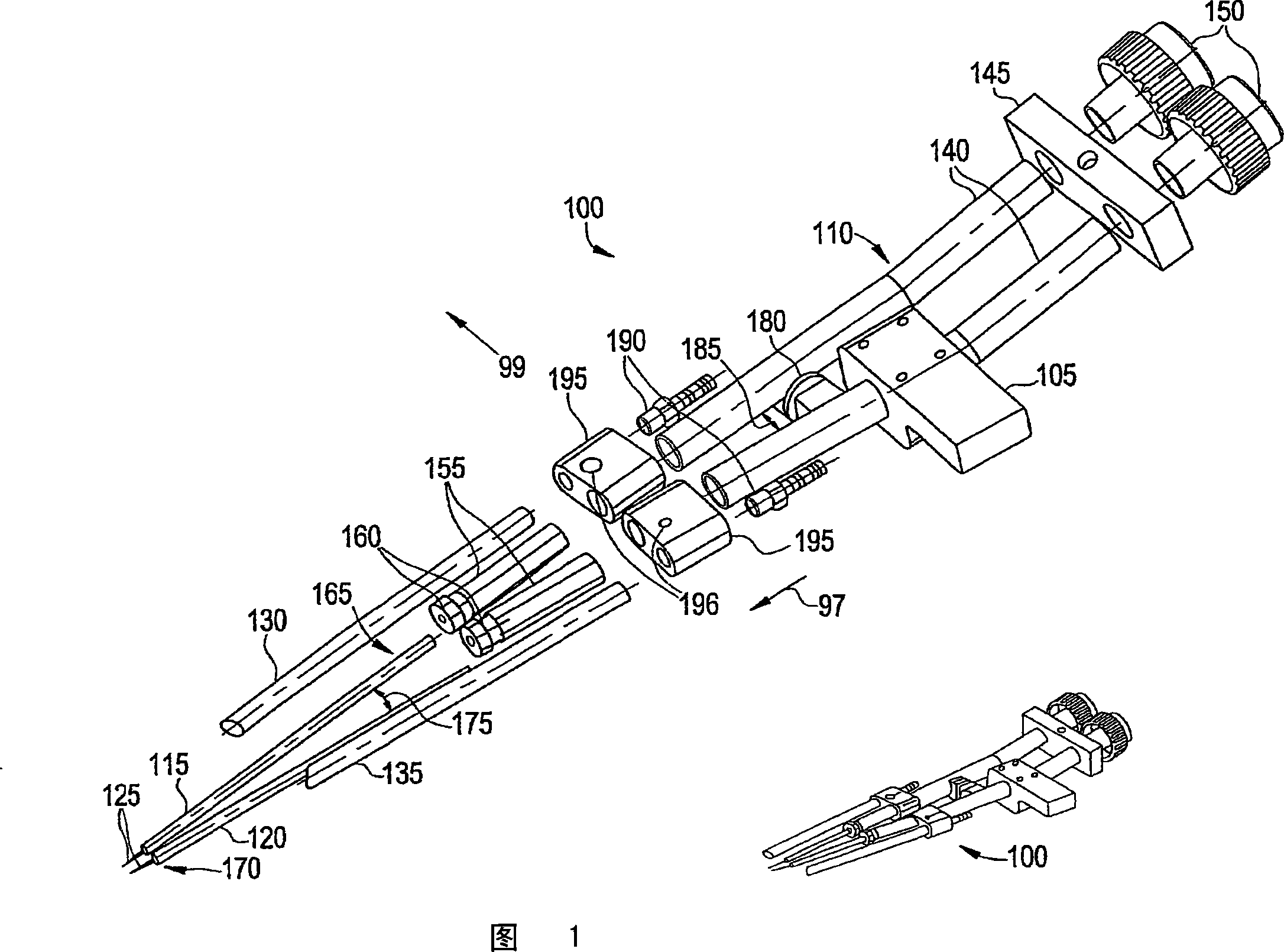

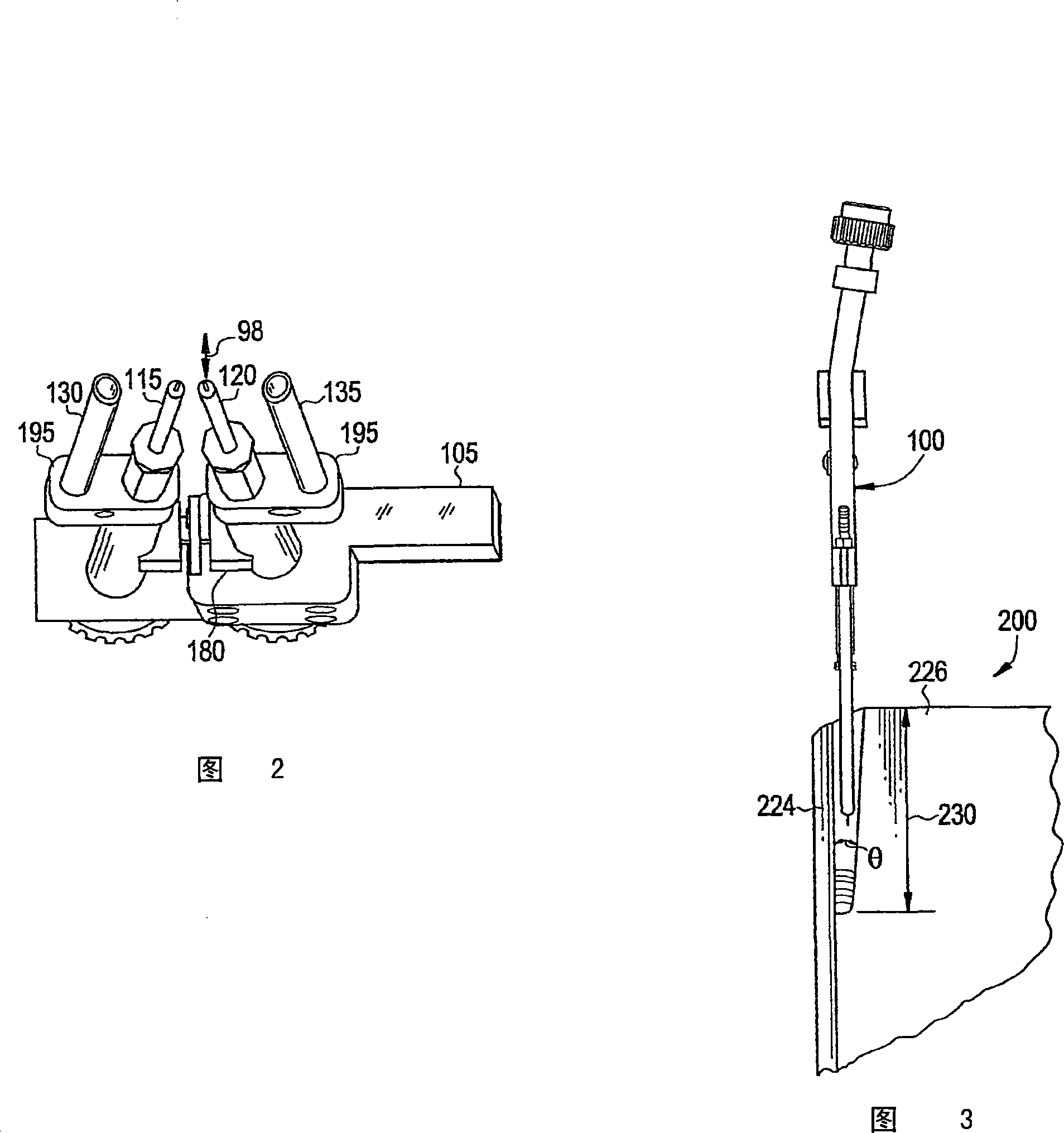

Apparatus for and method of deep groove welding for increasing welding speed

InactiveCN101219500AIncrease deposition rateReduced deformabilityElectrode accessoriesWelding accessoriesEngineeringGas supply

The present invention relates to equipment and methods for deep groove welding. Disclosed is a welding device. The welding device includes a welding torch body (110) having at least one core (140), a plurality of contact tips (115) (120) extending in a direction from the at least one core (140), and (115)(120) a plurality of gas supply tubes (130)(135) arranged, the plurality of gas supply tubes (130)(135) extending in a direction substantially similar to the plurality of contact tips (115)(120).

Owner:GENERAL ELECTRIC CO

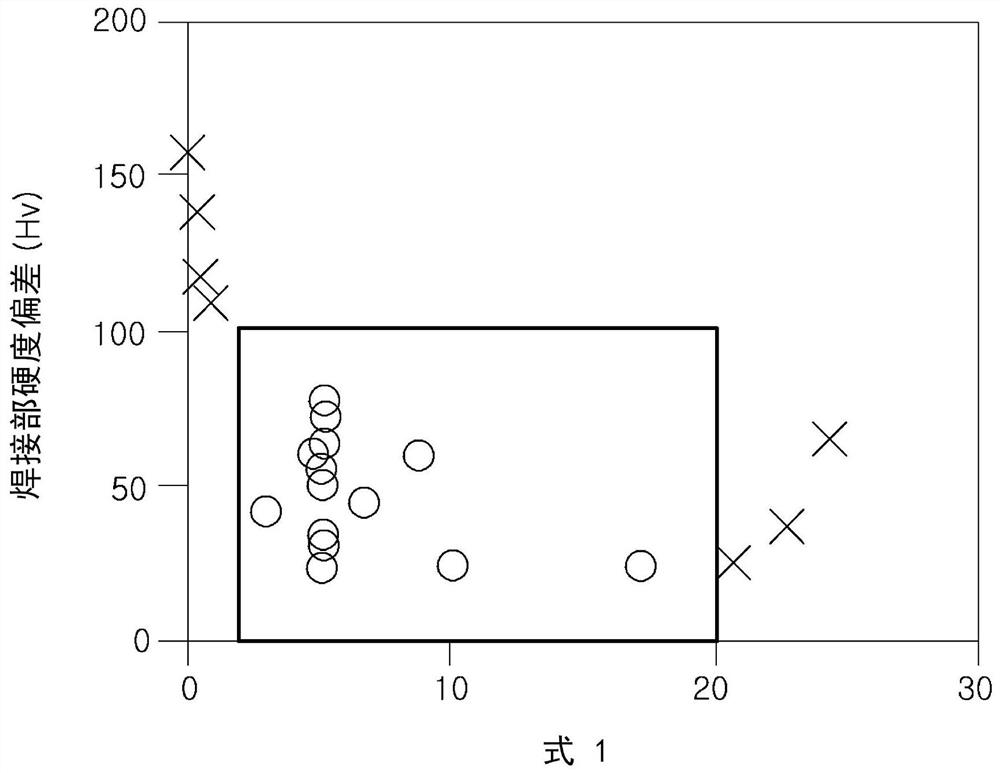

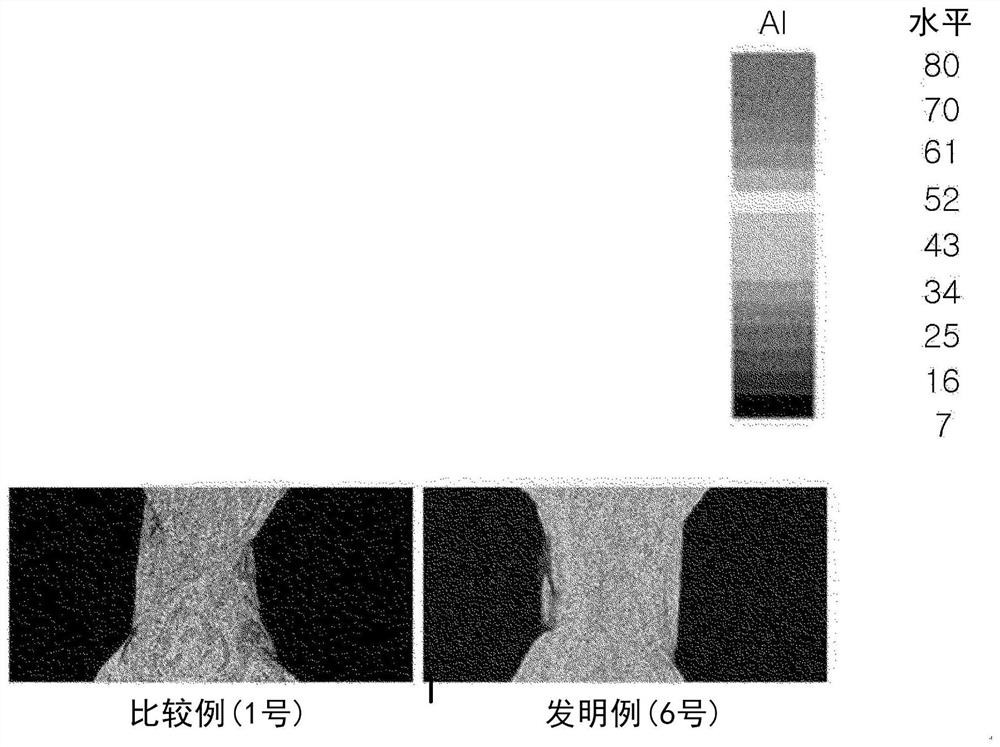

Al-fe-alloy plated steel sheet for hot forming, having excellent twb welding characteristics, hot forming member, and manufacturing methods therefor

PendingCN112218969AUniform hardnessExcellent welding characteristicsHot-dipping/immersion processesShaping toolsAlloyWeld zone

One preferred aspect of the present invention provides: an Al-Fe-alloy plated steel sheet for hot forming, having excellent TWB welding characteristics since excellent hardness uniformity of a TWB weld zone after hot forming is obtained by suitably controlling a batch annealing condition, after plating Al, such that an Al-Fe-alloy layer is formed; a hot forming member; and manufacturing methods therefor.

Owner:浦项股份有限公司

Piping for refrigeration, production method and application

InactiveCN105004108AExcellent welding characteristicsWon't burn throughMechanical apparatusFluid circulation arrangementEngineeringCopper

The invention provides a piping for refrigeration, a production method and application. The piping for refrigeration is compounded from a plurality of metal layers, wherein the metal layers comprise a metal base layer, a side wall formed on the metal base layer and at least one copper cover layer used for being welded with an external part. The piping for refrigeration provided by the invention can totally replace the composite structure of a piping and a connecting piece of the conventional refrigeration device, so that the welding procedure is greatly decreased, and the welding cost is reduced.

Owner:何珠华

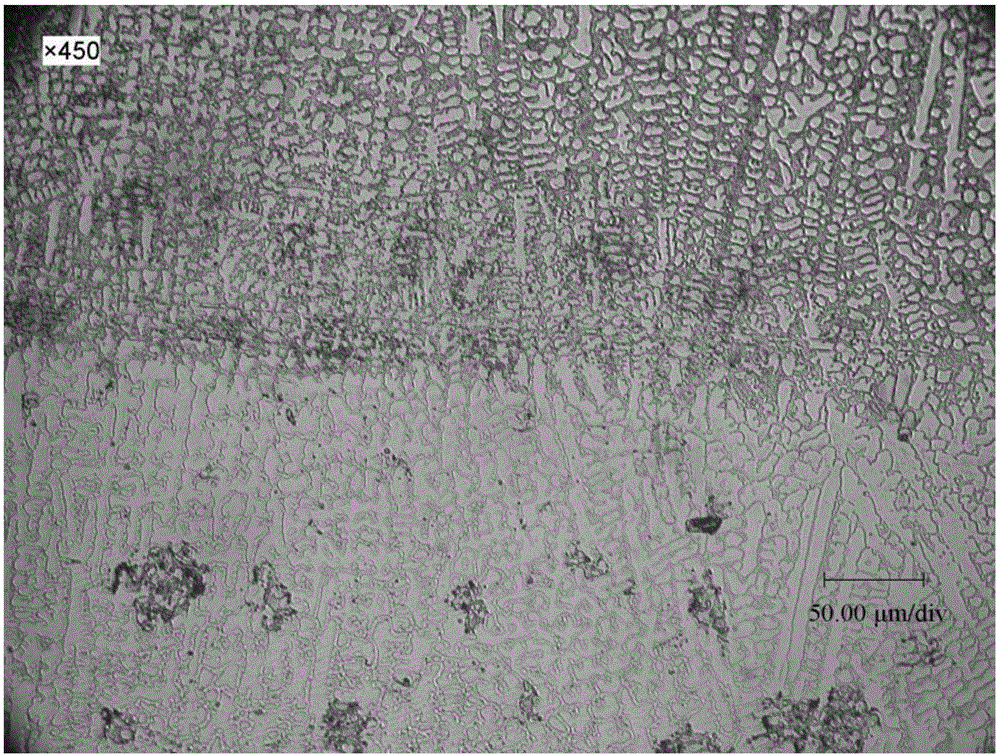

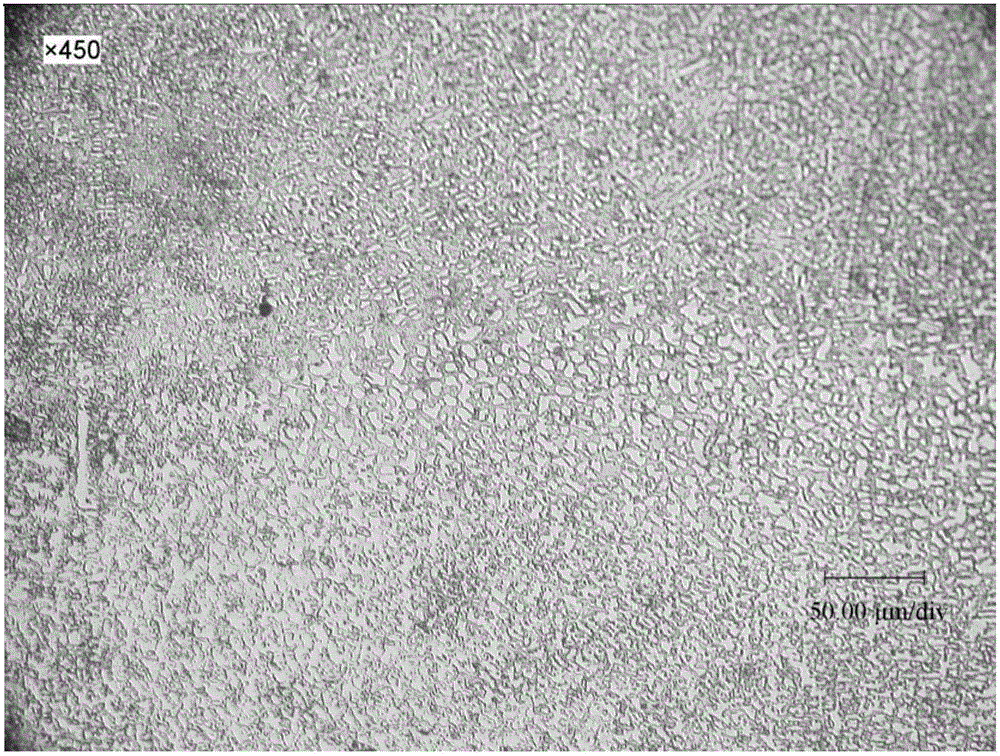

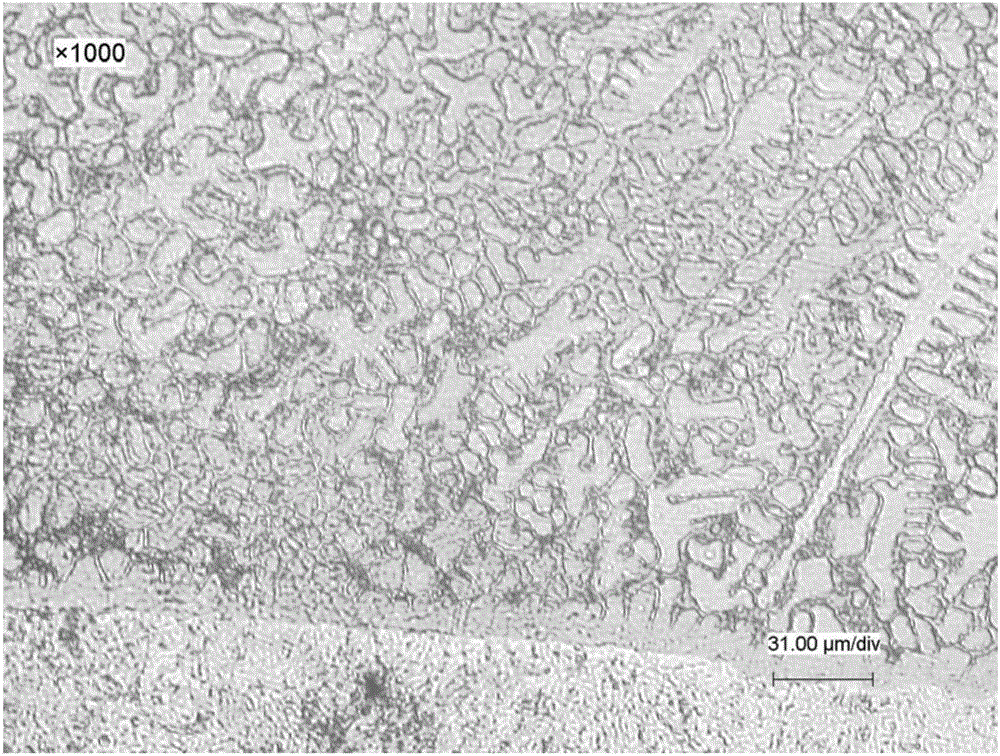

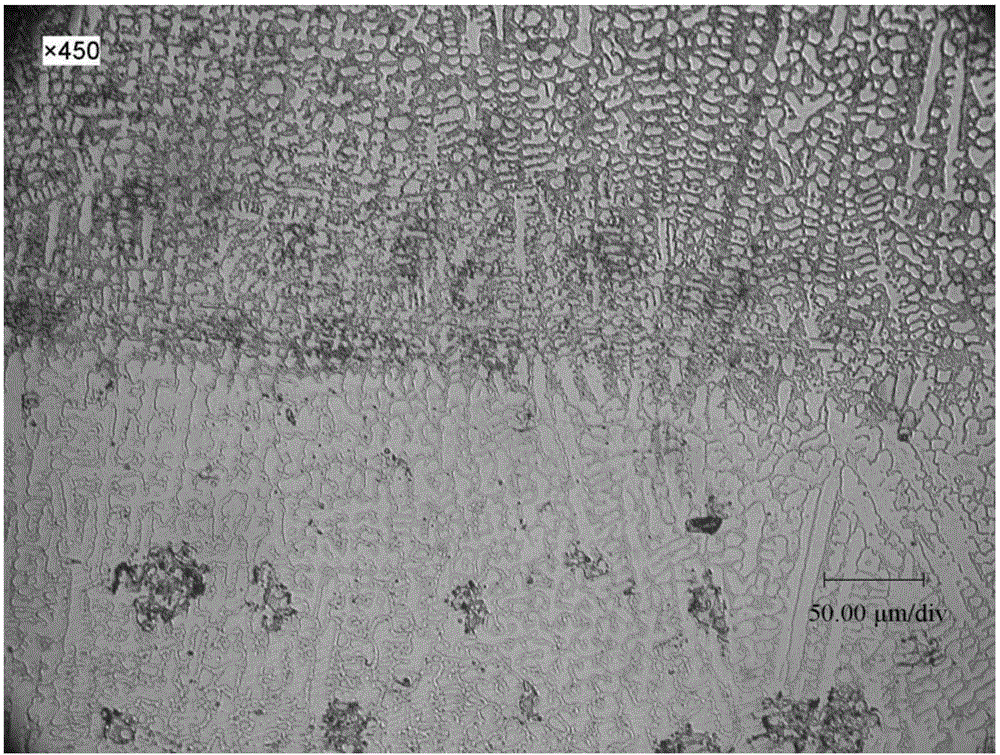

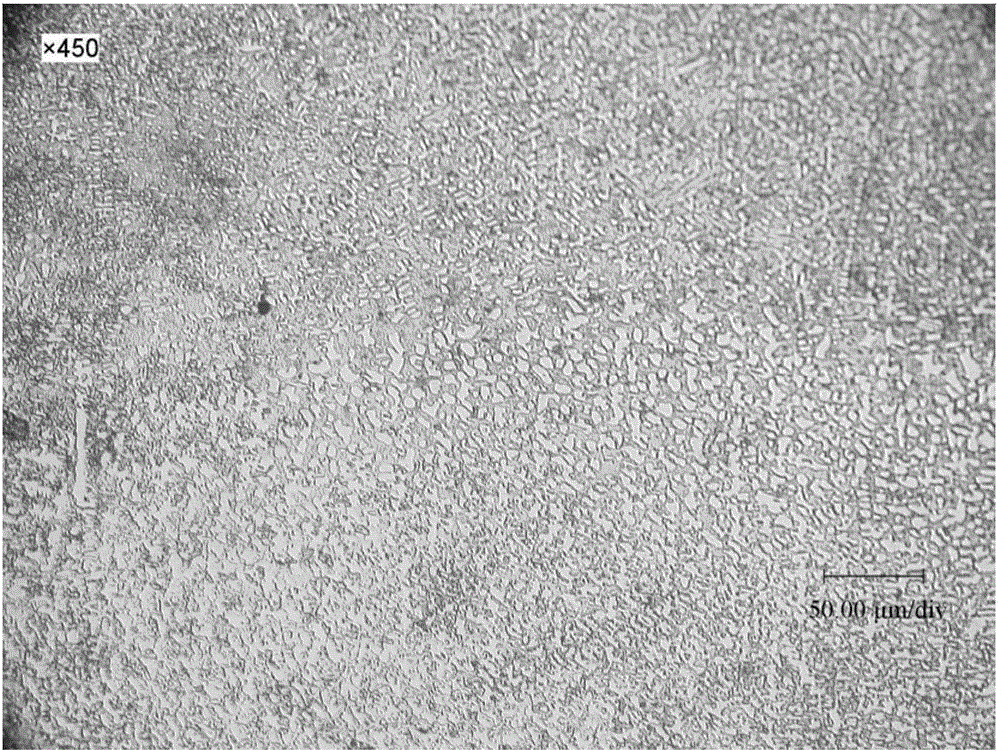

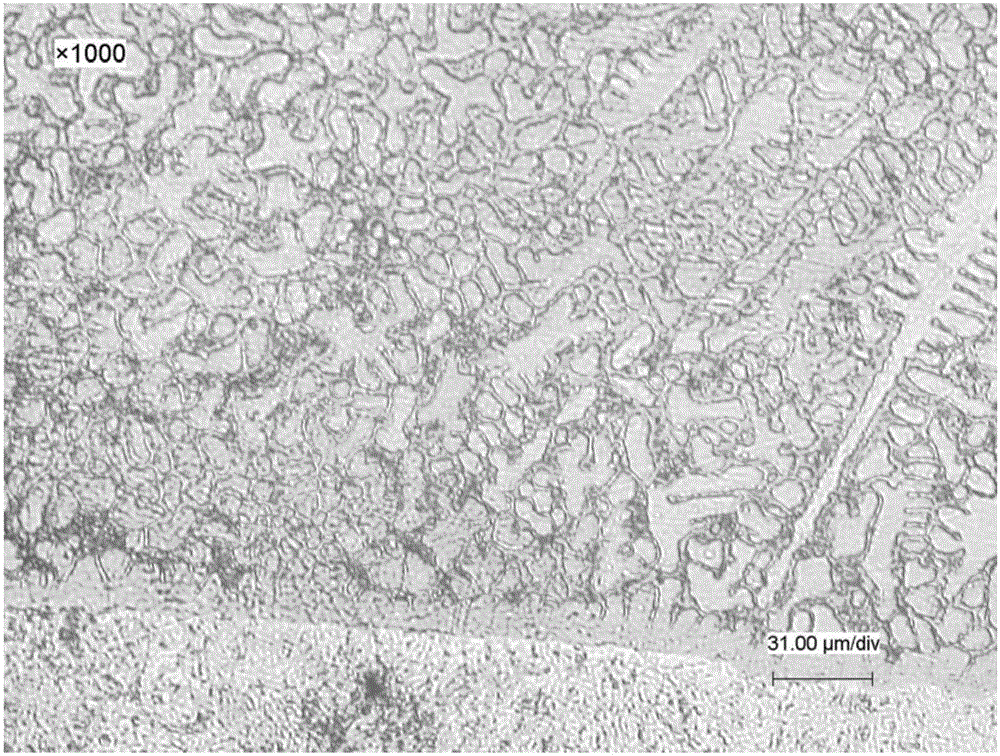

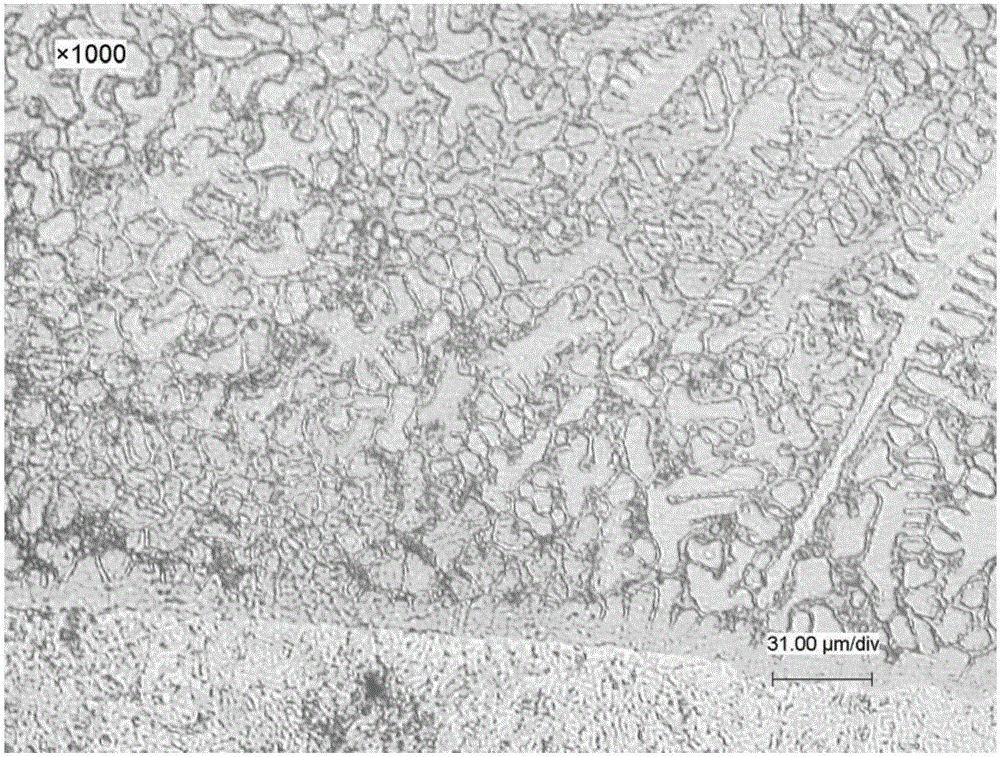

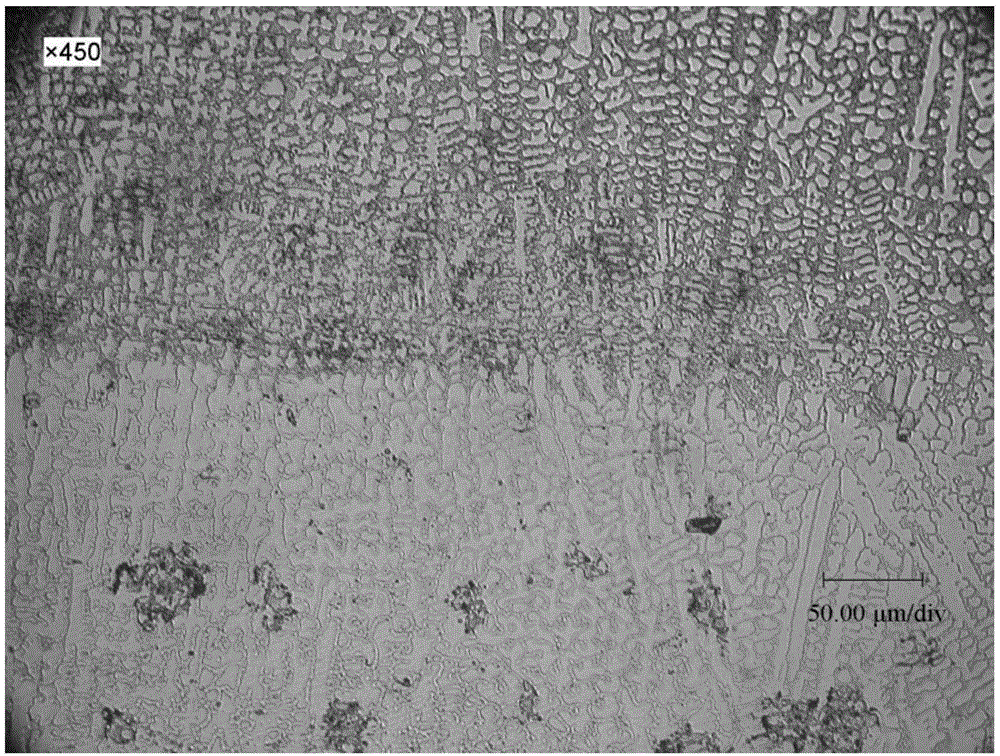

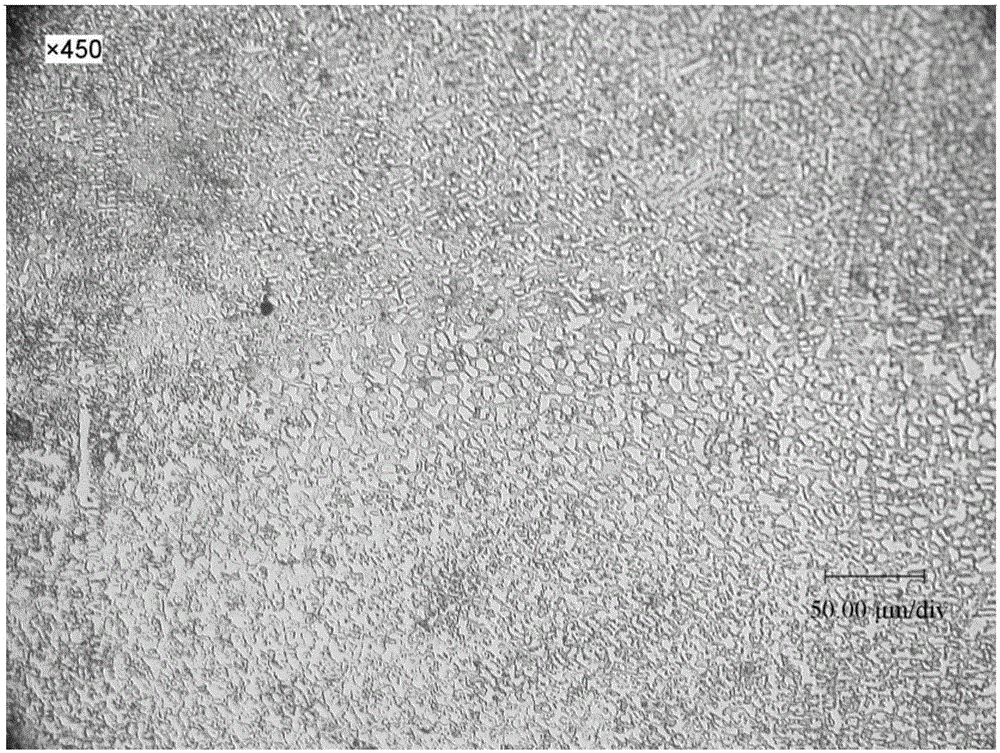

Laser repairing method for allowing roller surface of hot roller to have good thermal hardness after repairing

InactiveCN106567065APositive effectSmall amount of deformationMetallic material coating processesAlloyHardness

The invention relates to a laser repairing method for allowing the roller surface of a hot roller to have good thermal hardness after repairing. A transitional alloy layer, an intermediate alloy layer and a surface alloy layer are arranged on the surface of the hot roller in a laser cladding mode from inside one by one. The alloy powder adopted by the transitional alloy layer comprises, by mass, 0.21%-0.31% of C, 3.2%-3.6% of Si, 1.0%-1.1% of B, 2.2%-2.6% of Fe, 7%-8% of Cr and the balance Ni. The alloy powder adopted by the intermediate alloy layer comprises, by mass, 0.4%-0.5% of C, 3.8%-4.3% of Si, 11.2%-11.93% of B, 2.5%-3.2% of Fe, 10%-12% of Cr and the balance Ni. The alloy powder adopted by the surface alloy layer comprises, by mass, 0.05%-0.1% of C, 3.2%-3.6% of Si, 2%-4% of Fe, 16%-19% of Cr, 27%-30% of Mo and the balance Co. The surface of the hot roller repaired by using the laser repairing method for the hot roller has good abrasion resistance, corrosion resistance and thermal hardness, toughness and strength are taken into account in the interior, and the effect of laser cladding is good.

Owner:DANYANG HONGTU LASER TECH

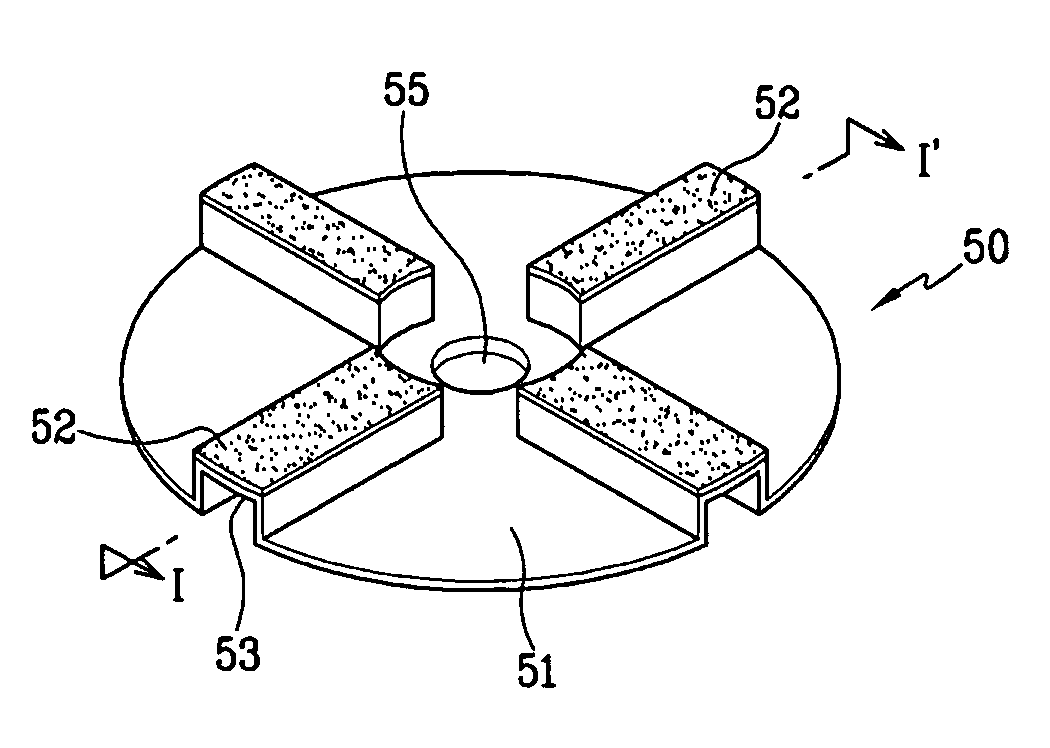

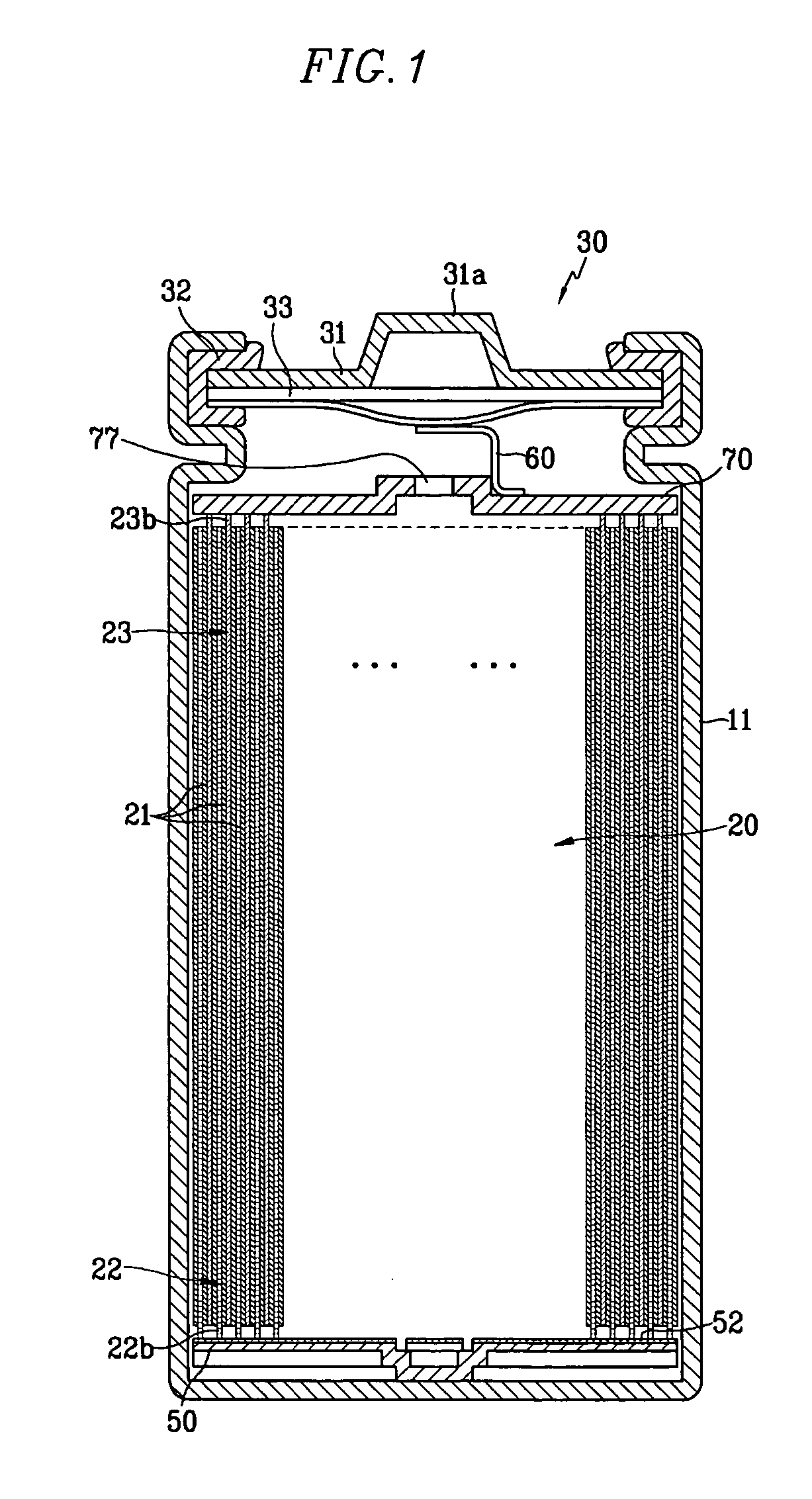

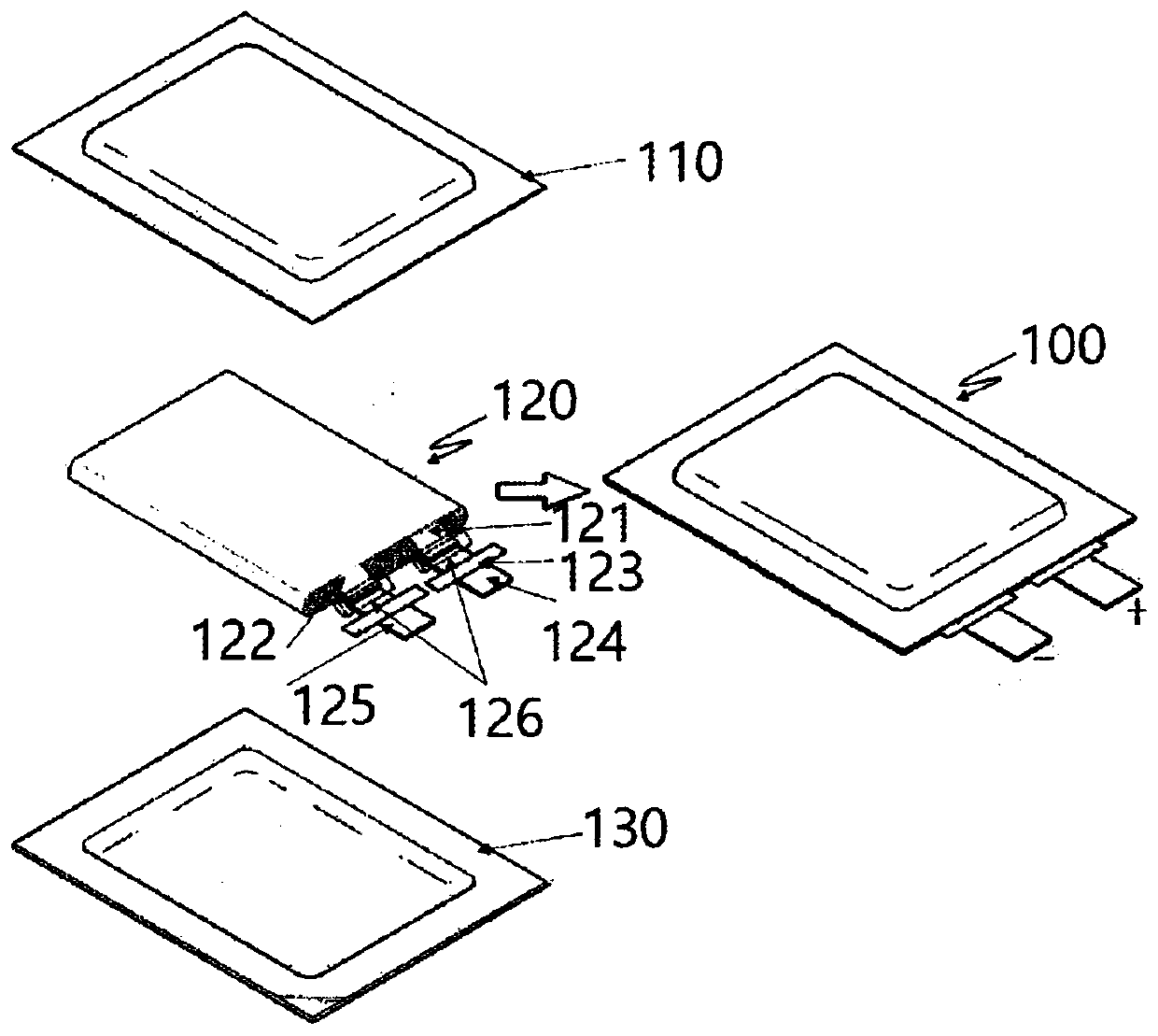

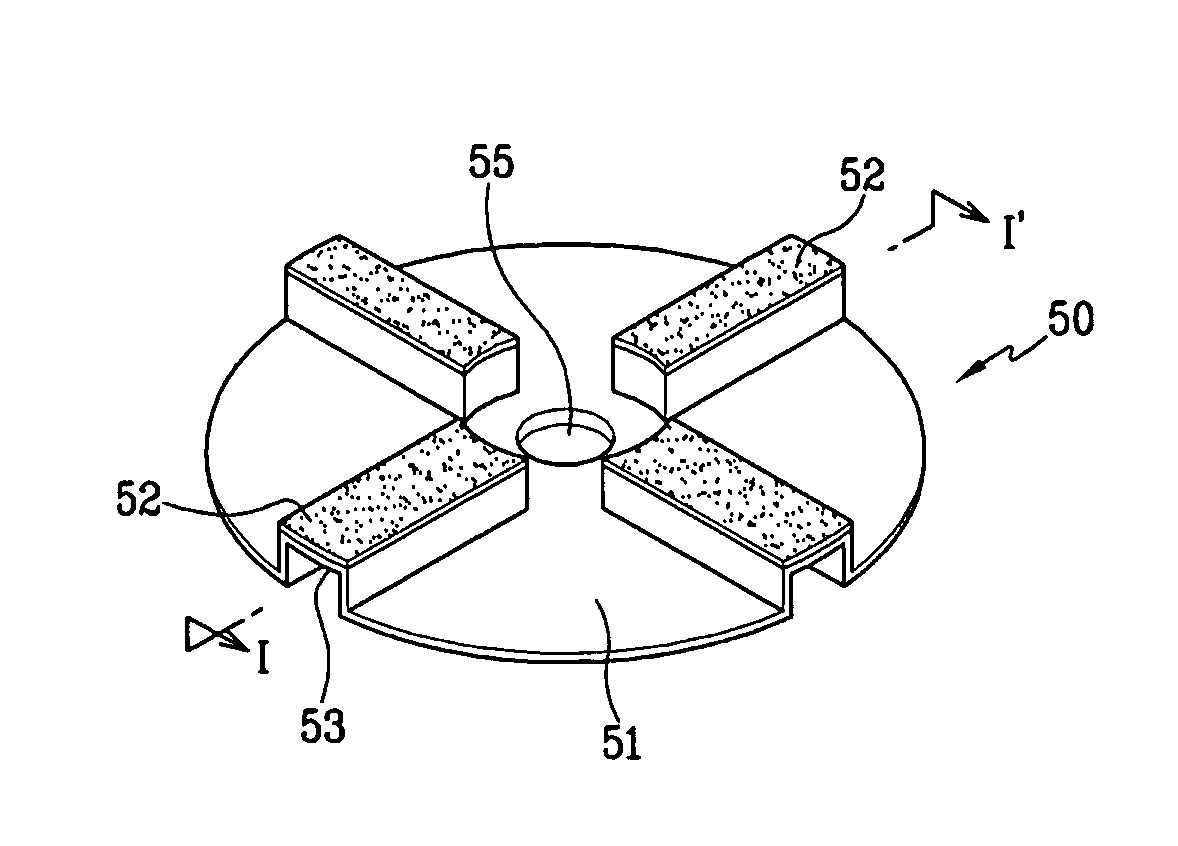

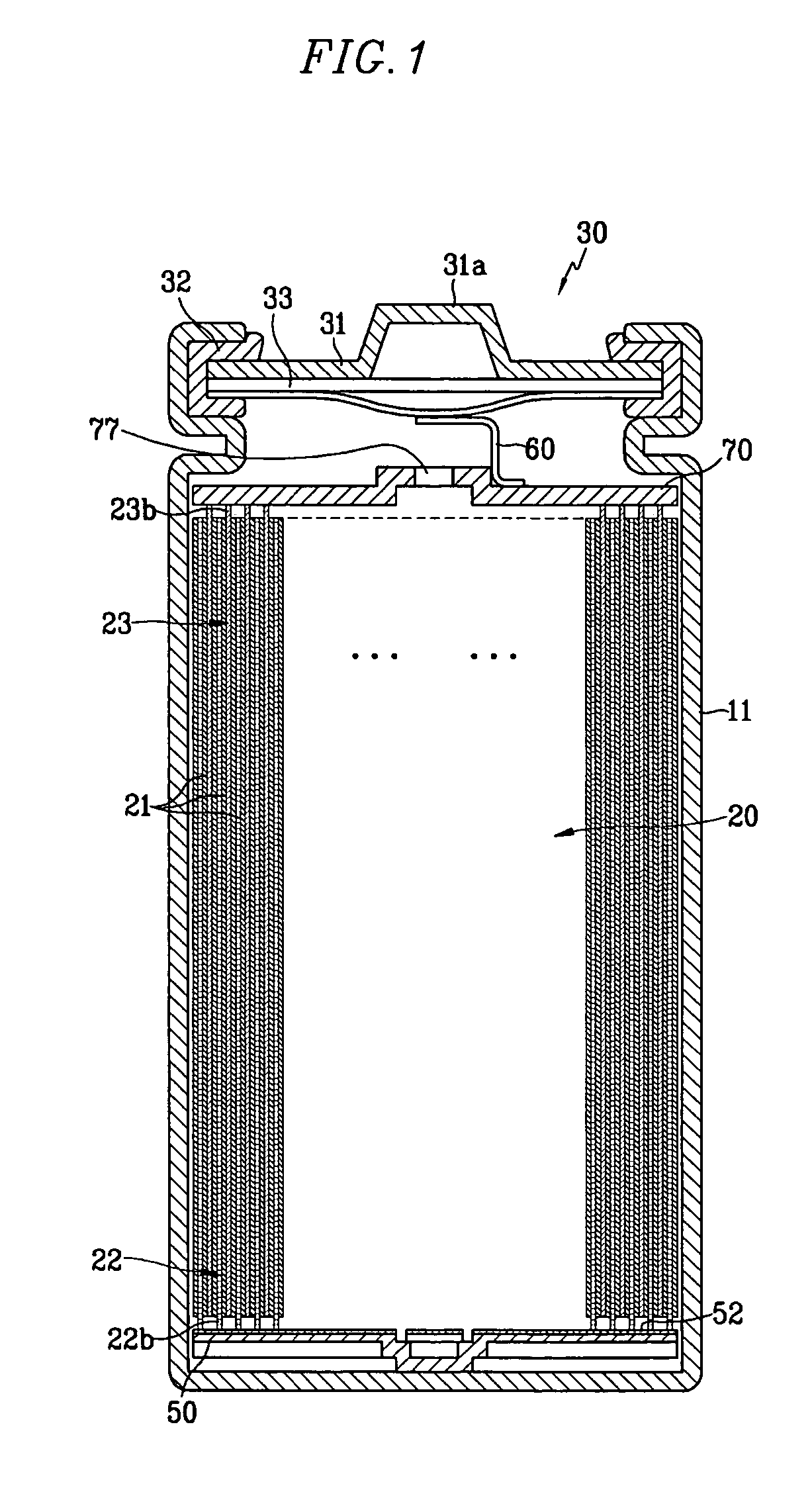

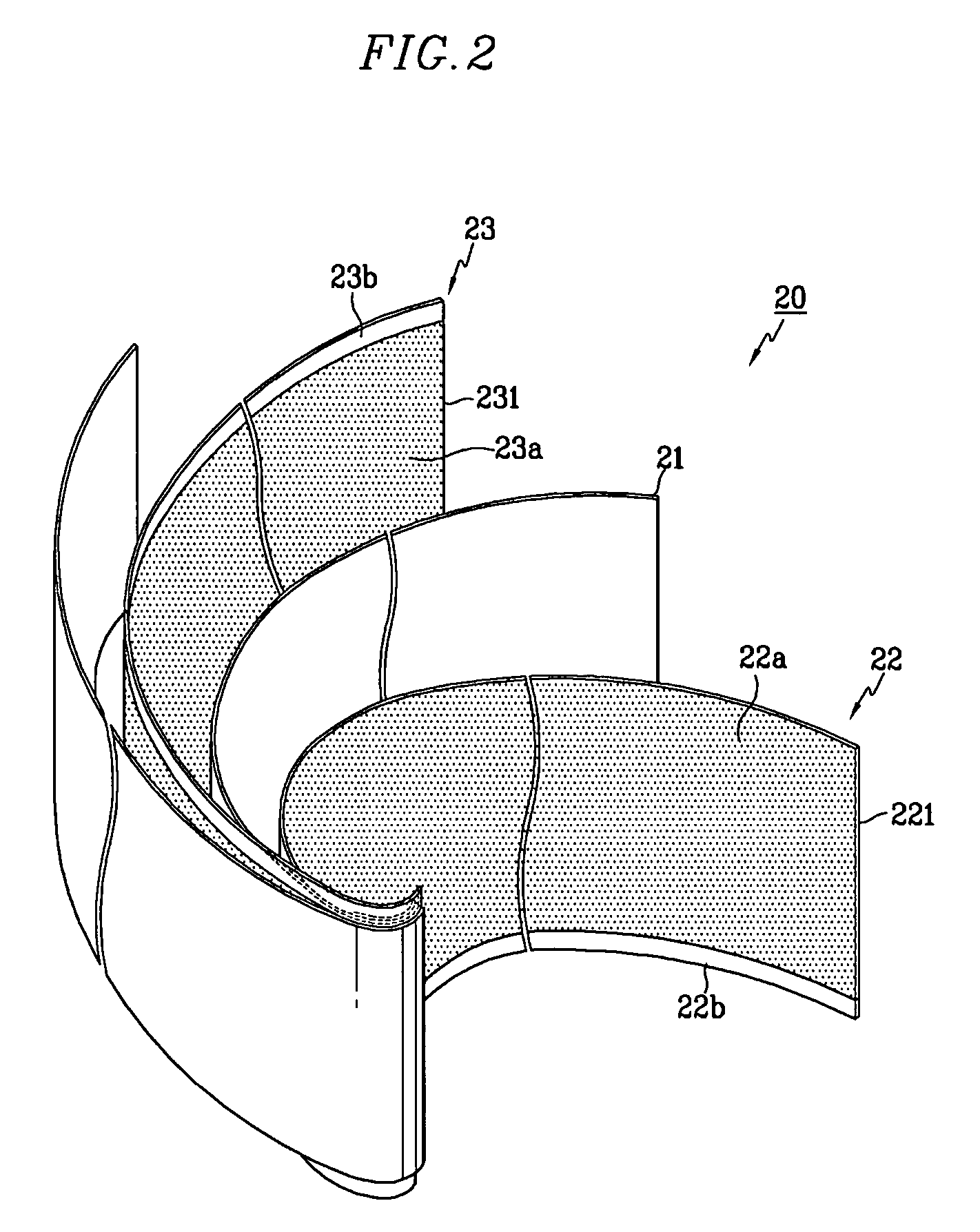

Secondary battery

ActiveUS20050287433A1Well formedExcellent welding characteristicsFinal product manufactureWound/folded electrode electrodesEngineeringMetal

The present invention provides a secondary battery including an electrode assembly comprising positive and negative electrodes with a separator interposed therebetween and wound together, a case, a cap assembly, and a negative current collecting plate. The negative current collecting plate includes a partially surface-treated region for fixing the negative current collecting plate to the negative electrode. The partially surface-treated region comprises a metal other than the metal of the negative current collecting plate. The use of a metal other than the metal of the negative current collecting plate provides an improved weld between the negative current collecting plate and the negative electrode which in turn provides improved battery performance, especially for high-load batteries.

Owner:SAMSUNG SDI CO LTD

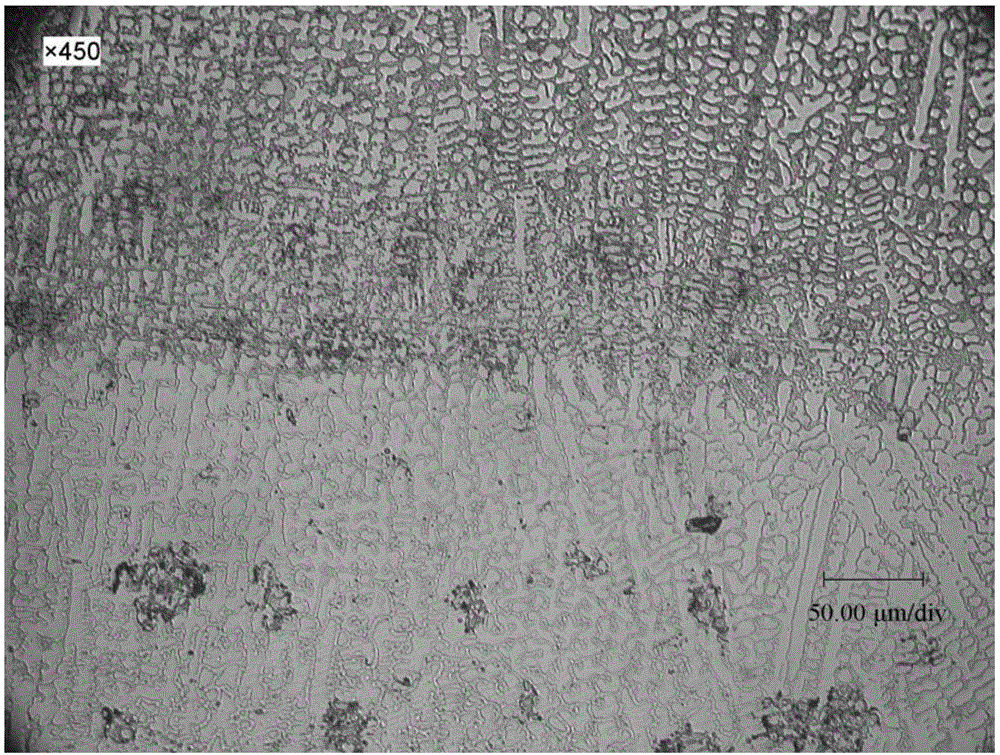

Low roller deformation hot roller laser repair method

InactiveCN106567071APositive effectSmall amount of deformationMetallic material coating processesAlloyUltimate tensile strength

The present invention relates to a low roller deformation hot roller laser repair method, wherein a transition alloy layer, an intermediate alloy layer and a surface alloy layer are sequentially subjected to laser cladding on the surface of a hot roller from the inner layer, the components of the alley powder used by the transition alloy layer comprise, by mass, 0.2-0.3% of C, 3.2-3.6% of Si, 1.2-1.8% of B, 2.2-2.6% of Fe, 7-8% of Cr and the balance of Ni, the components of the alley powder used by the intermediate alloy layer comprise, by mass, 0.4-0.5% of C, 3.8-4.3% of Si, 12-13% of B, 2.5-3.2% of Fe, 10-12% of Cr and the balance of Ni, and the components of the alley powder used by the surface alloy layer comprise, by mass, 0.05-0.1% of C, 3.0-3.16% of Si, 2-4% of Fe, 16-19% of Cr, 27-30% of Mo, and the balance of Co. According to the present invention, the hot roller repaired by using the hot roller laser repair method of the present invention has good abrasion resistance, good corrosion resistance and good thermal rigidity of the surface, has good toughness and good strength of the internal, and has good laser cladding effect.

Owner:DANYANG HONGTU LASER TECH

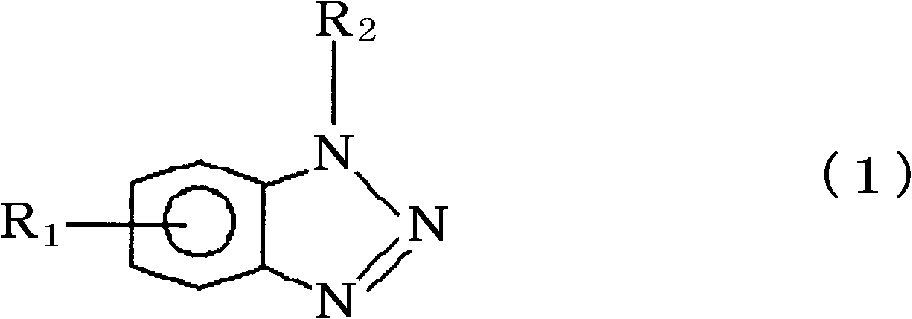

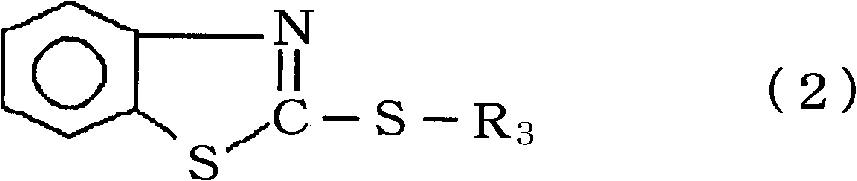

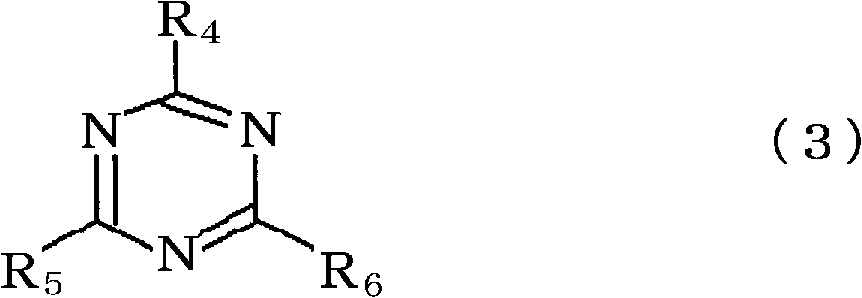

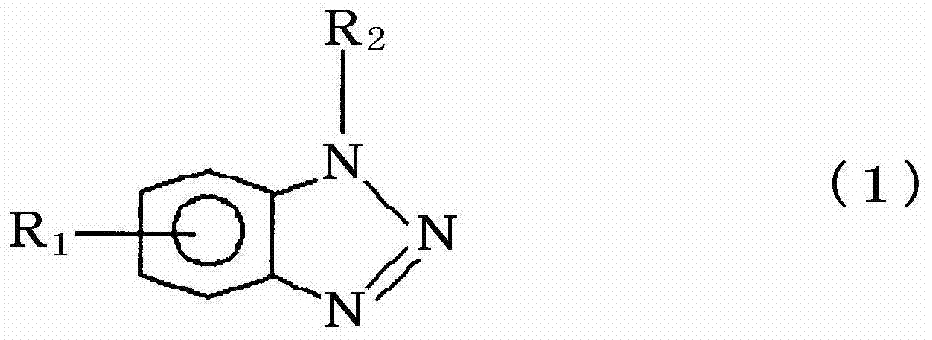

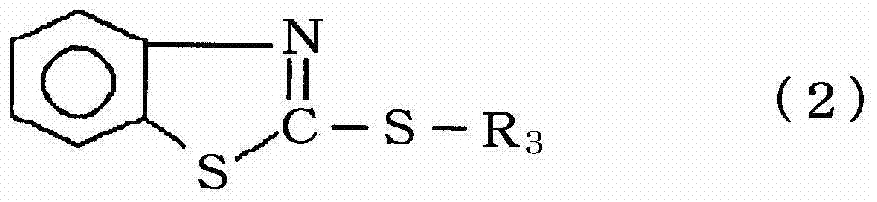

Agent for treatment of metal surface

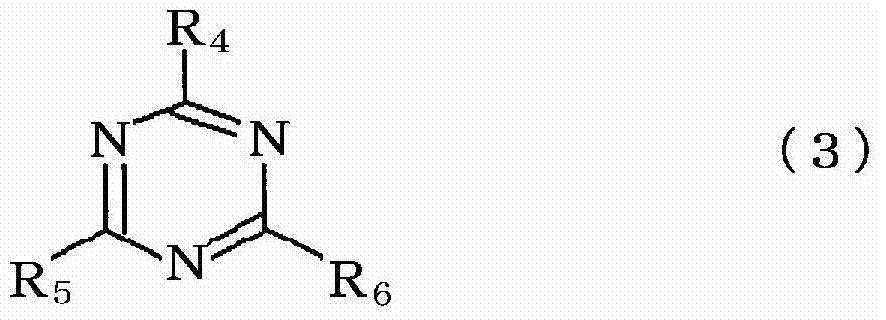

InactiveCN102713007AExcellent welding characteristicsNo appearance defectSemiconductor devicesBenzeneBenzotriazole

Disclosed is an agent for treating a metal surface, which can exhibit a high discoloration-preventing effect even when exposed to a heat treatment during a production process thereof or high temperature environments during use, has excellent wire bonding properties, and does not cause the deterioration in reflectivity when subjected to a surface treatment. The agent for treating a metal surface is characterized by being produced by dissolving or dispersing, as an inhibitor, at least specific compound selected from the group consisting of a benzotriazole compound represented by general formula (1), a mercaptobenzothiazole compound represented by general formula (2) and a triazine compound represented by general formula (3) in water and adjusting the pH value of the solution or dispersion to 4 to 7.

Owner:JX NIPPON MINING & METALS CO LTD

A hot roller laser restoration method capable of prolonging the service lifetime of a hot roller

InactiveCN106567064APositive effectSmall amount of deformationMetallic material coating processesRestoration methodWear resistance

The invention relates to a hot roller laser restoration method capable of prolonging the service lifetime of a hot roller. A transitional alloy layer, a middle alloy layer and a surface alloy layer are cladded with laser layer by layer from the inside on the surface of the hot roller. Alloy powder adopted by the transitional alloy layer includes components by mass: 0.12-0.19% of C, 3.2-3.6% of Si, 1.2-1.8% of B, 2.2-2.6% of Fe, and 7-8% of Cr, with the balance being Ni. Alloy powder adopted by the middle alloy layer includes components by mass: 0.4-0.5 % of C, 3.8-4.3% of Si, 12-13% of B, 2.5-3.2% of Fe, and 10-12% of Cr, with the balance being Ni. Alloy powder adopted by the surface alloy layer includes components by mass: 0.05-0.1% of C, 3.0-3.16% of Si, 2-4% of Fe, 16-19% of Cr and 27-30% of Mo, with the balance being Co. The surface of the hot roller restored by the method has good wear resistance, corrosion resistance and hot hardness, both toughness and strength of the inside of the hot roller are taken into account, and laser cladding effects are good.

Owner:DANYANG HONGTU LASER TECH

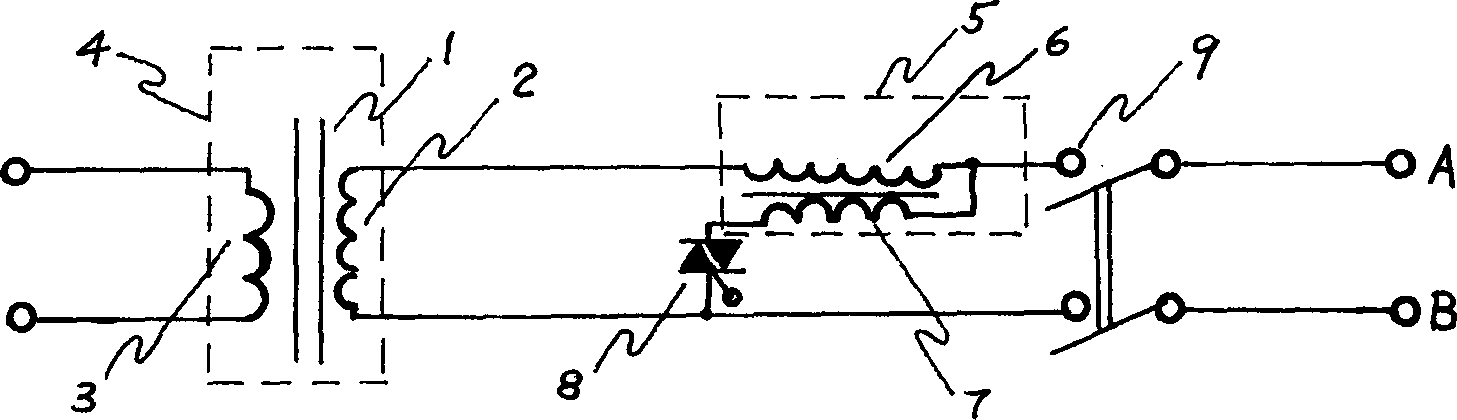

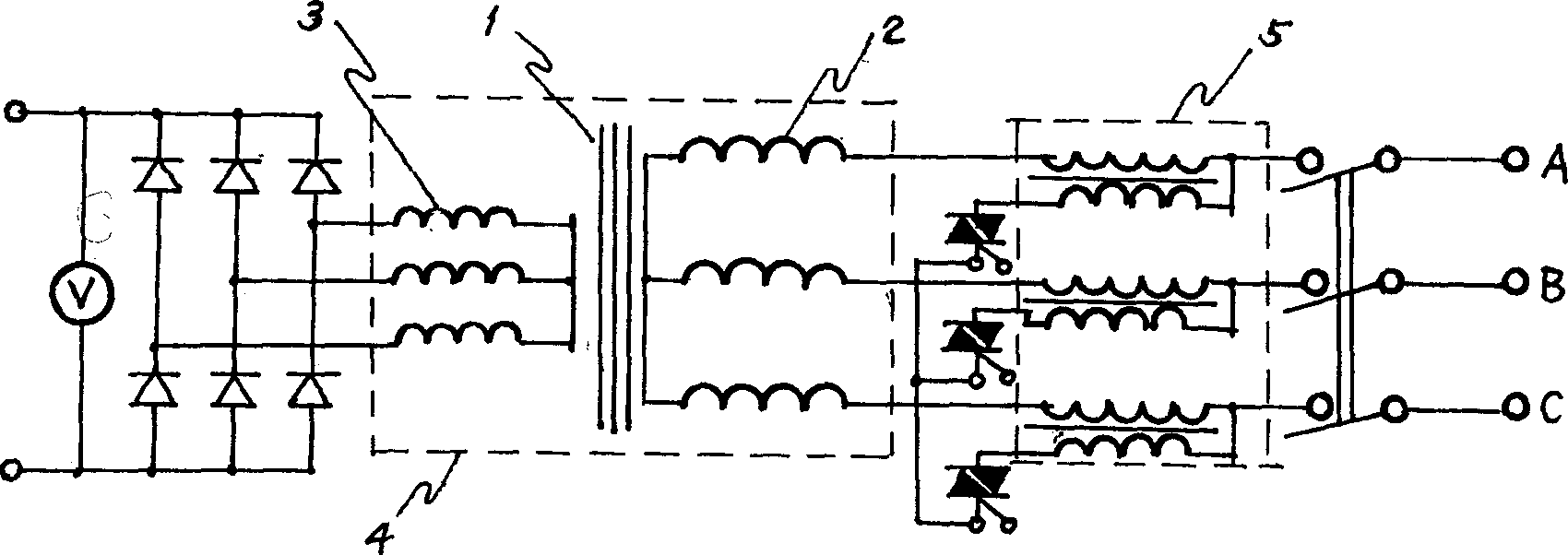

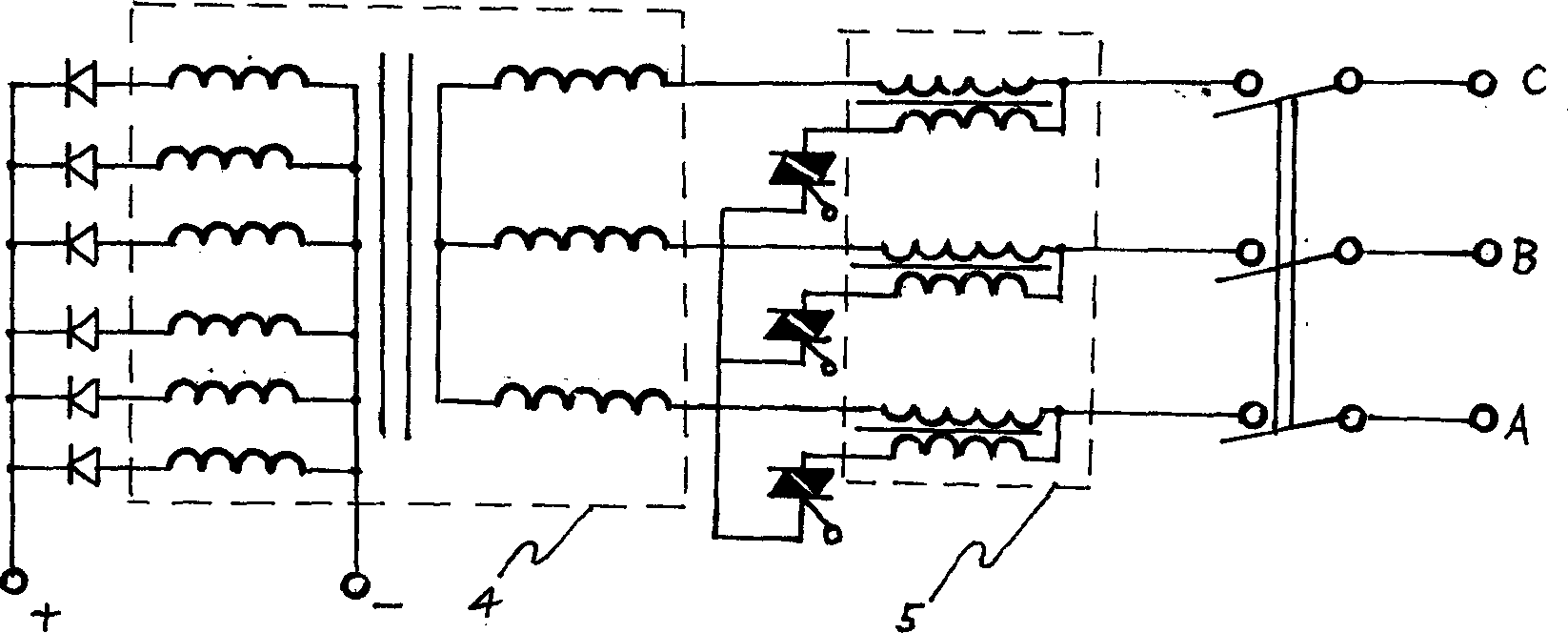

Power supply system for arc welding

InactiveCN1380156ANo pollution in the processReduce no-load lossTransformersArc welding apparatusDIACTransformer

The arc welding power supply system is formed from transformer consisting of iron core and first winding and second winding, and a auto compensator transformer is connected on the first winding of the transformer. The second winding of the auto compensator transsformer is series-connected with one end of first winding of the transformer, its first winding is series-connected with its second-winding, then is series-connected with bidirectinoal triod thyristor, finally connected on another end of first winding of the transformer, and the series-connected end of first winding and second winding of the compensator transformer is tapped and connected to power supply. The transformer and compensator transformer can be single-phase, also can be three-phase ones. The power factor is high, arc is stable, can be extensively used for transformation current regualtion and A.C and D.C. welding various metal material.

Owner:姜孟泽

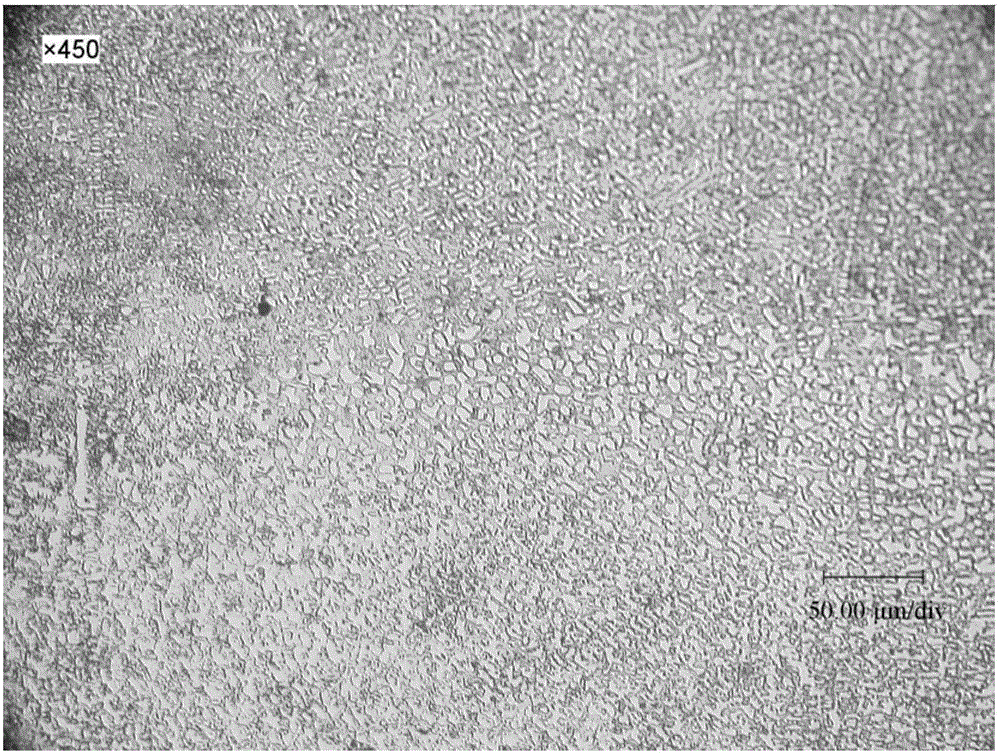

Laser repairing method of hot roll good in laser cladding effect

InactiveCN106567069APositive effectSmall amount of deformationSuperimposed coating processToughnessRepair method

The invention relates to a laser repairing method of a hot roll good in laser cladding effect. The surface of the hot roll is laser-cladded with a transition alloy layer, an intermediate alloy layer and a surface alloy layer from the inside layer by layer; alloy powder adopted by the transition alloy layer comprises, by mass, 0.21-0.31% of C, 3.2-3.6% of Si, 1.0-1.1% of B, 2.2-2.6% of Fe, 7-8% of Cr and the balance Ni; alloy powder adopted by the intermediate alloy layer comprises, by mass, 0.4-0.5% of C, 3.8-4.3% of Si, 11.2-11.93% of B, 2.5-3.2% of Fe, 10-12% of Cr and the balance Ni; and alloy powder adopted by the surface alloy layer comprises, by mass, 0.05-0.1% of C, 3.0-3.16% of Si, 2-4% of Fe, 16-19% of Cr, 27-30% of Mo and the balance Co. The hot roll repaired by the laser repairing method of the hot roll good in laser cladding effect has good abrasion resistance, corrosion resistance and hot hardness in surface, integrates toughness and strength inside, and is good in laser cladding effect.

Owner:DANYANG HONGTU LASER TECH

Solder paste for signal processing base board and preparation method of solder paste

ActiveCN105364340AModerate viscosityExtended shelf lifeWelding/cutting media/materialsSoldering mediaPolyethylene glycolX-ray

The invention discloses solder paste for a signal processing base board and a preparation method of the solder paste. The preparation method comprises the following steps of (1) mixing Sn-Zn alloy, nickel, cobalt, hydrated chloroauric acid, polyvinylpyrrolidone, reducing agents and water for contact reaction, so as to prepare an activated metal composition; (2) heating to dissolve rosin, rosin amine, organic acid, imidazole and diallyl phthalate isocyanuric acid, so as to prepare a mixed solution I; (3) mixing the mixed solution I, thixotropic agents and preservatives, and then cooling, so as to prepare a mixed solution II; (4) mixing the mixed solution II and polyethylene glycol, so as to prepare flux; (5) refrigerating the flux, and then dispersing and mixing the flux with the activated metal composition under vacuum in the presence of X rays, so as to prepare the solder paste for the signal processing base board. The solder paste prepared by using the preparation method has the advantages of excellent chemical stability, low welding temperature and excellent extension rate.

Owner:芜湖雅葆轩电子科技股份有限公司

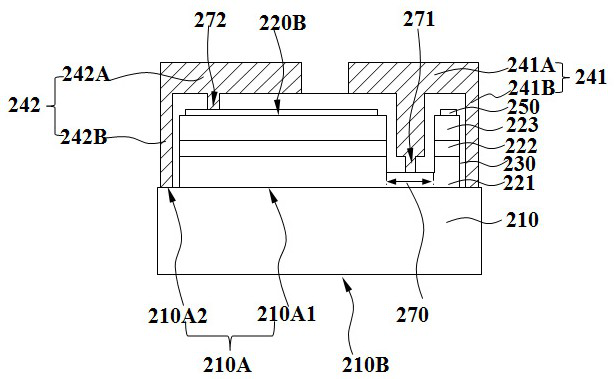

Electrode having improved electrode tab welding characteristic and secondary battery comprising same

ActiveCN110326130AExcellent welding characteristicsIncrease the number ofNegative electrodesPositive electrodesElectrical batteryElectrical polarity

The present invention relates to an electrode having an improved electrode tab welding characteristic, which includes one or more non-coated-part electrode tabs of the same polarity stacked on each other to maintain welding safety regardless of an increase in the number of stacked electrode layers in order to realize high output and high capacity, and a secondary battery comprising the same. The present invention can prevent disconnection which may occur when a plurality of electrode tabs are welded. Also, in the present invention, a lower end portion of an electrode lead, which is to be welded to the non-coated-part electrode tabs of the same polarity stacked on each other, is pressed to correspond to the non-coated-part electrode tabs. Therefore, the present invention can enhance the flexibility of an electrode step difference in a secondary battery.

Owner:LG ENERGY SOLUTION LTD

A hot roller laser restoration method allowing a restored surface to have good wear resistance

InactiveCN106567070ASmall amount of deformationExtended service lifeMetallic material coating processesRestoration methodWear resistance

The invention relates to a hot roller laser restoration method allowing a restored surface to have good wear resistance. A transition alloy layer, a middle alloy layer and a surface alloy layer are cladded with laser layer by layer from the inside on the surface of a hot roller. Alloy powder adopted by the transition alloy layer includes components by mass: 0.31-0.35% of C, 3.2-3.6% of Si, 1.2-1.8% of B, 2.2-2.6% of Fe, and 7-8% of Cr, with the balance being Ni. Alloy powder adopted by the middle alloy layer includes components by mass: 0.4-0.5 % of C, 3.8-4.3% of Si, 12-13% of B, 2.5-3.2% of Fe, and 10-12% of Cr, with the balance being Ni. Alloy powder adopted by the surface alloy layer includes components by mass: 0.05-0.1% of C, 3.2-3.6% of Si, 2-4% of Fe, 16-19% of Cr and 27-30% of Mo, with the balance being Co. The surface of the hot roller restored by the method has good wear resistance, corrosion resistance and hot hardness, both toughness and strength of the inside of the hot roller are taken into account, and laser cladding effects are good.

Owner:DANYANG HONGTU LASER TECH

Agent for treatment of metal surface

ActiveCN103789772AExcellent welding characteristicsNo appearance defectSemiconductor devicesBenzeneBenzotriazole

Owner:JX NIPPON MINING & METALS CORP

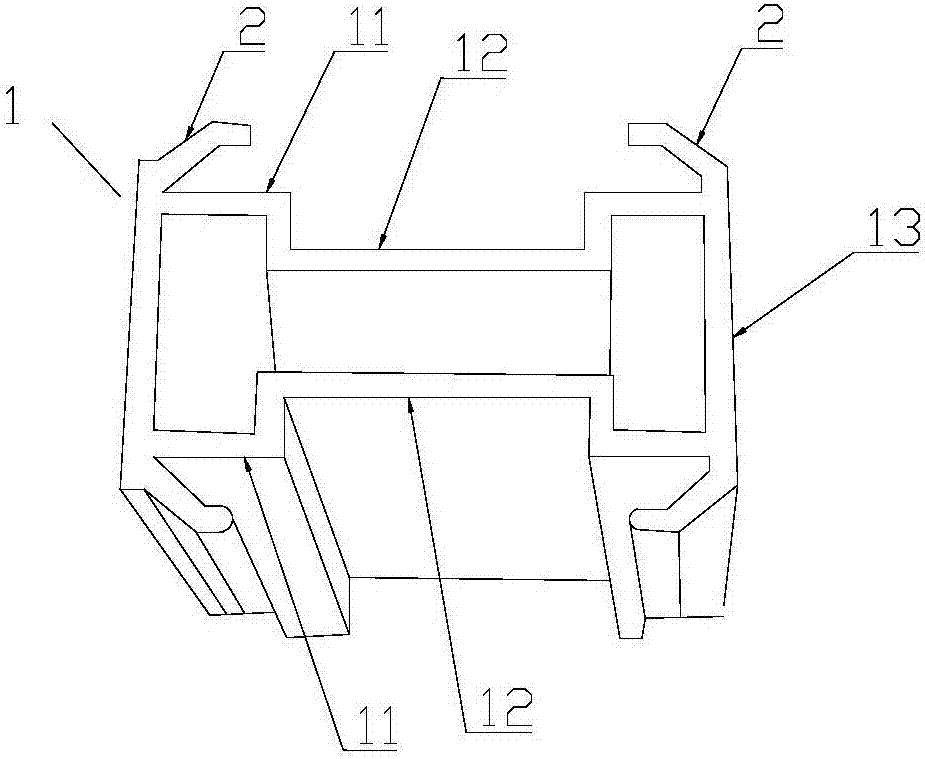

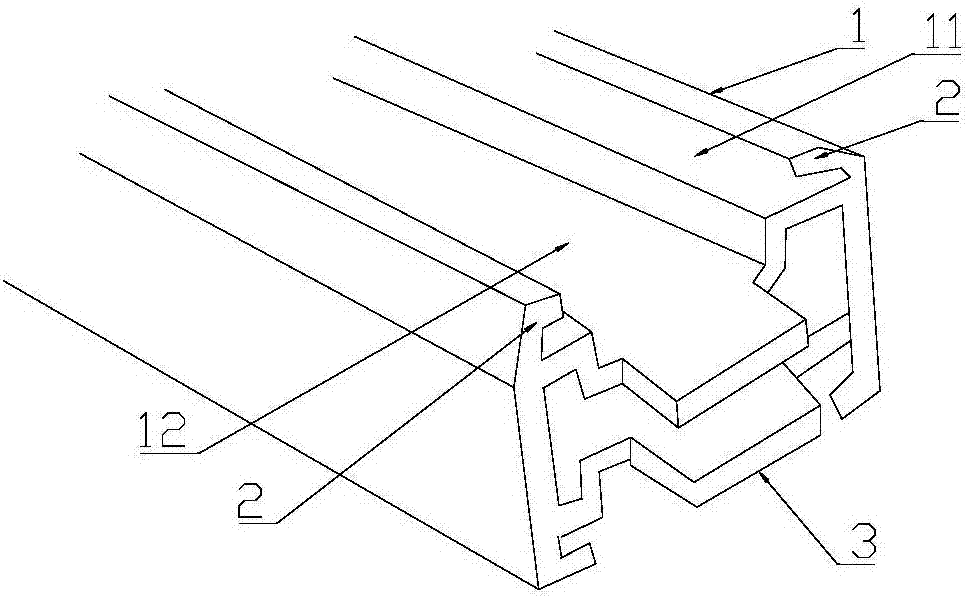

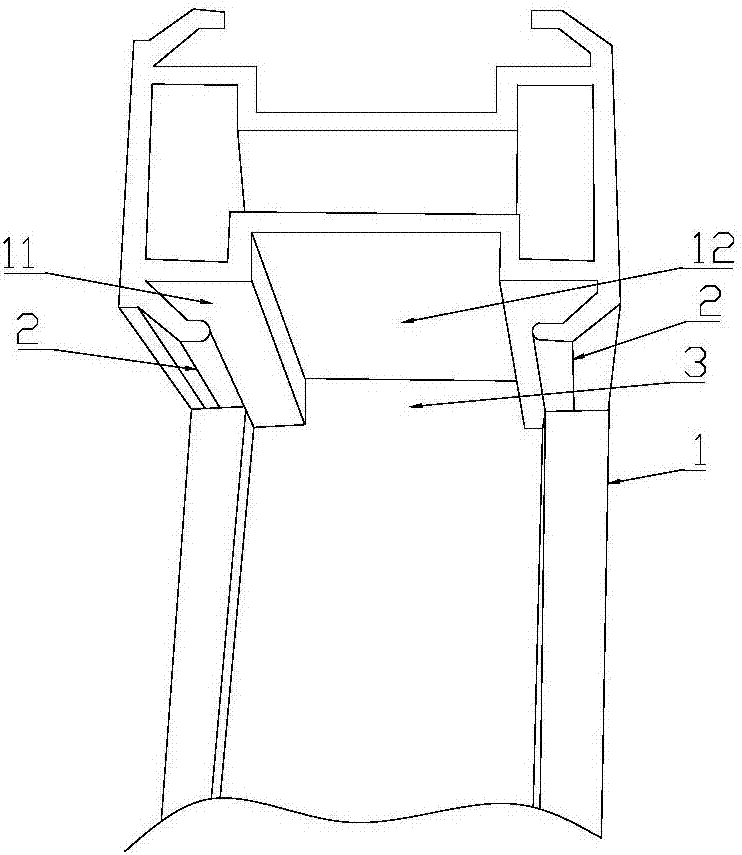

Process for machining shielding window through buckle cover sectional materials

ActiveCN107138833AQuality improvementIncrease productivityWindow/door framesWelding accessoriesEngineeringProduction quality

The invention provides a process for machining a shielding window through buckle cover sectional materials. The process comprises the following steps that (1) the main sectional material and the connecting sectional material used for being connected with the main sectional material are machined, the main sectional material and the connecting sectional material comprises square frames, and clamping blocks are arranged on the two sides of the opposite side walls of the square frames correspondingly; (2) the side walls without the clamping blocks of the main sectional material and the connecting section material are subjected to surface color treatment; (3) protruding parts are machined on the end faces of the two side faces, where the clamping blocks are arranged, of the connecting sectional material; and (4) the protruding parts of the end faces of the connecting sectional material are welded to the side walls, where the clamping blocks are arranged, of the main sectional material. Through the process for machining the shielding window through the buckle cover sectional materials, the production efficiency and production quality are improved.

Owner:安徽省觅沃玻璃有限公司

High strength thin steel sheet excelling in weldability and process for producing the same

Owner:POHANG IRON & STEEL CO LTD

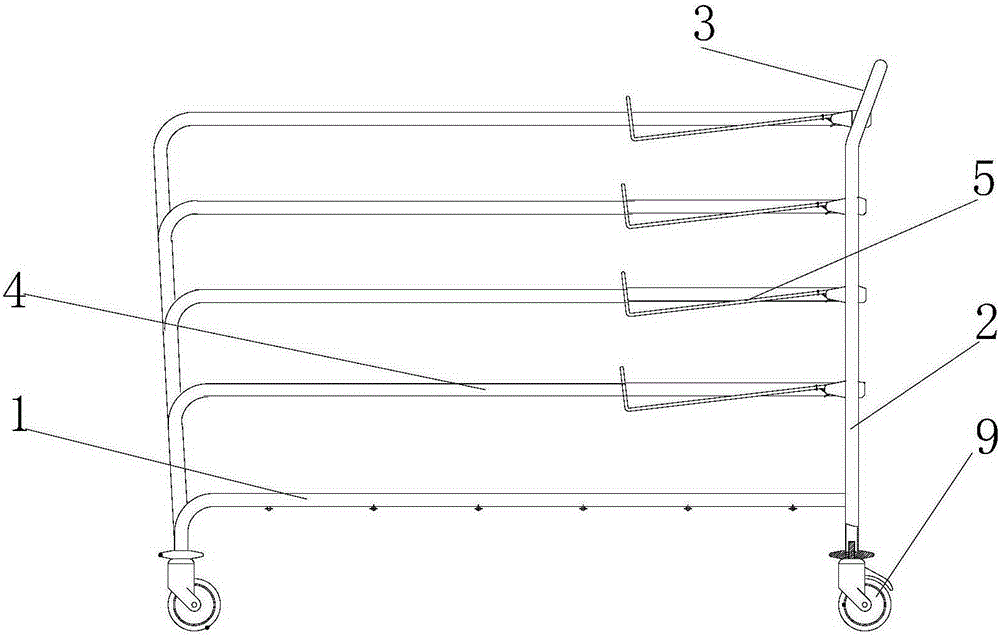

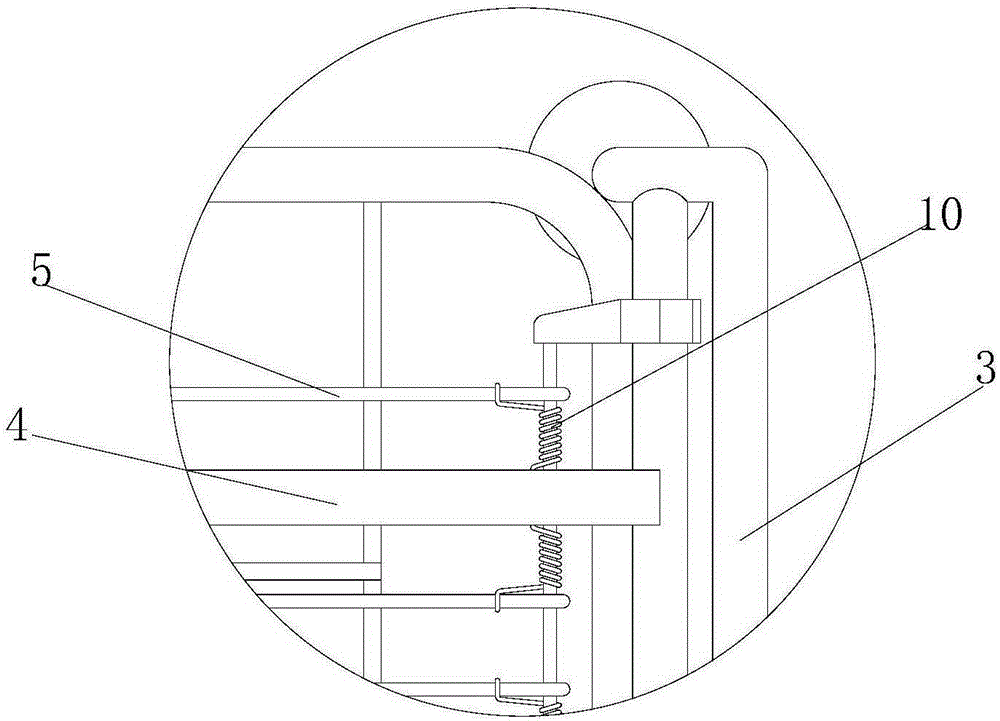

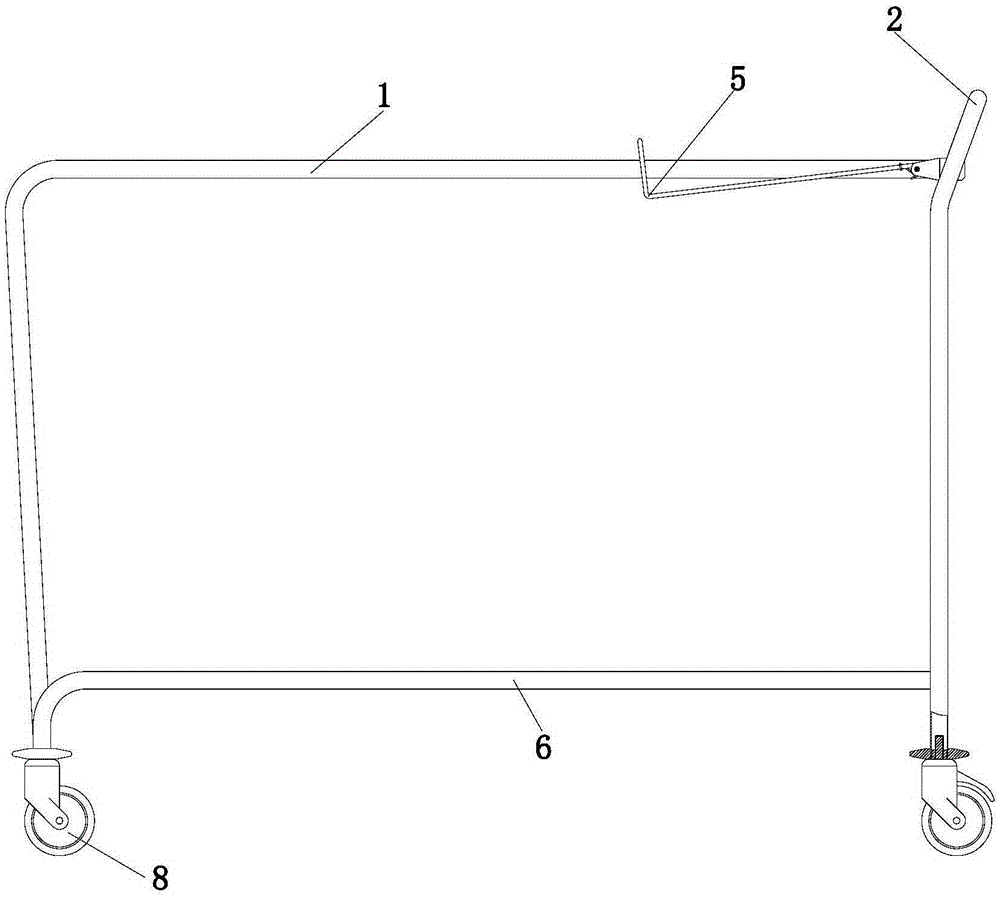

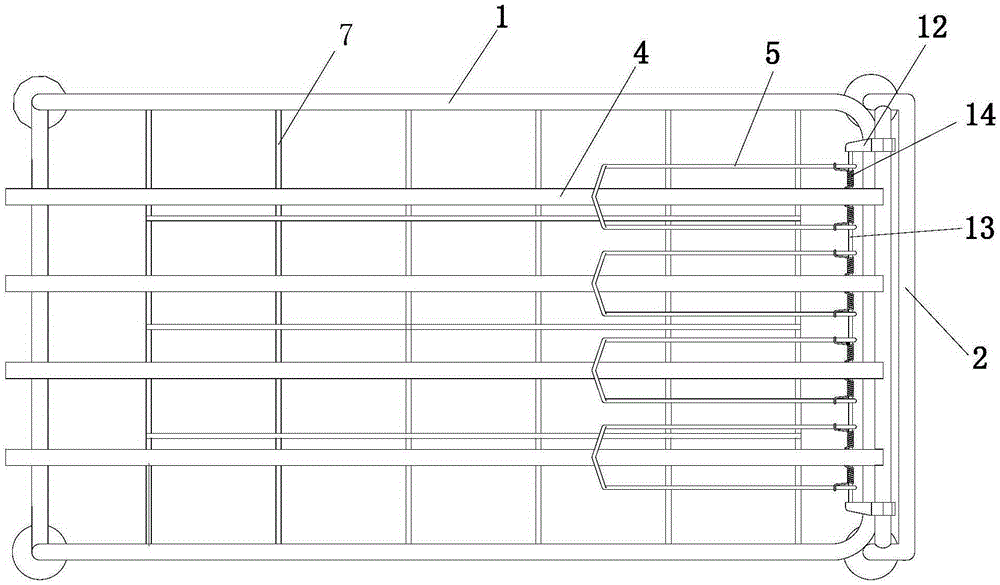

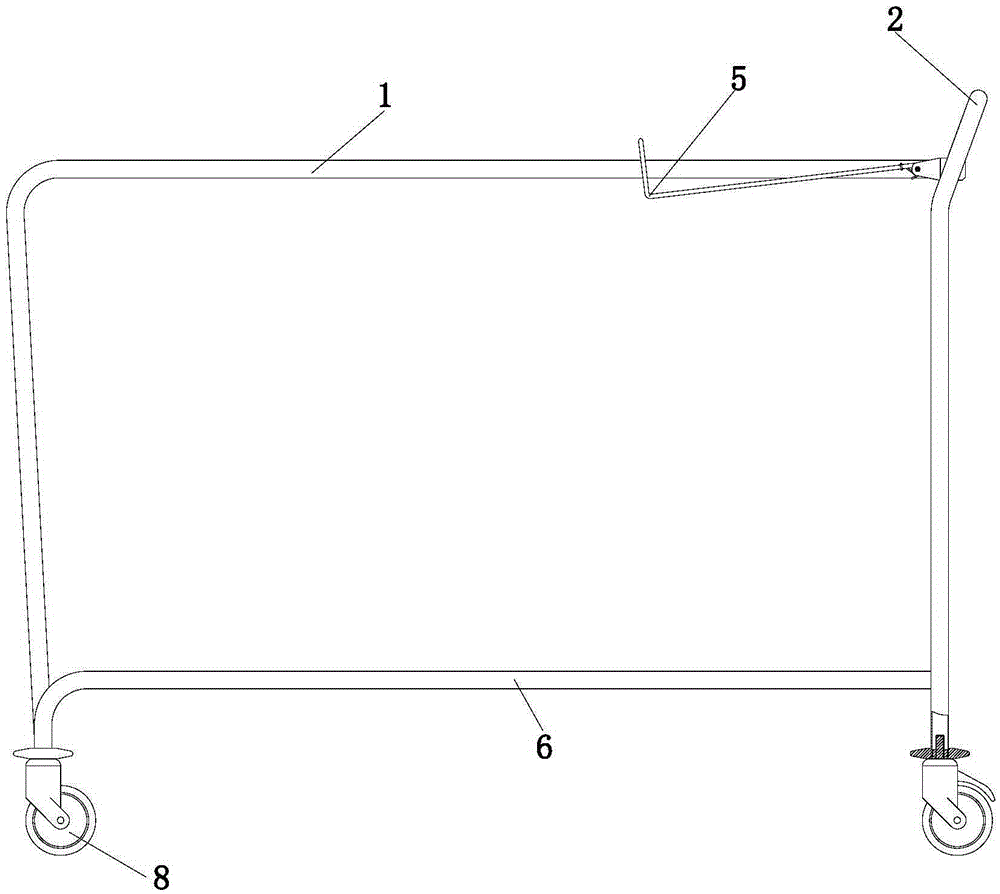

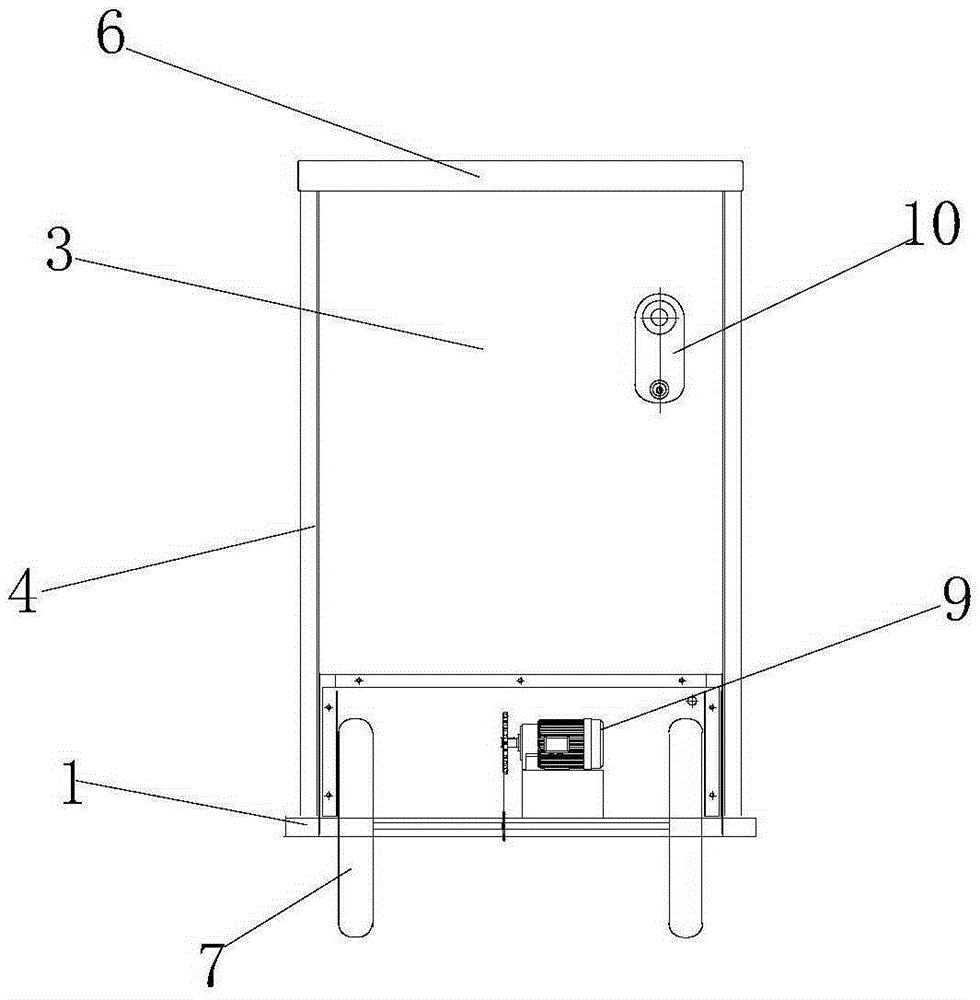

Wrapping cloth storage and transportation trolley and maintenance method thereof

InactiveCN106551769ASmall amount of deformationSuitable for noise control requirementsMetallic material coating processesNursing accommodationCoatingBreathing

The invention relates to a wrapping cloth storage and transportation trolley and a maintenance method thereof. The wrapping cloth storage and transportation trolley comprises an underframe, a trolley body arranged on the underframe, a push handle arranged on the rear side of the trolley body, a plurality of wrapping cloth pipes which are arranged on the trolley body and distributed in a stepped mode, wrapping cloth clamps arranged at the tail ends of the wrapping cloth pipes, and trundles which are arranged at the four ends of the underframe and provided with brakes. The tail ends of every two adjacent wrapping cloth pipes are connected through an inverted L-shaped connecting support. The wrapping cloth pipes are distributed in the stepped mode, so that aired wrapping cloth receives sunshine by a larger area, ventilation is facilitated, and the airing effect is remarkably improved. The wrapping cloth pipes are square pipes so that the wrapping cloth pipes and the wrapping cloth clamps can be matched more firmly and reliably. The trundles are arranged at the four ends, and thus transportation of the wrapping cloth is facilitated. The surfaces of the underframe, the trolley body, the push handle, fence assemblies, the wrapping cloth pipes, a lower transverse bracket and the inverted L-shaped connecting supports are coated with Teflon coatings, so that firmness and durability are achieved, dust is not liable to adhere to the surfaces, and cleaning and disinfection are easy.

Owner:WANSHENG PRECISION MACHINERY JIANGSU

Solder paste for signal processing substrate and preparation method thereof

ActiveCN105397343BModerate viscosityExtended shelf lifeWelding/cutting media/materialsSoldering mediaIndiumX-ray

The invention discloses a solder paste for a signal processing substrate and a preparation method thereof. The method comprises the following steps: 1) mixing Sn-Zn alloy, copper, indium, chloroauric acid hydrated, polyvinylpyrrolidone, a reducing agent and water to enable contact reaction so as to obtain an activating metal composition; 2) heating and dissolve rosin, rosin amine, organic acid, imidazole and tris(2-carboxyethyl) isocyanurate to obtain mixed liquor I; 3) mixing the mixed liquor I, a thixotropic agent and a preservative, and then cooling to obtain mixed liquor II; 4) mixing the mixed liquor II and polyethylene glycol to obtain a soldering flux; 5) refrigerating the soldering flux, and then performing dispersion mixing for the soldering flux and the activating metal composition under a vacuum condition and in the presence of X-rays, so as to obtain the solder paste for the signal processing substrate. The solder paste prepared by the preparation method is outstanding in chemical stability, low in welding temperature, and outstanding in expansion rate.

Owner:芜湖雅葆轩电子科技股份有限公司

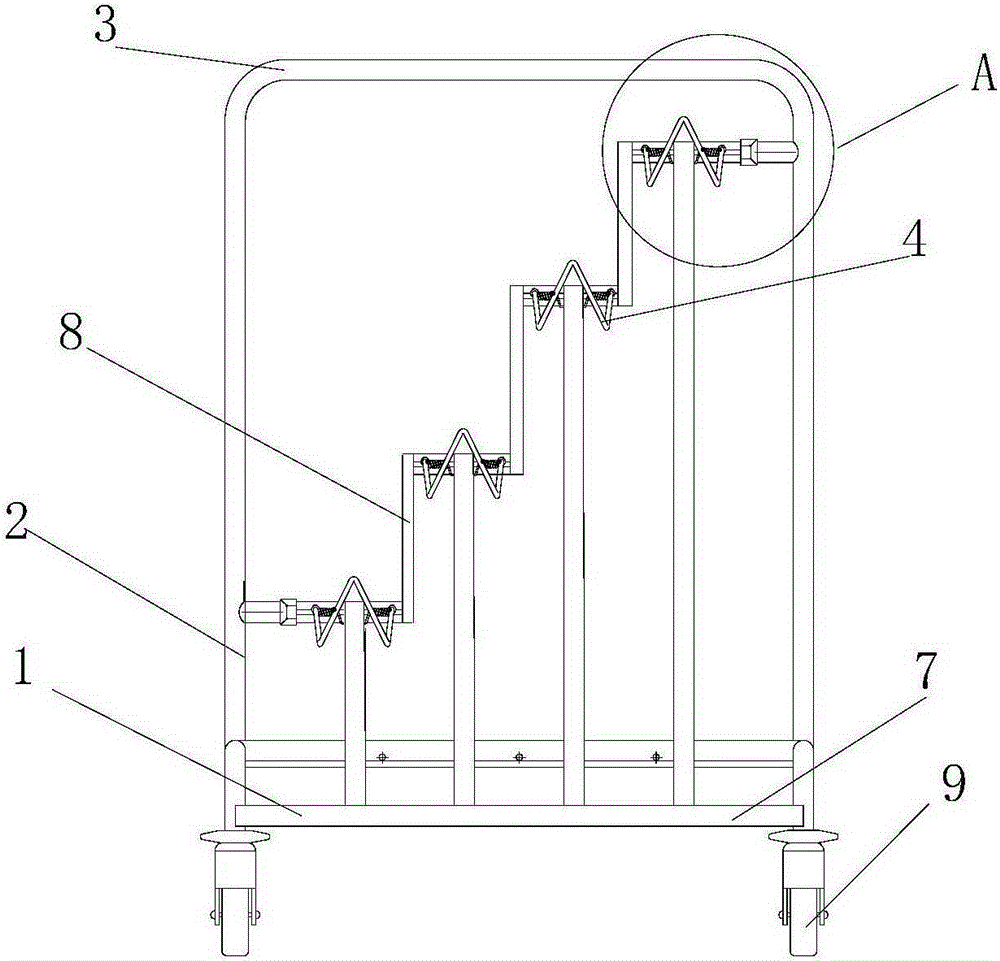

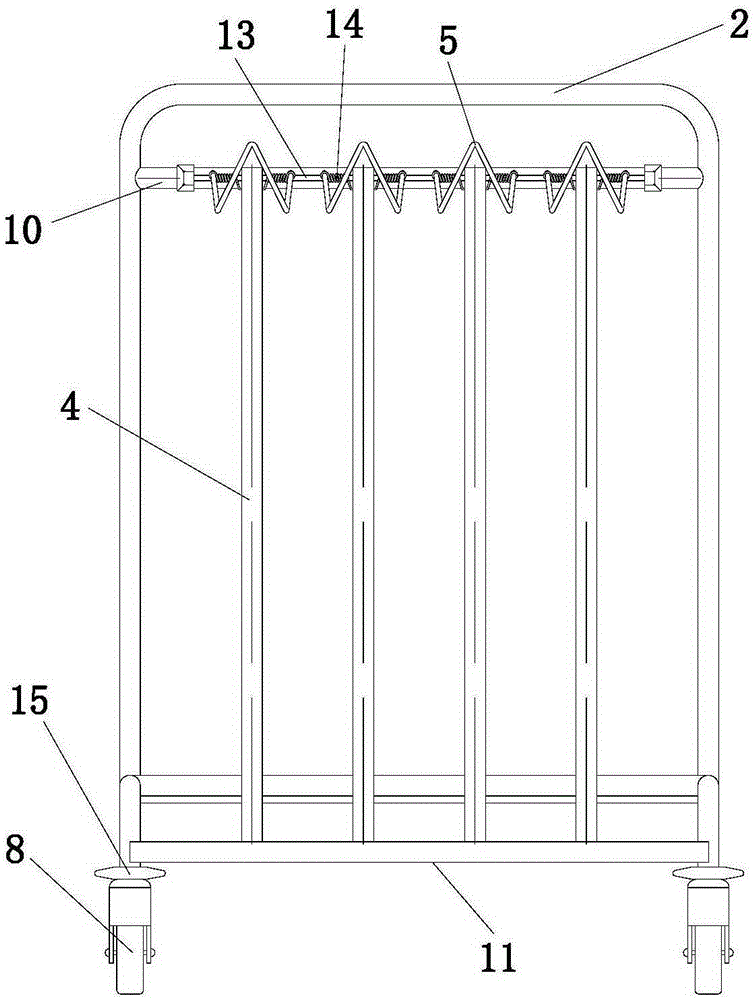

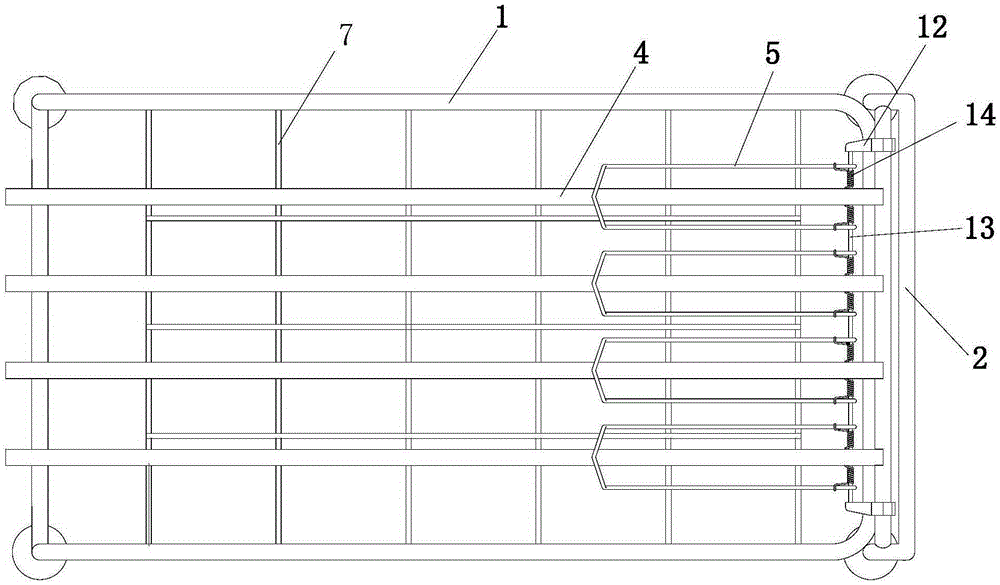

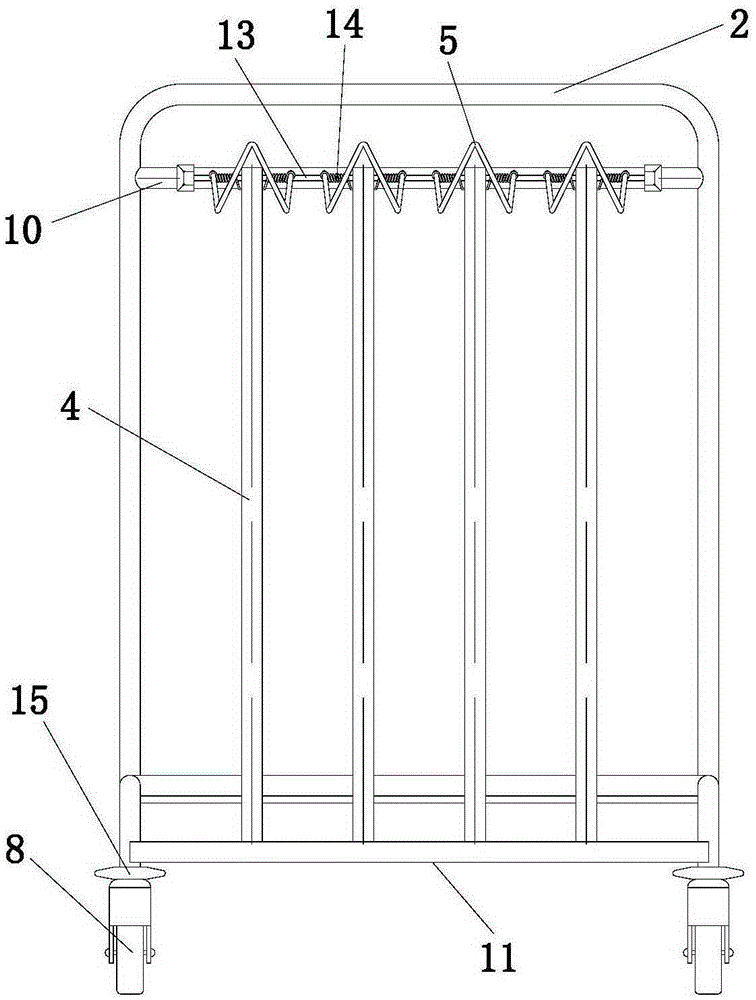

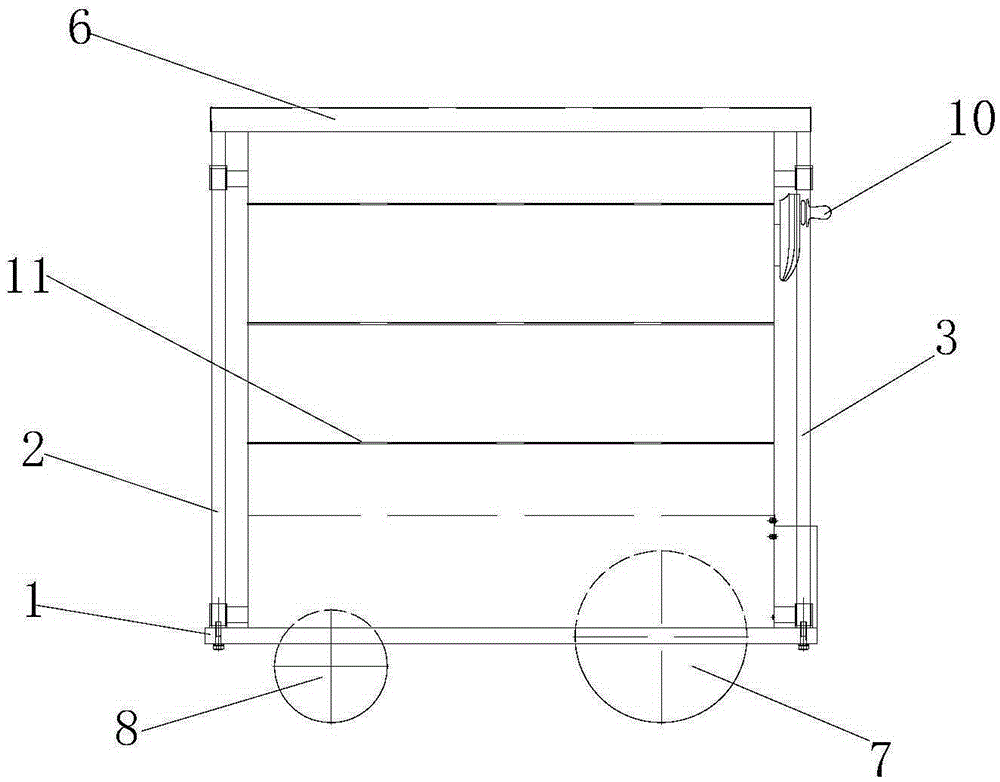

Medical wrapping cloth trolley

InactiveCN106551768AEasy to cleanPrevent the fabric from slippingMetallic material coating processesNursing accommodationTorsion springEngineering

The invention discloses a medical wrapping cloth trolley. The medical wrapping cloth trolley comprises a trolley frame and a push handle arranged on the rear side of the trolley frame. A set of square wrapping cloth pipes is arranged on the trolley frame in parallel. The wrapping cloth pipes are each provided with a wrapping cloth clamp. An underframe is arranged on the lower portion of the trolley frame, fence assemblies are arranged on the underframe, and a set of trundles with pedal brakes is arranged at the four ends of the underframe. A spring shock absorber is arranged inside each trundle. The top of each trundle is further provided with an anti-collision block. An upper transverse support and a lower transverse support are arranged close to the upper end and the lower end of the push hand correspondingly. The upper transverse support is provided with a pair of fixing block assemblies, and a supporting rod is arranged between the pair of fixing block assemblies. The wrapping cloth clamps are elastically arranged on the supporting rods through torsion springs, and the front ends of the wrapping cloth clamps are pressed on the wrapping cloth pipes. The medical wrapping cloth trolley is made of 304# stainless steel and is convenient to clean.

Owner:WANSHENG PRECISION MACHINERY JIANGSU

Wrapping cloth trolley and maintaining method thereof

InactiveCN106553677APlay the role of shock absorberPrevent slippingMetallic material coating processesHand carts with multiple axesVehicle frameEngineering

The invention discloses a wrapping cloth trolley and a maintaining method thereof. The wrapping cloth trolley comprises a trolley frame and a pushing handle arranged on the rear side of the trolley frame. A set of square wrapping cloth pipes is arranged on the trolley frame in parallel. The set of square wrapping cloth pipes are all provided with wrapping cloth clamps. An underframe is arranged under the trolley frame. A holding enclosure assembly is arranged on the underframe. A set of trundles with foot brakes are arranged at the four ends of the underframe. A spring damper is arranged in the set of trundles. Anticollision blocks are further arranged at the tops of the trundles. The parts close to the upper end and the lower end of the pushing handle are provided with an upper transverse support and a lower transverse support. The upper transverse support is provided with a pair of fixing block assemblies. A supporting rod is arranged between the pair of fixing block assemblies. The wrapping cloth clamps are elastically arranged on the supporting rod through torsional springs. The front ends of the wrapping cloth clamps are pressed on the wrapping cloth pipes. The medical wrapping cloth trolley is made from 304 stainless steel and is convenient to clean.

Owner:WANSHENG PRECISION MACHINERY JIANGSU

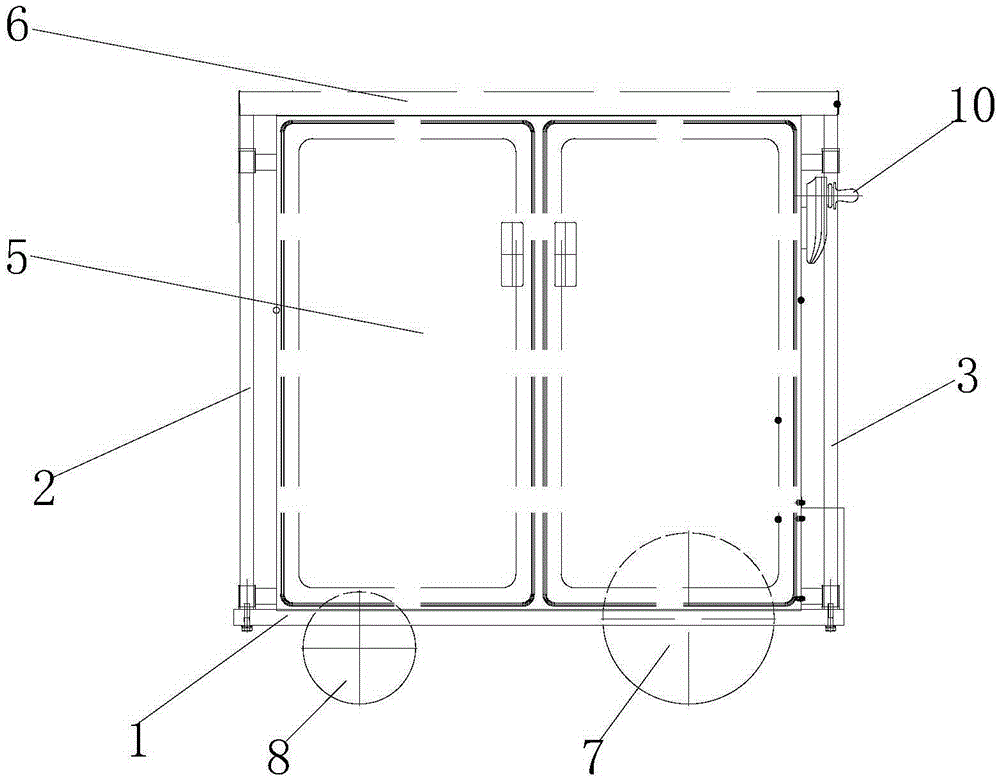

Sealed distributing and collecting trolley and maintaining method thereof

InactiveCN106553672AEasy to cleanEasy to disinfectMetallic material coating processesHand carts with multiple axesDrive wheelEngineering

The invention relates to a sealed distributing and collecting trolley and a maintaining method thereof. The trolley comprises a left side plate assembly, a right side plate assembly, a back plate, a double door assembly and a top cover assembly, wherein the left side plate assembly, the right side plate assembly, the back plate and the double door assembly are arranged on the four sides of a bottom plate assembly, the top cover assembly is arranged on the tops of the left side plate assembly, the right side plate assembly, the back plate and the double door assembly, and a sealed box body is jointly formed by the left side plate assembly, the right side plate assembly, the back plate, the double door assembly and the top cover assembly. The inner side face of the sealed box body is coated with a Teflon coating. Inner partition plates with the height capable of being freely adjusted are arranged in the sealed box body and made of stainless steel with the surface coated with the Teflon coating, dust staining is not likely to happen, and cleaning is easy. Multiple drive wheels connected with a motor driving system are arranged at the bottom of the right side of the bottom plate assembly. Multiple driven wheels are arranged at the bottom of the left side of the bottom plate assembly. A waterproof direct current motor is selected as a motor of the motor driving system, whole trolley cleaning and disinfecting are convenient, sanitation safety of equipment is ensured, the motor is used for driving the sealed distributing and collecting trolley, original manpower driving is replaced, and the labor intensity of medical workers is greatly lowered.

Owner:WANSHENG PRECISION MACHINERY JIANGSU

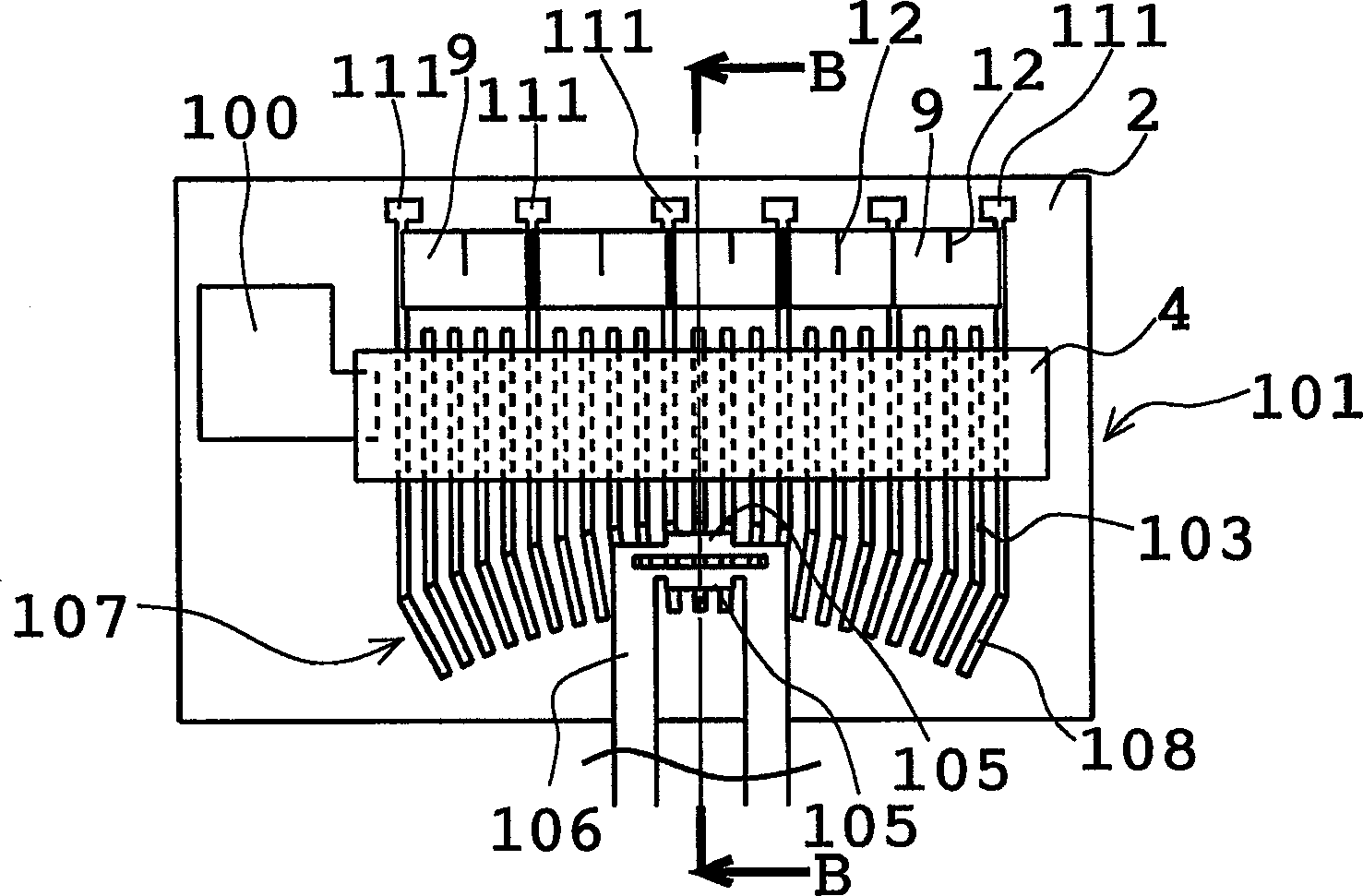

Secondary battery having a current collecting plate with improved welding characteristics

ActiveUS7776469B2Excellent welding characteristicsIncrease currentFinal product manufactureWound/folded electrode electrodesEngineeringMetal

The present invention provides a secondary battery including an electrode assembly comprising positive and negative electrodes with a separator interposed therebetween and wound together, a case, a cap assembly, and a negative current collecting plate. The negative current collecting plate includes a partially surface-treated region for fixing the negative current collecting plate to the negative electrode. The partially surface-treated region comprises a metal other than the metal of the negative current collecting plate. The use of a metal other than the metal of the negative current collecting plate provides an improved weld between the negative current collecting plate and the negative electrode which in turn provides improved battery performance, especially for high-load batteries.

Owner:SAMSUNG SDI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com