Predictive industrial equipment maintenance method and maintenance system based on edge computing

A technology of industrial equipment and edge computing, which is applied in the direction of prediction, calculation, and instrumentation, can solve problems such as lack of algorithms and modeling methods, poor practicality, and unpredictable maintenance, so as to avoid invalid manual operations and facilitate automation Operation and realization of the effect of predictive maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

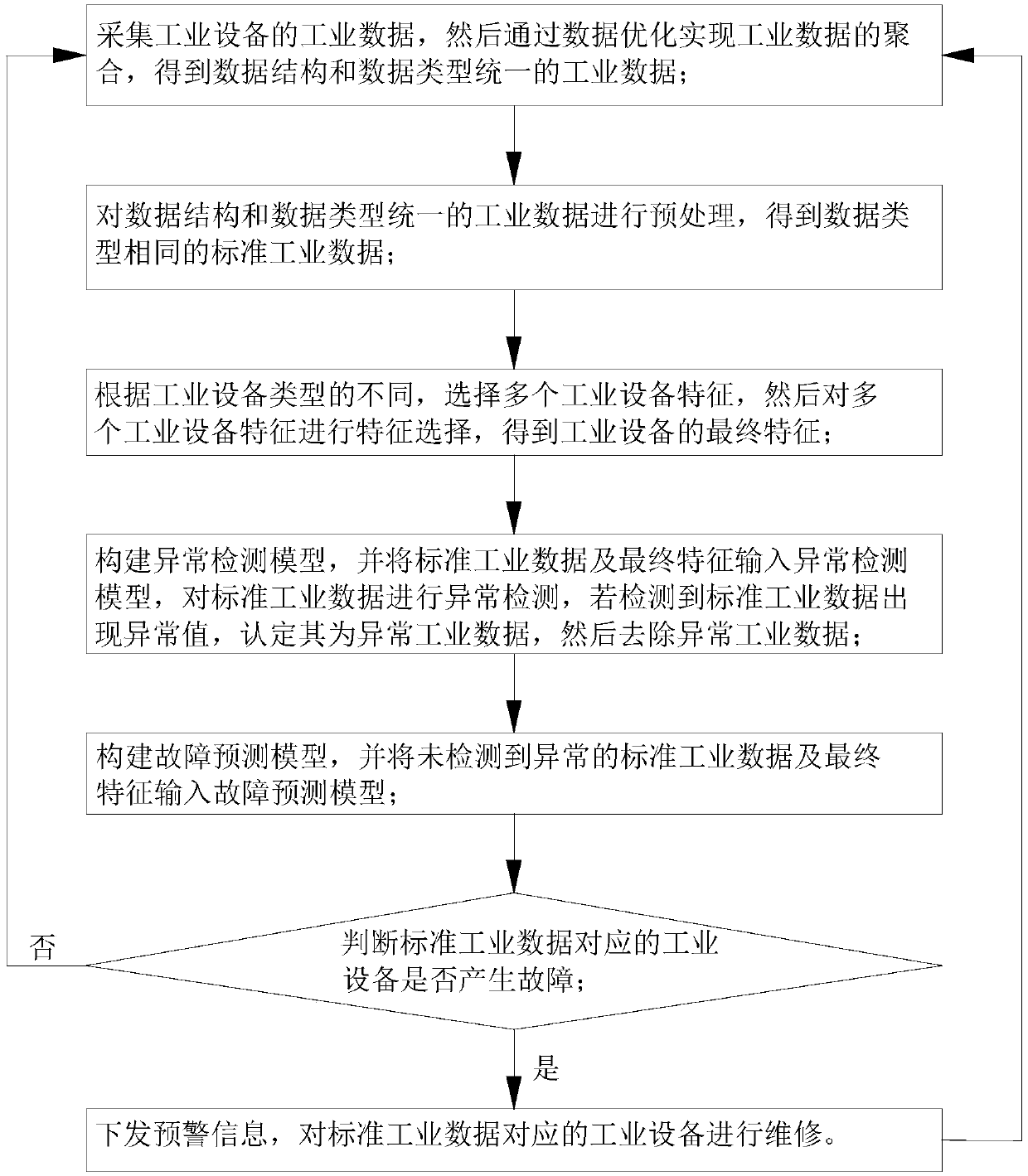

[0034] This embodiment provides a predictive industrial equipment maintenance method based on edge computing, including the following steps:

[0035] S1: Collect industrial data of industrial equipment, and then realize the aggregation of industrial data through data optimization to obtain industrial data with unified data structure and data type. It should be noted that in step S1, the industrial data can be the data of each phase when the industrial equipment is running, which is mainly PLC data, but also includes data in many other formats. The industrial data can be collected by using KEPWARE software, or It can be realized by using SimaticNet software, among which KEPWARE software is suitable for industrial automation. In addition, due to the large amount of diverse and heterogeneous data in the industrial field, data aggregation can be achieved through data optimization, and the data structure and data type can be unified to facilitate subsequent data processing.

[003...

Embodiment 2

[0044] This embodiment provides a predictive industrial equipment maintenance method based on edge computing, including the following steps:

[0045] S1: Collect industrial data of industrial equipment, and then realize the aggregation of industrial data through data optimization to obtain industrial data with unified data structure and data type. It should be noted that in step S1, the industrial data can be the data of each phase when the industrial equipment is running, which is mainly PLC data, but also includes data in many other formats. The industrial data can be collected by using KEPWARE software, or It can be realized by using SimaticNet software, among which KEPWARE software is suitable for industrial automation. In addition, due to the large amount of diverse and heterogeneous data in the industrial field, data aggregation can be achieved through data optimization, and the data structure and data type can be unified to facilitate subsequent data processing.

[0046]...

Embodiment 3

[0054] This embodiment provides a predictive industrial equipment maintenance method based on edge computing, including the following steps:

[0055] S1: Collect industrial data of industrial equipment, and then realize the aggregation of industrial data through data optimization to obtain industrial data with unified data structure and data type. It should be noted that in step S1, the industrial data can be the data of each phase when the industrial equipment is running, which is mainly PLC data, but also includes data in many other formats. The industrial data can be collected by using KEPWARE software, or It can be realized by using SimaticNet software, among which KEPWARE software is suitable for industrial automation. In addition, due to the large amount of diverse and heterogeneous data in the industrial field, data aggregation can be achieved through data optimization, and the data structure and data type can be unified to facilitate subsequent data processing.

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com