Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Excellent brush resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

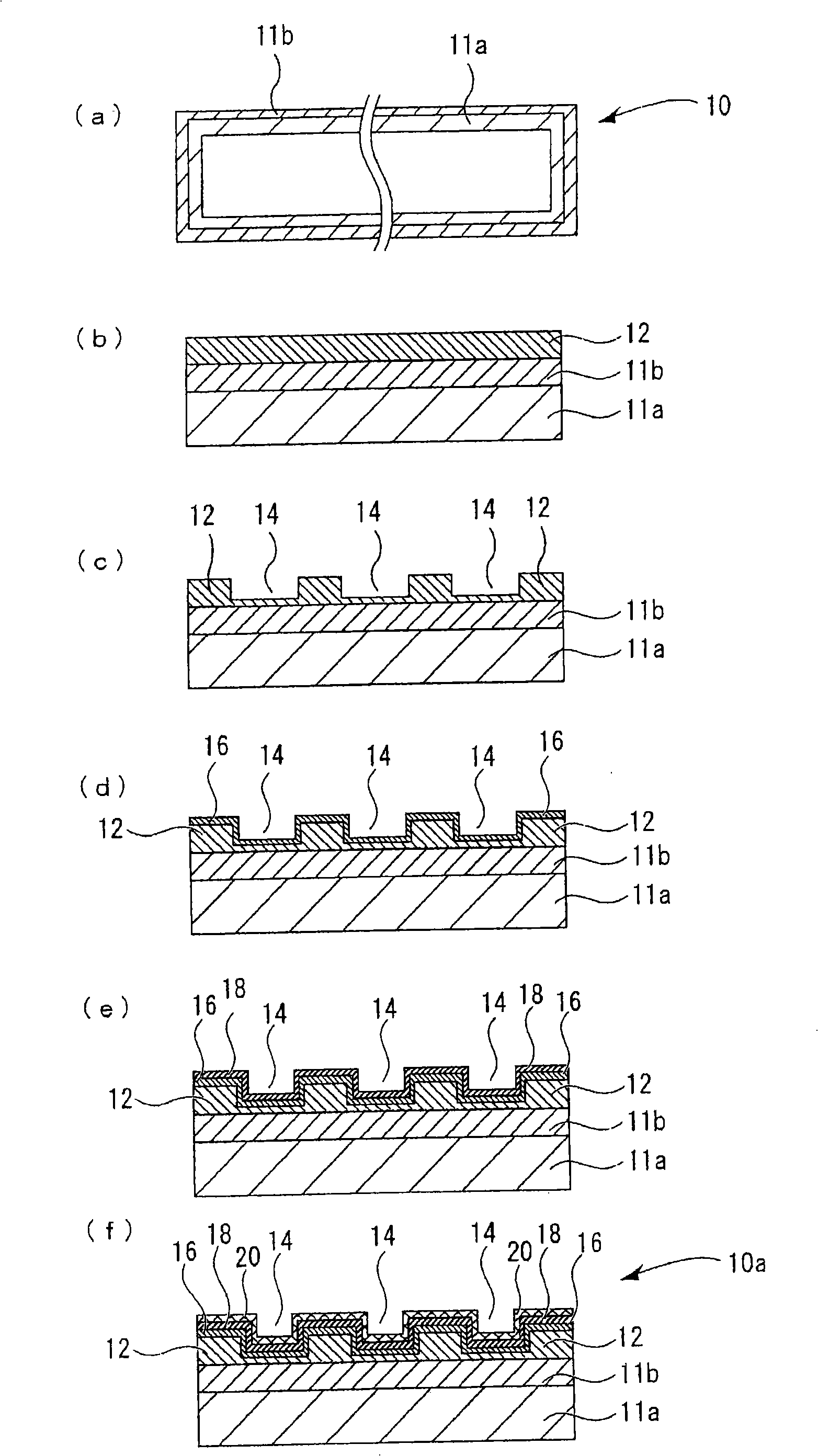

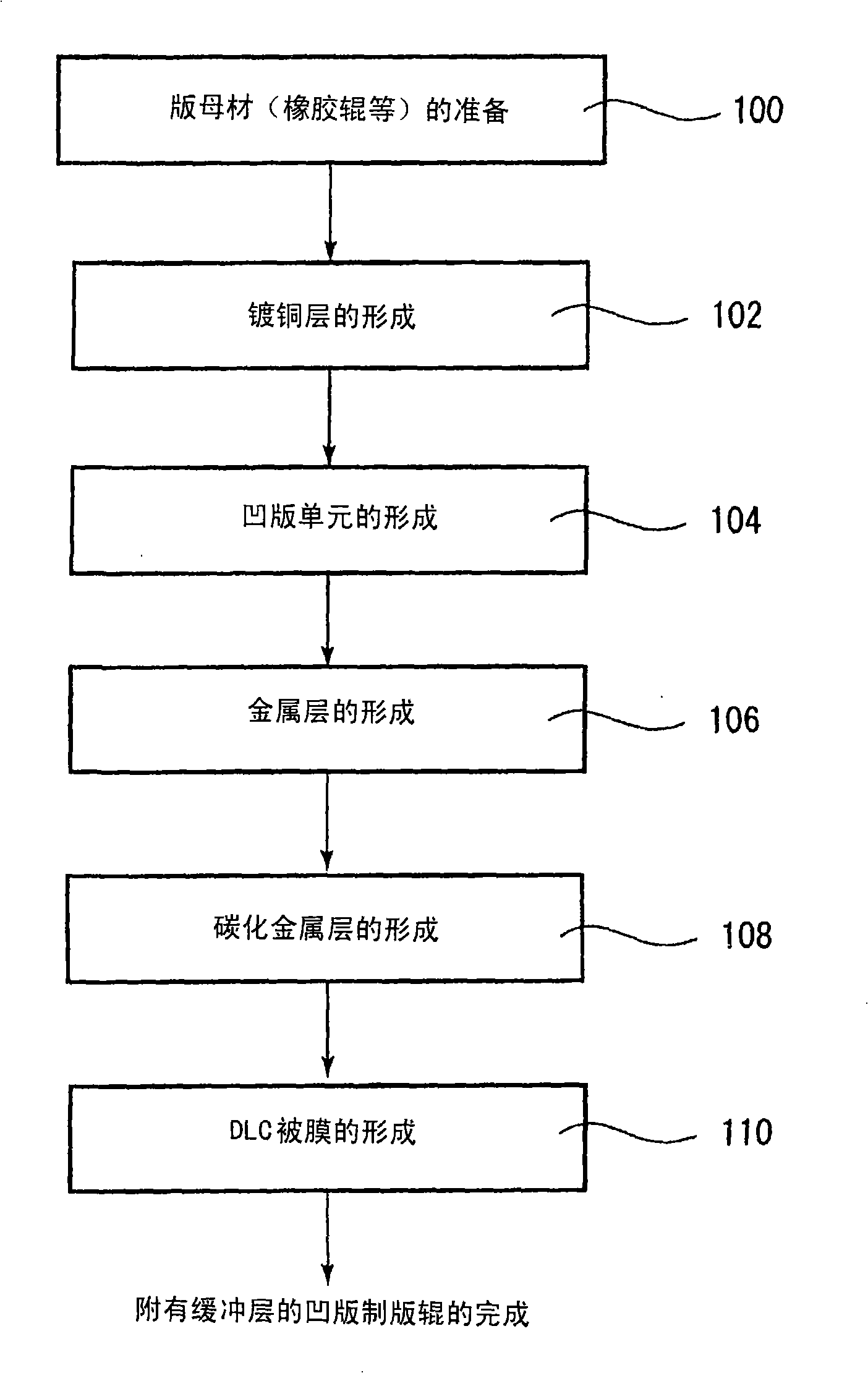

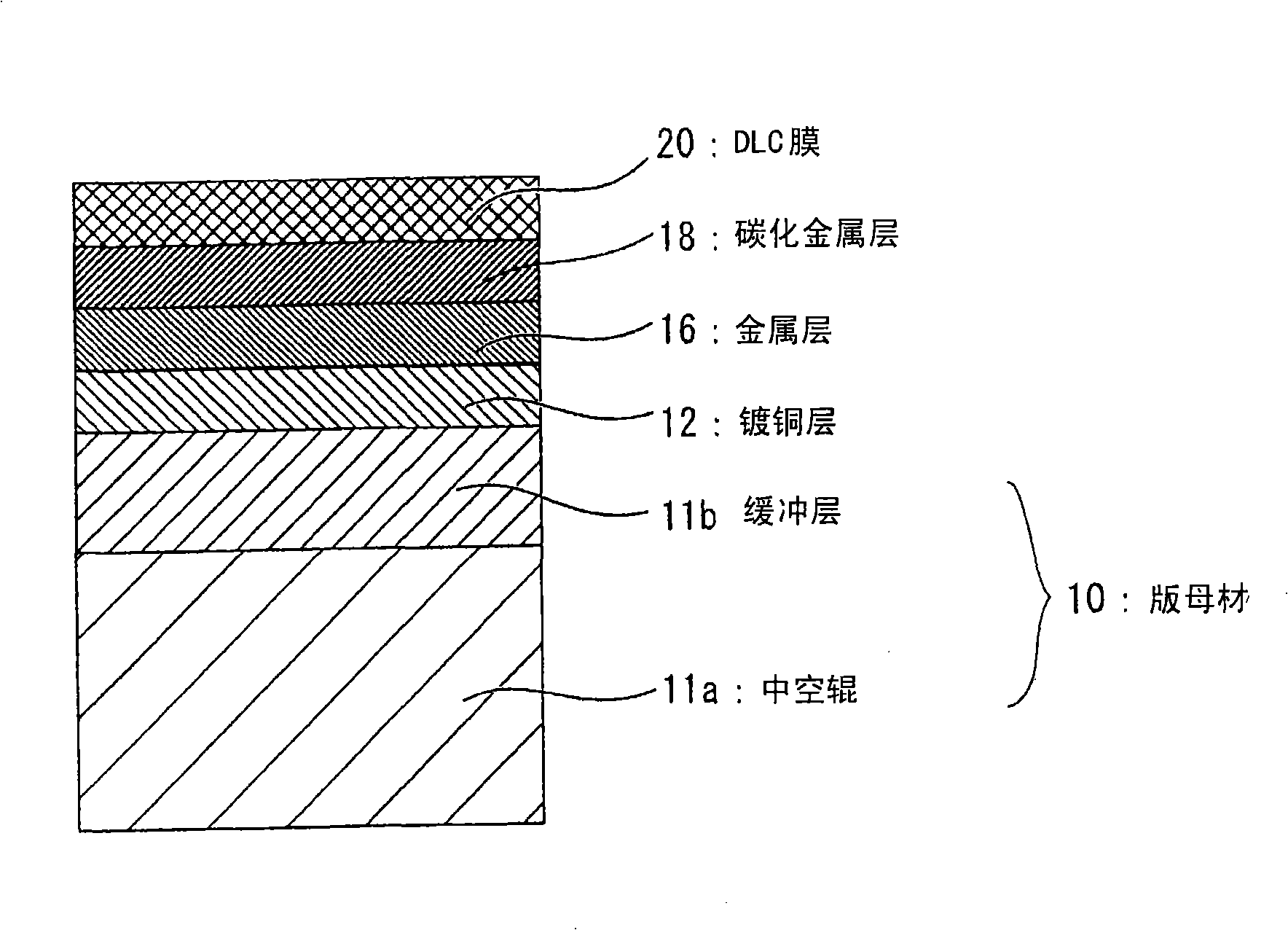

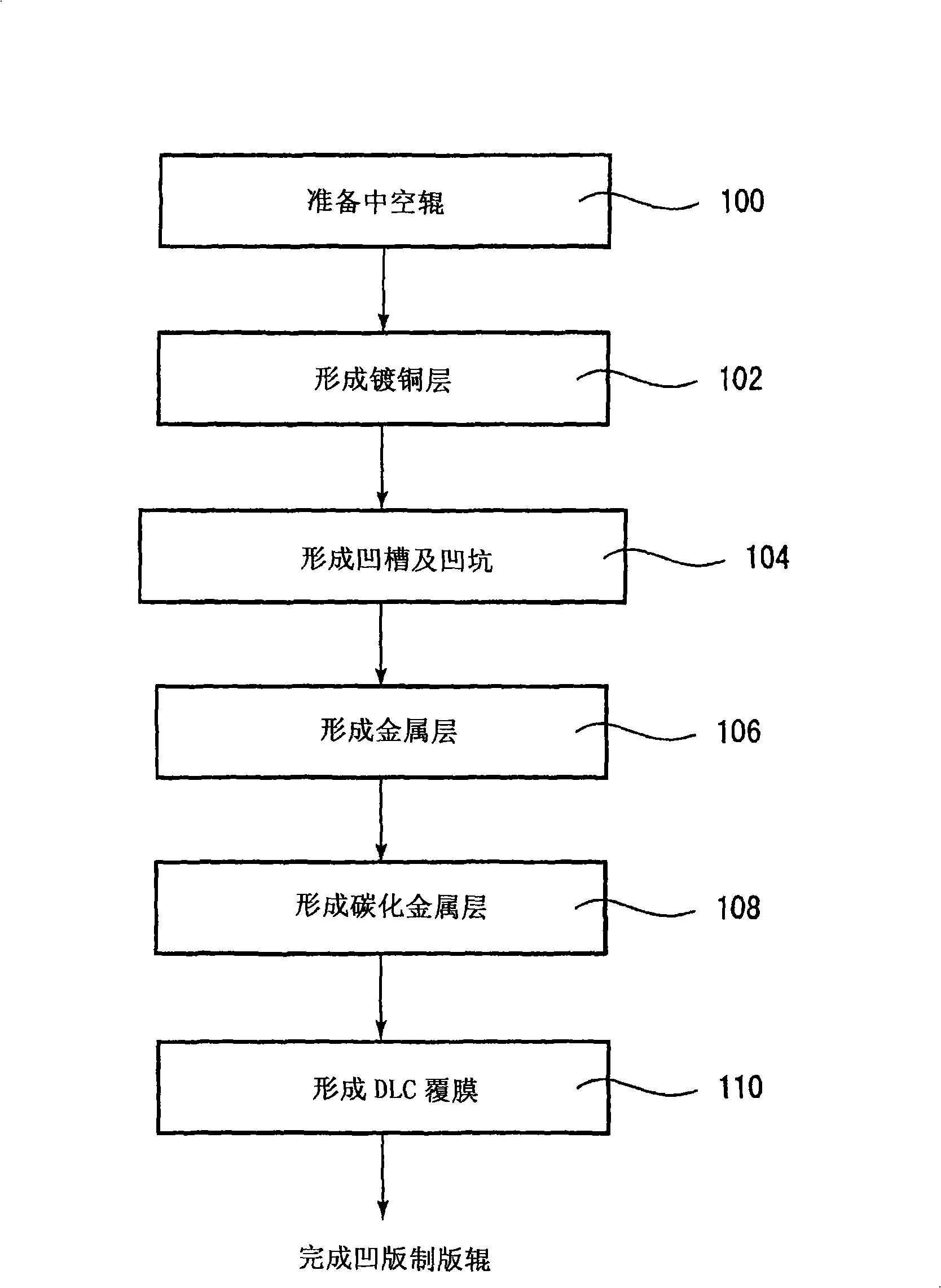

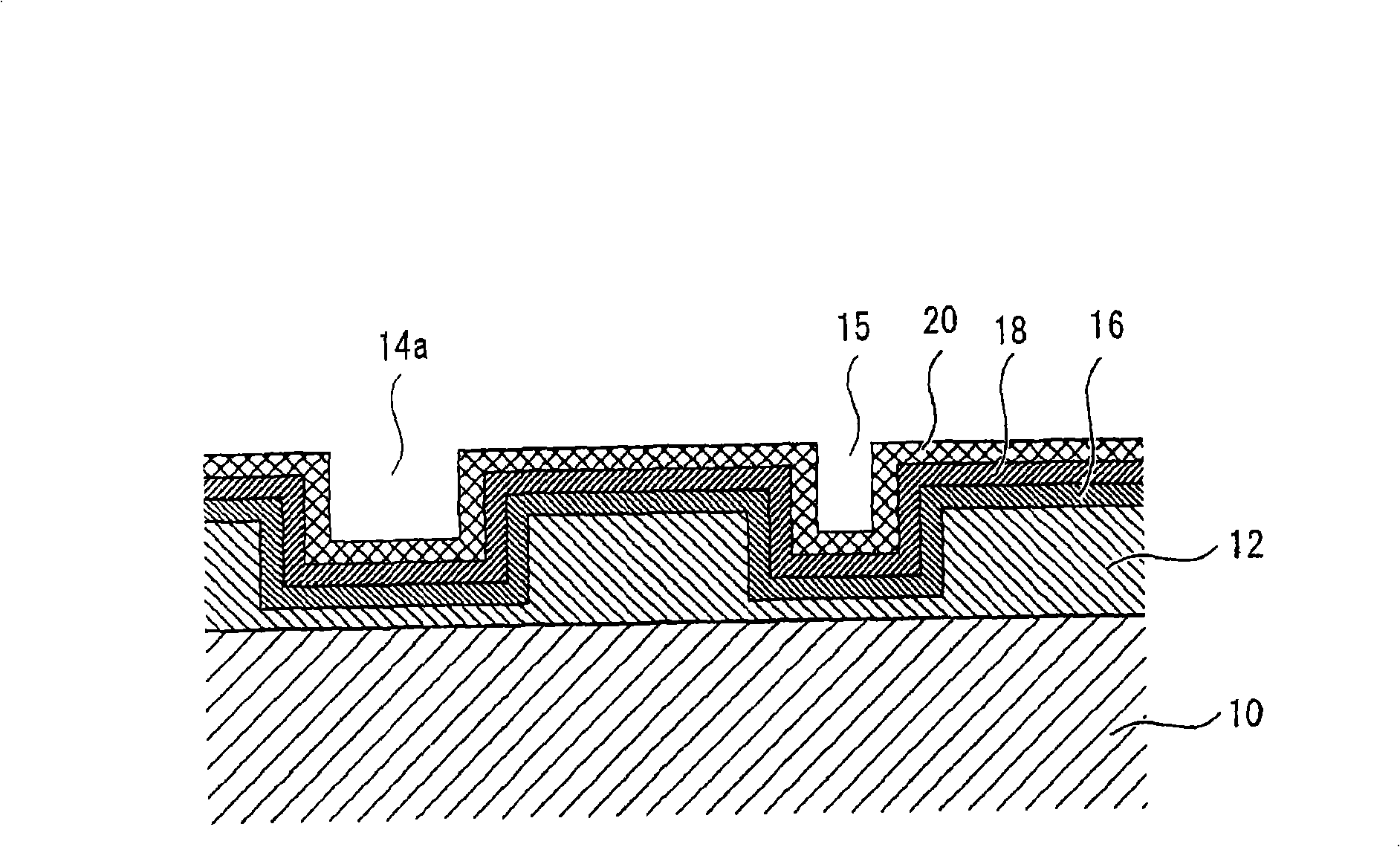

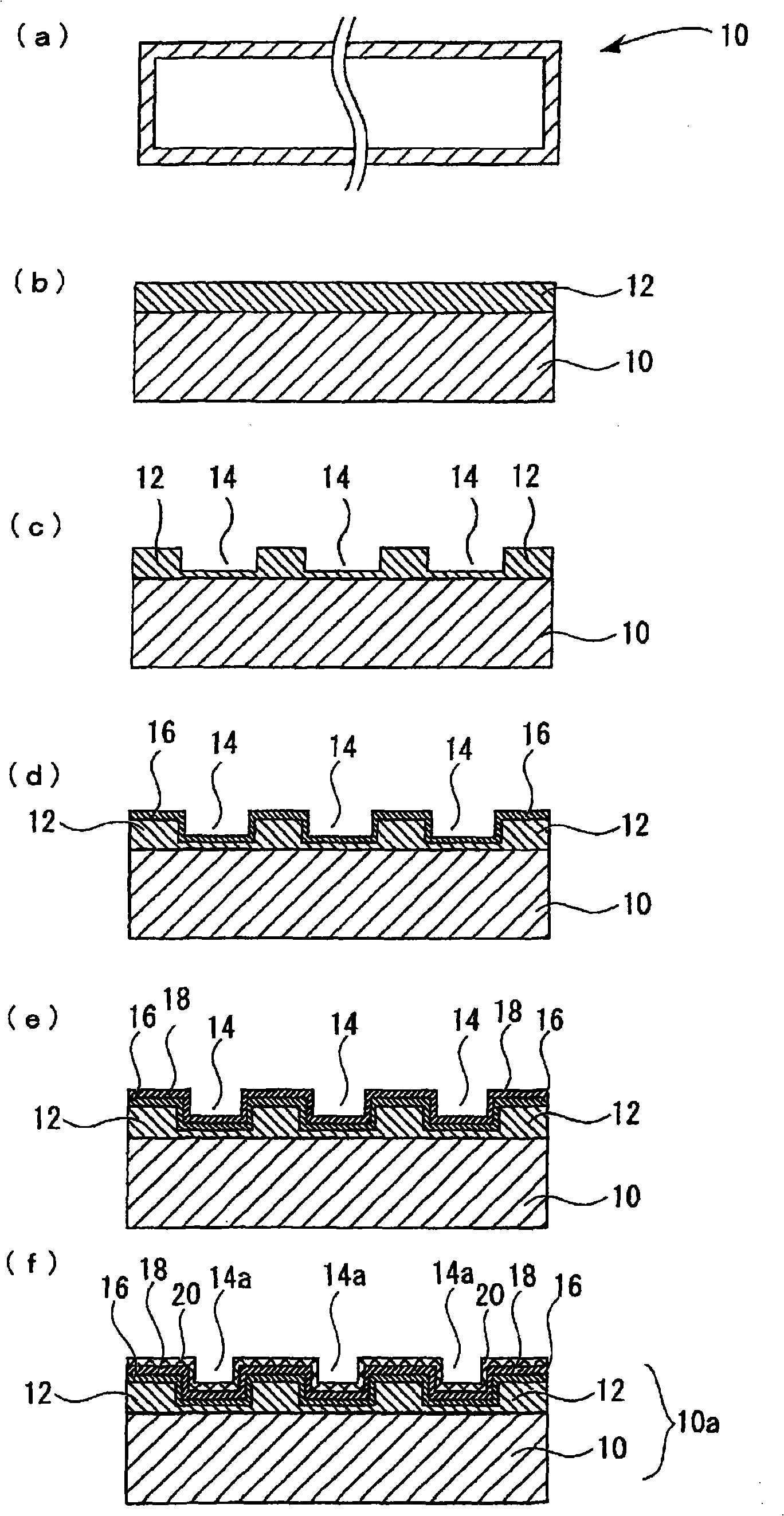

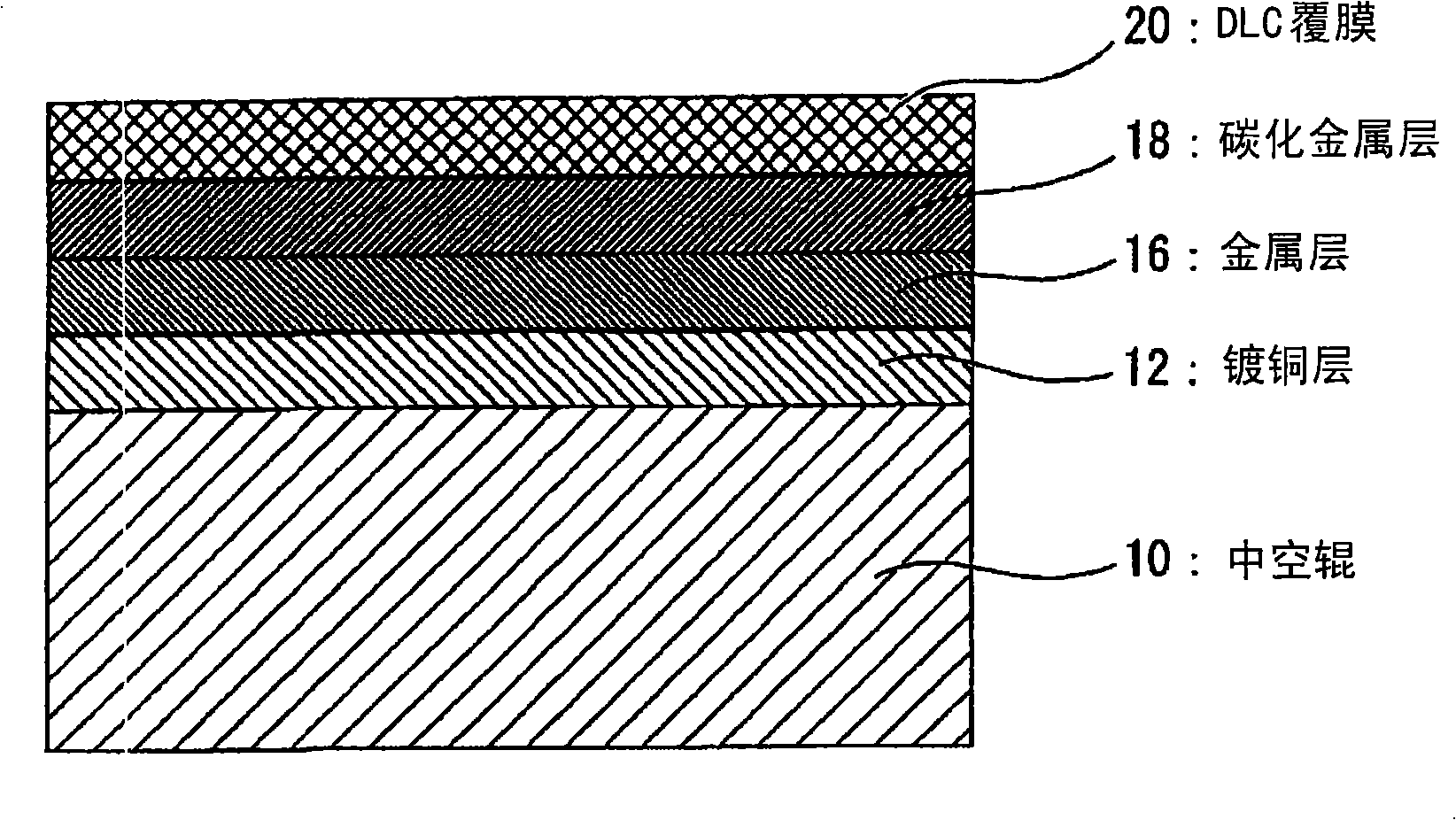

Photogravure reproduction roll with cushion layer and its manufacturing method

InactiveCN101272918AEfficient printingExcellent brush resistanceOptical filtersPlate printingCardboardDiamond-like carbon

A production method for a printing plate, especially a gravure plate with a cushioning property, which enables direct gravure printing on a hard printing matter without using a blanket roll by being provided with a cushioning property, effects a satisfactory gravure printing on a rough surface such as cardboard printing, and is suitable for color-printing a matrix image for forming a color filter on a liquid crystal panel-use glass sheet or an image on a compact disk or the like. The gravure plate comprises a hollow roll provided on the surface thereof with a cushioning layer consisting of rubber or cushioning resin, a copper plated layer provided on the surface of the cushioning layer and formed on the surface thereof with many gravure cells, a metal layer provided on the surface of the copper plated layer, a metal carbide layer provided on the surface of the metal layer, and a diamond-like carbon coating for coating the surface of the metal carbide layer.

Owner:THINK LABORATORY CO LTD

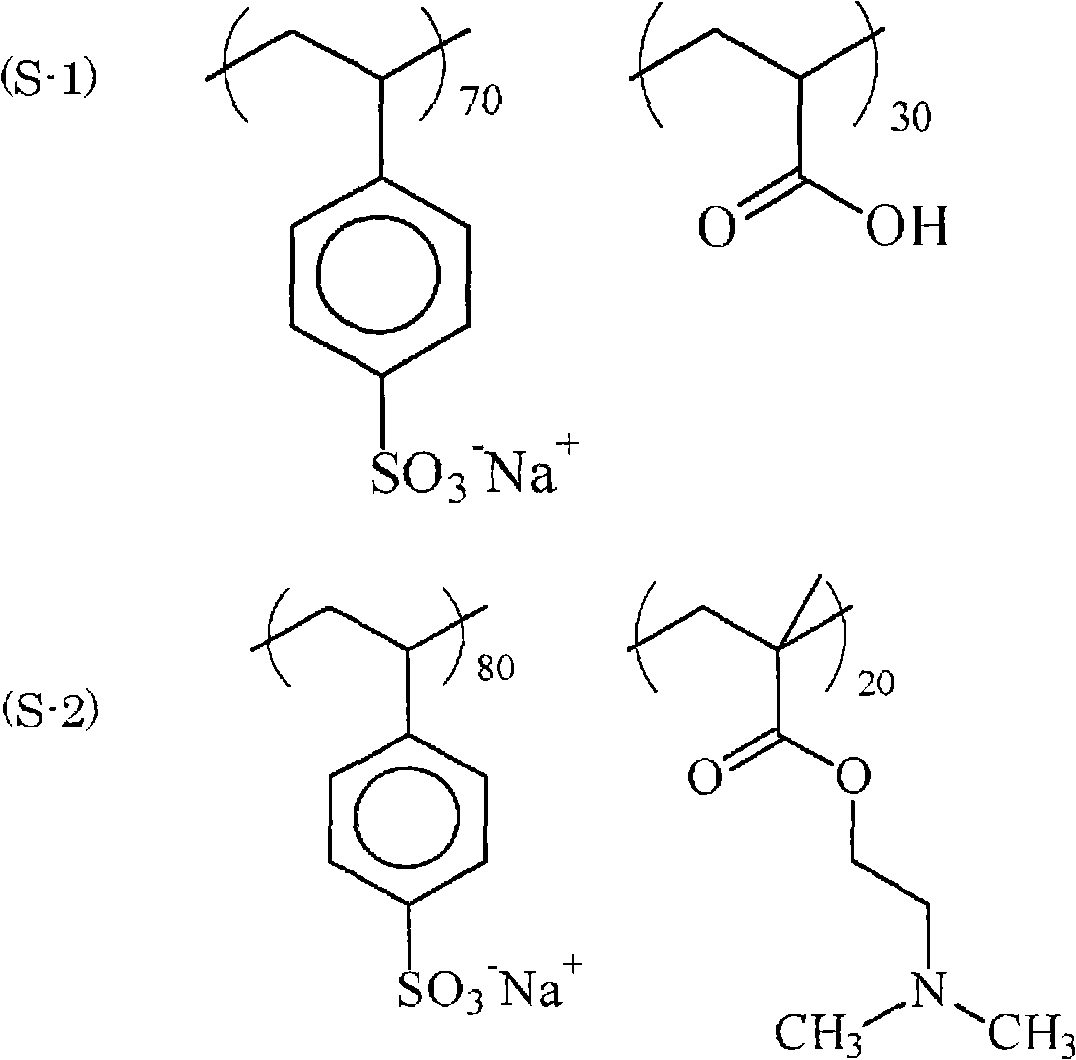

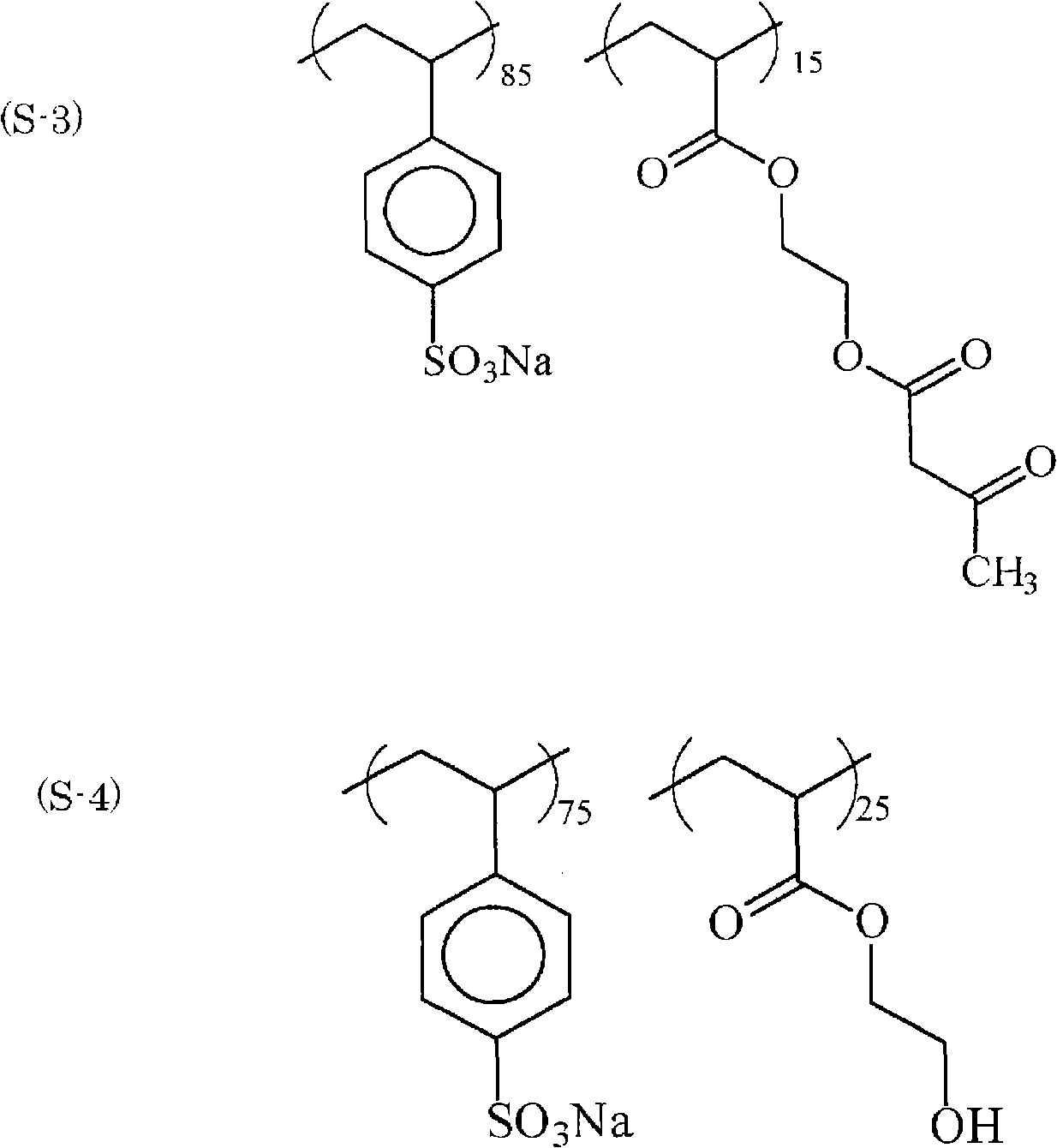

Photosensitive lithographic printing plate material developable with water

InactiveCN101636694ANo dirty versionExcellent brush resistancePrinting pre-treatmentLithographyColloidal silicaSide chain

A photosensitive lithographic printing plate material developable with water characterized by comprising: a substrate; a hydrophilic layer formed on the substrate and comprising a water-soluble polymer, a crosslinking agent for crosslinking the water-soluble polymer, and colloidal silica, the mass ratio of the water-soluble polymer to the colloidal silica being from 1:1 to 1:3; and a photocurable photosensitive layer formed on the hydrophilic layer and comprising a polymer having sulfo and vinylphenyl groups in side chains, the vinylphenyl group being bonded to the main chain through a connecting member comprising a heterocycle, a photopolymerization initiator, and a compound for sensitizing the initiator. The photosensitive lithographic printing plate material is a photosensitive lithographic printing plate having high sensitivity and usable in a CTP system. It can be developed with water, can be developed even on a printing machine, and has excellent suitability for printing.

Owner:MITSUBISHI PAPER MILLS LTD

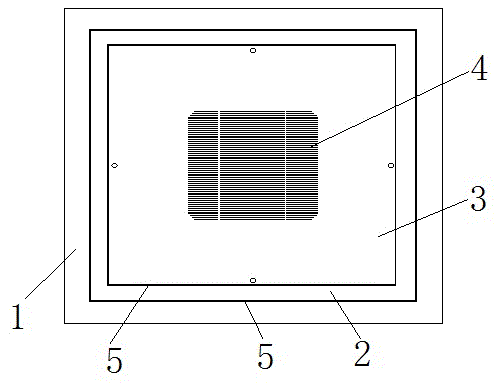

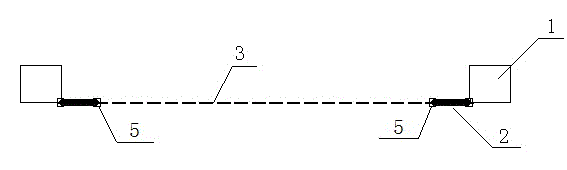

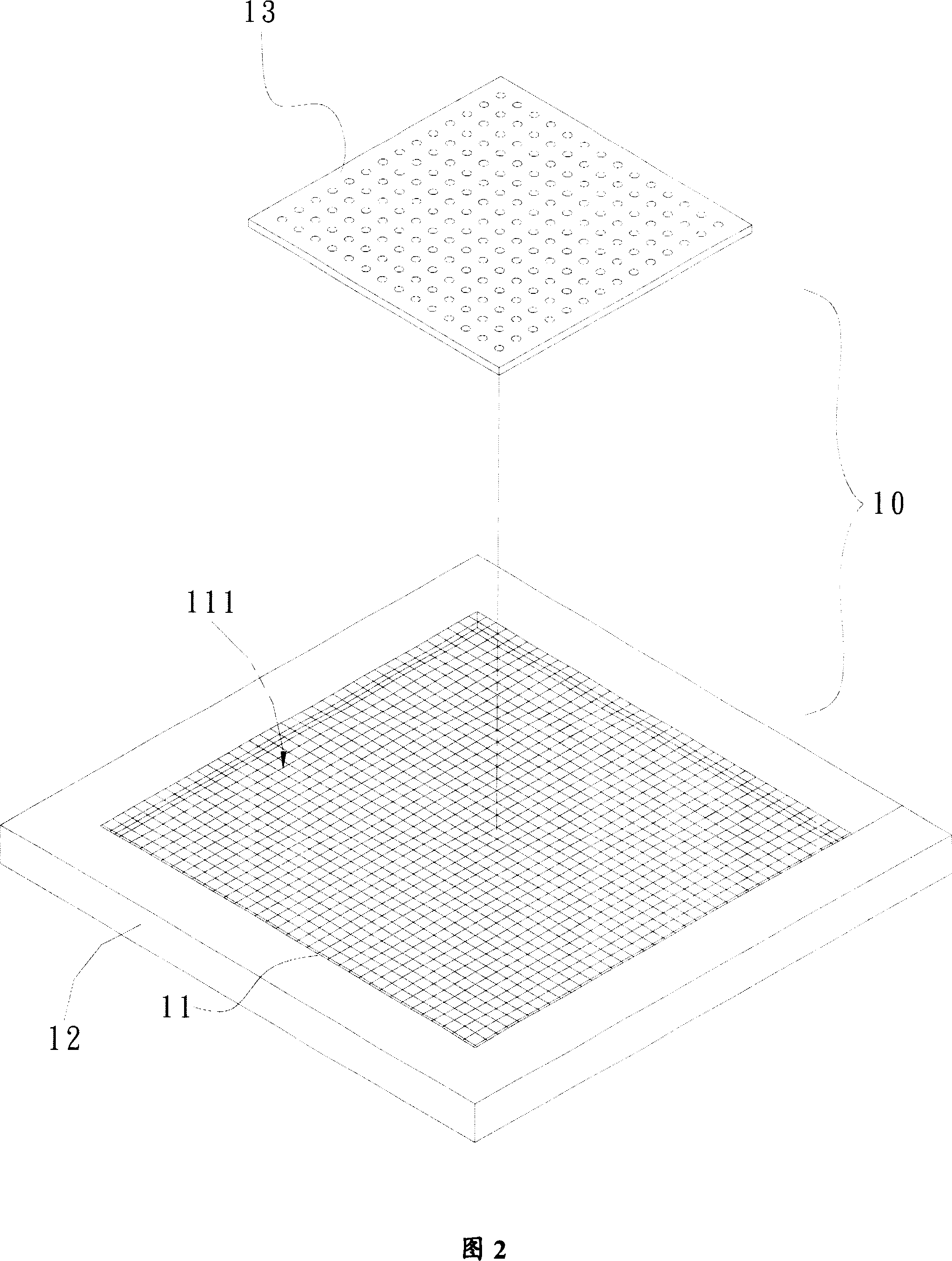

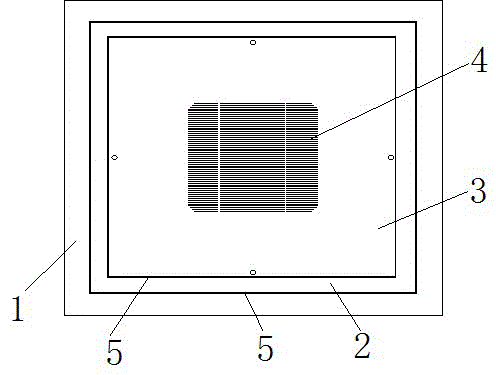

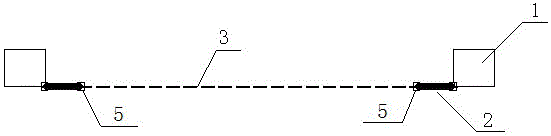

Electroforming metal film mesh plate for printing touch mesh spacing contacts

InactiveCN101555607AHigh hardnessExcellent brush resistanceElectroforming processesForme preparationYarnWire gauze

The invention discloses an electroforming metal film mesh plate for printing touch mesh spacing contacts; the invention is characterized by comprising an aluminium alloy section mesh frame, a nylon yarn mesh and a metal film; wherein, the metal film is formed by electroforming and provided with micro holes and a plurality of through holes; the nylon yarn mesh is stuck and connected with the aluminium alloy section mesh frame by solidified glue, and the periphery of the metal film is stuck and connected with the nylon yarn mesh by the solidified glue. The metal film mesh plate is made of nickel alloy material and overcomes the defects that photosensitive resistance material is easy to deform, break and the like; the surface of the mesh plate is high in rigidity and good in brushing resistance and dissolubility resistance; the electroforming metal film mesh plate is hard to misplace, and is higher in printing precision and circular degree, thus being capable of printing the touch mesh spacing contacts having the appearance circular degree of 99% and the diameter of 20mum.

Owner:昆山美微电子科技有限公司

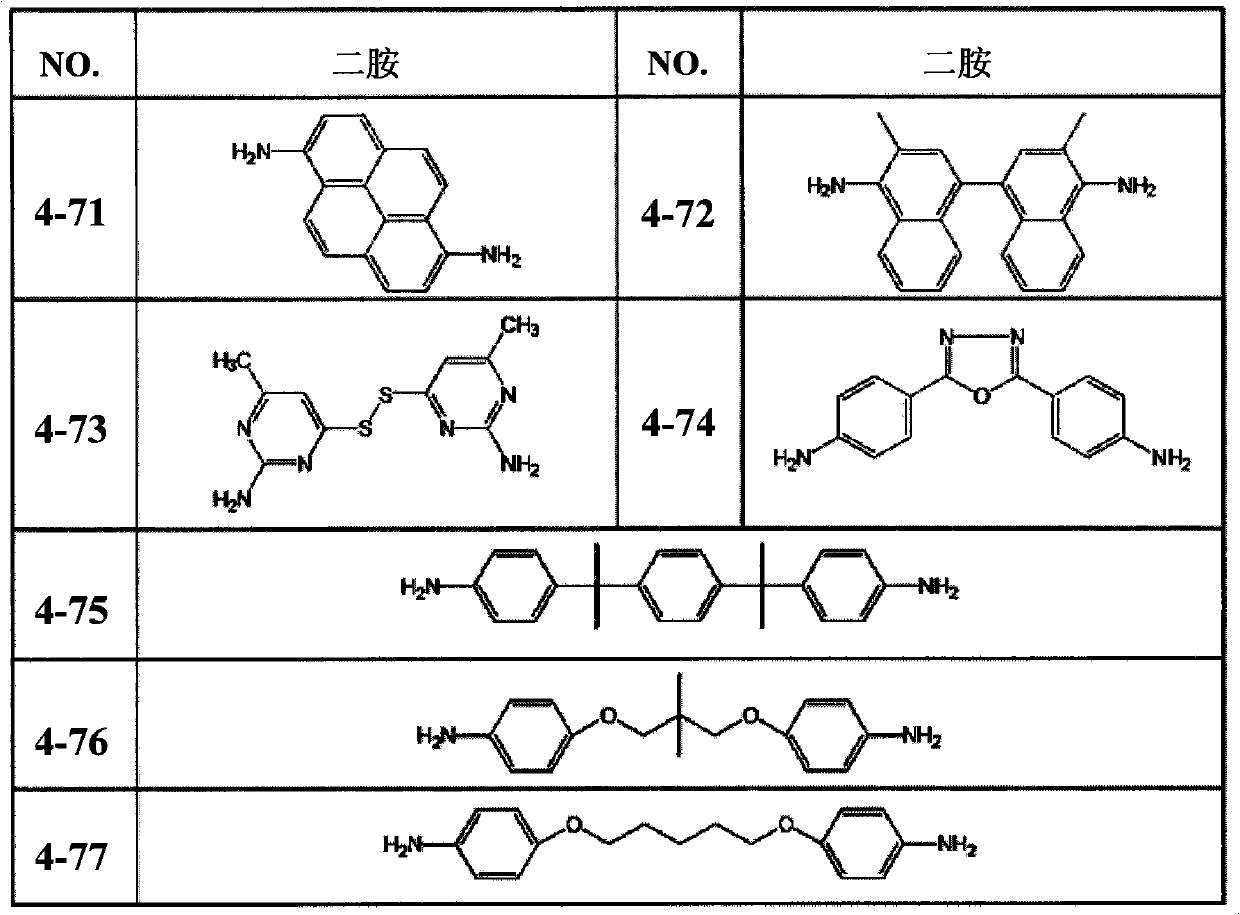

Liquid crystal alignment liquid

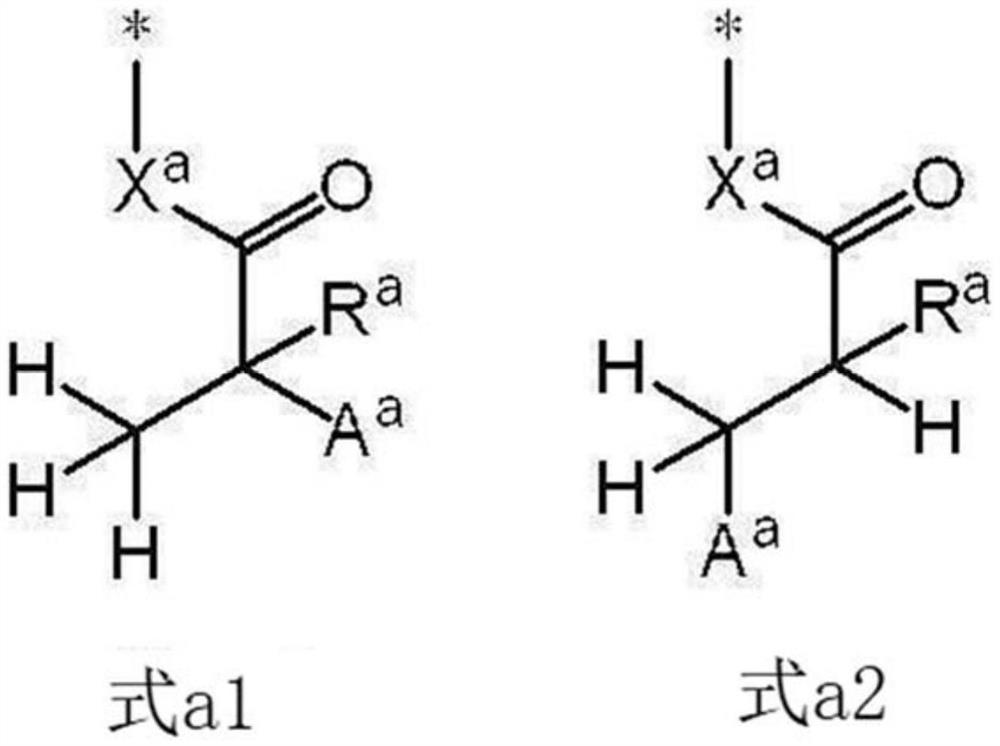

ActiveCN101885967AExcellent afterimage characteristicsHigh Reliability FeaturesLiquid crystal compositionsNon-linear opticsCrystallographyPolyamic acid

The invention provides a liquid crystal alignment liquid which comprises at least one polymer selected from a class formed by a polyamic acid- polyamic acid polymer, a polyimide-polyamic acid polymer and a polyimide-polyimide polymer, wherein the polyimide-polyamic acid polymer is shown in the following formula.

Owner:DAXIN MATERIALS

Composite metal steel plate for solar battery pure subline printing

ActiveCN102744997ANo imprintThe overall thickness is thinScreen printersPlate printingSilver pasteSheet steel

The invention discloses a composite metal steel plate for solar battery pure subline printing. The composite metal steel plate comprises a single-layer metal film, wherein a plurality of sublines of a solar battery positive electrode are arranged on the single-layer metal film; and a plurality of the sublines are respectively of a strip shape and are uniformly distributed on the single-layer metal film. The composite metal steel plate for the solar battery pure subline printing in the invention can replace the original weaving silk screen plate printing, does not produce moulage on a printed object and meets super-elaborate requirement on printing; electrical performance of the solar battery positive electrode can be improved after silver paste printing so that the conversion efficiency of solar energy is improved; and the composite metal steel plate has the advantages of high hardness and good printing resistance and dissolve resistance, and has good application prospect.

Owner:昆山美微电子科技有限公司

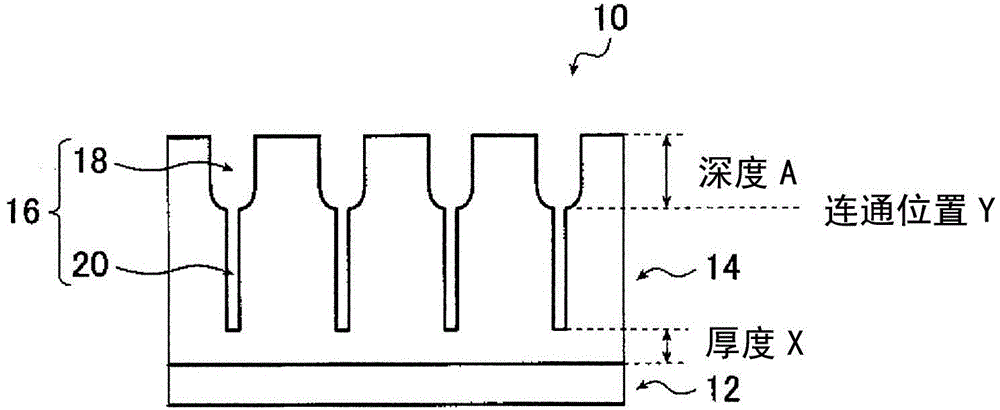

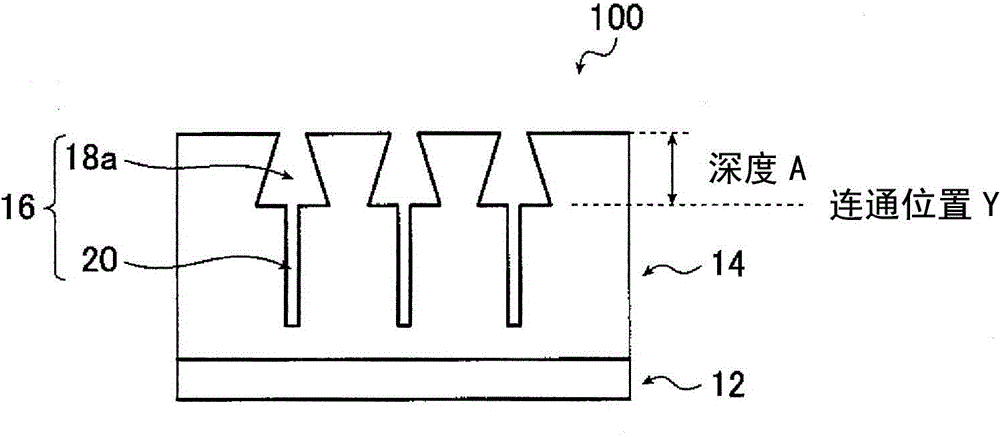

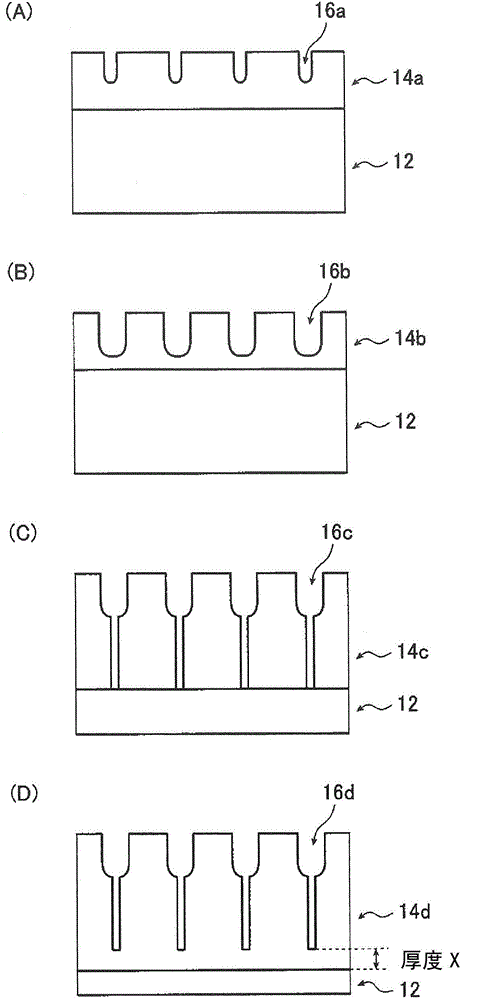

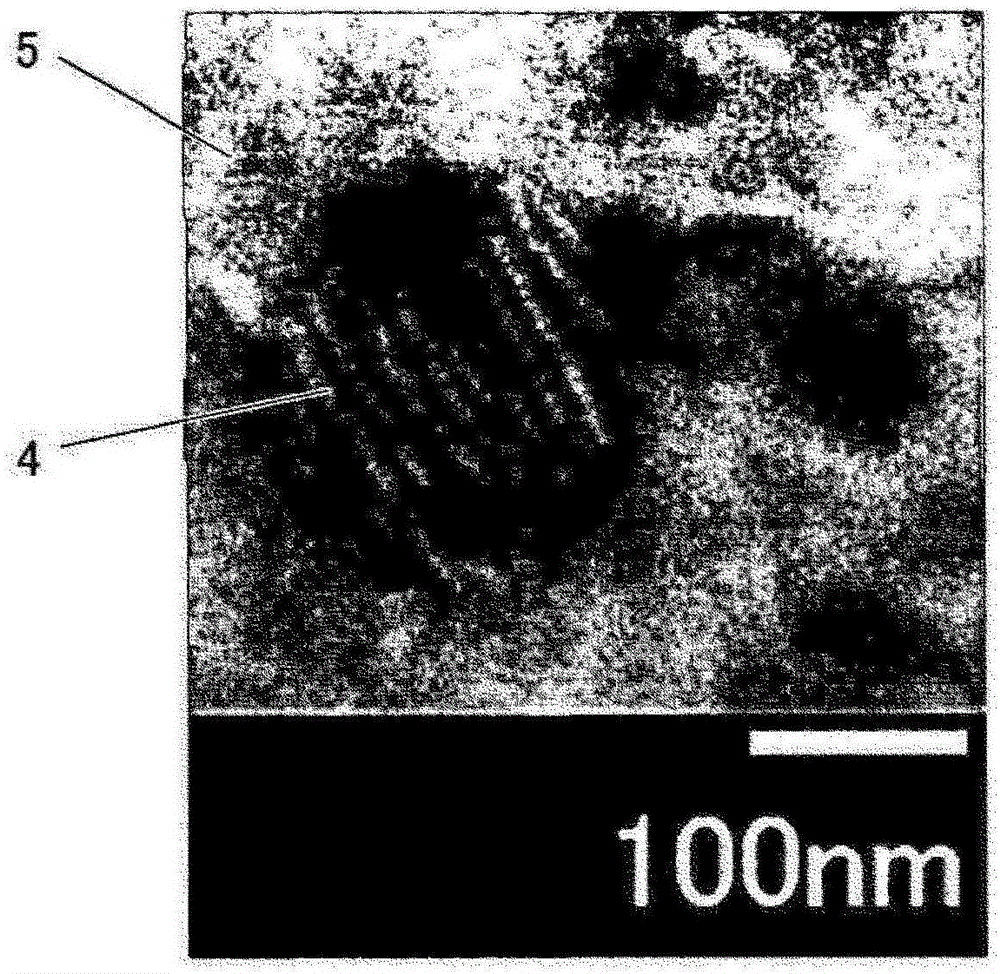

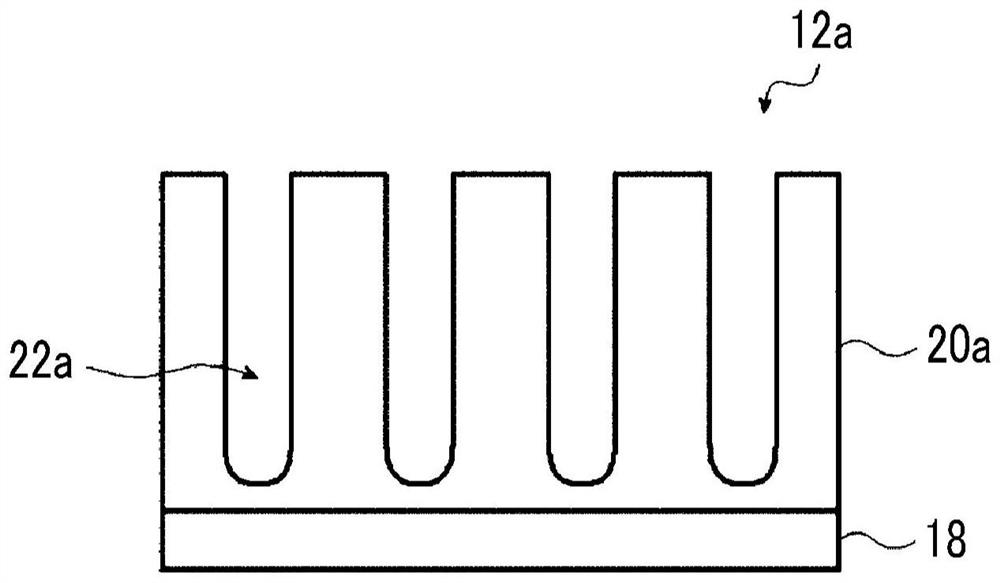

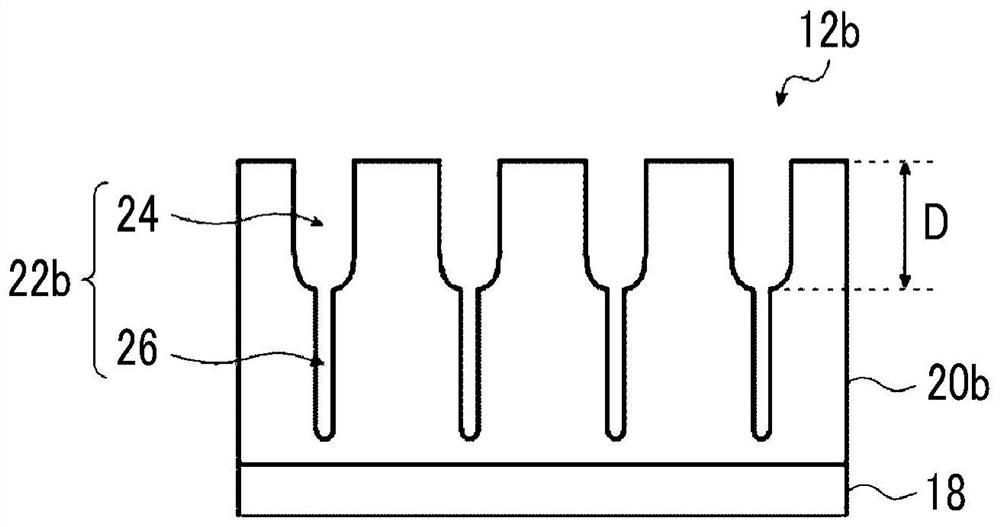

Support for lithographic printing plate and manufacturing method therefor, as well as original lithographic printing plate

ActiveCN104487261AImprove scratch resistanceExcellent brush resistanceAnodisationPlate printingMean diameterEngineering

The purpose of the present invention is to provide a support for a lithographic printing plate. The support has excellent scratch resistance and with the support, an original lithographic printing plate that has excellent printing durability when used as a lithographic printing plate and exhibits excellent on-machine developability can be obtained. For this support for a lithographic printing plate, which is provided with an aluminum plate and an anodized aluminum film thereon and which has micropores in the anodized film that extend in the depth direction from the surface that is on the opposite side from the aluminum plate: the micropores are configured from a large diameter hole section that extends from the surface of the anodized film to a mean depth of 75 - 120 nm (depth (A)) and a small diameter hole section that connects with the bottom of the large diameter hole section and extends from the connection position to a mean depth of 900-2000 nm; the mean diameter at the anodized film surface of the large diameter hole section is 10 nm to less than 30 nm, and the mean diameter and the depth (A) satisfy the relationship (depth (A) / mean diameter) = greater than 4.0 to 12.0; and the mean diameter at the connection position of the small diameter pore section is greater than 0 and less than 10 nm.

Owner:FUJIFILM CORP

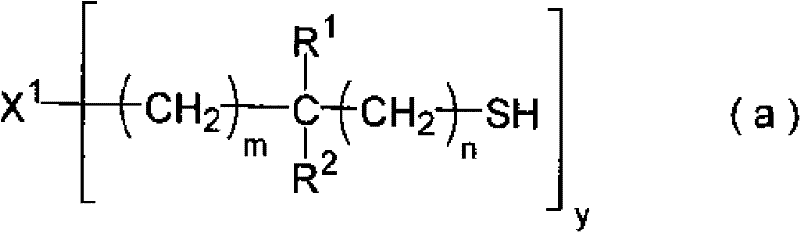

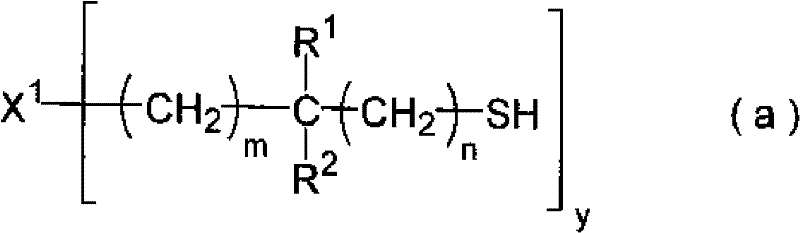

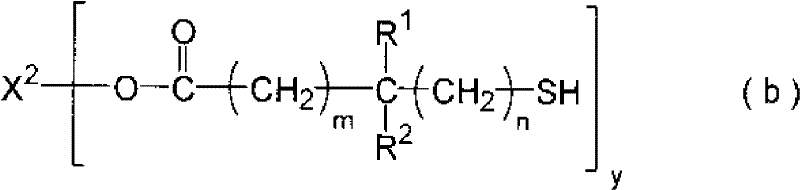

Lithographic printing plate precursor and lithographic printing method

ActiveCN102529310AImprove on-machine developabilityImprove brush resistanceLithographyPhotosensitive materials for photomechanical apparatusImage recordingRecording layer

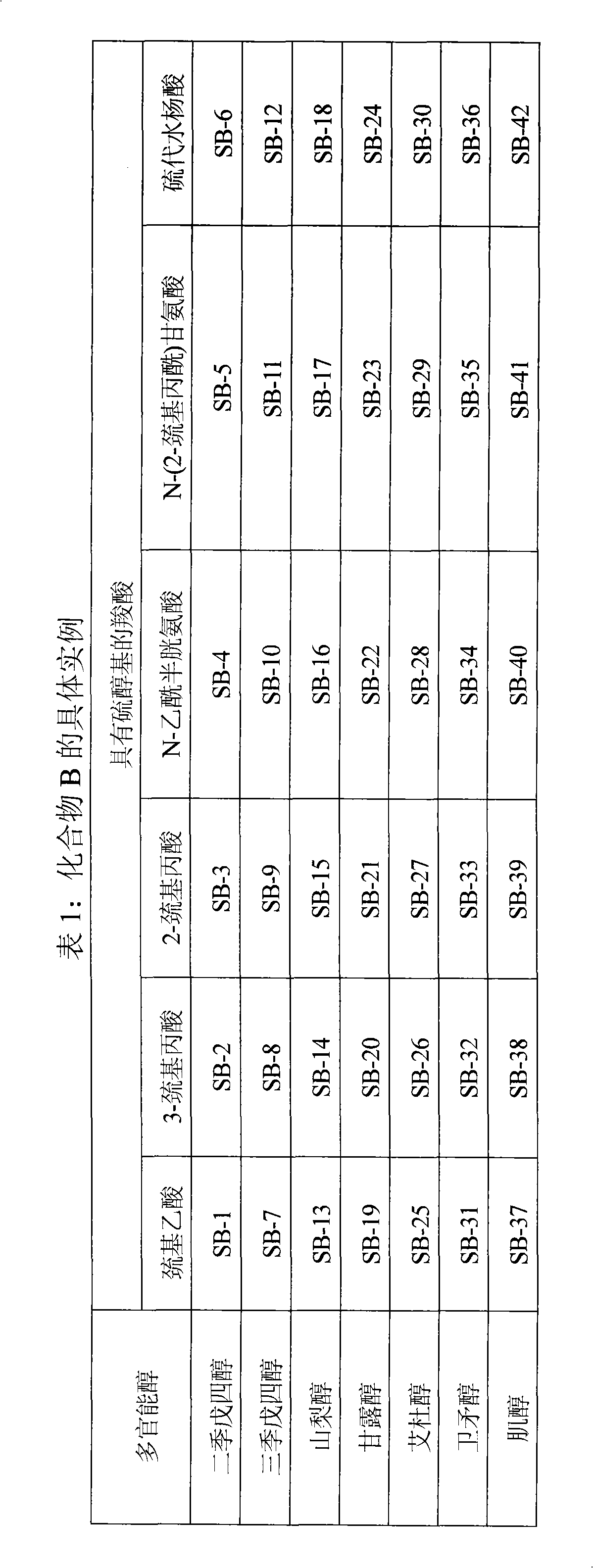

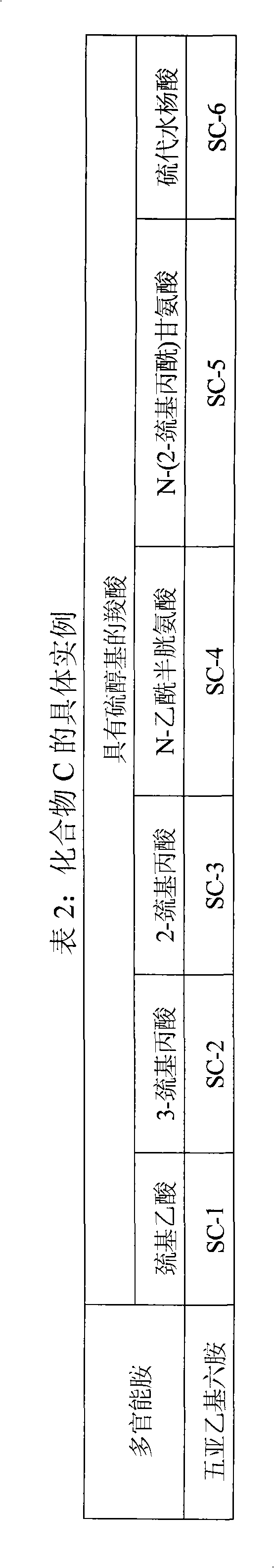

The invention relates to a lithographic printing plate precursor and a lithographic printing method. The lithographic printing plate precursor includes a support and an image-recording layer containing a binder, a radical polymerizable compound and a radical polymerization initiator, wherein the binder comprises a multifunctional thiol having from 6 to 10 functional groups as a nucleus and polymer chains connected to the nucleus through a sulfide bond and the polymer chains have polymerizable group.

Owner:FUJIFILM CORP

Electroforming foiled film screen-board

InactiveCN101100128AHigh precisionImprove printing qualityScreen printersPrinting pre-treatmentMetal foilMetal

The electroformed foiled screen plate includes one metal screen, one metal foil layer combined to the metal screen and one metal frame, and the metal foil layer is formed onto the metal screen through an electroforming process. The electroformed foiled screen plate has high strength and high printing density and quality.

Owner:FAITHFUL PRINTING EQUIP & SUPPLY

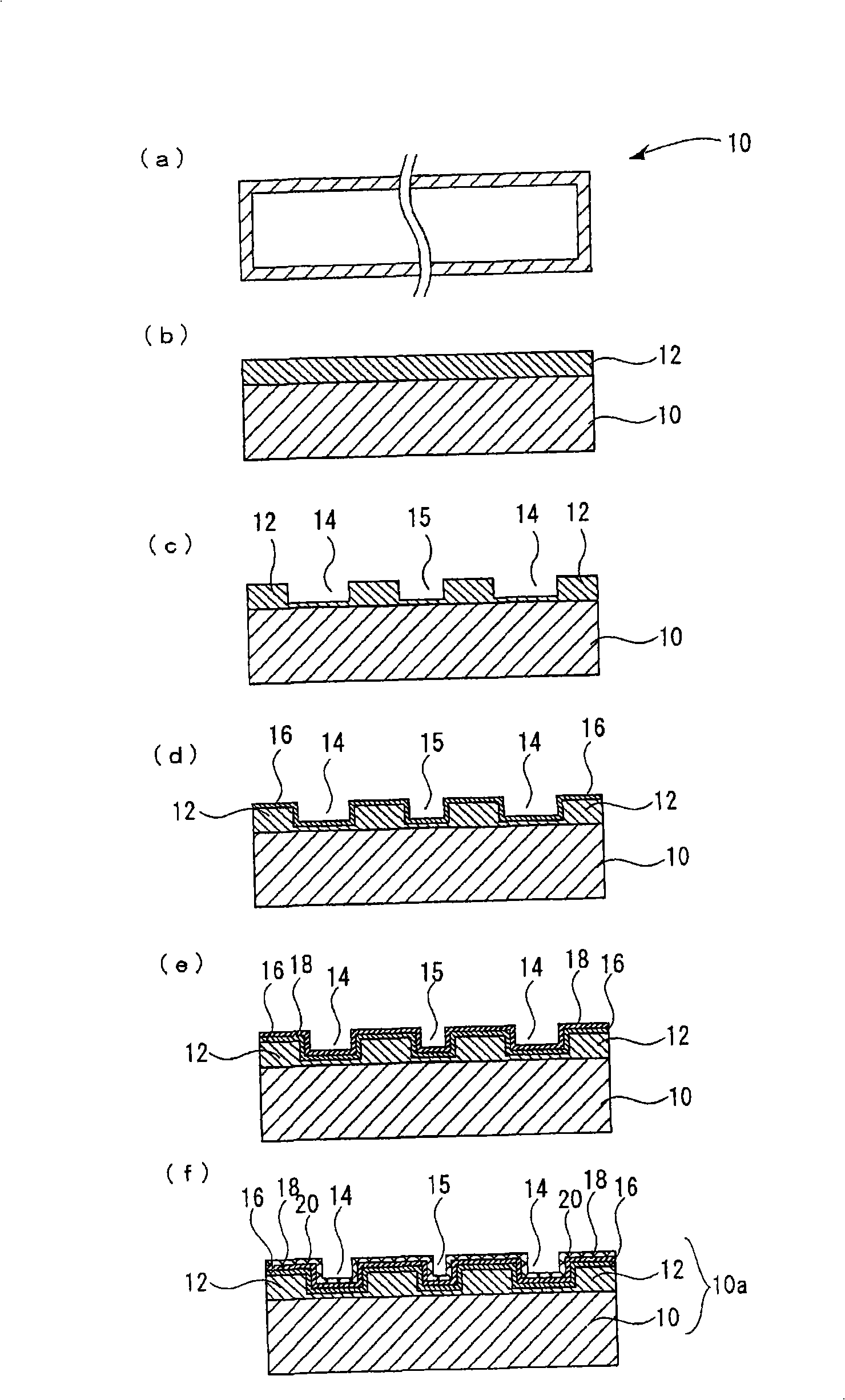

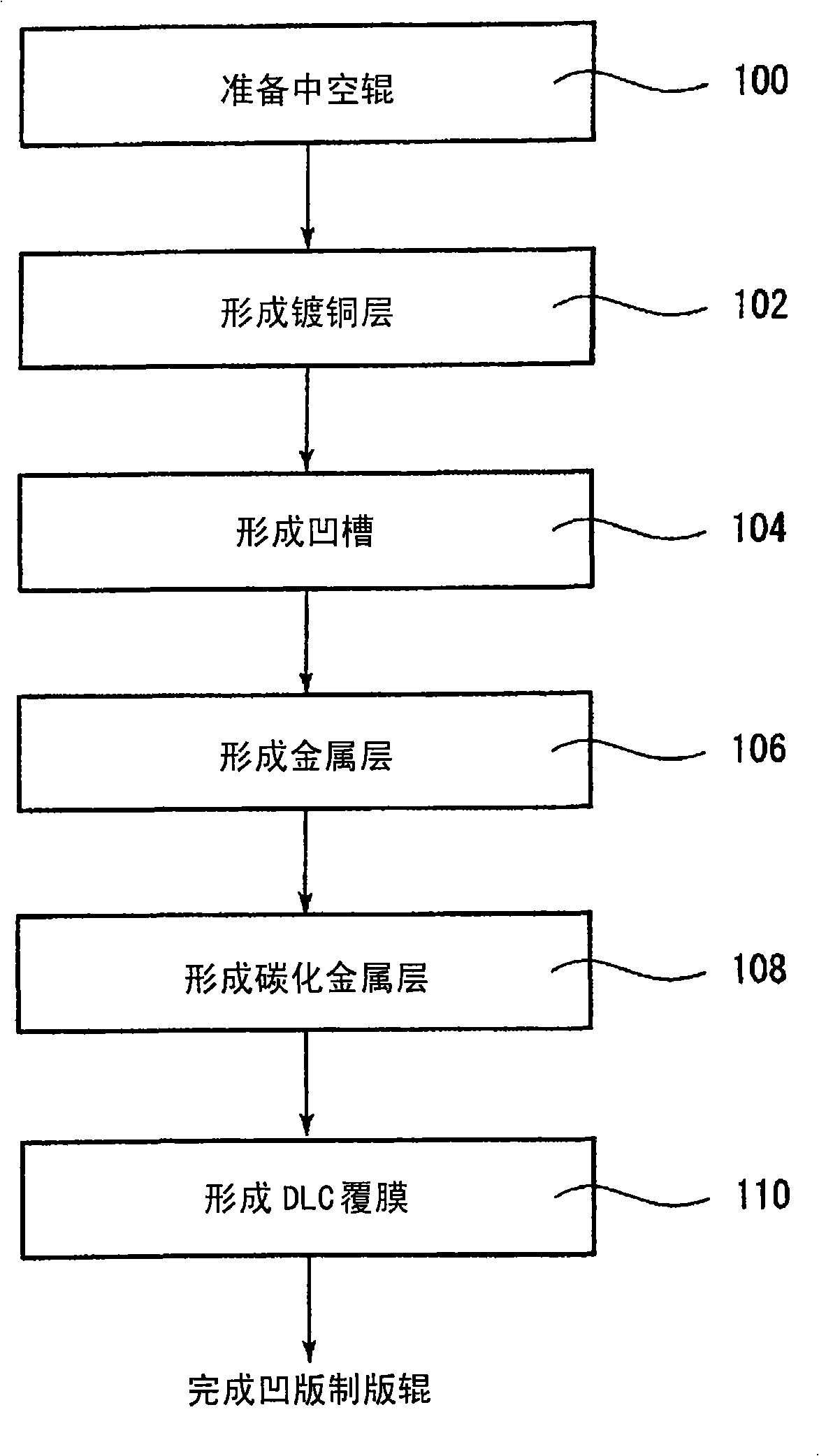

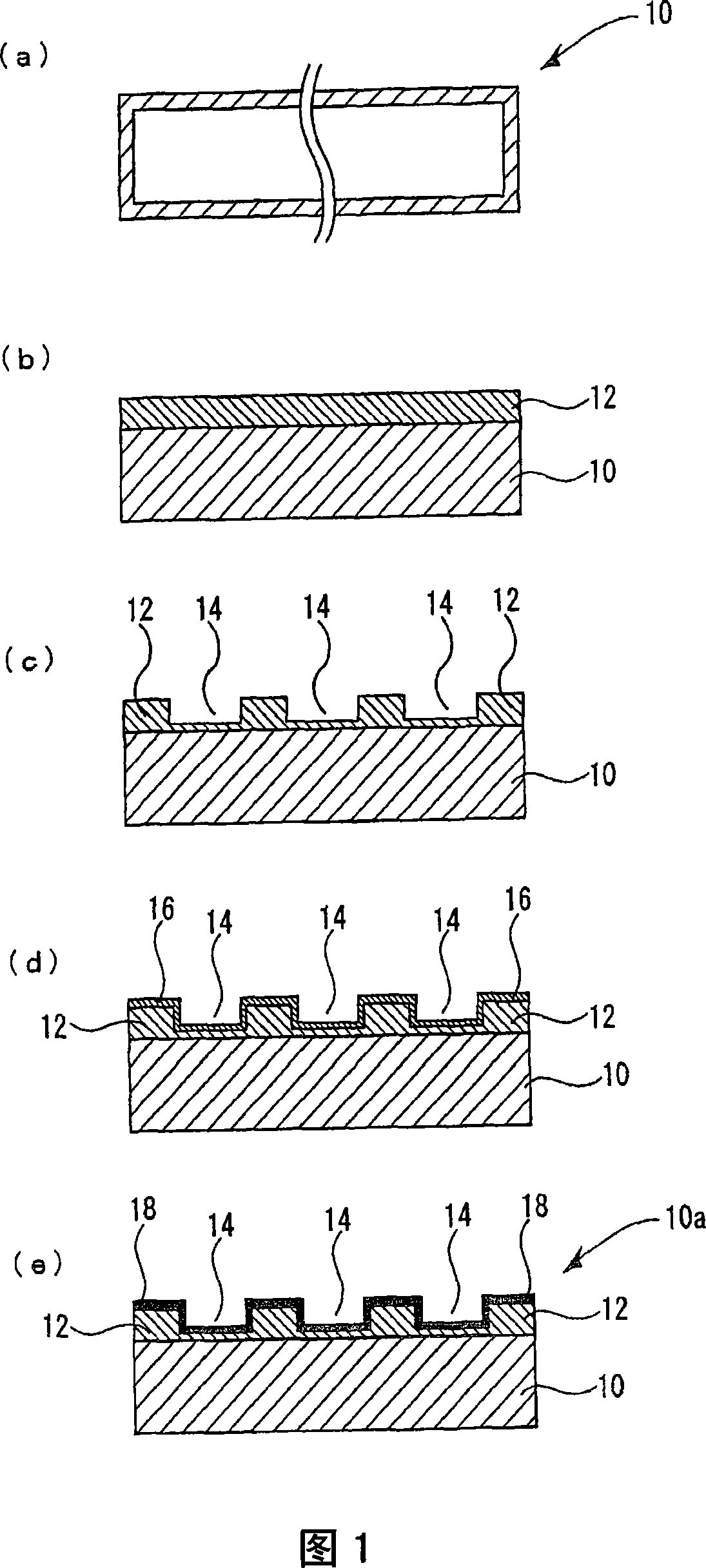

Gravure platemaking roll and its manufacturing method

InactiveCN101272913AFog EliminationHigh strengthVacuum evaporation coatingSputtering coatingCarbon filmDiamond-like carbon

A novel photogravure engraving roll capable of improving plate fog, being provided with a surface reinforcing film layer completely free from toxicity and the possibility of pollution, and being excellent in plate wear; and a production method of the roll. The photogravure engraving roll comprises a metal hollow roll, a copper-plated layer provided on the surface of the hollow roll and formed with many gravure cells on the surface thereof, a metal layer provided on the surface of the copper-plated layer, a metal carbide gradient layer of the metal provided on the surface of the metal layer, and a diamond-like carbon film covering the surface of the metal carbide gradient layer, wherein a pit being smaller than the minimum gravure cell in the highlighted portion of the copper-plated layer and having a size not permitting ink transfer is arranged so that at least one pit exists in the one-pitch area of a screen line in a non-printing image.

Owner:THINK LABORATORY CO LTD

Lithographic printing plate original and method for producing lithographic printing plate

InactiveCN104136996AGood inking effectExcellent brush resistancePlate printingPhotosensitive material processingPolymer scienceMeth-

Owner:FUJIFILM CORP

Novel refractory coating capable of preventing powder from falling

ActiveCN103319978AWith mattingHigh bonding strengthFireproof paintsEpoxy resin coatingsEpoxyAluminum silicate

The invention relates to a novel refractory coating capable of preventing powder from falling. The novel refractory coating is characterized by comprising the following components in mass ratio: 10 to 15 parts of epoxy resin, 0.5 to 0.9 part of antibacterial agent, 1 to 4 parts of mildew preventive, 10 to 25 parts of modified sericite, 10 to 20 parts of water, 5 to 10 parts of titanium dioxide, 9 to 15 parts of alumina powder, 1 to 2 parts of flexibilizer, 1 to 3 parts of flatting agent, 10 to 15 parts of chrome yellow, 10 to 15 parts of falling preventing agent, 5 to 10 parts of nickel iron chromite black spinel, 3 to 5 parts of coupling agent, 2 to 4 parts of expanded perlite, 1 to 2 parts of coalescing agent, 8 to 12 parts of quartz powder, 15 to 25 parts of melamine, 20 to 30 parts of aluminium silicate, 8 to 15 parts of monox, 1 to 3 parts of barium sulfate, 1 to 3 parts of antifoaming agent, 1 to 3 parts of wetting agent, 20 to 30 parts of mixed solvent, 5 to 10 parts of zinc oxide, 10 to 20 parts of zinc phosphate, 15 to 25 parts of aluminium triphosphate, 5 to 10 parts of sodium hydroxide, and 1 to 8 parts of hydrochloric acid.

Owner:安徽格锐新材料科技有限公司

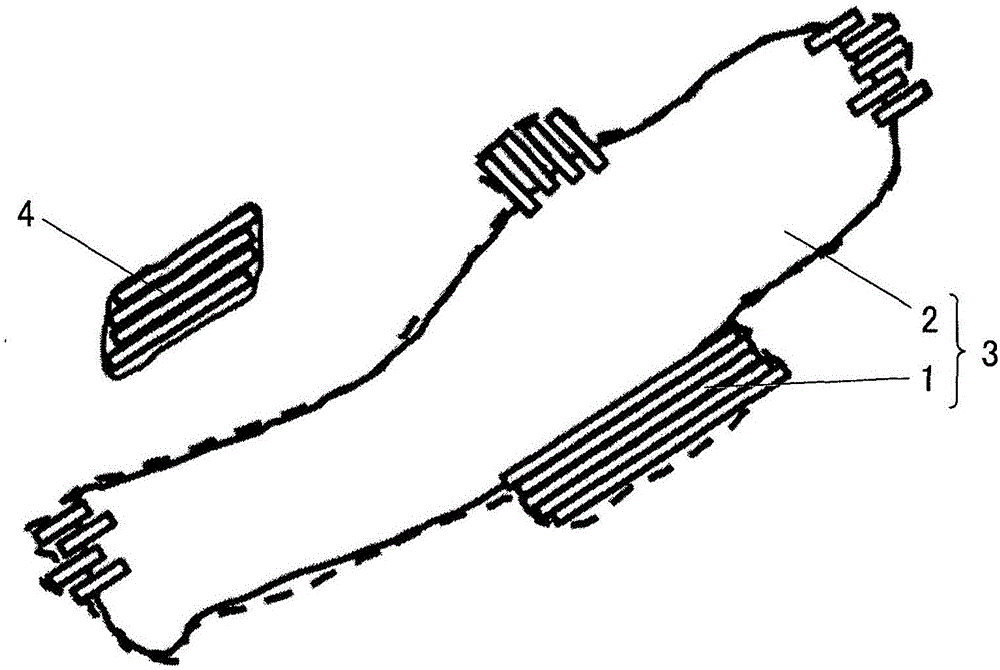

Gravure printing roll and method for manufacture thereof

InactiveCN101287612AExcellent brush resistanceOmit the chrome plating processVacuum evaporation coatingSputtering coatingCarbon coatingDiamond-like carbon

Disclosed is a novel gravure printing roll which has no toxicity, causes no deterioration of the environment, has a surface-reinforcing coating layer and is excellent in print durability and printing performance. Also disclosed is a method for manufacture of the gravure printing roll. The gravure printing roll comprises a hollow roll, a copper-plated layer which is provided on the surface of the hollow roll and has multiple gravure cells formed on its surface, and a diamond-like carbon coating film which coats the surface of the copper-plated layer, wherein each of the gravure cells coated with the diamond-like carbon coating film has a depth of 5 [mu]m or greater and less than 10 [mu]m.

Owner:THINK LABORATORY CO LTD

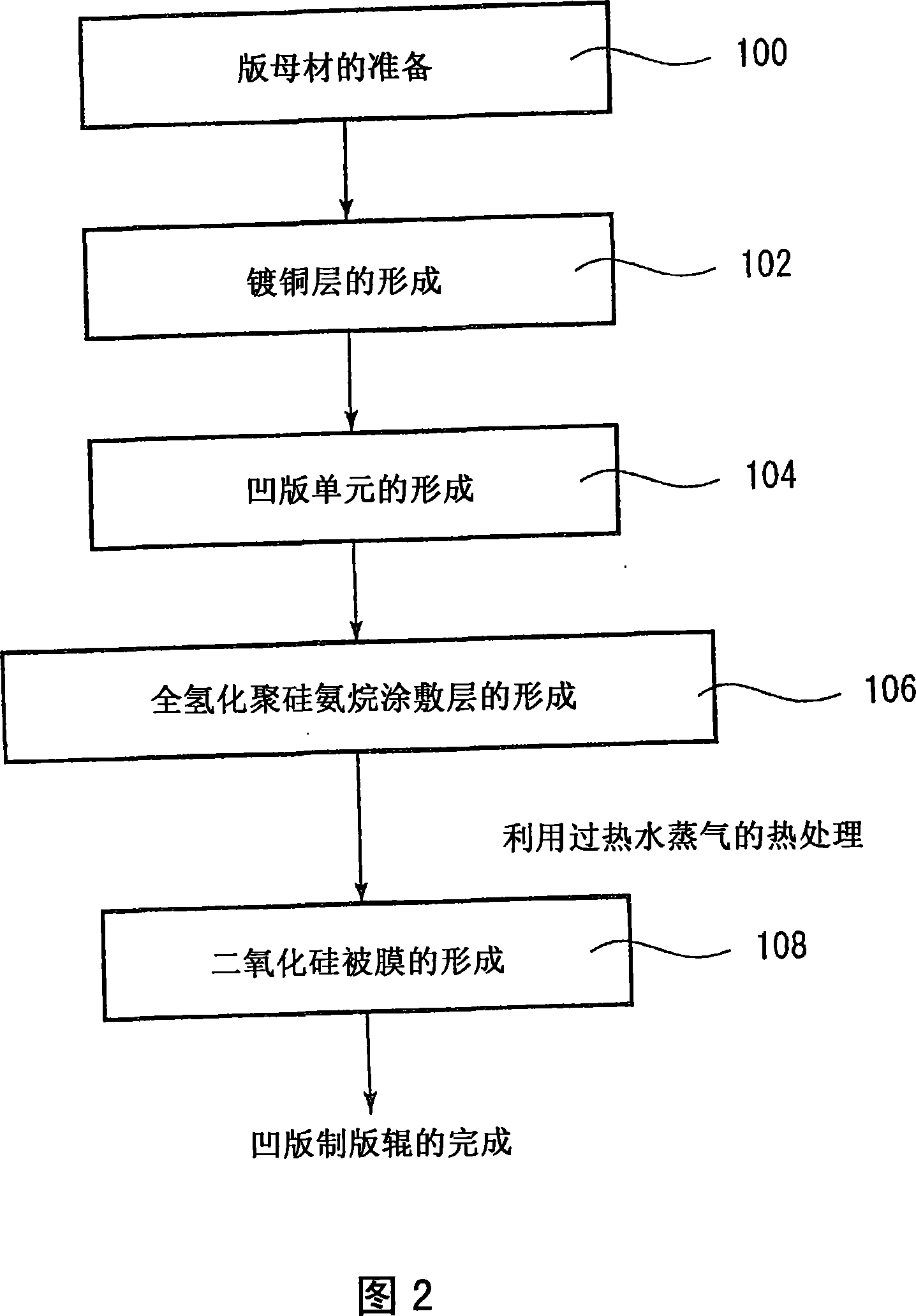

Gravure platemaking roll and process for producing the same

InactiveCN101228035AExcellent brush resistanceOmit the chrome plating processPretreated surfacesPlate printingCopper platingEngineering

The present invention provides a novel gravure printing roll which includes a surface reinforcing coating layer having no toxicity and no possibility of causing pollution, and which has excellent printing resistance, and a manufacturing method thereof. The gravure printing roll includes: a plate base material; a copper plating layer formed on a surface of the plate base material and having multiple gravure cells formed thereon; and a silicon dioxide film which covers a surface of the copper plating layer, in which the silicon dioxide film is formed by using a perhydropolysilazane solution. The copper plating layer has a thickness of from 50 to 200 µm, the gravure cell has a depth of from 5 to 150 µm, and the silicon dioxide film has a thickness of from 0.1 to 5 µm, preferably 0.1 to 3 µm, and more preferably 0.1 to 1 µm.

Owner:THINK LABORATORY CO LTD

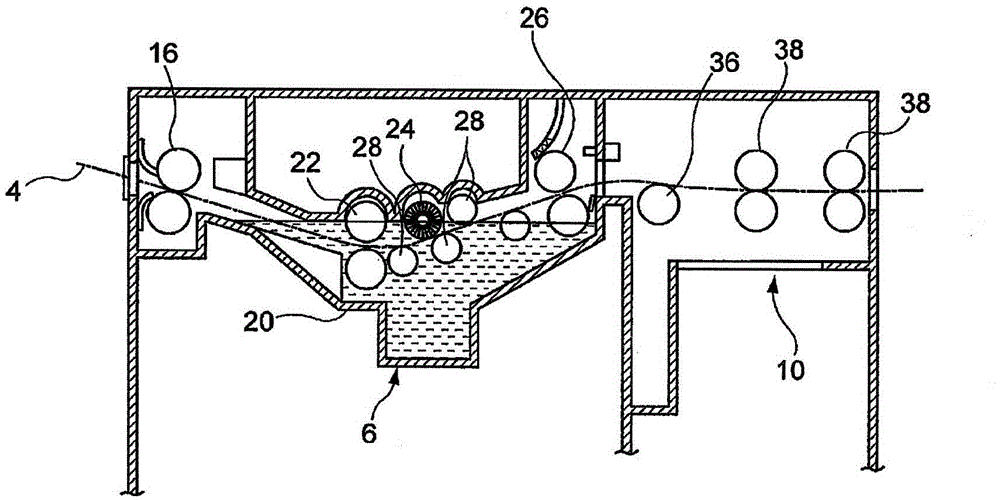

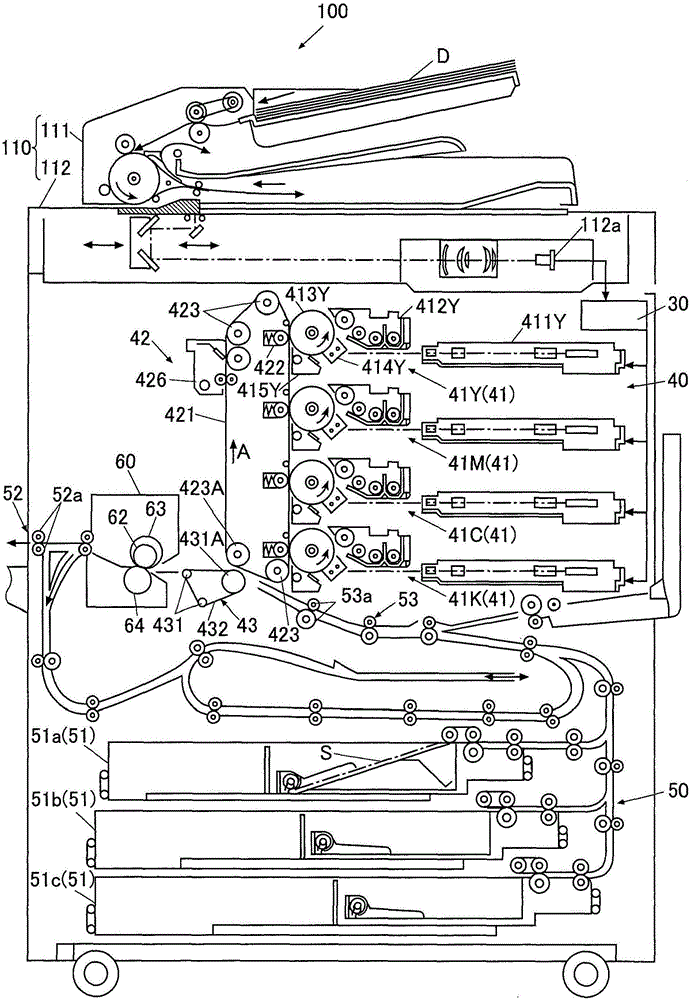

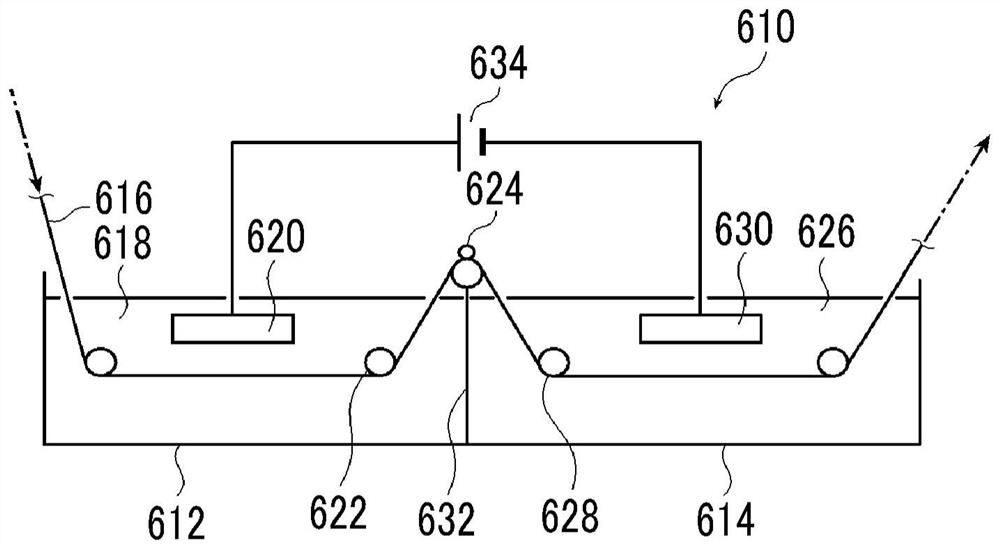

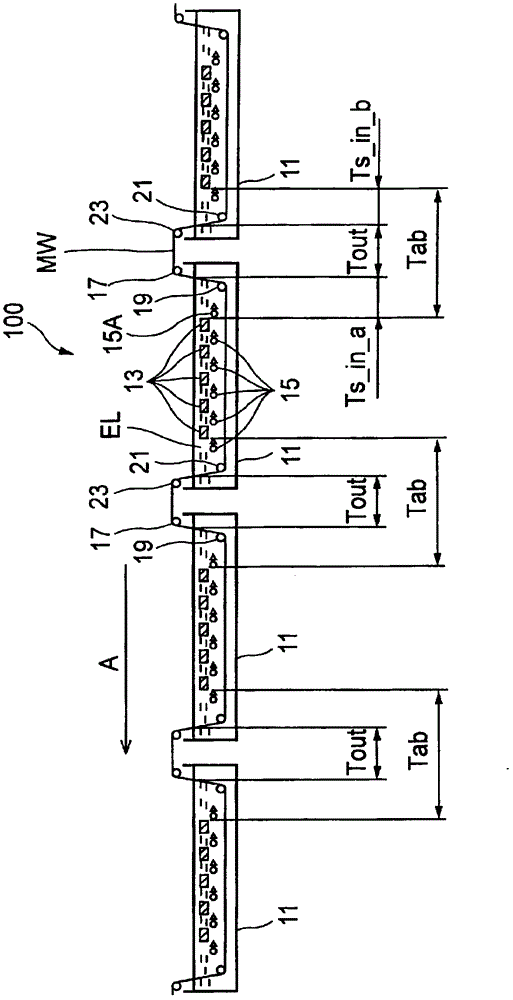

Method of manufacturing support for planographic printing plate

InactiveCN101983261AImprove uneven image qualityExcellent brush resistanceElectrolysis componentsPlate printingElectrochemistryImaging quality

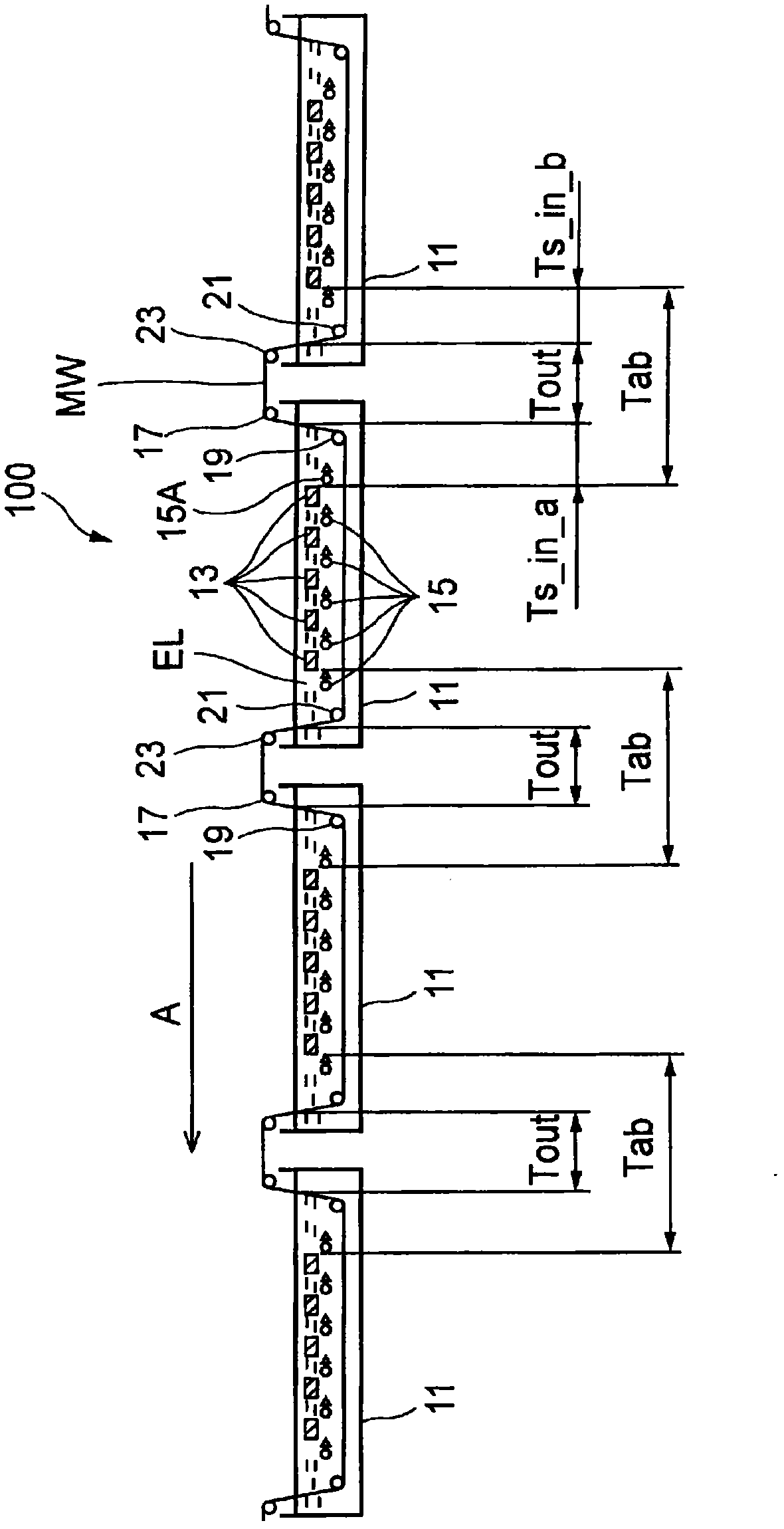

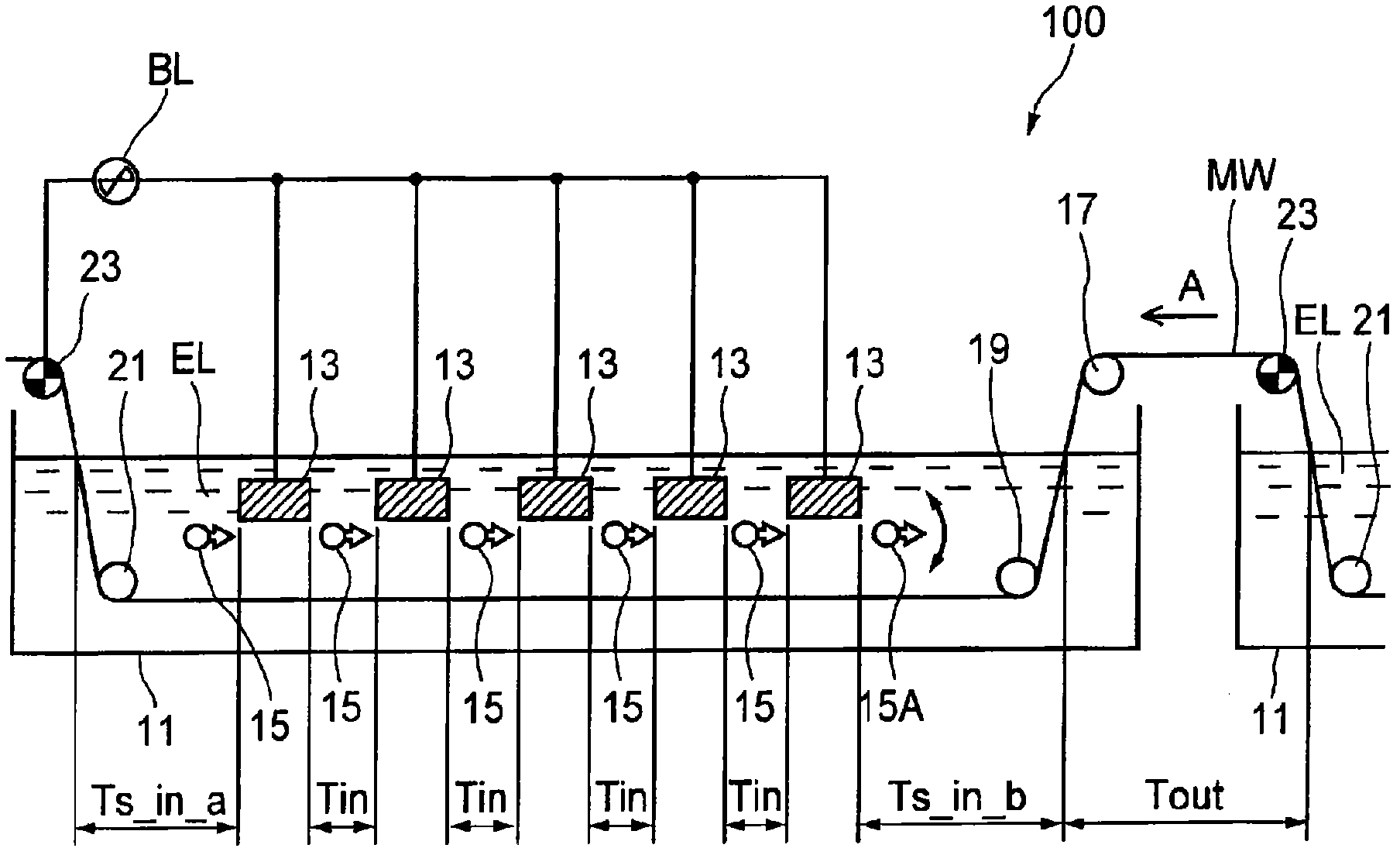

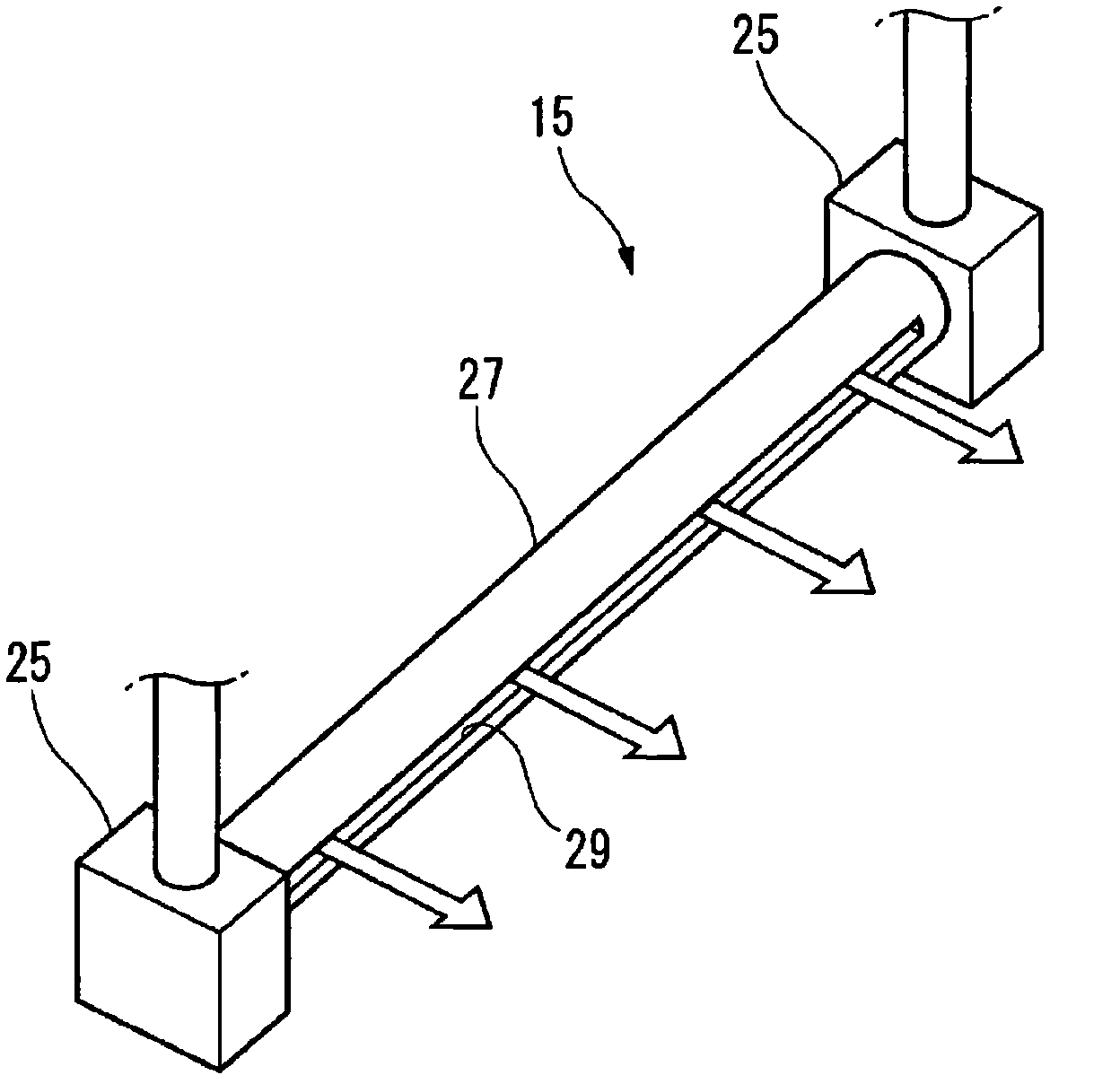

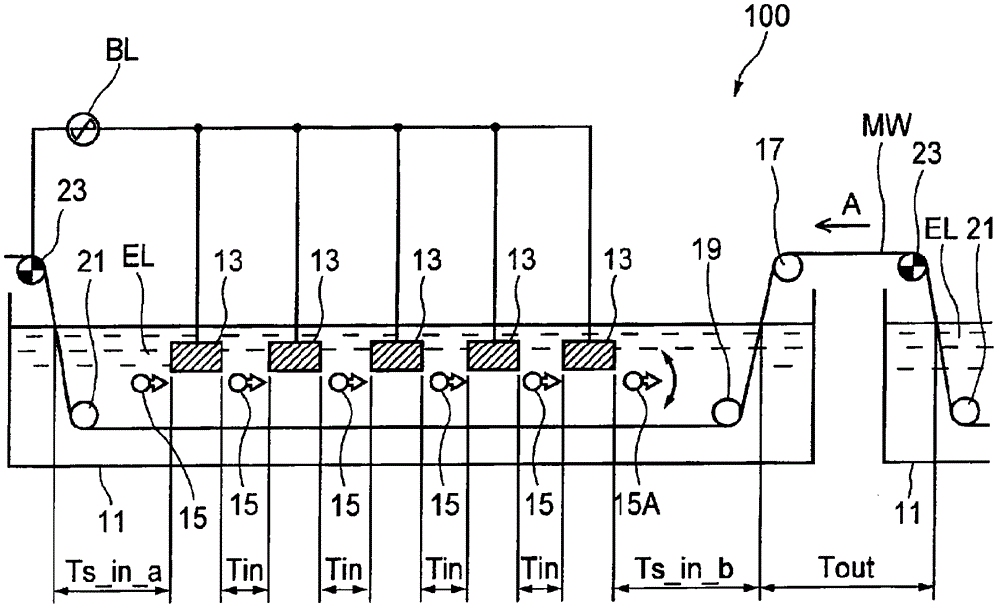

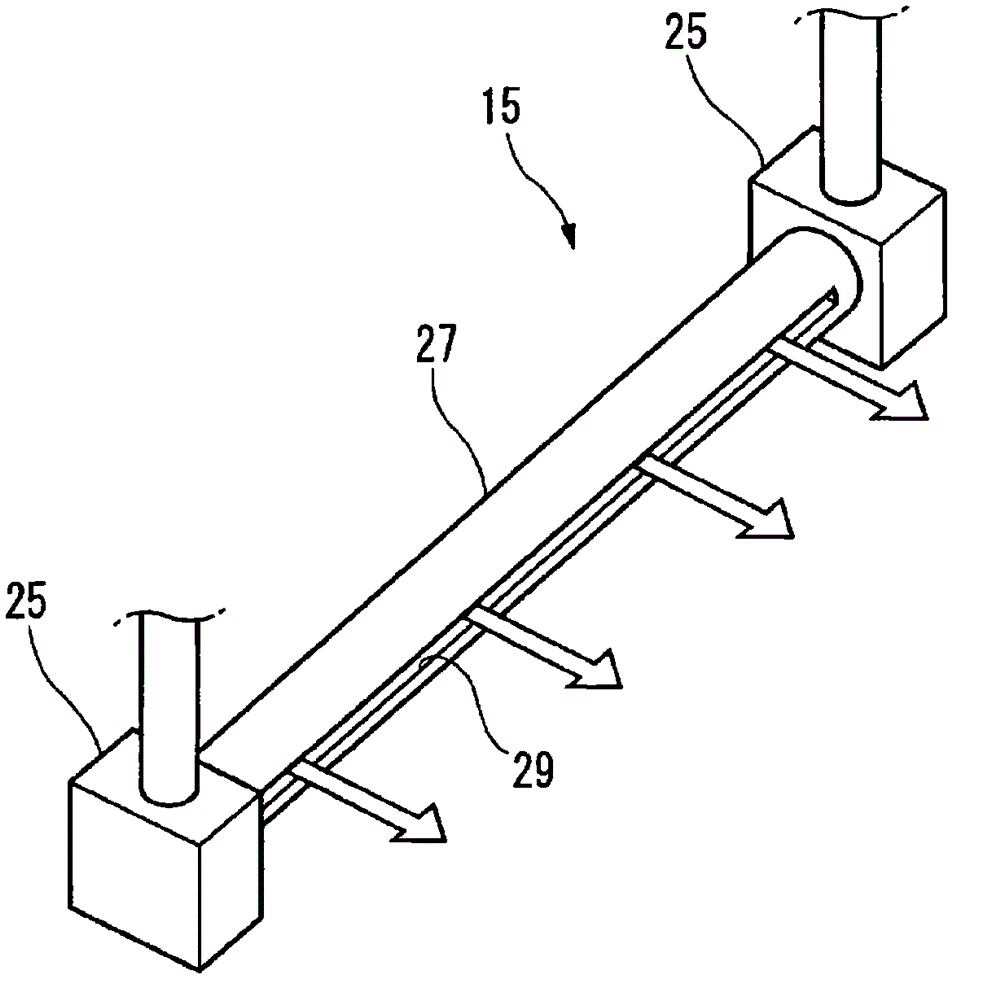

Provided is a method of manufacturing a support for a planographic printing plate, by which the variation in image quality can be reduced and an even tone of sand can be achieved stably. A metal web (MW) formed of aluminum or an aluminum alloy is transferred, being dipped in an electrolyte (EL) of a plurality of electrolyte baths (11) sequentially, and current is supplied between the metal web (MW) and a plurality of electrodes (13) opposite to the metal web (MW) in the electrolyte baths (11) to perform an electrochemical surface roughening treatment on the metal web (MW). During this treatment, the flow rate of the electrolyte (EL) in the electrolyte baths (11) are so set that an average flow rate in the electrolyte baths may be 500 to 4000 mm / sec. and a flow rate distribution of the electrolyte (EL) in the width direction perpendicular to the direction in which the metal web (MW) is transferred in the electrolyte baths (11) may be within + / - 50% of the average flow rate. Letting a region of the transfer path of the metal web which is opposite to a gap between each two adjacent electrodes be a treatment suspension zone between electrodes in the bath, the metal web (MW) is transferred at such a speed that the time (Tin) for the metal web (MW) to pass through one treatment suspension zone between electrodes in the bath may be 0.05 to 1 sec.

Owner:FUJIFILM CORP

Negative photosensitive composition and negative photosensitive lithography plate

InactiveCN1957300AHigh strengthGood storage stabilityPhotosensitive materials for photomechanical apparatusLithographyLithographic artistChemical compound

Owner:柯达彩色绘图日本株式会社

Planographic plate material for CTP, preparing method thereof and planographic plate made thereby

InactiveCN101373332AExcellent image retentionExcellent brush resistancePhotosensitive materials for photomechanical apparatusNear infrared absorptionComputer to plate

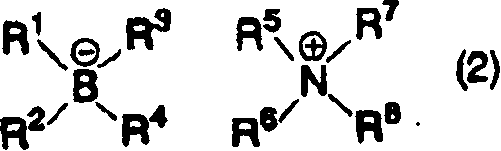

The problem of the invention aims to provide a technique for improving the stability of a light room and also improving the stability of a dark room, which is in the same way as the Computer-to-Plate (CTP) lithographic printing plate which is already proposed. The invention relates to the CTP lithographic printing plate, which includes an aluminum supporter, a photosensitive layer formed on the aluminum supporter, and a protective layer formed on the photosensitive layer, and is characterized in that the photosensitive layer is formed by ethylenic-linkage unsaturated compounds, alkali-soluble resin, near-infrared absorbing pigment, halogen-substituted methyl compounds and photosensitive resin compositions containing organic boron anionic compounds, wherein the protective layer is formed by resin compositions from a protective layer containing water-soluble or alkali-soluble resin and nitroxyl compounds.

Owner:NIPPON PAINT CO LTD

Resin composition for laser engraving, relief printing plate precursor for laser engraving, process for producing relief printing plate and relief printing plate

InactiveCN102314080AGood adhesionHigh hardnessPhotomechanical apparatusPlate printingLaser engravingEngineering

There are provided a resin composition for laser engraving that can give a relief printing plate having excellent hardness, film elasticity, printing durability, and aqueous ink transfer properties and that has excellent rinsing properties for engraving residue generated when laser-engraving a printing plate and excellent engraving sensitivity in laser engraving, a relief printing plate precursor employing the resin composition for laser engraving, a process for producing a relief printing plate employing the same, and a relief printing plate obtained thereby.

Owner:FUJIFILM CORP

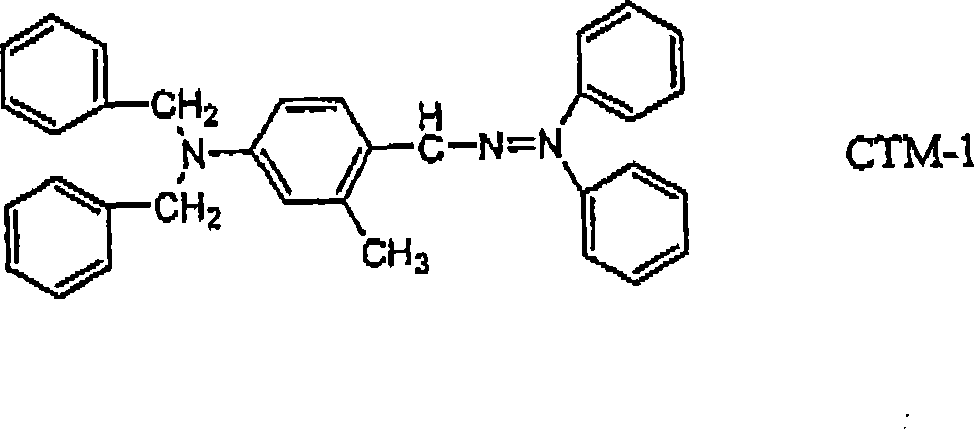

Electrophotographic photosensitive body

Disclosed is an electrophotographic photosensitive body having a photosensitive layer on a conductive base. This electrophotographic photosensitive body is characterized in that at least the outermost layer thereof contains particles having a double structure composed of a core member and a shell member having a lager rubber hardness than the core member. This electrophotographic photosensitive body exhibits excellent mechanical strength such as wear resistance, abrasion resistance and scratch resistance as well as excellent electrophotographic characteristics such as cleaning properties for a long time.

Owner:IDEMITSU KOSAN CO LTD

Electrostatic image developing toner

InactiveCN106802539AImproved file retentionImproved brush resistanceDevelopersElectrostatic dischargePolymer chemistry

Provided is an electrostatic image developing toner incorporating toner mother particles containing a binder resin and a releasing agent, wherein the binder resin contains an amorphous polyester resin and a crystalline resin; and the toner mother particles have a region (A) including a structure a formed with the releasing agent and the crystalline resin being in contact with each other, and a region (B) in which the crystalline resin forms a lamellar crystalline structure b independently existing without contacting with the releasing agent.

Owner:KONICA MINOLTA INC

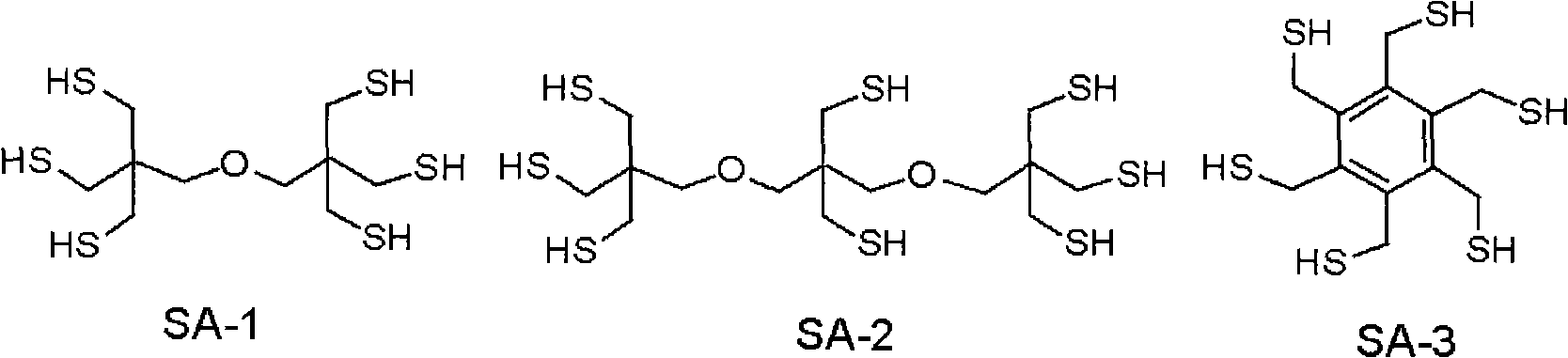

Photosensitive resin composition for flexographic printing and flexographic printing original plate

ActiveCN107850845BEasy to cleanExcellent ink resistancePlate printingPhotosensitive material processingElastomerPolymer science

Owner:ASAHI KASEI KK

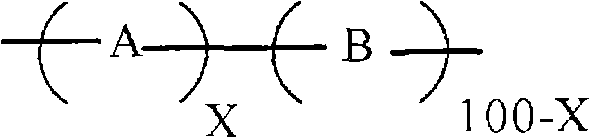

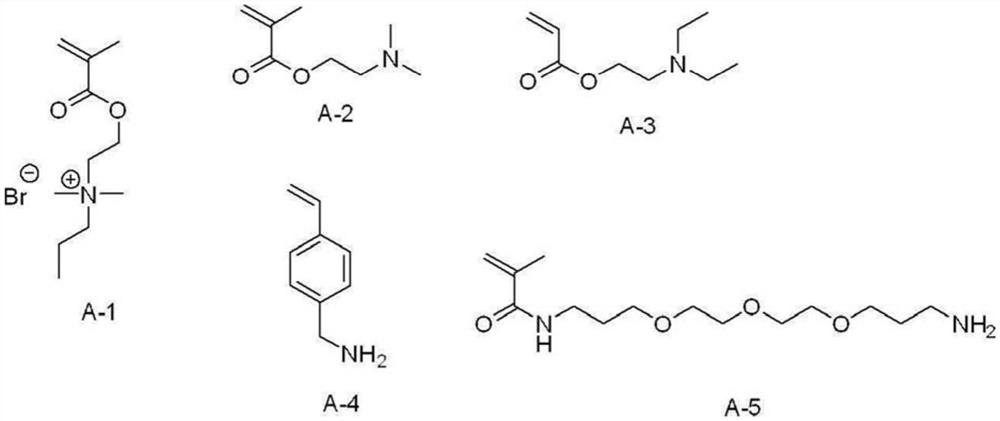

Lithographic printing plate precursor, method for manufacturing lithographic printing plate, and lithographic printing method

ActiveCN113474178AExcellent brush resistancePlate printingOther printing apparatusImage recordingRecording layer

Provided is a lithographic printing plate precursor that has a support body and an image recording layer disposed on the support body. The image recording layer contains organic particles including a resin that has a structural unit A having a cation site and a structural unit B having an anion site. Also provided is a method for manufacturing a lithographic printing plate that uses said lithographic printing plate precursor.

Owner:FUJIFILM CORP

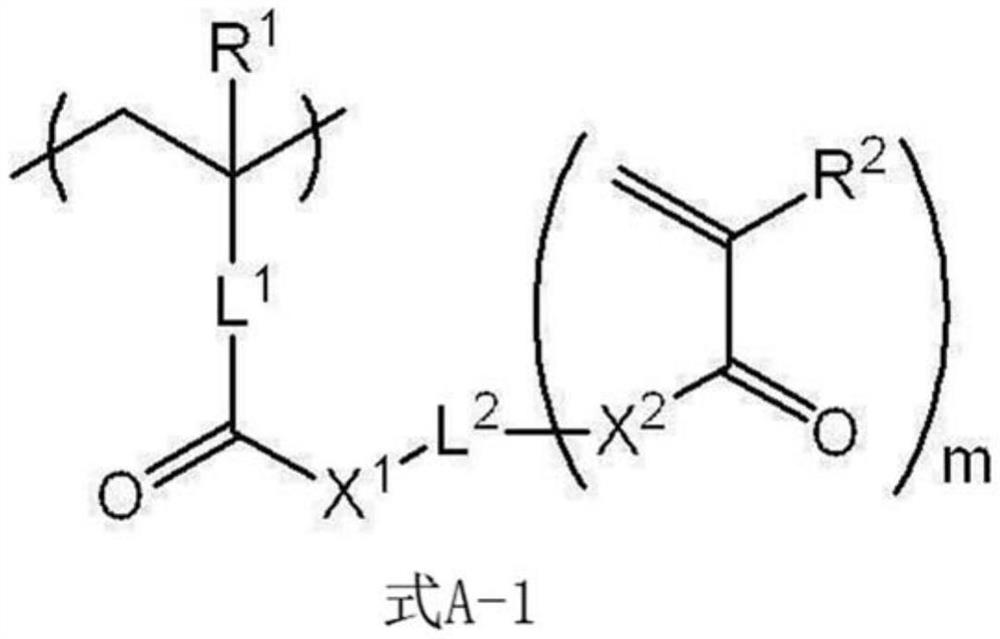

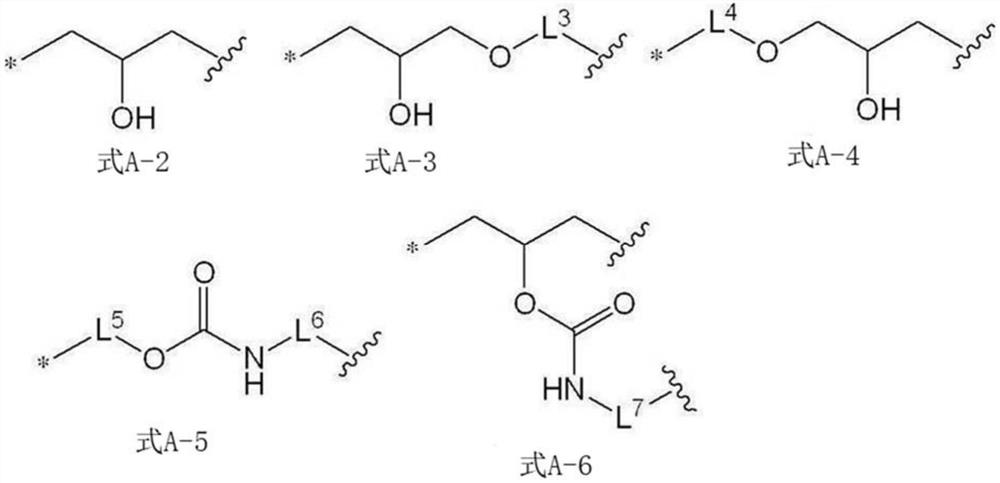

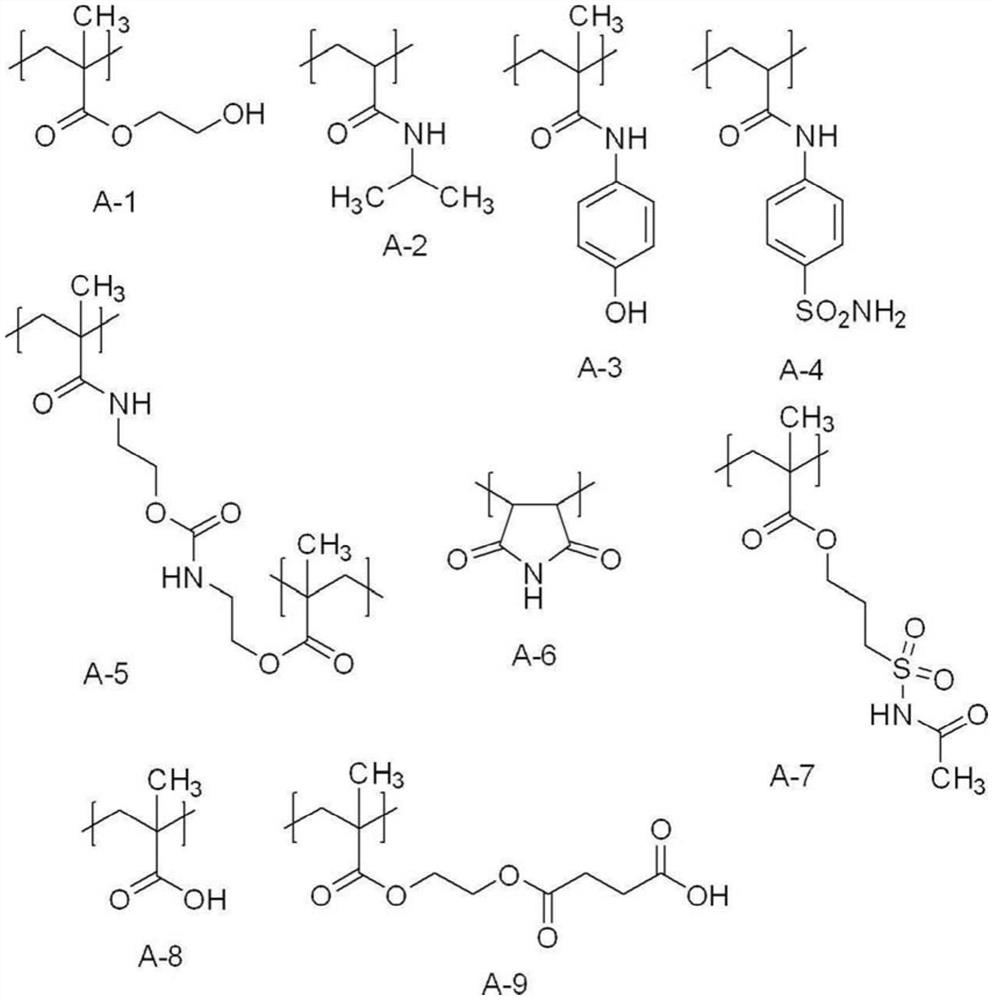

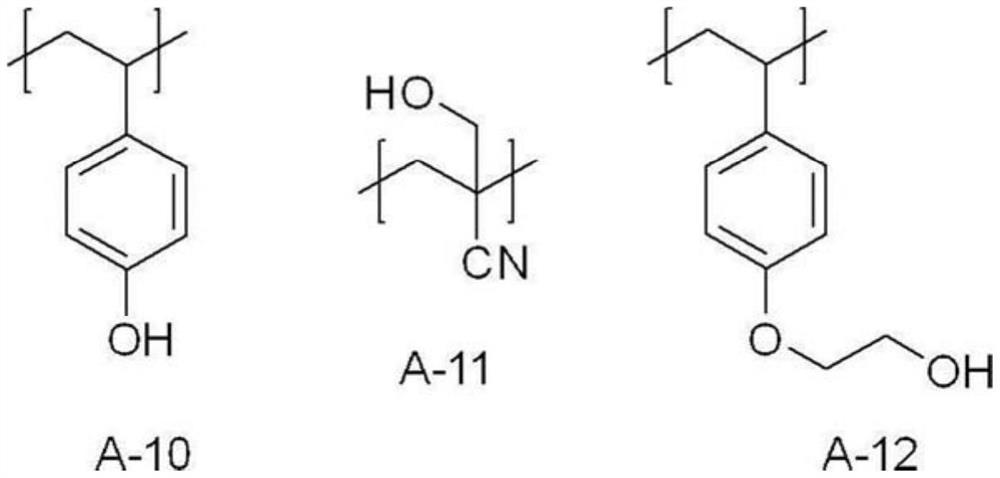

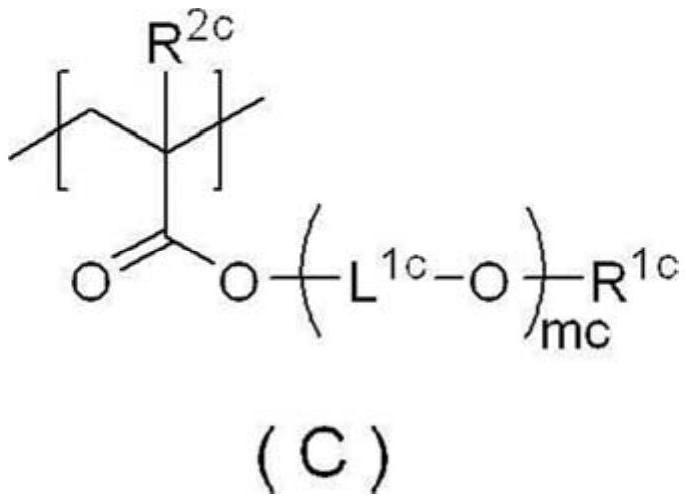

Planographic printing plate precursor, and production method for planographic printing plate

ActiveCN111683820AExcellent brush resistancePlate printingFoil printingPolymer scienceRecording layer

Provided is a planographic printing plate precursor that includes a support and an image-recording layer formed on the support. The image-recording layer contains a polymer A comprising a structural unit A1 having an ethylenic unsaturated group. The weight-average molecular weight of the polymer A is 2,500-35,000. The content of the structural unit A1 in the polymer A is 15 mol% or more. Also provided is a production method for a planographic printing plate using said planographic printing plate precursor.

Owner:FUJIFILM CORP

Composite metal steel plate for solar battery pure subline printing

ActiveCN102744997BNo imprintThe overall thickness is thinScreen printersPlate printingSilver pasteElectrical performance

The invention discloses a composite metal steel plate for solar battery pure subline printing. The composite metal steel plate comprises a single-layer metal film, wherein a plurality of sublines of a solar battery positive electrode are arranged on the single-layer metal film; and a plurality of the sublines are respectively of a strip shape and are uniformly distributed on the single-layer metal film. The composite metal steel plate for the solar battery pure subline printing in the invention can replace the original weaving silk screen plate printing, does not produce moulage on a printed object and meets super-elaborate requirement on printing; electrical performance of the solar battery positive electrode can be improved after silver paste printing so that the conversion efficiency of solar energy is improved; and the composite metal steel plate has the advantages of high hardness and good printing resistance and dissolve resistance, and has good application prospect.

Owner:昆山美微电子科技有限公司

Electroforming metal film mesh plate for printing touch mesh spacing contacts

The invention discloses an electroforming metal film mesh plate for printing touch mesh spacing contacts; the invention is characterized by comprising an aluminium alloy section mesh frame, a nylon yarn mesh and a metal film; wherein, the metal film is formed by electroforming and provided with micro holes and a plurality of through holes; the nylon yarn mesh is stuck and connected with the aluminium alloy section mesh frame by solidified glue, and the periphery of the metal film is stuck and connected with the nylon yarn mesh by the solidified glue. The metal film mesh plate is made of nickelalloy material and overcomes the defects that photosensitive resistance material is easy to deform, break and the like; the surface of the mesh plate is high in rigidity and good in brushing resistance and dissolubility resistance; the electroforming metal film mesh plate is hard to misplace, and is higher in printing precision and circular degree, thus being capable of printing the touch mesh spacing contacts having the appearance circular degree of 99% and the diameter of 20[mu]m.

Owner:昆山美微电子科技有限公司

Precursor of lithographic printing plate and method for producing lithographic printing plate

ActiveCN111683820BExcellent brush resistancePlate printingFoil printingPolymer scienceImage recording

The present invention provides a lithographic printing plate precursor and a method for making a lithographic printing plate using the lithographic printing plate precursor. The lithographic printing plate precursor has a support and an image recording layer formed on the support. The image recording layer contains The polymer A having the structural unit A1 of an ethylenically unsaturated group has a weight average molecular weight of 2,500 to 35,000, and the content of the structural unit A1 in the polymer A is 15 mol% or more.

Owner:FUJIFILM CORP

A kind of anti-powder refractory coating

ActiveCN103319978BWith mattingHigh bonding strengthFireproof paintsEpoxy resin coatingsEpoxyAluminum silicate

The invention relates to an anti-powdering refractory coating. The coating includes the following components, according to the mass ratio: 10-15 parts of epoxy resin, 0.5-0.9 parts of antibacterial agent, 1-4 parts of anti-fungal agent, modified 10-25 parts of sericite, 10-20 parts of water, 5-10 parts of titanium dioxide, 9-15 parts of alumina powder, 1-2 parts of toughening agent, 1-3 parts of leveling agent, 10-15 parts of chrome yellow 10-15 parts of anti-stripping agent, 5-10 parts of ferrochrome black, 3-5 parts of coupling agent, 2-4 parts of expanded perlite, 1-2 parts of film-forming aid, 8-12 parts of quartz powder, 15-25 parts of melamine, 20-30 parts of aluminum silicate, 8-15 parts of silicon oxide, 1-3 parts of barium sulfate, 1-3 parts of defoamer, 1-3 parts of wetting agent, 20-30 parts of mixed solvent , 5-10 parts of zinc oxide, 10-20 parts of zinc phosphate, 15-25 parts of aluminum tripolyphosphate, 5-10 parts of sodium hydroxide, 1-8 parts of hydrochloric acid, 1-2 parts of hollow glass powder, the hollow glass The diameter of the fine powder is 5-8 microns.

Owner:安徽格锐新材料科技有限公司

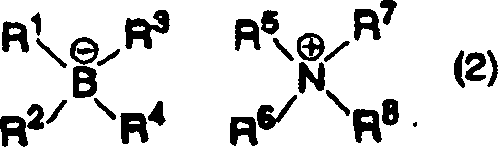

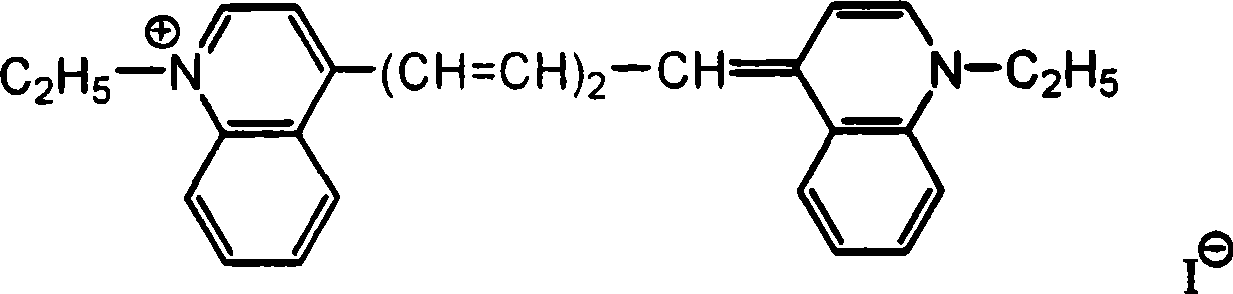

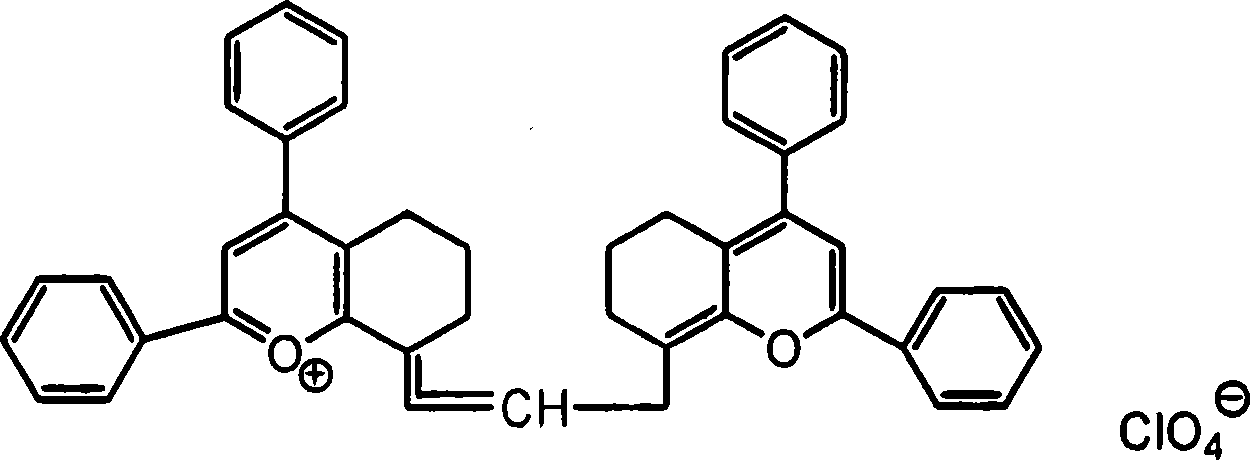

Lithographic printing plate original plate, method for producing lithographic printing plate and lithographic printing method

ActiveCN112930266AExcellent brush resistancePlate printingFoil printingPolymer scienceRecording layer

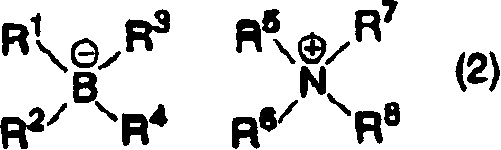

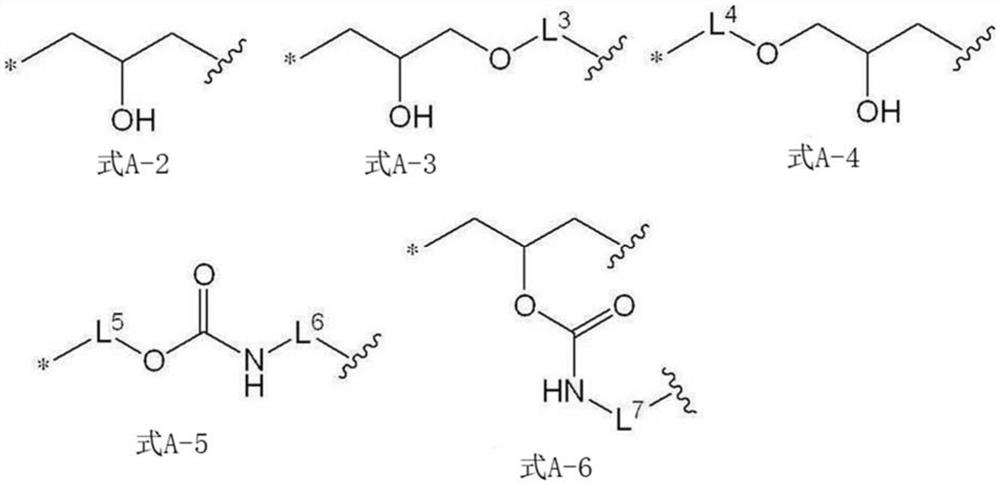

A lithographic printing plate original plate having an image-recording layer on a support body, wherein the image-recording layer contains an infrared absorbent represented by formula 1-1, a polymerization initiator and a polymerizable compound. The description specifies the details of R<1>, R<11>-R<18>, n<11>-n<14>, L, Za, A1 and A<2> in formulas 1-1 and 2.

Owner:FUJIFILM CORP

Method of manufacturing support for planographic printing plate

InactiveCN101983261BExcellent stain performanceExcellent brush resistanceElectrolysis componentsPlate printingElectrolytic agentMetallurgy

Provided is a method of manufacturing a support for a planographic printing plate, by which the variation in image quality can be reduced and an even tone of sand can be achieved stably. A metal web (MW) formed of aluminum or an aluminum alloy is transferred, being dipped in an electrolyte (EL) of a plurality of electrolyte baths (11) sequentially, and current is supplied between the metal web (MW) and a plurality of electrodes (13) opposite to the metal web (MW) in the electrolyte baths (11) to perform an electrochemical surface roughening treatment on the metal web (MW). During this treatment, the flow rate of the electrolyte (EL) in the electrolyte baths (11) are so set that an average flow rate in the electrolyte baths may be 500 to 4000 mm / sec. and a flow rate distribution of the electrolyte (EL) in the width direction perpendicular to the direction in which the metal web (MW) is transferred in the electrolyte baths (11) may be within + / - 50% of the average flow rate. Letting a region of the transfer path of the metal web which is opposite to a gap between each two adjacent electrodes be a treatment suspension zone between electrodes in the bath, the metal web (MW) is transferred at such a speed that the time (Tin) for the metal web (MW) to pass through one treatment suspension zone between electrodes in the bath may be 0.05 to 1 sec.

Owner:FUJIFILM CORP

Lithographic printing plate precursor, method for manufacturing lithographic printing plate, and lithographic printing method

ActiveCN113382870AExcellent brush resistancePlate printingOther printing apparatusPolymer scienceImage recording

Provided is a lithographic printing plate precursor that has a support body and an image recording layer disposed on the support body. The image recording layer contains organic particles including an additive polymerization-type resin that has a structural unit A having a hydrogen bond-donating site. The content of the structural unit A in the additive polymerization-type resin is more than 20 mass% with respect to the total mass of the additive polymerization-type resin. Also provided is a method for manufacturing a lithographic printing plate that uses said lithographic printing plate precursor.

Owner:FUJIFILM CORP

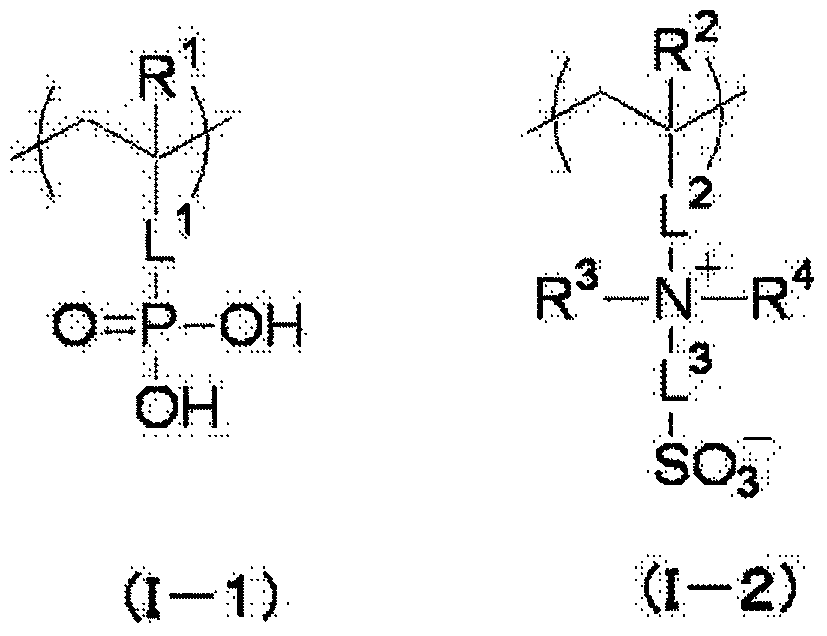

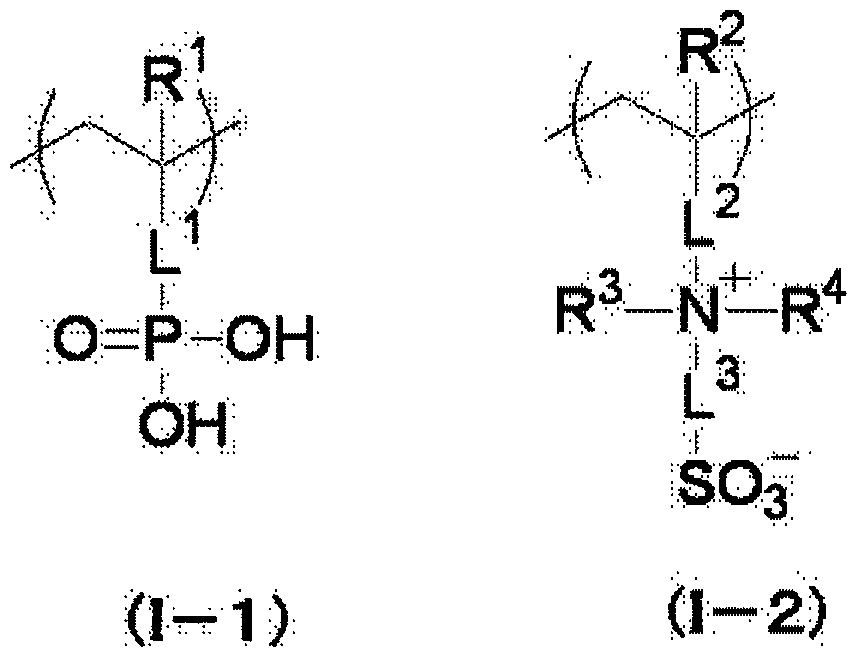

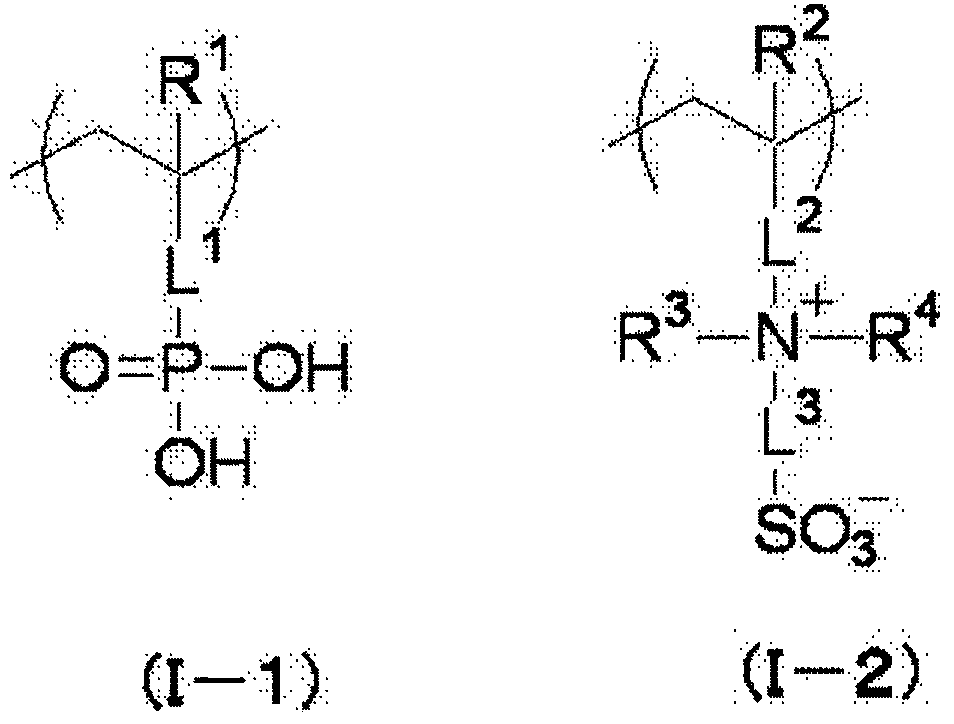

Process for producing lithographic printing plate and lithographic printing plate

InactiveCN103797419AExcellent brush resistancePhotosensitive material processingPhotosensitive materials for photomechanical apparatusInter layerPlanographic printing

A process for producing a lithographic printing plate which comprises a step of subjecting a positive presensitized plate for lithographic printing to image-wise exposure and a step of developing the thus exposed plate with a treatment fluid having a pH of 7 to 12, said positive presensitized plate being provided with both an intermediate layer that contains a polymer comprising repeating units represented by general formula (I-1) and repeating units represented by general formula (I-2) and that has a dry-base coating weight of 2 to 200 mg / m2 and a positive image forming layer on the substrate successively.

Owner:FUJIFILM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com