Wrapping cloth storage and transportation trolley and maintenance method thereof

A technology for transport vehicles and wrapping cloth, which is applied in coatings, medical science, hospital equipment, etc. It can solve problems such as difficult ventilation and insufficient sunlight, and achieve the effects of easy transportation, improved drying effect, and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

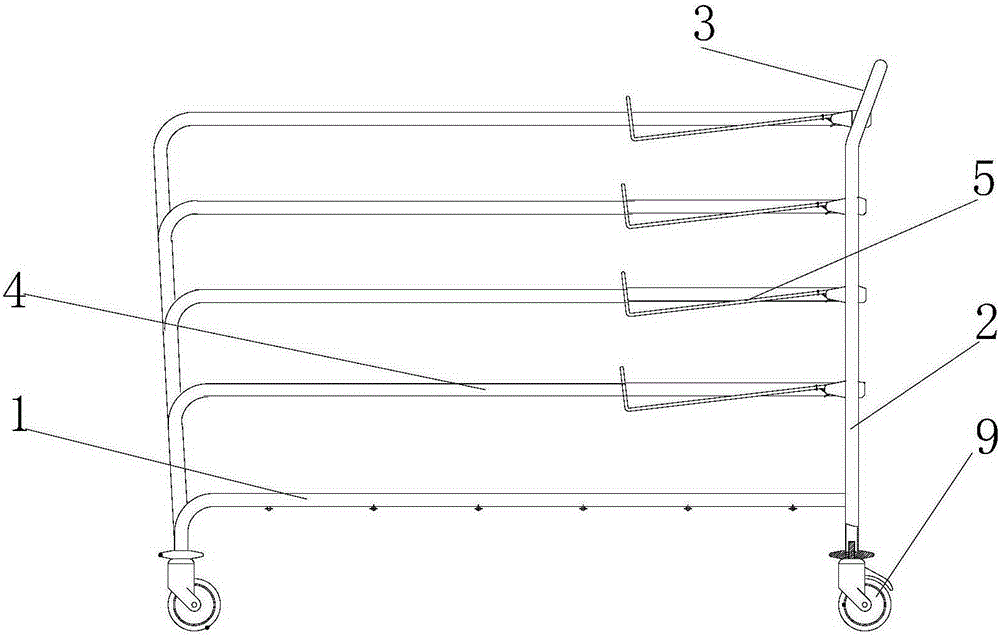

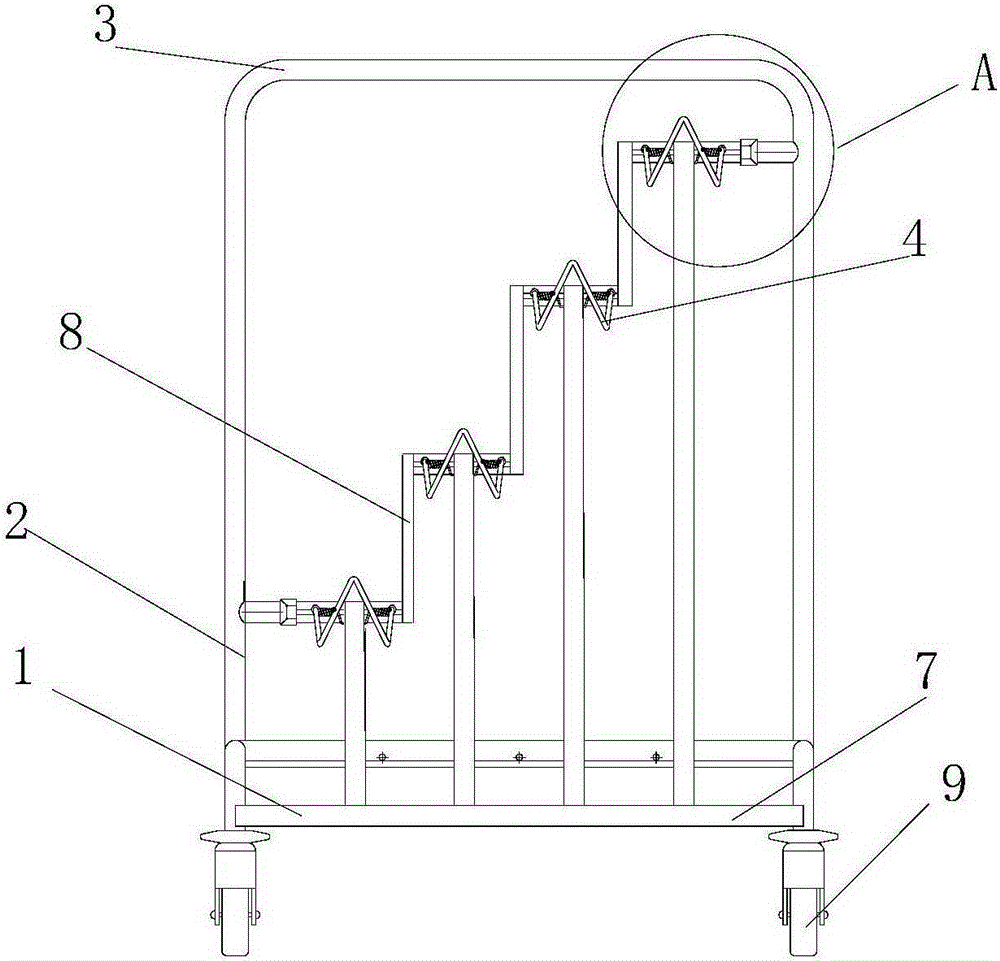

[0024] Example 1 as figure 1 , the wrapped cloth storage transport vehicle of the present embodiment comprises an underframe 1, a vehicle body 2 disposed on the underframe 1, a push handle 3 disposed on the rear side of the vehicle body 2, and a plurality of cloth wrapped cloths arranged in a stepped distribution on the vehicle body 2. Pipe 4, be located at the wrapping clip 5 of wrapping pipe tail end, be located at the caster wheel 9 with brake of chassis 1 four ends.

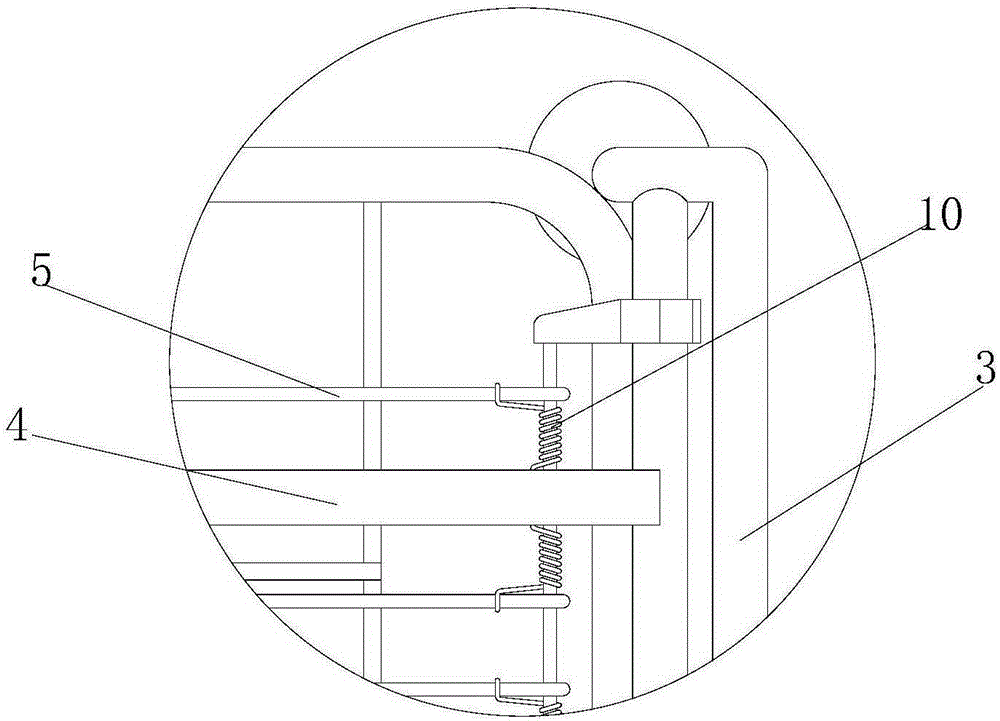

[0025] The bottom frame 1 is provided with a railing assembly 6, and the top of the caster 9 is provided with an anti-collision block. The bottom frame 1 is provided with a lower cross brace 7 for fixing the front end of the cloth wrapping pipe 4 . The tail ends of the adjacent wrapping pipes 4 are connected in a stepped form by a "Γ"-shaped connecting bracket 8 .

[0026] The horizontal direction of the "Γ" type connecting bracket 8 is provided with a torsion spring 9, and the torsion spring 9 is used to f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com