Process for producing lithographic printing plate and lithographic printing plate

A technology for lithographic printing plates and manufacturing methods, applied in lithographic printing equipment, printing, printing technology, etc., can solve the problems of tolerance (insufficient development latitude, reduced printing resistance, reduced strength of image parts, etc., and achieve pollution suppression Occurrence, good pollution, and improved hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0299]

[0300] For the JIS A1050 aluminum plate with a thickness of 0.3mm, use pumice-water suspension as the abrasive to grind the surface with a rotating nylon brush. The surface roughness (center line average roughness) at this time was 0.5 μm. After washing with water, immerse in a solution heated to 70°C with 10% sodium hydroxide aqueous solution so that the amount of aluminum dissolved becomes 6g / m 3 etched in a manner. After washing with water, it was immersed in a 30% nitric acid aqueous solution for 1 minute to neutralize, and it was fully washed with water.

[0301] Then, in a 0.7% nitric acid aqueous solution, use a rectangular wave AC waveform voltage with a voltage of 13 volts at the anode and a voltage of 6 volts at the cathode for 20 seconds for electrolytic roughening, immerse in a 50°C solution of 20% sulfuric acid, and wash the surface , wash with water. In a 20% sulfuric acid aqueous solution, the roughened aluminum plate was subjected to a porous anod...

Embodiment 2~7、 comparative example 1~4

[0333] The specific polymer (P-1) used in the above-mentioned intermediate layer coating liquid 1 was replaced with the specific polymer (P-2), (P-3), (P-4), (P-5) exemplified above, respectively. ), (P-6) and (P-7), except that, in the same manner as in Example 1, an intermediate layer and an image forming layer were formed to obtain lithographic printing plate precursors in Examples 2 to 7.

[0334]In addition, the specific polymer (P-1) used in the above-mentioned intermediate layer coating liquid 1 was replaced with the comparative polymers (PN-1), (PN-2), (PN-3) and ( PN-4), except that, it carried out similarly to Example 1, formed the intermediate layer and the image formation layer, and obtained the lithographic printing plate precursor of Comparative Example 1-Comparative Example 4.

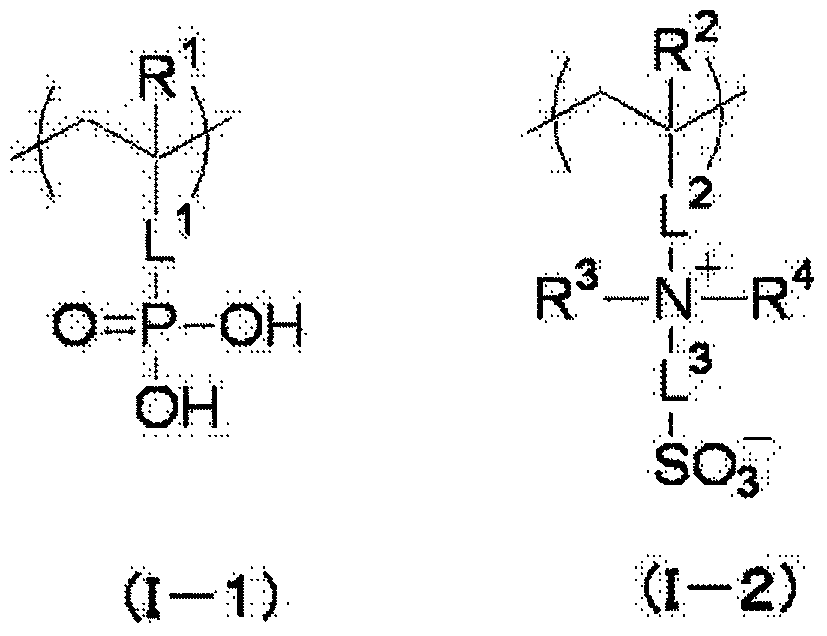

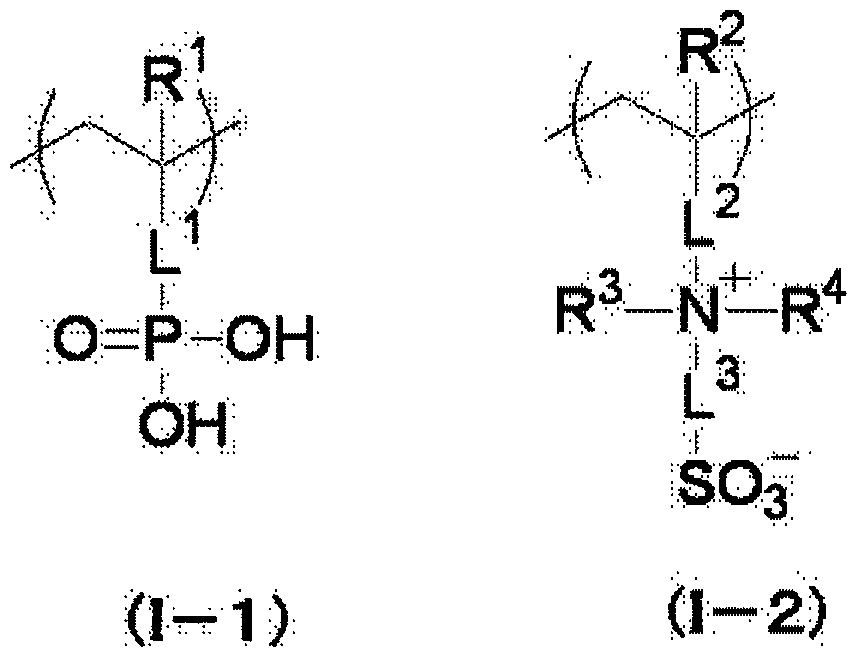

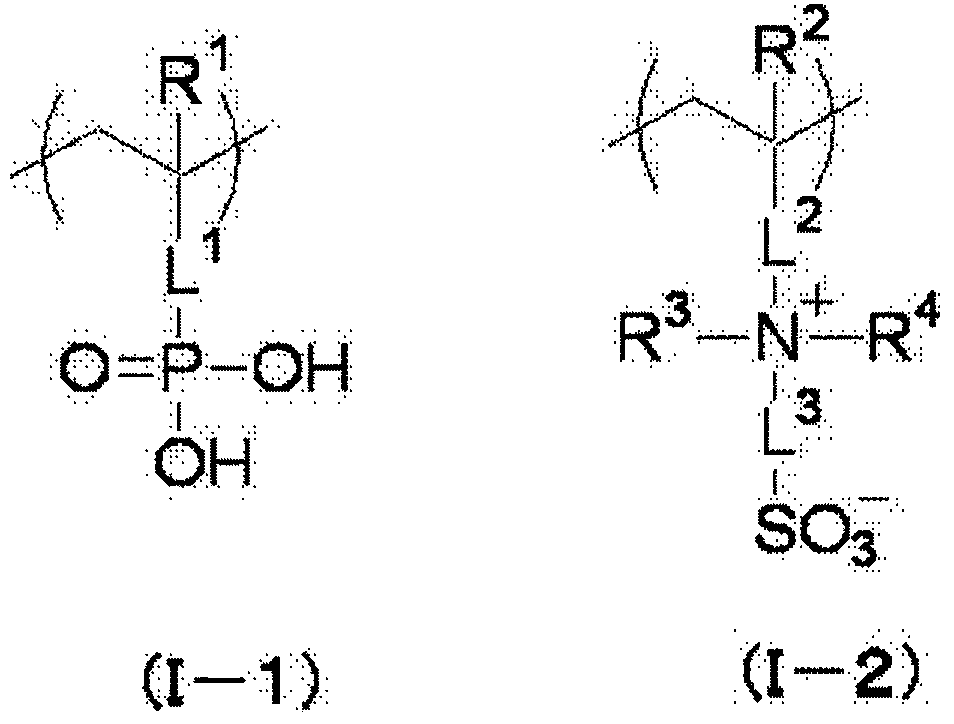

[0335] [chemical formula 25]

[0336]

[0337] (Plate making and evaluation of lithographic printing plate masters)

[0338] Using the obtained lithographic printing plate precursor...

Embodiment 8

[0369] (Example 8 to Example 9, Reference Example 10)

[0370] The lithographic printing plate precursor according to the present invention obtained in Example 2 above was used, and the treatment solutions (D-2), (D-3) and (D-4) were used instead of the treatment solution (D-1), except that Except that, it carried out similarly to Example 2, the lithographic printing plate was produced, and it evaluated similarly. The results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com