Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54results about How to "Enable predictive maintenance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

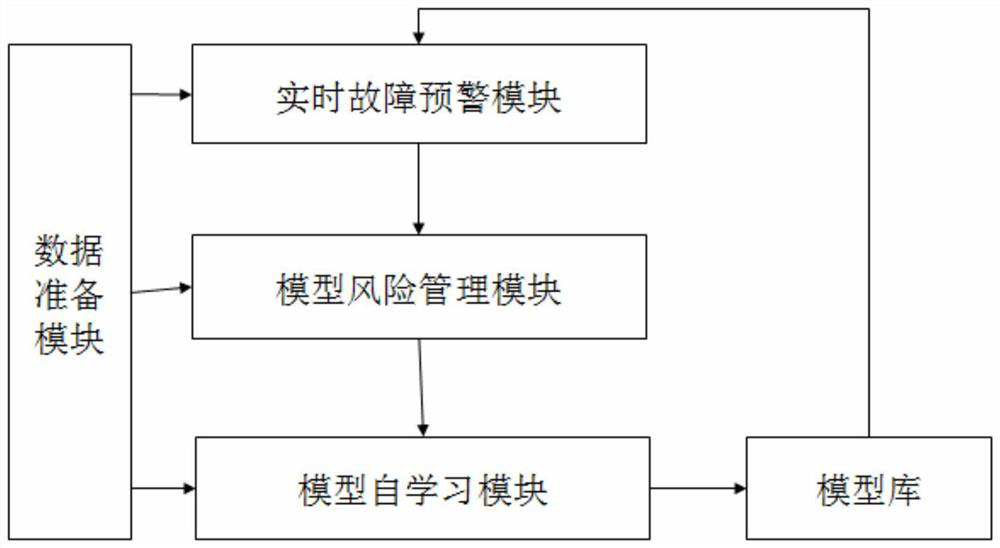

Equipment failure early-warning system based on model lifecycle management

ActiveCN109947088APre-warning results are consistently accurateEnable predictive maintenanceElectric testing/monitoringResourcesEarly warning systemReal-time data

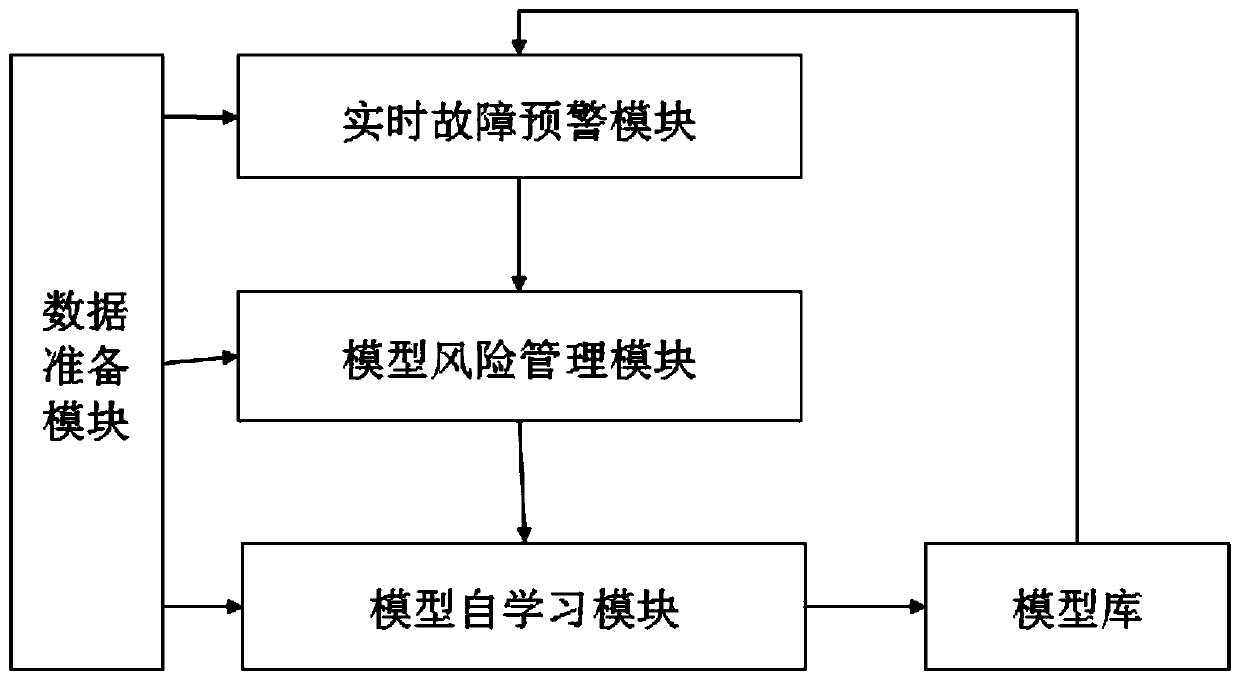

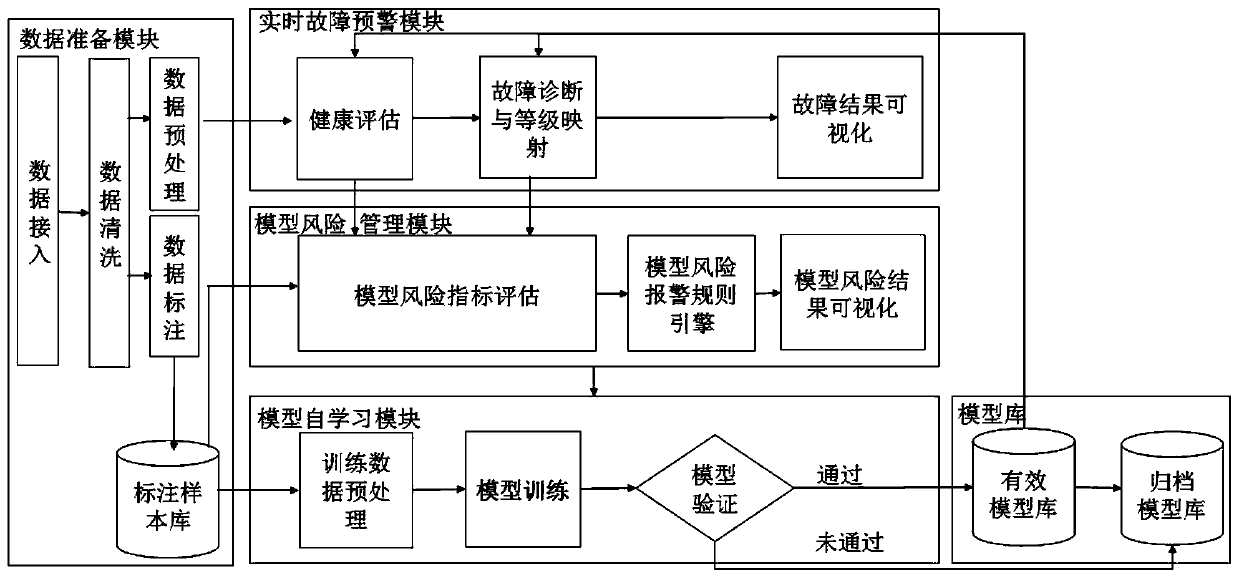

The invention relates to an equipment failure early-warning system based on model lifecycle management. The system comprises a data preparation module, a real-time failure early-warning module, a model risk management module, a model self-learning module and a model base, wherein the data preparation module reads in and preprocesses external real-time data and transmits the processed external real-time data to the real-time failure early-warning module and the model risk management module for analysis; the real-time failure early-warning module predicts failure risks and generates early-warning information and maintenance suggests; the model risk management module evaluates reliability of model results; the model self-learning module reads in accumulated annotation samples and retrains models in the real-time failure early-warning module. The system can realize failure early-warning of equipment, online monitoring of model lifecycle and dynamic update of models, and the continuity reliability of model results is guaranteed; besides, running data and operation data are introduced simultaneously, so that early-warning errors are smaller.

Owner:CYBERINSIGHT TECH CO LTD

Predictive industrial equipment maintenance method and maintenance system based on edge computing

InactiveCN109635958AEnable predictive maintenanceAvoid Ineffective Manual WorkForecastingAnomaly detectionEdge computing

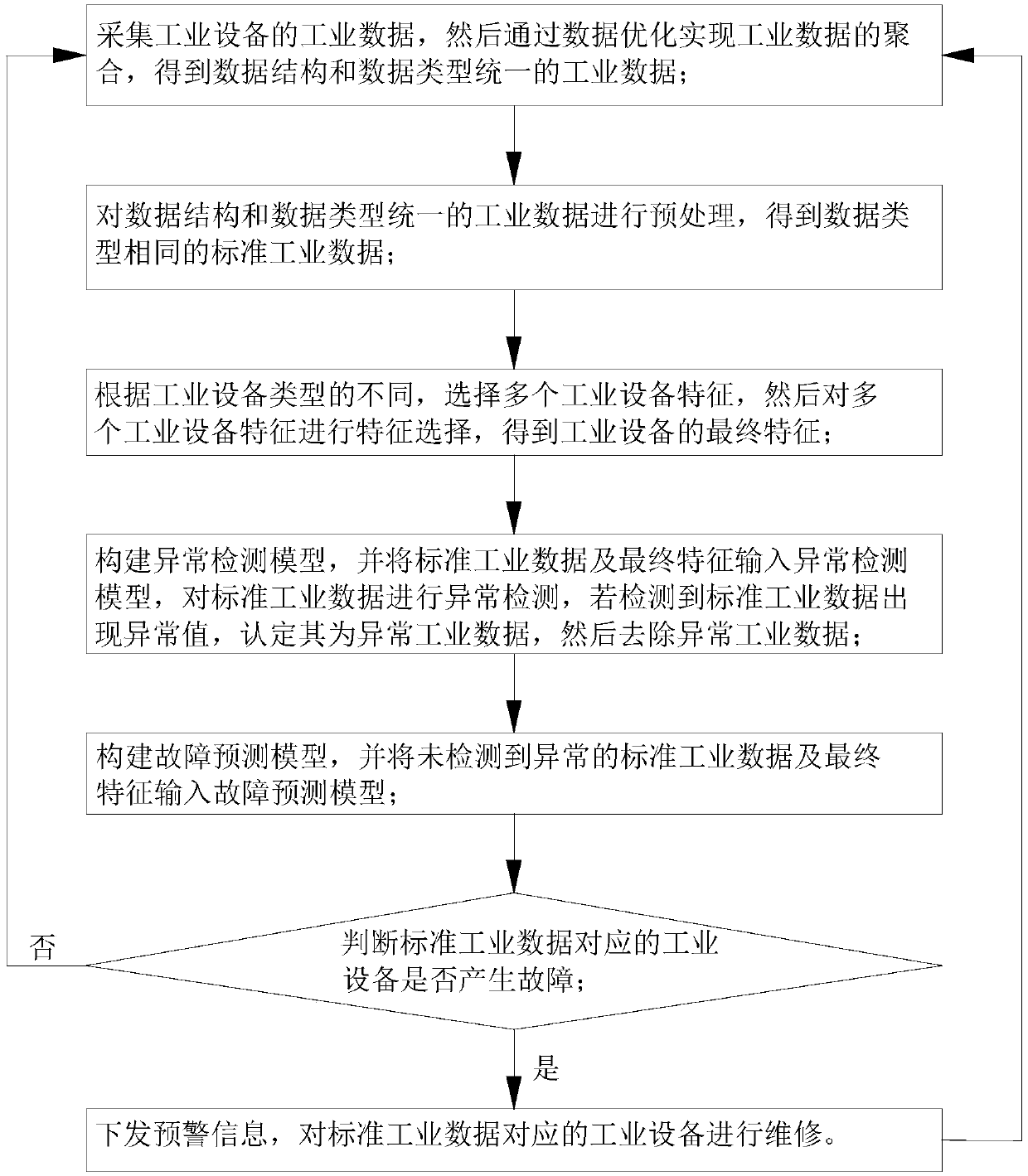

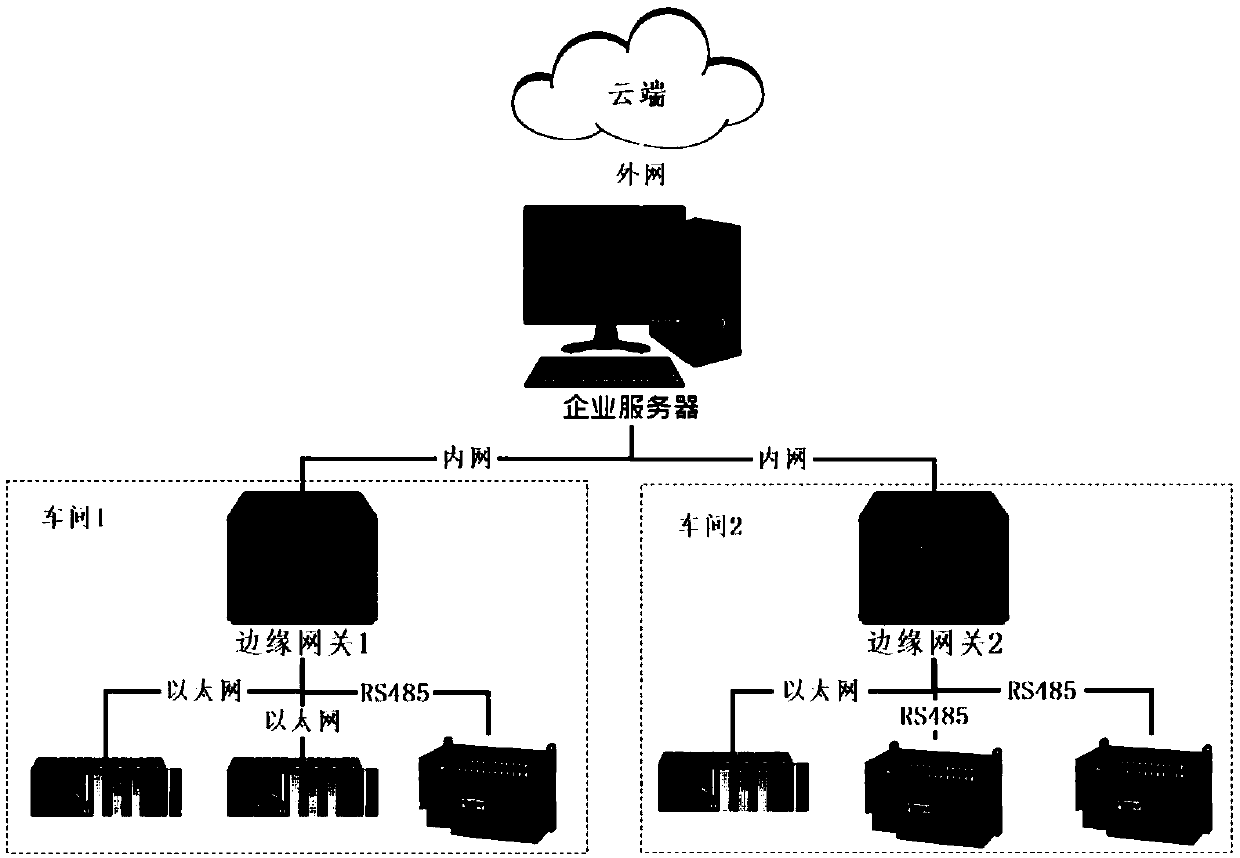

The invention relates to the technical field of industrial information collection and analysis, and aims to provide a predictive industrial equipment maintenance method and maintenance system based onedge computing. The invention discloses a predictive industrial equipment maintenance method based on edge calculation. The method comprises the following steps: S1, collecting industrial data; S2, preprocessing the industrial data to obtain standard industrial data; S3, performing feature selection to obtain a final feature; S4, constructing an abnormity detection model, inputting the standard industrial data and the final features into the abnormity detection model, and carrying out abnormity detection on the standard industrial data; and S5, constructing a fault prediction model, judging whether the industrial equipment corresponding to the standard industrial data has a fault or not, if yes, issuing early warning information, and if not, entering the step S1. A maintenance system comprises industrial equipment, an edge gateway and a server which are sequentially connected. Predictive maintenance of industrial equipment can be achieved, invalid manual operation is avoided, and automatic operation is facilitated.

Owner:成都航天科工大数据研究院有限公司

Method for degradation modeling and life prediction of lithium battery with self-healing effect

InactiveCN106353691AEnable predictive maintenanceImprove securityElectrical testingSelf-healingSimulation

The invention discloses a method for degradation modeling and life prediction of a lithium battery with a self-healing effect. The method comprises the following steps: 1) mathematically describing self-healing phenomenon and degradation influence on the lithium battery; 2) considering the degradation modeling for the automobile lithium battery with a self-healing feature; 3) estimating the parameters of a degradation model; 4) updating the degradation model and predicting the remained life. According to the method provided by the invention, the performance degradation rule of the automobile lithium battery is modeled and the remained life is predicted, so that the predictable maintenance of the lithium battery can be realized and the safety of an electric automobile can be promoted.

Owner:CAPITAL NORMAL UNIVERSITY

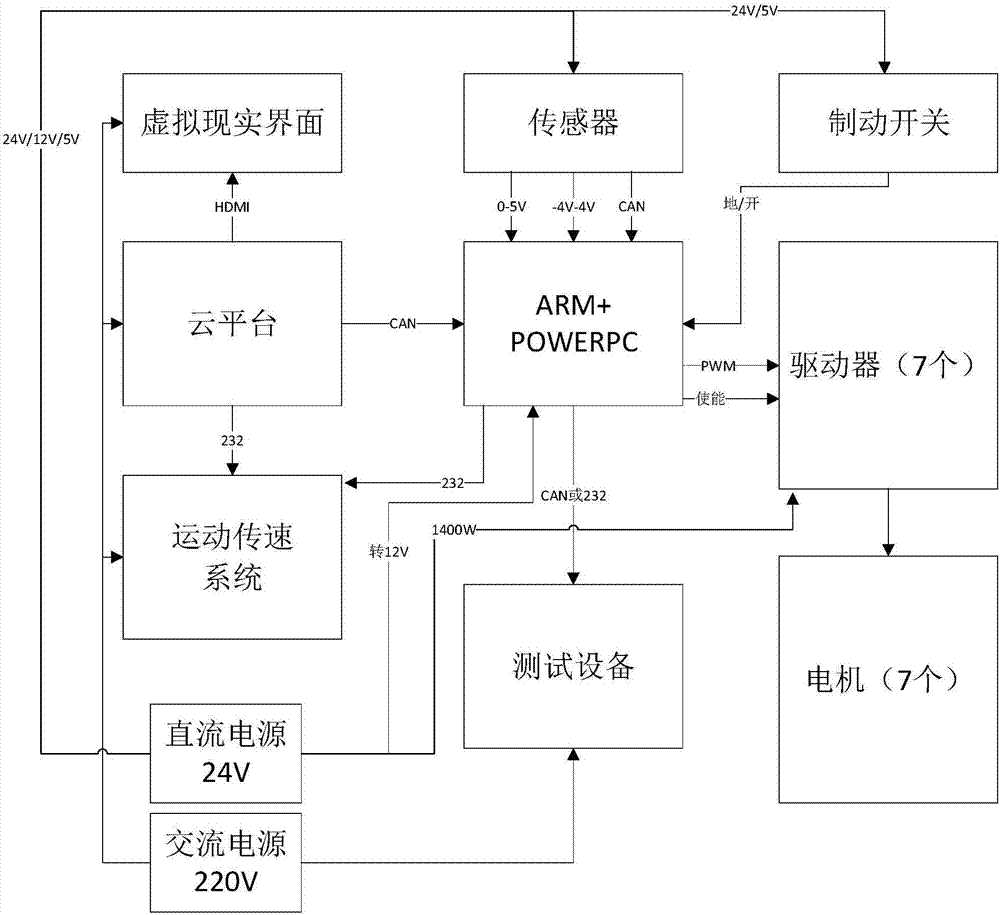

Intelligent medical robot for lower limb rehabilitation therapy

PendingCN107374911AHigh control precisionAchieving Adaptive ControlDiagnosticsChiropractic devicesHuman bodyExoskeleton robot

The invention provides an intelligent medical robot for lower limb rehabilitation therapy. A movement suspension system is mounted above a movement transmission system through a stand column; weight reduction and position holding of a patient subjected to lower limb rehabilitation therapy are implemented by the suspension system; the patient uprightly walks on the movement transmission system under the driving effect of a lower limb exoskeleton robot system; the lower limb exoskeleton robot system is connected with a rotating system by a gravity center self-balancing system; the height of the lower limb exoskeleton robot system is adjusted according to change of center of gravity of the patient during walking of the patient; and a sensor system acquires equipment parameters and human body parameters, and transmits the equipment parameters and the human body parameters to an embedded control system to be displayed. The intelligent medical robot for lower limb rehabilitation therapy is high in control precision and high in intelligence, and can be used for rehabilitation training of upright walking of the patient.

Owner:中航创世机器人(西安)有限公司

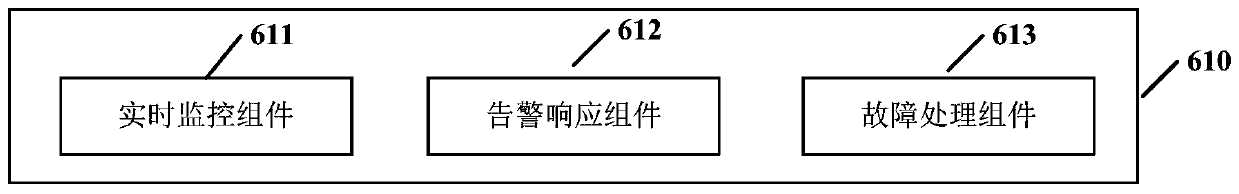

Method and system of predictive maintenance of a textile machine

InactiveCN109844193AEnable predictive maintenanceActivate online support serviceTesting/monitoring control systemsAlarmsProcess engineeringPredictive maintenance

Owner:MASCHINENFABRIK RIETER AG

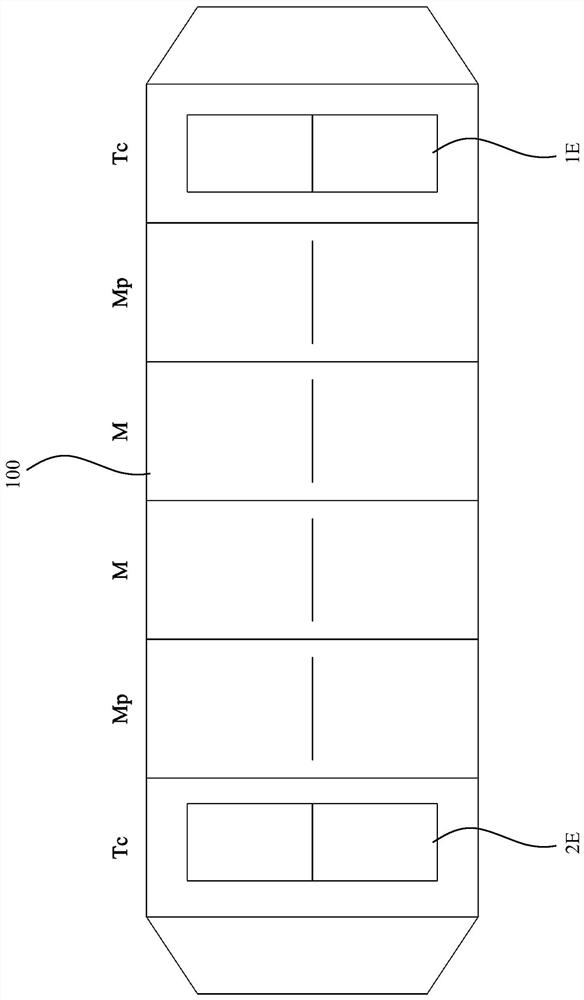

Train storage battery pack fault early warning system and method

ActiveCN111830415ARealize fault warningRealize real-time fault warning functionCircuit monitoring/indicationDifferent batteries chargingEarly warning systemNetwork data

The invention discloses a train storage battery pack fault early warning system and method. The system comprises a storage battery pack, a charger, a train control and management system, a data processing unit and a fault early warning unit. The charger uploads the real-time state data of the storage battery pack to the train control and management system. The train control and management system sends the real-time network data to the data processing unit. The data processing unit analyzes the received real-time network data and extracts real-time state data of the storage battery pack from the real-time network data. The fault early warning unit analyzes the extracted real-time state data of the storage battery pack to obtain the state of the storage battery pack and outputs fault early warning prompt information. The technical problems that an existing train storage battery pack fault early warning method is insufficient in coverage, early fault symptoms are difficult to find, and early fault early warning cannot be achieved can be solved.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

Equipment predictive maintenance method and device

PendingCN111563606AAvoid wastingEnable predictive maintenanceForecastingSpecial data processing applicationsEnergy technologyDowntime

The invention relates to the technical field of energy, and provides an equipment predictive maintenance method and device, and the method comprises the steps: obtaining a knowledge graph according tothe effective information of target equipment needing predictive maintenance, wherein the effective information at least comprise historical data, expert experience and an operation record; processing the knowledge graph to obtain a fault tree corresponding to the knowledge graph; processing the fault tree by adopting a Monte Carlo model to obtain a function relationship between the fault of thetarget equipment and the fault reason; and performing preset simulation operation on the function relationship to obtain the fault probability of the target equipment. According to the method, the knowledge graph is acquired by taking the effective information of the equipment as basic data, modeling is performed on the basis of the knowledge graph, and the simulated fault probability is obtainedin cooperation with large-scale simulation prediction; predictive maintenance of the equipment is realized, the downtime is reduced, the production loss caused by equipment faults is effectively avoided, and the method is accurate in prediction and simple and reliable in operation processing.

Owner:ENNEW DIGITAL TECH CO LTD

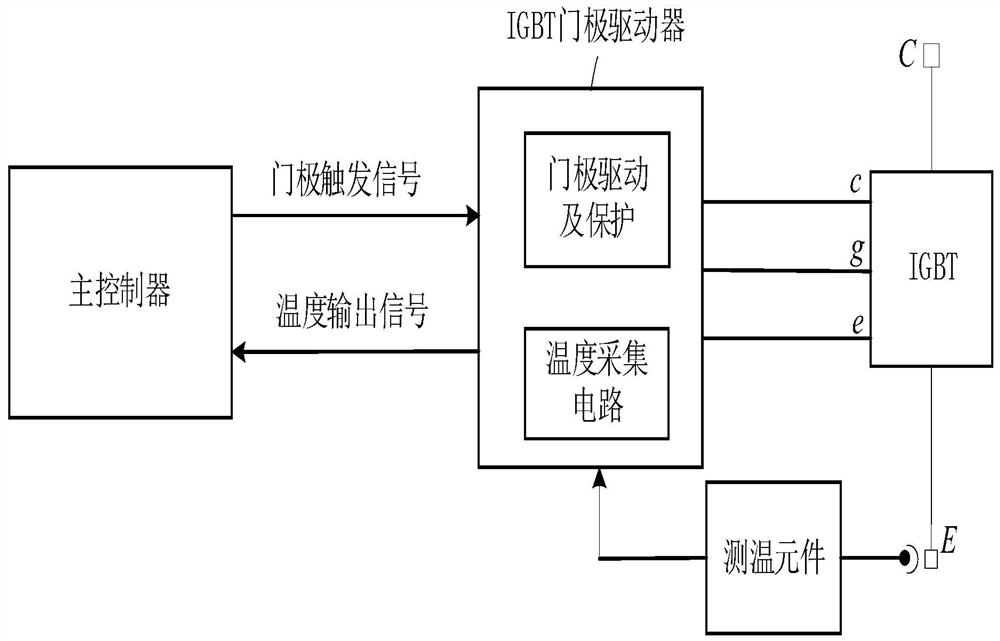

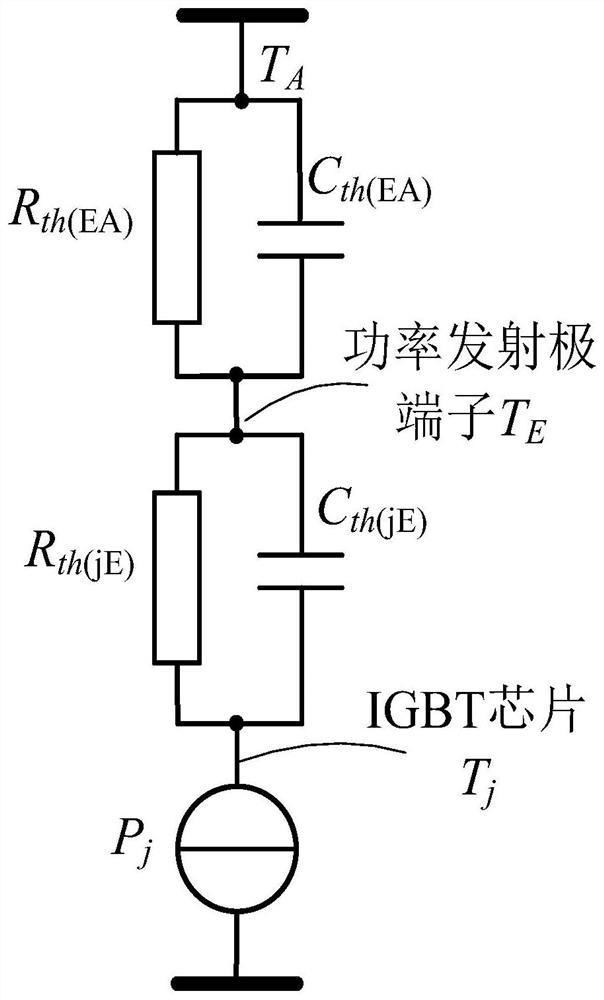

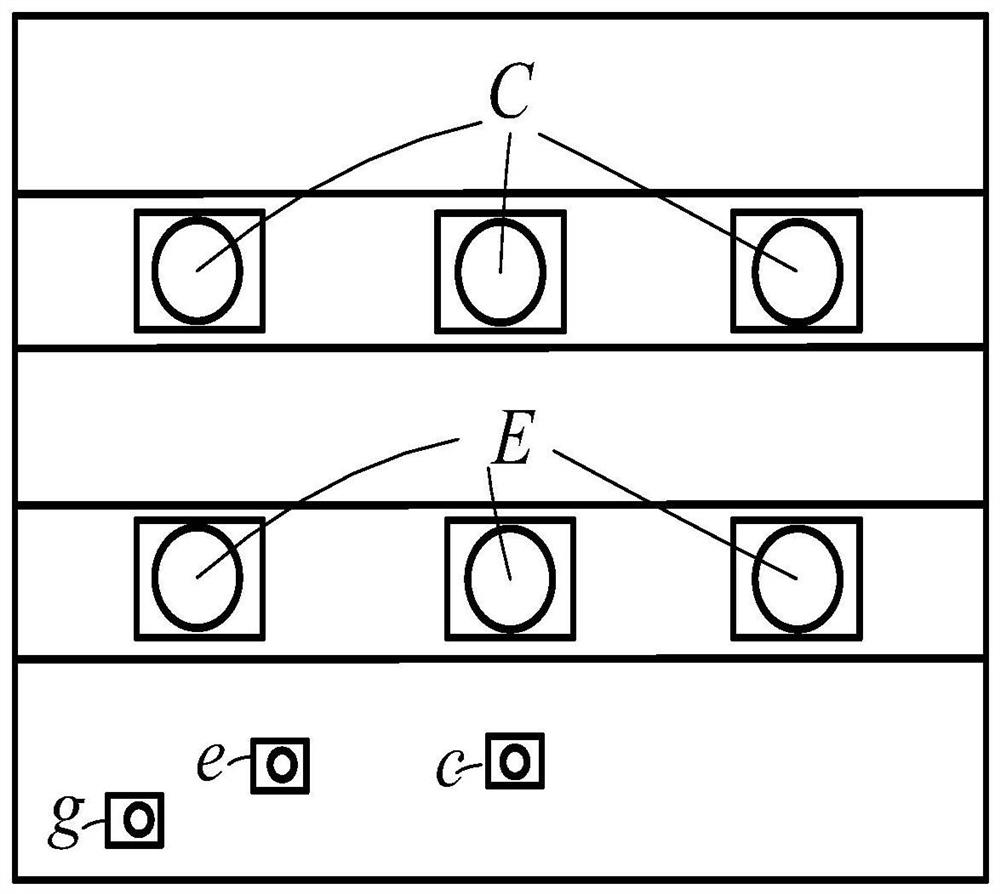

IGBT junction temperature estimation system and method based on temperature of emitter power terminal

PendingCN111830389AMonitor aging issuesImplement over temperature protectionEmergency protective circuit arrangementsIndividual semiconductor device testingPhysicsSignal on

The invention provides an IGBT junction temperature estimation system and method based on the temperature of an emitter power terminal. The system comprises a temperature measurement element, a temperature collection circuit, an IGBT gate driver, and a main controller, wherein the temperature measurement element is used for measuring the temperature of an IGBT power emitter terminal, the IGBT gatedriver comprises a gate drive and protection circuit and a temperature acquisition circuit, the gate drive and protection circuit is mainly used for on-off control and short circuit protection of a power device IGBT, the temperature acquisition circuit is used for acquiring a temperature signal, outputted by the temperature measurement element, on the IGBT power emitter terminal, and the main controller is used for sending a gate trigger signal to the IGBT gate driver, receiving a temperature signal on the IGBT power emitter terminal transmitted by the IGBT gate driver, and estimating the IGBT junction temperature according to the temperature signal on the IGBT power emitter terminal. According to the system, the over-temperature protection of the IGBT is realized, and IGBT temperature estimation is realized on the controller side.

Owner:CHAJNA MAJNING DRAJVS EHND AUTOMEHJSHN KO

Oil well pump inspection period prediction method and device and storage medium

InactiveCN110276493AImprove pump efficiencyIncrease profitForecastingResourcesRegression analysisOil well

The embodiment of the invention aims to provide an oil well pump inspection period prediction method and device and a storage medium, and the method comprises the steps: obtaining a sample data set influencing an oil well pump inspection period, the sample data set comprising a plurality of index data influencing the oil well pump inspection period; determining a plurality of principal component data influencing the oil well pump inspection period from a plurality of index data of the sample data set through principal component analysis; performing regression analysis on the plurality of principal component data to obtain a regression analysis result; and predicting the pump inspection period of the oil well according to a regression analysis result.

Owner:北京月新时代科技股份有限公司

Integrated automatic control hydraulic servomotor

InactiveCN105937509ACompact structureReduce volumeAccumulator installationsFluid-pressure actuator componentsAutomatic controlElectro hydraulic

An integrated automatic control hydraulic servomotor comprises an oil tank, an oil supply pipeline and an oil return pipeline, the oil supply pipeline passing a supply oil filter and the oil return pipeline passing a return oil filter are connected with the oil tank. The oil supply pipeline is connected with an energy accumulator and a hydraulic oil cylinder through an oil pump. The oil pump is connected with a motor used for driving the oil pump to act. A temperature sensor used for collecting the oil temperature and a heating control device used for temperature rising of oil liquid are arranged on the oil tank. A cylinder block of the hydraulic oil cylinder is connected with a pressure sensor used for collecting pressure in the hydraulic oil cylinder. A position sensor is connected to an output shaft of the hydraulic oil cylinder. The temperature sensor, the pressure sensor and the position sensor are all connected with a center controller. The signal output end of the center controller is connected with a motor driver and an electro-hydraulic change-over valve. The motor driver is connected with the motor in a control manner. The electro-hydraulic change-over valve is connected with the hydraulic oil cylinder in a control manner. By the adoption of the integrated automatic control hydraulic servomotor, site construction and maintenance are convenient, integrated integral mounting is conducted according to the mounting position, the requirement on site construction and maintenance is lowered, the fault probability is reduced, and automatic control can be achieved.

Owner:XIAN QIANGYUAN ELECTRIC APP CO LTD

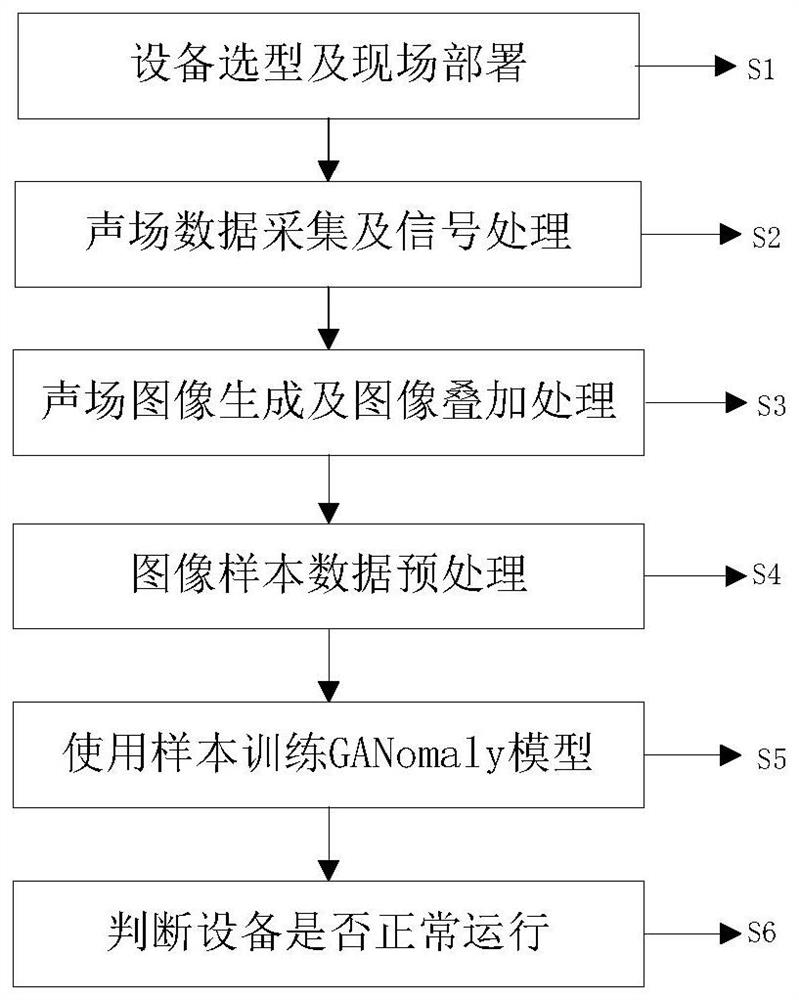

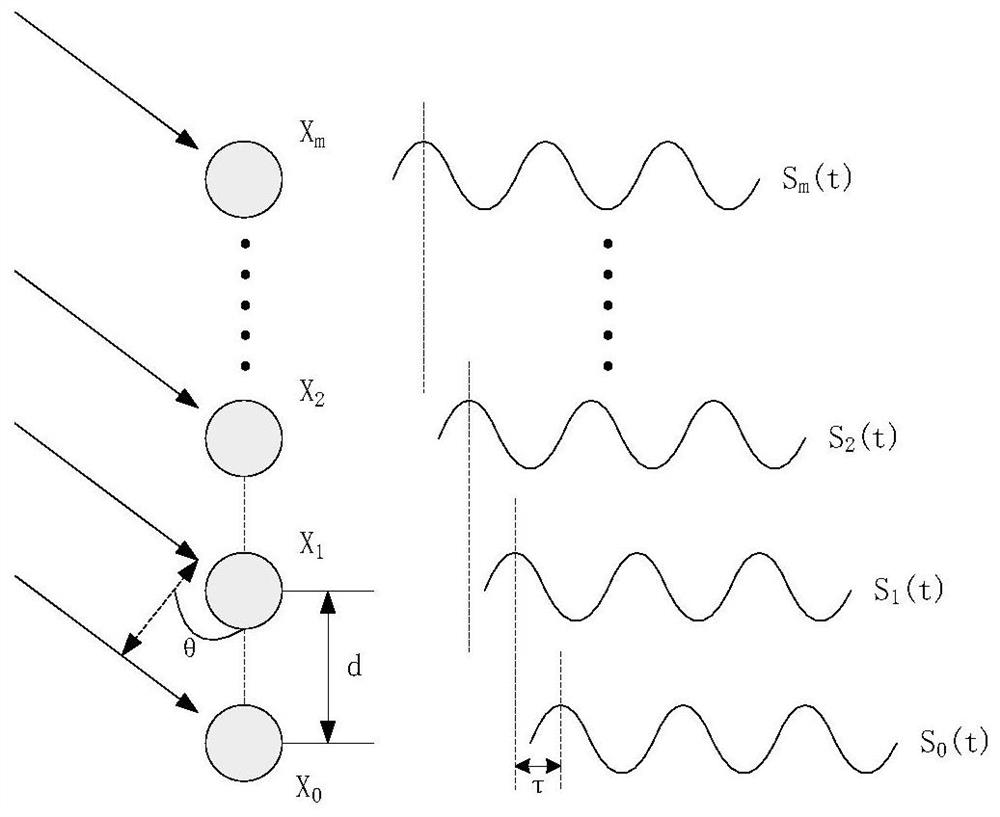

Method for intelligently monitoring abnormal operation state of equipment

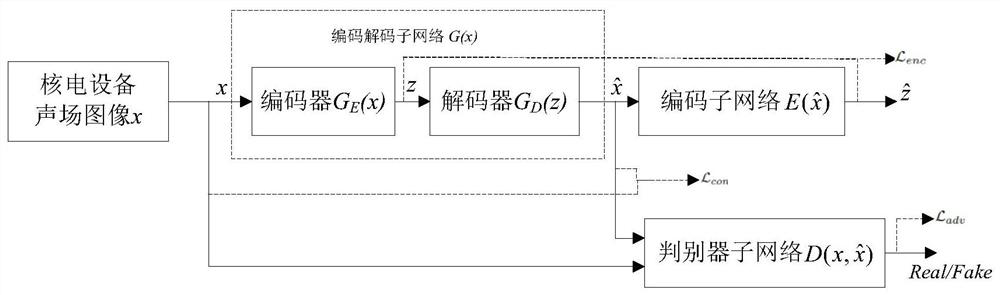

ActiveCN113313146ARealize full lifecycle managementMake up for deficienciesSpeech analysisCharacter and pattern recognitionSensing dataControl engineering

The invention aims to disclose a method for intelligently monitoring an abnormal operation state of equipment. Compared with the prior art, comprehensive perception of equipment is realized in a non-contact manner; equipment state information is obtained by monitoring sound generated during equipment operation, and the defects of traditional sensing data can be effectively overcome; and meanwhile, fault monitoring diagnosis and predictive maintenance of the equipment and full-life-cycle management of the industrial equipment are realized based on big data and deep learning, so that the aim of the invention is fulfilled.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

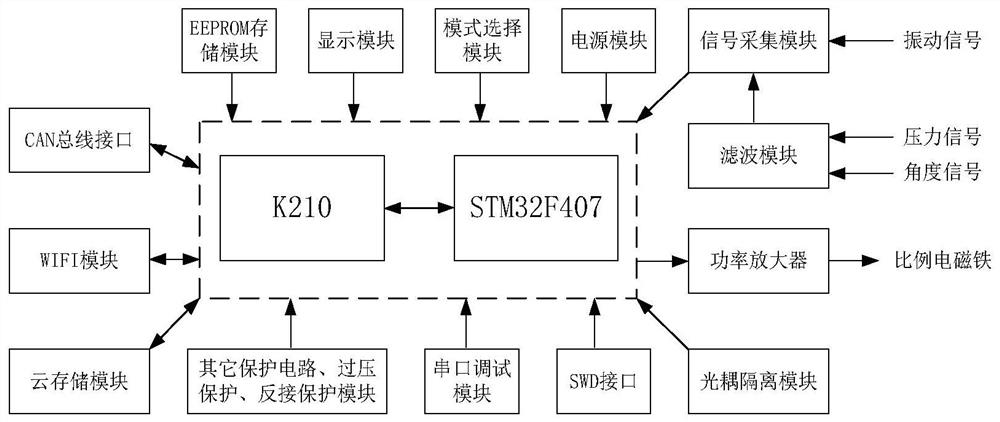

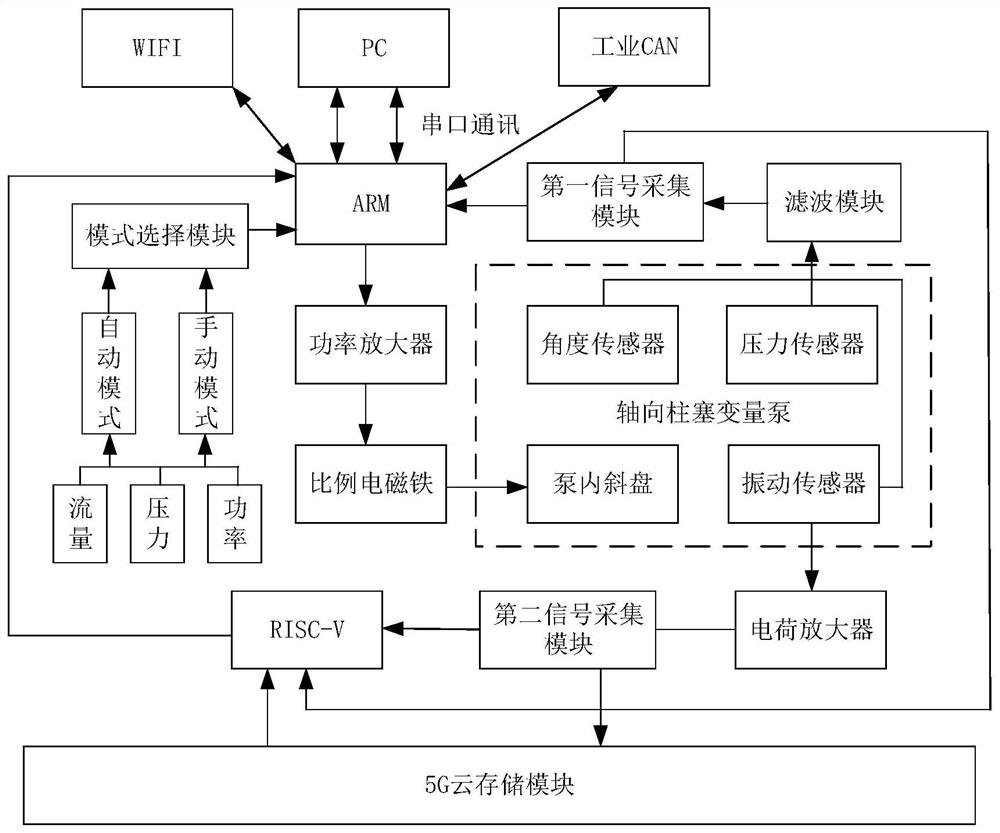

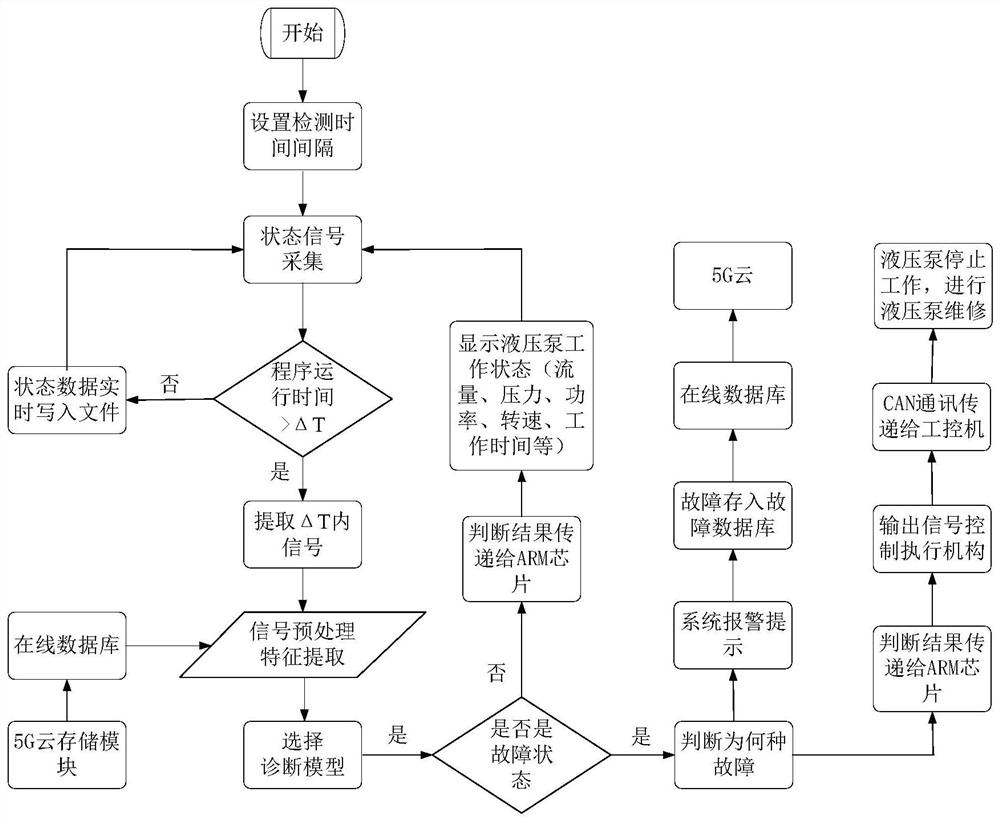

Intelligent programmable axial plunger pump controller and control method

ActiveCN113027741ARealize composite controlEnable predictive maintenanceEnergy industryPump controlHydraulic pumpControl engineering

The invention provides an intelligent programmable axial plunger pump controller and a control method, and belongs to the field of intelligent hydraulic elements. The controller comprises a sensor group, a control panel, and an ARM chip, an RISC-V chip, a signal acquisition module, a filtering module, a charge amplifier, a power amplifier, a mode selection module, a display module and a cloud storage module which are installed on the control panel; and the control panel is further provided with a plurality of external interfaces. The magnitude of flow in a variable piston cavity of a hydraulic pump and the swing angle of a swash plate can be controlled by the ARM chip; automatic compound control over the pressure, flow and power of the axial plunger pump is achieved; meanwhile, the pressure, flow and power of the axial plunger pump can be controlled by detecting signals such as the outlet pressure of the hydraulic pump, the swing angle of the swash plate and vibration on a pump shell; the state of the hydraulic pump is monitored and recognized based on the RISC-V chip, common faults of the hydraulic pump are judged, and judgment results are transmitted to the ARM chip, thus implementing predictive maintenance of the hydraulic pump.

Owner:ZHEJIANG UNIV

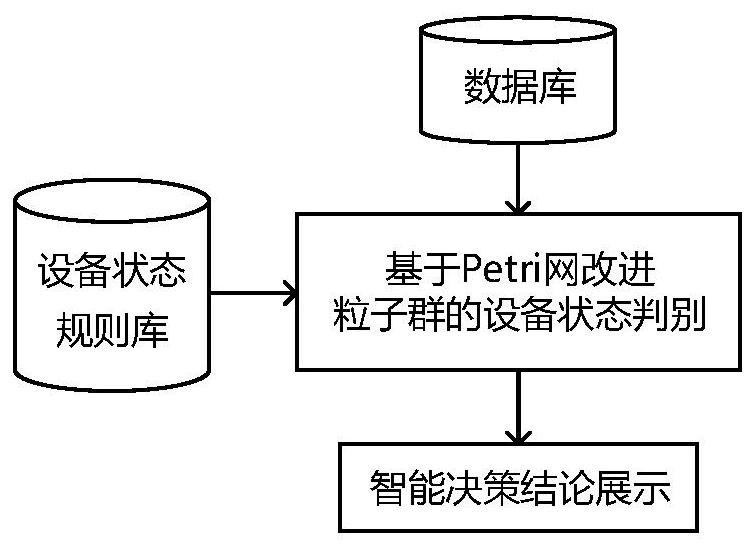

PHM system of fully mechanized coal mining equipment

ActiveCN111896244AEnable predictive maintenanceSignificant economical improvementMachine gearing/transmission testingDynamo-electric machine testingDecision modelPredictive maintenance

The invention provides a PHM system of fully mechanized coal mining equipment. A performance evaluation module is used for constructing a verification evaluation model; a simulation experiment moduleis used for building a simulation experiment verification platform; a PHM cloud sharing verification module is used for building a PHM cloud sharing verification platform; a model construction moduleis used for determining a multi-type accurate life prediction model and a maintenance decision model; and a result verification module is used for outputting a verification result. The beneficial effects of the system are that the system covers all contents of fault diagnosis through a fault prediction and health management (PHM) system, adds a fault prediction and maintenance decision technology,and improves the usability, start-up rate and production efficiency of the system through the prolonging of a maintenance period and the timely maintenance activity; through predictive maintenance and accurate maintenance, the fault shutdown time and the accessory inventory period, the maintenance cost is remarkably reduced, and the production efficiency is improved; and finally, the full-life-cycle cost of the product is reduced, the maintenance workload is reduced, and labor and efficiency are improved.

Owner:TIANDI CHANGZHOU AUTOMATION

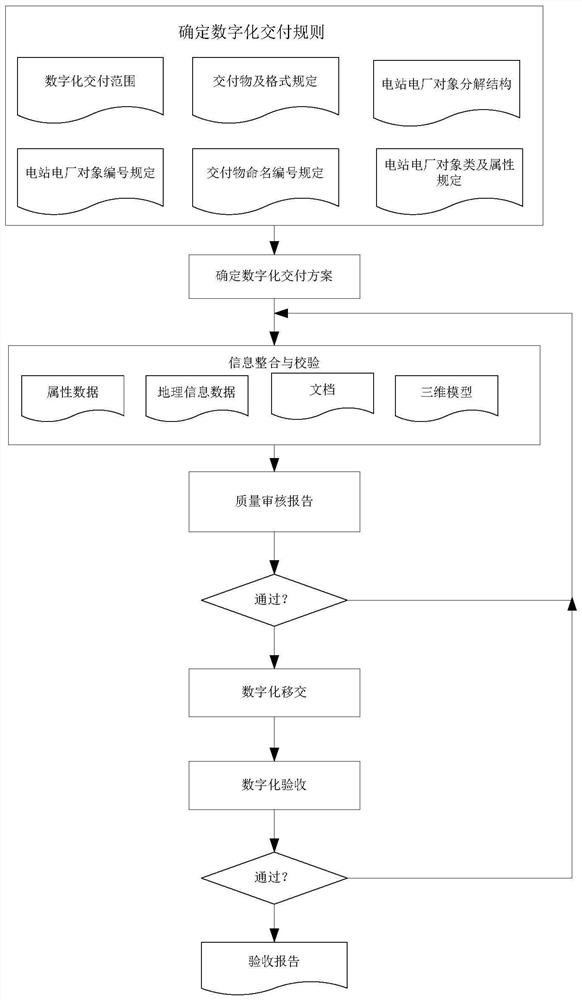

Digital power station delivery method based on BIM and GIS, medium and equipment

InactiveCN112685820AOvercoming inefficienciesOvercoming low accuracyGeometric CADData processing applicationsPower stationDigitization

The invention discloses a digital power station delivery method based on BIM and GIS, a medium and equipment. The method comprises the following steps: determining a digital delivery rule; determining a digital deliverable delivery requirement; determining a digital delivery scheme to establish a BIM, a GIS model or a BIMGIS model of a digital deliverable in the power station; digital delivery information association: determining that a digital deliverable in the power station needs to deliver associated information and associates the associated information to the deliverable; taking the BIM, the GIS model or the BIMGIS model of the deliverable associated with the completed information and the information associated with the deliverable as delivery objects for delivery; and after the delivery is completed, checking the detailed information of the deliverable through the local window. According to the method, paperless digital interaction can be achieved, the technical problems that traditional delivery is low in efficiency and accuracy are solved, a source is provided for digitization of a power station through three-dimensional design, source-to-end direct connection of information is achieved, and it is fundamentally ensured that the information is correct.

Owner:QINGYUAN PUMPED STORAGE POWER GENERATION CO LTD +1

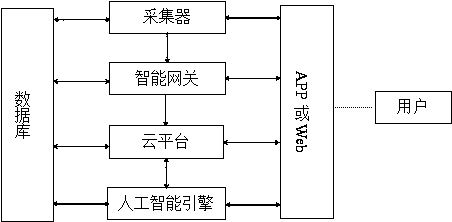

Predictive maintenance method and system for mechanical equipment

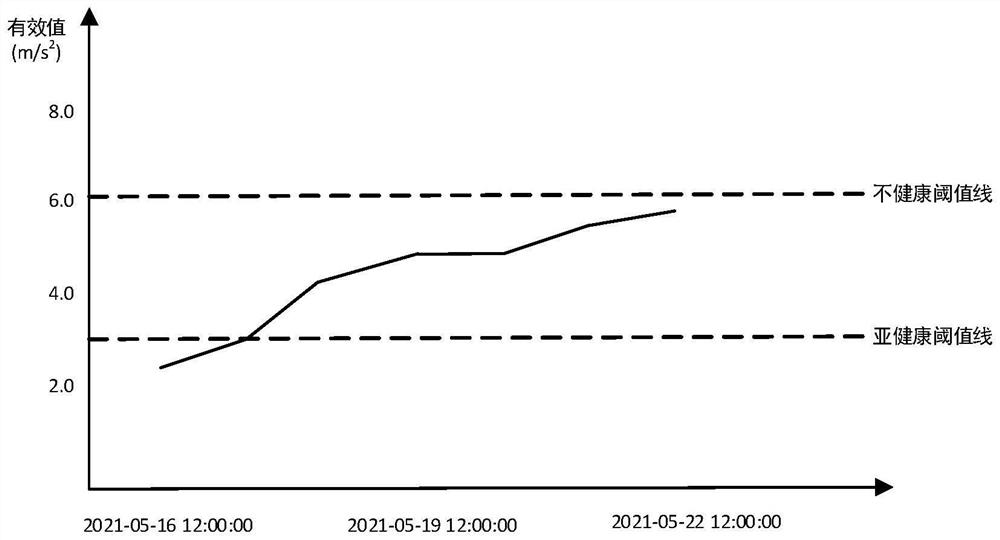

ActiveCN111401661AReal-time monitoring of running statusEnable predictive maintenanceForecastingAlarmsVibration accelerationEngineering

The invention discloses a predictive maintenance method and system for mechanical equipment, and belongs to the technical field of industrial information acquisition and analysis. The predictive maintenance method of the mechanical equipment comprises the steps that a collector acquires original vibration acceleration data and original temperature data of equipment to be tested; an intelligent gateway preprocesses the original vibration acceleration data to obtain vibration acceleration amplitude data with timestamps; a cloud platform processes and stores the vibration acceleration amplitude data and the corresponding relation between the original temperature data and the to-be-tested equipment; an artificial intelligence engine analyzes and processes the vibration acceleration amplitude data to obtain labeled fault features; the cloud platform sends the fault features with the labels and the original temperature data; an APP or Web displays the fault features; and the equipment to betested is maintained according to the fault characteristics with the labels or the original temperature data. Predictive maintenance of mechanical equipment is realized, invalid manual operation is avoided, and automatic operation is facilitated.

Owner:深圳市科通技术股份有限公司

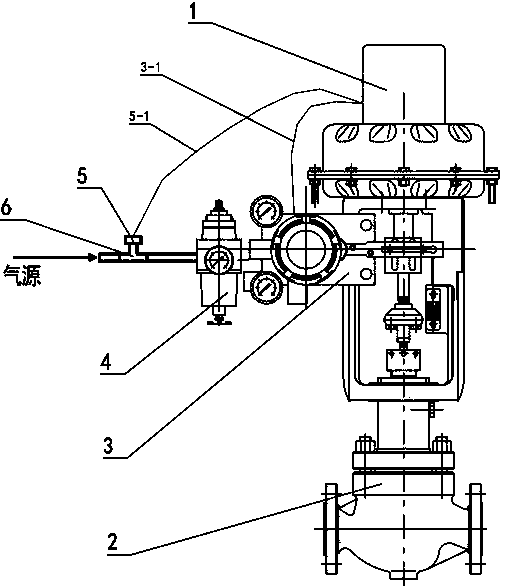

Regulating valve detection device

ActiveCN109737236ACan monitor actual operating conditionsEnable predictive maintenanceValve arrangementsMultiple sensorFault analysis

The invention discloses a regulating valve detection device. A regulating valve is connected with an execution mechanism. A positioner is mounted on a regulating valve. The outer end of a control lever of the execution mechanism is connected with a connecting rod. The axis of the connecting rod is provided with a through hole. The outer end of the connecting rod is connected with a membrane chamber pressure sensor and a dynamic thrust strain sensor through a straight joint. A displacement sensor is further mounted on the connecting rod. An air inlet pipe of the execution mechanism is connectedwith an air source pressure sensor. The positioner is internally provided with an input signal collector used for monitoring input signals of the positioner. The regulating valve detection device canmonitor the actual operation conditions of the regulating valve, control variation of technological parameters of a pipeline controlled through the regulating valve and realize predictive maintenanceon the regulating valve. The regulating valve detection device is provided with the multiple sensors, can be configured with various types of execution mechanisms and regulating valves and is extensive in application and capable of effectively realizing fault analysis, maintenance plan making and field maintenance service, and users can feel relieved to use.

Owner:徐州化工机械有限公司

Blockchain-based intelligent management method for power supply system

ActiveCN113344470AEliminate instances of false positivesImprove accuracyImage enhancementDatabase distribution/replicationImaging processingPredictive systems

The invention discloses a blockchain-based intelligent management method for a power supply system, and the method comprises the following steps: S1, monitoring the operation state of the power supply system in real time through a monitoring terminal, storing effective data in a blockchain system through an intelligent contract, and triggering the abnormal alarm of the power supply system according to the effective data; s2, establishing a convolutional network, and evaluating and predicting the aging condition of the power supply system according to the video image information collected by the monitoring terminal; and S3, creating a deep learning network, and evaluating and predicting the intact state of the power supply system according to the monitoring parameters of the monitoring terminal and the aging condition evaluation value of the power supply system. The block chain technology is adopted, so that the monitoring accuracy of the system is greatly improved; an image processing technology is adopted, so that the aging degree of the system can be monitored, and predictive maintenance is realized; and the overall intact state of the power supply system can be evaluated and predicted, and predictive system maintenance is further guided.

Owner:深圳市易图资讯股份有限公司

Remote control method and system for smart tea bag packaging machine

ActiveCN110794776ARealize remote alarm managementConvenient centralized monitoringTechnology managementProgramme total factory controlRemote monitoring and controlTime control

The invention discloses a remote control method and system for a smart tea bag packaging machine, and the system comprises the smart tea bag packaging machine, an industrial remote gateway, an IP cloud camera, an industrial computer, a mobile phone, and a cloud server, wherein remote control terminals such as the industrial computer and mobile phone establish a network connection with the industrial remote gateway at the production site through the cloud server; the PLC controller and IP cloud camera in the smart packaging machine are connected to the industrial gateway. The remote control system is good in real-time control effect and simple in operation of the remote human-machine interface, and can remotely and centrally monitor the field equipment at any time and place through the remote control terminal, which can not only meet the needs of equipment suppliers for remote debugging, but also facilitate the user of the equipment to monitor the operating status and data of the equipment anywhere, thereby achieving remote monitoring and predictive maintenance of the performance of on-site equipment, and further reducing management costs and improving economic efficiency.

Owner:CAMALUOYANGELECTROMECHANIC

Server fault prediction method and device, equipment and storage medium

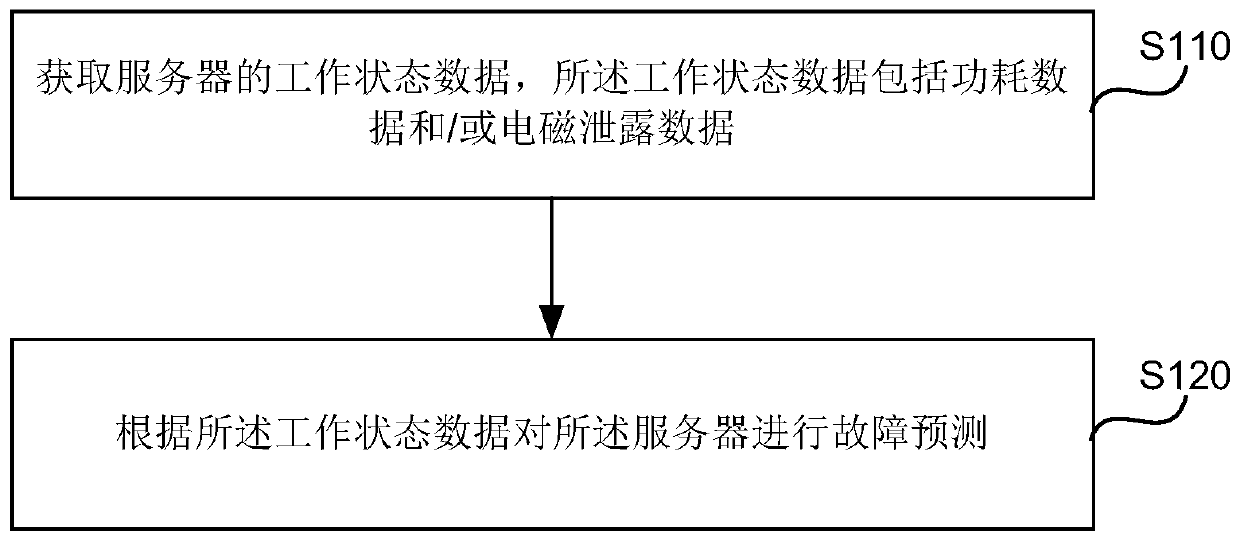

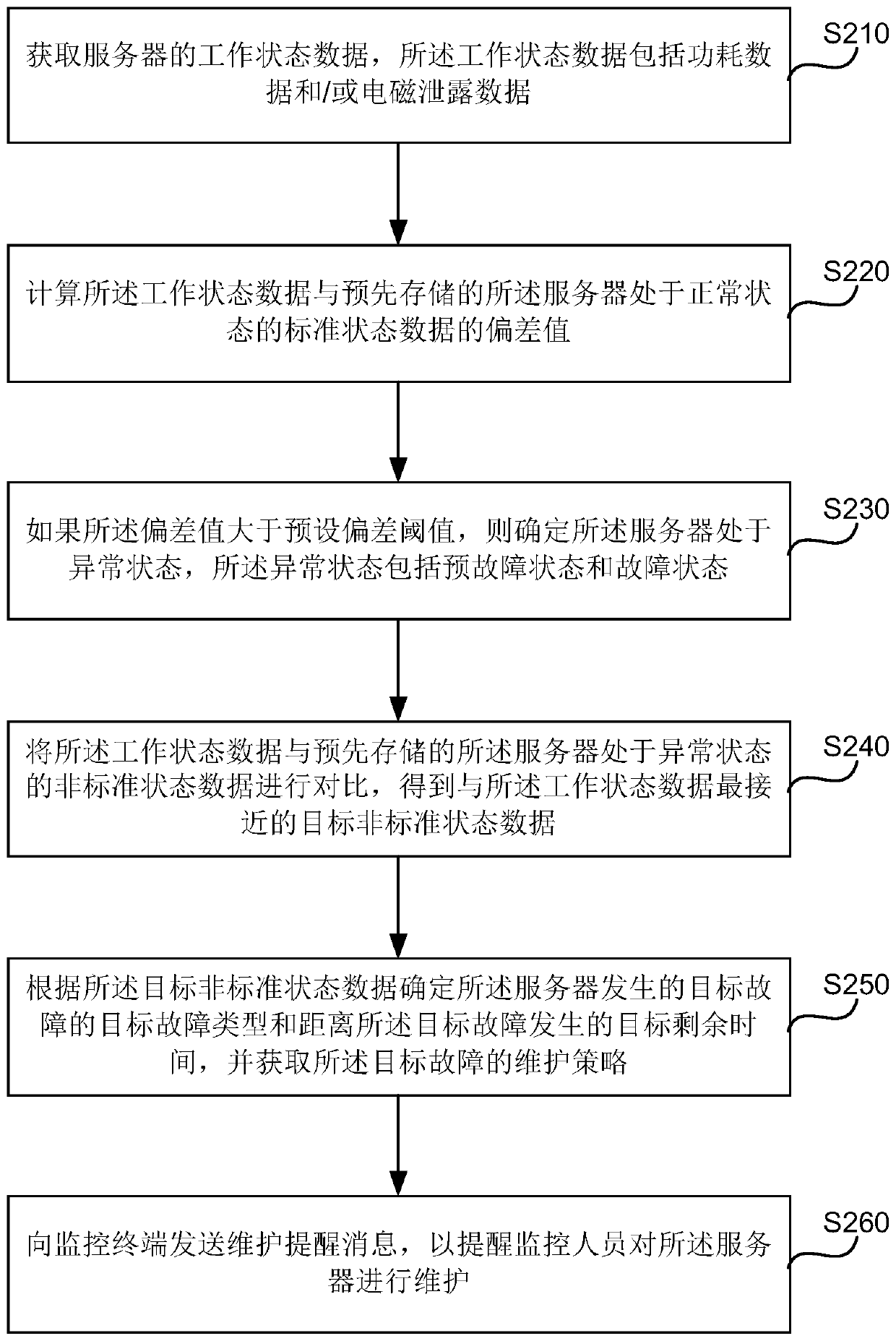

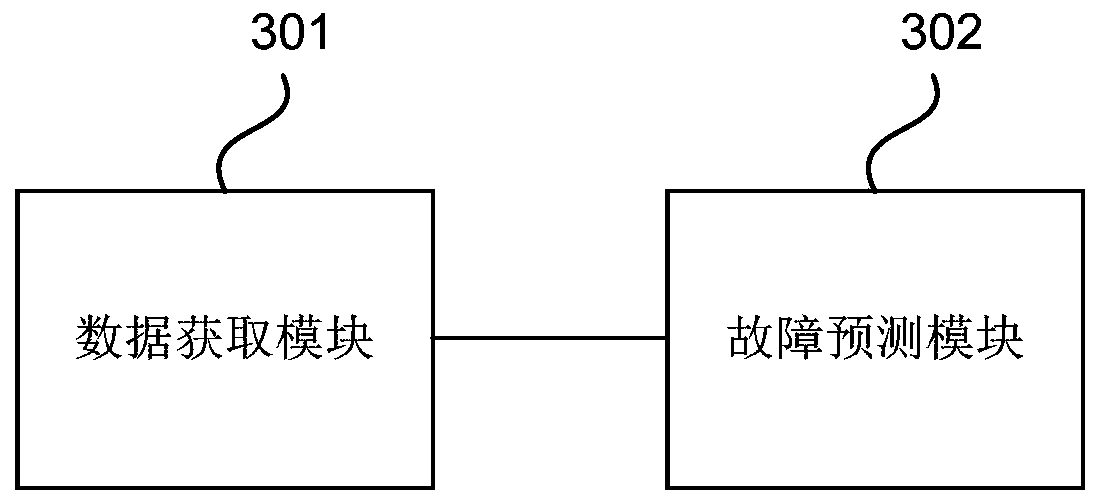

PendingCN111309562AEnable predictive maintenanceReduce the probability of downtimeHardware monitoringEnergy efficient computingEmbedded systemData security

The embodiment of the invention discloses a server fault prediction method and device, equipment and a storage medium. The method comprises the following steps: acquiring working state data of a server, wherein the working state data comprises power consumption data and / or electromagnetic leakage data; and performing fault prediction on the server according to the working state data. By the adoption of the technical scheme, predictive maintenance of the server can be achieved, and the downtime rate of the server and the maintenance cost of the server are effectively reduced; and the data security of the server can be effectively guaranteed, and heavy loss is avoided. Moreover, since the server is subjected to fault prediction through the fault maintenance equipment, hardware of the serverdoes not need to be modified, and a software program does not need to be additionally installed on the server, occupation of internal resources of the server by fault prediction can be avoided, and the running speed of the server is increased.

Owner:上海上大鼎正软件股份有限公司

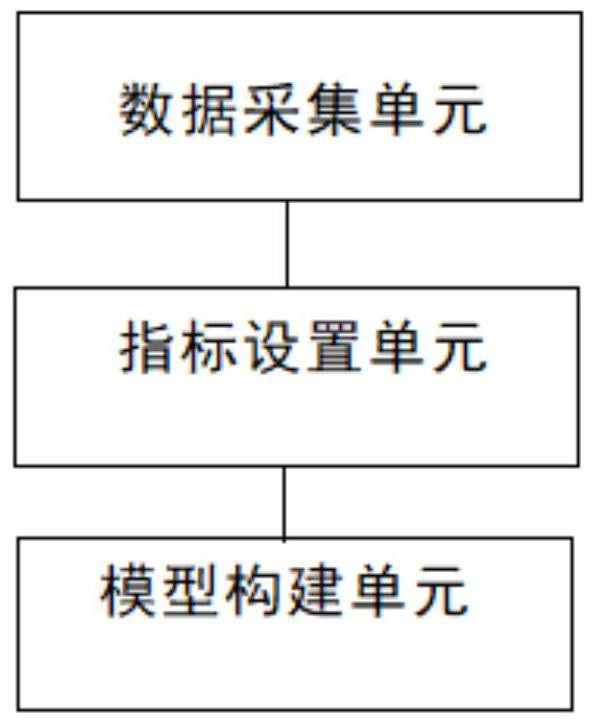

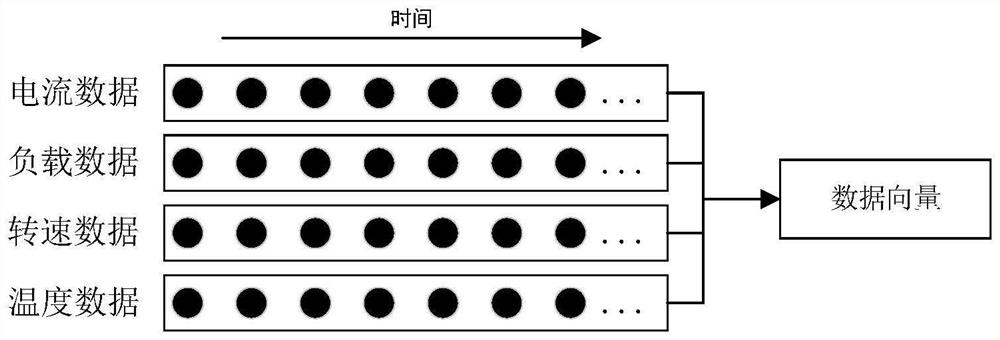

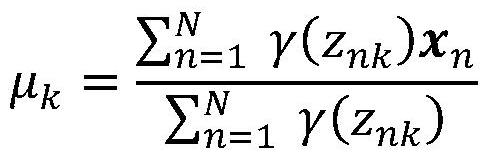

Health state evaluation method, system and equipment of numerical control machine tool and medium

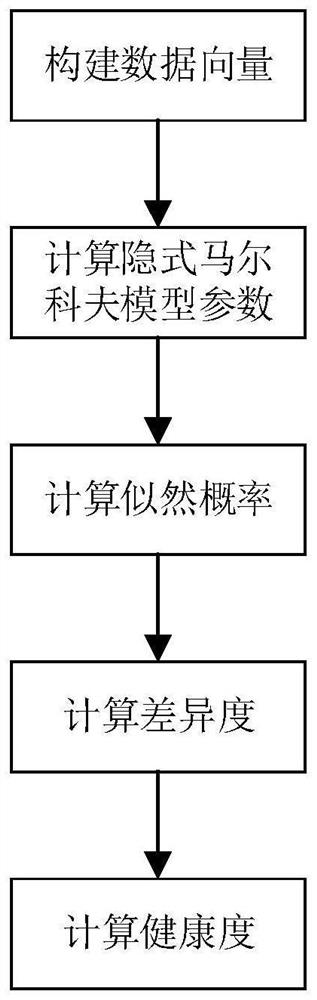

PendingCN114693143AEnable predictive maintenanceEnable accurate predictive maintenanceResourcesManufacturing computing systemsNumerical controlAnalytic model

The invention relates to a health state evaluation method, system and device for a numerical control machine tool and a medium, and the method comprises the steps: training model parameters of a health state analysis model based on each pre-obtained training sample data set, and calculating a corresponding likelihood probability, forming a preset model parameter set representing different preset working condition states of the machine tool by each group of trained model parameters, and forming a preset likelihood probability set by each likelihood probability; and based on the obtained preset model parameter set and the preset likelihood probability set, evaluating the health state of the current numerical control machine tool. According to the method, the historical monitoring data of the numerical control machine tool is utilized to construct the multi-dimensional data vector, the health state of the numerical control machine tool is evaluated by calculating the health degree, the number of machine tool sensors does not need to be increased, the model has wider practicability, the calculation complexity is reduced, and accurate, rapid and real-time health degree evaluation is achieved; the method can be widely applied to the numerical control machine tool health state monitoring field.

Owner:BEIJING UNIV OF TECH

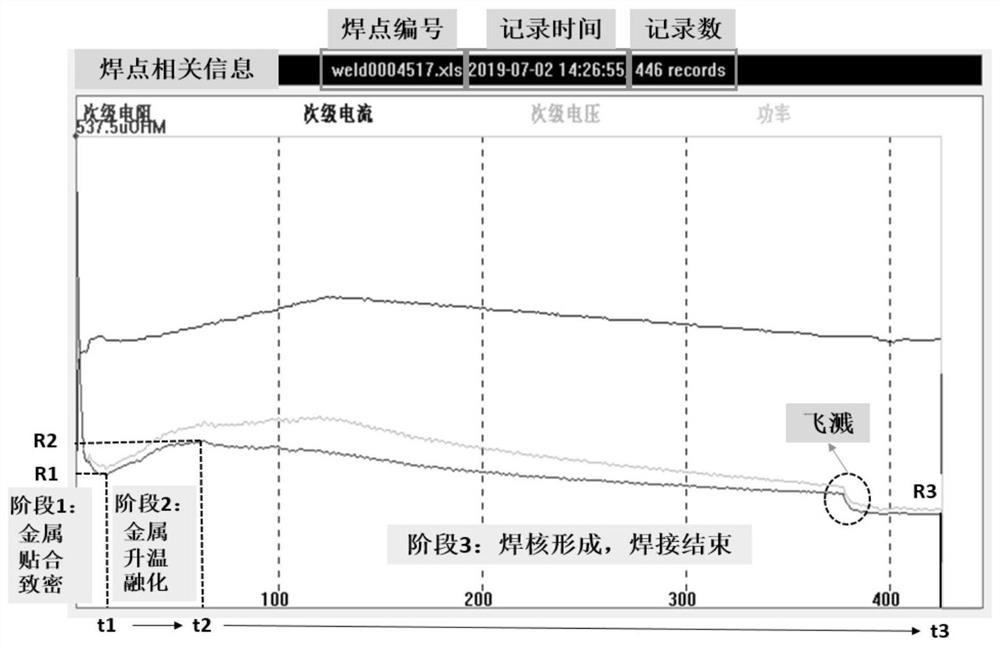

Electrode cap grinding cycle energy consumption calculation system and method

ActiveCN113420185ALow costEnable predictive maintenanceOther databases indexingOther databases browsing/visualisationProcess engineeringCorrelation analysis

The invention discloses an electrode cap grinding cycle and energy consumption correlation analysis system which is characterized in that a feature information acquisition module is used for acquiring basic feature information of an electrode cap grinding cycle from welding spot main file data corresponding to a welding spot needing to be analyzed and a corresponding welding spot index file through big data analysis software; derivative characteristic information of energy consumption calculation of the electrode cap grinding cycle of each welding spot needing to be analyzed in the three stages is calculated by utilizing the basic characteristic information of the electrode cap grinding cycle; and the energy consumption calculation module obtains the electrode cap grinding cycle energy consumption of each welding spot in the three stages through a self-adaptive Simpson algorithm by utilizing the basic characteristic information of the electrode cap grinding cycle of each welding spot in the three stages and derivative characteristic information calculated by the energy consumption of the electrode cap grinding cycle. According to the method, through a big data mathematical statistical analysis means, mathematical statistical analysis is carried out on mass welding spot data, and the electrode cap grinding cycle energy consumption of the welding robot in the welding spot welding process is accurately calculated.

Owner:DONGFENG MOTOR GRP

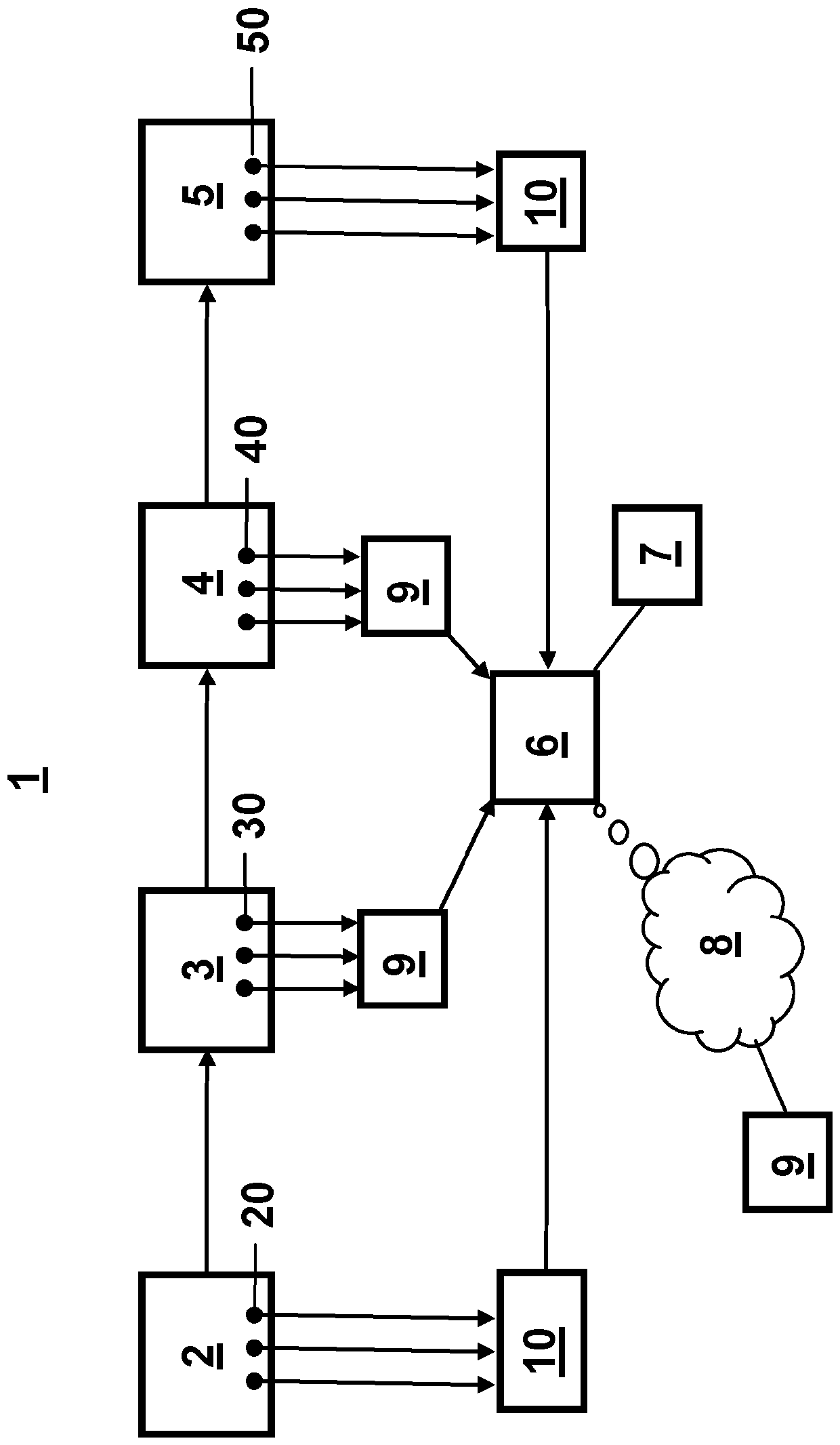

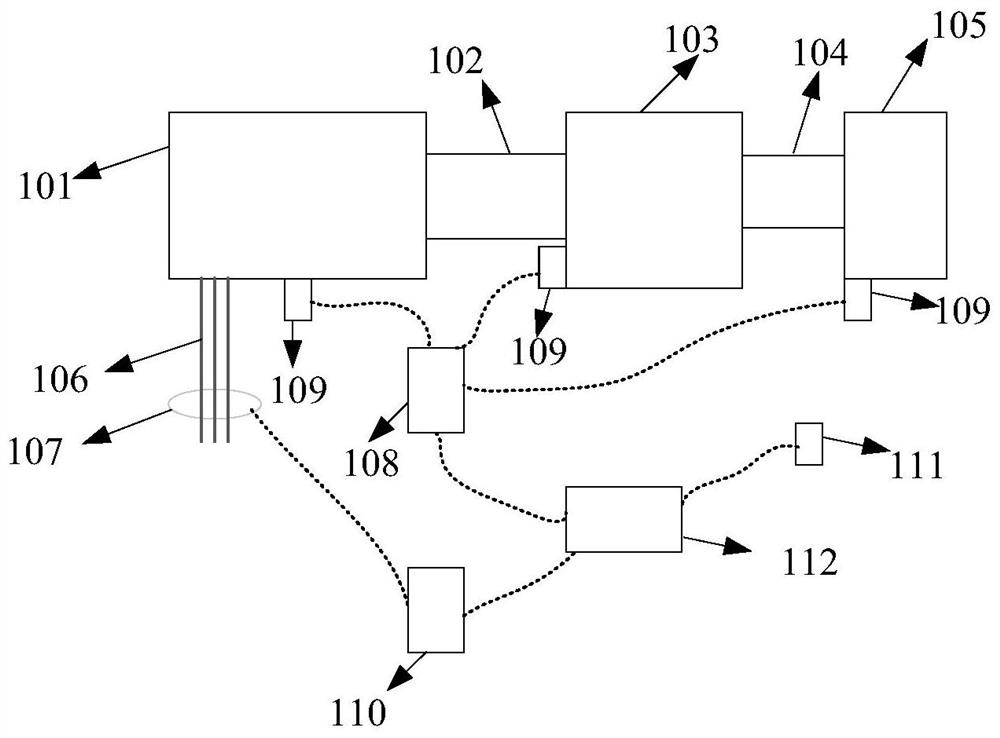

Complex transmission chain predictive maintenance system and method based on industrial Internet of Things

PendingCN111783880ADistributed processing capabilityImprove stabilityMachine part testingCharacter and pattern recognitionIndustrial InternetPredictive maintenance

The invention discloses a complex transmission chain predictive maintenance system based on the industrial Internet of Things. Hardware equipment of the system comprises a high-frequency sensor network, a high-frequency signal processing device and intelligent hardware, wherein the high-frequency sensor network is used for collecting working signals in real time or periodically, the high-frequencysignal processing device is used for preprocessing the working signals, and the intelligent hardware carries out data processing at a local end by utilizing a wavelet characteristic extraction algorithm and uploads the data to a cloud end; and the cloud is used for verifying and storing the data, analyzing the data by utilizing an intelligent algorithm with feature extraction, and finally outputting a corresponding fault feature state. An exclusive data processing device is adopted for related high-frequency signals, processing capacity required by a core processing unit is dispersed, and thestability of the system is improved; aiming at the characteristics of complex vibration signals, high-frequency data dimension reduction is completed on the edge side through feature extraction, an equipment state degradation analysis side cloud data architecture is constructed through cooperative use of a cloud algorithm, and predictive maintenance of a complex transmission chain mechanism is realized.

Owner:TSINGHUA UNIV TIANJIN HIGH END EQUIP RES INST LUOYANG ADVANCED MFG IND RES & DEV BASE

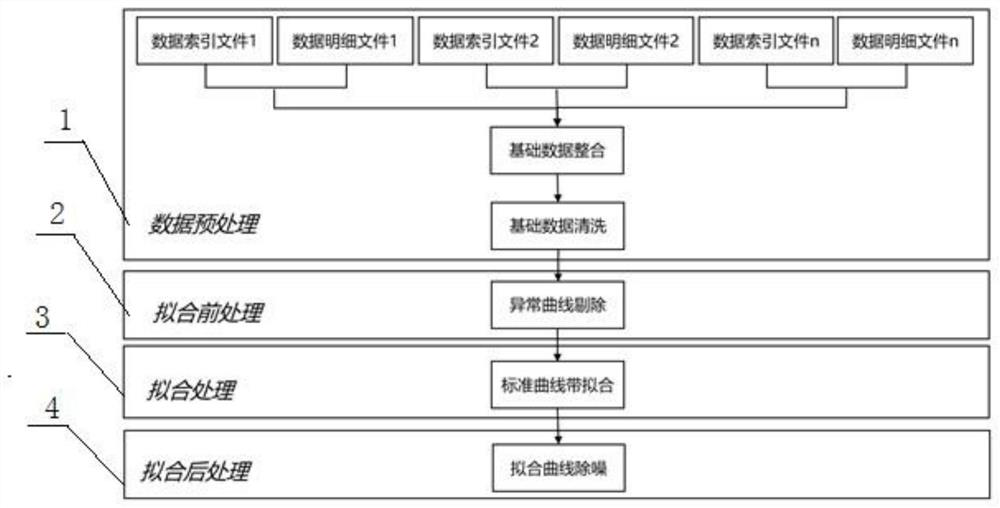

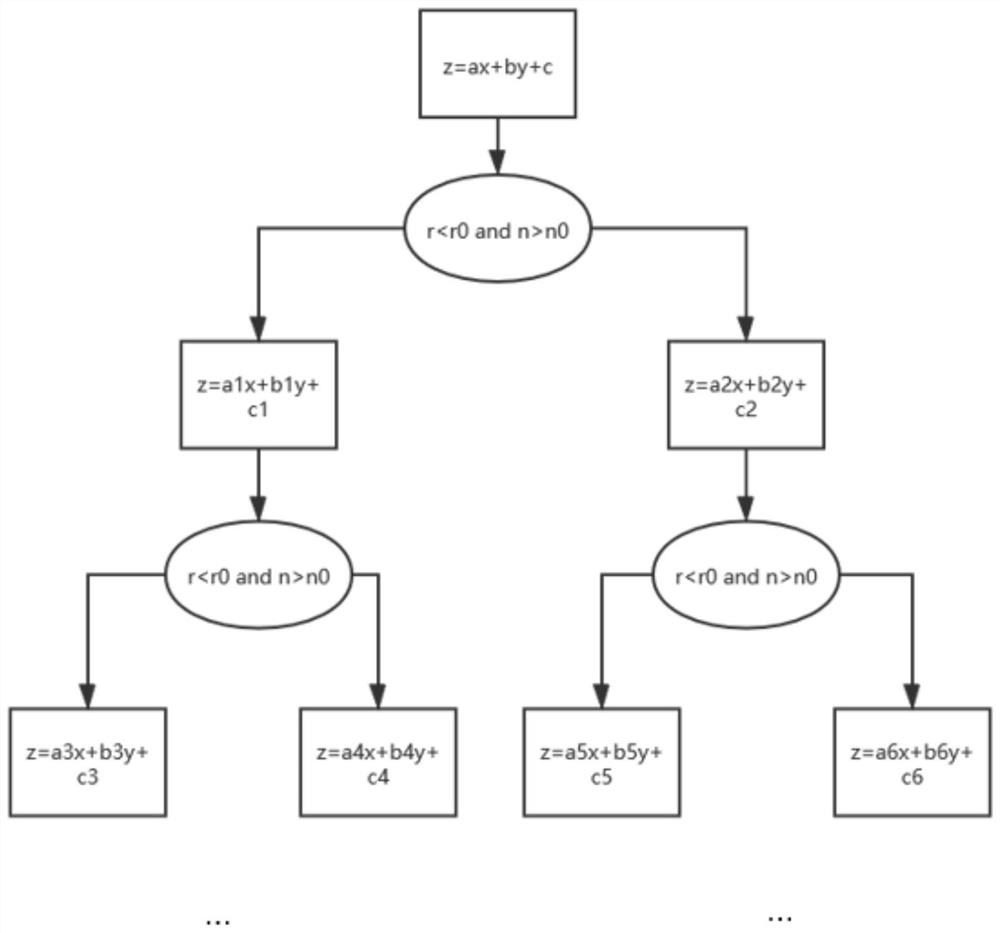

Welding spot standard curve band fitting system and method

ActiveCN113553659AEnable predictive maintenanceQuickly find quality defectsGeometric CADWelding/cutting auxillary devicesStatistical analysisLinear regression

The invention discloses a welding spot standard curve band fitting system and method. A data preprocessing module of the system is used for conducting data preprocessing on welding spot basic data formed by a welding robot within a preset time period; the pre-fitting processing module is used for filtering and removing the abnormal resistance data through big data analysis software to obtain pre-fitting data; the fitting processing module is used for carrying out linear iteration fitting by adopting linear regression based on a decision tree to obtain an upper boundary and a lower boundary of a welding spot resistance curve of a welding spot needing to be analyzed in a welding time period; and the fitting post-processing module is used for performing curve denoising on the upper boundary and the lower boundary of the welding spot resistance curve to obtain the corresponding upper boundary and the lower boundary of the welding spot resistance standard curve. Through a big data mathematical statistical analysis means, the function relationship between the welding spot resistance and the time of the welding object and the welded object under the condition that disturbance factors are eliminated is reflected, and the method has important value for further research on the welding spot process.

Owner:DONGFENG MOTOR GRP

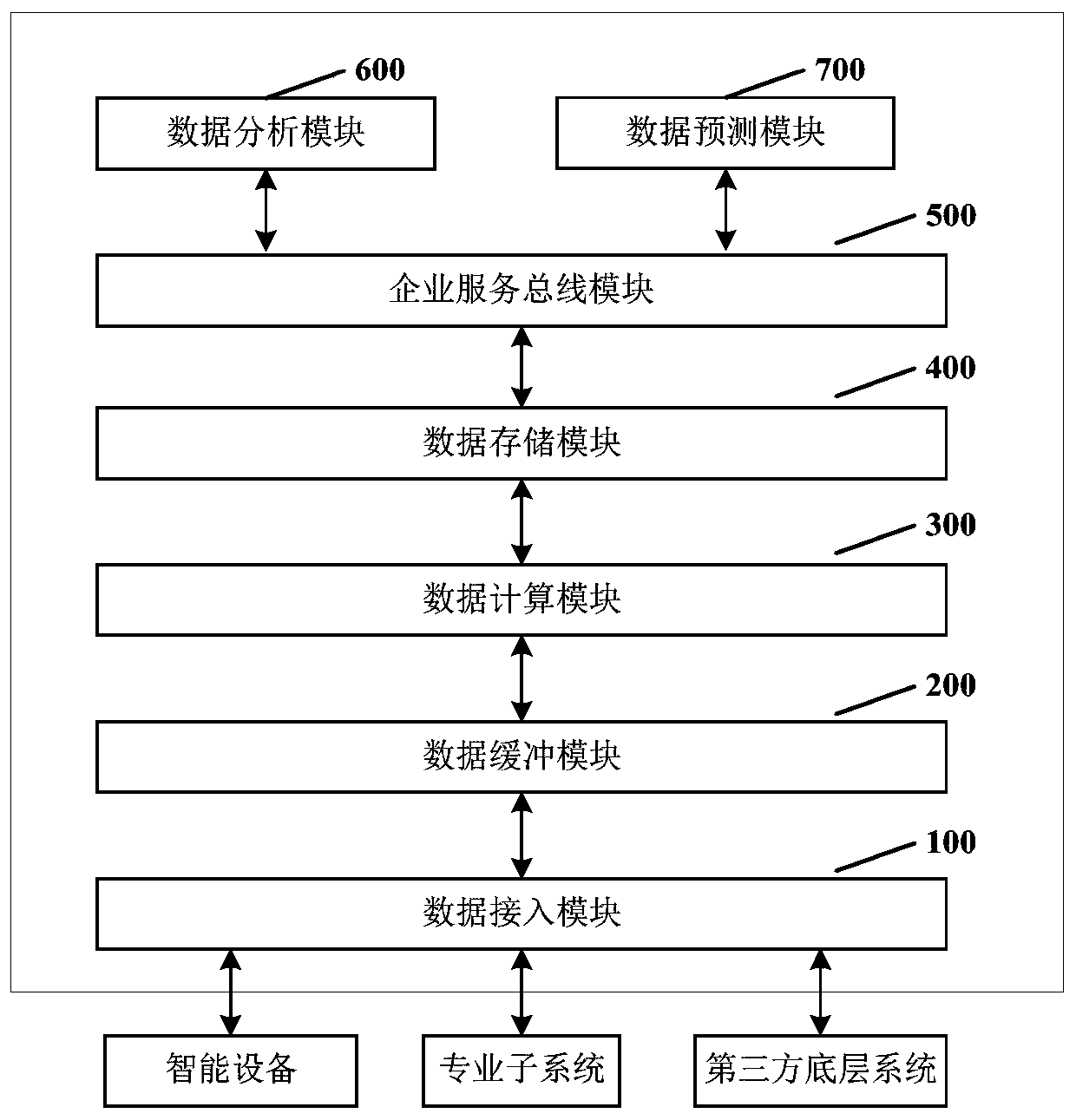

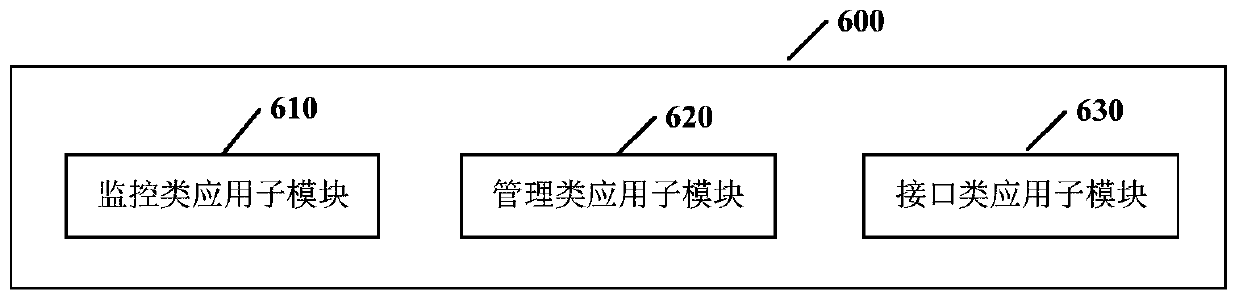

Power environment monitoring system for hyperscale data center

InactiveCN110647070AImplement asynchronous processingImprove reliabilityProgramme controlComputer controlData accessData store

The invention provides a power environment monitoring system for a hyperscale data center to achieve real-time reliable monitoring of the running state of the hyperscale data center. The system comprises a data access module, a data buffer module, a data calculation module, a data storage module, an enterprise service bus module and a data analysis module, wherein the data buffer module is used for adding data collected by the data access module into a maintained data queue and reading monitoring data from the queue to submit the monitoring data to the data calculation module; the data calculation module is used for judging whether alarm information needs to be generated or not according to the obtained monitoring data; the data storage module is used for storing configuration data, real-time and historical monitoring data and alarm data; the data storage module stores the data by adopting different database combination modes; and the data analysis module is used for obtaining corresponding data from the data storage module through the enterprise service bus module to respond to a service request after receiving the service request.

Owner:NAT COMP NETWORK & INFORMATION SECURITY MANAGEMENT CENT

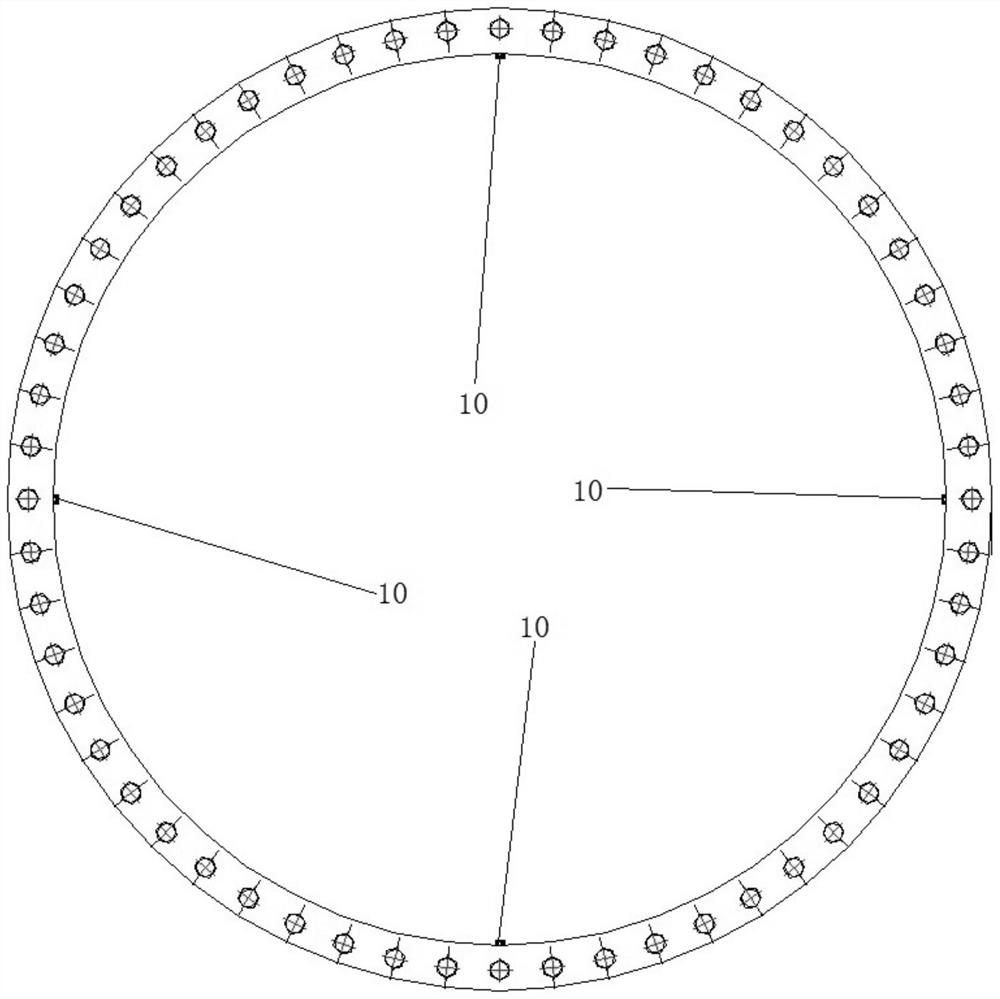

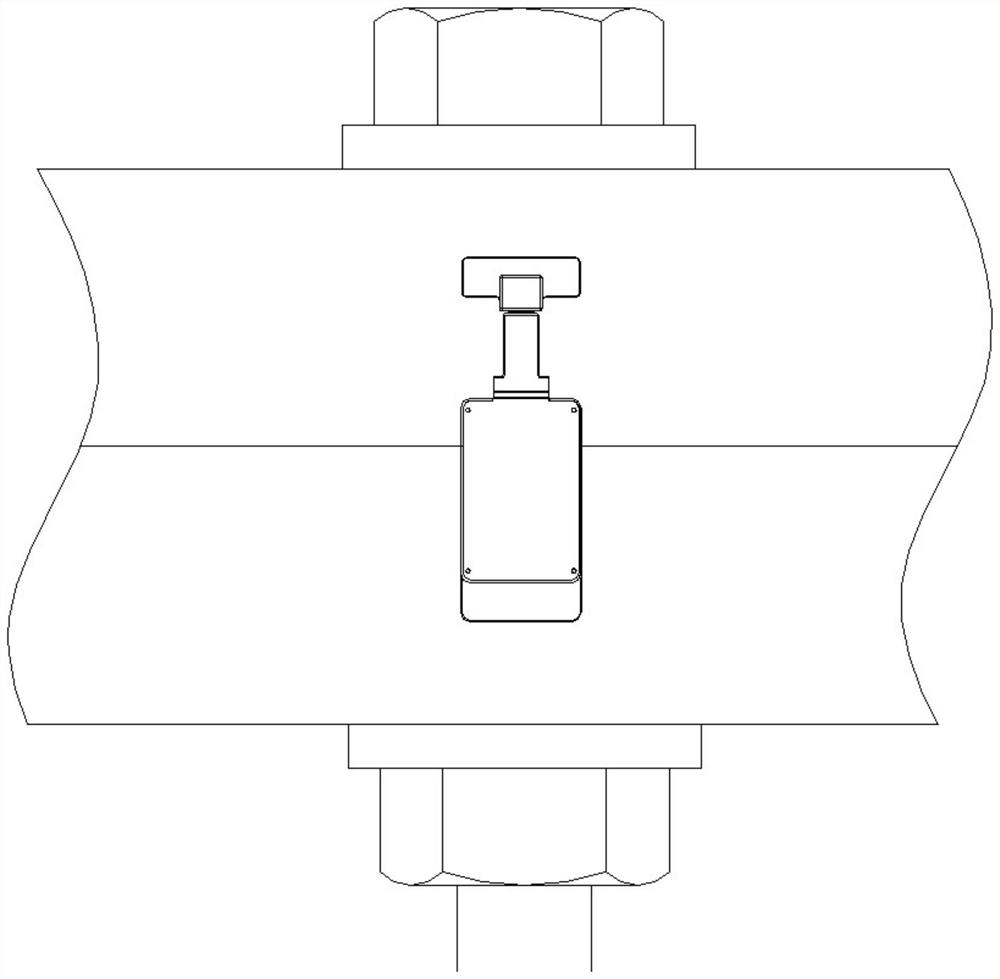

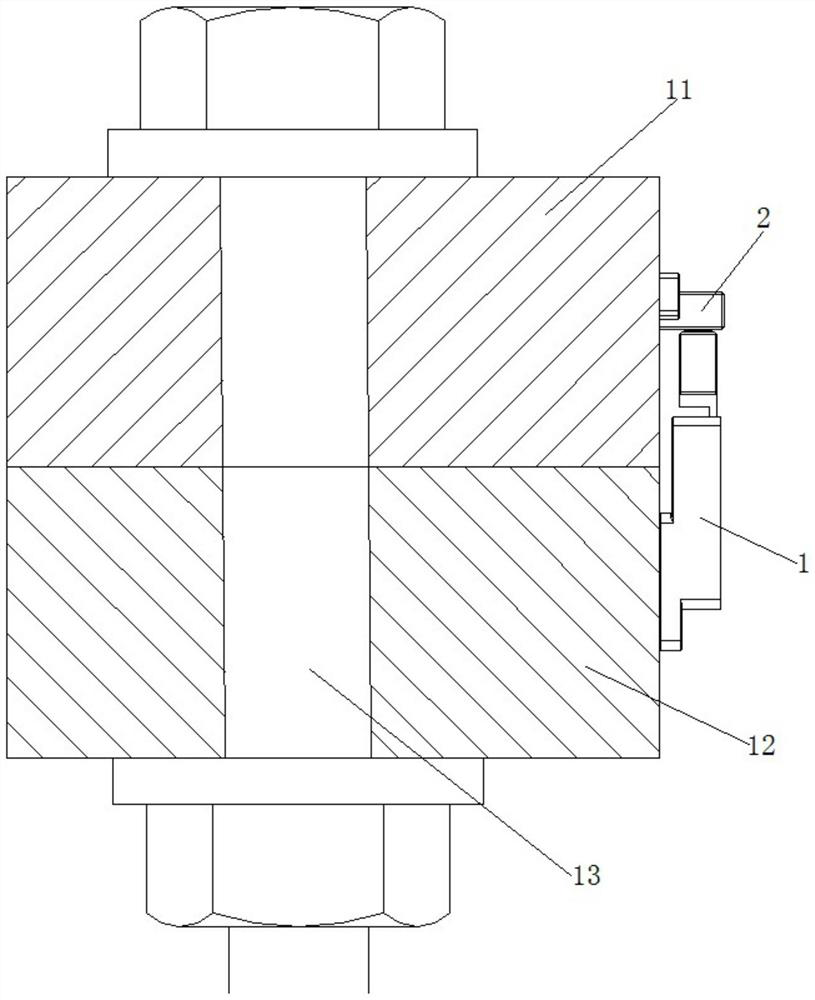

A method for monitoring flange connection bolt looseness

ActiveCN111351423BContinuous monitoring of gap sizeReal-time monitoring of gap sizeMachine part testingUsing electrical meansMicrocontrollerData transformation

The invention provides a method for monitoring the looseness of flange connection bolts. First, a split displacement sensor is installed at the flange connection, and connected with a data acquisition instrument or an edge computing gateway; when abnormal conditions such as loosening and fracture occur, the high The precision electromagnetic induction chip captures changes in the magnetic field, the temperature sensor chip collects ambient temperature data, and the vibration sensor chip samples external vibration signals and converts them into level signals. All three signals are transmitted to the single-chip microcomputer; the single-chip microcomputer performs data processing on the received signals. Conversion, and then correct the displacement data based on the ambient temperature data and vibration data, and finally send the data to the data collector or edge computing gateway; the collector or edge computing gateway counts and analyzes the received data, and then judges the flange Whether the connecting bolts are loose, broken or other abnormal conditions. The monitoring method provided by the invention has the advantages of accurate monitoring results, stable and reliable operation, and low cost.

Owner:郑州爱因特电子科技有限公司

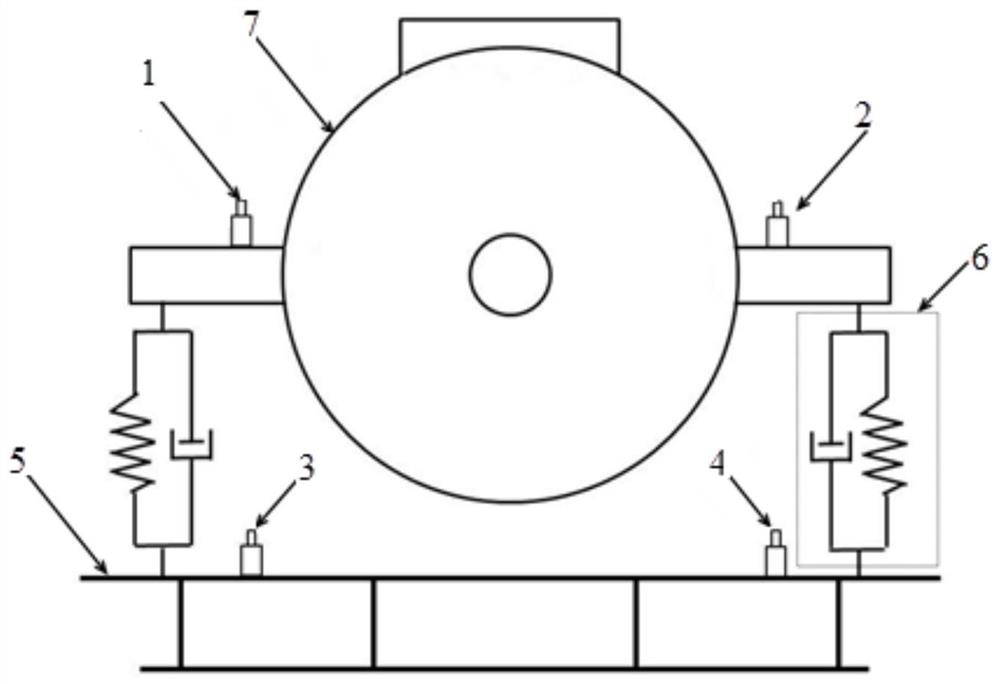

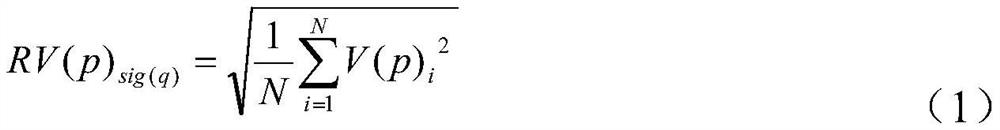

Device and method for monitoring damping effect of elastic support of gearbox of wind turbine generator

ActiveCN112761900ASafe and stable operationAccurate monitoringMachines/enginesEngine control parametersStructural engineeringPredictive maintenance

The invention discloses a device and method for monitoring the damping effect of an elastic support of a gearbox of a wind turbine generator, and belongs to the technical field of state monitoring of the wind turbine generator. According to the vibration characteristics of the gearbox and the vibration isolation rule design of the elastic support, filtering processing and multi-band monitoring are carried out on collected signals, comprehensive monitoring is ensured, the monitoring effectiveness can be ensured by performing filtering and frequency-band-division processing on collected signals, and vibration effective values are compared in a targeted manner according to frequency bands, so that the operation state of the elastic support is mastered, the vibration reduction effect is effectively calculated, and the operation state of the elastic support is mastered. Parametric variables involved in calculation are few, calculation errors can be greatly reduced, and robustness is improved. The operation state of the elastic support of the gearbox can be monitored on line in real time, damage to a unit caused by failure of the elastic support is prevented, the predictive maintenance function is achieved, and safe and stable operation of the unit is guaranteed.

Owner:HUANENG CLEAN ENERGY RES INST

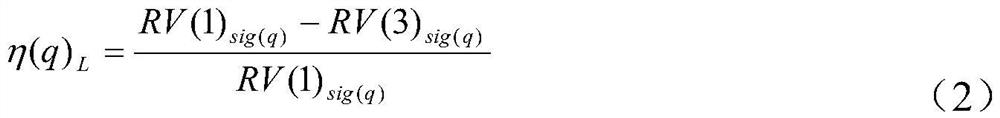

CVT state evaluation system and method

PendingCN112001616AReduce riskEnable predictive maintenanceResourcesComplex mathematical operationsData acquisitionData acquisition module

The embodiment of the invention discloses a CVT state evaluation system and method. The system comprises a data acquisition module, an in-situ monitoring module and a station end monitoring module; the data acquisition module is used for acquiring test data of the running state of the CVT; the in-situ monitoring module comprises a data processing unit, and the data processing unit is in communication connection with the data acquisition module and is used for performing fuzzy quantization processing on the test data through a fuzzy mathematical control algorithm and establishing a data quantization model; and the station end monitoring module comprises a state comprehensive evaluation unit, and the state comprehensive evaluation unit is in communication connection with the data processingunit and used for analyzing and comparing the data quantification model through imported historical sample data so as to evaluate the running state of the CVT and provide a corresponding operation andmaintenance strategy. According to the technical scheme provided by the embodiment of the invention, the evaluation of the running state of the CVT is realized, a basis and a direction are provided for power failure pre-test, the operation inspection efficiency is improved, and the power grid risk is reduced.

Owner:GUANGDONG POWER GRID CO LTD +1

Predictive maintenance system and method for machine tool spindle

PendingCN114298334AEnable predictive maintenanceAvoid affecting productionDigital data information retrievalComplex mathematical operationsPredictive maintenanceSystem diagnosis

The invention provides a predictive maintenance system and method for a machine tool spindle. According to the system, vibration data of the machine tool spindle under the idle working condition are collected through a data collection unit. Based on analysis of the vibration data, the state monitoring unit displays the health state of the machine tool spindle; and meanwhile, the fault of the machine tool spindle is diagnosed through the health diagnosis unit, and a diagnosis result is input into the system. On-site operation and maintenance personnel can check and confirm the fault diagnosis result in the diagnosis confirmation unit and record the check result into the system. The diagnosis result query unit can query historical diagnosis results. In addition, the system configuration unit can flexibly adapt to system acquisition parameters, vibration thresholds and the like. Predictive maintenance of the machine tool spindle can be realized based on the system, and non-planned shutdown of the machine tool and influence on production caused by a post-maintenance method in a traditional method are avoided.

Owner:盛景智能科技嘉兴有限公司

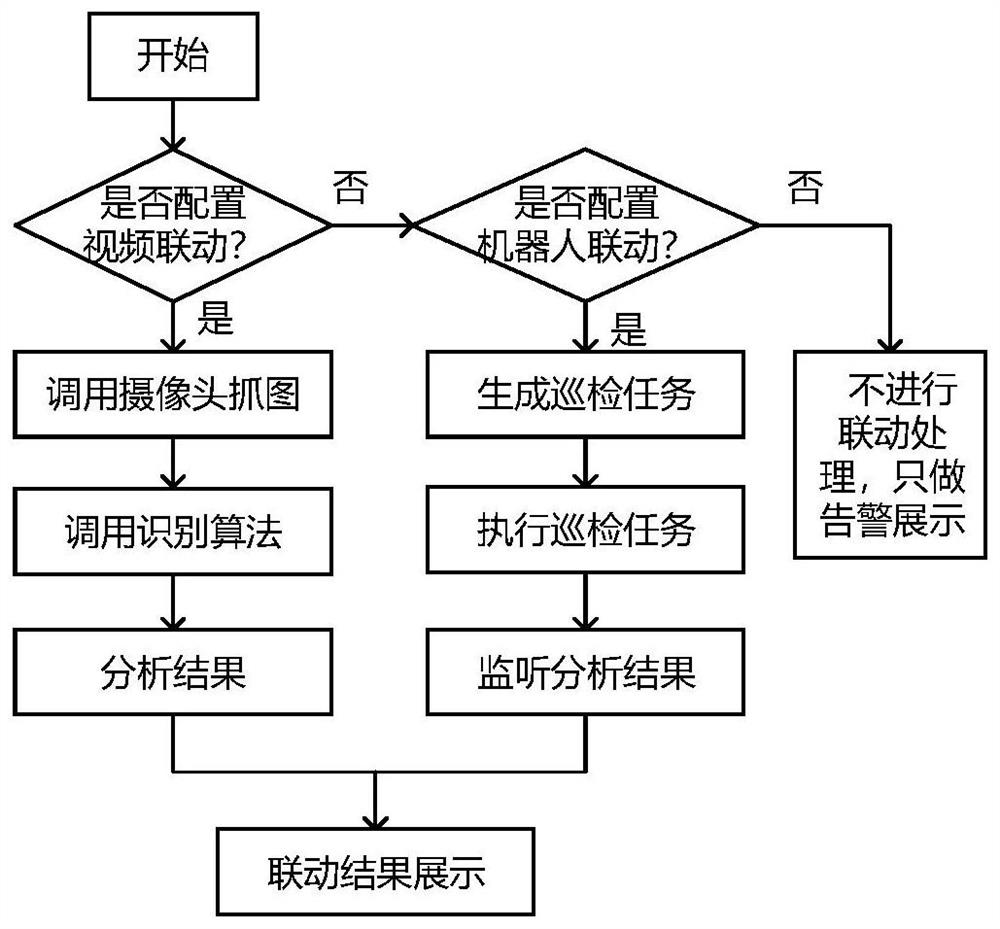

Power transformation equipment intelligent analysis linkage system and method based on multi-source information fusion

PendingCN113709334AImprove autonomy in emergency repairsImprove prior control abilityTelevision system detailsCircuit arrangementsTransformerControl engineering

The invention relates to a power transformation equipment intelligent analysis linkage system and method based on multi-source information fusion. Data of a plurality of systems are subjected to fusion analysis, panoramic data of the transformer substation can be obtained, and one-sidedness of equipment state diagnosis is avoided; when the in-station equipment is abnormal, the state data or the alarm signal of the equipment can trigger a configured video or robot linkage event, the linked camera or robot inspects an abnormal point, records a fault condition in detail, and automatically pushes a video picture and an inspection result of a corresponding area; and meanwhile, the equipment state comprehensive diagnosis module pushes an equipment state diagnosis result and an intelligent decision-making conclusion, comprehensive and multi-dimensional inspection data and intelligent auxiliary decision-making are provided for operation and maintenance personnel of the transformer substation, predictive maintenance is realized to a certain extent, the first-aid repair autonomy and the beforehand control capability of the transformer substation can be effectively improved, and the operation efficiency and security of substation operation and maintenance are improved.

Owner:XUCHANG XJ SOFTWARE TECH +2

Equipment failure early warning system based on model full life cycle management

ActiveCN109947088BPre-warning results are consistently accurateEnable predictive maintenanceElectric testing/monitoringResourcesEarly warning systemReal-time data

Owner:CYBERINSIGHT TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com