Polyamide resin composition for molded article to be in contact with high-pressure hydrogen, and molded article obtained therefrom

A technology of polyamide resin and composition, which is applied to the field of polyamide resin composition and molded products formed by molding the same, can solve the problems of reduced strength and toughness, poor adhesion, poor appearance, etc., and achieves excellent welding characteristics, The effect of less defect points and fast crystallization speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~9、 comparative example 1~12

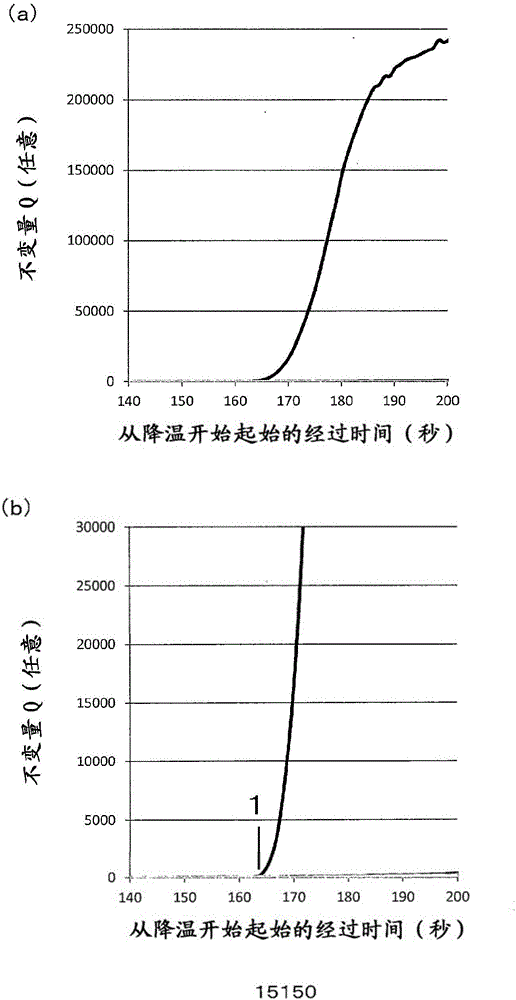

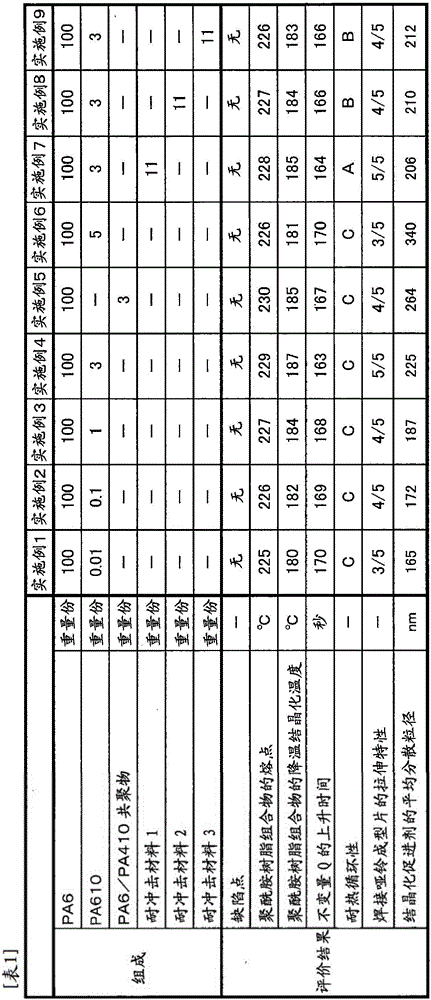

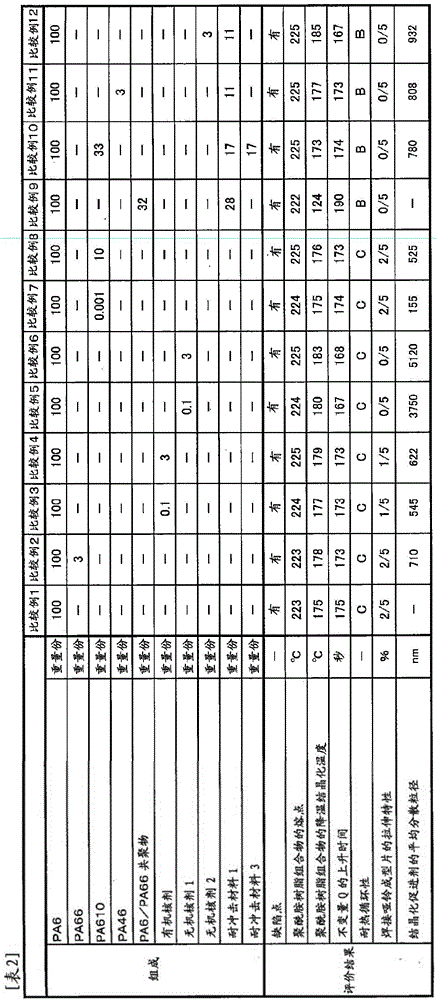

[0113] Each raw material described in Table 1 and Table 2 was supplied to a twin-screw extruder (JSW) whose barrel temperature was set at 240° C., the screw configuration was provided with one kneading zone, and the screw rotation speed was 150 rpm. TEX30α-35BW-7V manufactured by the company) (L / D=45 (in addition, L here is the length from the raw material supply port to the discharge port)) was melt-kneaded. Let the gut (gut) discharged from the die at a speed of 20 kg / h pass through a cooling bath filled with water whose temperature has been adjusted to 10° C. for 10 seconds, thereby performing rapid cooling, and then use a wire cutter Granulation is performed to obtain granules. The obtained granules were vacuum-dried at a temperature of 80° C. for 12 hours using a vacuum dryer, and the dried granules were used for evaluation by the above-mentioned method. The results are shown in Tables 1 and 2. In addition, the measurement results of the rise time of the invariant Q in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com